Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

59results about "Collotype printing form production" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

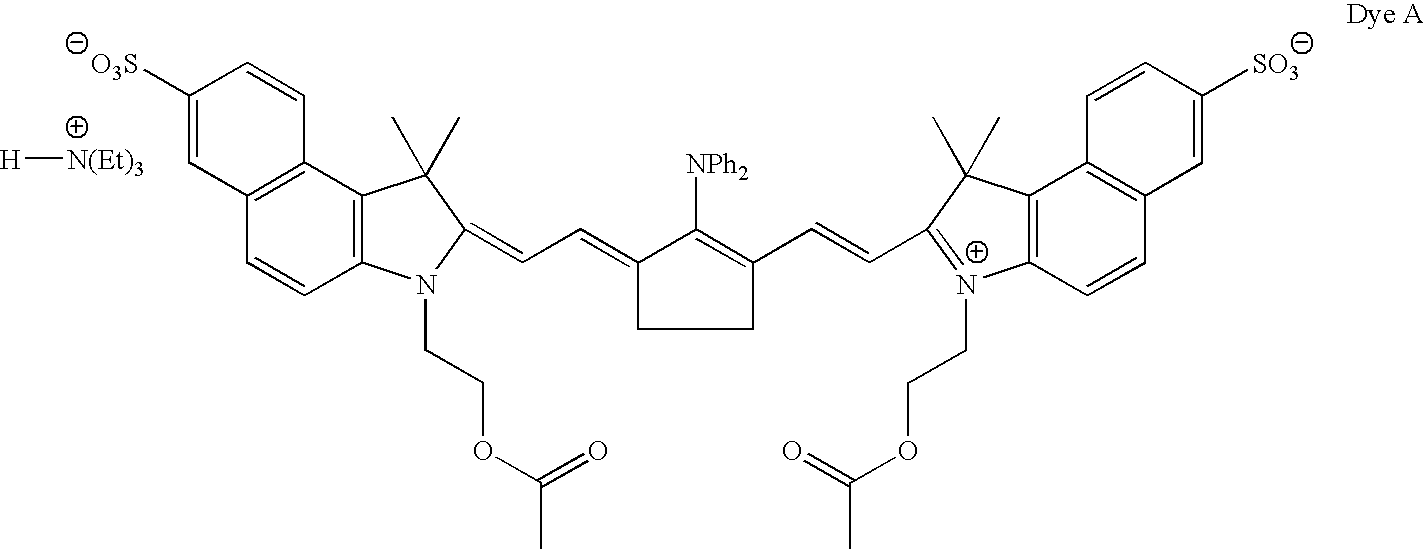

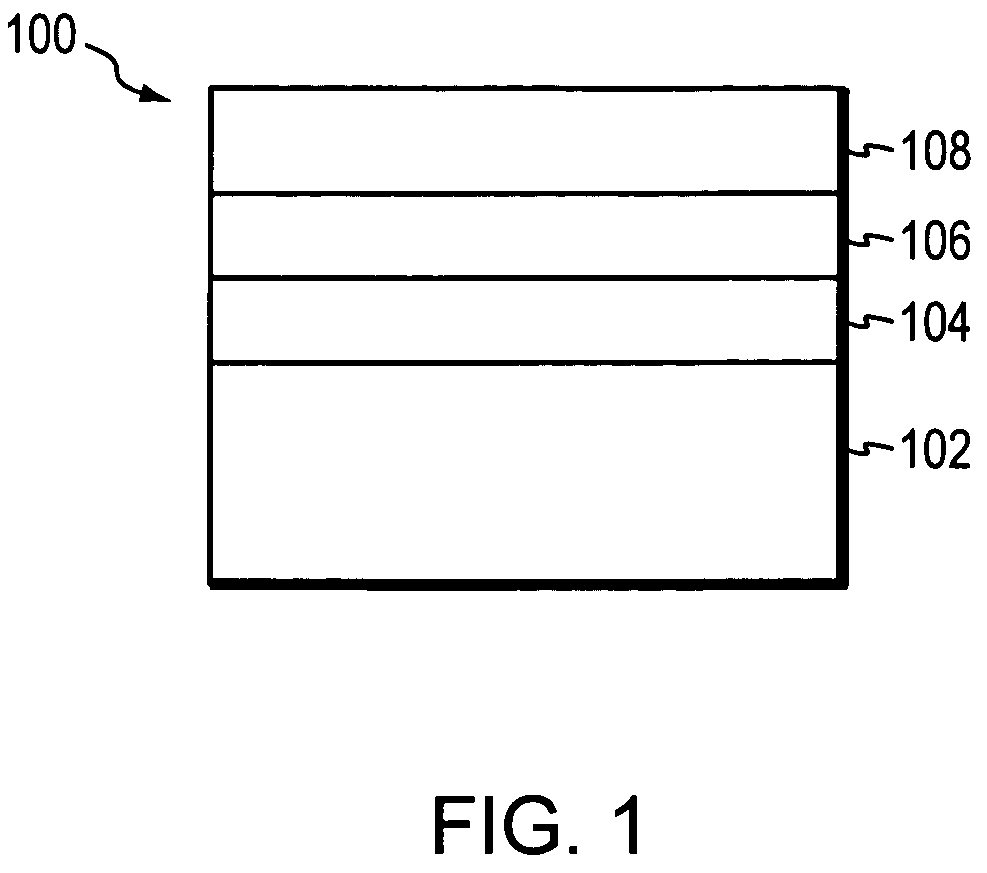

Radiation-sensitive compositions and imageable materials

InactiveUS7153632B1Maintaining photo speedMaintaining visible print outPhotosensitive materialsRadiation applicationsPolymer sciencePolymer

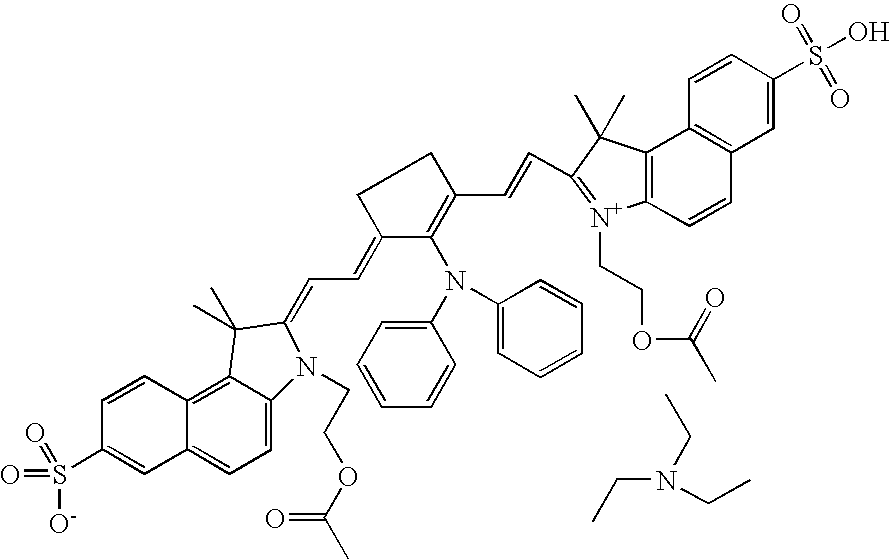

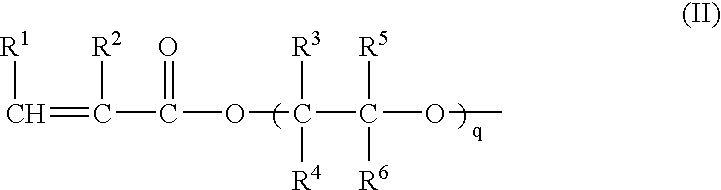

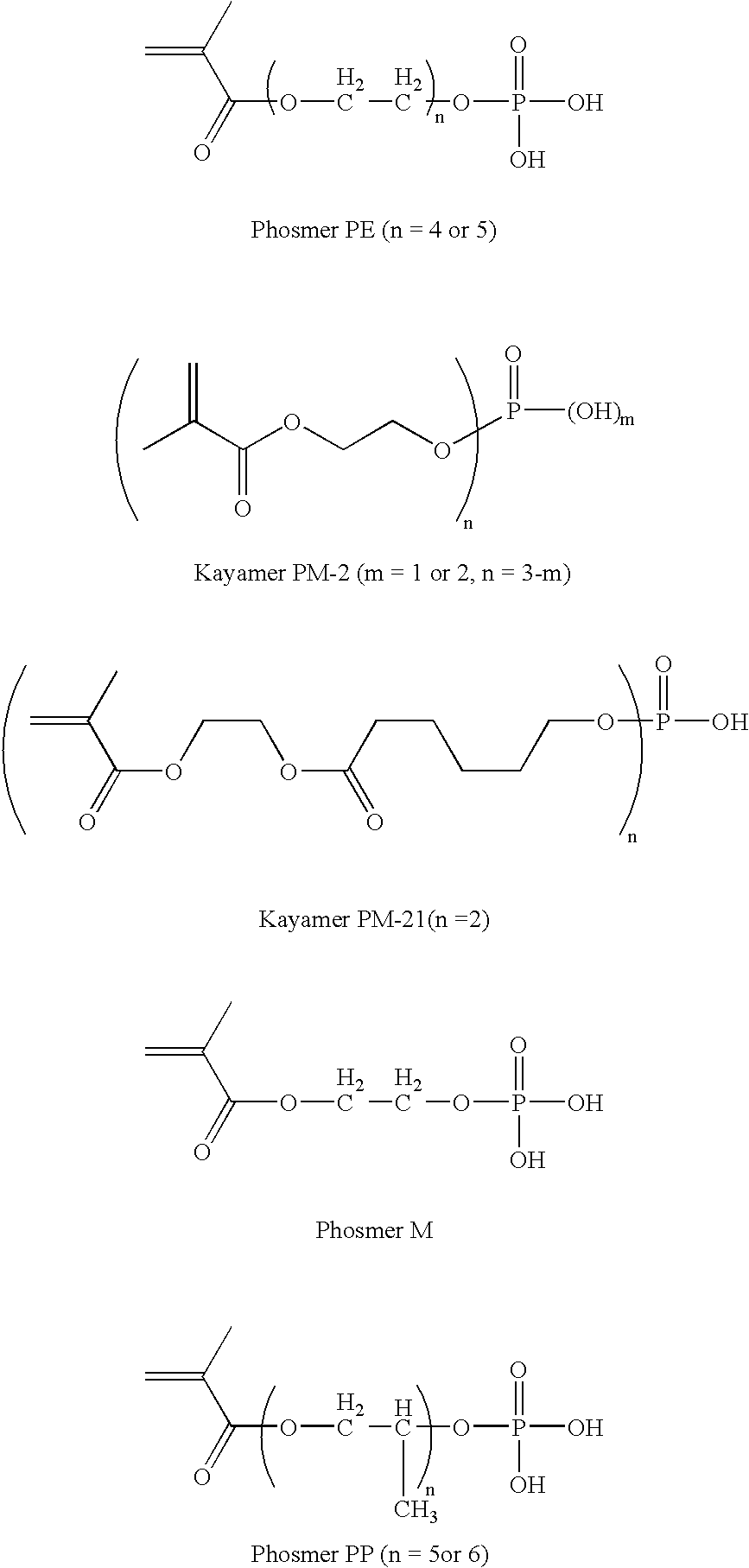

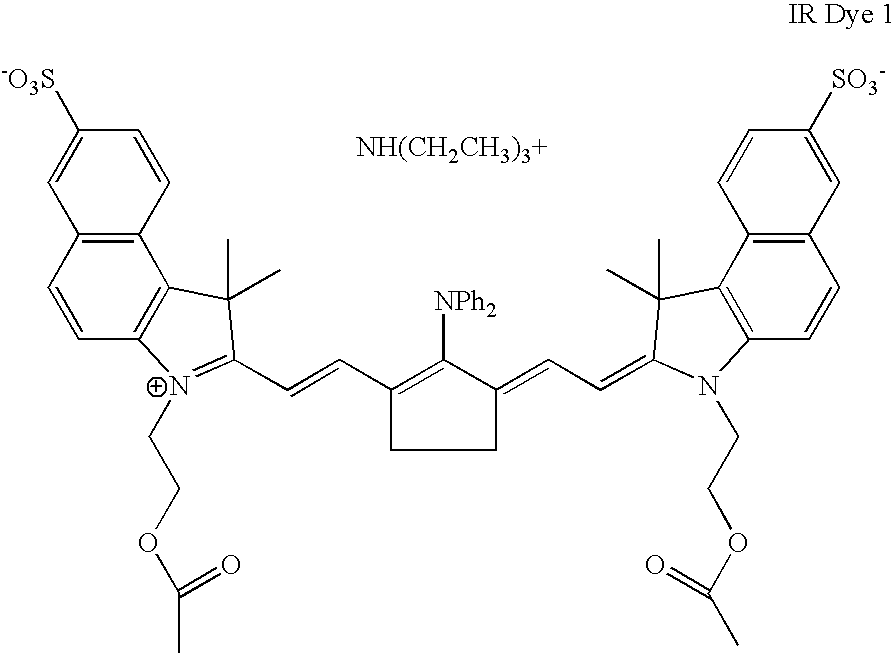

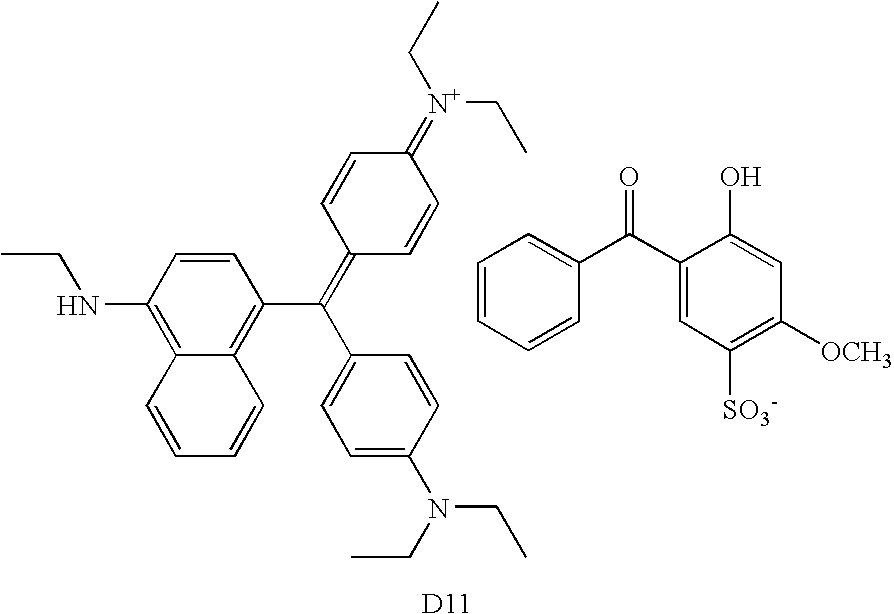

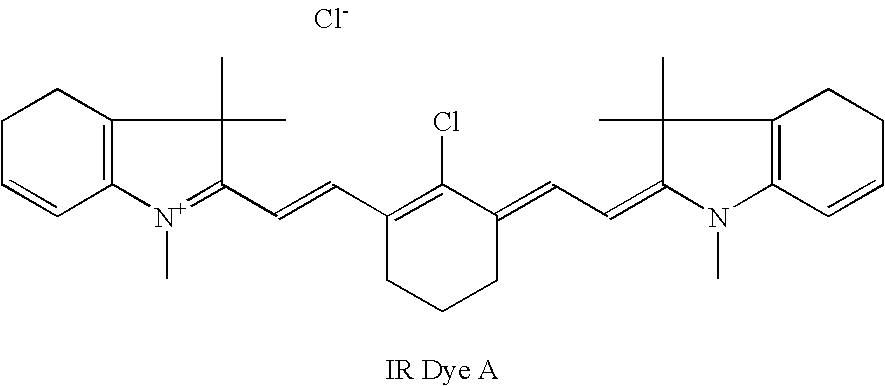

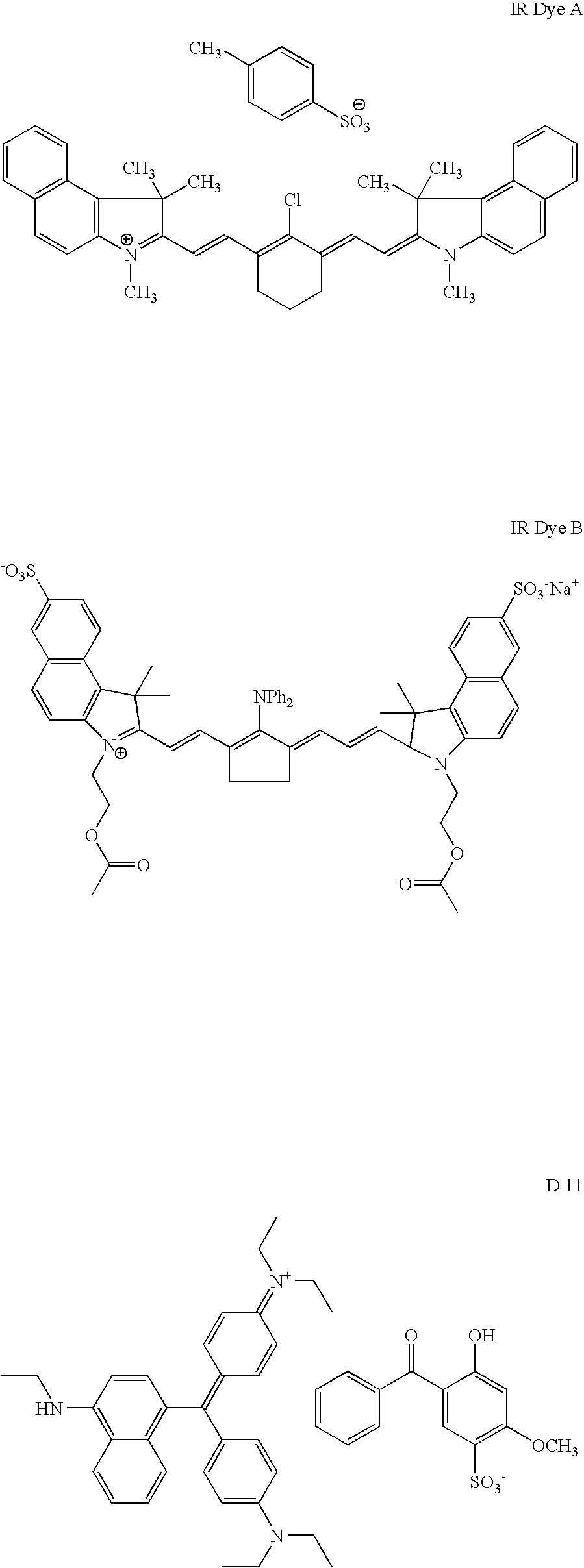

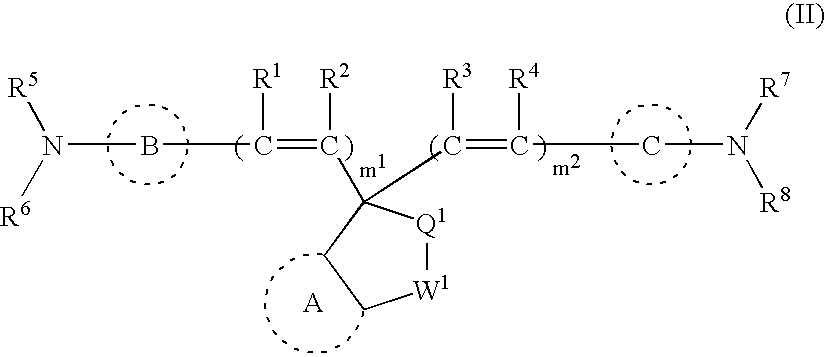

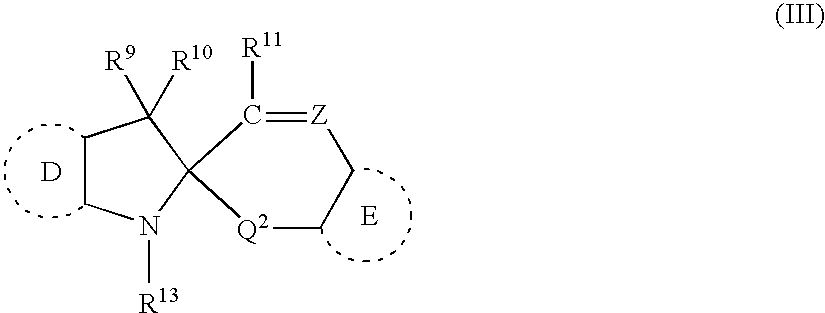

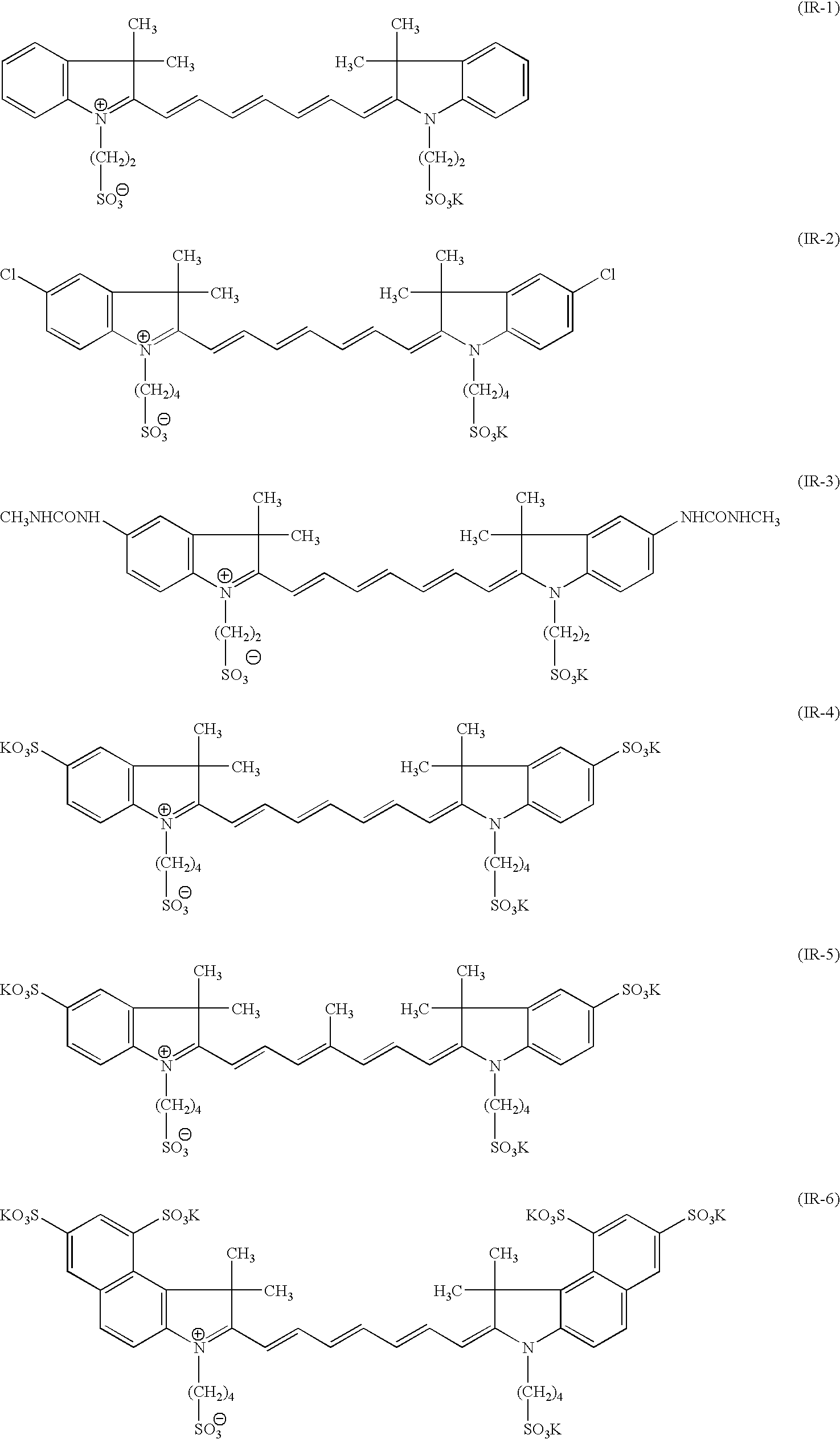

A radiation-sensitive composition includes a radically polymerizable component that comprises carboxy groups, an initiator composition to generate radicals, and a polymeric binder comprising poly(alkylene oxide) segments and optionally pendant cyano groups. This composition can be used to prepare imageable elements such as negative-working, on-press developable printing plate precursors.

Owner:EASTMAN KODAK CO

Visual inspection and verification system

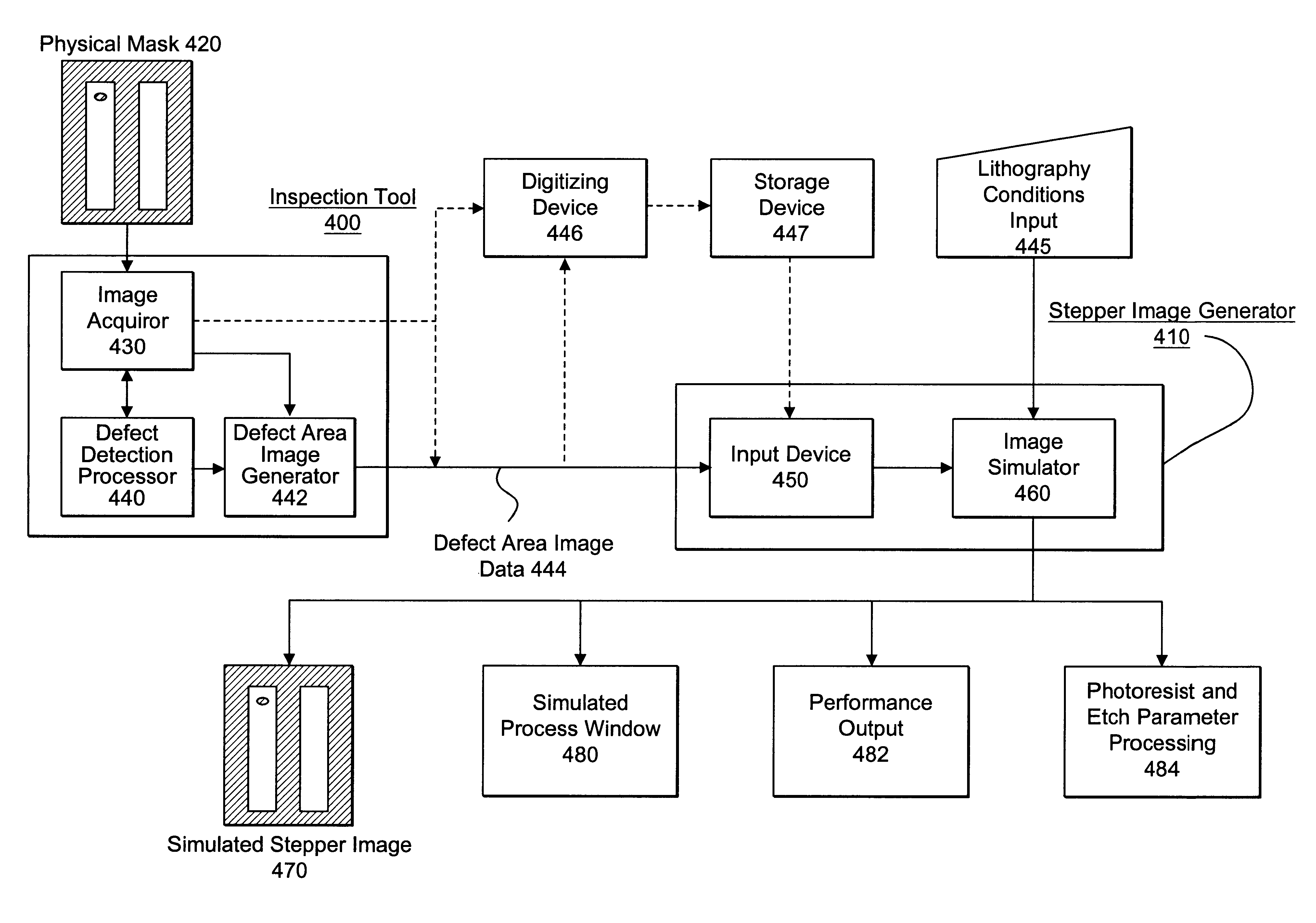

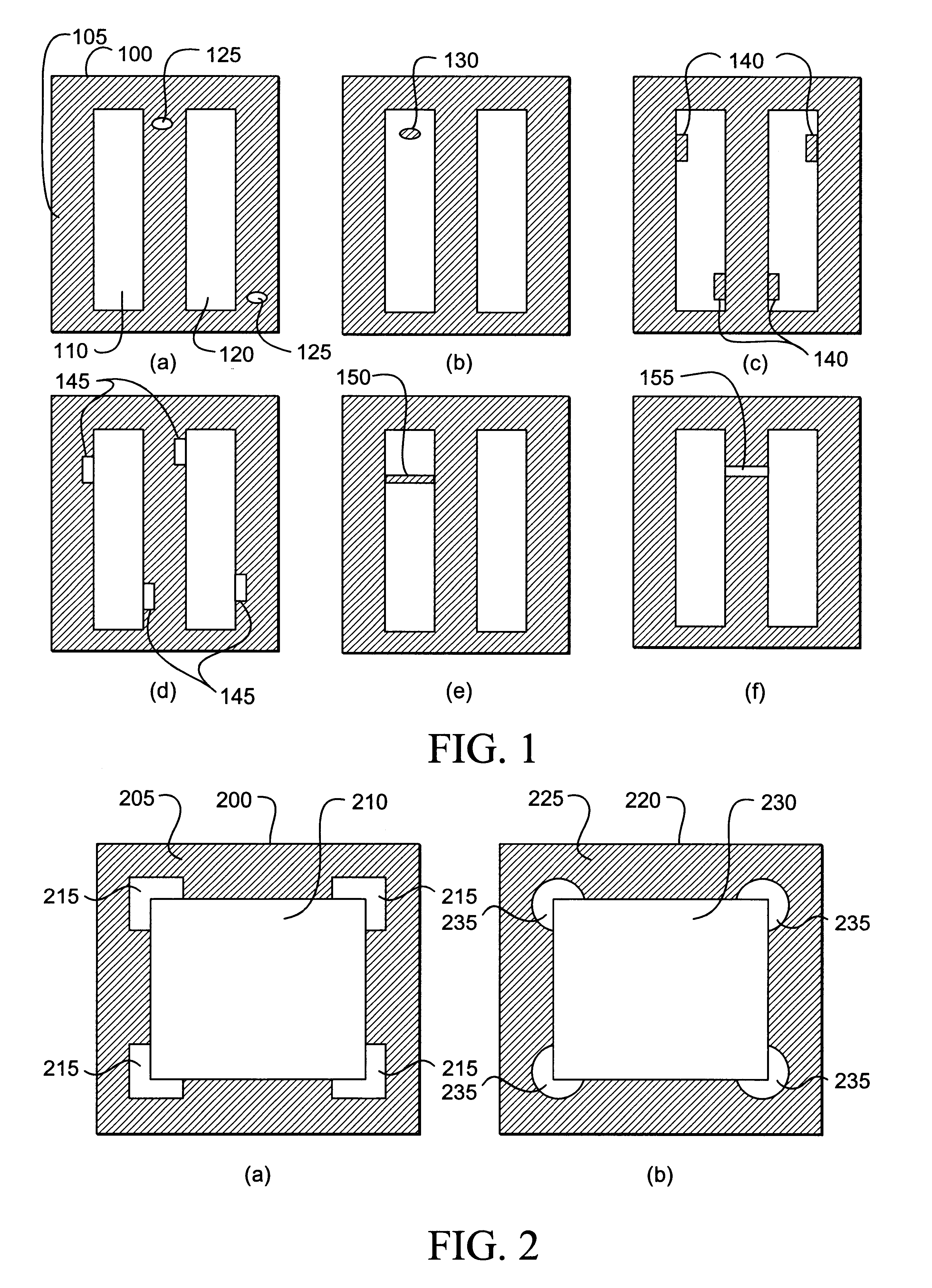

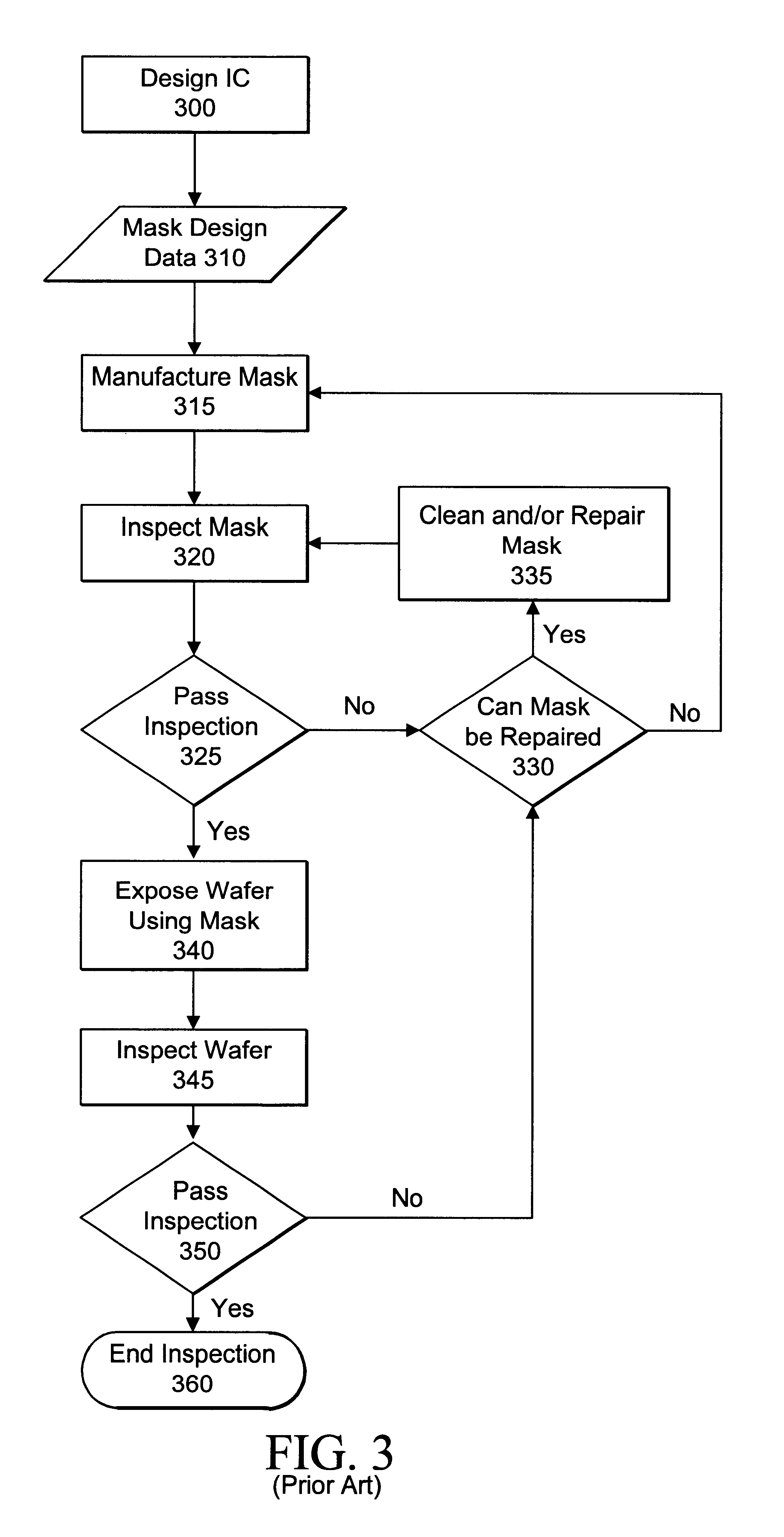

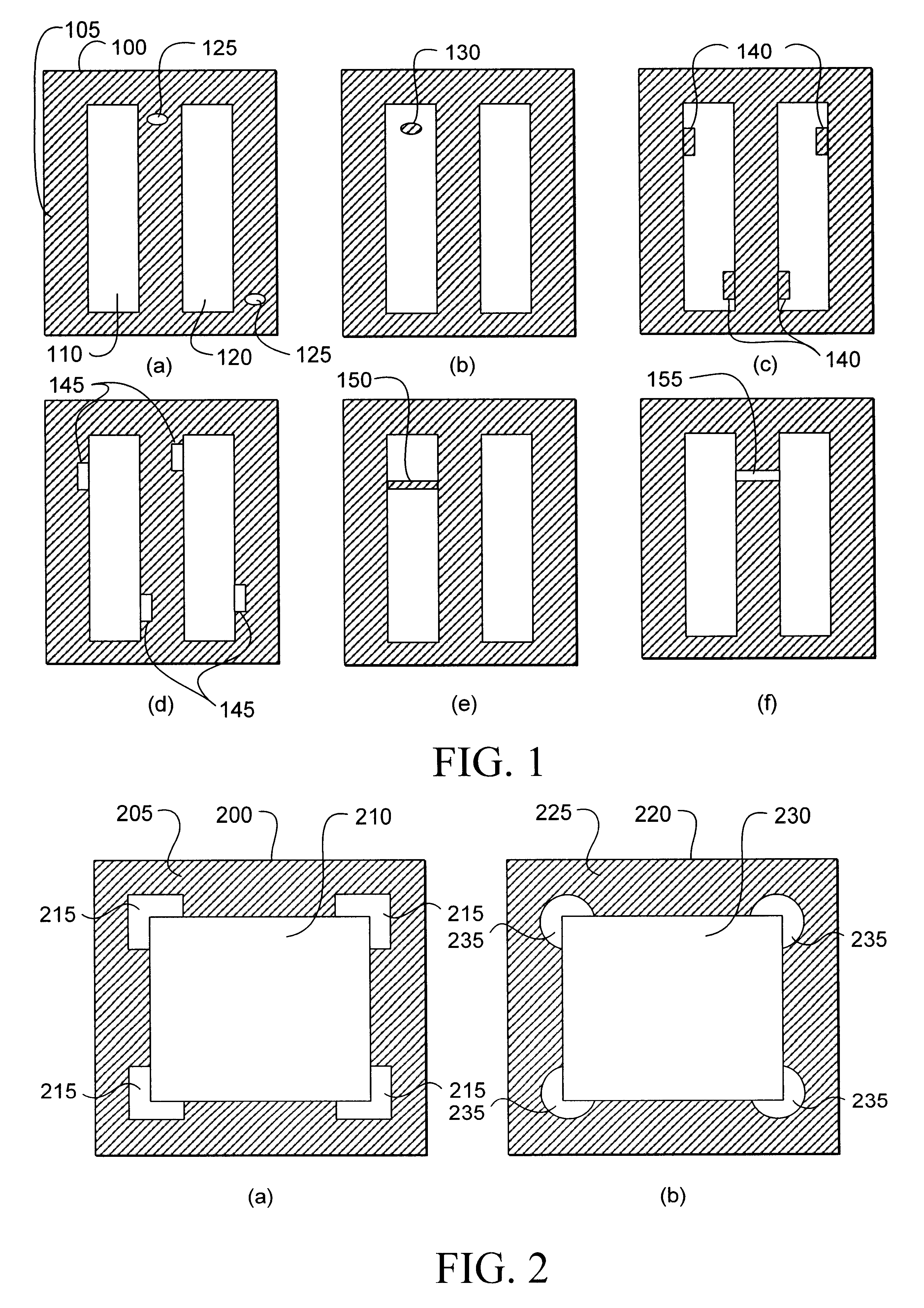

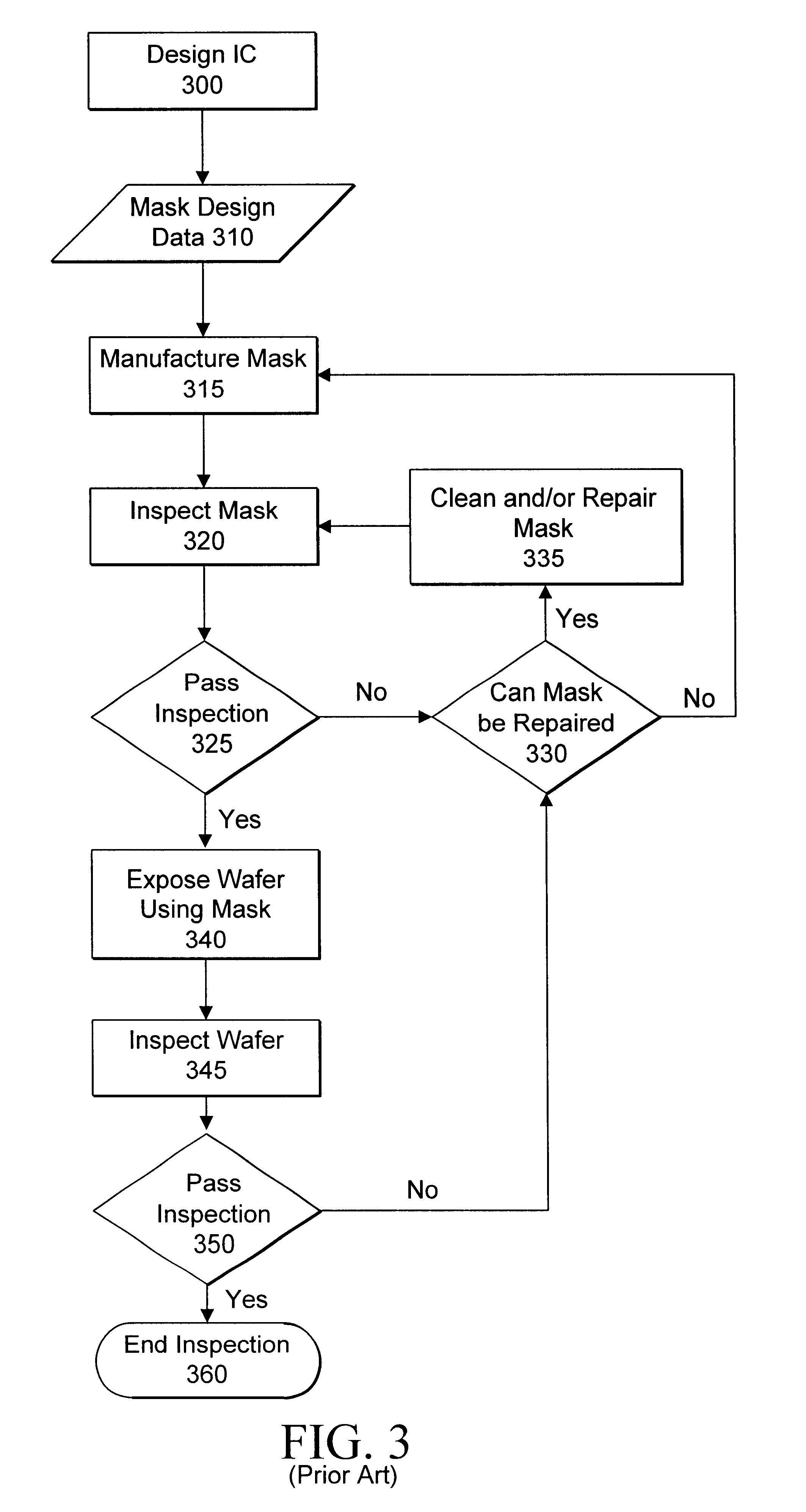

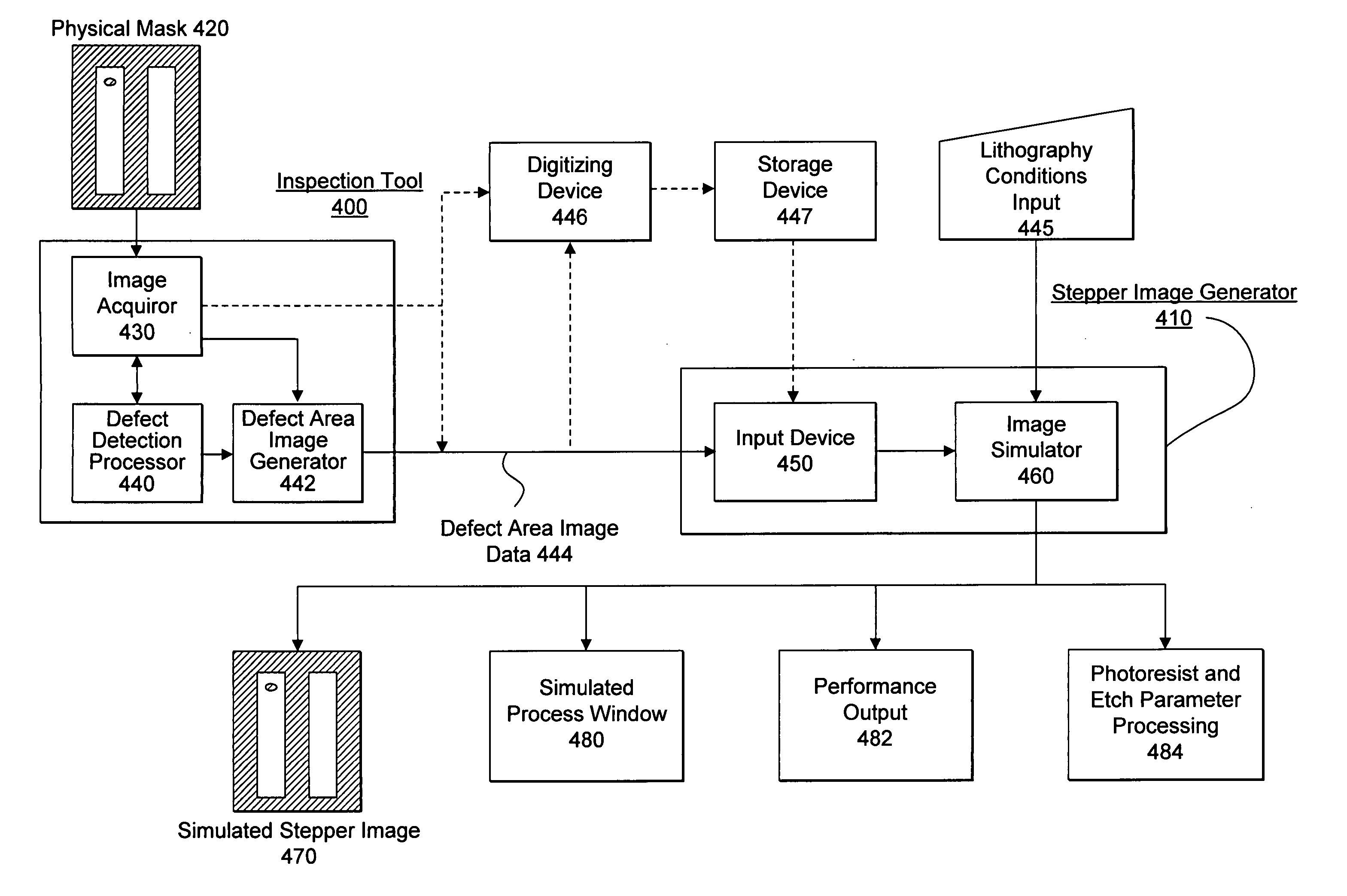

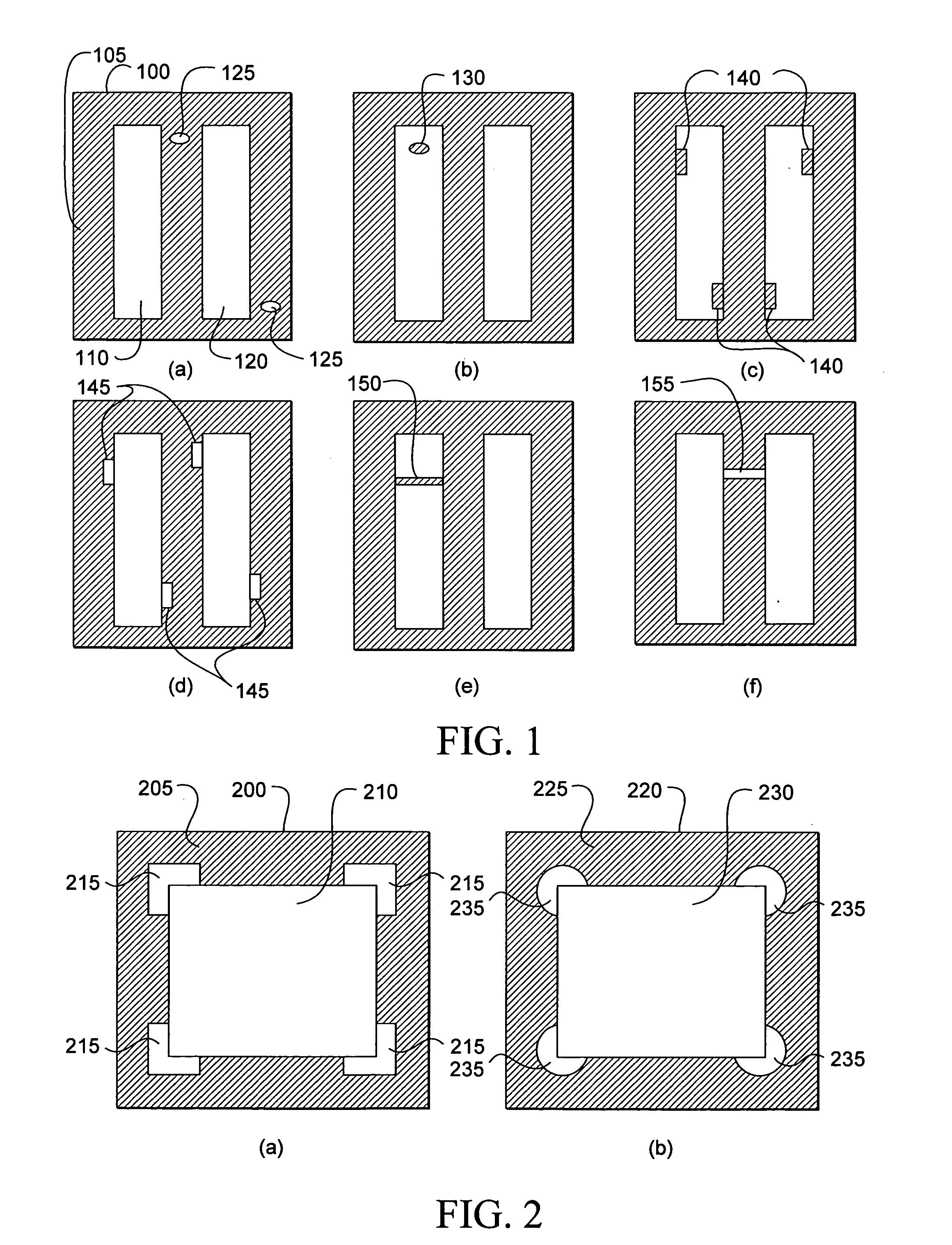

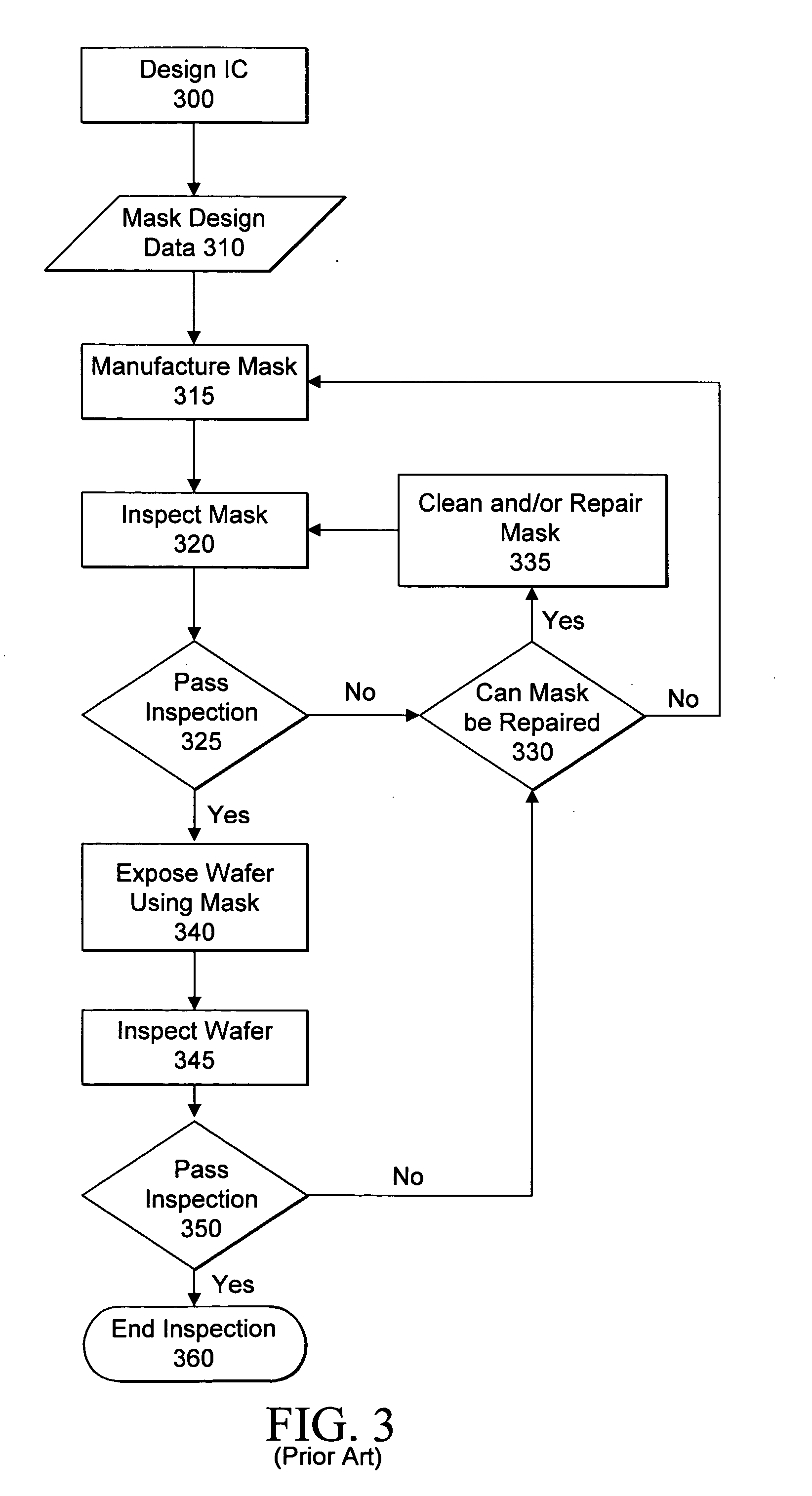

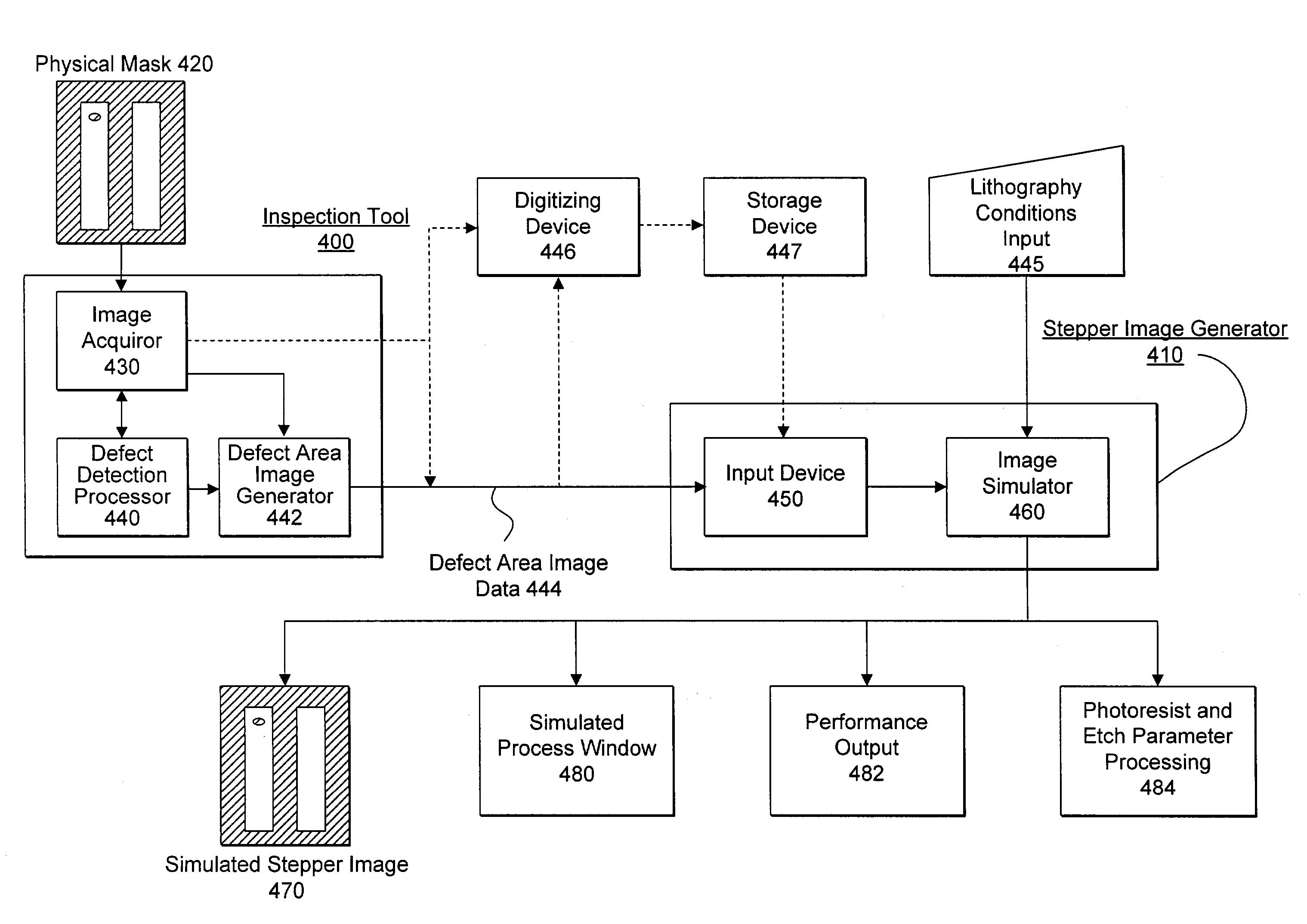

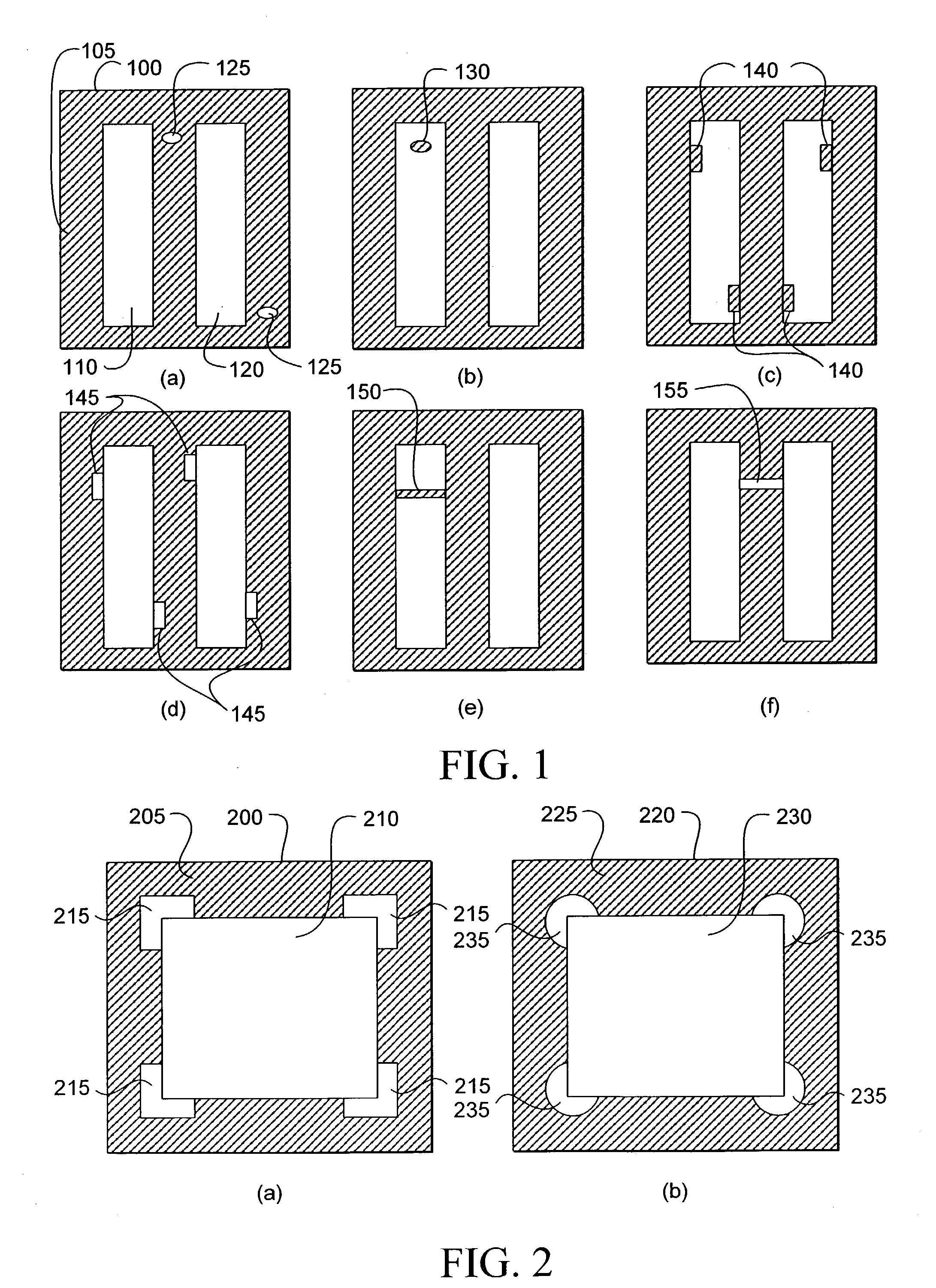

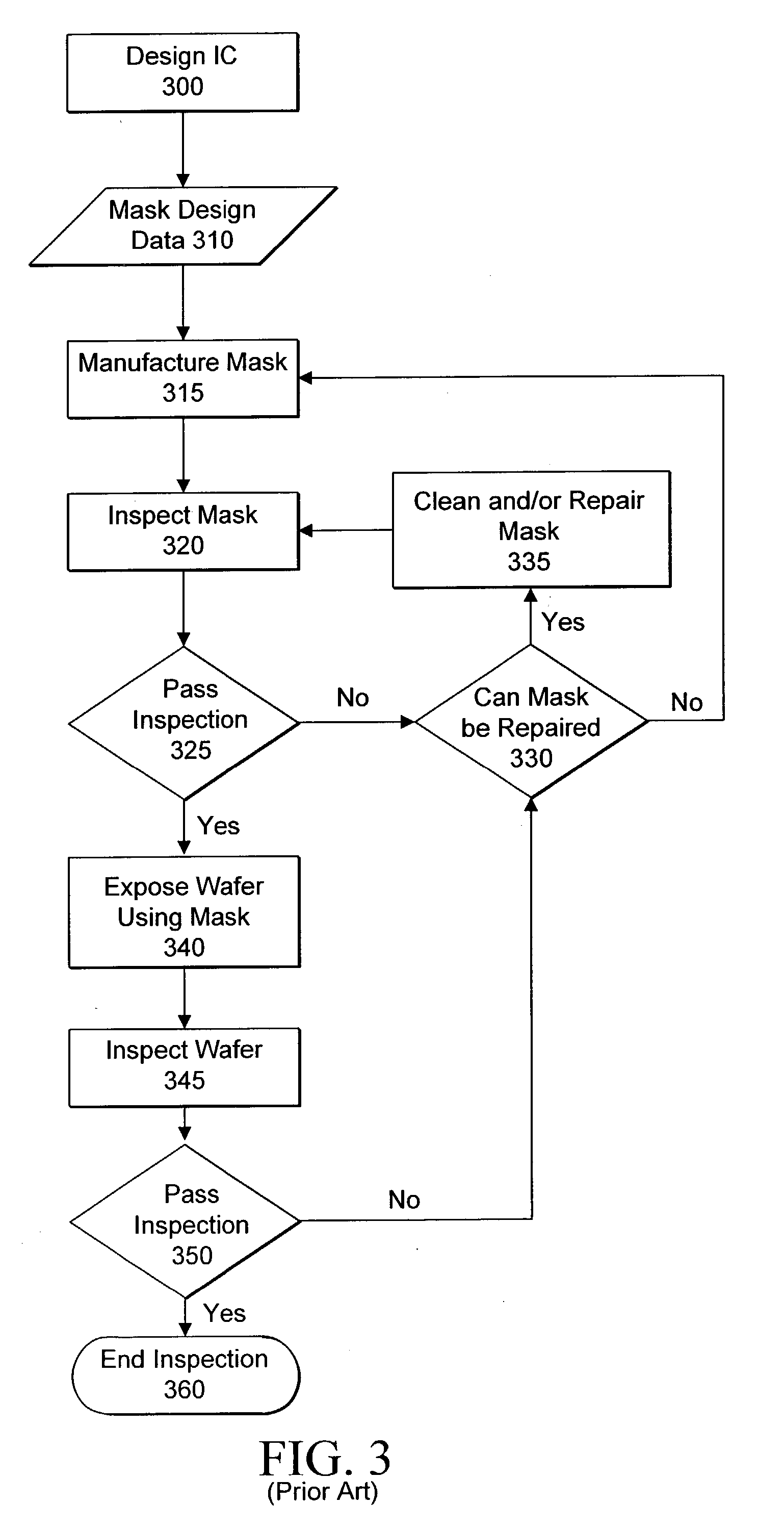

A method and apparatus for inspecting a photolithography mask for defects is provided. The inspection method comprises providing a defect area image to an image simulator wherein the defect area image is an image of a portion of a photolithography mask, and providing a set of lithography parameters as a second input to the image simulator. The defect area image may be provided by an inspection tool which scans the photolithography mask for defects using a high resolution microscope and captures images of areas of the mask around identified potential defects. The image simulator generates a first simulated image in response to the defect area image and the set of lithography parameters. The first simulated image is a simulation of an image which would be printed on a wafer if the wafer were to be exposed to an illumination source directed through the portion of the mask. The method may also include providing a second simulated image which is a simulation of the wafer print of the portion of the design mask which corresponds to the portion represented by the defect area image. The method also provides for the comparison of the first and second simulated images in order to determine the printability of any identified potential defects on the photolithography mask. A method of determining the process window effect of any identified potential defects is also provided for.

Owner:SYNOPSYS INC

Method and apparatus for a network-based mask defect printability analysis system

InactiveUS6578188B1Minimal additional costCode for implementing the network server is extremely robustImage enhancementNanotechThe InternetSimulation

A mask defect printability simulation server provides simulations, one-dimensional analysis, and reports to multiple clients over a wide area network, such as the Internet. This network-based simulation server allows a client to leverage a core of highly-trained engineers. Additionally, the network-based simulation server can be easily supported since only a single source for the tools associated with the simulation server is necessary for multiple clients. A client can access the simulation server using a standard personal computer having a browser, thereby eliminating the need for client to maintain an expensive database for the server. Finally, in the network-based simulation server, multiple users can view the same mask defect image and provide real-time comments to each other as simulation and analysis are performed on the defect image, thereby encouraging problem solving and decision-making dialogue among the users.

Owner:SYNOPSYS INC

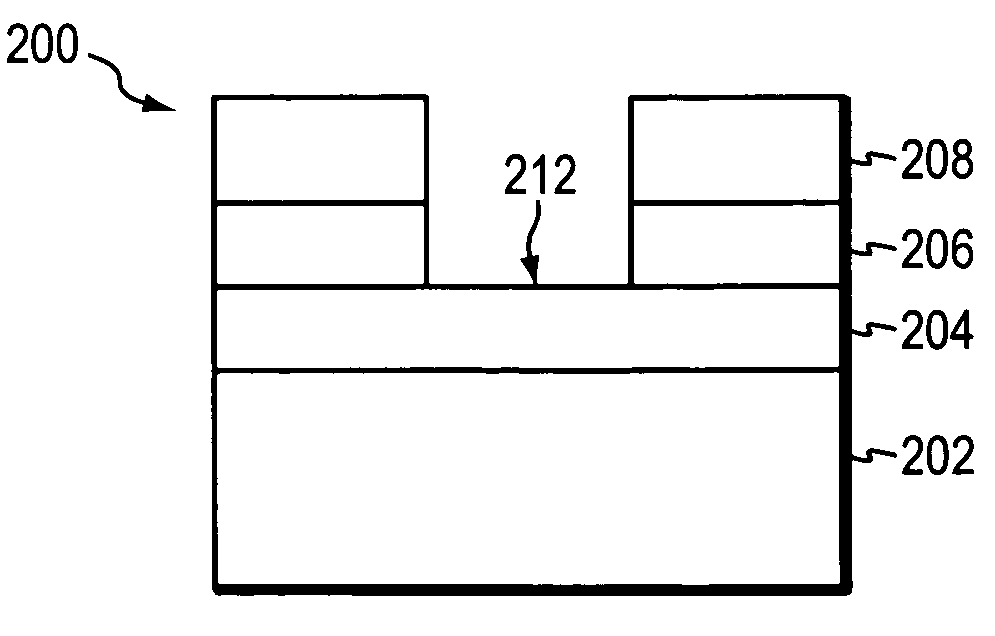

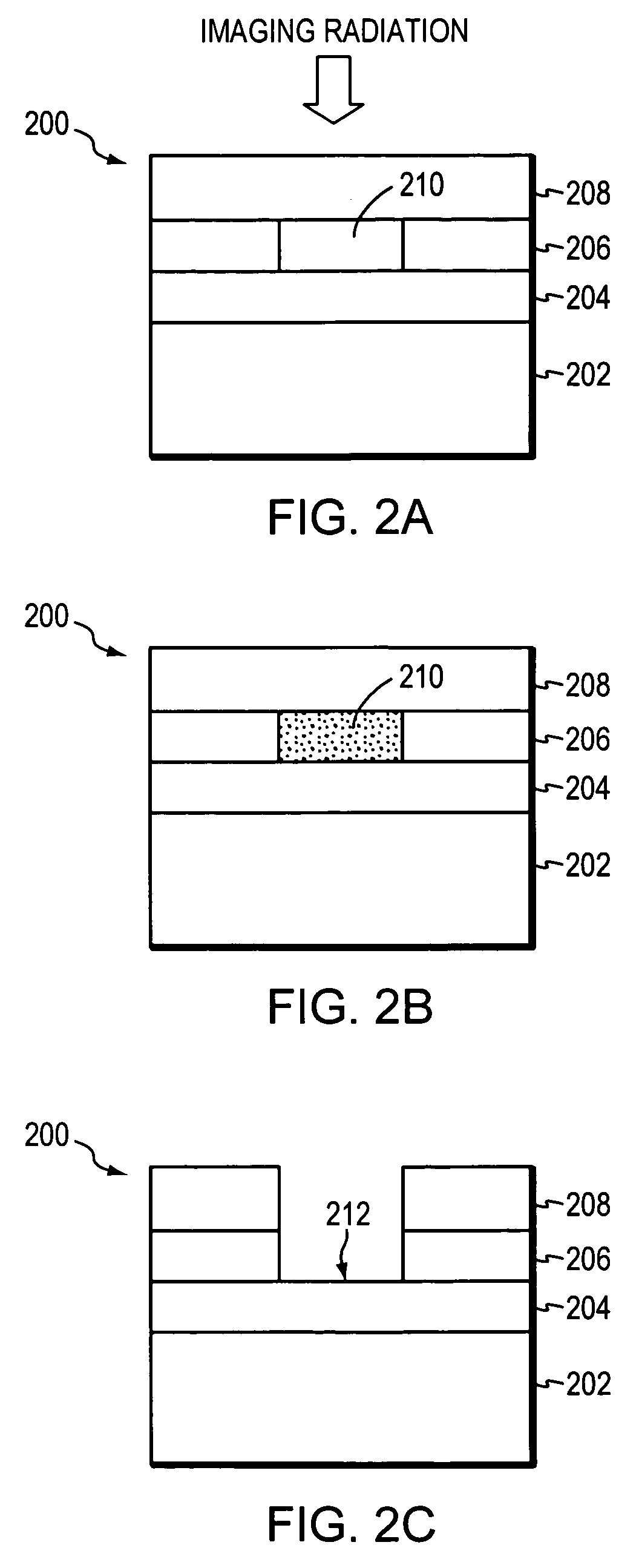

Method of preparing negative-working radiation-sensitive elements

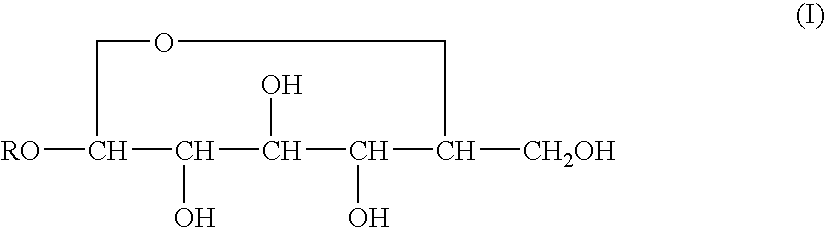

ActiveUS7175969B1Excellent developabilityReduced background stainingPhotosensitive materialsRadiation applicationsSide chainMoisture

A method of preparing negative-working, single-layer imageable elements improves their storage stability in a humid environment. The method includes enclosing the coated imageable elements in a water-impermeable sheet material that substantially inhibits the transfer of moisture to and from the imageable element. Such imageable elements include a radiation-sensitive composition that includes a radically polymerizable component, an initiator composition to provide radicals upon exposure to imaging radiation, a radiation absorbing compound, and a polymeric binder having poly(alkylene glycol) side chains.

Owner:EASTMAN KODAK CO

Visual inspection and verification system

A method and apparatus for inspecting a photolithography mask for defects is provided. The inspection method comprises providing a defect area image to an image simulator wherein the defect area image is an image of a portion of a photolithography mask, and providing a set of lithography parameters as a second input to the image simulator. The defect area image may be provided by an inspection tool which scans the photolithography mask for defects using a high resolution microscope and captures images of areas of the mask around identified potential defects. The image simulator generates a first simulated image in response to the defect area image and the set of lithography parameters. The first simulated image is a simulation of an image which would be printed on a wafer if the wafer were to be exposed to an illumination source directed through the portion of the mask. The method may also include providing a second simulated image which is a simulation of the wafer print of the portion of the design mask which corresponds to the portion represented by the defect area image. The method also provides for the comparison of the first and second simulated images in order to determine the printability of any identified potential defects on the photolithography mask. A method of determining the process window effect of any identified potential defects is also provided for.

Owner:SYNOPSYS INC

User interface for a network-based mask defect printability analysis system

InactiveUS20030126581A1Encouraging invaluable problem-solving dialogue among usersComplicate to learnImage enhancementNanotechUser inputTalk box

Mask simulation tools are typically extremely complicated to learn and to use effectively. Therefore, providing access to a mask simulation tool over a wide area network (WAN) to multiple on-line users can be very cost effective. Specifically, in a network-based simulation server, multiple users can view the same mask image, simulations, and analysis results and provide real-time comments to each other as simulation and analysis are performed, thereby encouraging invaluable problem-solving dialogue among users. The user interface for this mask simulation tool can advantageously facilitate this dialogue. For example, the user interface can include an enter box for a user to enter a message and a talk box for capturing any message sent by any user of the simulation tool using the enter box.

Owner:SYNOPSYS INC

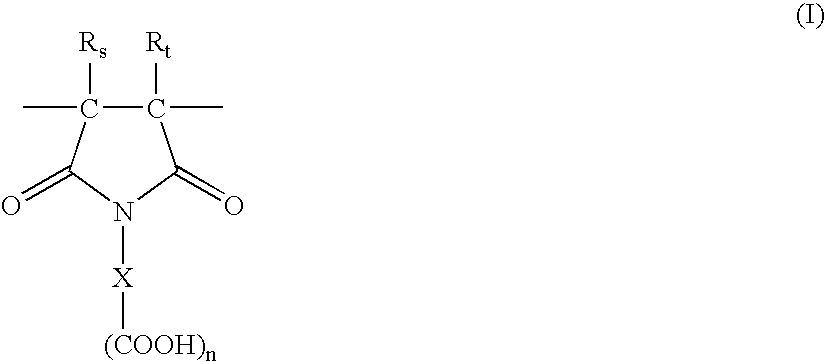

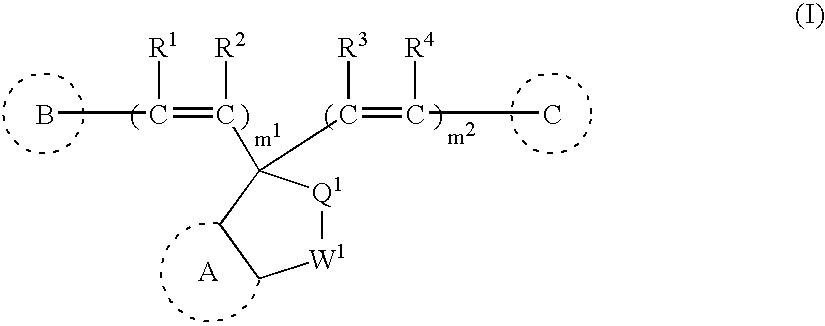

Multilayer imageable elements

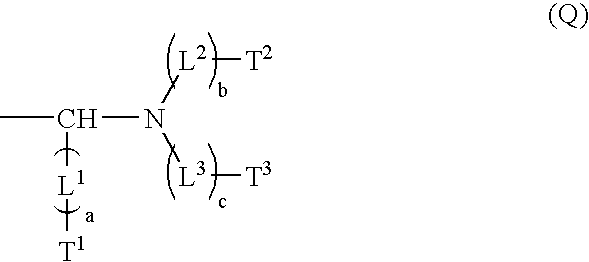

InactiveUS6893783B2Increase the lengthPhotosensitive materialsRadiation applicationsN-phenylmaleimidePolymer science

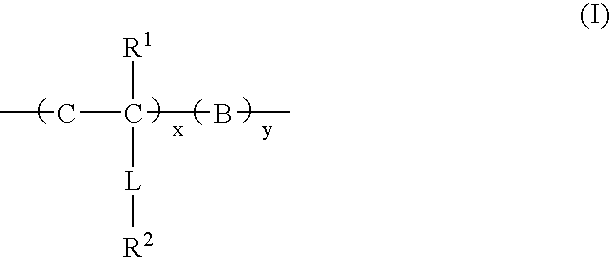

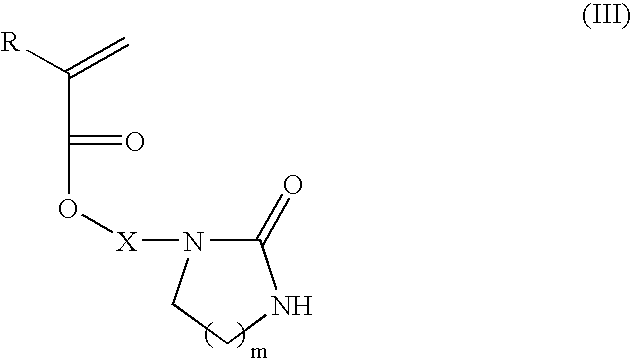

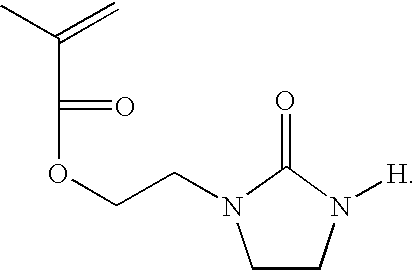

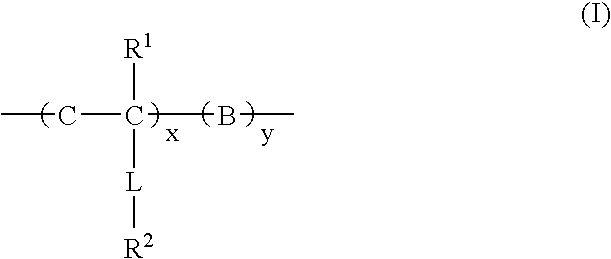

Multilayer, positive working, thermally imageable elements are disclosed. The elements produce bakeable lithographic printing plates that are resistant to press chemistries. The elements have a substrate, an underlayer, and a top layer. The underlayer comprises a resin or resins having activated methylol and / or activated alkylated methylol groups, such as a resole resin, and a polymeric material that comprises, in polymerized form, (a) methacrylic acid; (b) N-phenylmaleimide, N-cyclohexylmaleimide, N-benzylmaleimide, or a mixture thereof; and (c) one or more monomers of the structure: [0001]in which:[0002]R1 is H or methyl; X is —(CH2)n—, where n is an integer from 2 to 12; —(CH2—CH2—O)p—CH2—CH2—, where p is an integer from 1 to 3; or —Si(R′)(R″)— where R′ and R″ are each independently methyl or ethyl; and m is 1, 2, or 3.

Owner:KODAK POLYCHROME GRAPHICS

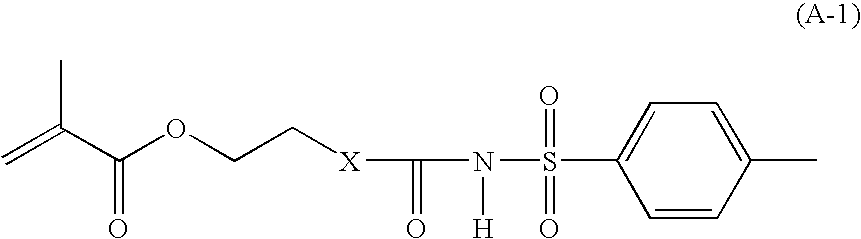

Multilayer imageable element containing sulfonamido resin

InactiveUS7163770B1Reduces sludge formationSlow down the dissolution ratePhotosensitive materialsRadiation applicationsHydrogenChemical compound

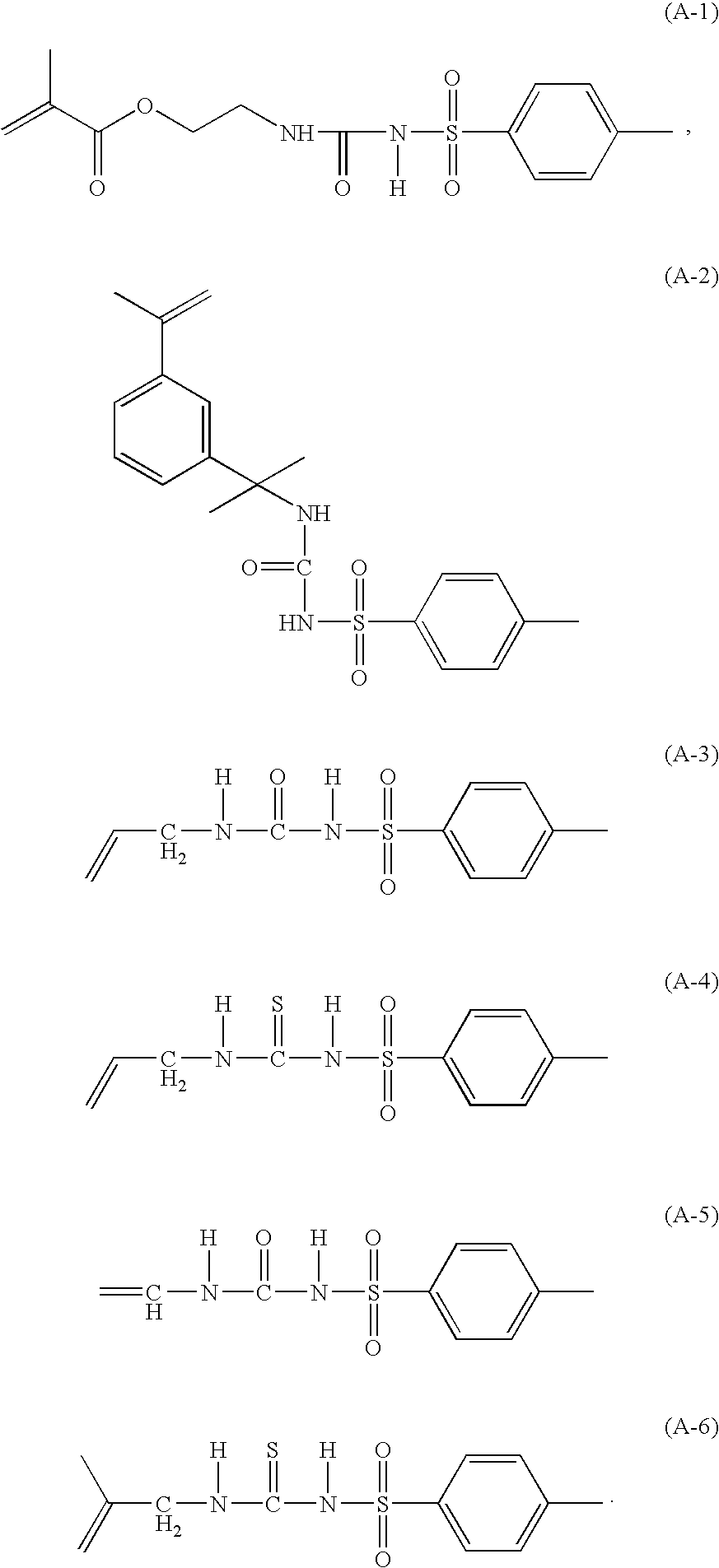

A positive-working imageable element comprises inner and outer layers and a radiation absorbing compound such as an IR absorbing dye. The inner layer includes a first polymeric material. The ink receptive outer layer includes a second polymeric binder comprising a polymer backbone and an —X—C(═T)—NR—S(═O)2— moiety that is attached to the polymer backbone, wherein —X— is an oxy or —NR′— group, T is O or S, R and R′ are independently hydrogen, halo, or an alkyl group having 1 to 6 carbon atoms. After thermal imaging, the element can be developed using an alkaline developer. Use of the particular second polymeric binder reduces sludging in the developer. Its dissolution rate in the developer is slow enough to resist developer attack in the non-imaged areas of the outer layer but rapid enough for the second polymeric binder to be quickly loosened from imaged areas and kept suspended or dissolved for a considerable time.

Owner:EASTMAN KODAK CO

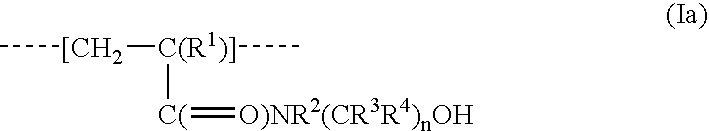

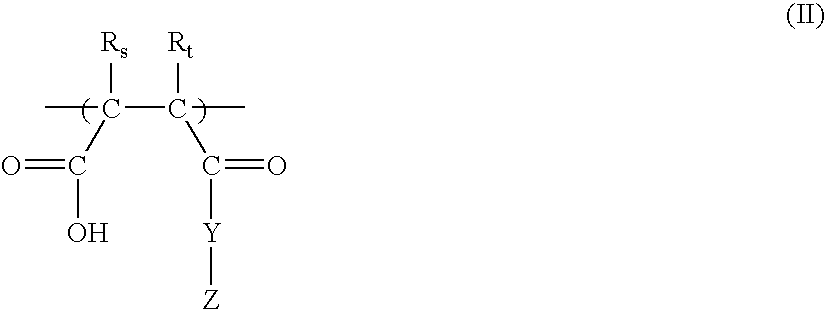

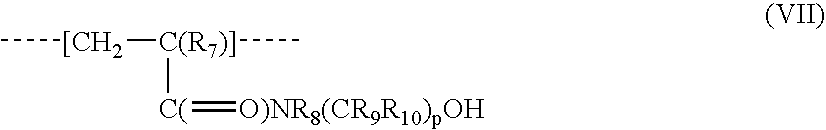

Multilayer imageable element with improved chemical resistance

InactiveUS7144661B1Good chemical resistanceIncrease press run lengthPhotosensitive materialsRadiation applicationsHydrogenSolvent

Positive-working imageable elements comprise a radiation absorbing compound and inner and outer layers on a substrate having a hydrophilic surface. The inner layer comprises a polymer that is removable using an alkaline developer and in which from about 1 to about 50 mol % of its recurring units are derived from one or more of the ethylenically unsaturated polymerizable monomers represented by the following Structure (I):CH2═C(R1)C(═O)NR2(CR3R4)nOH (I)wherein R1, R2, R3, and R4 are independently hydrogen, lower alkyl, or phenyl, and n is 1 to 20. The imageable elements having improved resistance to development and printing chemicals and solvents.

Owner:EASTMAN KODAK CO

Multilayer imageable elements

InactiveUS7186482B2Increase press run lengthIncrease the lengthPhotosensitive materialsRadiation applicationsN-phenylmaleimideHydrogen

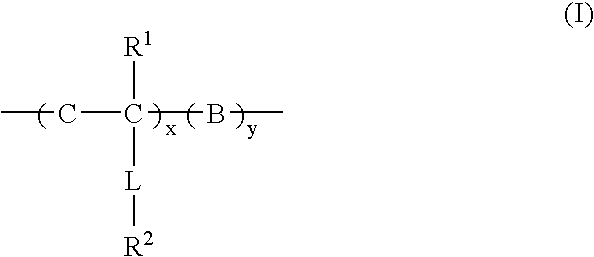

Multilayer, positive working, thermally imageable, bakeable imageable elements have a substrate, an underlayer, and a top layer. The underlayer comprises a polymeric material that comprises, in polymerized form from about 5 mol % to about 30 mol % of recurring units derived from an ethylenically unsaturated polymerizable monomer having a carboxy group; from about 20 mol % to about 75 mol % of recurring units derived from N-phenylmaleimide, N-cyclohexylmaleimide, N-benzylmaleimide, or a mixture thereof; and from about 3 mol % to about 50 mol % of recurring units derived from a compound represented by the formula:CH2═C(R2)—C(O)—NH—CH2—OR1,in which R1 is C1 to C12 alkyl, phenyl, C1 to C12 substituted phenyl, C1 to C12 aralkyl, or Si(CH3)3; and R2 is hydrogen or methyl. Other materials, such as a resin or resins having activated methylol and / or activated alkylated methylol groups, such as a resole resin, may be present in the underlayer. The elements can be used to produce bakeable lithographic printing plates that are resistant to press chemistries.

Owner:EASTMAN KODAK CO

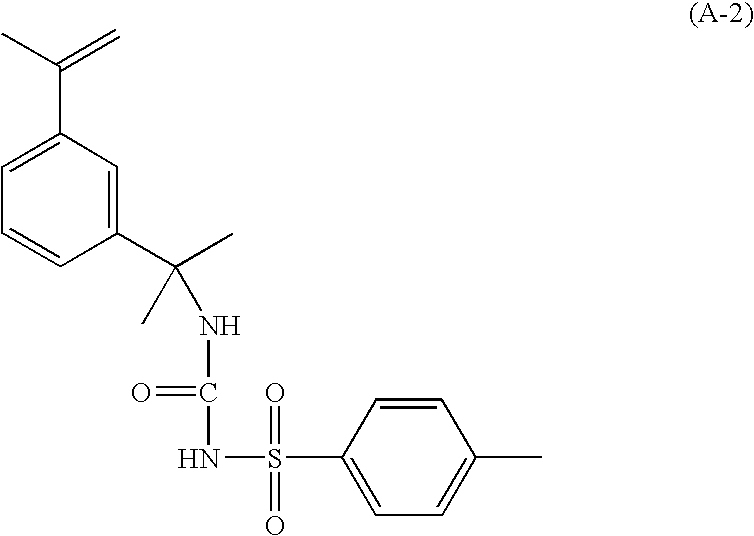

Imageable members with improved chemical resistance

InactiveUS7223506B1Improve the immunityPhotosensitive materialsRadiation applicationsHydrogenChemical compound

Single-layer and multilayer imageable elements have a substrate and at least one imageable layer and can be used to prepare positive-working lithographic printing plates. The imageable elements also include a radiation absorbing compound and a solvent-resistant polymer binder comprising an —N(R)—C(═X)—N(R′)—S(═O)2— moiety that is attached to the polymer backbone, wherein X is O or S, R and R′ are independently hydrogen, halo, or an alkyl group having 1 to 6 carbon atoms. This solvent-resistant polymer binder is located in the imageable layer closest to the substrate and provides improved chemical resistance.

Owner:EASTMAN KODAK COMPANT

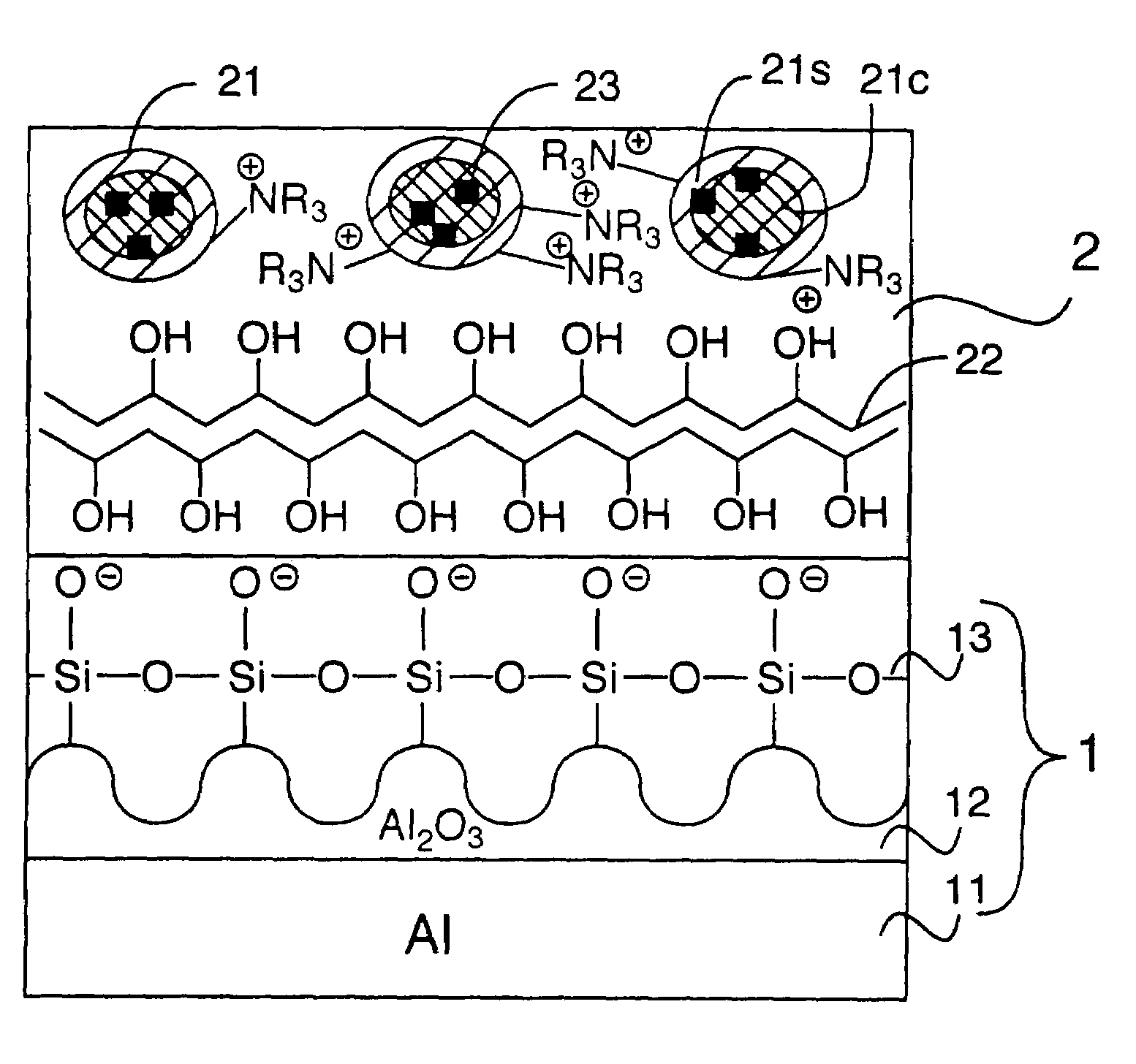

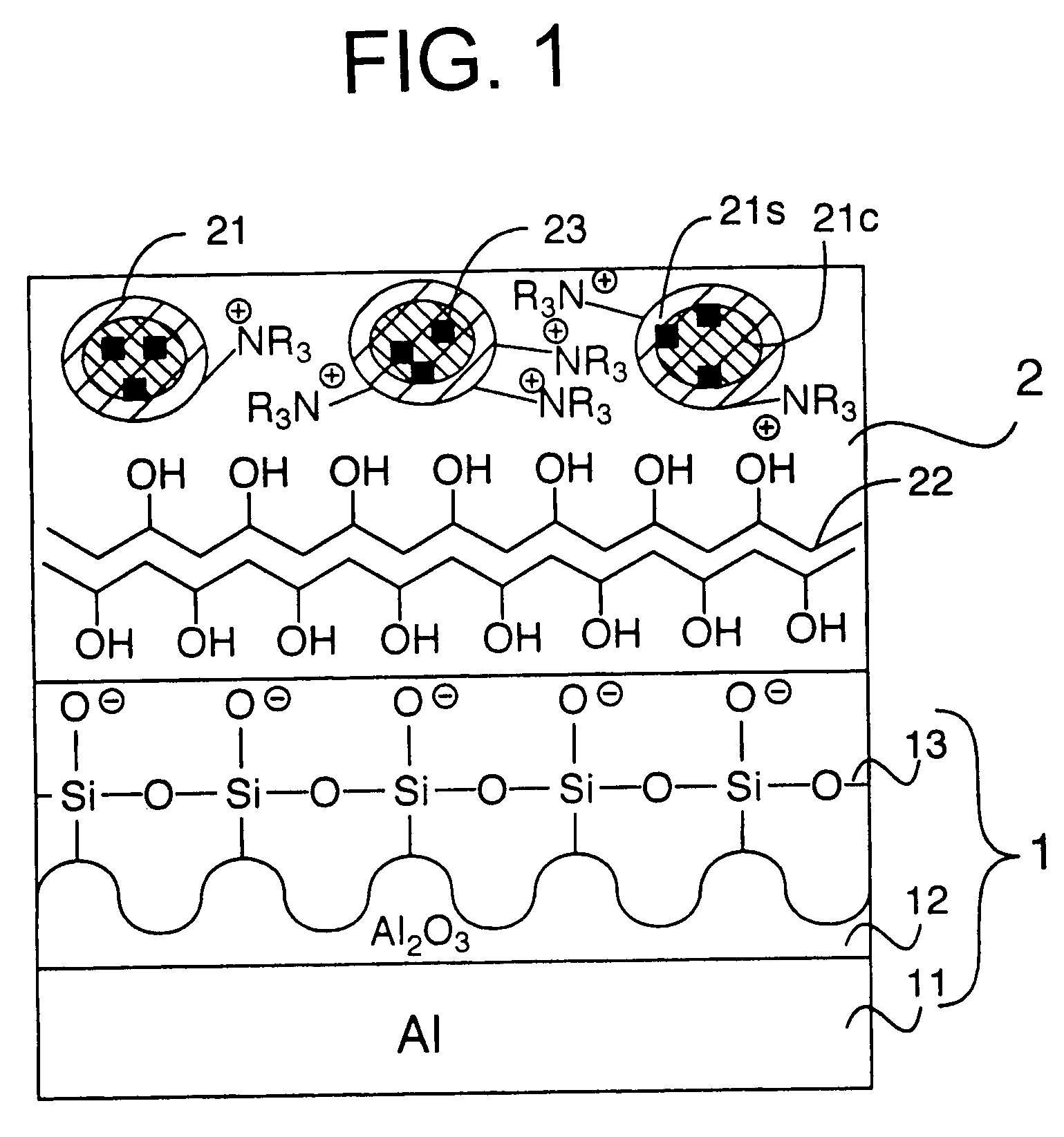

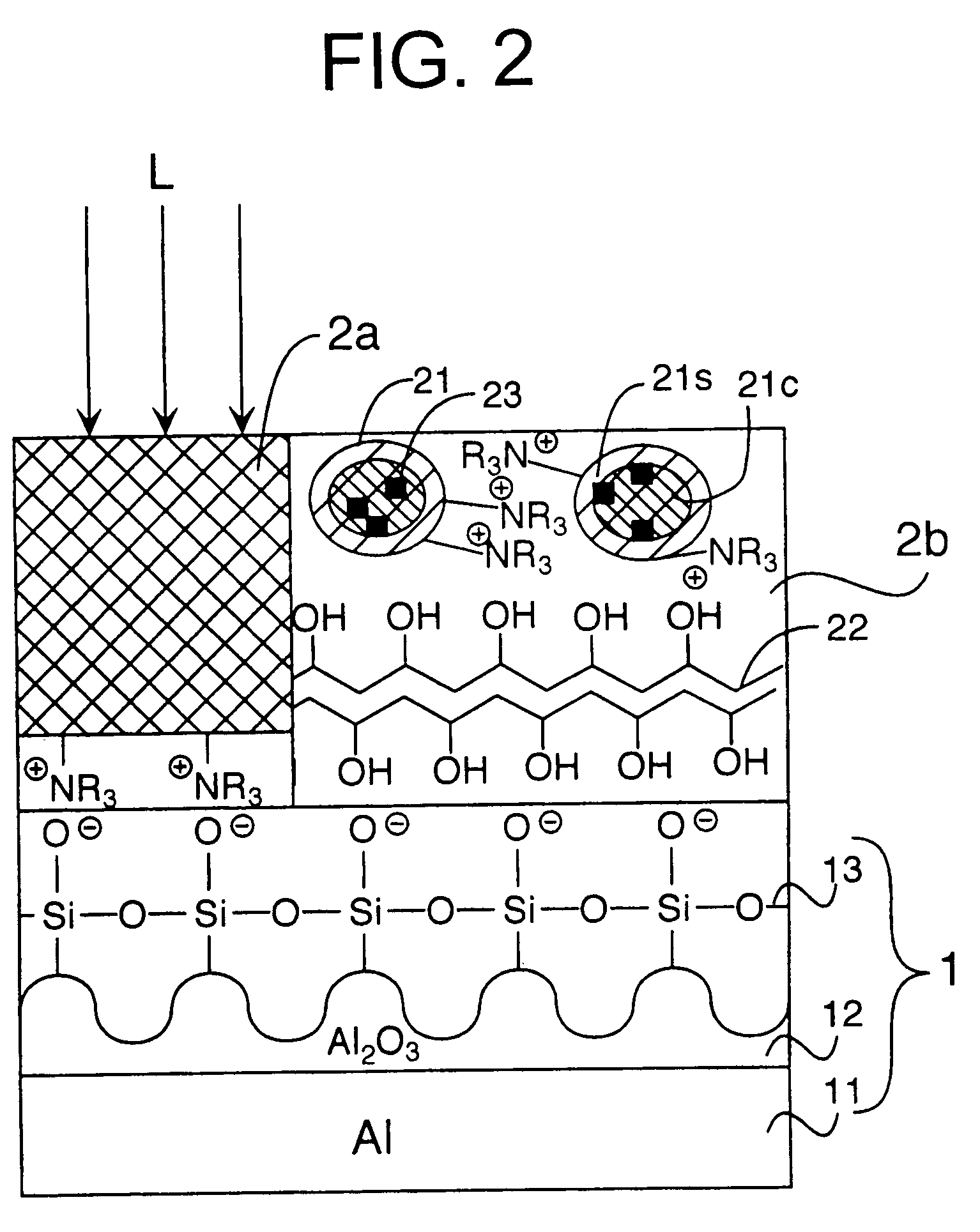

Presensitized lithographic plate comprising microcapsules

InactiveUS7001704B2Excellent plate wearEasy to wearRadiation applicationsSemiconductor/solid-state device manufacturingPlanographic printingPolymer chemistry

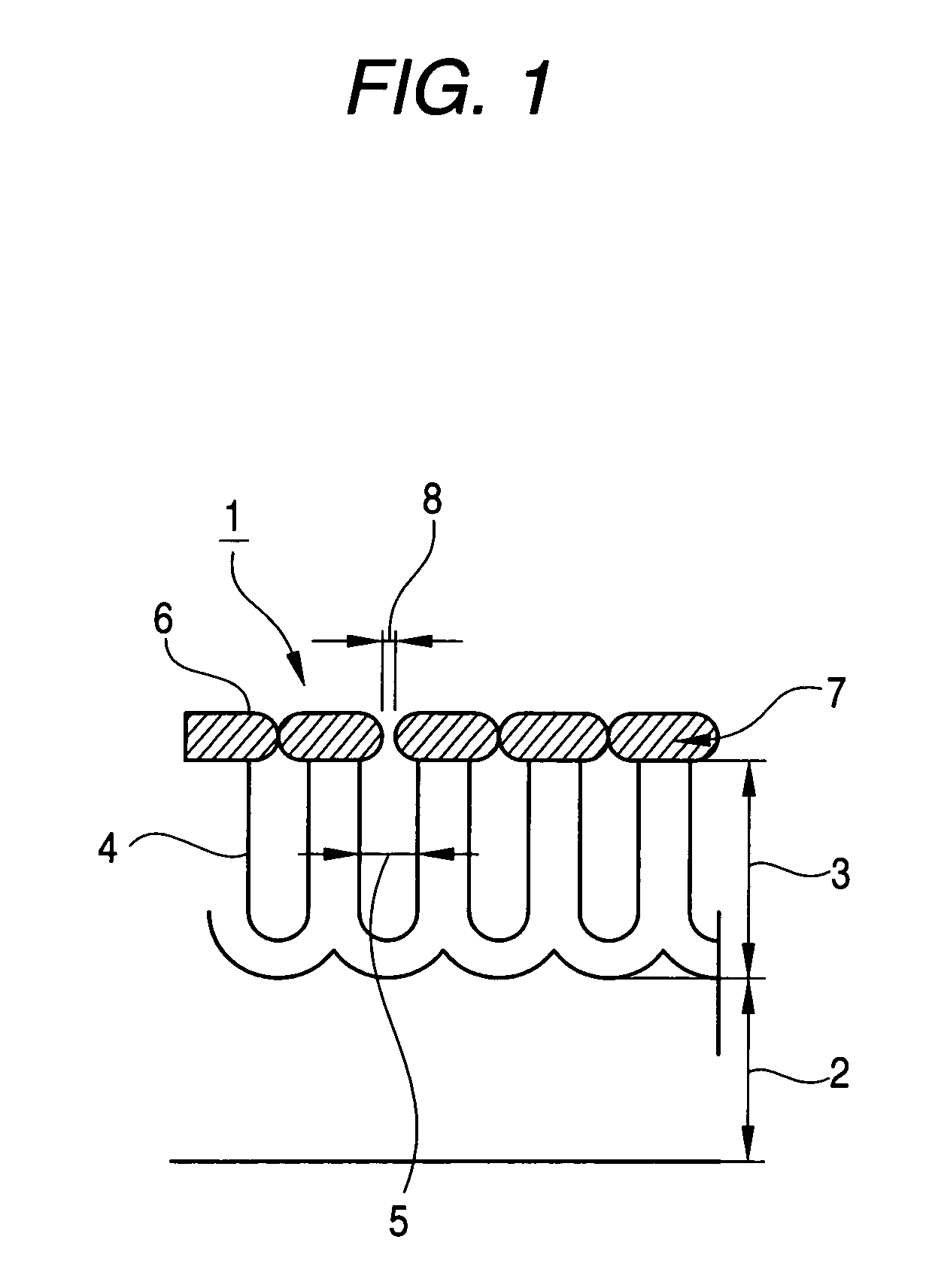

A presensitized lithographic printing plate comprises a hydrophilic support and an image-forming layer. The image-forming layer contains microcapsules and a hydrophilic compound. The microcapsules are dispersed in the image forming layer. The hydrophilic compound is arranged outside of the microcapsules. The microcapsules comprise a core and a shell. The core comprises a polymerizable compound. The shell comprises a polymer. The polymer of the shell has adherence to a surface of the hydrophilic support.

Owner:FUJIFILM HLDG CORP +1

Multilayer imageable element containing epoxy resin

InactiveUS7160653B1Extended shelf lifeImprove imaging resolutionPhotosensitive materialsRadiation applicationsEpoxyPolymer

A positive-working imageable element comprises inner and outer layers and a radiation absorbing compound such as an IR absorbing dye. The inner layer includes a polymeric material that is removable using an alkaline developer. An ink receptive outer layer is not removable using an alkaline developer before its exposure to imaging radiation. The outer layer includes a polymer binder having pendant epoxy groups that are substantially unreacted during exposure.

Owner:EASTMAN KODAK CO

Pattern forming method, image forming method, fine particle adsorption pattern forming method, conductive pattern forming method, pattern forming material and planographic printing plate

InactiveUS7306895B2Improve adhesionImprove conductivitySemiconductor/solid-state device manufacturingPhotomechanical coating apparatusCross-linkPolymer science

The invention provides a pattern forming method including providing a polymerization initiation layer which is obtained by fixing, by a cross-linking reaction, a polymer having functional groups having polymerization initiation ability and cross-linking groups at side chains, on a support, and forming a pattern including a preparation zone and a non-preparation zone of a graft polymer by preparing the graft polymer on the surface of the polymerization initiation layer using graft polymerization, by contacting a compound having a polymerizable group on the polymerization initiation layer and supplying energy imagewise; an image forming method which applies the pattern forming method; a pattern forming material; and a planographic printing plate. A fine particle adsorption pattern forming method and a conductive pattern forming method are also provided.

Owner:FUJIFILM HLDG CORP +1

Alkali resistant polymeric interlayers for lithoplates

Substrates for lithographic printing plate precursors and lithographic printing plate precursors are disclosed. The substrates comprise an aluminum or aluminum alloy support and the a layer of interlayer material on the support. The interlayer material is a co-polymer that comprise (1) acid groups and / or phosphonic acid groups, and (2) silyl groups substituted with three alkoxy and / or phenoxy groups. The lithographic printing plate precursors additionally comprise an imageable layer over the interlayer.

Owner:KODAK POLYCHROME GRAPHICS

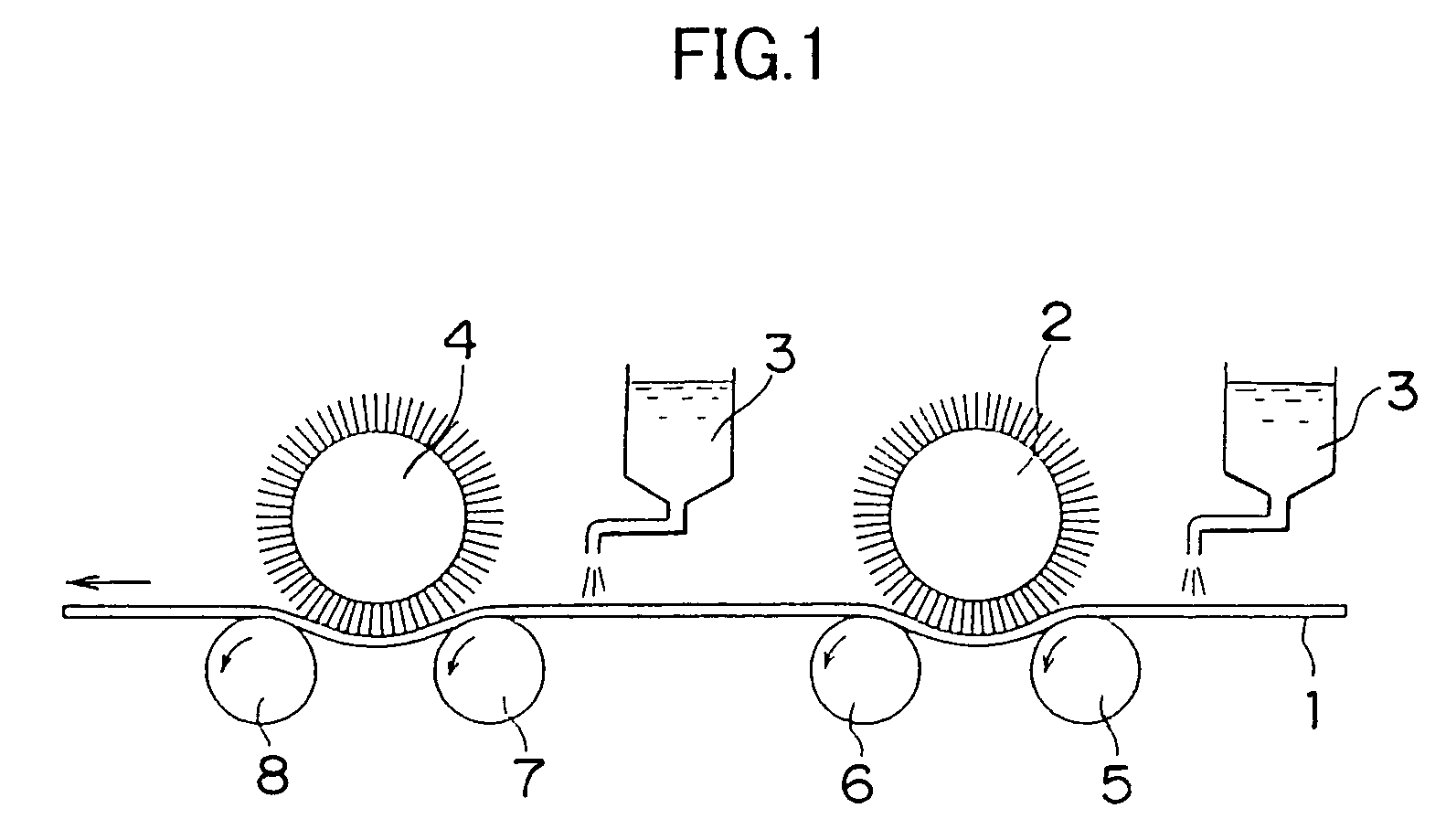

Process for preparing a flexographic printing plate

InactiveUS7348123B2Easy to disassembleQuality improvementSemiconductor/solid-state device manufacturingPhotosensitive material processingEngineeringHeat treated

Owner:DUPONT ELECTRONICS INC

Support for lithographic printing plate, method of preparing the support and presensitized plate

InactiveUS7087361B2Prolong lifeIncrease resistancePhotosensitive materialsRadiation applicationsImage recordingRecording layer

Owner:FUJIFILM HLDG CORP +1

Thermally switchable imageable elements containing betaine-containing co-polymers

Imageable elements useful as lithographic printing plate precursors are disclosed. The element comprises an imageable layer over a support. The imageable layer contains a photothermal conversion material and a polymeric binder that comprises a polymer backbone with sulfobetaine- and / or carboxybetaine-containing side chains. The imageable elements do not require processing in a developer. They can be thermally imaged and immediately treated with fountain solution and ink without a development step.

Owner:KODAK POLYCHROME GRAPHICS

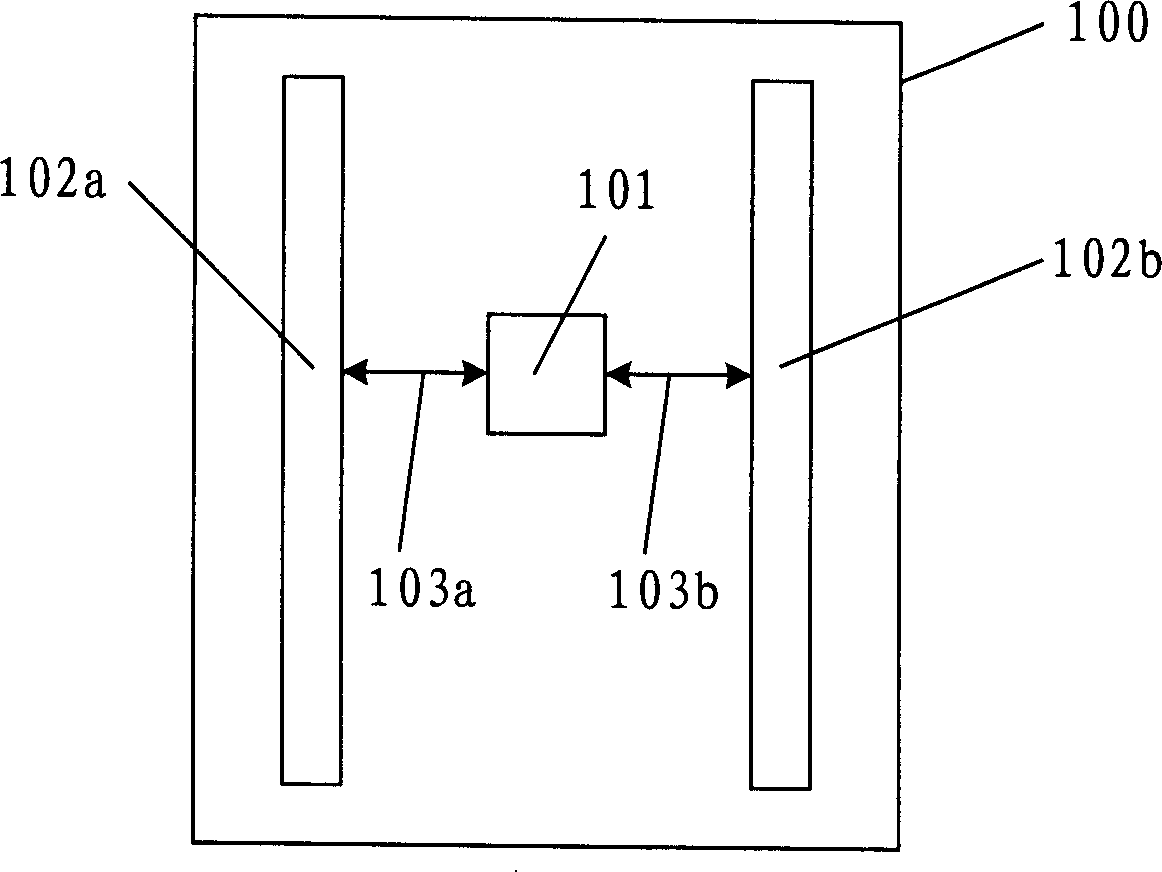

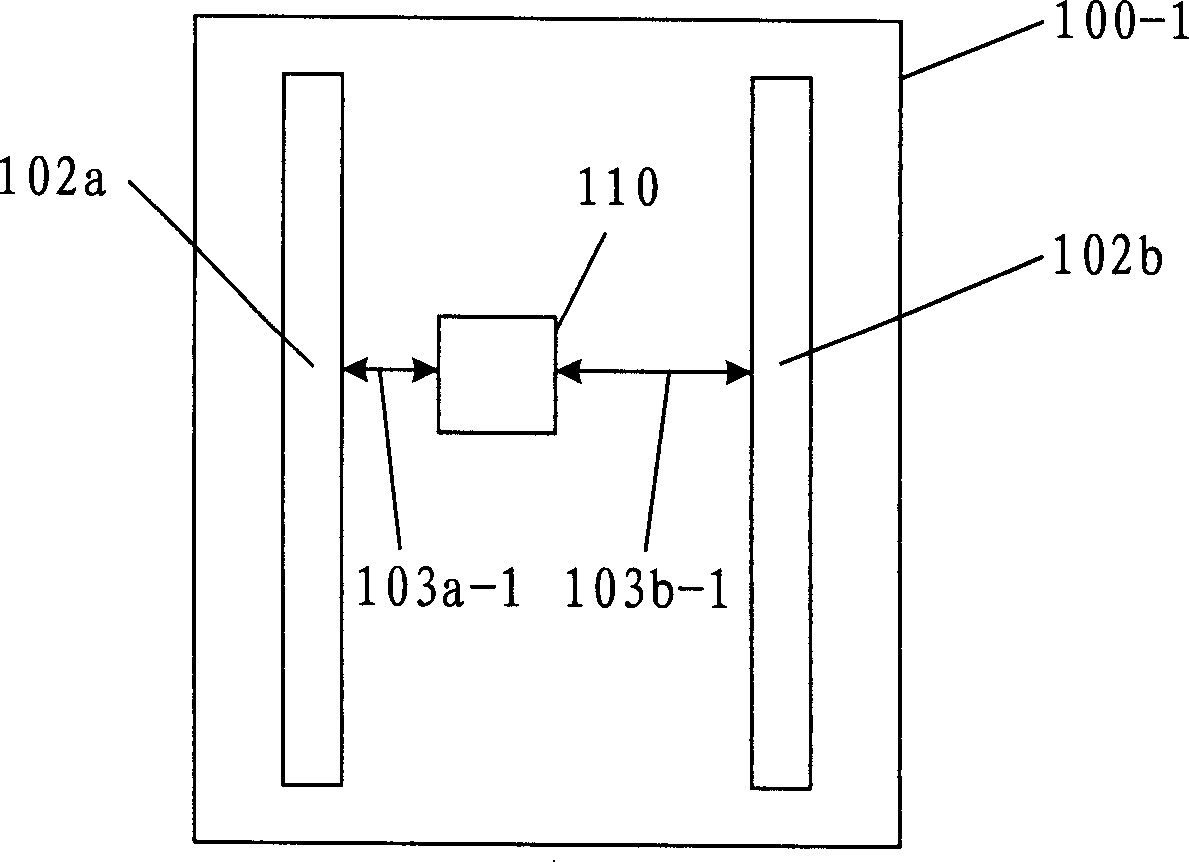

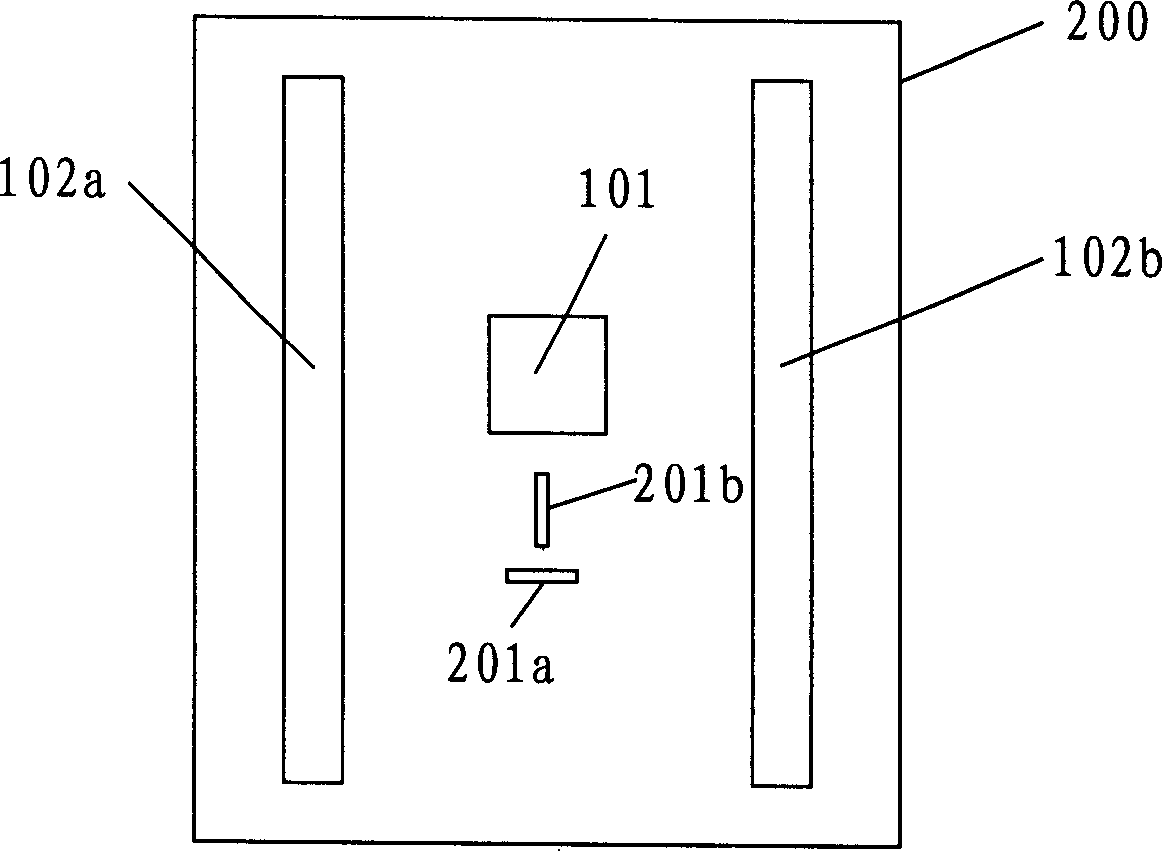

Mask plate, mask plate layout design method and defect repairing method

InactiveCN101192007ASolve scrapProduction has no effectSemiconductor/solid-state device manufacturingOriginals for photomechanical treatmentDefect repairTransmittance

The present invention discloses a mask plate, comprising a flat plate having light transmittance to exposure light, wherein, a printable geometric figure having light shading property to exposure light is formed on the flat plate; the geometric figure comprises at least one isolated figure; the isolated figure is provided with no other geometric figure or only the periodically repeated geometric figure along the X-axis and / or Y-axis direction in defect detection range. The present invention adopts a new layout design method, and is provided with the additional figure which cannot be printed in the detection range of the isolated figure in the geometric figure, so as to ensure that the defects of all positions can be positioned and repaired when defect repair is performed to the mask plate. Adopting the present invention can decrease the rejection rate of mask plates during mask plate manufacture and delay delivery risk.

Owner:SEMICON MFG INT (SHANGHAI) CORP

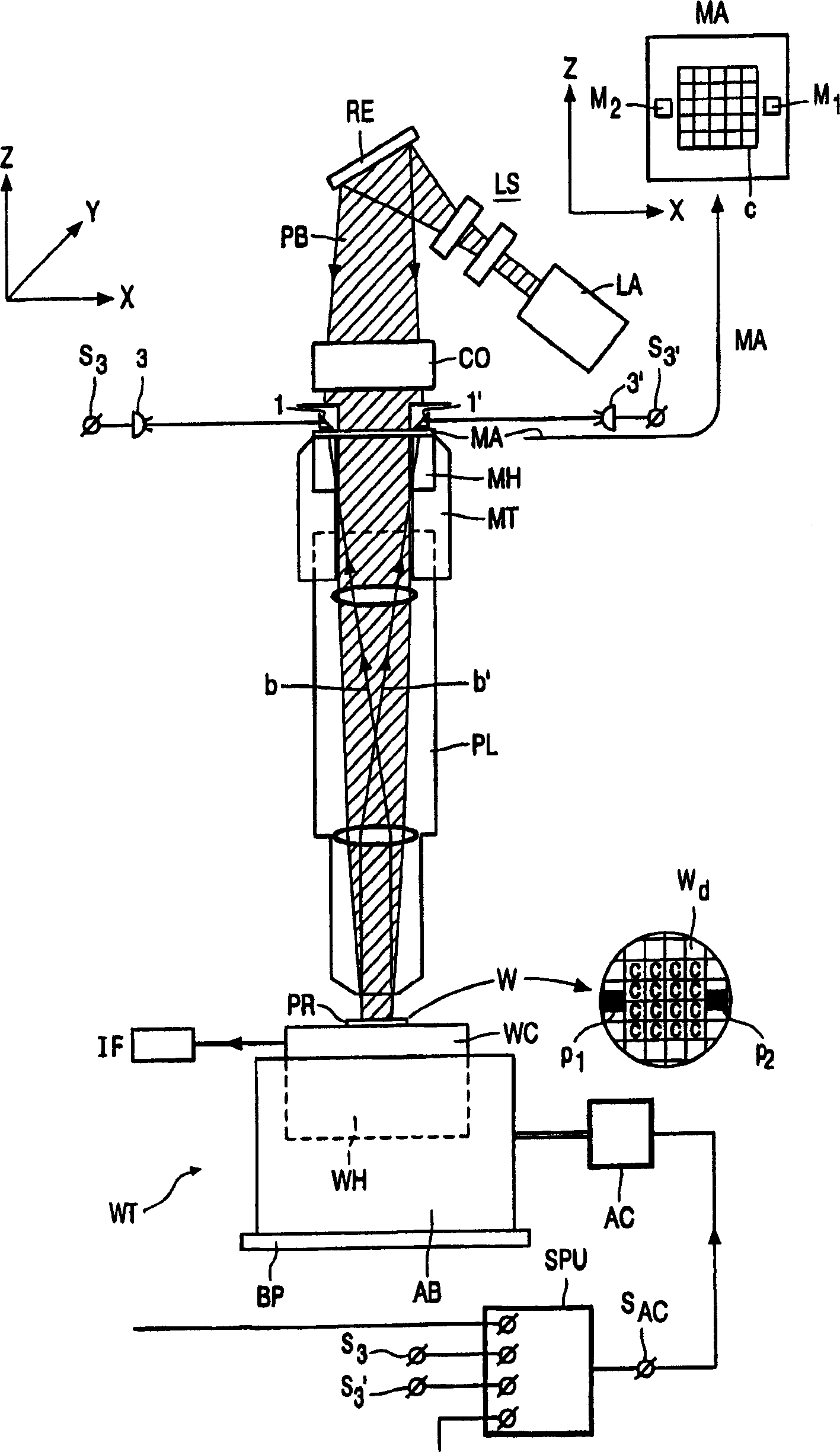

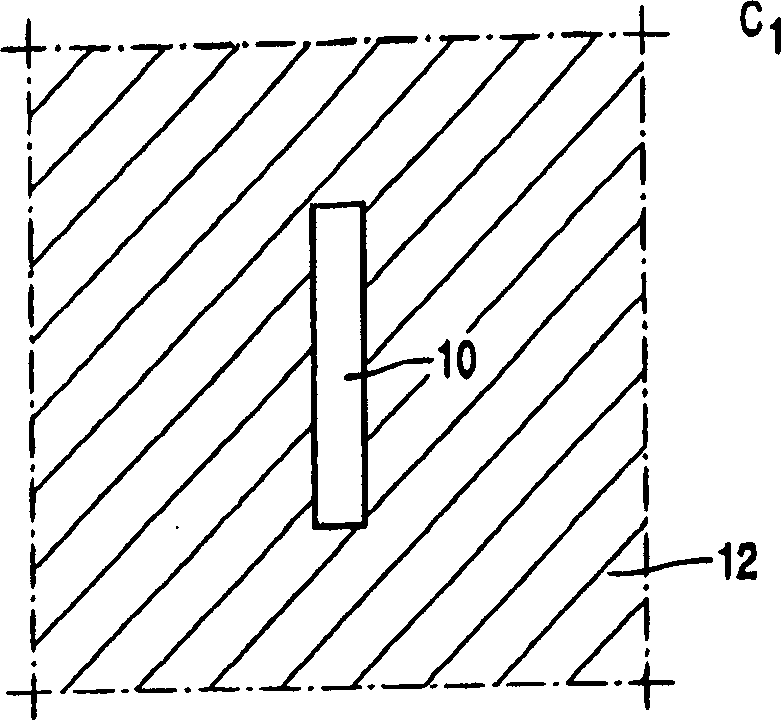

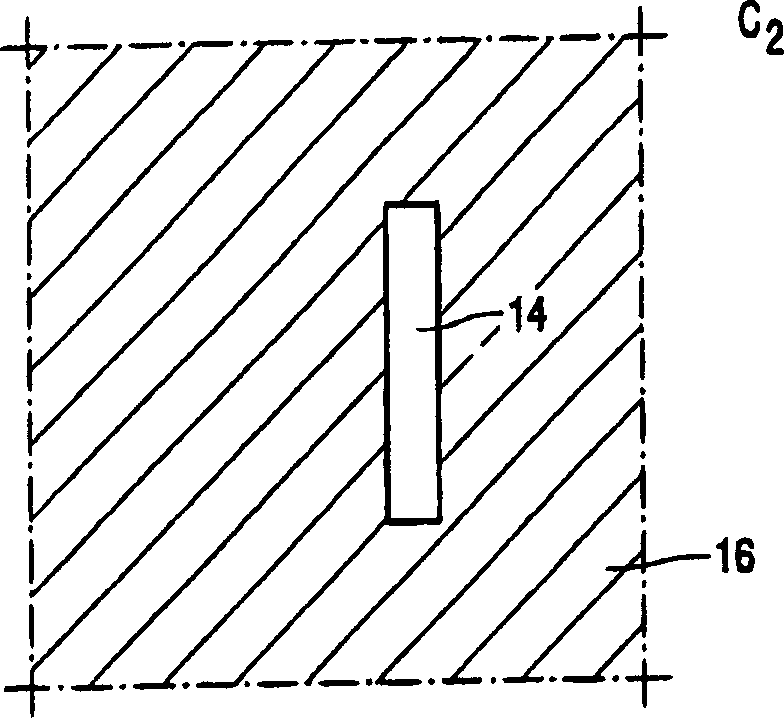

Lithographic method of manufacturing device

InactiveCN1474960AFix issues with disabled parametersReduce distanceSemiconductor/solid-state device manufacturingPhotomechanical exposure apparatusResistHigh density

For lithographically manufacturing a device with a very high density, a design mask pattern (120) is distributed on a number of sub-patterns (120a, 120b, 120c) by means of a new method. The sub-patterns do not comprise "forbidden" structures (135) and can be transferred by conventional apparatus to a substrate layer to be patterned. For the transfer, a new stack of layers is used, which comprise a pair of a processing layer (22; 26) and an inorganic anti-reflection layer (24; 28) for each sub-pattern. After a first processing layer (26) has been patterned with a first sub-pattern, it is coated with a new resist layer (30) which is exposed with a second sub-pattern, and a second processing layer (22) under the first processing layer is processed with the second sub-pattern.

Owner:KONINKLIJKE PHILIPS ELECTRONICS NV

Method of making a heat-sensitive lithographic printing plate

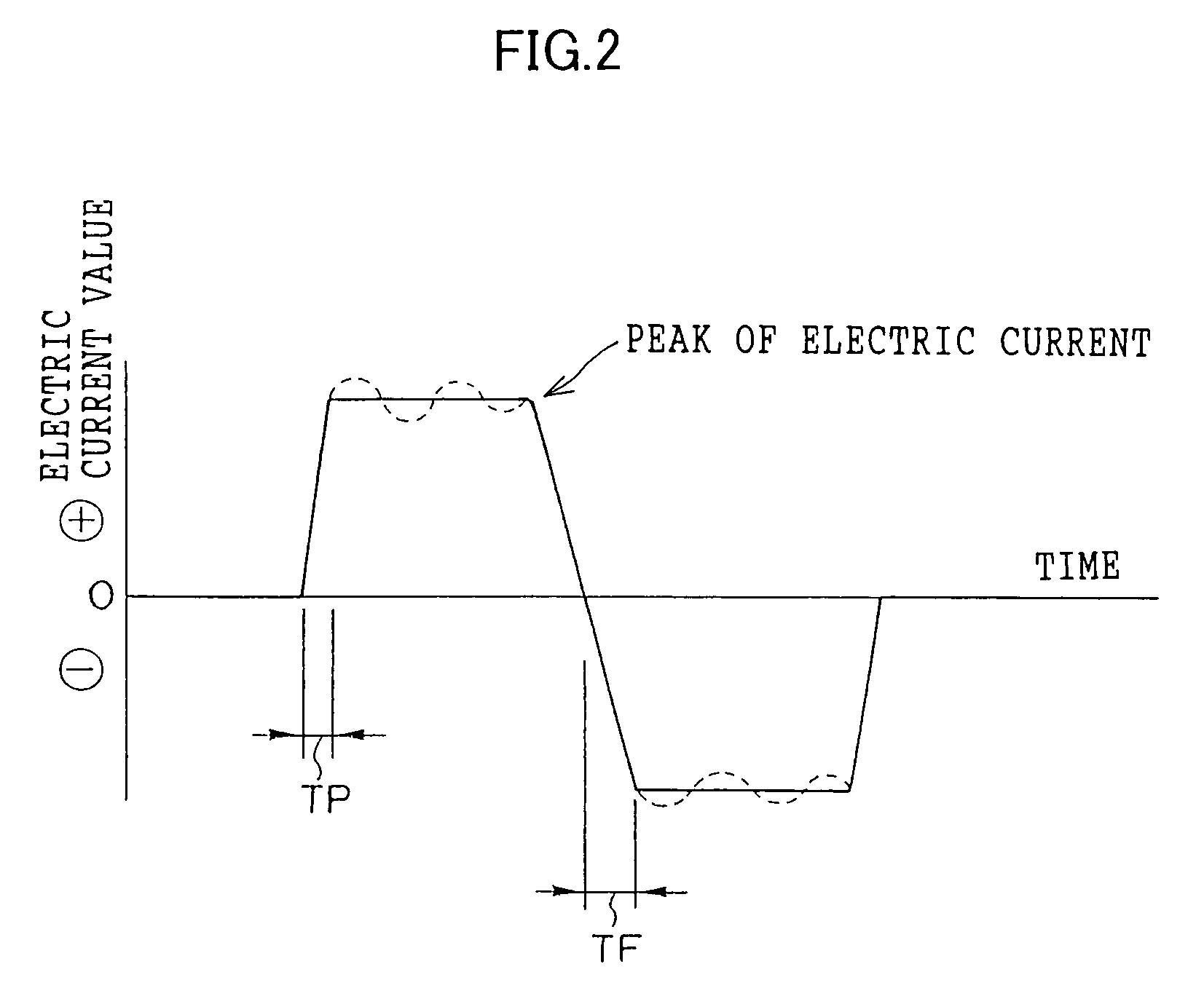

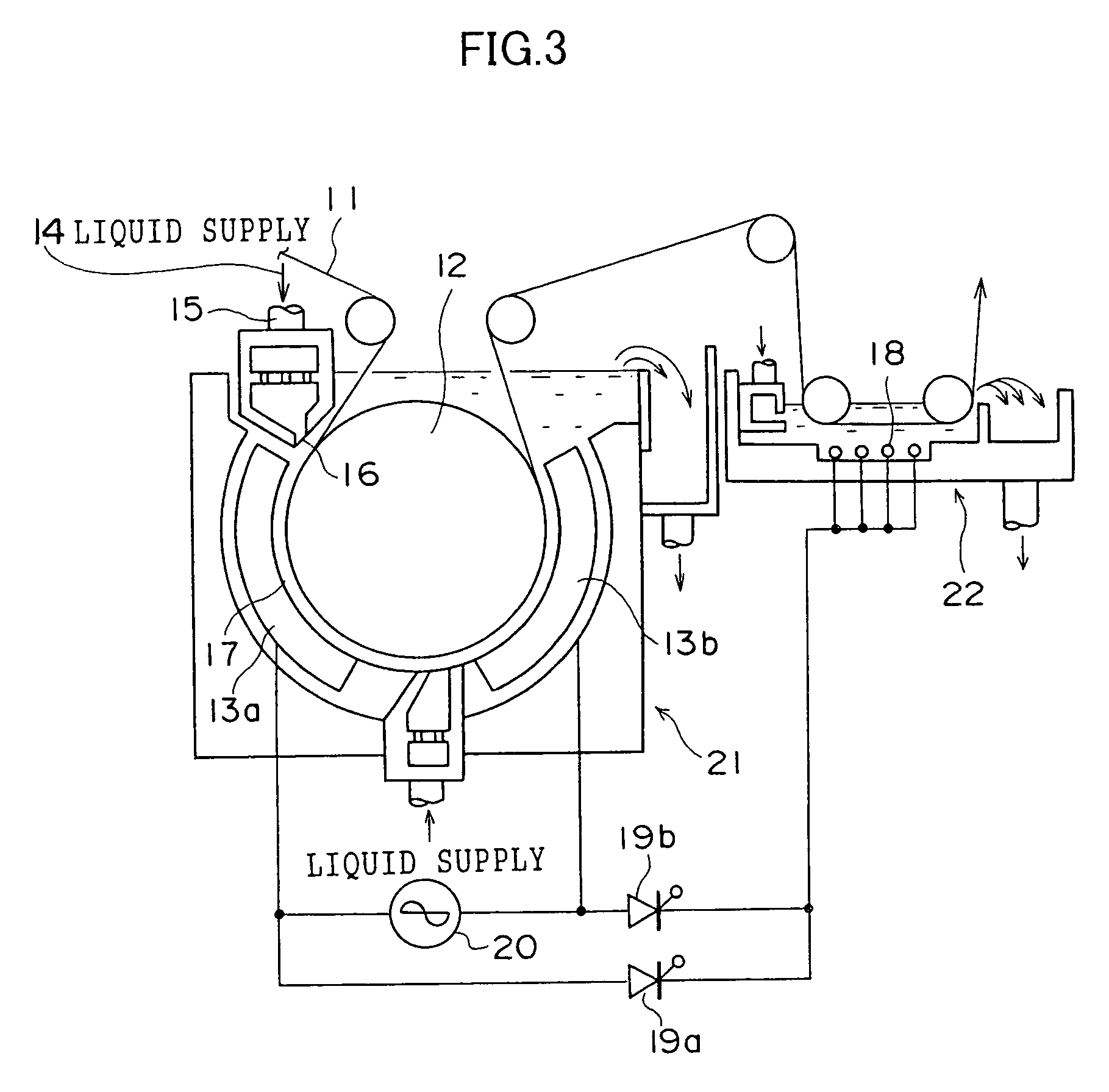

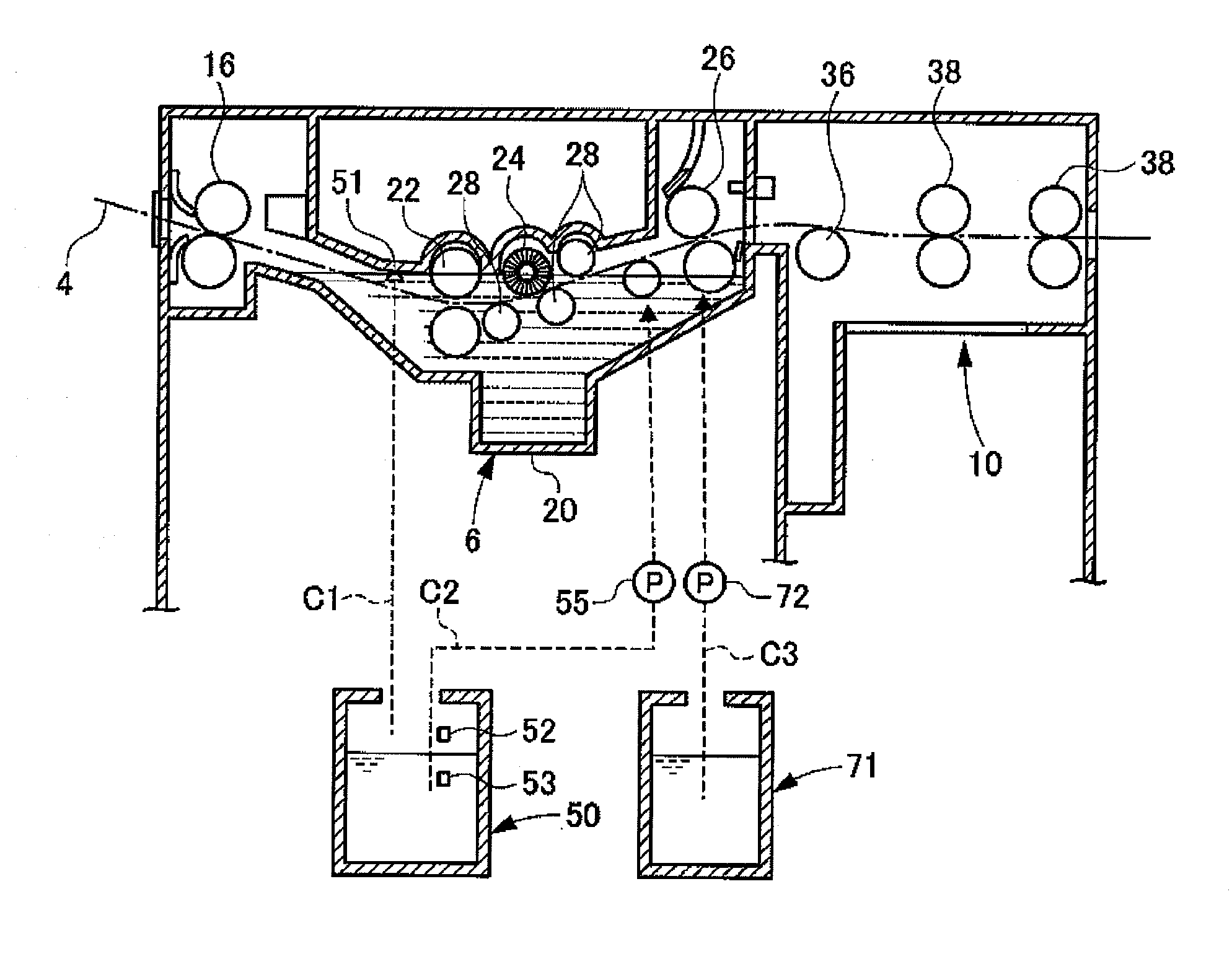

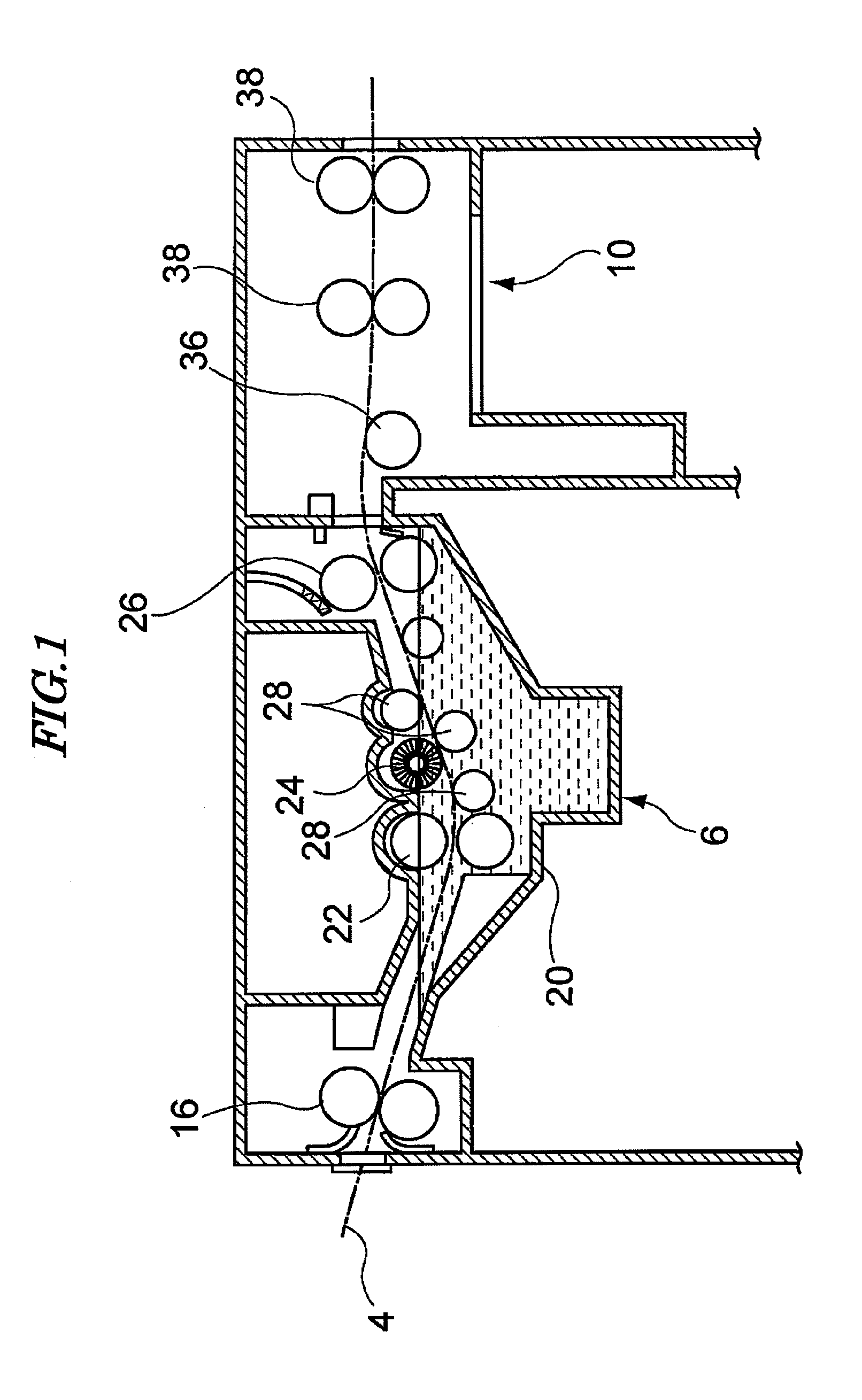

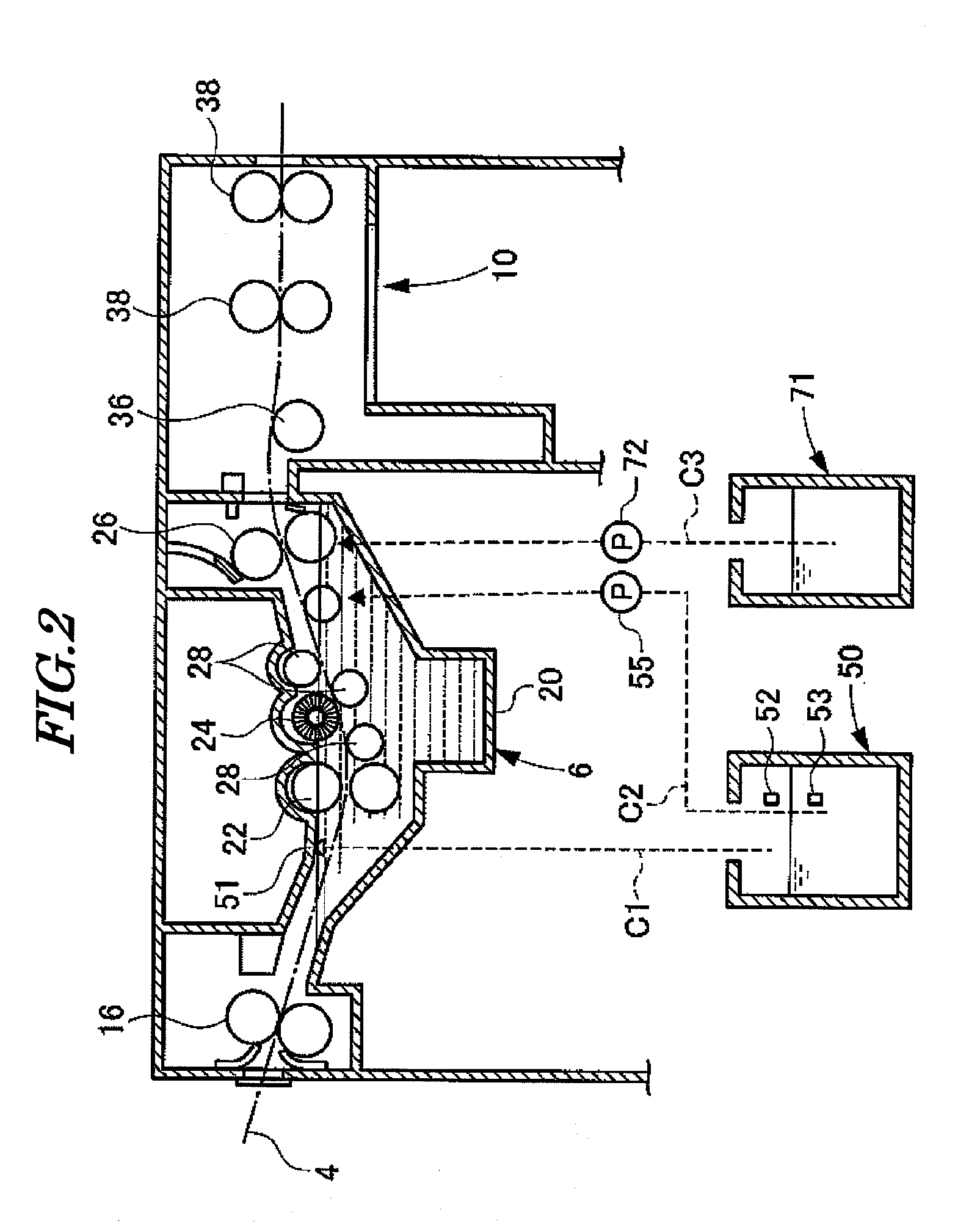

ActiveUS7297467B2Radiation applicationsSemiconductor/solid-state device manufacturingSpray nozzlePrinting press

Owner:AGFA OFFSET BV

Multilayer imageable element with improved chemical resistance

InactiveUS7169518B1Good chemical resistancePhotosensitive materialsRadiation applicationsSide chainPhotochemistry

A positive-working imageable element comprises inner and outer layers and an infrared radiation absorbing compound such as an IR absorbing dye. The inner layer includes a first polymeric material. The ink receptive outer layer includes a second polymeric binder comprising pendant carboxy groups that provides improved chemical resistance to the imageable element and reduced residue from development.

Owner:EASTMAN KODAK CO

Lithographic printing with printing members having primer layers

InactiveUS7205091B2Inhibit productionImprove efficiencyPhotosensitive materialsRadiation applicationsEngineeringPlanographic printing

A primer layer that includes a surface-tension modifier dispersed within a polymer binder is disposed between the imaging layer and the substrate of a lithographic printing member to inhibit the production of thermal degradation products that disrupt the oleophilicity of the exposed imaged areas, thereby improving print-making performance and efficiency. In addition, embodiments of the primer layer inhibit static charge buildup during production and during the print-making process.

Owner:MARK ANDY

Photosensitive composition

ActiveUS7052822B2Highly curableIncreased durabilityPhotosensitive materialsRadiation applicationsChemical compoundAcid value

The present invention provides an infrared photosensitive composition including a binder polymer (A), a polymerizable compound (B), an infrared absorber (C), and a compound (D) which can generate radicals by the action of light or heat, wherein an acid value of a film produced from the composition is from 0.15 mmol / g to 0.8 mmol / g. The invention also provides a planographic printing plate precursor including a substrate having disposed thereon a recording layer that contains the infrared photosensitive composition.

Owner:FUJIFILM HLDG CORP +1

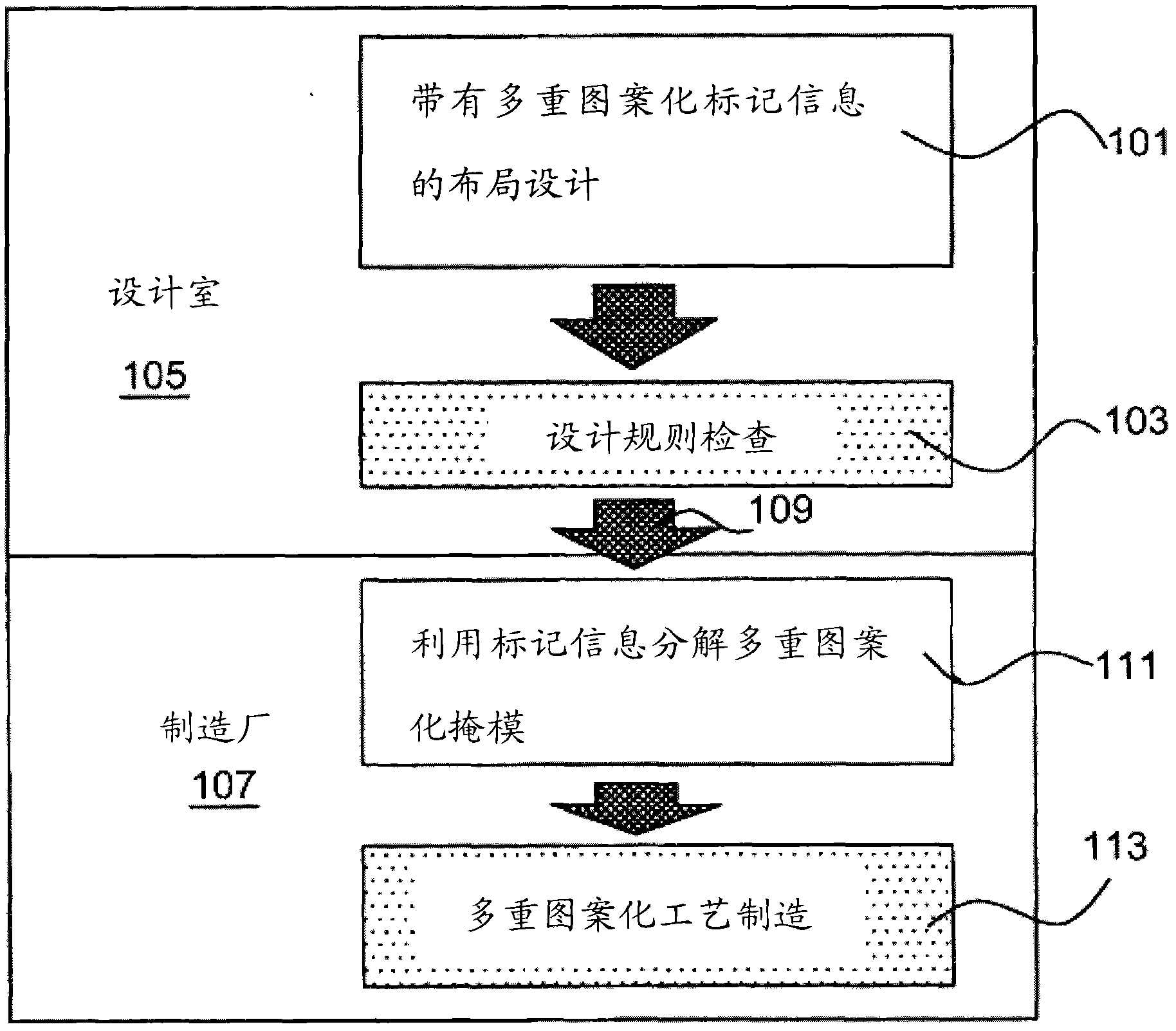

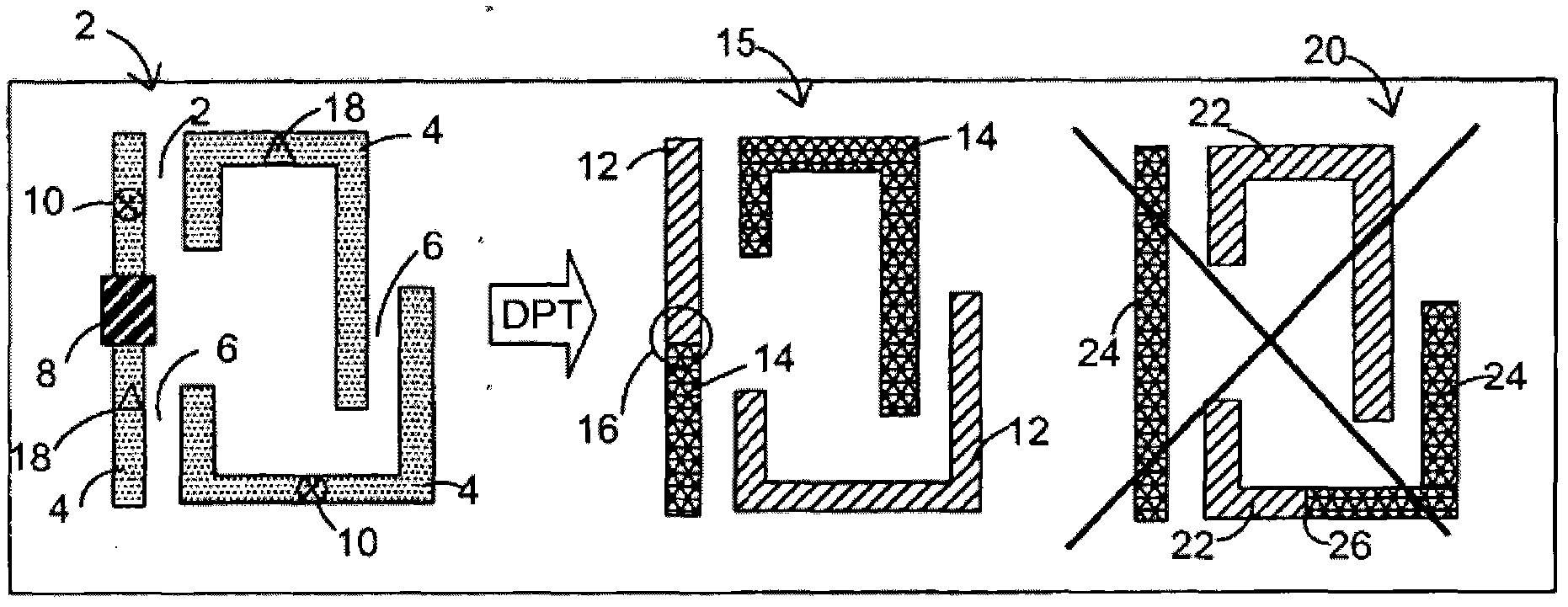

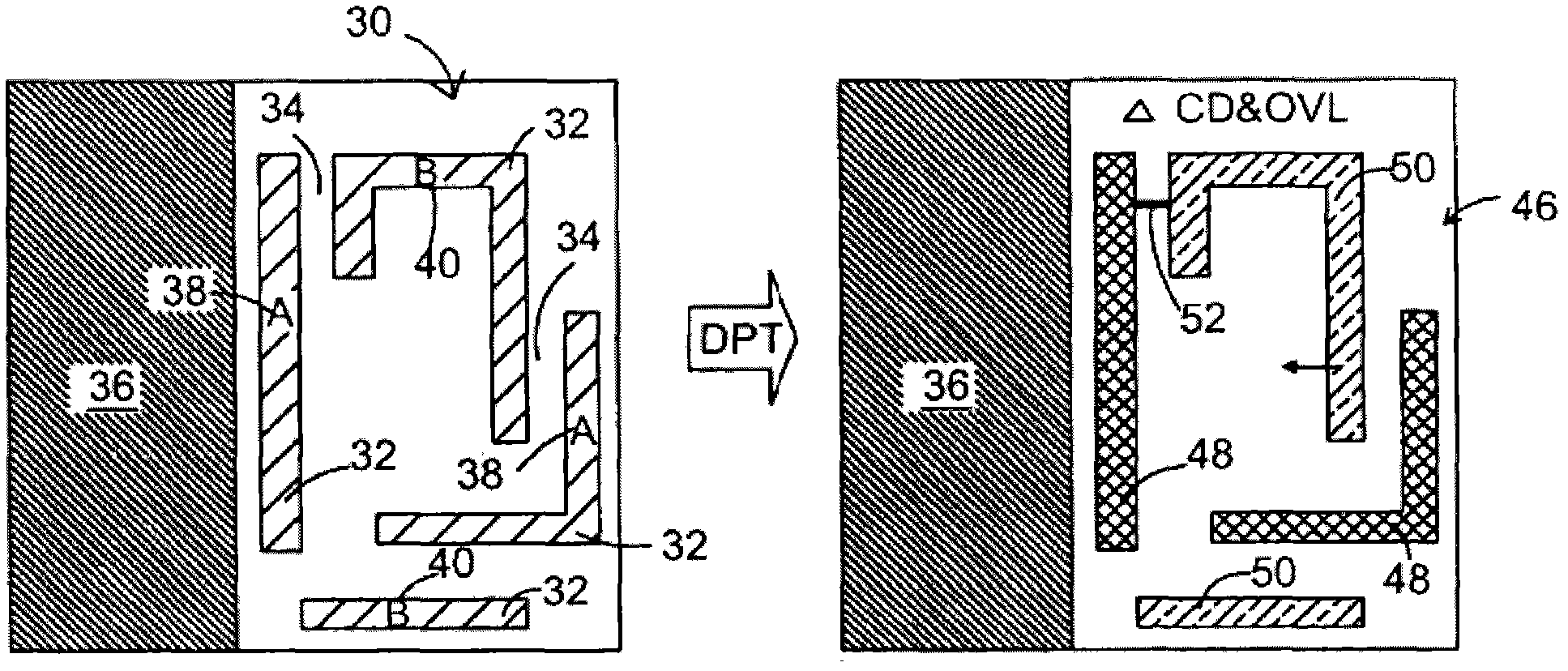

Decomposition and marking of semiconductor device design layout in double patterning lithography

Provided is a system and method for assessing a design layout for a semiconductor device level and for determining and designating different features of the design layout to be formed by different photomasks by decomposing the design layout. The features are designated by markings that associate the various device features with the multiple photomasks upon which they will be formed and then produced on a semiconductor device level using double patterning lithography, DPL, techniques. The markings are done at the device level and are included on the electronic file provided by the design house to the photomask foundry. In addition to overlay and critical dimension considerations for the design layout being decomposed, various other device criteria, design criteria processing criteria and their interrelation are taken into account, as well as device environment and the other device layers, when determining and marking the various device features.

Owner:TAIWAN SEMICON MFG CO LTD

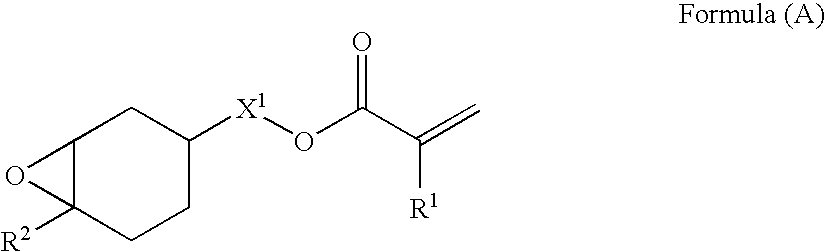

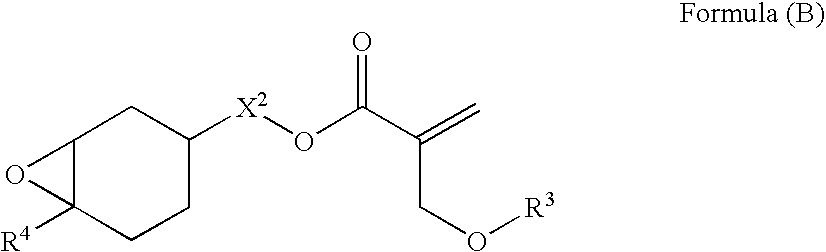

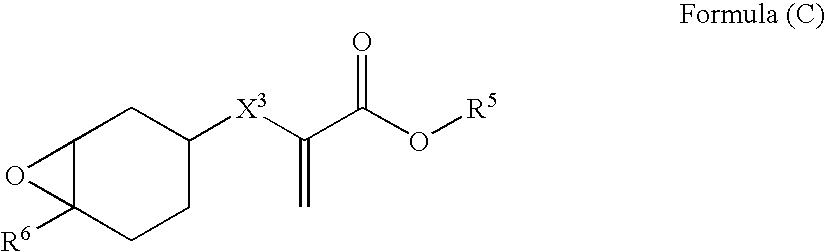

Photosensitive composition, photosensitive lithography plate and method for producing lithography plate

InactiveUS7285375B2Good effectImprove adhesionPhotosensitive materialsRadiation applicationsCompound aCationic polymerization

Disclosed is a light sensitive composition containing a compound A having a group capable of undergoing radical polymerization, a compound B having a group capable of undergoing cationic polymerization, a photopolymerization initiator C, and a polymer binder D, the light sensitive composition being characterized in that the photopolymerization initiator C comprises an iron-arene complex and a halogenated alkyl group-containing compound.

Owner:KONICA MINOLTA MEDICAL & GRAPHICS INC

Imaging members with IR-sensitive polymer imageable layer

A negative-working, imageable element comprises a substrate and an IR-sensitive imageable layer comprising a dispersion of nanofibers of a preformed IR-sensitive polymer. The nanofibers can be composed of polyaniline, polypyrrole, or polythiophene. The IR-sensitive imageable layer containing the nanofibers can be imaged using infrared radiation and used for printing without further processing. Thus, both imaging and printing can be carried out on-press.

Owner:EASTMAN KODAK CO

Process for making lithographic printing plate, developer for lithographic printing plate precursor, and replenisher for lithographic printing plate precursor development

InactiveUS20120021358A1Excellent developabilityImprove printing effectSemiconductor/solid-state device manufacturingEnzymesActive agentSurface-active agents

A process for making a lithographic printing plate is provided that includes (A) a step of preparing a lithographic printing plate precursor that includes above a support a photosensitive layer that includes (i) a binder polymer, (ii) an ethylenically unsaturated compound, and (iii) a radical polymerization initiator, (B) an exposure step of exposing the lithographic printing plate precursor, and (C) a development step of removing the photosensitive layer of a non-exposed area of the lithographic printing plate precursor, the development step (C) being carried out by means of a developer that includes an enzyme. There are also provided a developer for a lithographic printing plate precursor, the developer including (a) an enzyme and (b) a surfactant, and a replenisher for lithographic printing plate precursor development, the replenisher including an enzyme.

Owner:FUJIFILM CORP

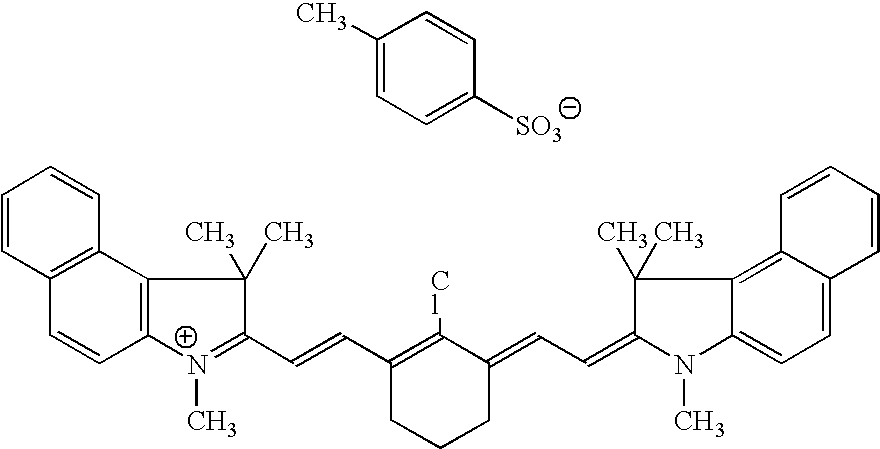

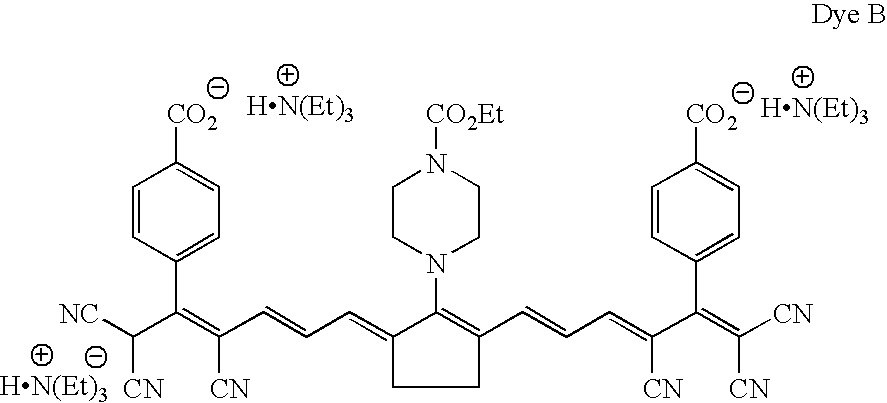

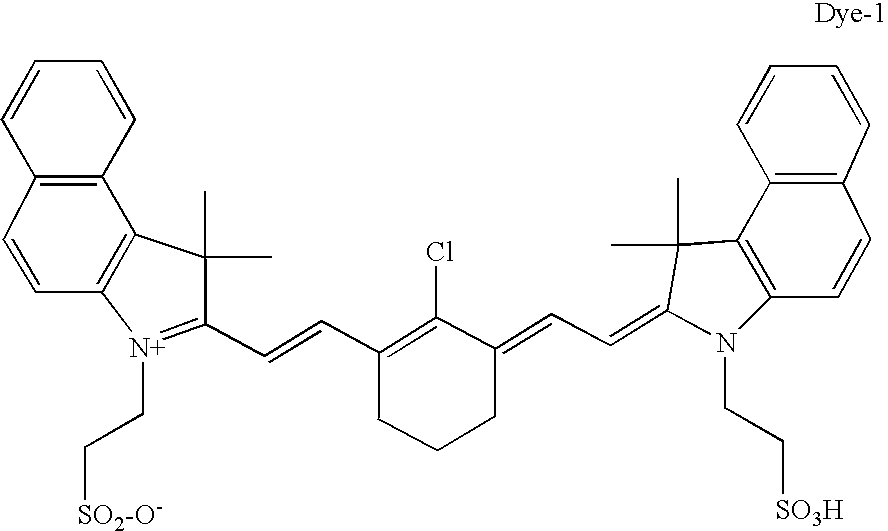

Color image-forming material and lithographic printing plate precursor

ActiveUS7217500B2Excellent in image visibility and storage stability and white light stabilityExcellent developabilityPhotosensitive materialsRadiation applicationsVisibilityColor image

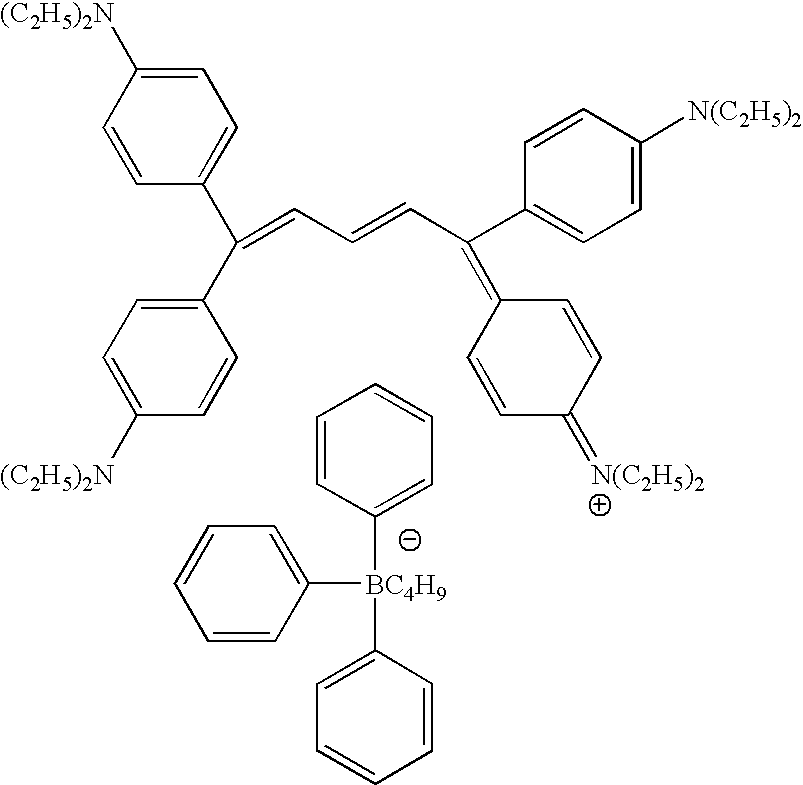

A color image-forming material capable of drawing an image by infrared laser exposure and excellent in image visibility, storage stability and white light stability, and an on-press development or non-processing (non-development) type lithographic printing plate precursor ensuring high sensitivity and high press life and being excellent in image visibility, on-press developability and the like, are provided, which are a color image-forming material comprising an image recording layer capable of drawing an image by infrared laser exposure, the color image-forming material forming a color image without passing through a development processing step after image recording, wherein the image recording layer comprises (A) an infrared absorbent, (B) a cyclic color-forming compound having a cyclic structure within the molecule and forming a dye by a ring opening, and (C) a dye stabilizer which is a compound interacting with the cyclic color-forming compound to stabilize the ring-opened dye body and cause color formation and which is released from the interaction upon laser exposure to decrease in the color formation; and a lithographic printing plate precursor using this color image-forming material.

Owner:FUJIFILM CORP

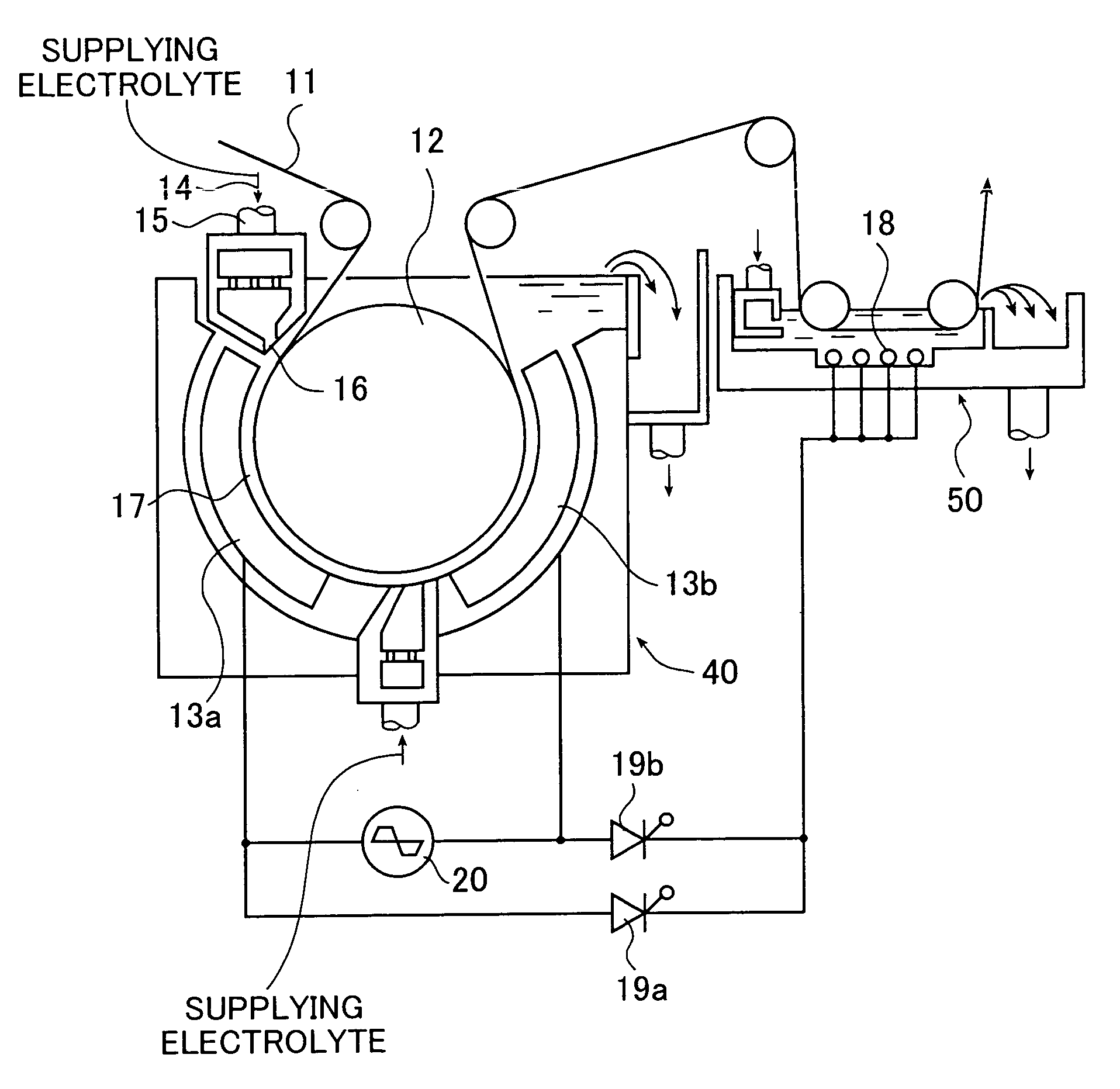

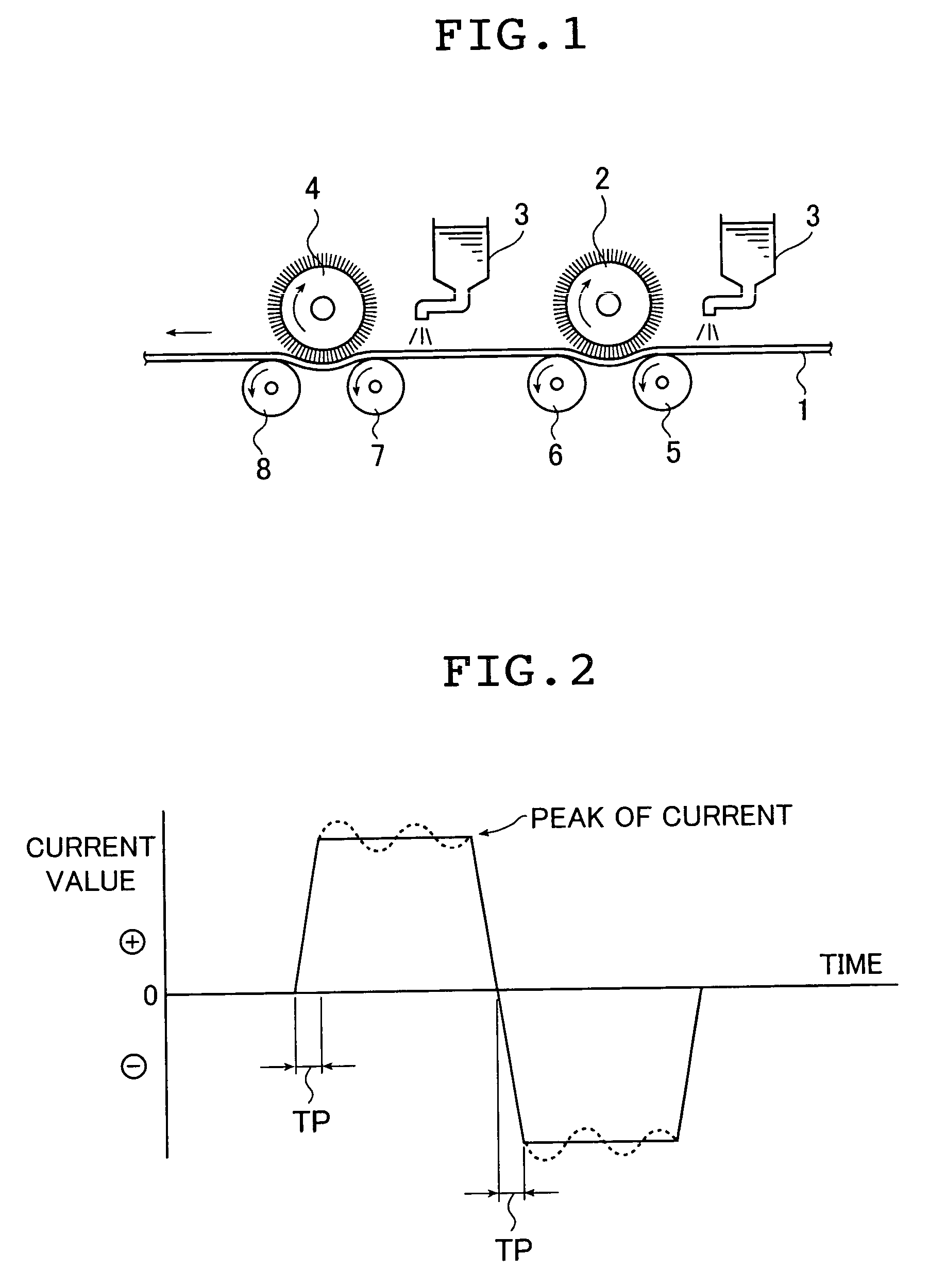

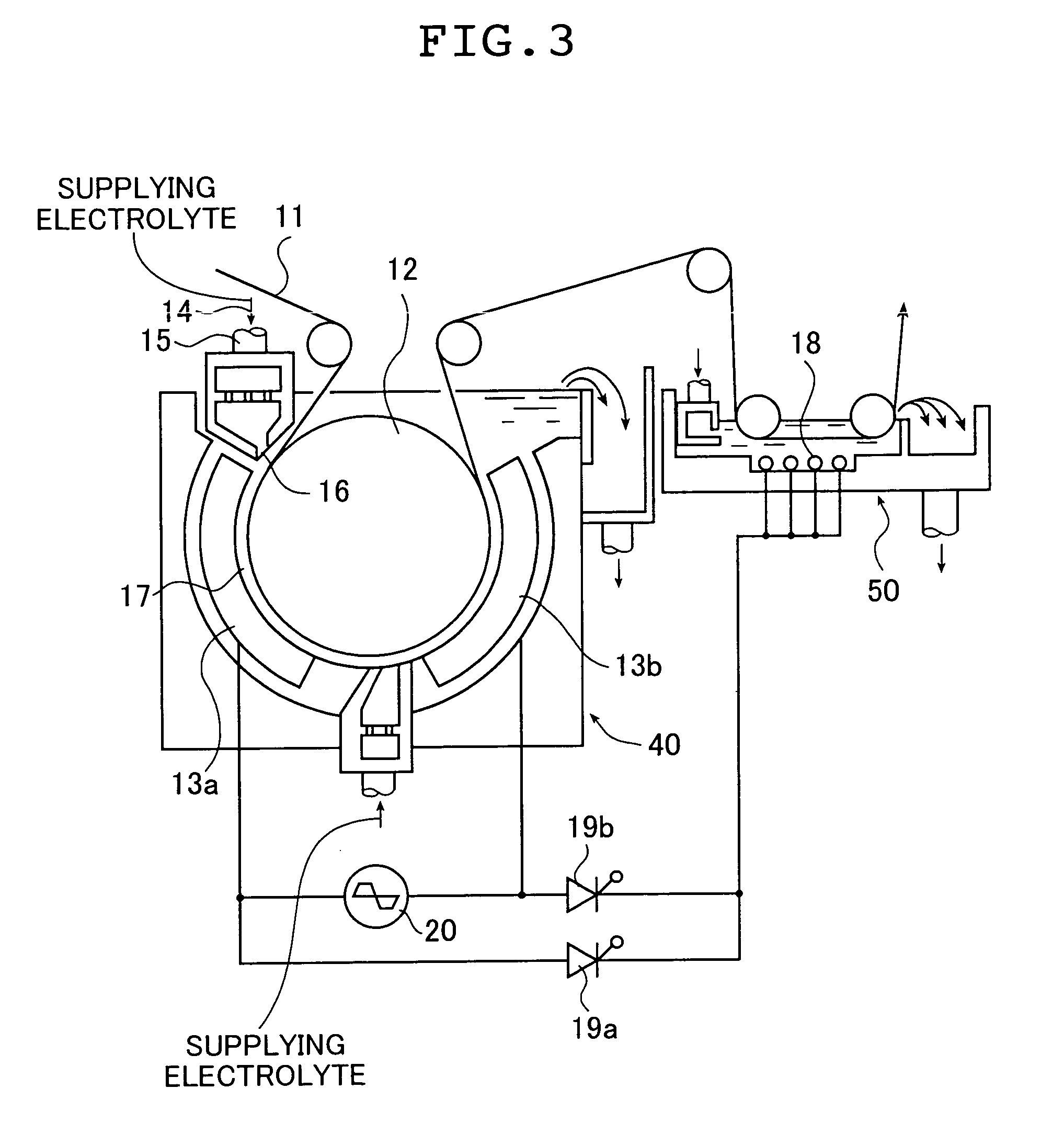

Method for production of support for lithographic printing plate precursor and support for lithographic printing plate precursor

InactiveUS7026096B2Reduce in quantityEfficient use ofPhotosensitive materialsSurface reaction electrolytic coatingPore diameterPlanographic printing

A method for the production of a support for a lithographic printing plate precursor that comprises providing on a grained aluminum support having an anodic oxide film formed thereon a layer of inorganic compound particles having a major axis larger than a pore diameter of the anodic oxide film and treating the layer of inorganic compound particles with a treating solution capable of dissolving the inorganic compound particles, thereby fusing together the inorganic compound particles to form a layer of the inorganic compound.

Owner:FUJIFILM HLDG CORP +1

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com