A high-frequency high-power microwave device

A high-power microwave and high-frequency technology is applied in the direction of the circuit components of the time-of-flight electron tube and the coupling device of the time-of-flight electron tube. It can solve the problems of reducing the radial size and power capacity, and achieve the axial And the effect of compact radial size, light weight and simple structure size

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

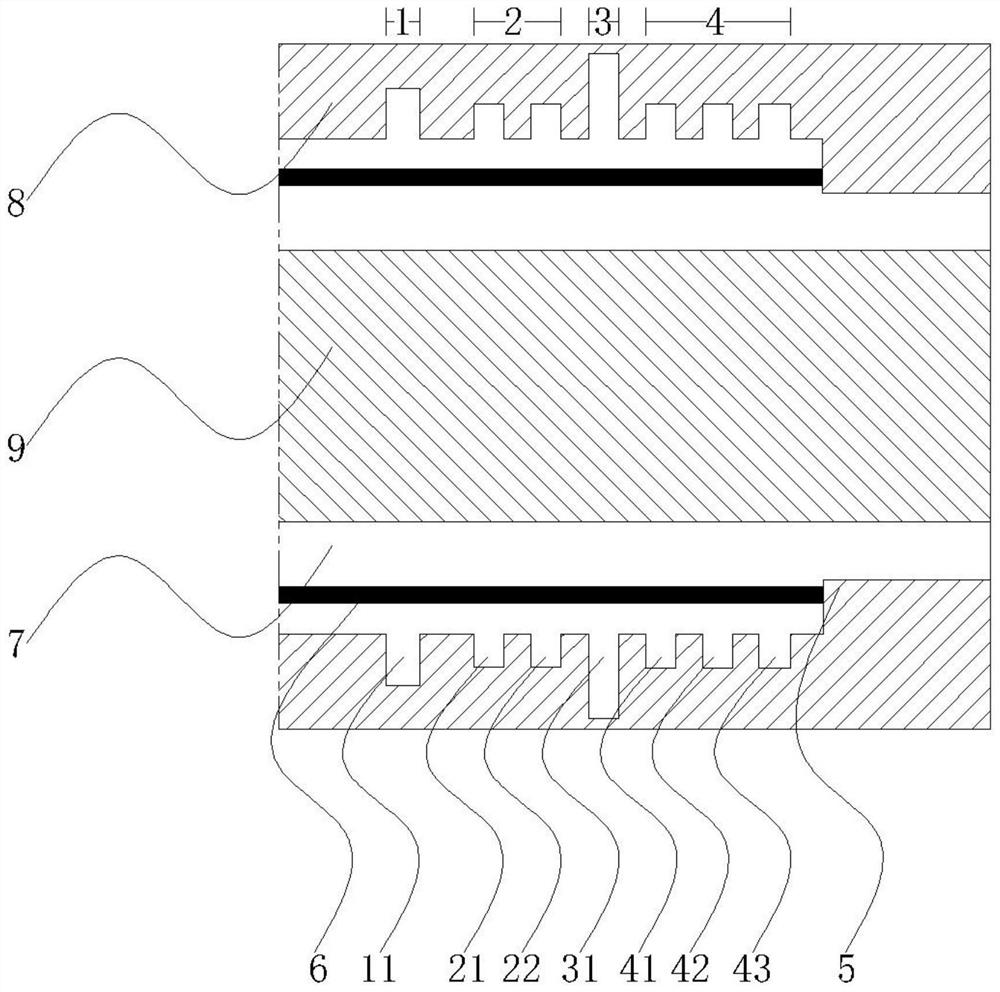

[0028] Such as figure 1 As shown, a high-frequency high-power microwave device in this embodiment includes a circular waveguide sleeve and an inner conductor coaxial with the circular waveguide sleeve. One end of the circular waveguide sleeve is provided with a cathode emitting an annular electron beam. The inner diameter of the circular waveguide sleeve is 14.6 mm, and the diameter of the inner conductor is 8 mm.

[0029] The coaxial reflection area, beam pre-modulation area, phase modulation area and beam conversion area are arranged in sequence along the electron beam transmission direction; the reflection area, beam pre-modulation area, phase modulation area and beam conversion area are respectively arranged in the An annular groove-shaped reflective cavity with a rectangular section, a beam pre-modulation cavity, a phase modulation cavity and a beam conversion cavity are arranged on the top.

[0030] The outer diameter of the reflective cavity in the reflective area is 1...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| length | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com