Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

42results about How to "Achieve premix" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

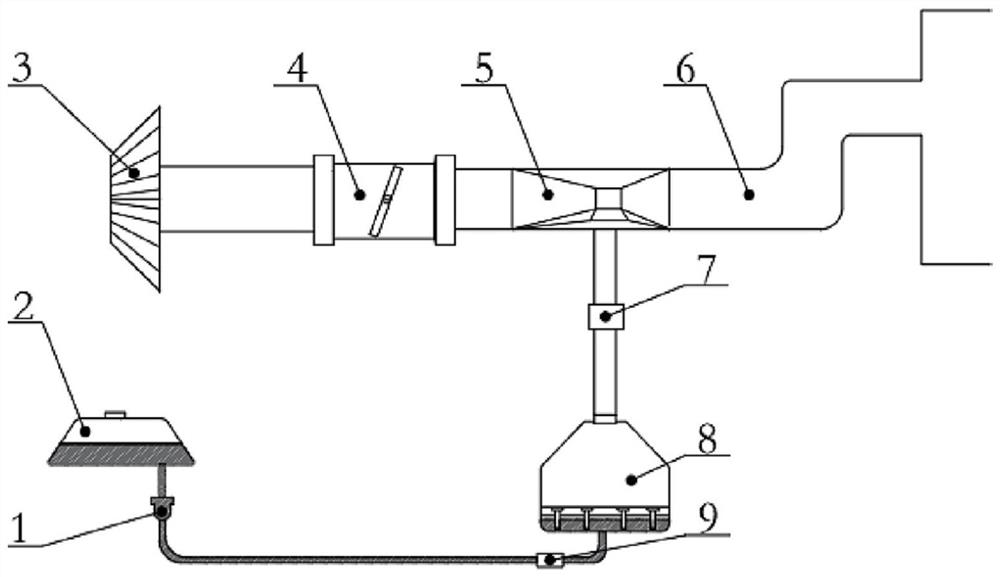

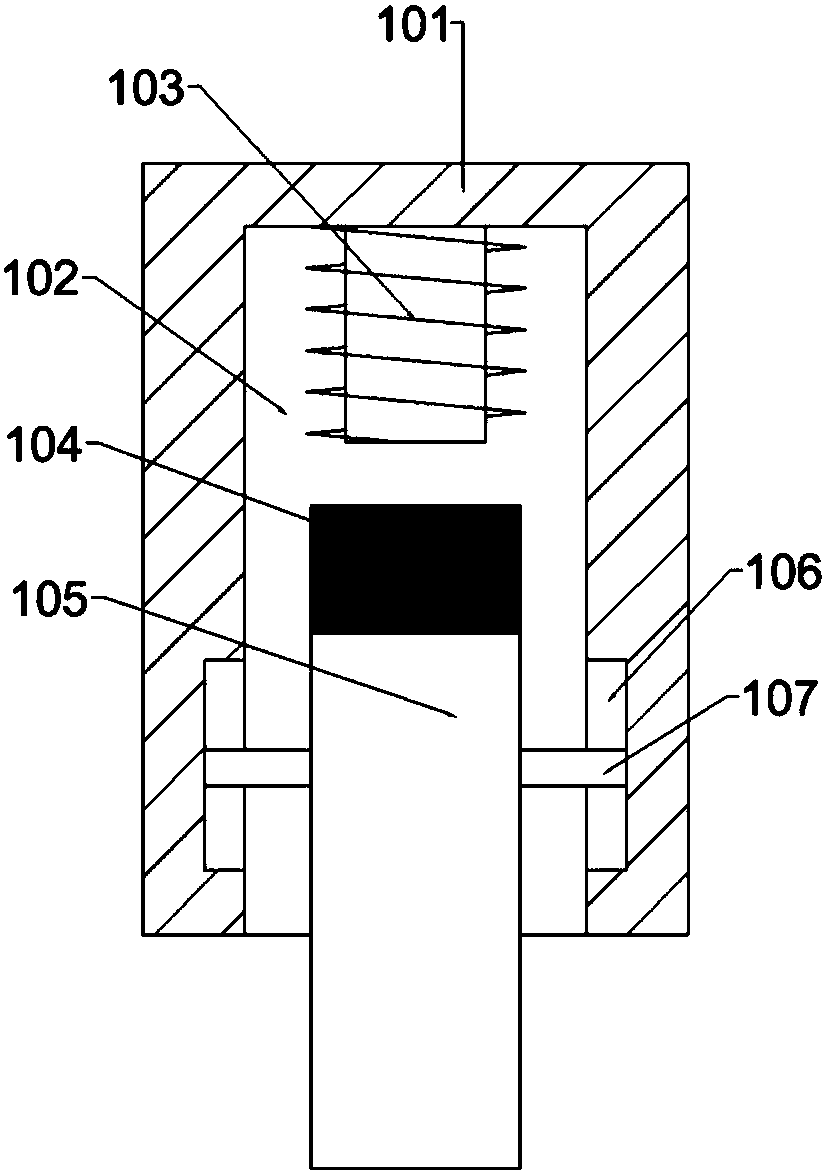

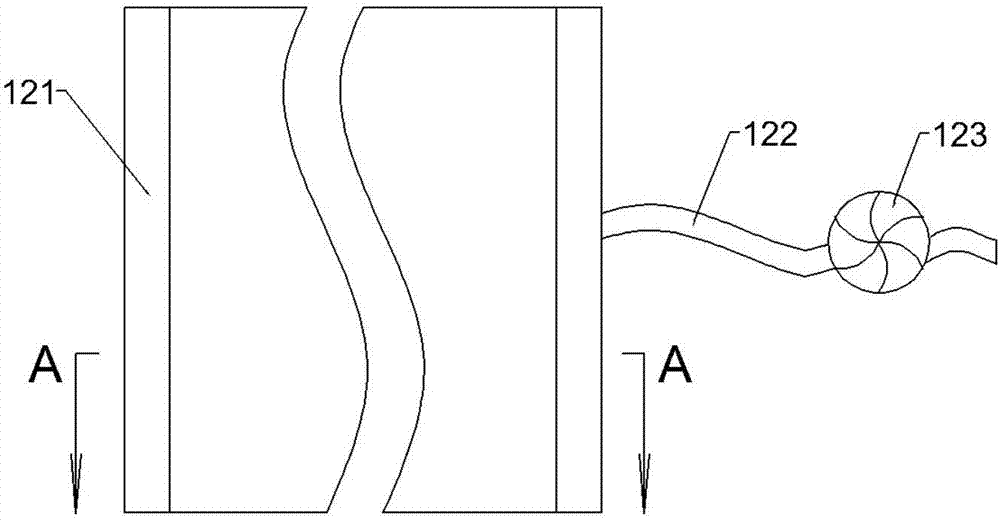

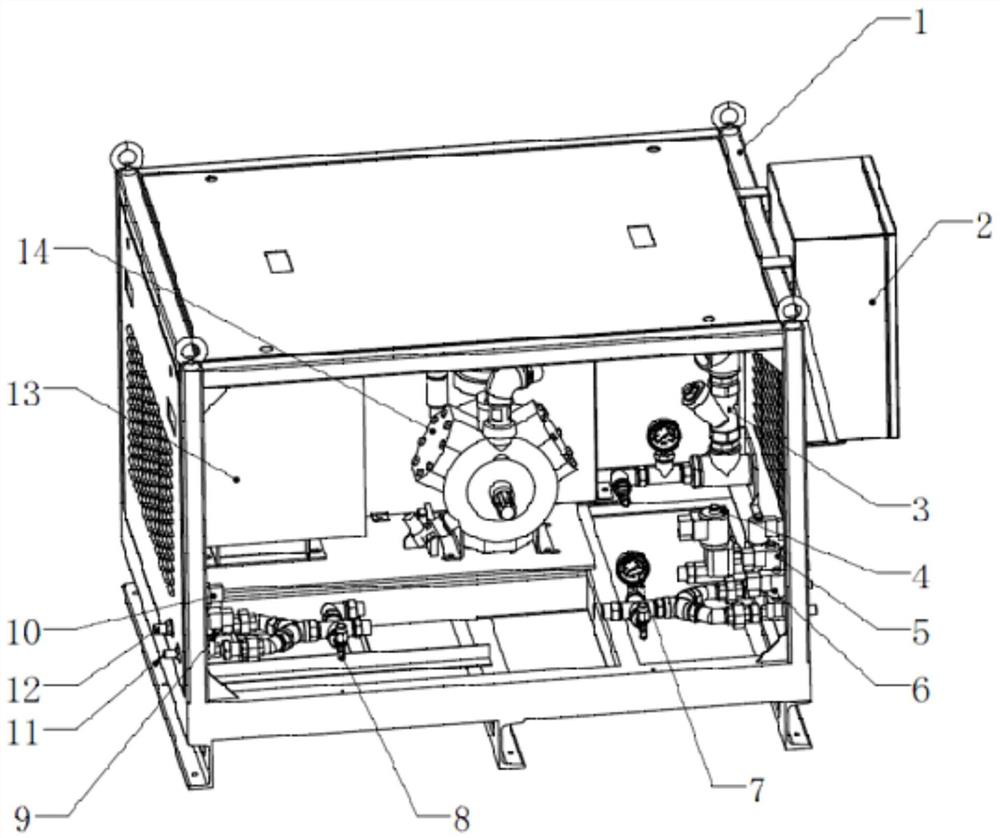

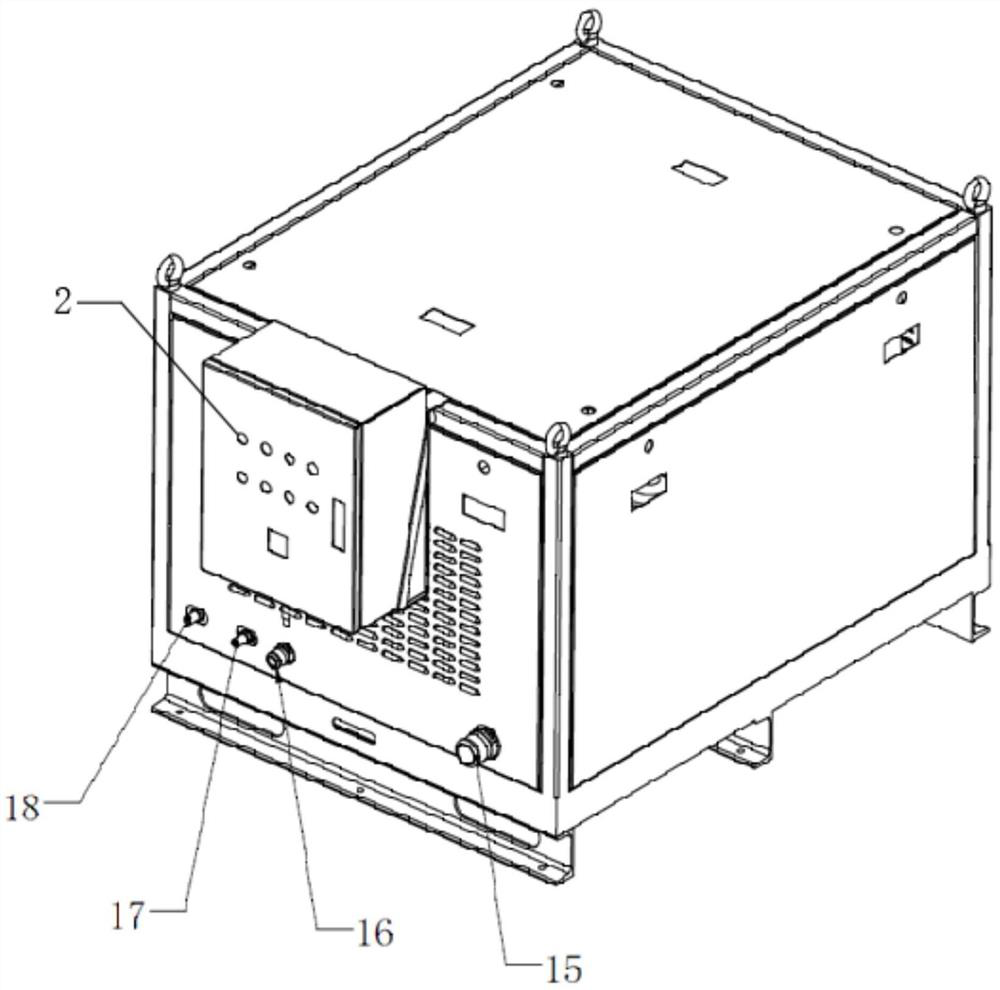

Ultrasonic atomization fuel auxiliary supply system

InactiveCN111828208ASmall change in intake resistanceAchieve premixCombustion-air/fuel-air treatmentMachines/enginesElectronic throttleUltrasonic atomization

The invention discloses an ultrasonic atomization fuel auxiliary supply system. The system is characterized in that an ultrasonic atomization generator is matched with a Venturi mixer for use, so thatpremixed fuel gas with a certain proportion of fresh charge entering an engine is realized, the combustion heat efficiency of the engine is effectively improved, the emission of harmful gas of the engine is reduced. The system mainly aims at a fuel supply system of methanol which is a clean fuel, utilizes the ultrasonic atomization unit to atomize methanol into methanol mist, is matched with thenegative pressure adsorption principle of the Venturi tube, and realizes premixing of air and methanol mist through the adjusting function of an electronic throttle valve on the air inlet flow; and the heat efficiency of the engine is improved in an auxiliary fuel gas supply mode of the premixing part, and emission of the engine is improved.

Owner:唐山阳光动力科技有限公司

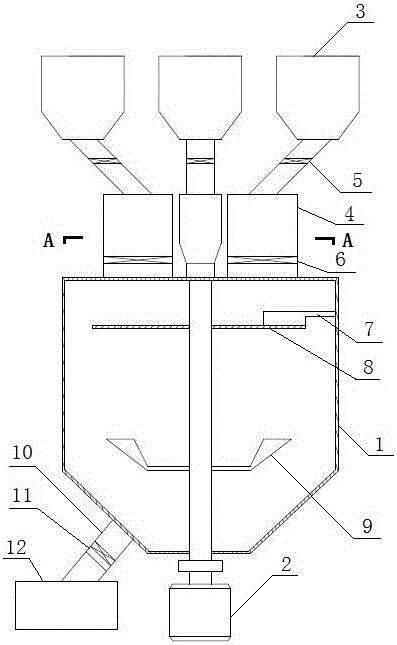

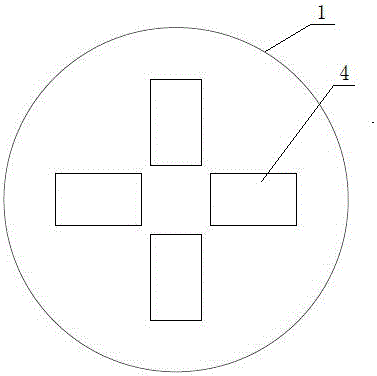

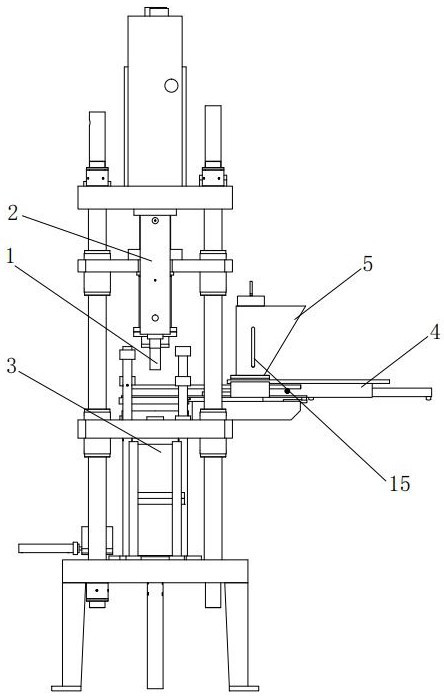

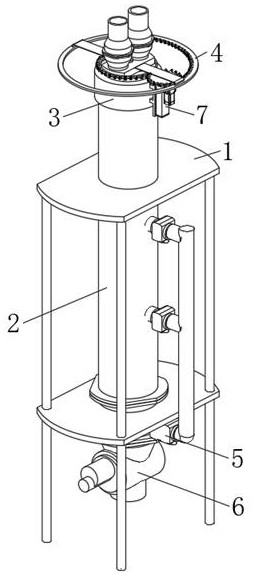

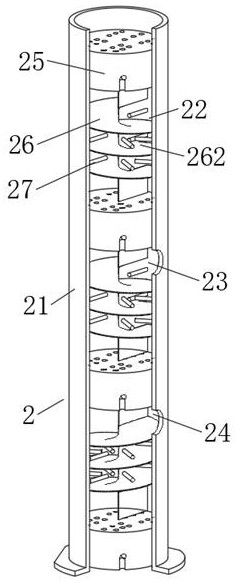

Material mixing device provided with distributing device and capable of improving mixing efficiency and material mixing method

InactiveCN106268435AAchieve premixGood effectTransportation and packagingMixing methodsEngineeringCrankshaft

The invention relates to the technical field of material mixing equipment, and particularly relates to a material mixing device provided with a distributing device and capable of improving the mixing efficiency, and a material mixing method. The material mixing device comprises a plurality of material bins, a plurality of weighing devices matched with the material bins, a material mixing bin and a motor, wherein a first valve is arranged at the bottom part of the material bin, the material bin is connected with the weighing device through the first valve, a second valve is arranged at the bottom part of the weighing device, the weighing device is connected with the material mixing bin through the second valve, the motor is arranged at the bottom part of the material mixing bin, a crankshaft of the motor penetrates through the material mixing bin, the crankshaft in the material mixing bin is provided with a distributing disc and a stirring part, the stirring part is arranged below the distributing disc, a scraper plate is arranged on a side wall of the material mixing bin, the bottom surface of the scraper plate is adjacent to the upper surface of the distributing disc, a discharge port is further arranged at the bottom part of the material mixing bin, and a third valve is arranged on the discharge port. The material mixing device is simple in structure, convenient to operate and low in cost, and compared with a traditional material mixing device, the efficiency is improved by 30%.

Owner:四川省民众日化有限公司

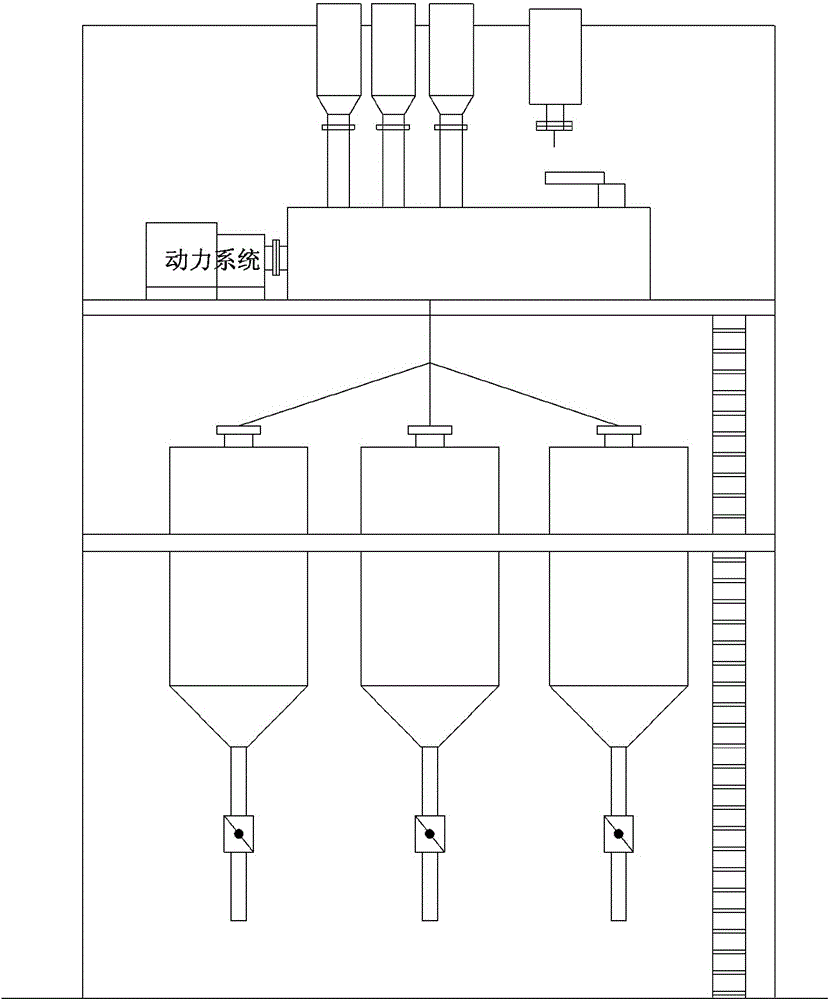

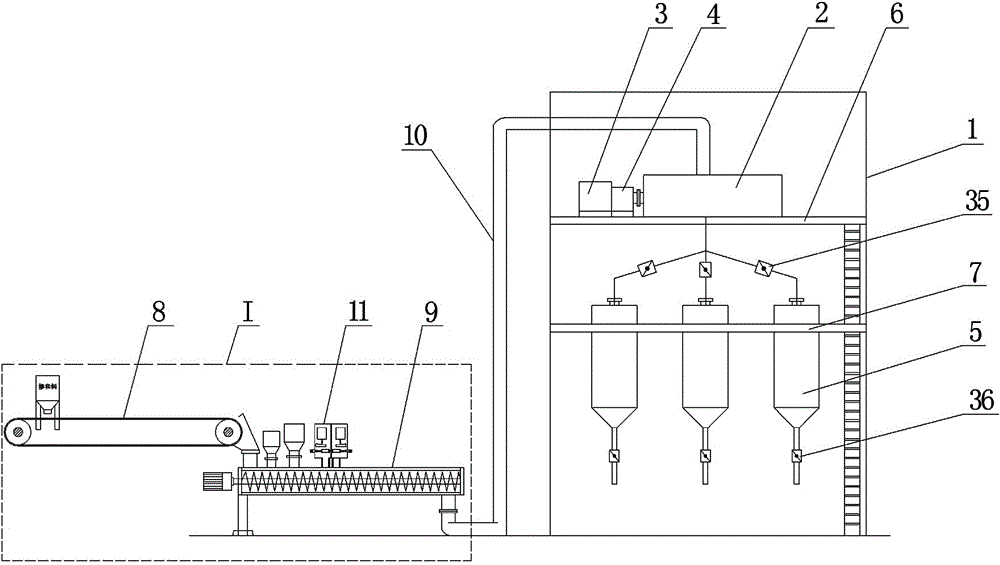

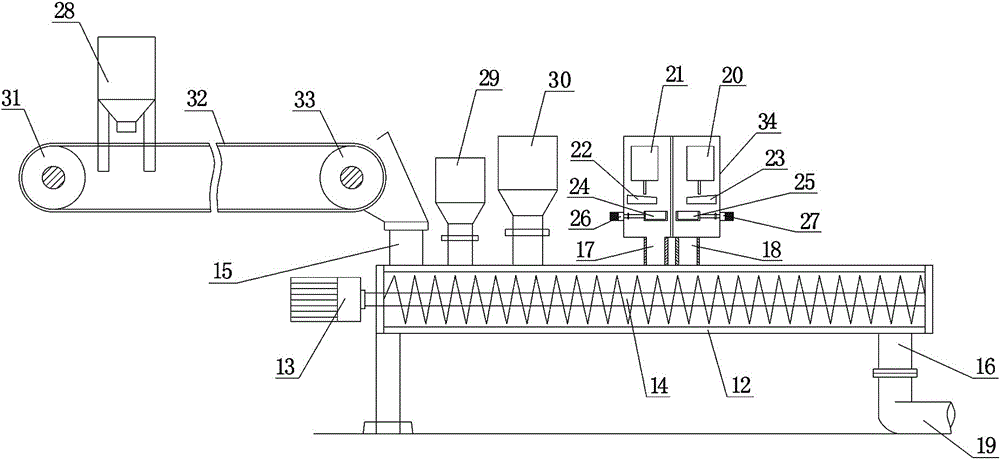

System and method for preparing dry-mixed mortar

ActiveCN105710973AImprove accurate weighingAchieve the perfect combinationMixing operation control apparatusCement mixing apparatusEngineeringLoad cell

The invention discloses a system for preparing dry-mixed mortar. The system comprises a conveying device (8), a spiral material conveying device (9), a lifter (10) and a two-stage metering device (11); the lifter (10) is composed of a bend (19) and a packing auger arranged in the bend (19), and the other end of the bend (19) is communicated with a stirrer (2); the two-stage metering device (11) is composed of a coarse additive bin (20), a fine additive bin (21), a vibrating disk A (22), a vibrating disk B (23), a weighing sensor A (24), a weighing sensor B (25), an overturning motor A (26) and an overturning motor B (27); and slopes are arranged on the top surface of the vibrating disk A (22) and the top surface of the vibrating disk B (23), and the vibrating disk B (23) is arranged below the discharging end of the coarse additive bin (20). The system has the beneficial effects that the production efficiency of the dry-mixed mortar is improved, the service life of the system is prolonged, accurate adding of an additive is achieved, and mixing of the additive is even.

Owner:QINGSHEN XINTONGLING BUILDING MATERIALS CO LTD

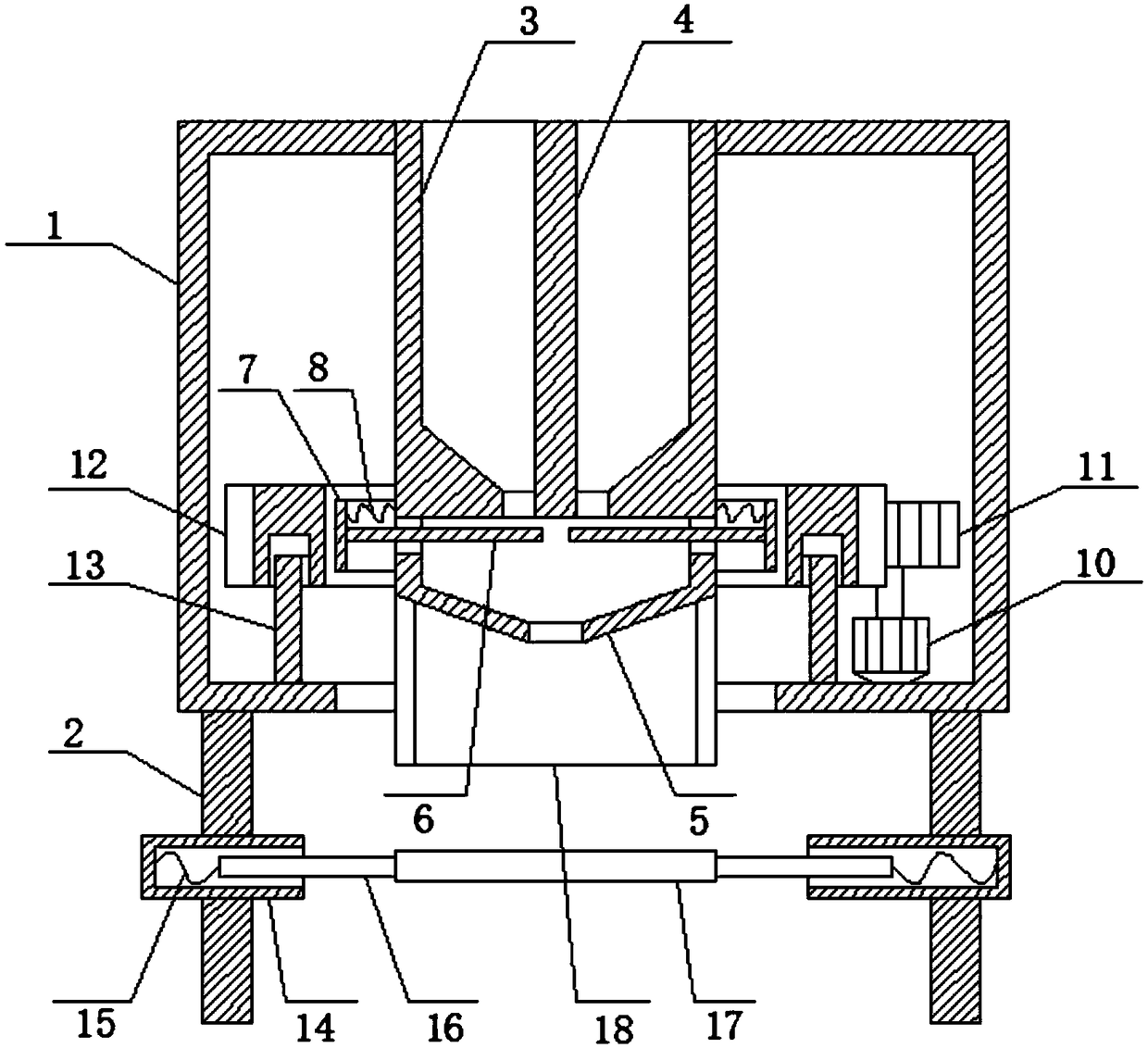

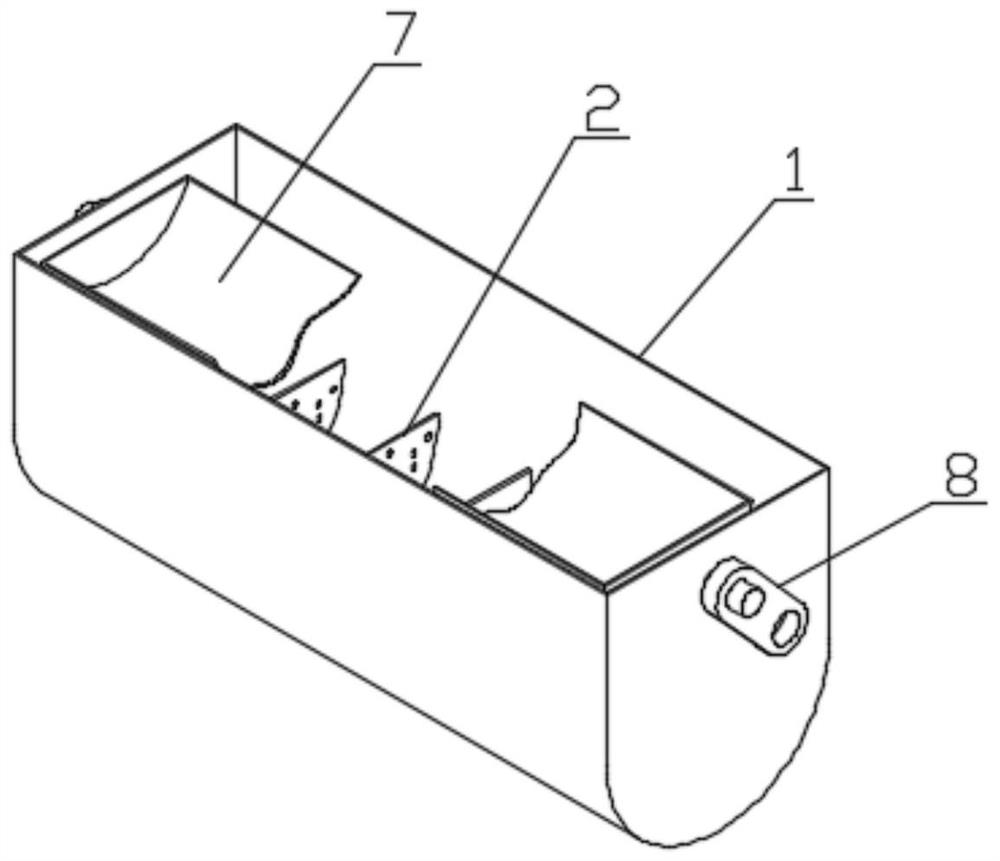

Printing ink raw material pre-mixing device

InactiveCN108854632AAchieve premixShorten mixing timeFlow mixersTransportation and packagingEngineeringPrinting ink

The invention relates to the technical field of printing ink production, in particular to a printing ink raw material pre-mixing device. The printing ink raw material pre-mixing device comprises an enclosure, wherein the bottom wall of the enclosure is provided with a first discharge outlet, the lower end of the enclosure is connected with two supporting legs, the upper wall of the enclosure is fixedly spliced with a barrel, the barrel is arranged above the first discharge outlet, the inner side wall of the barrel is connected with a partition plate, the partition plate divides the barrel intothree cavities, the bottom wall of each of the cavities is provided with a second discharge outlet, the bottom wall of the barrel is connected with a bucket, three baffles matching the cavities are arranged in the bucket, and one end of each of the baffles movably penetrates through the side wall of the bucket and is connected with an arc iron plate. An arc notch of a second gear in the printingink raw material pre-mixing device can be rotated to different arc iron plates to open the second discharge outlet of each of the cavities to drop different printing ink raw materials in a periodicalway and layer the printing ink raw materials to pre-mix the printing ink raw materials to reduce mixing time of mixing equipment while enhancing mixing effects.

Owner:安徽雅美油墨有限公司

Roflumilast solid dispersion and medicinal composition containing same

InactiveCN102988297AImprove solubilityDissolution rate is fastPowder deliveryPharmaceutical non-active ingredientsSolubilityMedicine

The invention discloses a roflumilast solid dispersion and a medicinal composition containing the same. The roflumilast solid dispersion comprises (1) roflumilast, (2) one or several of crosslinked polyvinylpyrrolidone, lactose, polyethylene glycol and microcrystalline cellulose, and (3) sodium dodecyl sulfate. The medicinal composition comprises the roflumilast solid dispersion and a pharmaceutically acceptable carrier. By preparing roflumilast into a solid dispersion, the solubility of a medicine is improved, the dissolution speed of the medicine is increased, and the dissolution rate of a medicinal composition containing the roflumilast solid dispersion in a dissolution medium is greatly improved; and in a grinding process, premixing of the medicine and some accessories is realized, and the problem in the content uniformity of a small dose of preparation is greatly reduced.

Owner:WUXI HONGXING BIOMEDICAL TECH

Herba violae planting and fertilizing device

ActiveCN108650964AImprove mixing efficiencyReduce energy consumptionTransportation and packagingMixersPistonFertilizer

The invention relates to the field of agricultural fertilizing equipment and discloses a herba violae planting and fertilizing device. The herba violae planting and fertilizing device comprises a rack, a mixing box is arranged on the rack, a hopper is communicated with the mixing box, a discharge pump is communicated with the mixing box, a discharge pipe is communicated with the discharge pump, aturbine is rotatably connected in the hopper, a cam is rotatably connected on the hopper, the cam is coaxially connected with the turbine, two symmetrical airbags are further arranged in the hopper, around tube is fixed onto the outer wall of the hopper, the airbags are communicated with the round tube, a first piston cylinder is fixed on the hopper, a first piston is slidably connected in the first piston cylinder, a first tapered bar is fixed on the first piston, a second tapered bar is slidably connected on the rack, rotary discs are rotatably connected in the mixing box, and stirring rodsare evenly distributed on the rotary discs circumferentially. Compared with the prior art, the herba violae planting and fertilizing device has the advantages that premixing and further mixing of fertilizer are combined, and mixing efficiency is improved obviously; sliding of the mixing box is not needed, energy consumption is reduced, and resources are saved.

Owner:贵州黔峰百草科技发展有限公司

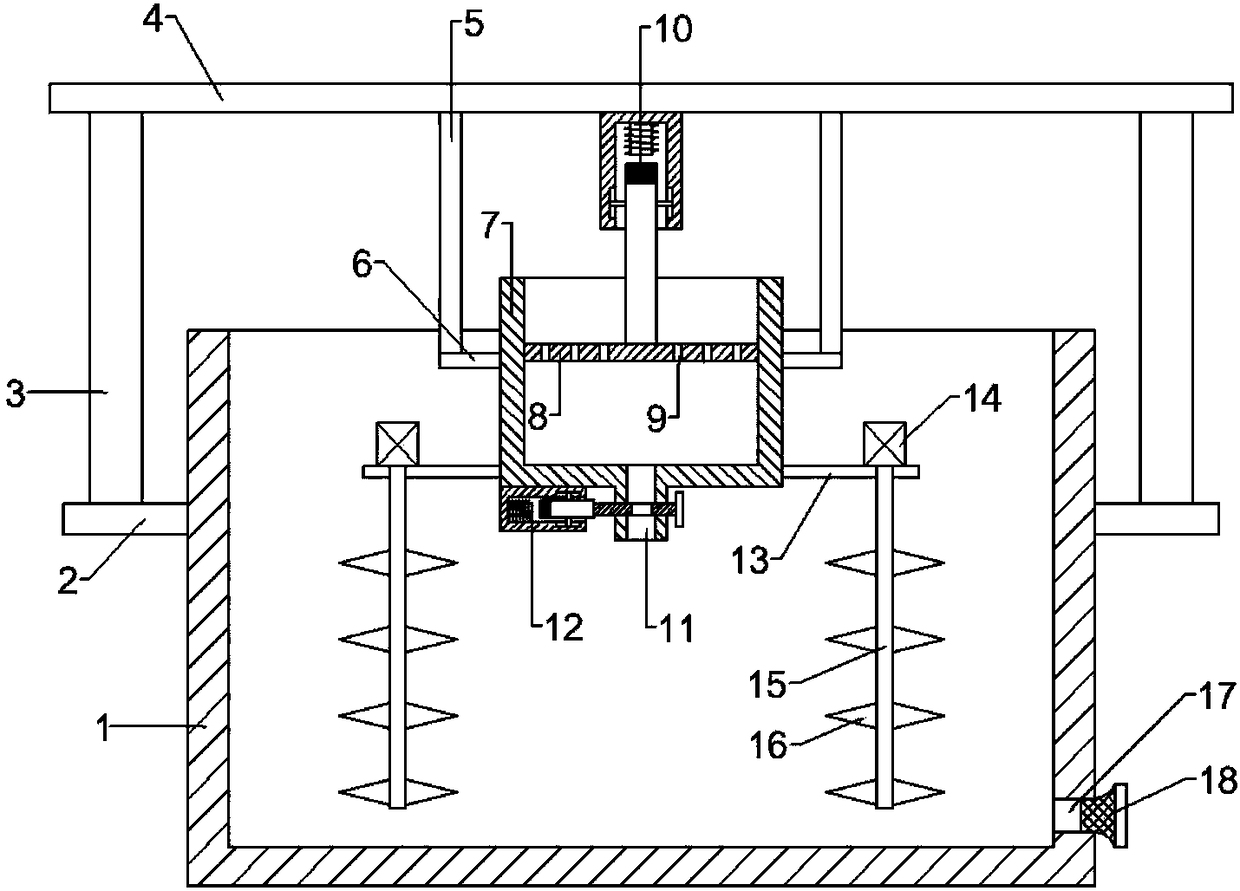

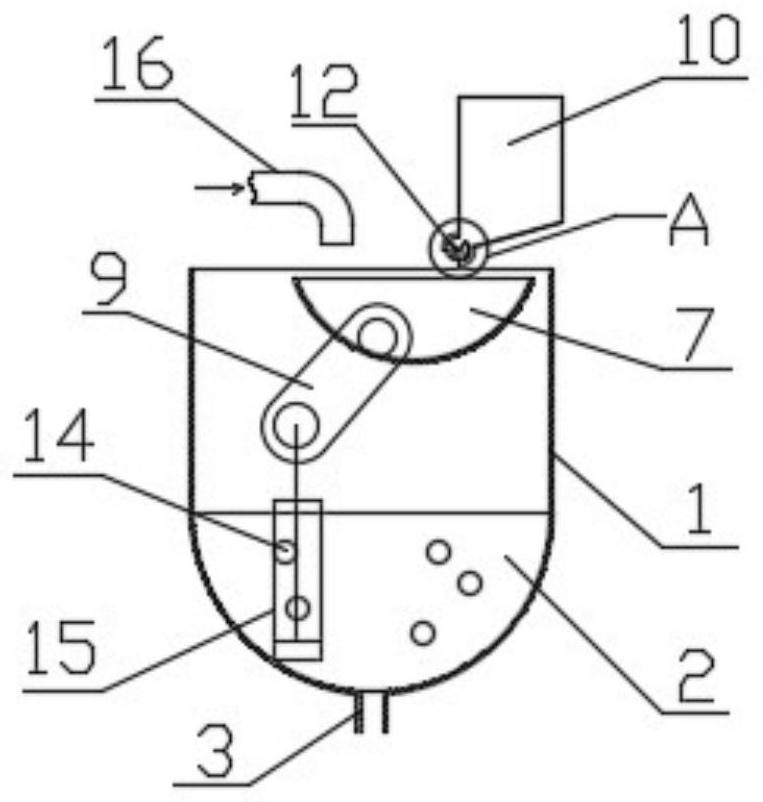

Sewage treatment equipment with flocculating agent premixing function

InactiveCN108128858AAchieve emissionsImprove solubilityTransportation and packagingMixersReverse currentBiochemical engineering

The invention relates to sewage treatment equipment with a flocculating agent premixing function. The sewage treatment equipment comprises a pool body, wherein two installing seats are symmetrically and fixedly connected onto the outer side wall of the pool body; a support post is fixedly connected onto each installing seat; the top ends of the two support posts are simultaneously and fixedly connected with a support plate; the lower side of the support plate is fixedly connected with two vertical rods; a horizontal rod is fixedly connected onto the bottom end of the vertical rods. The sewagetreatment equipment has the beneficial effects that reverse current is introduced into a first electromagnet; the first electromagnet repels a first magnetic pole, so that the first magnetic pole drives a reciprocating column to downwards move; the reciprocating column drives the extrusion plate to downwards move; the extrusion plate performs extrusion on the mixed liquid at the bottom of the reciprocating frame, so that the mixed liquid can upwards overflow through a through hole; when the mixed liquid passes through the through hole, a flocculating agent can realize the effective mixing effect on the sewage. The premixing of the flocculating agent and the sewage is realized through such repeated operation, so that the flocculating agent can be sufficiently dissolved; the mixing with a great amount of sewage in the subsequent process is convenient.

Owner:刘子亮

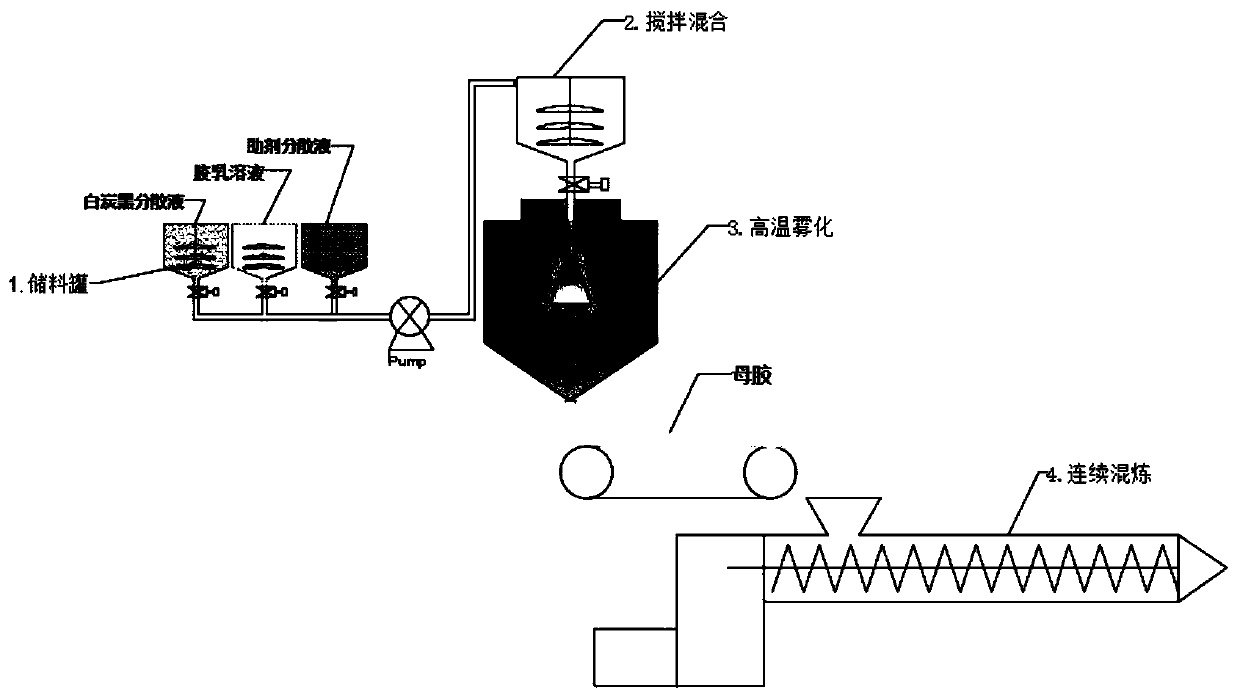

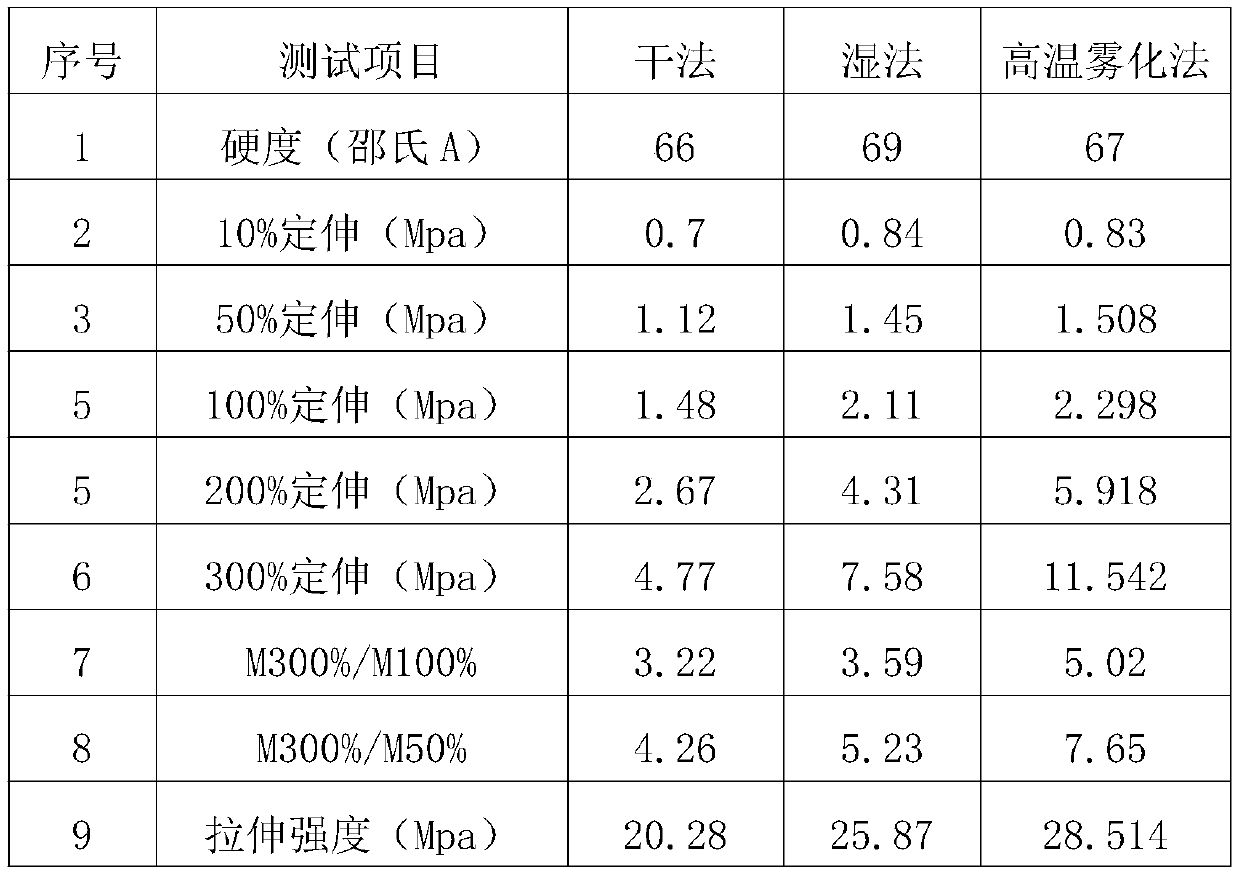

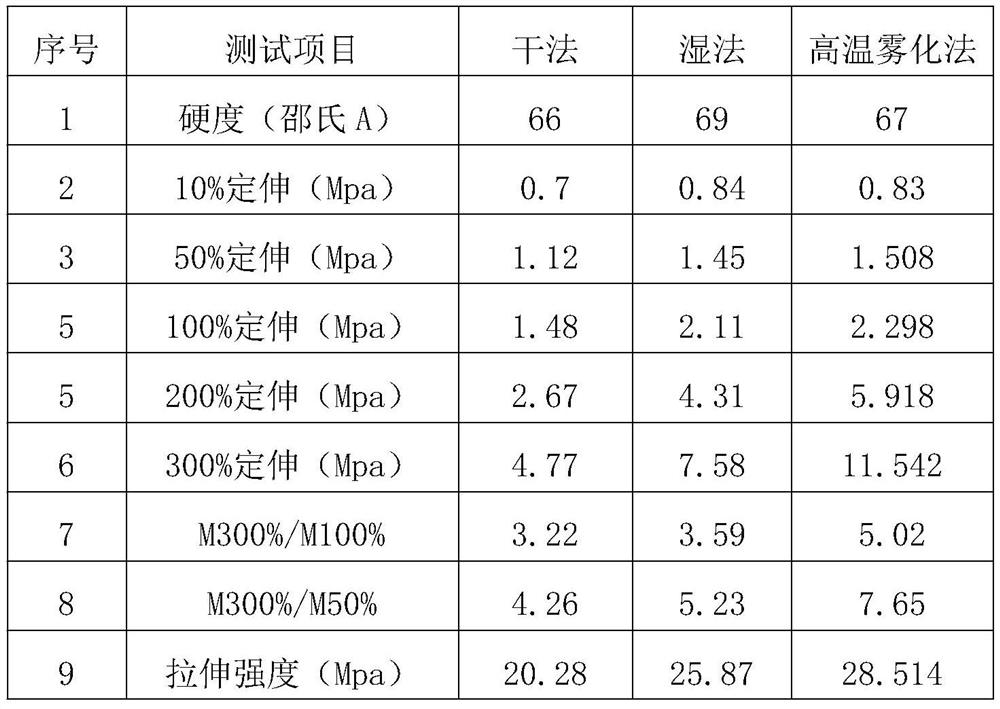

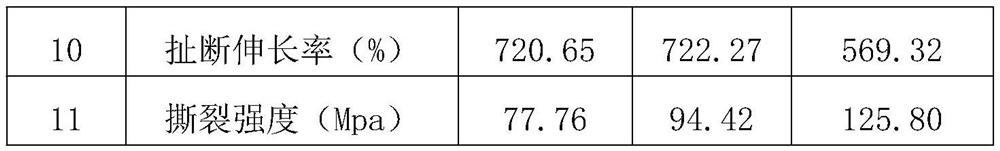

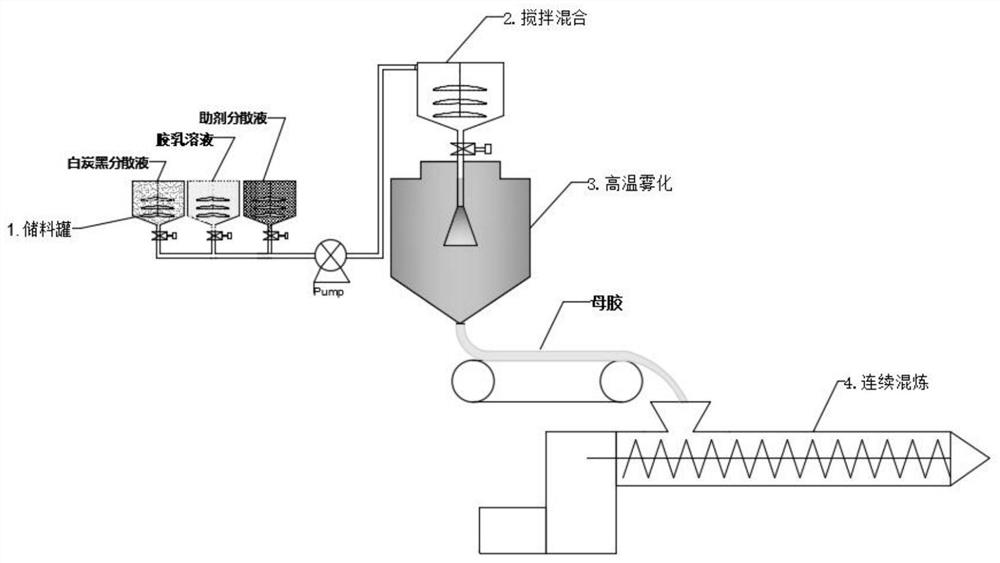

Preparation method of white carbon black/natural rubber composite material

The invention belongs to the technical field of natural rubber wet mixing, and relates to a preparation method of a white carbon black / natural rubber composite material. Wet mixing process is adopted,the preparation method comprises the following steps: preparing white carbon black into a uniform dispersion solution through mechanical grinding; mixing the obtained dispersion solution with naturallatex, slowly stirring to enable the natural latex to be in full contact with the white carbon black; carrying out flocculation of negatively charged natural latex with positive charges generated bya high-temperature atomization method, and coating the white carbon black in an obtained flocculate; and carrying out dehydration drying to prepare the white carbon black / natural rubber composite material. The white carbon black / natural rubber composite material and the preparation method thereof have the innovation points that: first, other rubber auxiliaries except afiller and the latex in the formula are added together, so that premixing of the materials in the formula is realized, later processing is facilitated, the mixing time is shortened, and dust pollution generated during mixing is reduced; and second, the processing mode is continuous, aprepared masterbatch is put into a continuous mixing mill, and continuous production can be realized.

Owner:QINGDAO UNIV OF SCI & TECH

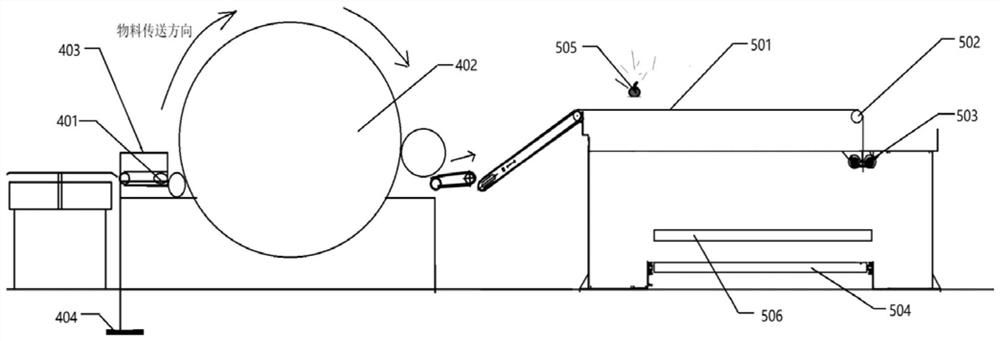

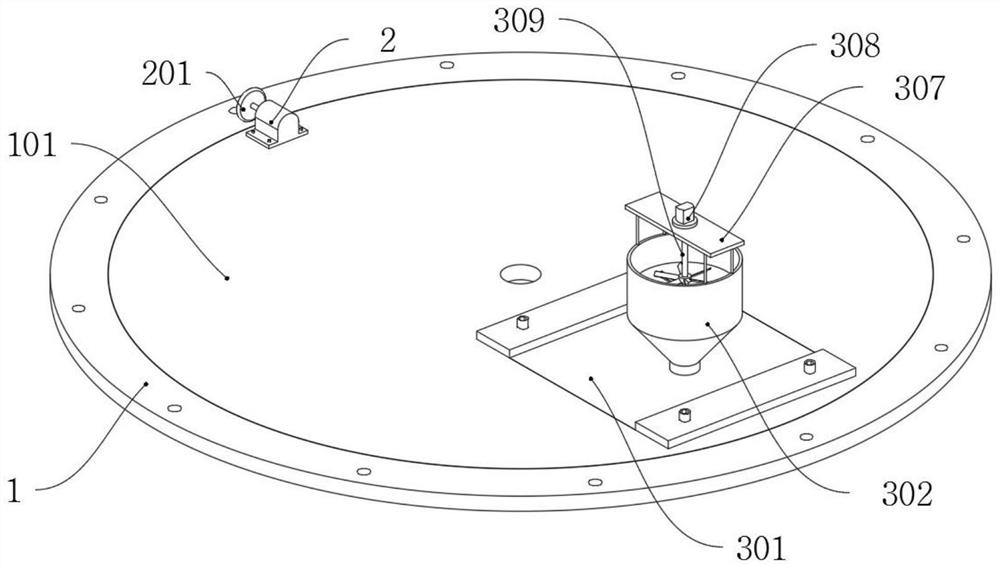

Complete equipment for preparing liquefied consolidated soil from waste residue soil and construction method of complete equipment

PendingCN112776182AWell mixedQuality improvementIngredients weighing apparatusCement mixing apparatusProcess engineeringMaterial storage

The invention discloses complete equipment for preparing liquefied consolidated soil from waste residue soil and a construction method of the complete equipment. The complete equipment comprises a screening device, an ingredient conveying device, a material storage device, a material conveying device, a stirring device, a finished product material temporary storage bin, a pumping device, a finished product material conveying pump and a control device. The discharging end of the screening device is connected with the feeding end of the ingredient conveying device. The discharging ends of the ingredient conveying device and the pumping device are both connected with the feeding end of the stirring device, the discharging end of the stirring device is connected with a feeding port of the finished product material temporary storage bin, a discharging port of the material storage device is connected with a feeding port of the material conveying device, and a discharging port of the material conveying device is connected with the ingredient conveying device. The finished product material conveying pump is connected with a discharging port of the finished product material temporary storage bin through a pipeline, and the screening device and the ingredient conveying device are arranged in a radial offset mode. In general, the complete equipment for preparing the liquefied consolidated soil from the waste residue soil and the construction method of the complete equipment have the advantages of being convenient to use, accurate and stable in metering, small in operation difficulty, short in construction period and good in construction quality.

Owner:河南绿岩工程科技有限公司

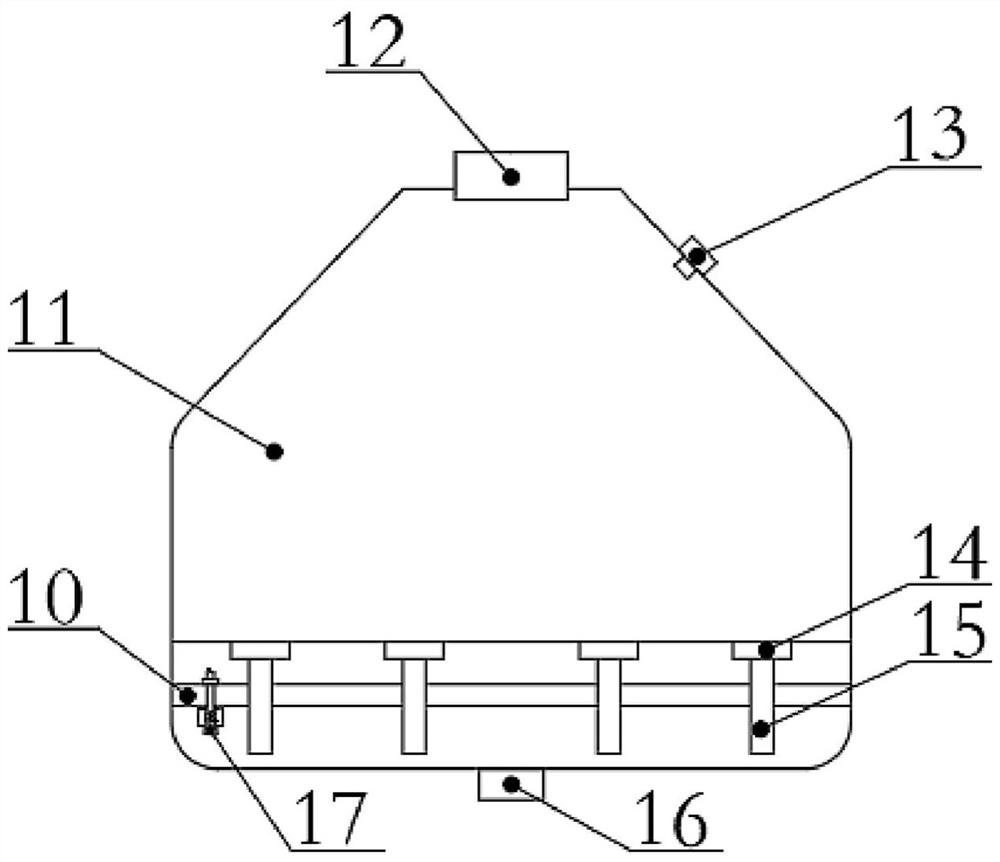

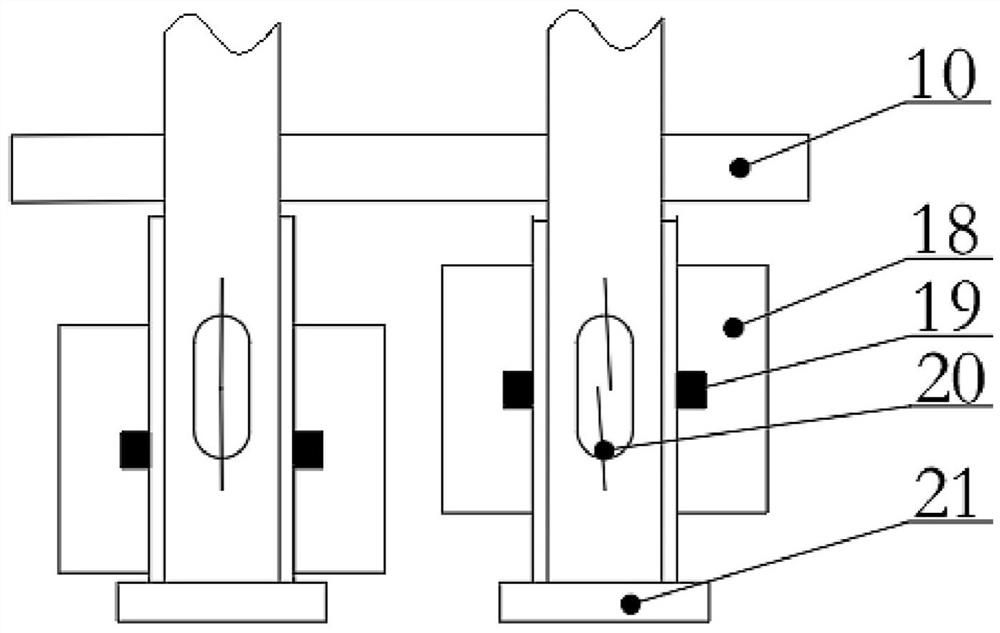

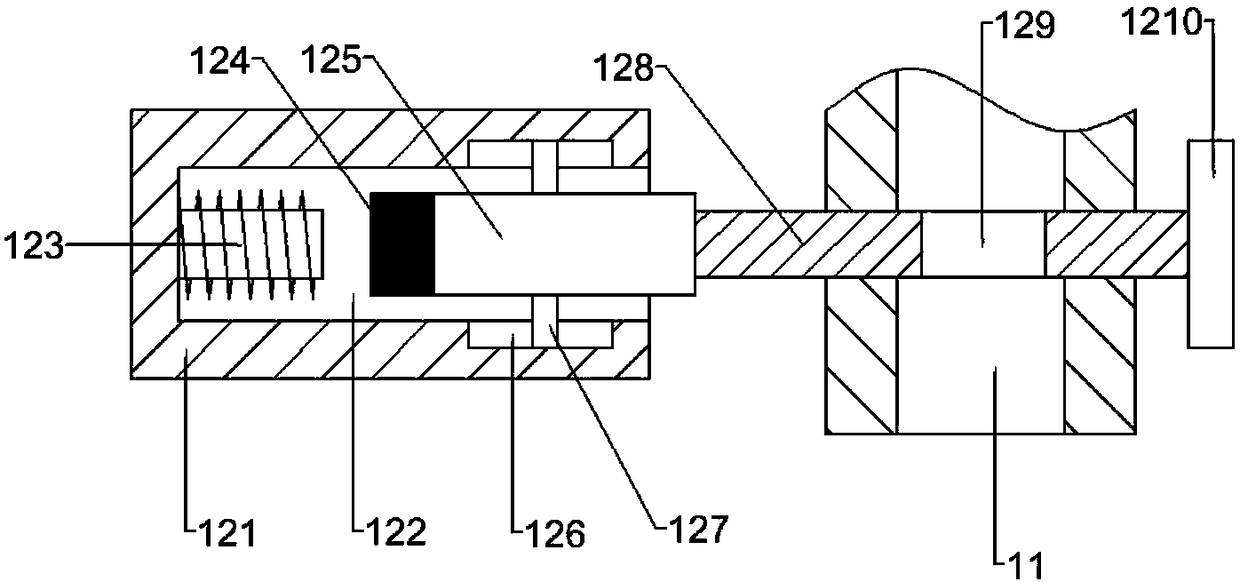

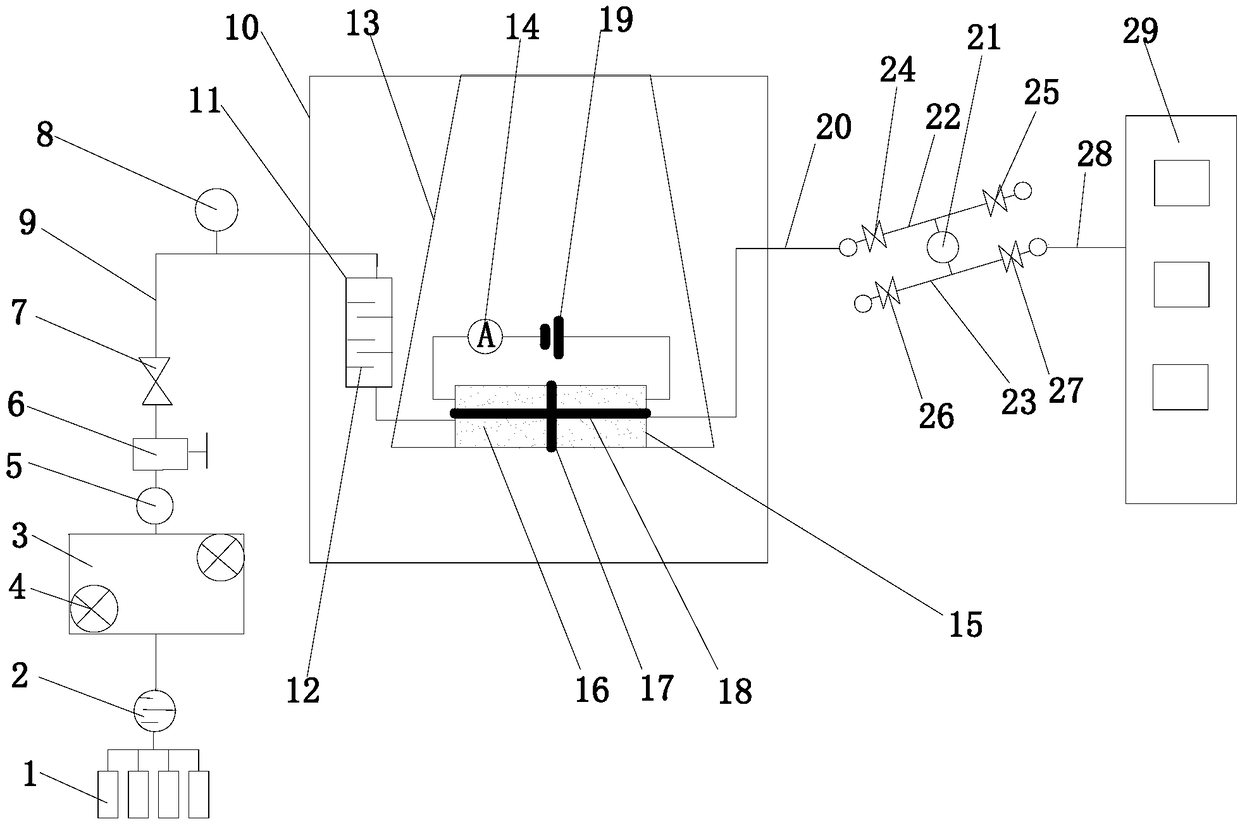

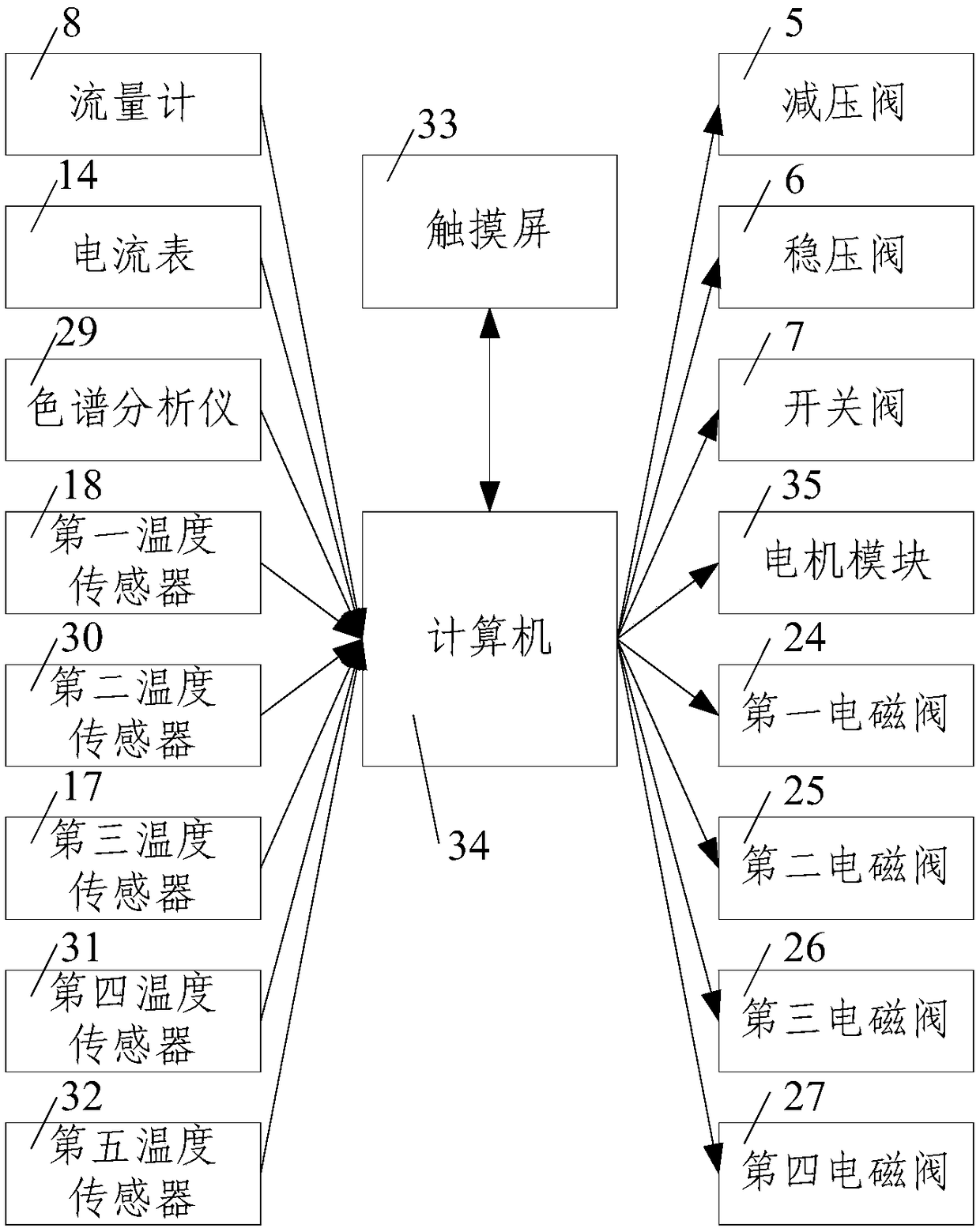

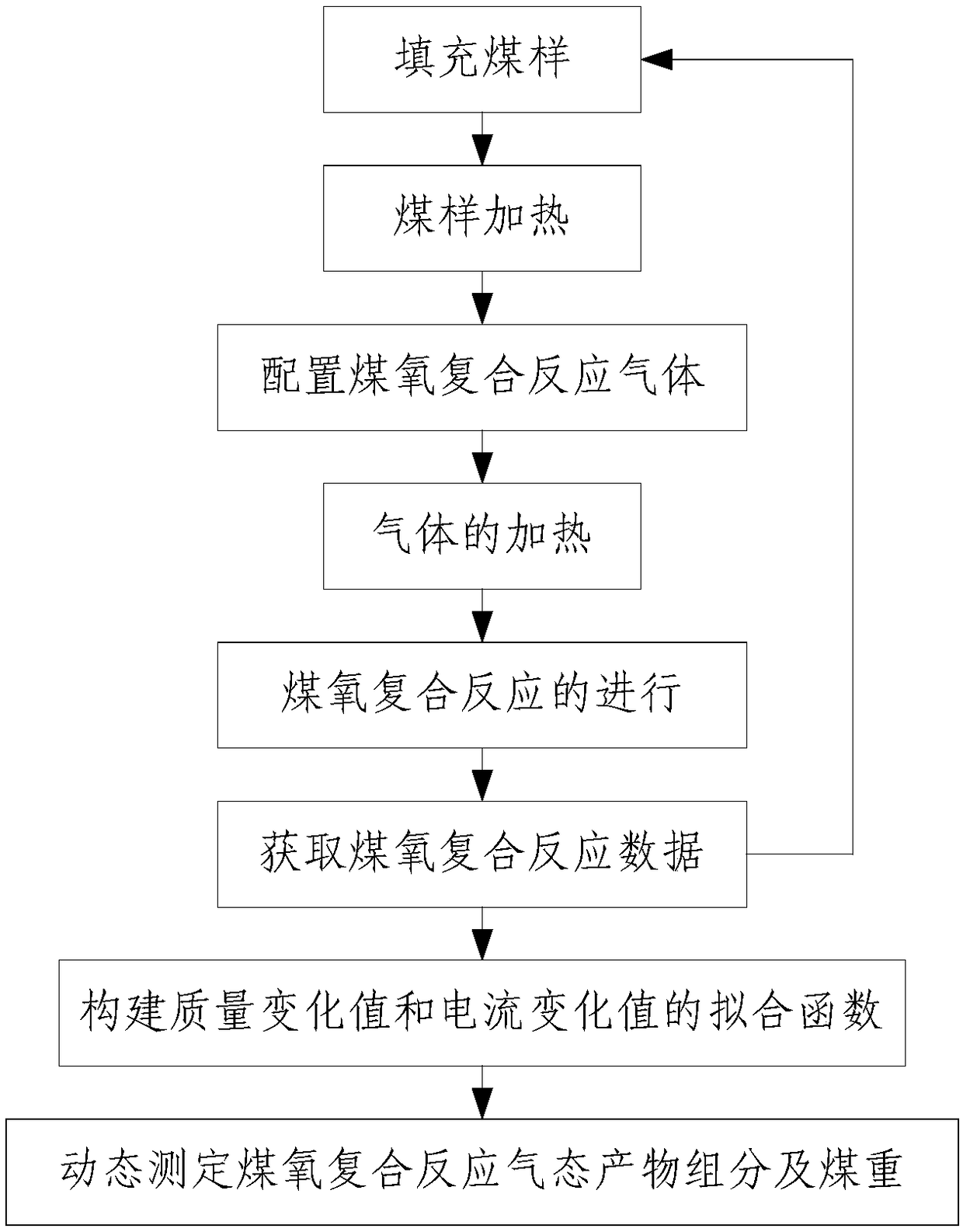

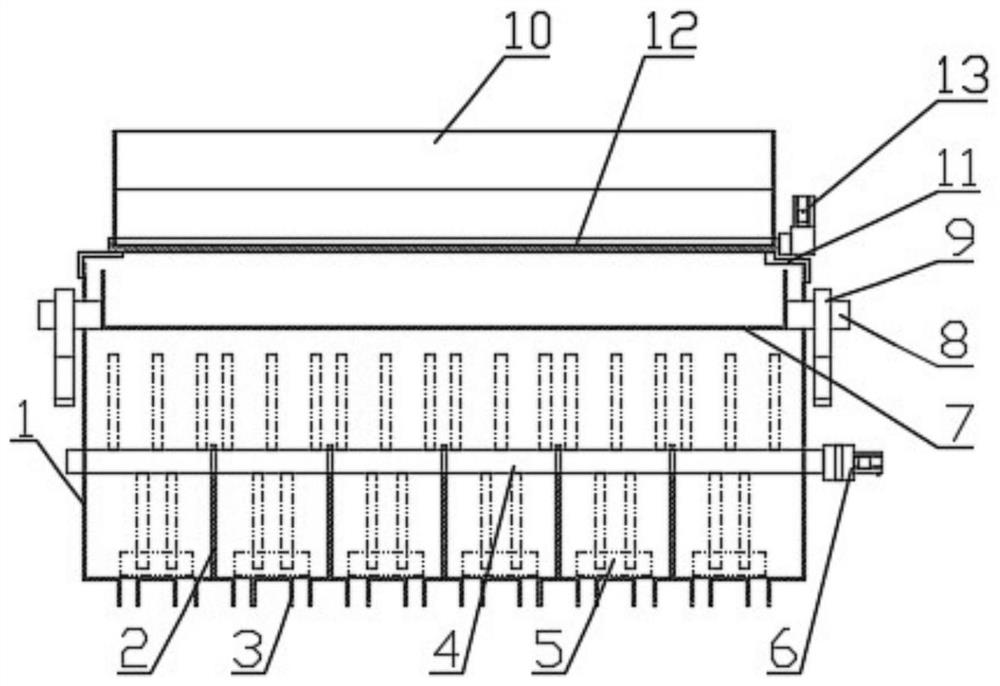

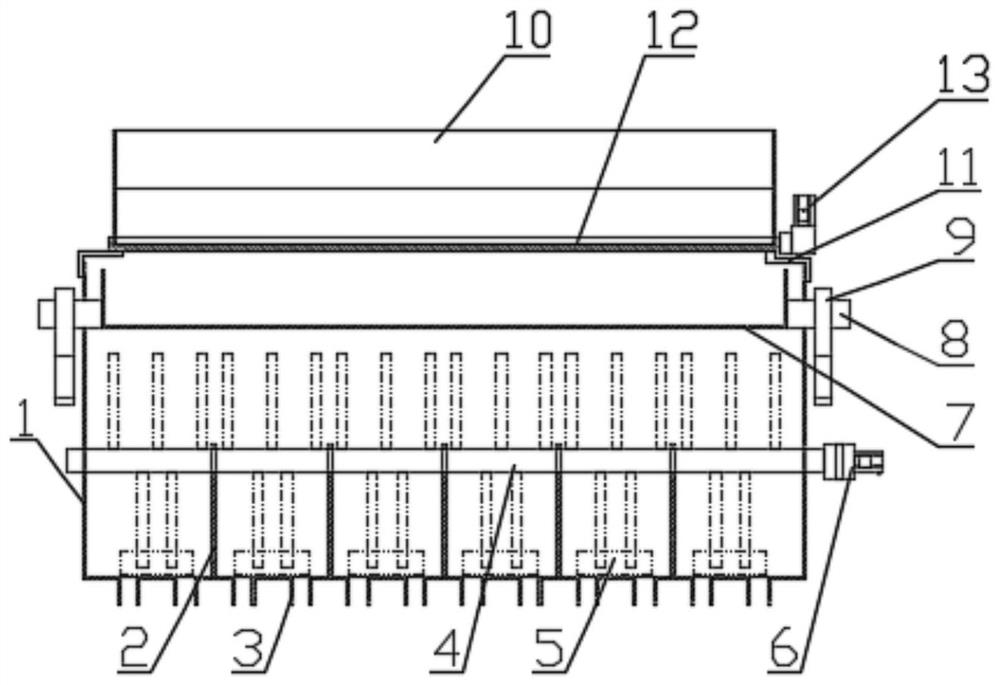

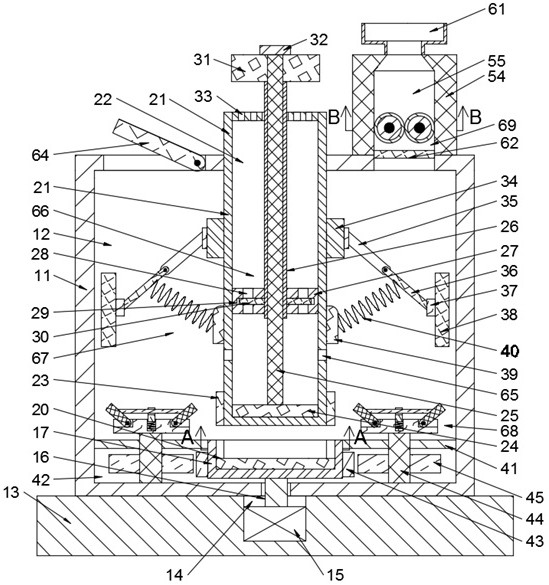

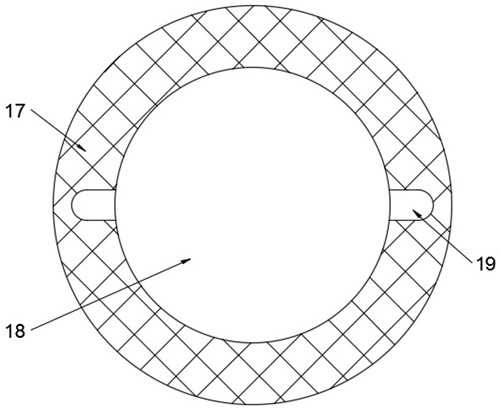

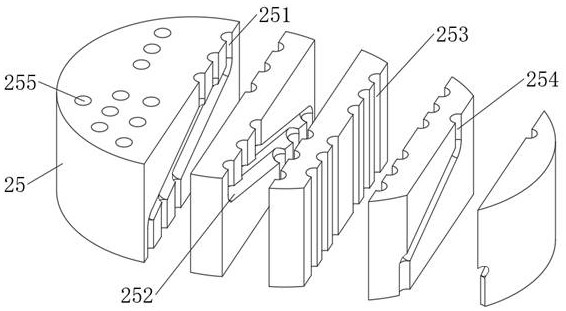

Dynamic measurement device and method for coal-oxygen composite reaction gaseous product component and coal weight

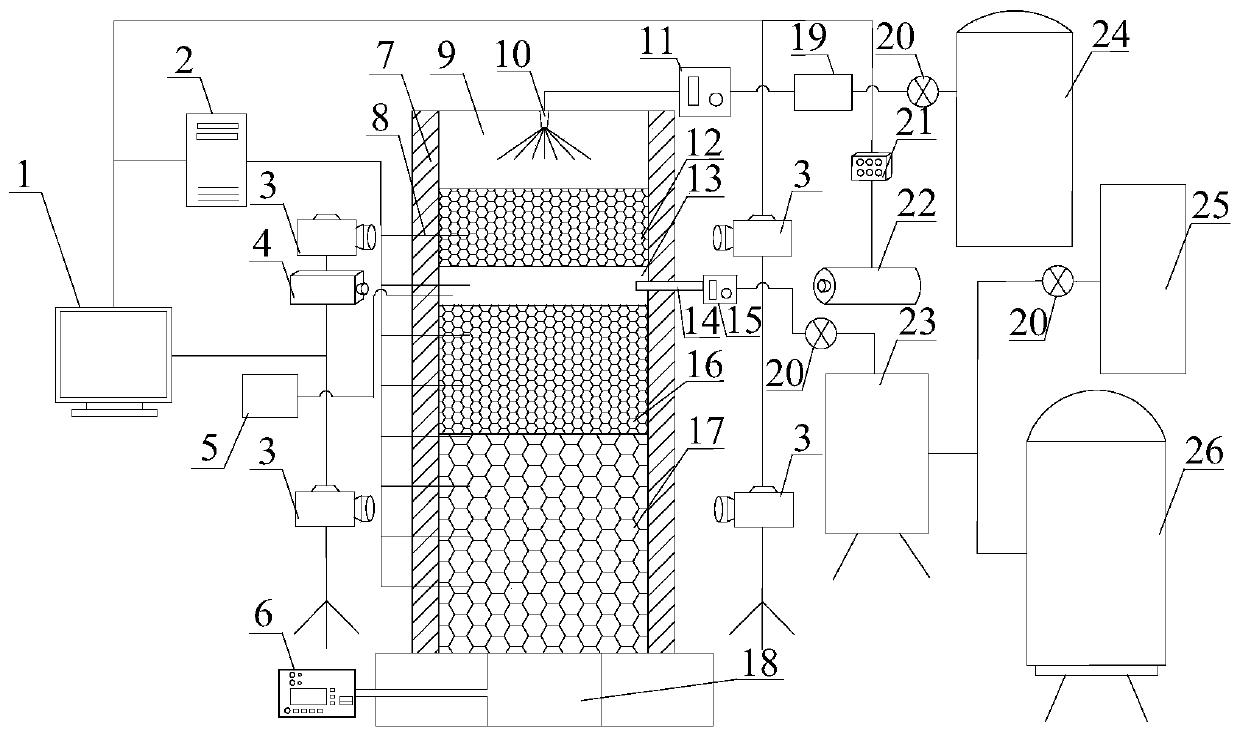

ActiveCN109342171AAchieve premixAchieve secondary thorough mixingComponent separationWithdrawing sample devicesChemical reactionMeasurement device

The invention discloses a dynamic measurement device and method for a coal-oxygen composite reaction gaseous product component and coal weight. The device comprises an air inlet mechanism, a compoundreaction mechanism, a quantitative gas extraction mechanism and a chromatographic analyzer which are sequentially connected. The method comprises the following steps of: 1, filling coal samples; 2, heating coal samples ; 3, configuring a coal oxygen composite reactant gas; 4, heating the gas; 5, performing a coal oxygen composite reaction; 6, acquiring coal oxygen composite reaction data; 7, repeating the steps from step 1 to 6; 8, constructing a fitting function of the mass change value and the current change value; 9, and dynamically determining the coal-oxygen composite reaction gaseous product component and coal weight. The invention fully mixes all the experimental gases to meet various high requirements of experimental gas. The coal oxygen can be accurately reacted, the system erroris small, and the quantitative gas extraction mechanism is used to obtain the gaseous product components of the coal-oxygen composite reaction in each stage. The temperature, weight and gas componentswhich characterize the nature of the relatively slow chemical reaction process are reliably extracted, and the comprehensive measurement is performed.

Owner:XIAN UNIV OF SCI & TECH +1

Indacaterol solid dispersion and pharmaceutical composition containing same

InactiveCN103830194AImprove solubilityDissolution rate is fastPowder deliveryOrganic active ingredientsIndacaterolSolubility

The invention provides an indacaterol solid dispersion and a pharmaceutical composition containing the same. The indacaterol solid dispersion comprises (1) indacaterol, (2) one or more of crosslinked polyvinylpyrrolidone, lactose, polyethylene glycol and microcrystalline cellulose; (3) sodium dodecyl sulfate. The pharmaceutical composition comprises the indacaterol solid dispersion and a pharmaceutically acceptable carrier. By making the indacaterol into a solid dispersion, the drug solubility is improved, the dissolution speed of the drug is increased, and the dissolution rate of the pharmaceutical composition containing the solid dispersion is greatly improved in a dissolving medium; moreover, in a grinding process, the premixing of the drug and partial accessories is realized, and the problems in the content uniformity of a small-dose preparation are remarkably reduced.

Owner:熊妲妮

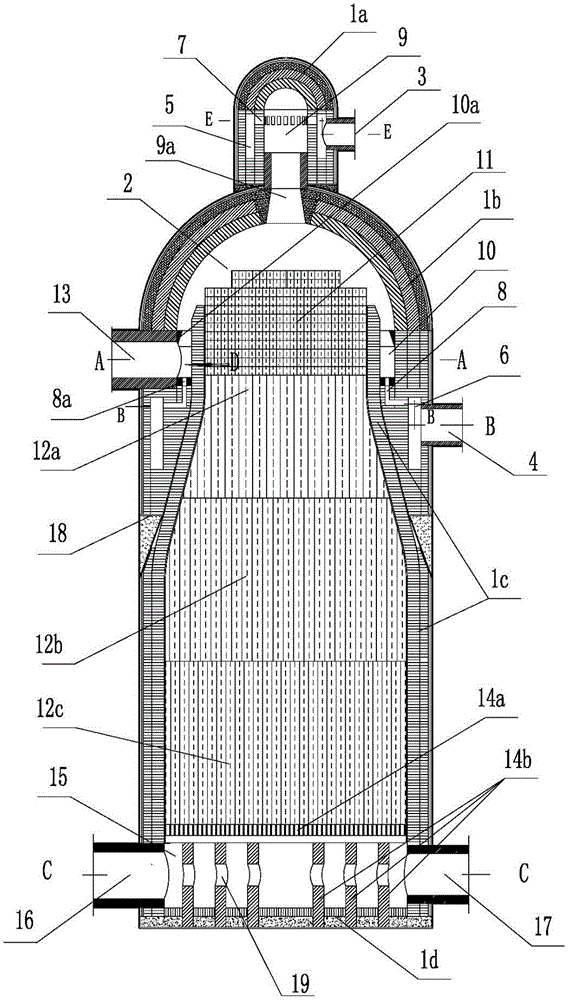

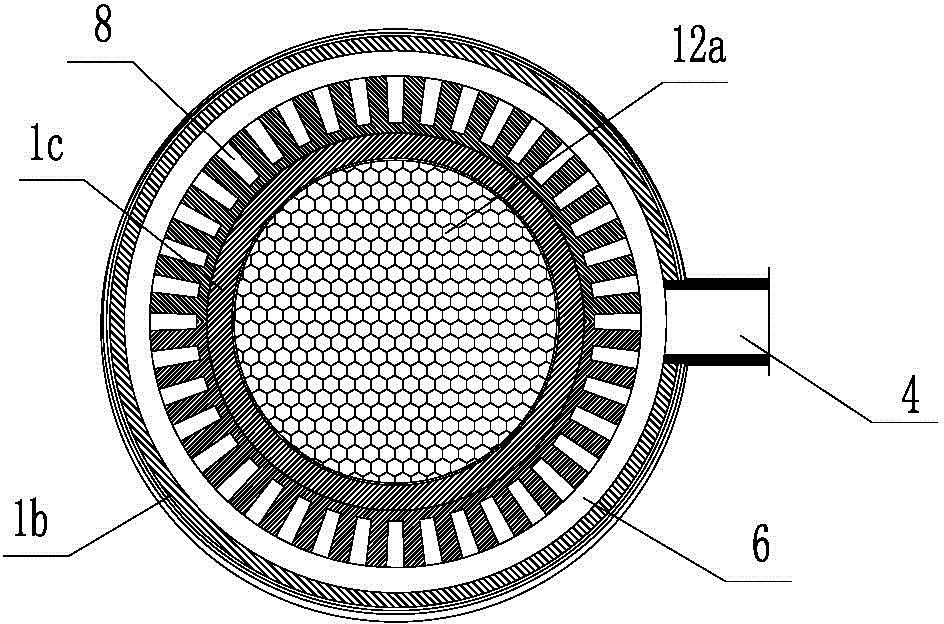

Heat storage body gas and air swirl entrainment pre-mixing combustion hot-blast stove

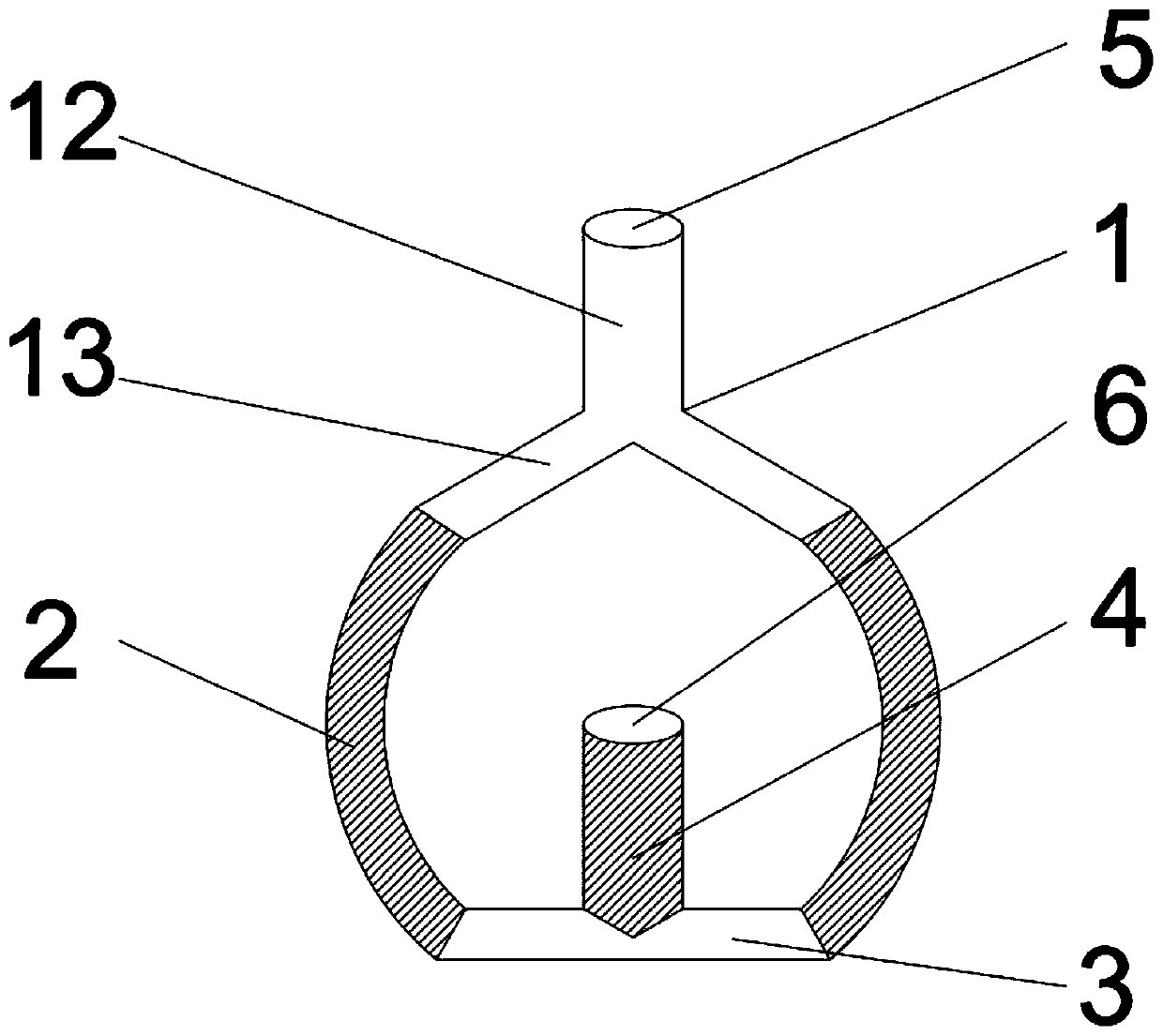

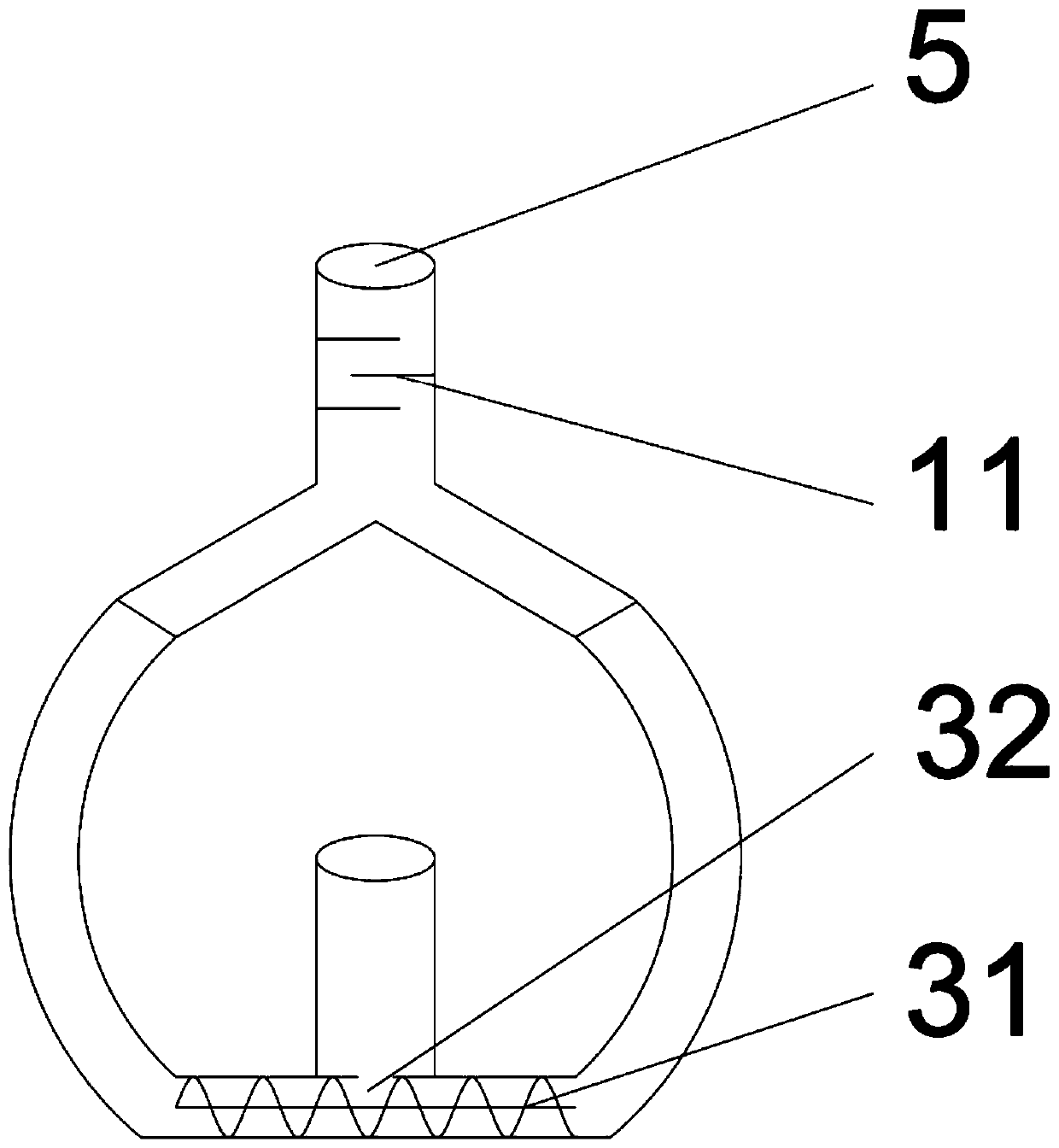

ActiveCN104962677AIncrease temperatureImprove heat utilizationBlast furnace detailsHeating stovesCombustion chamberEngineering

The invention relates to a heat storage body gas and air swirl entrainment pre-mixing combustion hot-blast stove. The hot-blast stove solves the problems of low mixing rate, non-uniform mixing effects, and low intensity, low temperature and incomplete combustion. A sleeve-type heat storage block is arranged in the wall of a combustion chamber, a gas inlet pipe at the lower part is connected to a gas distribution circuit, a gas main nozzle of the gas distribution circuit is communicated with a gas adjustment nozzle, the gas adjustment nozzle is connected to the bottom of a gas mixing circuit, the top of the gas mixing circuit is provided with an annular adjustment baffle plate, an air inlet pipe of the wall of an air mixing chamber at the top is connected to an air distribution circuit, the air distribution circuit is provided with an air distribution nozzle, the bottom of the air mixing chamber is provided with an air nozzle, the wall is provided with a hot air outlet pipe, the wall of a heat storage chamber is sleeved by the wall of the combustion chamber and is built on the stove bottom, support columns on the stove bottom are provided with a grate, the heat storage block is arranged on the grate, and the lower part of the grate is provided with a flue gas outlet pipe and a cold air inlet pipe. The hot-blast stove has the advantages of uniform mixing, high combustion intensity, uniform air-flow distribution, good heat transfer uniformity and high heat utilization rate.

Owner:陈维汉

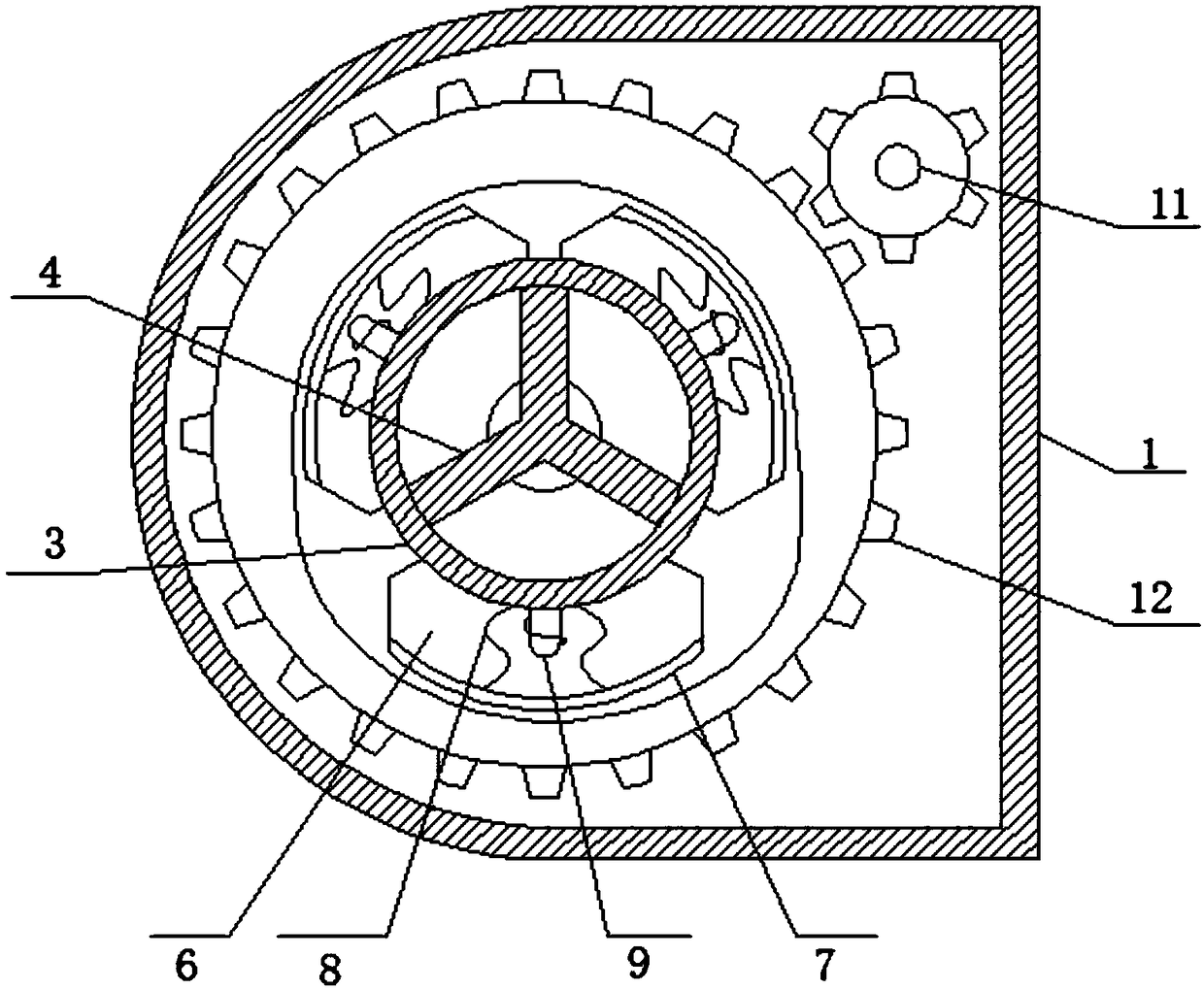

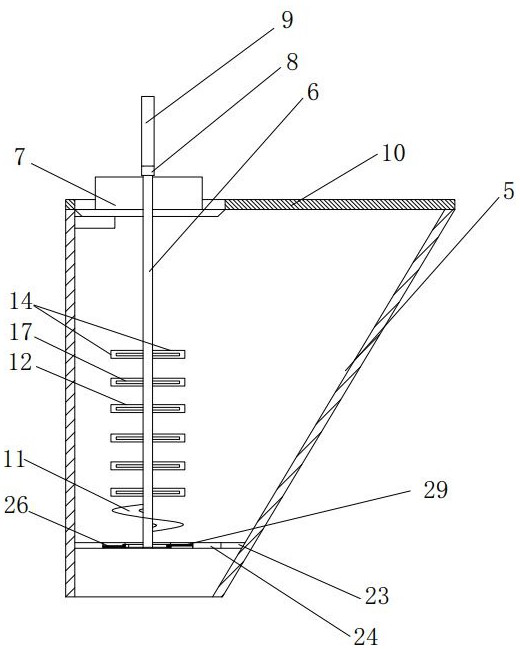

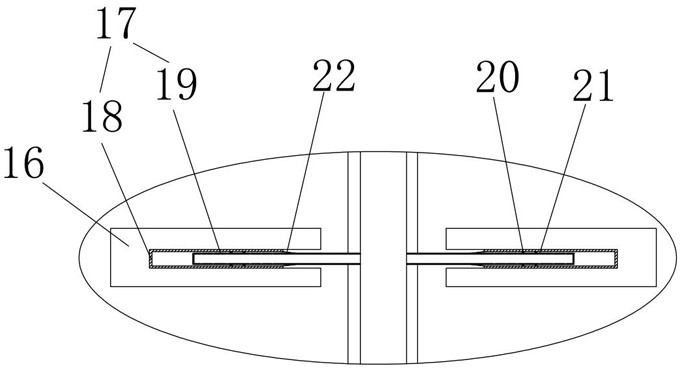

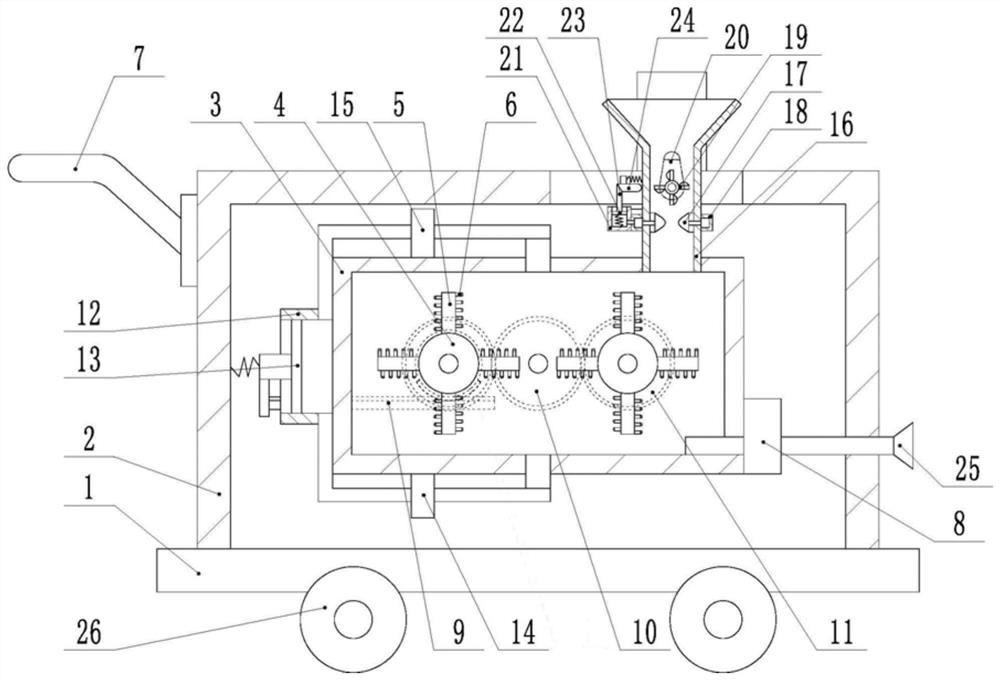

Cotton blending machine device with pre-blending function

ActiveCN111472071AAvoid the problem of poor premixing effectAchieve premixFibre mixingIsosceles trapezoidFiber

The invention discloses a cotton blending machine device with a pre-blending function. The cotton blending machine device comprises a bottom plate, and a box is arranged at the top end of the bottom plate. A feeding port is formed in the middle of the top end of the box, and a discharging port is formed in the lower portion of the right side wall of the box. A conveying mechanism is arranged at the bottom of an inner cavity of the box. The right portion of the conveying mechanism penetrates through the discharging port, and convex blocks are arranged on the upper portion of the inner cavity ofthe box in a bilateral symmetry manner. The cross sections of the convex blocks are in the shapes of isosceles trapezoids, and through holes are formed in the middles of the faces, close to each other, of the convex blocks. Pre-blending mechanisms are arranged in the through holes in the two sides. According to the cotton blending device, by means of the arranged pre-blending mechanisms, multiplekinds of fabric can be pulled and dispersed before entering cotton blending pin rolls, and therefore different kinds of fabric are pre-blended, and the subsequent blending effect is improved; and according to the pre-blending mechanisms, cotton fibers wound around blending rods can be automatically separated, and the problem that due to cotton fiber winding, the pre-blending effect is poor is avoided.

Owner:杭州煜凯服饰股份有限公司

Liquid fuel combustion condition parameter measuring device and method

ActiveCN111505199AAchieve premixWiden the lean limitChemical analysis using combustionChamber safety arrangementThermodynamicsCombustor

The invention discloses a liquid fuel combustion working condition parameter measuring device and method. A porous medium combustor comprises a fuel injection cavity, a porous medium gasification area, a premixing observation chamber, a porous medium anti-backfire area, a porous medium combustion area, a product collection chamber and heat insulation layers which are sequentially arranged from topto bottom, wherein the heat insulation layers are arranged on the two sides. Tracer particles are added into liquid fuel through a tracer particle generator, the change of the tracer particles is monitored through a PIV tester, and a schlieren instrument is used for capturing a transient image when the liquid fuel is gasified; and the high-speed camera is used for shooting a picture of liquid gasification time in the porous medium combustor and a flame surface at complete combustion time. According to the invention, the schlieren instrument and the PIV technology are adopted to capture the mixing state of two gas flow fields of liquid fuel and air in time, record the gasification moment of the liquid fuel and record the complete combustion moment of the liquid fuel by using the high-speedcamera to shoot the flame surface, so that the research on the working condition limit, especially the gasification rate and the complete combustion rate of the liquid fuel is facilitated.

Owner:WUHAN UNIV OF TECH

Chemical liquid shunting spiral hedging mixer

PendingCN110756073AAchieving a hedged mixAchieve premixFlow mixersTransportation and packagingEngineeringPipe

The invention discloses a chemical liquid shunting spiral hedging mixer, which comprises a material shunting pipe, a plurality of diversion pipes, a spiral hedging mixing pipe and a finished product discharging pipe which are connected in sequence, and is characterized in that the material shunting pipe comprises a main pipe and a plurality of branch pipes; the end part of each branch pipe is connected with a flow guide pipe, and the other end of each flow guide pipe is connected with the left end or the right end of the spiral hedging mixing pipe; at least one flow guide pipe is connected toeach of the two ends of the spiral hedging mixing pipe; and the middle part of the spiral hedging mixing pipe is connected with the finished product discharging pipe. Materials are divided into two paths through the material shunting pipe, and finally hedging and mixing of the materials are achieved; spoilers are arranged on the main pipe of the material shunting pipe, so that premixing of variousliquid materials is realized; by means of spiral fins, the materials flow in a spiral motion mode, the two strands of the materials rotate and impact in opposite directions during hedging, and the mixing effect is better.

Owner:新榕能源(福建)有限公司

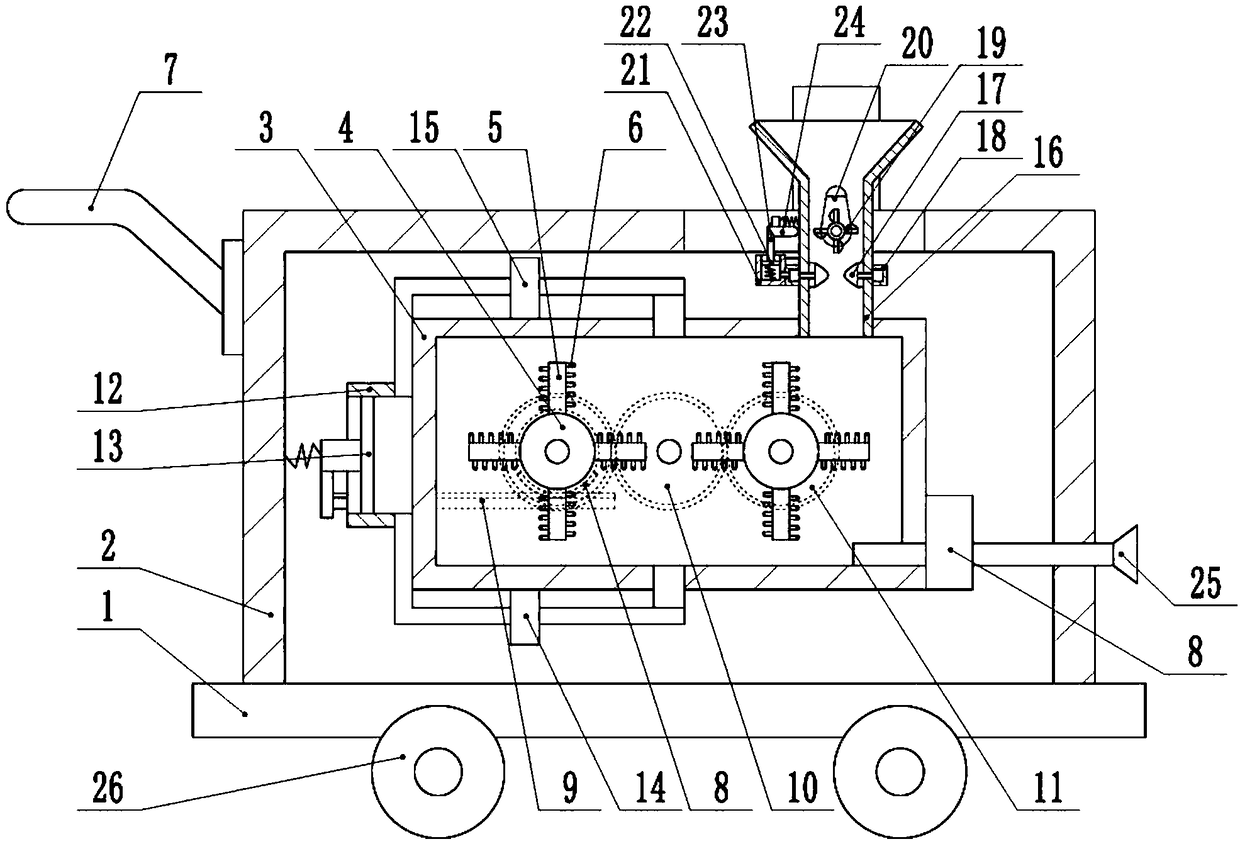

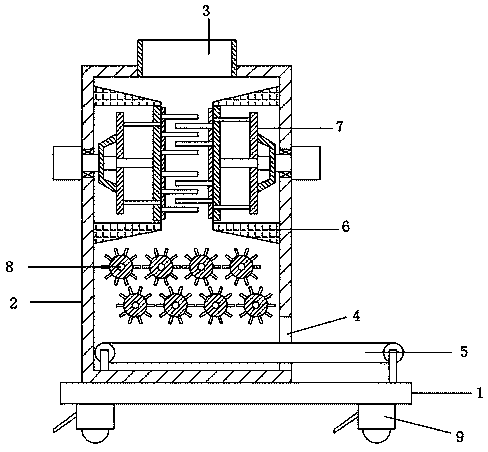

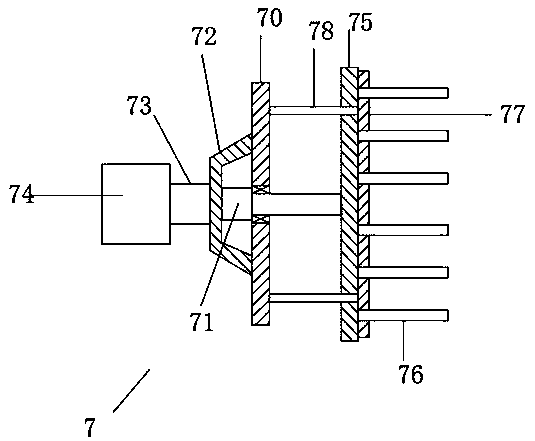

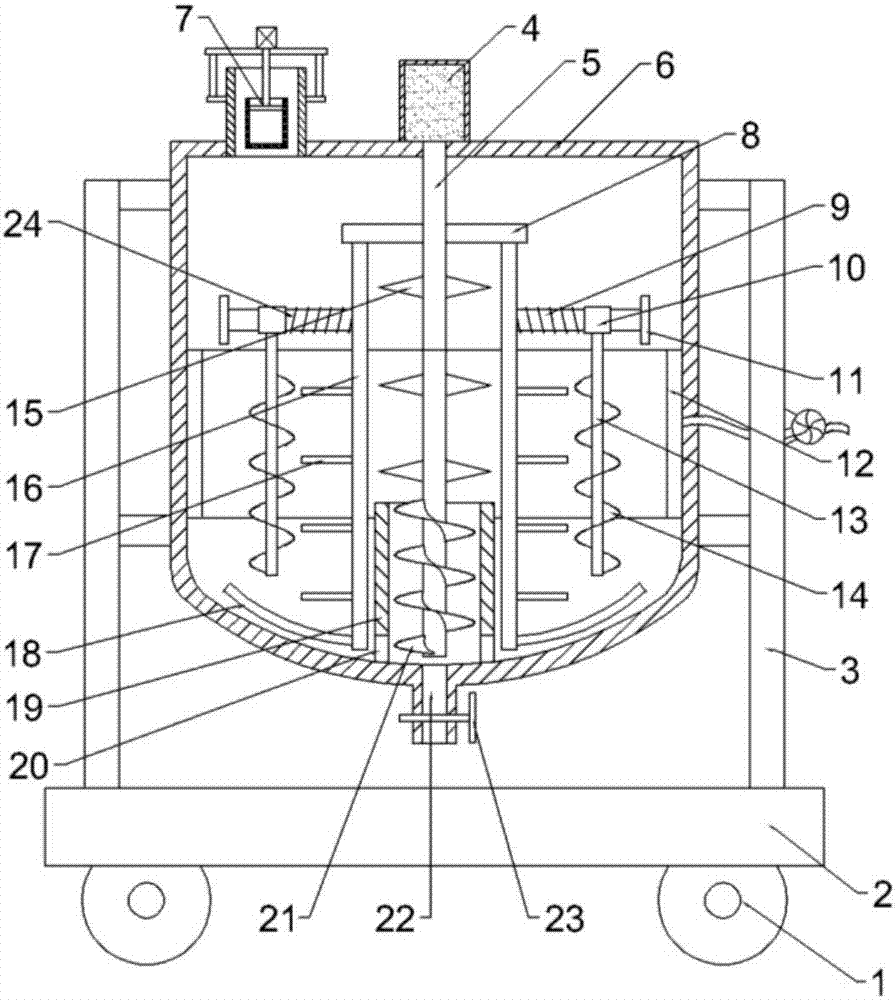

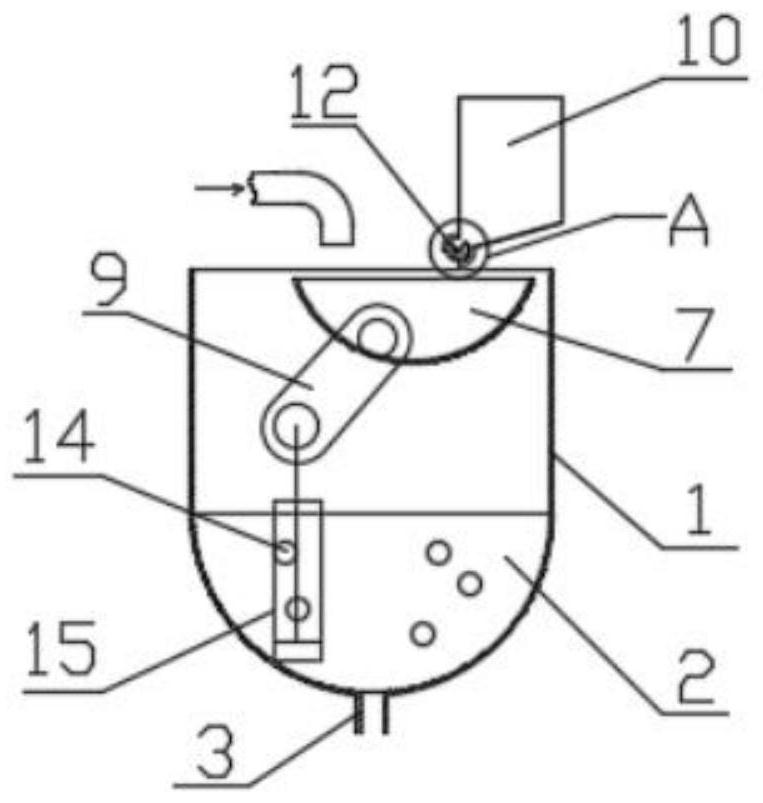

Health care medicine production and manufacturing equipment with premixing function

InactiveCN107456911AWell mixedImprove the mixing effectTransportation and packagingMixer accessoriesHelical bladeEngineering

The invention relates to health care medicine production and manufacturing equipment with a premixing function. The health care medicine production and manufacturing equipment comprises a base and rolling wheels arranged at the lower side of the base, wherein two support frames are arranged on the base; a material mixing casing is fixedly connected between the support frames; the top of the material mixing casing is provided with a premixing device; the bottom of the material mixing casing is provided with a circular arc part; a first rotating shaft is arranged in the material mixing casing; the top end of the first rotating shaft is connected with a first motor positioned above the material mixing casing; the inner bottom of the material mixing casing is provided with a lifting sleeve. The health care medicine production and manufacturing equipment has the beneficial effects that the material premixing of materials is realized by the premixing device; the burden of the subsequent mixing is reduced; the mixing effect is improved; the materials at the bottom of the lifting sleeve are lifted by a first helical blade; the material sinking at the bottom of the material mixing casing is prevented; a circular arc rod is used for stirring the circular arc part of the material mixing casing; the material sinking is further prevented; the material stirring and mixing effects are effectively improved; the stirring rod is also used for stirring and mixing the materials.

Owner:石岩

Degradable environment-friendly cinerary casket and production process thereof

PendingCN114479201ASpeed up the conversion processImprove the level of energy saving and emission reductionShaping pressFood additiveFood material

The invention discloses a degradable environment-friendly cinerary casket material which comprises the following components in percentage by weight: 70%-75% of corn starch, 15%-20% of sorbitol, 6%-10% of microcrystalline cellulose and 0.5%-1% of glycerol. The corn starch is used as a main material of the tank body, is a food material, is widely used for processing various foods, is affordable in price, and is mainly green and environment-friendly when being used for the product. Sorbitol is a food additive, is a wetting agent, a chelating agent and a stabilizing agent, and has the effects of preserving moisture, chelating metal ions, improving tissue fineness and preventing starch aging. The microcrystalline cellulose has the functions of moisture absorption, stable substances, lubrication, disintegration, binding and easy demolding. The glycerol has the effects of retaining water and being easy to demould. The defects that existing cinerary caskets are all made of wood, cannot be quickly degraded and are not environmentally friendly are overcome.

Owner:浙江祥泰礼仪服务有限公司

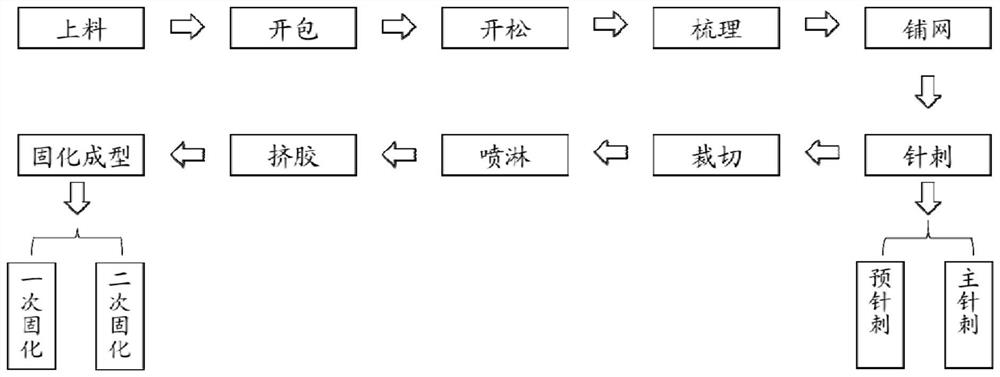

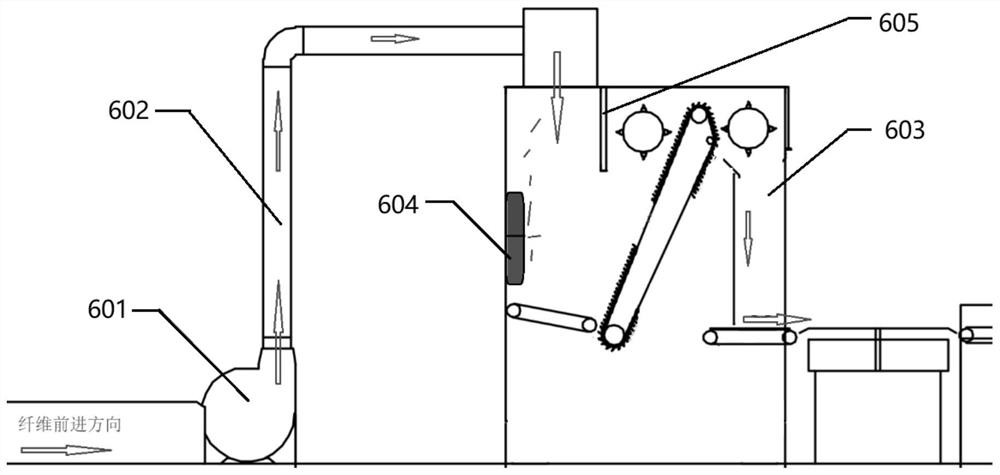

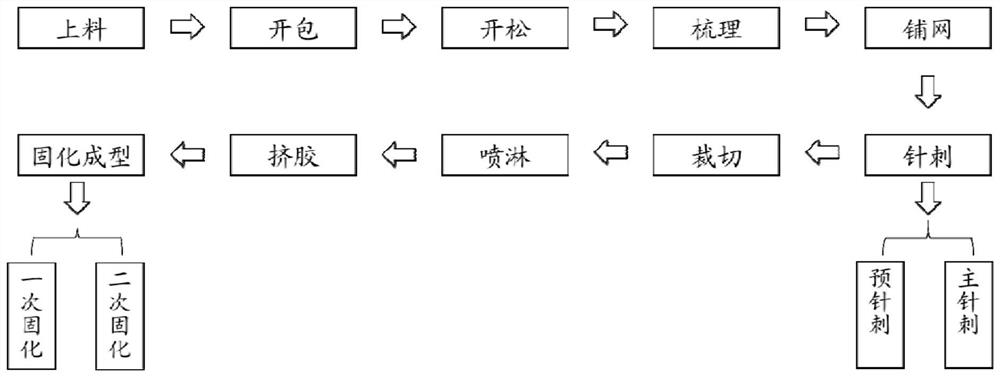

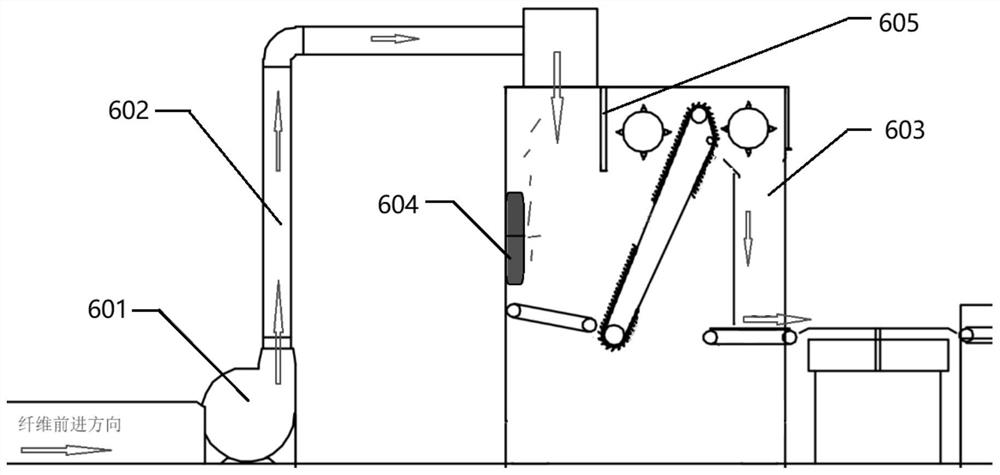

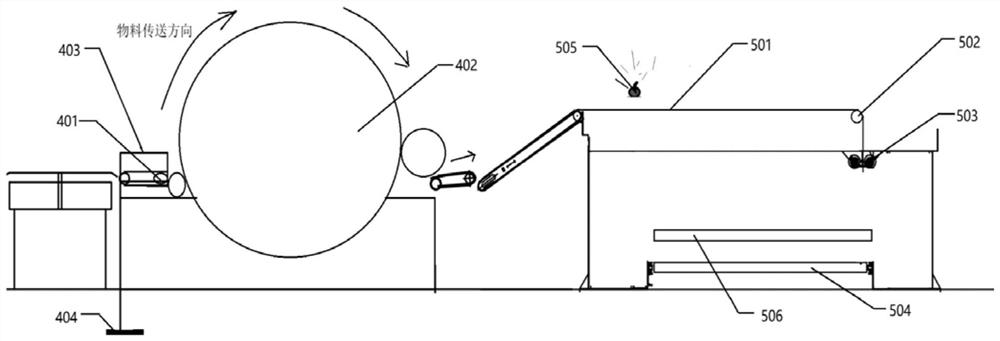

Insulation board production line

ActiveCN111764050AAchieve mass productionSolve the problem of multi-factor matchingTextile treatment by spraying/projectingNon-woven fabricsAdhesive cementCarding

The invention provides an insulation board production line. The production line takes inorganic fiber and water-soluble adhesive as a raw material to produce an insulation board, loading, unpacking, loosening, carding, lapping, needling, cutting, spraying, glue extruding and curing forming procedures are included, production equipment in the procedures is developed and modified, the production canbe carried out in a high-efficiency manner, the shutdown rate is low, the capacity matching aim of the equipment of the procedures can be achieved, the produced insulation board can meet the fireproof, thermal insulation and non-poisonous needs, and has the advantage of high-perpendicularity plate face tensile strength, and the high-volume-weight large-thickness needs can be met.

Owner:BEIJING SATELLITE MFG FACTORY

Uniform mixing device and ice product manufacturing equipment

ActiveCN112691596AEvenly distributedIncrease the degree of mixingRotary stirring mixersFrozen sweetsEngineeringSolid particle

The invention provides a uniform mixing device and ice product manufacturing equipment. The uniform mixing device comprises a feed tank and a balance tank. The feed tank is provided with a feed port, and the feed port is located below a feed liquid injection port and a particle tank. The balance tank is installed at the feed port in a turnover mode and arranged in the length direction of the feed tank, the balance tank moves and is switched between a material taking position and a material placing position through turnover, and the balance tank can receive material liquid from the material liquid injection port and solid particles from the particle tank at the material taking position and pour a feed liquid mixture mixed with solid particles into the feed tank at the material placing position. The uniform mixing device disclosed by the invention can realize premixing of particles and feed liquid by utilizing the balance tank, so that the mixed liquid entering the feed tank is uniformly distributed, the number and dispersion density of the particles in the effective volume of a product are prevented from being too large, the condition that the particles block a discharge port is reduced or even completely avoided, and the production speed and the production rhythm are improved.

Owner:INNER MONGOLIA MENGNIU DAIRY IND (GRP) CO LTD

Discharging control method and device, material conveying system and mixing station

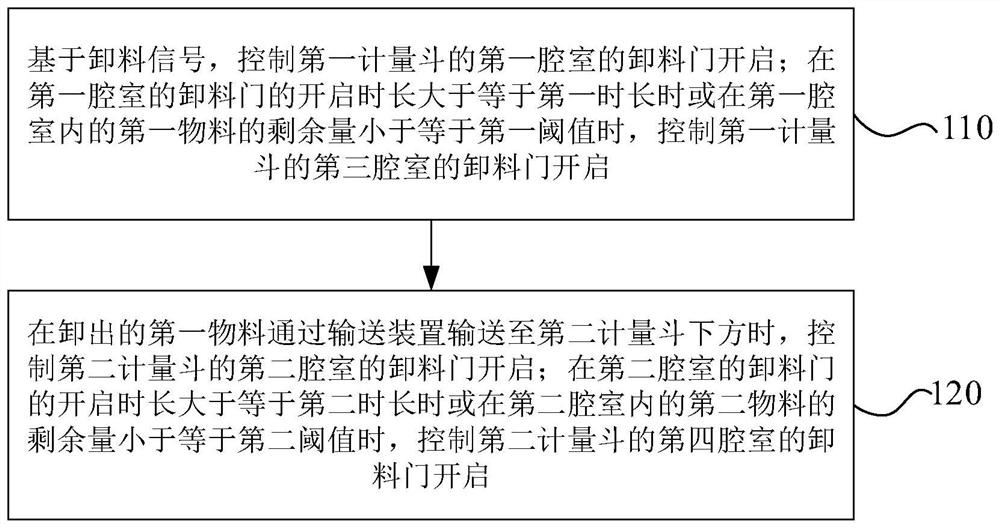

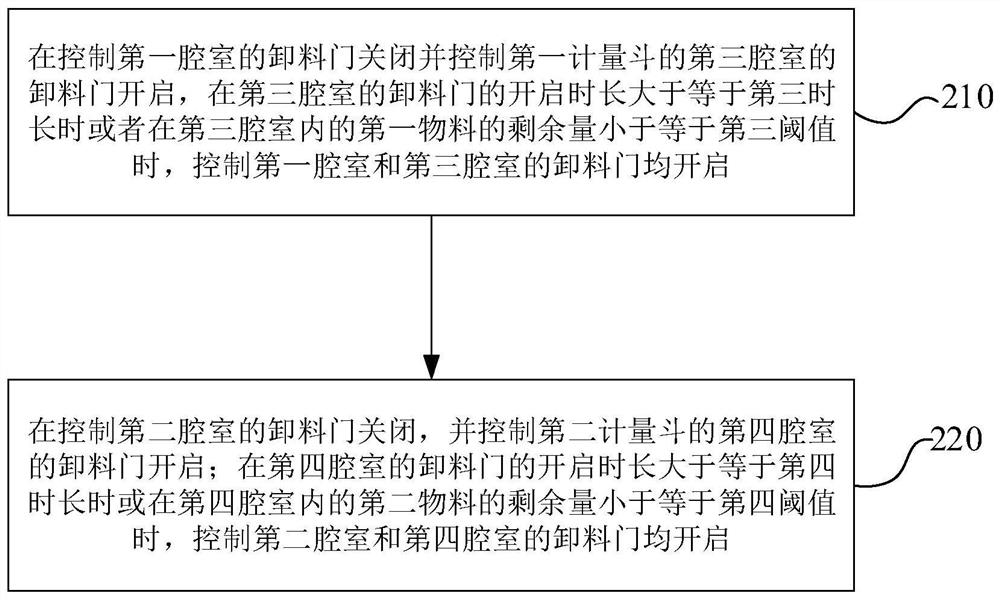

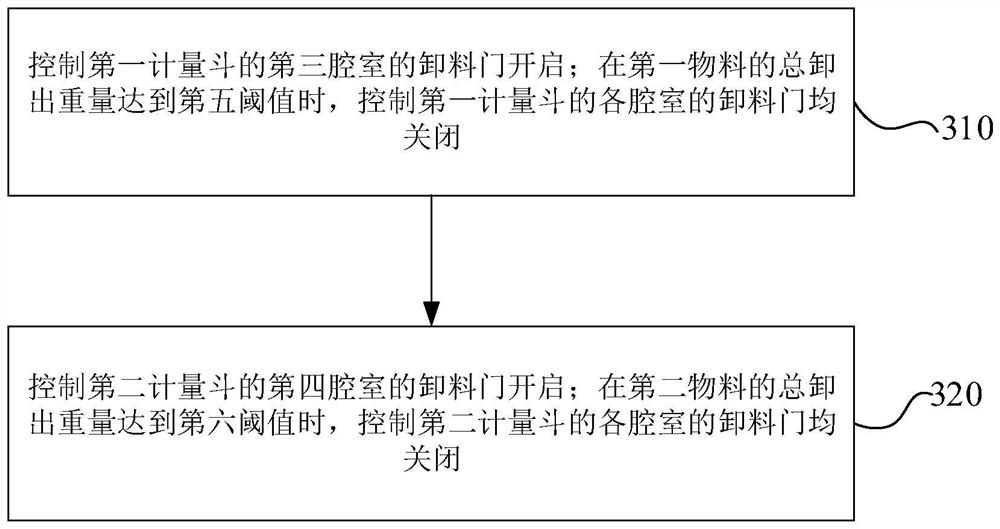

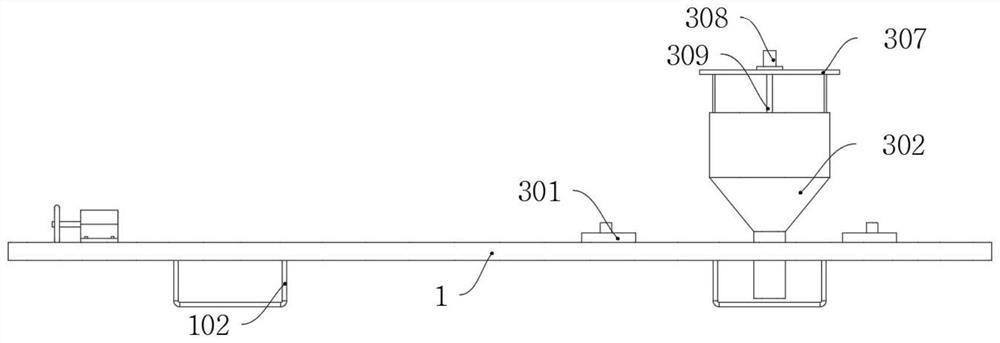

PendingCN114347262ARealize continuous unloadingRealize overlapping conveyingMixing operation control apparatusMixing operation plantControl theoryMechanical engineering

The invention provides an unloading control method and device, a material conveying system and a mixing station, and relates to the technical field of material conveying and metering. The method comprises the steps that based on a discharging signal, a discharging door of a first cavity of a first metering hopper is controlled to be opened; when the discharged first material is conveyed to the position below the second metering hopper through the conveying device, a discharging door of a second cavity of the second metering hopper is controlled to be opened; when the opening duration of the discharging door of the first cavity is larger than or equal to the first duration or the remaining amount of the first material in the first cavity is smaller than or equal to a first threshold value, the discharging door of a third cavity of the first metering hopper is controlled to be opened; and when the opening duration of the discharge door of the second chamber is greater than or equal to a second duration or the remaining amount of the second material in the second chamber is smaller than or equal to a second threshold value, the discharge door of the fourth chamber of the second metering hopper is controlled to be opened, so that the chambers continuously discharge materials, the first material and the second material are stacked and conveyed, premixing is realized, and the stirring efficiency is improved.

Owner:SANY AUTOMOBILE MFG CO LTD

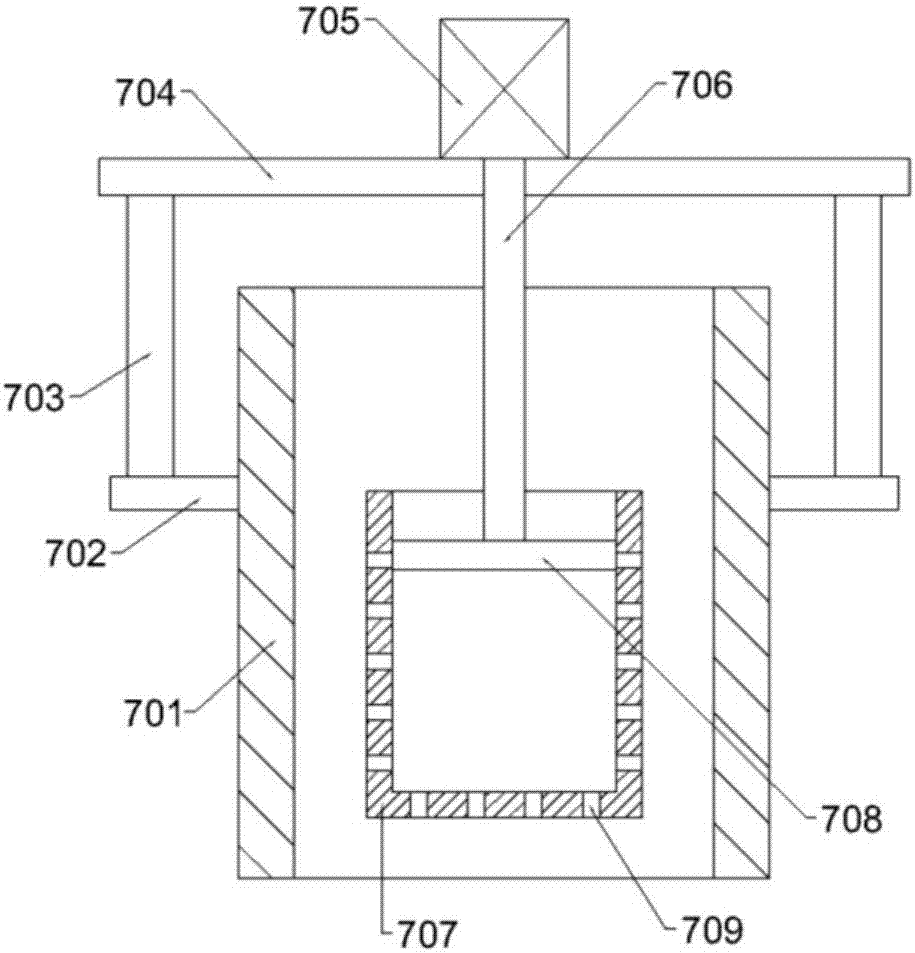

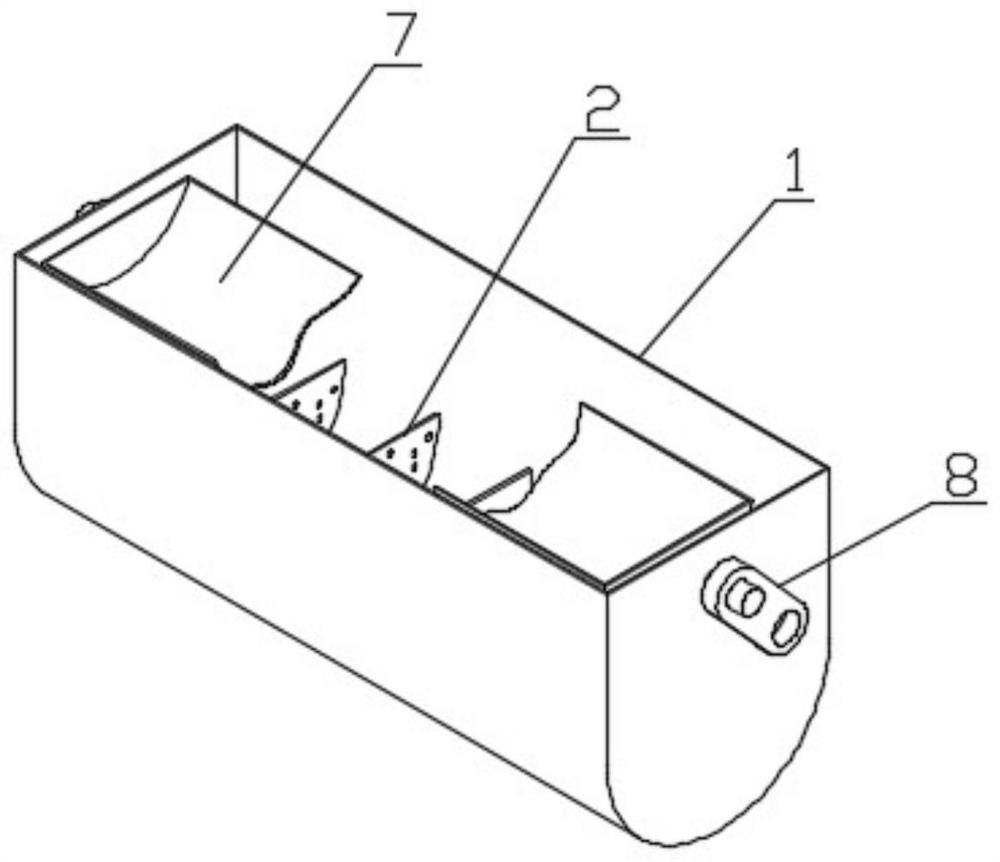

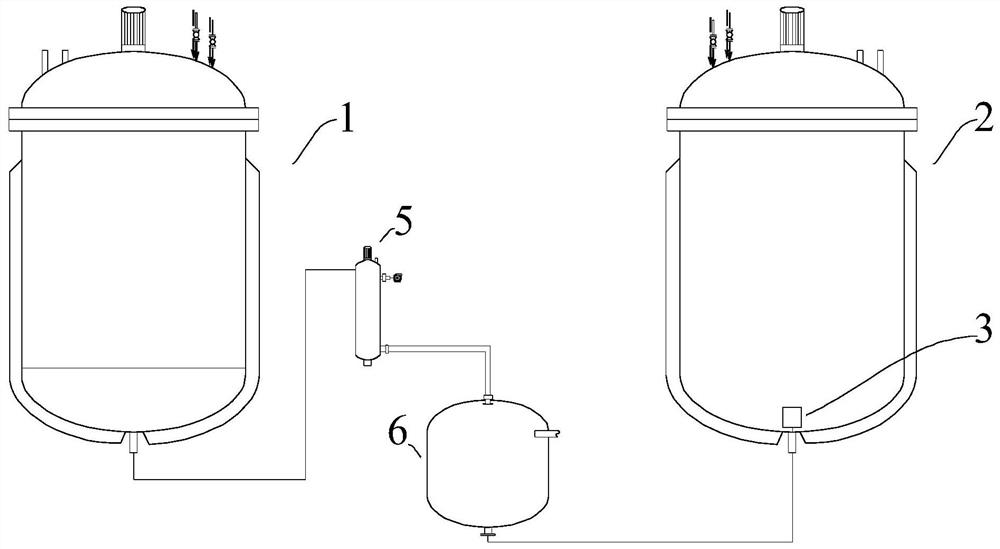

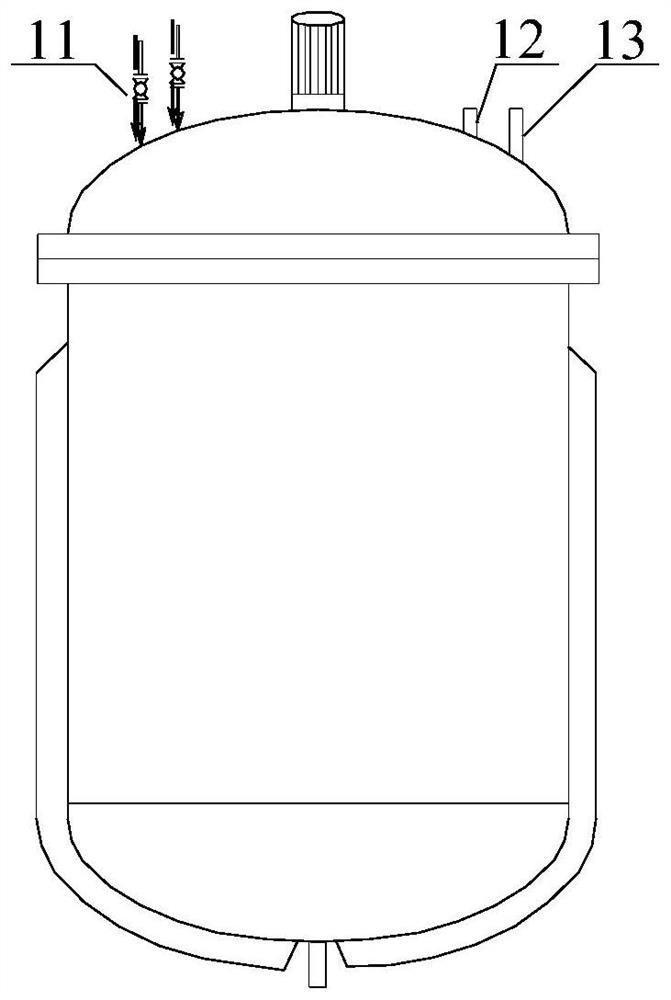

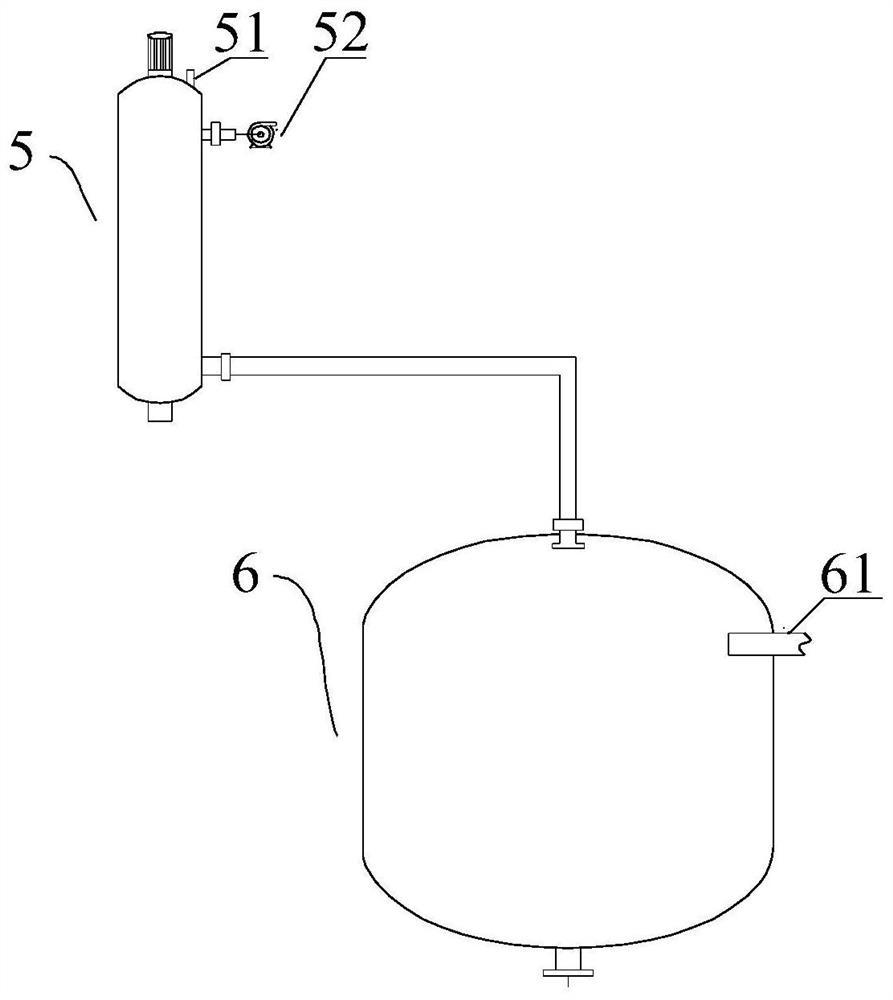

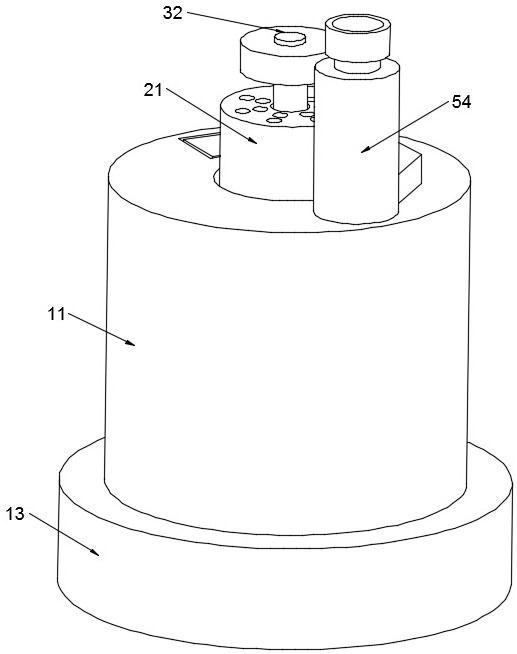

Fermentation auxiliary feeding device based on probiotics

InactiveCN114517146AEnsure comprehensivenessAchieve premixBioreactor/fermenter combinationsBiological substance pretreatmentsBiotechnologyProbiotic bacteria

The invention provides a probiotic-based fermentation auxiliary feeding device, and relates to the technical field of feeding devices, the probiotic-based fermentation auxiliary feeding device comprises a cover plate, a driving motor A and a feeding part; the cover plate is fixedly connected to a probiotic fermentation barrel through bolts, and an auxiliary plate is rotationally connected to the cover plate; and the driving motor A is fixedly connected to the auxiliary plate through a bolt. The three auxiliary seats are welded to the left side of the bottom end face of the auxiliary plate in the linear array shape, the three auxiliary seats are also welded to the right side of the bottom end face of the auxiliary plate in the linear array shape, and the six auxiliary seats jointly form a supporting and protecting structure of the cover plate. Therefore, the cover plate can be prevented from being in contact and collided with hard objects on the ground when being placed, so that the edge of the cover plate is prevented from being deformed to influence the sealing with the fermentation barrel, and the problems that raw materials and additives are easy to adhere to the feeding hopper during feeding and incomplete feeding is caused are solved; and raw materials adhered to the feeding hopper cannot be automatically shaken off in the feeding process.

Owner:蒋钊

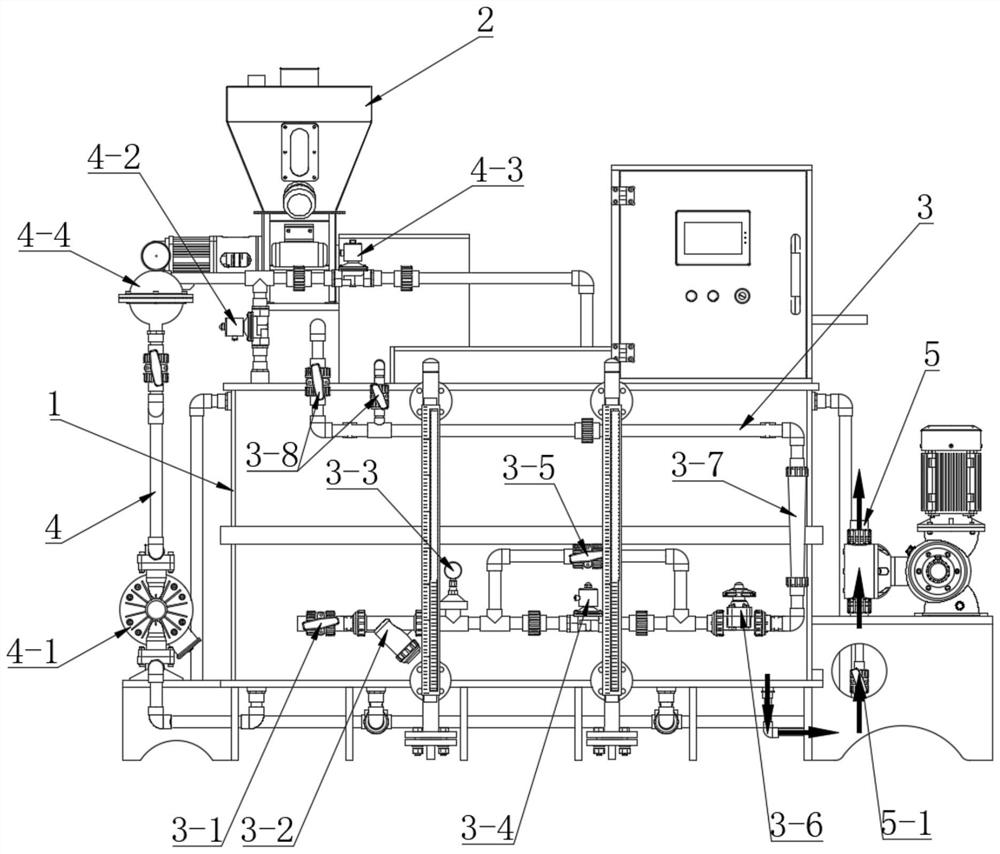

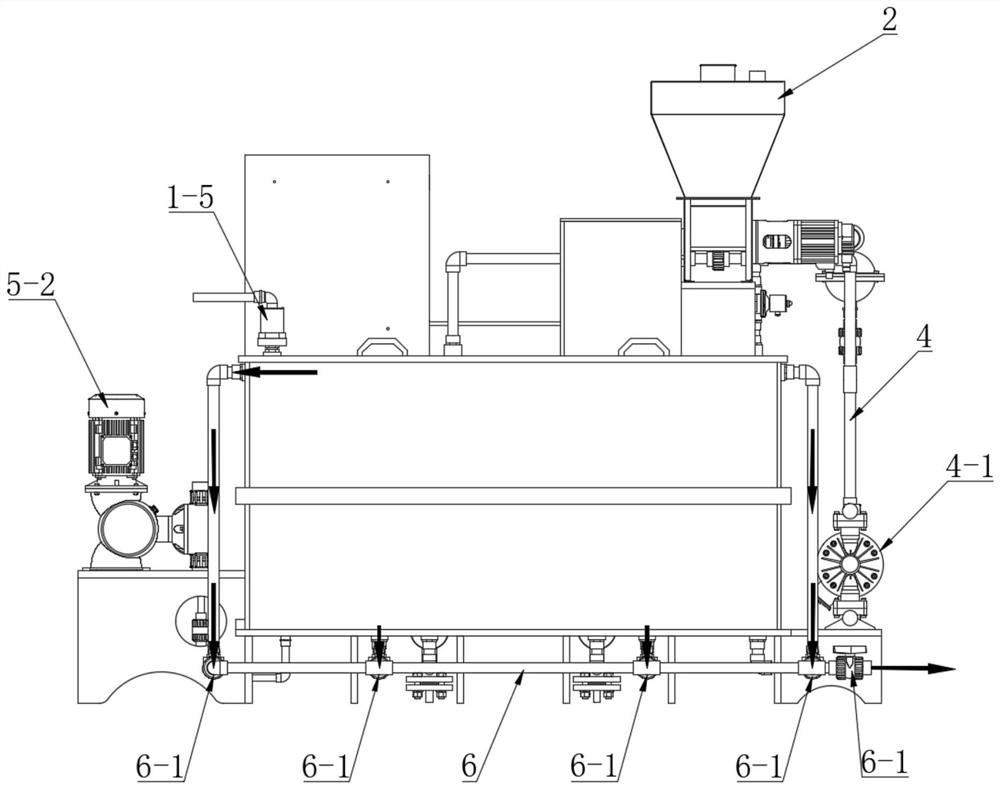

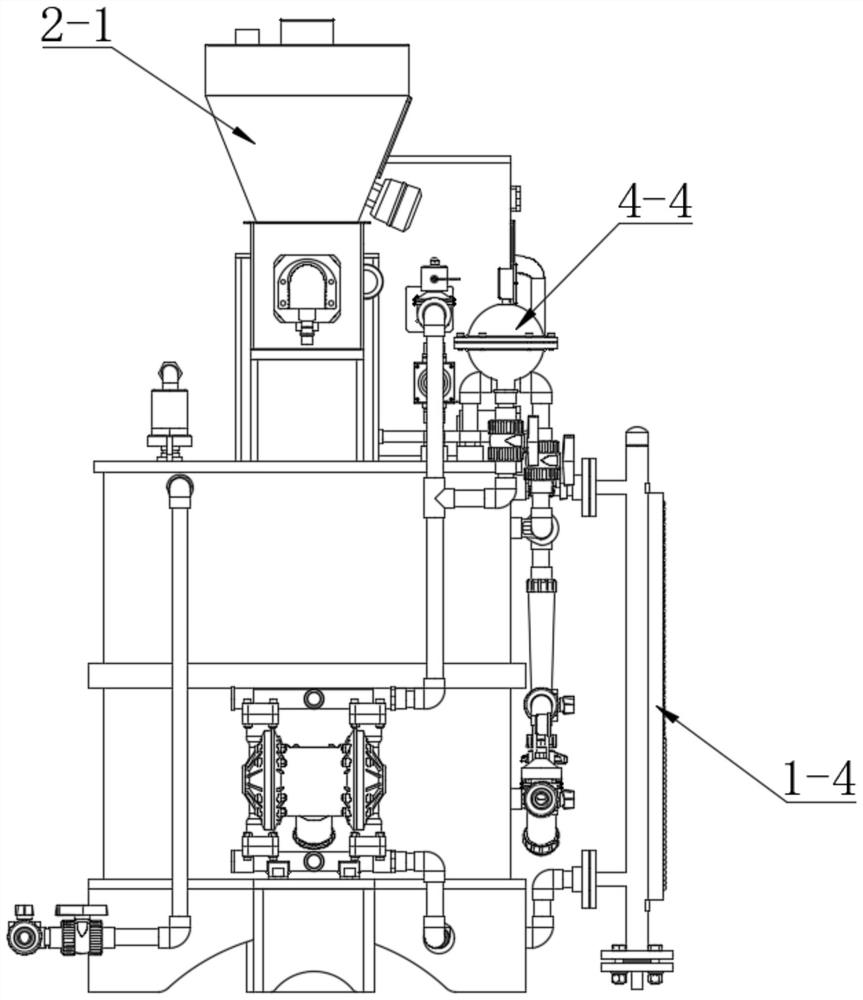

Full-automatic precise ingredient filling equipment and ingredient filling method thereof

PendingCN114713054AImprove solubilityImprove consistencyFlow mixersTransportation and packagingProcess engineeringIndustrial engineering

The invention discloses full-automatic precise ingredient filling equipment and an ingredient filling method thereof. The full-automatic precise ingredient filling equipment comprises a main box body, a weighing and charging mechanism, a water supply pipeline, a circulating feeding pipeline and a finished product liquid output pipeline, a solution cavity and a finished product cavity which are isolated from each other are arranged in the main box body; a blanking, spraying and dissolving hopper communicated with the solution cavity is arranged at the top of the main box body; the weighing and feeding mechanism is used for conveying the medicine powder into the blanking, spraying and dissolving hopper; the water supply pipeline supplies water to the solution cavity and the blanking, spraying and dissolving hopper; an inlet of the circulating feeding pipeline is communicated with the solution cavity from the bottom of the main box body, and an outlet of the circulating feeding pipeline is communicated with the solution cavity and the finished product cavity; an inlet of the finished product liquid output pipeline is communicated with the finished product cavity from the bottom of the main box body. The device is not limited by use occasions, the consistency of the concentration of the output liquid medicine is very high, a stirring device does not need to be configured, the cost is saved, the noise is low, and vibration is little.

Owner:JIANGSU TOM PACKAGING MACHINERY

Strengthening system and process for preparing 1, 4-butanediol through allyl alcohol hydrogenation

PendingCN112457165AHigh separation purityAchieve premixPreparation by isomerisationOrganic compound preparationPropanolHydrogenation reaction

The invention relates to the field of 1, 4-butanediol preparation, and provides a strengthening system for preparing 1, 4-butanediol through allyl alcohol hydrogenation, which comprises a primary hydrogenation reaction kettle, a secondary hydrogenation reaction kettle, a product separation mechanism and a micro-interface generator, the micro-interface generator comprises an interface generating mechanism and an interface crushing mechanism. Therefore, the product separation mechanism and the micro-interface generator are arranged between the two stages of hydrogenation reaction kettles; the separation purity of effective components is improved, premixing of the effective components and reaction gas is achieved, and bubbles formed by the reaction gas in the effective components are broken into micron-sized bubbles; and reaction efficiency is improved. The operation parameters of the strengthening system are automatically detected in an artificial intelligence mode, and adjustment is conducted in time according to changes of the parameters to maintain normal operation of the system. The automation degree and the operation stability of the system are improved. The invention also provides a preparation process of the 1, 4-butanediol based on the strengthening system.

Owner:NANJING YANCHANG REACTION TECH RES INST CO LTD

A thermal insulation board production line

ActiveCN111764050BAchieve mass productionSolve the problem of multi-factor matchingNon-woven fabricsTextile treatment by spraying/projectingFiberAdhesive cement

Owner:BEIJING SATELLITE MFG FACTORY

A kind of white carbon black/natural rubber composite material preparation method

The invention belongs to the technical field of natural rubber wet mixing, and relates to a preparation method of white carbon black / natural rubber composite material, which uses a wet mixing process to prepare white carbon black into a uniform dispersion solution through mechanical grinding, and mixes with natural latex After mixing, stir at a slow speed to fully contact the natural rubber latex and white carbon black, use the positive charge generated by the high-temperature atomization method to flocculate the negatively charged natural rubber latex, wrap the white carbon black in it, and make white carbon black after dehydration and drying. The innovation of carbon black / natural rubber composite material lies in: First, adding other rubber additives in the formula except filler and latex together to realize the premixing of the materials in the formula, which is convenient for later processing and reduces mixing time and mixing time. Second, the processing method is continuous, and the prepared masterbatch is put into the continuous mixer to realize continuous production.

Owner:QINGDAO UNIV OF SCI & TECH

Viola planting and fertilizing device

ActiveCN108650964BWell mixedAchieve premixTransportation and packagingMixersAgricultural engineeringCam

Owner:贵州黔峰百草科技发展有限公司

Special pesticide applying machine

PendingCN113678813AReduce labor intensityPracticalWeed killersInsect catchers and killersAgricultural scienceAgricultural engineering

The invention relates to a special pesticide applying machine. The special pesticide applying machine comprises an equipment main machine frame and a machine body assembling plate, the equipment main machine frame is fixed to the machine body assembling plate, a water outlet valve assembly and an electric assembly are arranged in the equipment main machine frame, a control electric box is installed on the equipment main machine frame, a pesticide storage assembly is arranged on the machine body assembling plate, the machine body assembling plate is provided with an injection mechanism, and the water outlet valve assembly, the electrical assembly, an injection mechanism and the control electric box are electrically connected. Mechanical operation is used for replacing manual operation, the labor intensity is reduced, the influence of pesticide on human health is avoided, the safety is high, and the practicability is high; by arranging a water return valve and a motor pump set in the equipment main machine frame, pesticide can circulate in the system, then premixing of water and the pesticide is achieved, the effect of follow-up spraying operation is improved, the purity of the pesticide is guaranteed, and weeding operation can be carried out efficiently.

Owner:上海水威环境技术股份有限公司

Homogeneous mixing device and ice product manufacturing equipment

ActiveCN112691596BEvenly distributedIncrease the degree of mixingTransportation and packagingRotary stirring mixersProcess engineeringSolid particle

The invention provides a uniform mixing device and ice product manufacturing equipment. The uniform mixing device includes: a material trough, which is provided with a feeding port, and the feeding port is located below the material liquid injection port and the particle trough; a balance tank, which can be installed on the feeding port rotatably and is arranged along the length direction of the material trough, The balance tank moves between the reclaim position and the discharge position by turning over. The balance tank can respectively receive the material liquid from the material liquid injection port and the solid particles from the particle tank at the reclaim position, and can mix the mixed material at the discharge position. The feed-liquid mixture with solid particles is poured into the trough. The uniform mixing device of the present invention can realize the pre-mixing of the particles and the material liquid by using the balance tank, so that the mixed liquid entering the material tank is evenly distributed, and the particle number and dispersion density of the particles in the effective volume of the product are avoided. , reducing or even completely avoiding the occurrence of particles blocking the discharge port, thereby improving the production speed and production rhythm.

Owner:INNER MONGOLIA MENGNIU DAIRY IND (GRP) CO LTD

A kind of mixing equipment for titanate friction material production

ActiveCN113648917BGood effectAchieve premixTransportation and packagingMixer accessoriesPhysical chemistryElectric machinery

The invention discloses a mixing equipment for titanate friction material production, which comprises a mixing tank, a stirring chamber is arranged inside the mixing tank, a partition plate is fixed on the inner wall of the stirring chamber, a partition chamber is provided on the lower side of the partition board, and a stirring chamber is arranged on the inner wall of the stirring chamber. The bottom of the barrel is fixed with a power box; the present invention realizes pre-mixing of controlled reaction conditions through the cooperation between the treatment cylinder and the compression plate, the effect of mixing and molding is good, and the adaptability is good and the operation is convenient. Cooperate, while stirring and mixing, the raw materials adhered to the inner wall of the mixing chamber can be removed within a certain range and scraped off, so that the raw materials can be fully stirred and mixed, and the efficiency is high. It also uses the crushing motor and active crushing The cooperation between the wheels can crush the raw materials with large particles into small particles or powder in advance, so that the mixing effect is better and the mixing time is shortened.

Owner:ZHANGJIAGANG OTSUKA CHEM

Static mixing device for silicone adhesive production

ActiveCN114832706AAchieve premixFacilitates static mixingShaking/oscillating/vibrating mixersFlow mixersPolymer scienceDrive motor

The invention discloses a static mixing device for silicone adhesive production, and particularly relates to the technical field of silicone adhesive production.The static mixing device comprises a supporting frame, a static mixing mechanism is fixedly clamped to the top of the supporting frame, a premixing assembly is arranged at the top of the static mixing mechanism, and a driving assembly is arranged on the outer side of the premixing assembly. By arranging the premixing assembly and cooperatively using the driving assembly and the driving motor, the two premixing pipes are driven to rotate forwards and backwards by 180 degrees, so that two different raw materials indirectly enter the feeding pipes on the two sides, premixing of the raw materials for silicone adhesive production on the two sides is achieved, subsequent static mixing of the raw materials is facilitated, and the production efficiency is improved. Further, the mixing efficiency during silicone adhesive production is improved; by arranging the static mixing mechanism, the raw materials can be subjected to primary static mixing and secondary static mixing for three times, so that effective static mixing of the raw materials is realized, and during secondary static mixing, a heating piece in a mixing convex shaft can be started to uniformly heat the mixed raw materials, so that the raw material mixing efficiency is improved.

Owner:杭州正创新材料有限公司

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com