Discharging buffering device for paper products after high-speed cutting

A buffer device and paper product technology, applied in thin material handling, transportation and packaging, sending objects, etc., can solve the problems affecting continuous production, low-speed paper feeding can not match, etc., to achieve the effect of smooth movement

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

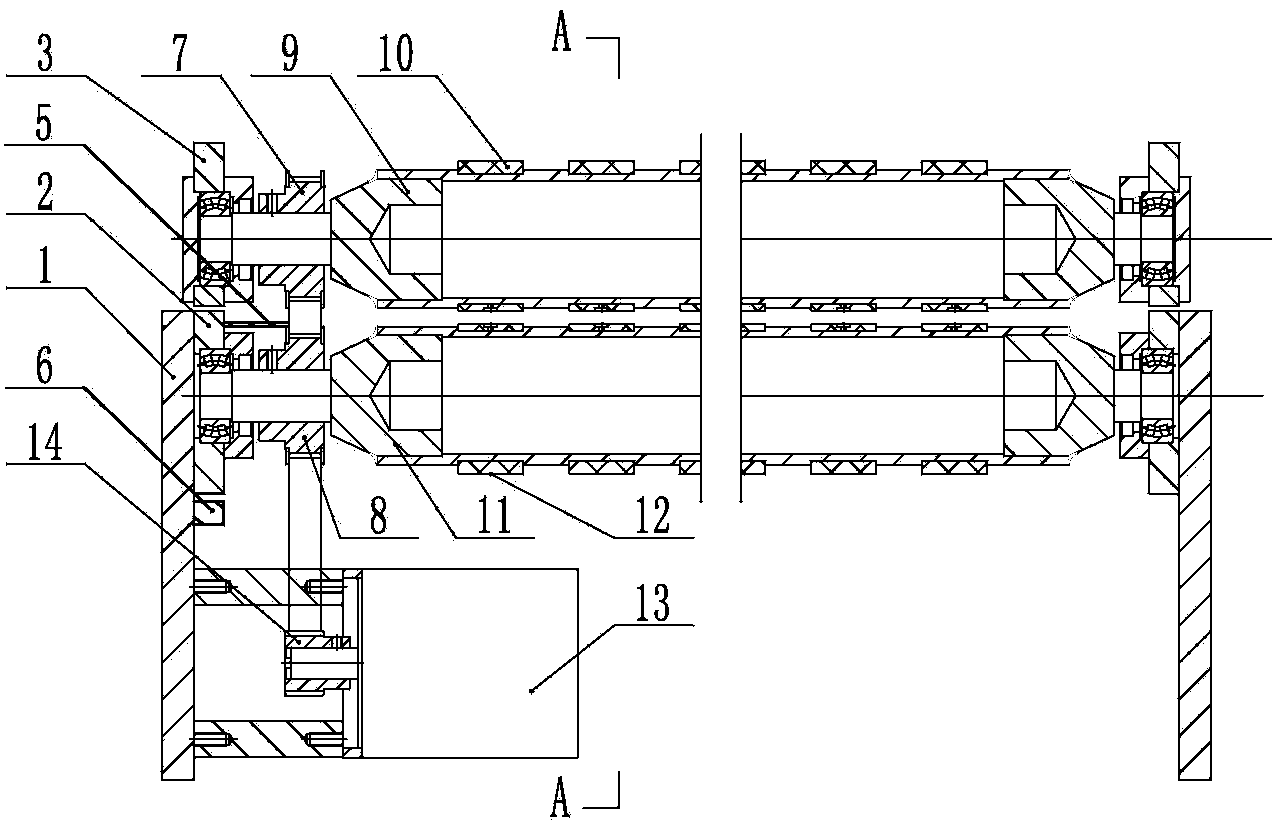

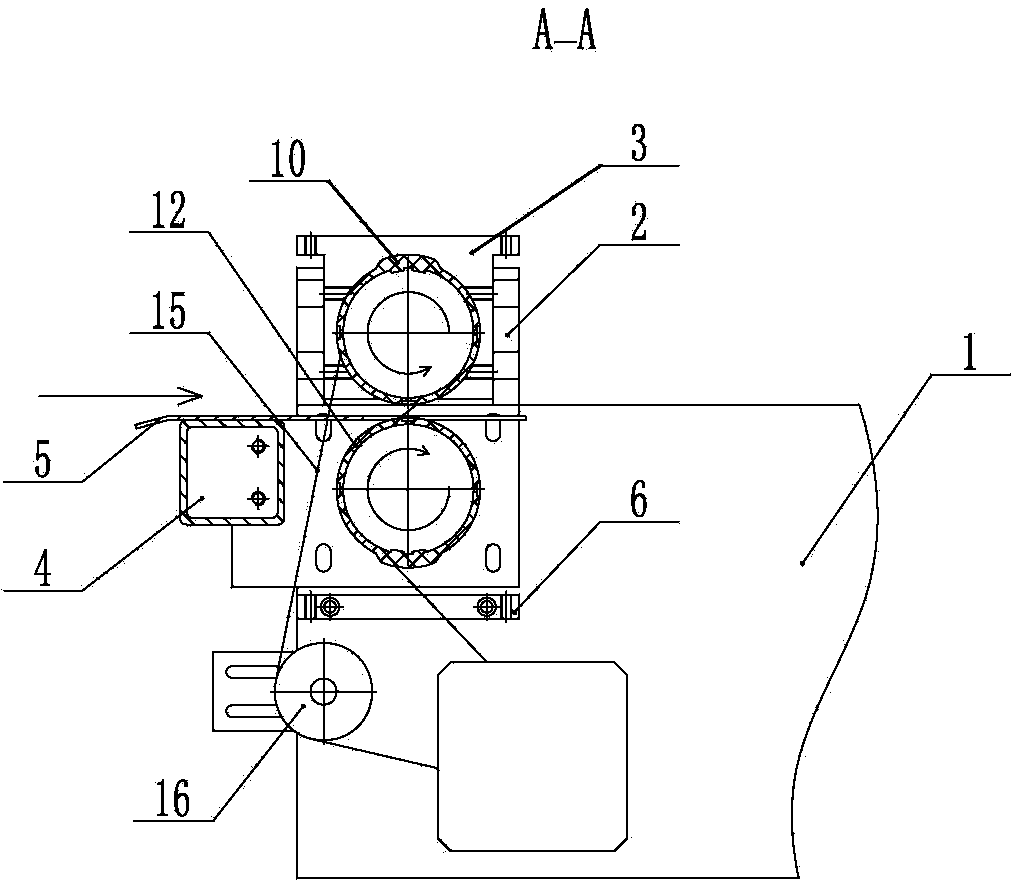

[0013] Description with reference to the accompanying drawings.

[0014] The outer surfaces of the two lower shaft mounting plates 2 are in contact with the inner surfaces of the two wall panels 1 , and the two vertical wall panels 1 are parallel to each other. The two ends of the cross brace 4 are fixed on the inner side surfaces of the lower shaft mounting plates 2 on both sides. There are two rows of four elongated holes on the lower shaft mounting plate 2, see figure 2 , the bolt passes through the elongated hole, screwed into the screw hole on the wallboard 1, and connects the lower shaft mounting plate 2 with the wallboard 1. The adjustment block 6 of the lower shaft adjustment mechanism is fixed on the wallboard 1 and is located below the lower shaft installation plate 2 . The adjusting bolt passes through the vertical screw holes on the left and right sides of the adjusting block, and its end is in contact with the lower end surface of the lower shaft mounting plate...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com