Lithographic method of manufacturing device

A device and etching technology, applied in the field of manufacturing devices, can solve the problems of imaging, inability to use lighting devices, etc., to achieve the effect of reducing distance and solving the problem of disabled parameters

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

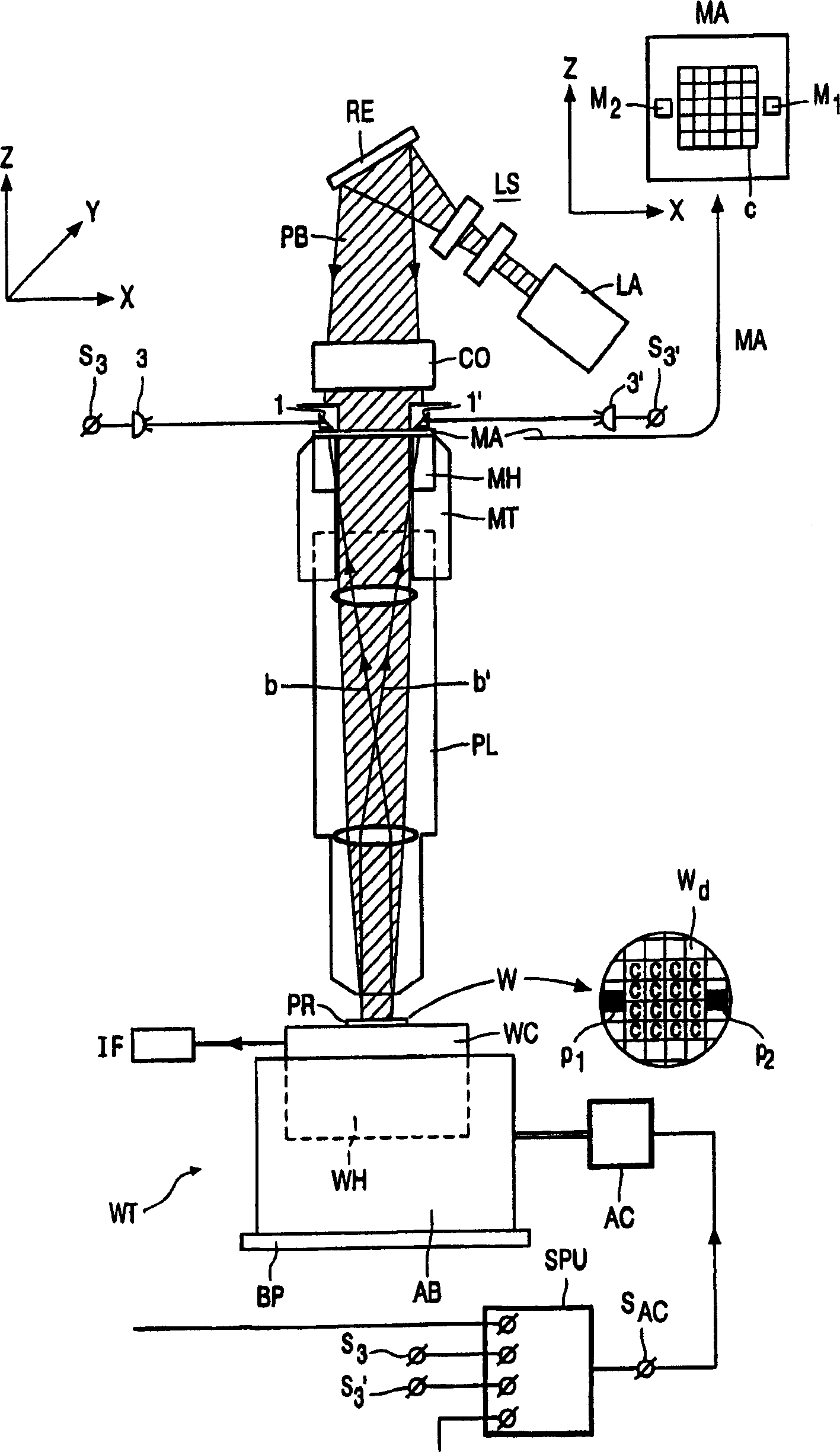

[0116] figure 1 The schematic diagram shows only the most important modules of one embodiment of a lithographic projector. The apparatus comprises a projection column housing a projection device, such as a lenticular projection device PL. On this apparatus is placed a mask holder MH which includes a mask pattern C to be imaged and which is used to transfer a mask MA. The mask holder forms part of the mask table MT. A pedestal WT is disposed in the projection column under the projection lens arrangement. The stage is equipped with a substrate holder WH that supports a substrate W such as a semiconductor substrate (also referred to as a wafer). A photosensitive layer PR such as a photosensitive resin layer is coated on the substrate. The mask pattern C is to be imaged multiple times in the resist layer, each time in another IC region, or stamp Wd. The submount can be moved in the X direction and the Y direction, so after the mask pattern is imaged in one IC region, the next...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com