Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

66 results about "Zinc tin oxide" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

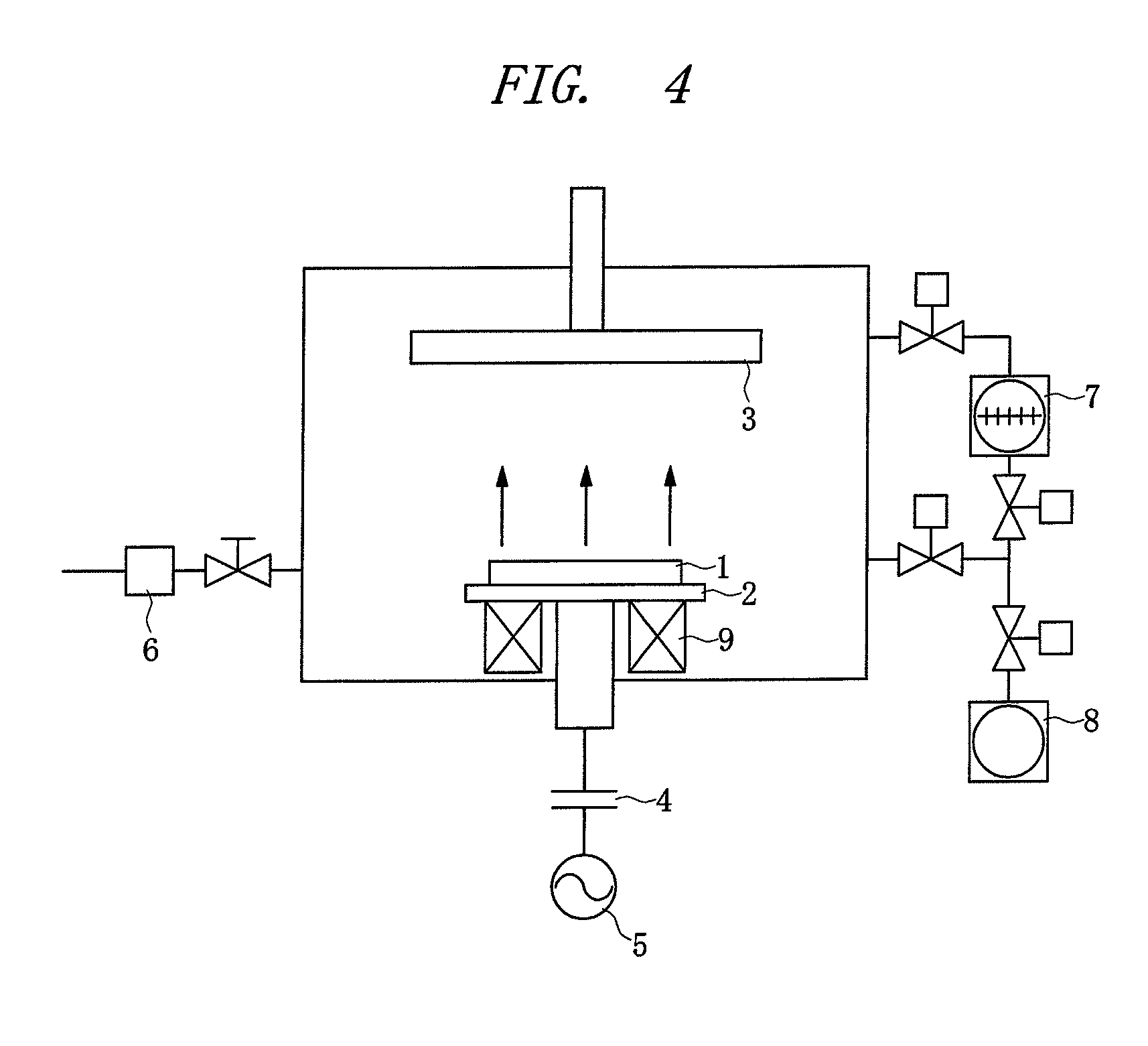

Oxide semiconductor device and method of manufacturing the same and active matrix substrate

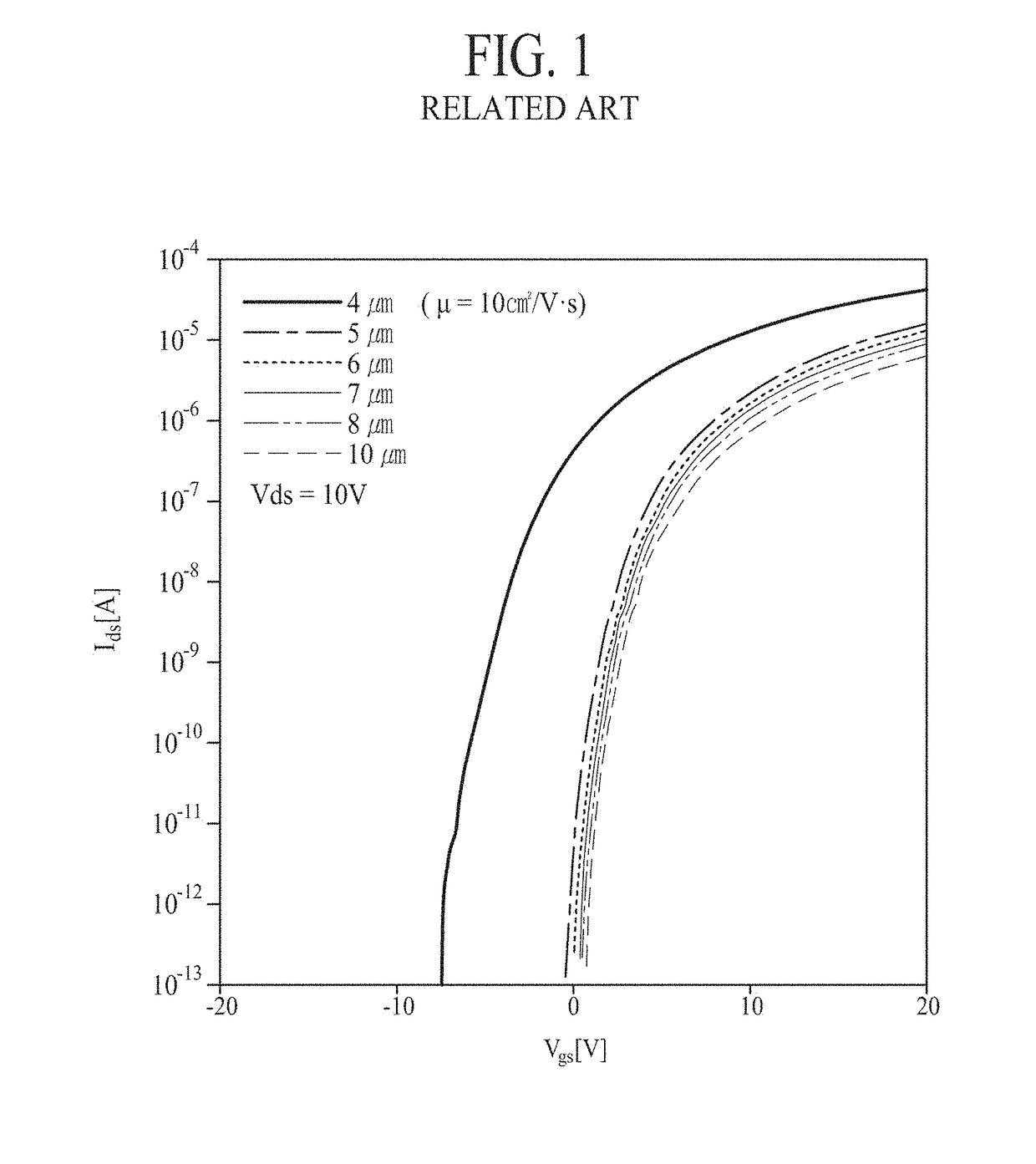

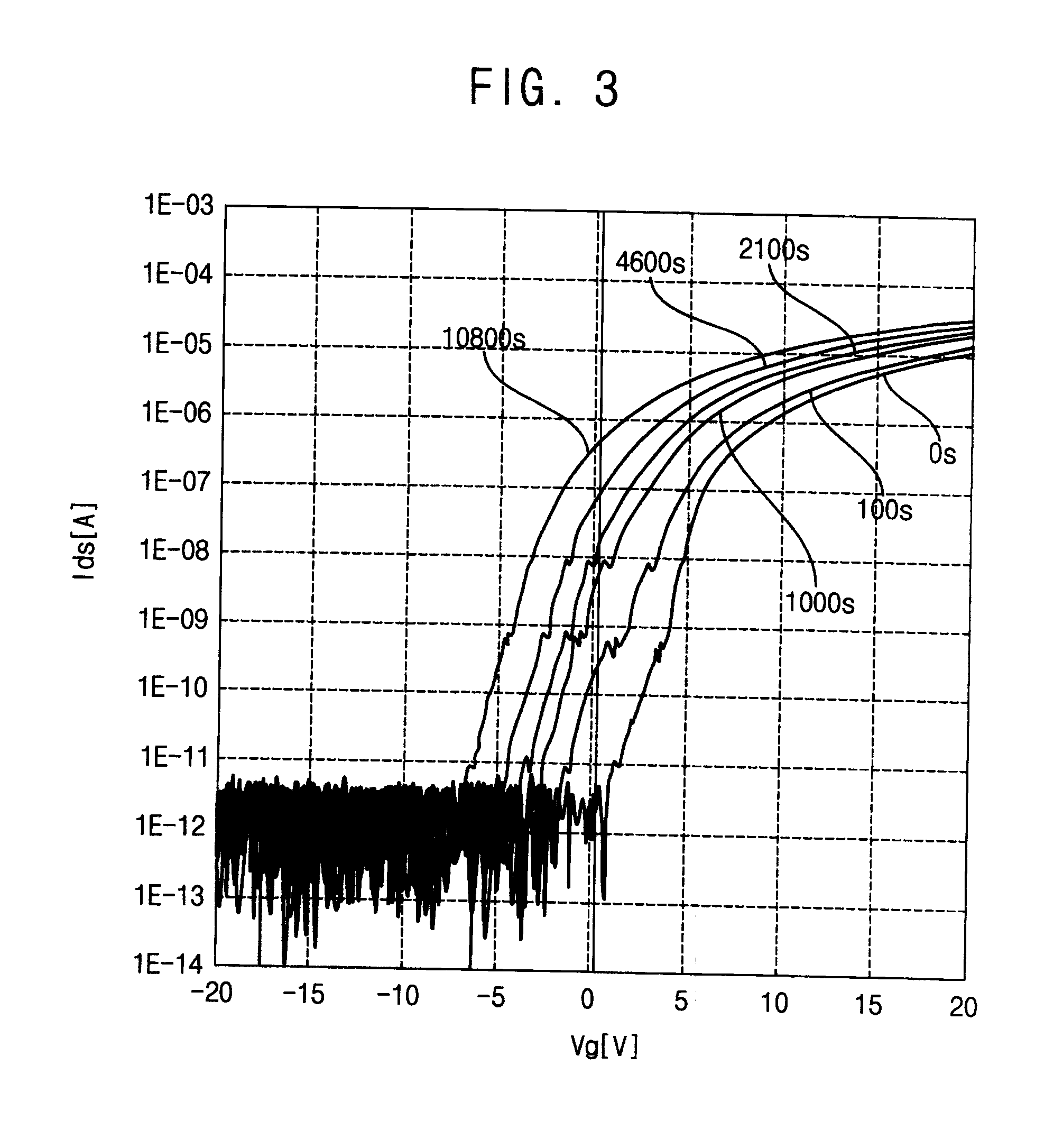

InactiveUS20100140614A1High content ratioImprove contact effectTransistorSolid-state devicesActive matrixThreshold potential

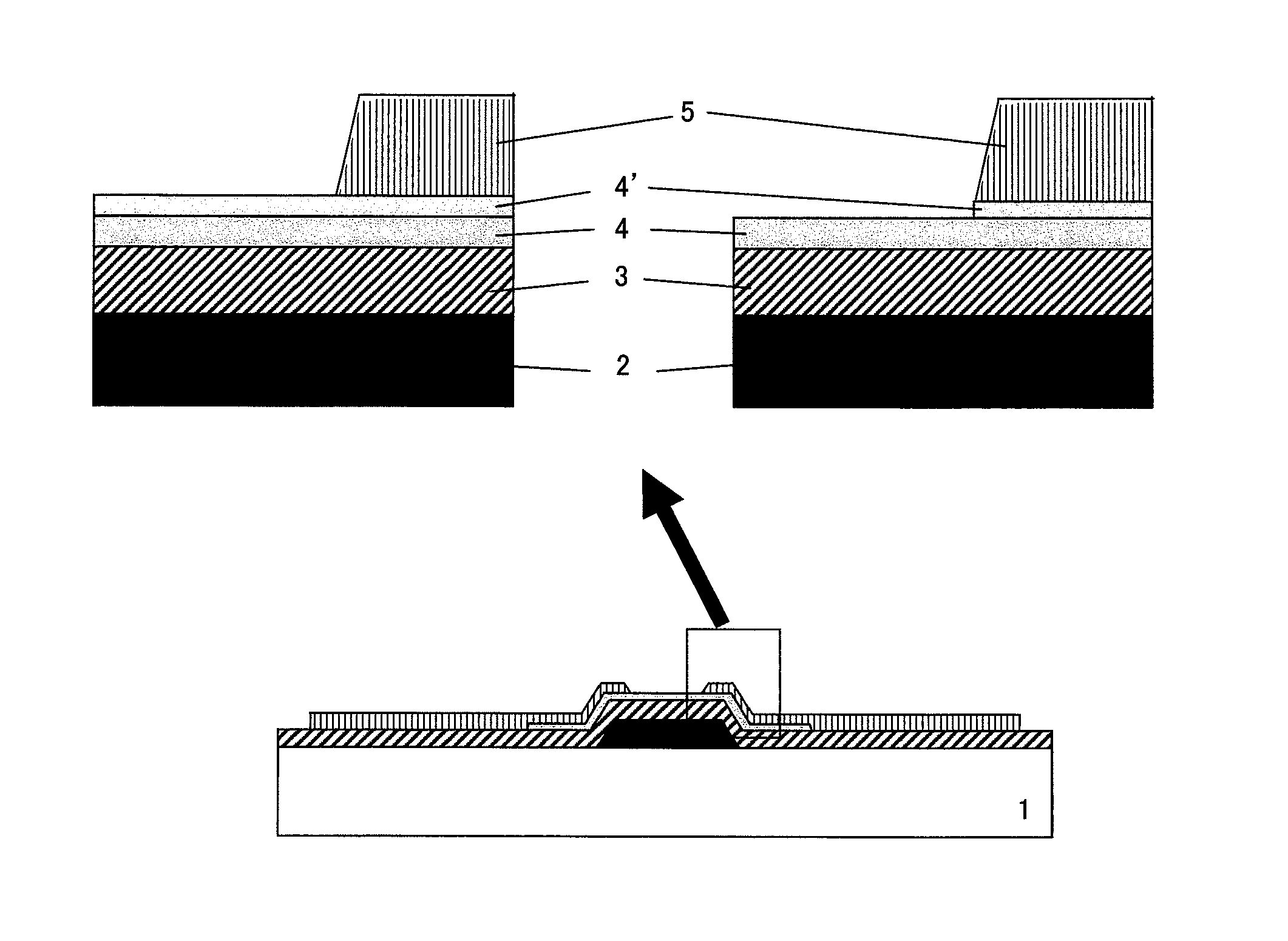

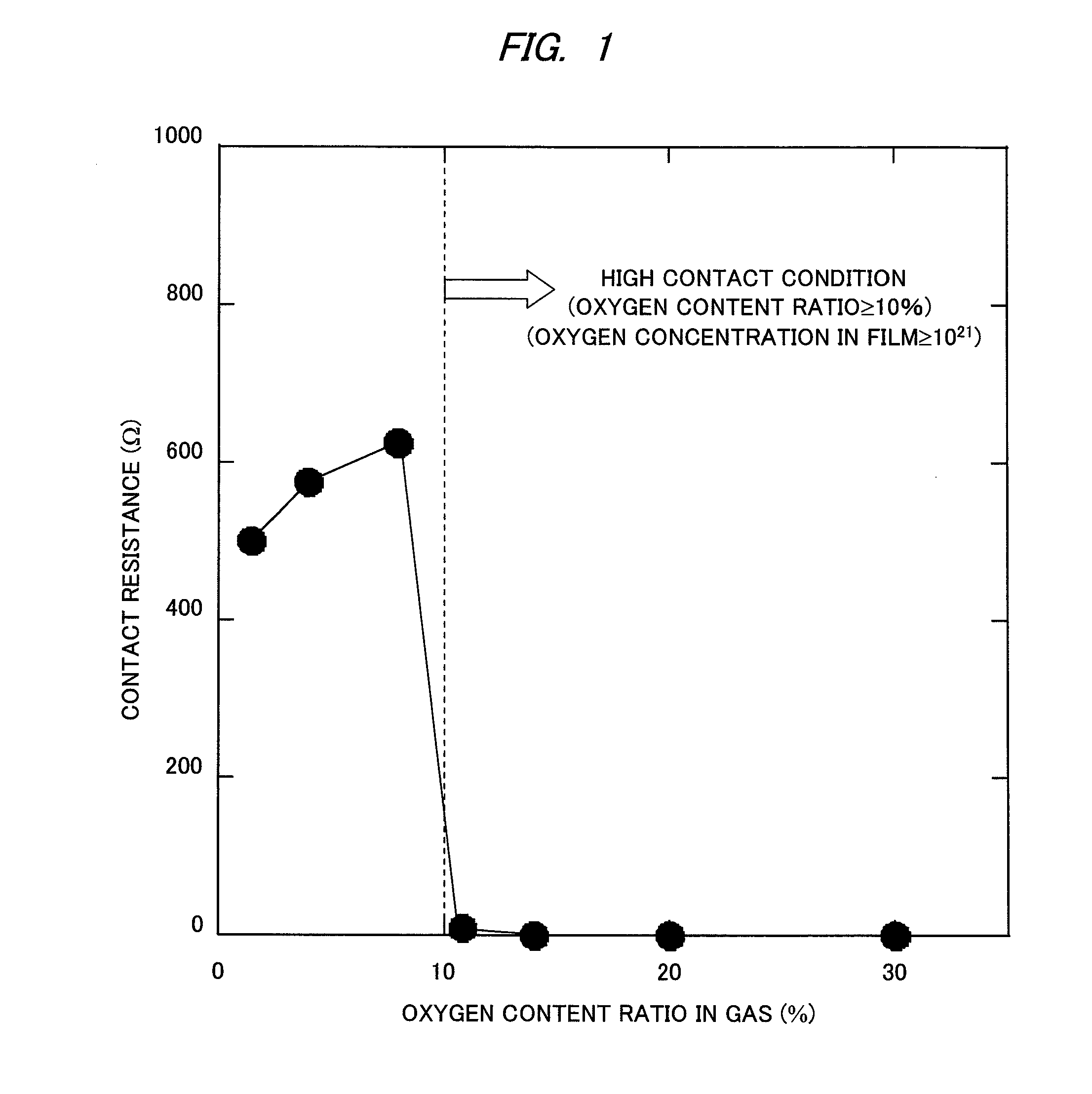

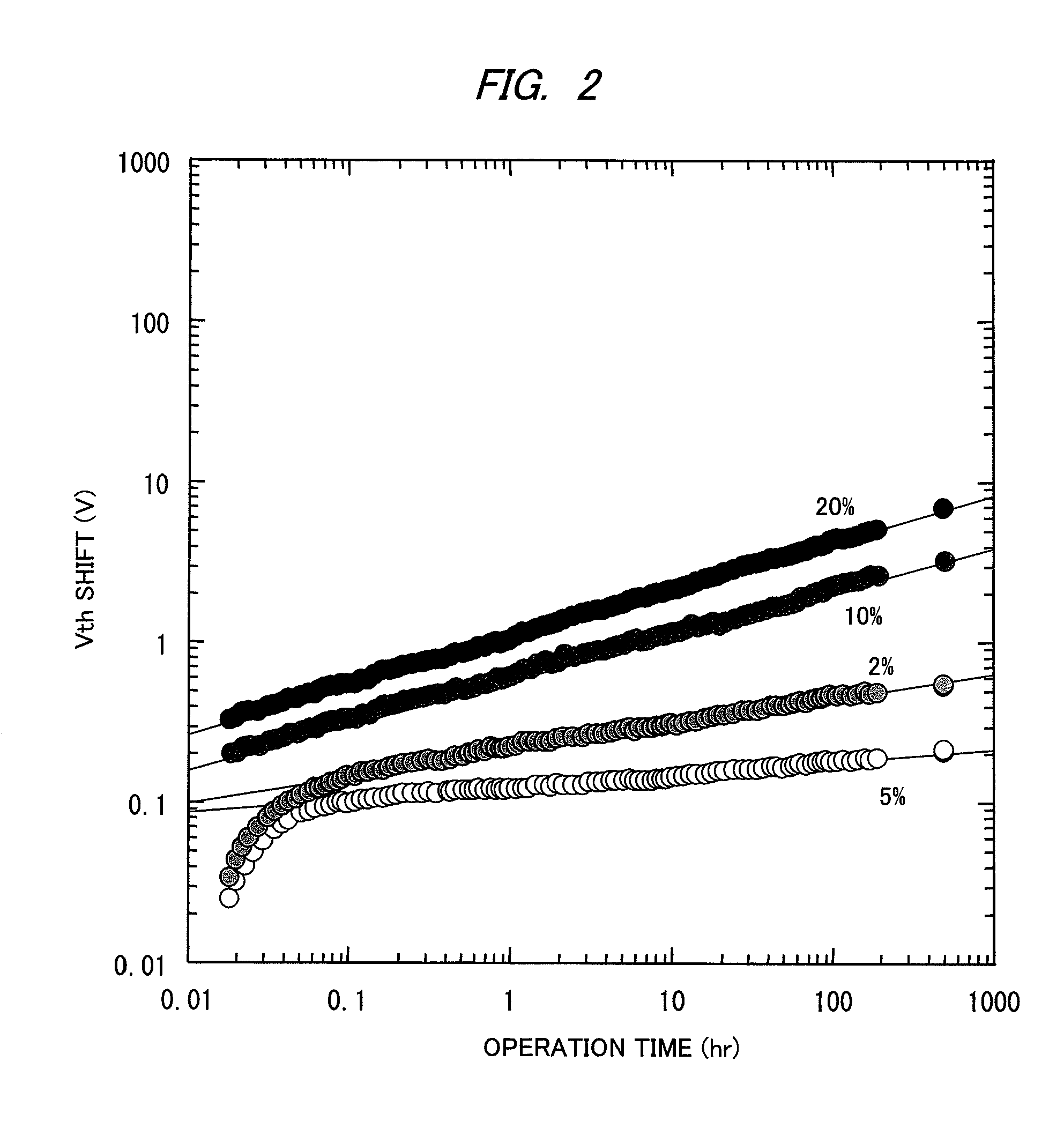

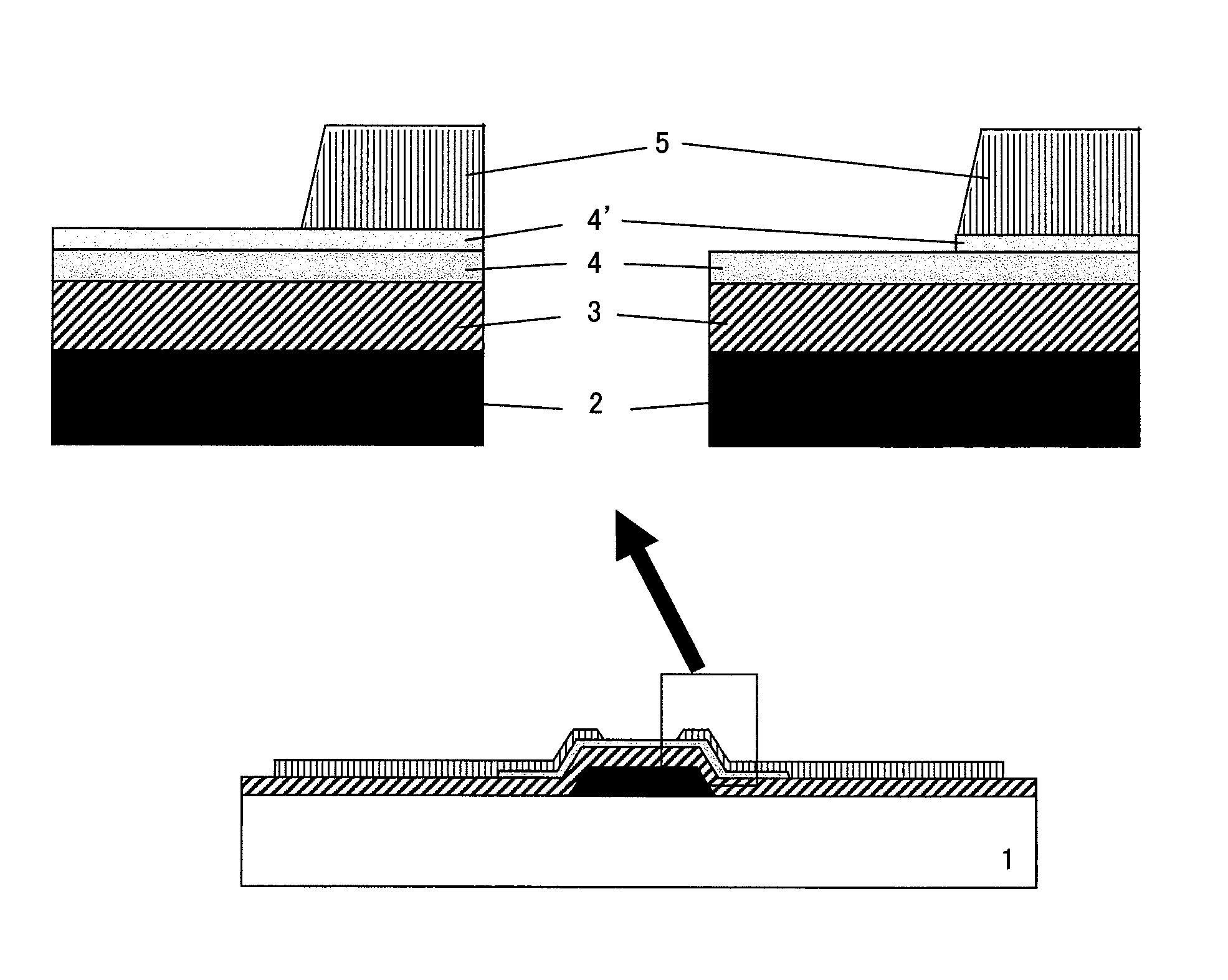

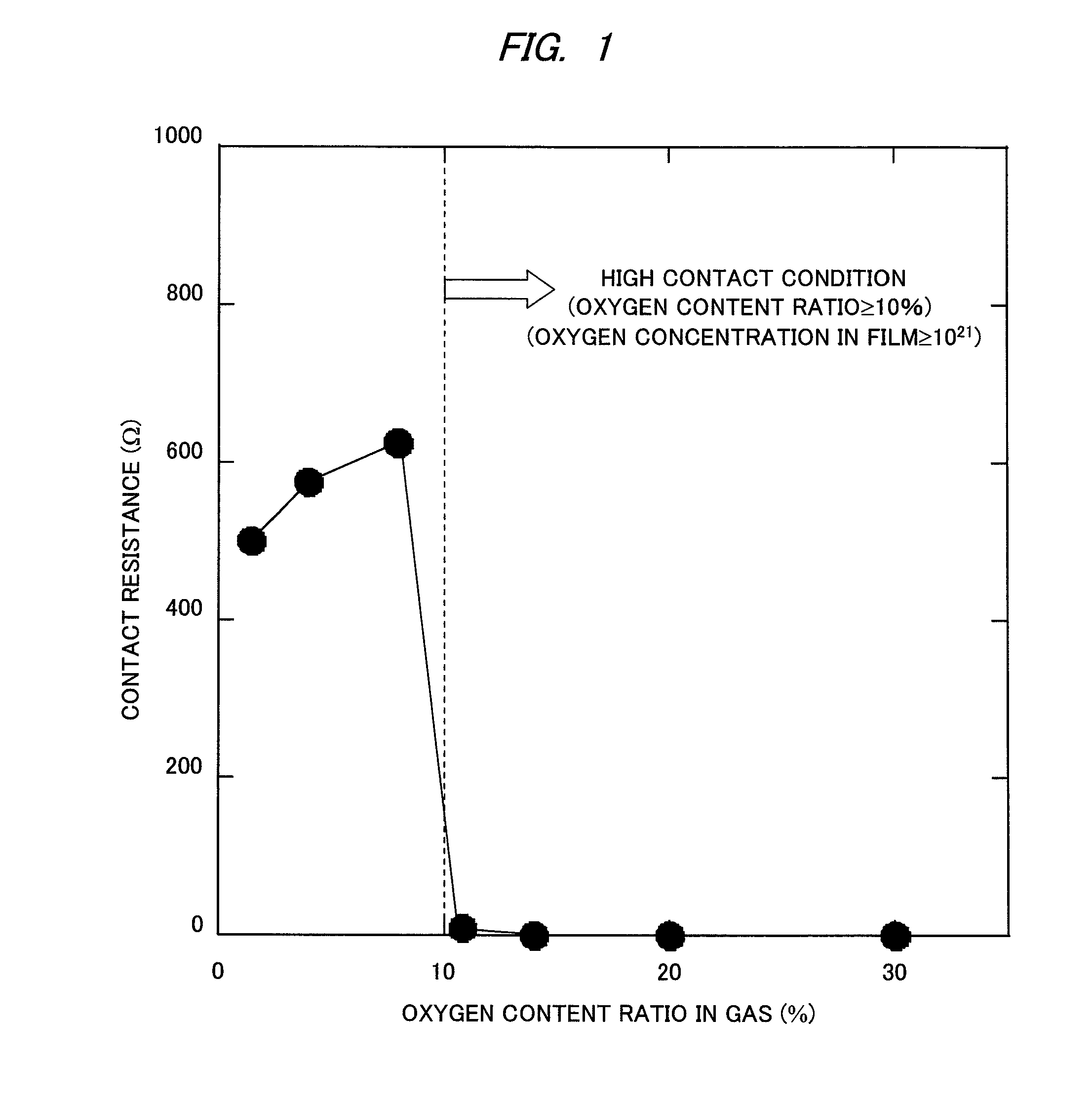

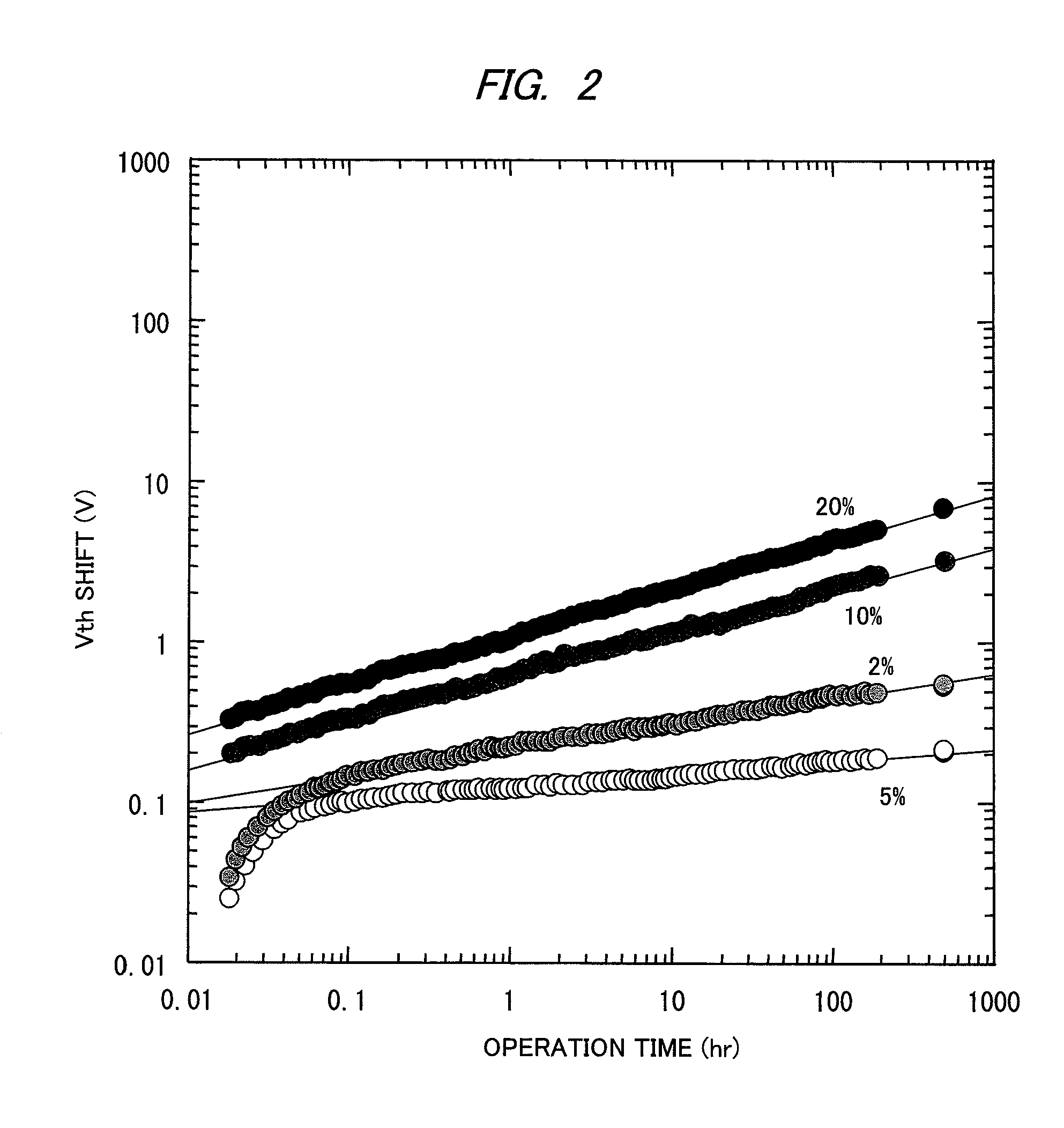

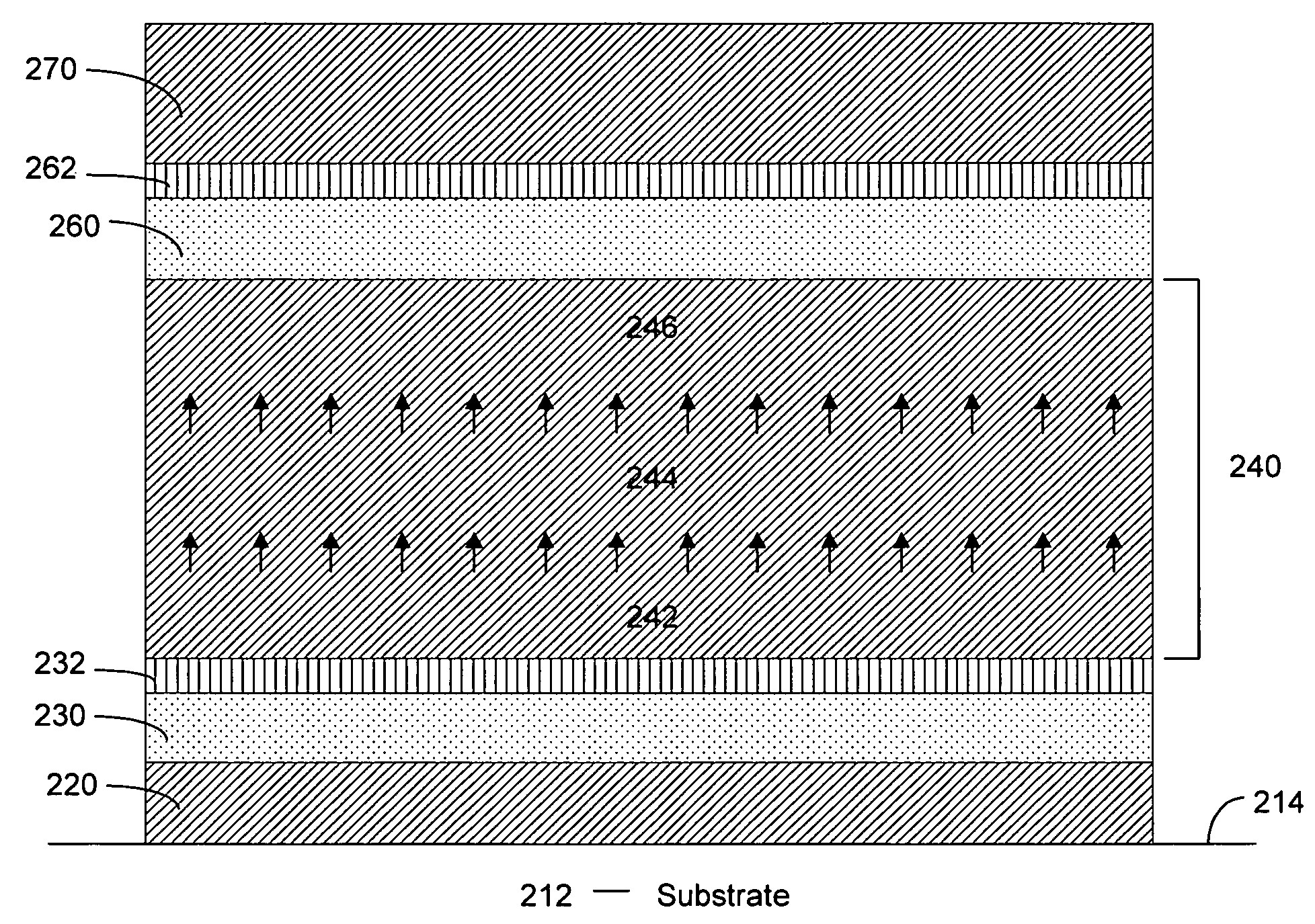

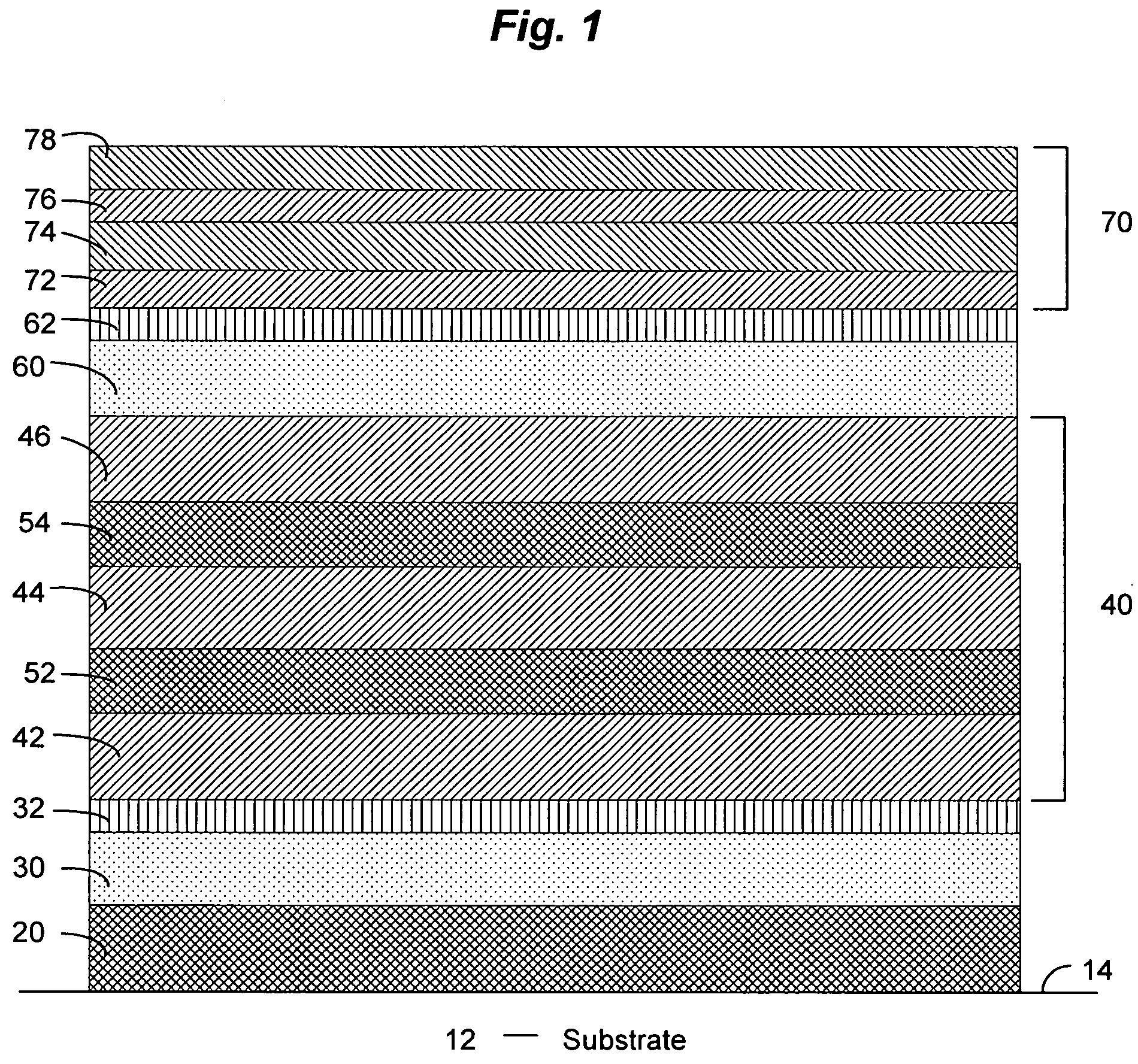

A phenomenon of change of a contact resistance between an oxide semiconductor and a metal depending on an oxygen content ratio in introduced gas upon depositing an oxide semiconductor film made of indium gallium zinc oxide, zinc tin oxide, or others in an oxide semiconductor thin-film transistor. A contact layer is formed with an oxygen content ratio of 10% or higher in a region from a surface, where the metal and the oxide semiconductor are contacted, down to at least 3 nm deep in depth direction, and a region to be a main channel layer is further formed with an oxygen content ratio of 10% or lower, so that a multilayered structure is formed, and both of ohmic characteristics to the electrode metal and reliability such as the suppression of threshold potential shift are achieved.

Owner:HITACHI LTD

Oxide semiconductor device with oxide semiconductor layers of different oxygen concentrations and method of manufacturing the same

InactiveUS8368067B2Easiness of flexibilityImprove the level ofTransistorSolid-state devicesThreshold potentialMain channel

A phenomenon of change of a contact resistance between an oxide semiconductor and a metal depending on an oxygen content ratio in introduced gas upon depositing an oxide semiconductor film made of indium gallium zinc oxide, zinc tin oxide, or others in an oxide semiconductor thin-film transistor. A contact layer is formed with an oxygen content ratio of 10% or higher in a region from a surface, where the metal and the oxide semiconductor are contacted, down to at least 3 nm deep in depth direction, and a region to be a main channel layer is further formed with an oxygen content ratio of 10% or lower, so that a multilayered structure is formed, and both of ohmic characteristics to the electrode metal and reliability such as the suppression of threshold potential shift are achieved.

Owner:HITACHI LTD

Method of fabricating zto thin film, thin film transistor employing the same, and method of fabricating thin film transistor

InactiveUS20100019239A1TransistorSemiconductor/solid-state device manufacturingDeposition temperatureZinc tin oxide

Owner:ELECTRONICS & TELECOMM RES INST

Thin film transistor, gate driver including the same, and display device including the gate driver

Disclosed are a thin film transistor (TFT) including an oxide semiconductor layer capable of being applied to high-resolution flat panel display devices requiring high-speed driving, a gate driver including the TFT, and a display device including the gate driver. The TFT includes first oxide semiconductor layer consisting of indium-gallium-zinc-tin oxide (IGZTO) and a second oxide semiconductor layer including indium-gallium-zinc oxide (IGZO). A content ratio (Ga / In) of gallium (Ga) to indium (In) of the second oxide semiconductor layer is higher than a content (Ga / In) of Ga to In of the first oxide semiconductor layer, and a content ratio (Zn / In) of zinc (Zn) to In of the second oxide semiconductor layer is higher than a content (Zn / In) of Zn to In of the first oxide semiconductor layer.

Owner:LG DISPLAY CO LTD

Thin film transistor substrate and method of manufacturing the same

ActiveUS20150069382A1Prevent display degradationImprove display reliabilityTransistorSolid-state devicesZinc tin oxideManganese oxide

A thin film transistor substrate includes a substrate, a data line disposed on the substrate and which extends substantially in a predetermined direction, a light blocking layer disposed on the substrate and including a metal oxide including zinc manganese oxide, zinc cadmium oxide, zinc phosphorus oxide or zinc tin oxide, a gate electrode disposed on the light blocking layer, a signal electrode including a source electrode and a drain electrode spaced apart from the source electrode, where the source electrode is connected to the data line, and a semiconductor pattern disposed between the source electrode and the drain electrode.

Owner:SAMSUNG DISPLAY CO LTD

Protective layers for sputter coated article and method for making sputter coated articles

InactiveUS20050129863A1Reduce smogReduce heatVacuum evaporation coatingSputtering coatingInfraredOptoelectronics

The present invention provides is a method of making an infrared reflective coated article, including the steps of: providing a substrate; depositing a first dielectric layer over at least a portion of the substrate, the layer comprising a first zinc stannate film deposited over the substrate, and an electrical enhancing film deposited over the first zinc stannate film, the electrical enhancing film selected from zinc oxide-tin oxide film and a second zinc stannate film; forming an infrared reflective layer on the first dielectric layer; forming a metal primer layer over the infrared reflective layer; forming a second dielectric layer over the primer layer; and forming a protective layer of at least two films in a position where it can provide durability to the dielectric layer, infrared reflective layer, metal primer layer, and second dielectric layer.

Owner:VITRO FLAT GLASS LLC

Preparation technology of ZnSnOx ceramic target and method for preparing ZnSnOx coated film by using same

InactiveCN104087906APure filmUniform particle sizeVacuum evaporation coatingSputtering coatingZincOxide

The invention provides a ZnSnOx ceramic target which is characterized by being prepared by mixing zinc oxide powder the purity of which is 99.99 and tin oxide powder the purity of which is 99.99, wherein the mass percent of the zinc oxide powder to tin oxide powder is any one of (6:4)-(7:3). The invention further provides a preparation technology of the ZnSnOx ceramic target, and a method for preparing ZnSnOx coated film by using the ZnSnOx ceramic target. The prepared ZnSnOx thin film is pure, uniform in particle size, strong in the stability of sputtering voltage, the technology is easy to control, and the film layer is strong in binding power, and good in compactness, and can be applied into a low-radiation coated film glass under the oxygen-free condition.

Owner:林嘉佑

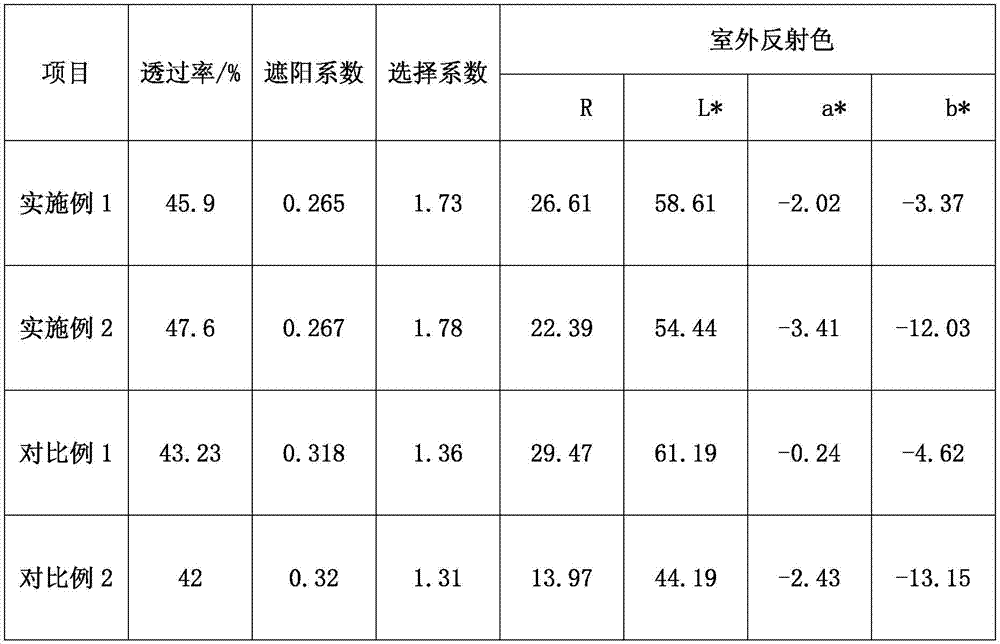

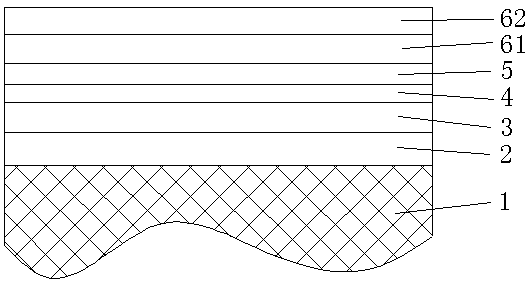

Preparation method of high-transmittance tempered low-emissivity coated glass

PendingCN104230182ALow emissivityIncrease reflectionMetal layered productsLow emissivityTitanium oxide

The invention discloses a preparation method of high-transmittance tempered low-emissivity coated glass. The preparation method comprises the following steps: setting a glass base plate and plating a titanium oxide dielectric layer, a silicon nitride dielectric layer, a zinc oxide dielectric layer, a nickel-chromium metal alloy layer, a silver functional layer, a nickel-chromium metal alloy layer, a zinc tin oxide dielectric layer and a silicon nitride dielectric layer on the glass base plate in sequence. The preparation method has the benefit that a multilayer film structure is prepared on the surface of a float glass base material through the offline magnetron sputtering technology, so that the glass has relatively high transmittance and selective coefficient and has high reflection for the infrared areas and the emissivity of the glass can be effectively reduced.

Owner:CHINA TRIUMPH INT ENG

Method for improving high temperature resistance of temperable low-radiation coated glass

The invention discloses a method for improving the high temperature resistance of temperable low-radiation coated glass. A film coating layer in the coated glass at least comprises a zinc-tin-antimony oxide film layer. In film coating, a zinc-tin-antimony target material in a film coating chamber comprises the following components by weight percent: 40-55 percent of metal zinc, 40-55 percent of metal tin and 1-5 percent of metal antimony. In the invention, products can be heated for about 400 seconds in a tempering furnace the temperature of which is about 730 DEG C as long as a tin oxide film layer with a zinc oxide film layer or a zinc-tin oxide film layer is replaced with the zinc-tin-antimony oxide film layer under the premise that other hard pieces of film coating wires are not changed and other film layer parameters of deposition are not changed, and thereby, the 8mm and 10mm low-radiation coated glass can be tempered.

Owner:洛阳新晶润工程玻璃有限公司

High-performance double-silver low-radiation energy-saving glass

PendingCN107471785AAvoid damageImprove performanceGlass/slag layered productsDomestic wallsEngineeringProtection layer

The invention discloses high-performance double-silver low-radiation energy-saving glass, which belongs to the field of an eco-friendly energy-saving building material. The structure of an energy-saving glass membrane layer comprises, in sequence, a glass substrate, a first base layer which is a silicon nitride layer, a second seed layer which is a zinc oxide layer, a third functional layer which is silver layer, a fourth protective layer which is a nickel cadmium layer, a fifth dielectric layer which is a silicon nitride layer, a sixth dielectric layer which is a tin zinc oxide layer, a seventh seed layer which is a zinc oxide layer, an eighth functional layer which is a silver layer, a ninth protective layer which is a nickel cadmium layer, a tenth dielectric layer which is an aluminum zinc oxide layer, an eleventh layer which is a silicon nitride layer, and a twelfth protective layer which is a graphite layer. Through arrangement of a coating membrane layer material on the glass substrate and arrangement of a membrane layer thickness, the energy-saving glass reflects gray and blue colors outdoors, and has visible light transmittance between 42-60%. The energy-saving glass is excellent in performance, has a shading coefficient less than 0.3 and selectivity coefficient more than 1.4, and is quite suitable for hot areas that have high environment temperature all the year round and intense average sunshine.

Owner:SICHUAN NANBO ENERGY SAVING GLASS CO LTD

Preparation method of TZO semiconductor material for high-transmittance energy-saving glass

InactiveCN105272210AImprove transmittanceFast sputtering rateVacuum evaporation coatingSputtering coatingSputteringZinc tin oxide

The invention discloses a preparation method of a TZO semiconductor material for high-transmittance energy-saving glass and a preparation method thereof. ZnO and SnO2 powder is used as main materials; even mixing is carried out, a biscuit is manufactured, and drying, sintering and machining are carried out to obtain a zinc / tin oxide semiconductor material with the relative density larger than 95%; volume resistivity is smaller than or equal to 6*10<-2> omega.cm, the material is used as the magnetron sputtering target material for manufacturing Low-E glass with the transmittance larger than or equal to 85% and replaces zinc-tin alloy coating materials which are greatly used at present, the process of producing a zinc / tin oxide film through magnetron sputtering is more stable, the production technology is simpler, the sputtering speed is high, the production efficiency is improved by more than 5%, the large-area coating film layer has uniform ingredients and fine structure, the requirement of manufacturing double-silver three-silver Low-E glass for sputtering equipment is lowered, and the TZO semiconductor material has the advantages for preparing large-size high-transmittance glass.

Owner:NANJING TEMCH OPTOELECTRONICS MATERIAL CO LTD

Tnalspreparation method of zinc-tin composite transparent conductive oxide films by using electron cyclotron resonance plasma chemical vapor deposition

InactiveUS20100075177A1Improve conductivityHigh strengthConductive materialOxide conductorsZinc tin oxideElectron cyclotron resonance

The present invention relates to a process of preparing zinc-tin composite transparent conductive oxide films ZnxSnyOz superior in light transmission, interfacial adhesion strength and electric conductivity by an organic chemical deposition method by using an electron cyclotron resonance (ECR).Zinc-tin oxide film composite ZnxSnyOz (x=1, y=8.7, Z=12) stably prepared by an electron-cyclotron chemical vapor deposition according to the present invention is superior to ZnSnO3 and Zn2SnO4 prepared by a physical deposition method in electric conductivity, thereby being applicable in a wide range of electric appliances including a heating element.

Owner:LEE JOONG KEE +4

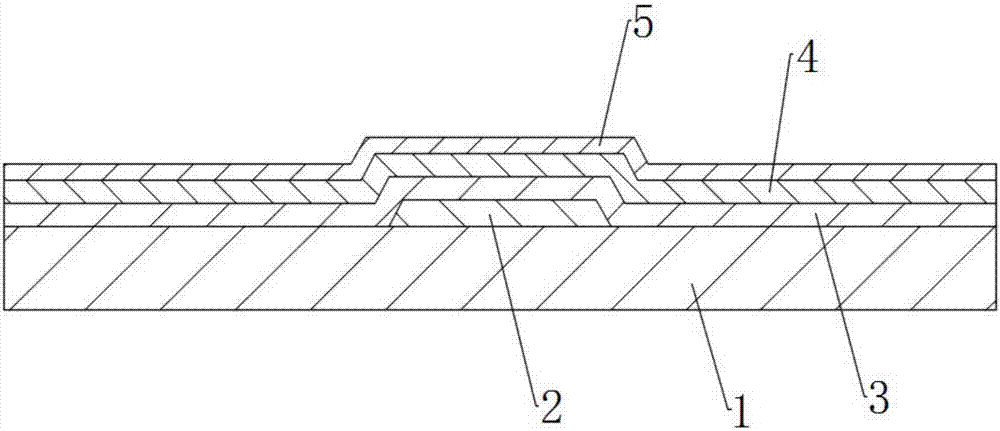

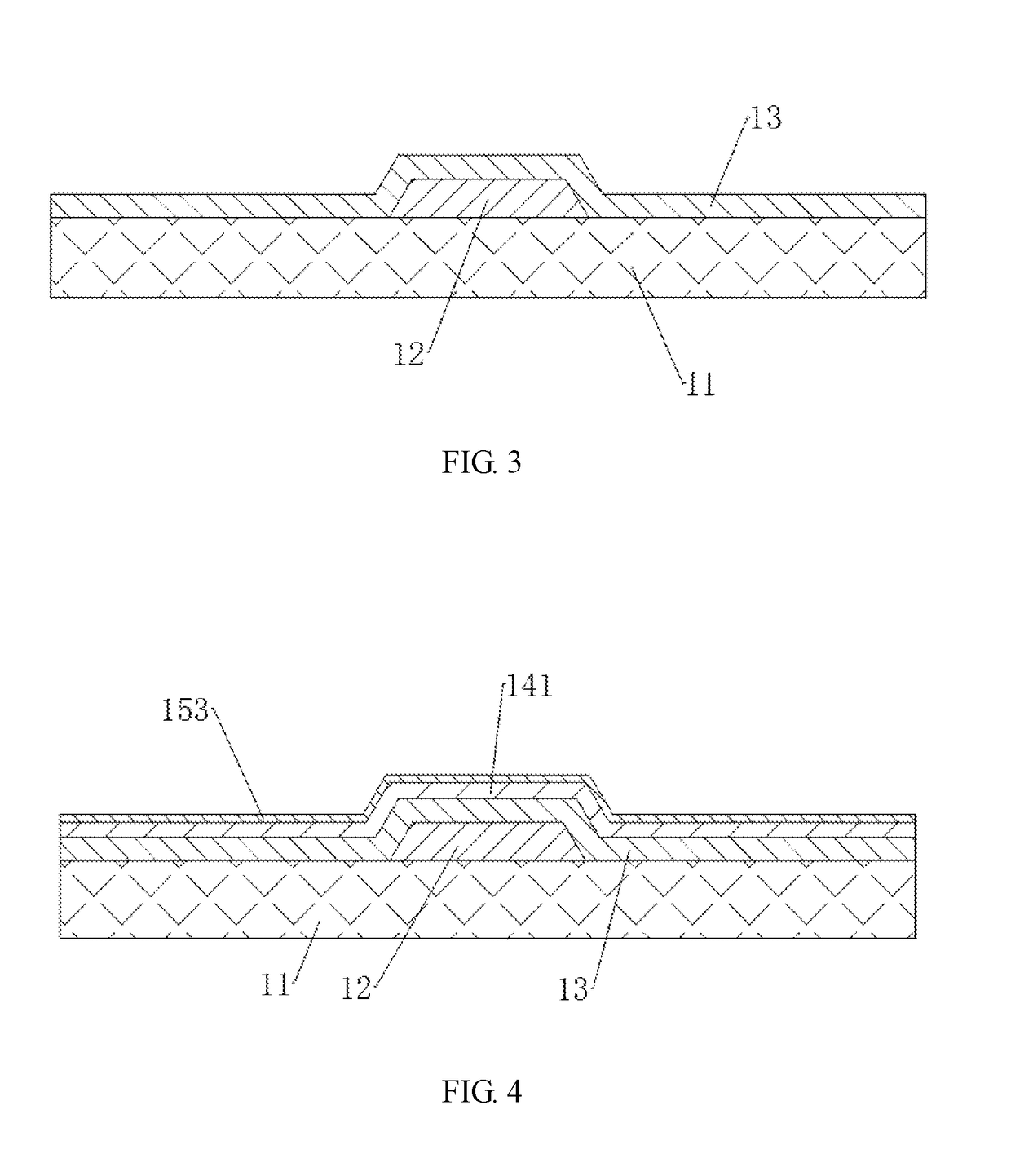

Manufacture method of array substrate

InactiveCN107146771AAvoid damageImprove device characteristicsSolid-state devicesSemiconductor/solid-state device manufacturingInsulation layerIndium

The invention discloses a manufacture method of an array substrate. The manufacture method includes forming a grid electrode on a substrate; forming a grid electrode insulation layer on a side of the substrate facing the grid electrode, wherein the grid electrode covers the grid electrode; settling an indium gallium zinc tin oxide layer and an indium gallium zinc oxide layer on a side of the grid electrode insulation layer away from the grid electrode; patterning the indium gallium zinc tin oxide layer and the indium gallium zinc oxide layer through a first yellow light processing so as to form a protection layer and an active layer, wherein the protection layer covers the active layer; settling a metal layer on a side of the protection layer away from the active layer; patterning the metal layer and the protection layer through second yellow light processing so as to form a source electrode, a drain electrode and an isolation zone, wherein the source electrode and the drain electrode are spaced from each other and are connected to the two ends of the active layer respectively and the isolation zone is formed on the protection layer and is disposed between the source electrode and the drain electrode. By adopting the above manufacture method, devices of the array substrate are good in performance.

Owner:SHENZHEN CHINA STAR OPTOELECTRONICS TECH CO LTD

Technology for high-transmittance, high-performance and low-emissivity glass

The invention discloses a technology for high-transmittance, high-performance and low-emissivity glass. According to the technology, a glass substrate is provided, and a silicon nitride dielectric layer, a zinc oxide dielectric layer, a silver functional layer, a nickel-chromium alloy target alloy layer and a two-layer composite dielectric layer comprising a zinc tin antimony oxide layer and a silicon nitride layer are sequentially coated on the glass substrate. According to the technology for the high-transmittance, high-performance and low-emissivity glass, a multilayer film layer structure which is high in reflectivity to an infrared region and low in absorption property to near infrared and far infrared is coated on the surface of the glass substrate by an offline megnetron sputtering technology and at least comprises the silver functional layer capable radiating the sunshine; the high-transmittance, high-performance and low-emissivity glass has the characteristics of flexibility in adjustment of transmittance, absorption and reflection values and can effectively reduce the emissivity rate of the glass and increase the glass thermal resistance; furthermore, the required color and the required sunshade coefficient can be obtained. Moreover, the visible transmittance and the photothermal selectivity of the glass substrate surface can be effectively improved.

Owner:SHANGHAI NORTH GLASS COATING TECHNOLOGY INDUSTRIAL CO LTD +2

Zinc tin oxide thin film and preparation method thereof, and thin film transistor and preparation method thereof

ActiveCN103510086AIncrease the carrier concentrationIncreased oxygen vacancy contentTransistorSemiconductor/solid-state device manufacturingZinc tin oxideSemiconductor

The invention discloses a preparation method for a zinc tin oxide thin film, which relates to the field of thin film transistors. The preparation method comprises the following steps: preparing a precursor solution by using tin(II) 2-ethylhexanoate as a precursor material of tin; then coating the precursor solution on a coating surface formed by an amorphous material so as to form a thin film; and finally, carrying out heat treatment, wherein a heating rate of 20 to 80 DEG C / min is adopted so as to obtain the zinc tin oxide thin film. The invention also provides the zinc tin oxide thin film prepared by using the preparation method, a thin film transistor using the zinc tin oxide thin film as a semiconductor layer and a preparation method for the thin film transistor. According to the invention, the problem of low carrier mobility of the thin film transistor formed by the zinc tin oxide thin film prepared with tin(II) 2-ethylhexanoate as the precursor material of tin in the prior art is overcome.

Owner:KUNSHAN VISIONOX DISPLAY TECH +2

Array substrate, manufacturing method thereof, and display panel

ActiveUS20180337199A1Improve device performanceImprove performanceTransistorSolid-state devicesIndiumZinc tin oxide

The present disclosure discloses an array substrate comprising: a substrate; a gate electrode; a gate insulating layer formed on one side of the substrate facing the gate electrode, the gate insulating layer covering the gate electrode; an active layer formed on one side of the gate insulating layer away from the gate electrode and made of an indium gallium zinc tin oxide material; an ohmic contact layer formed on one side of the active layer away from the gate insulating layer and made of a conductive indium gallium zinc oxide material, the ohmic contact layer covering both ends of the active layer; and a source electrode and a drain electrode formed on one side of the ohmic contact layer away from the active layer, the source electrode and the drain electrode being electrically connected to both ends of the active layer by the ohmic contact layer, respectively.

Owner:TCL CHINA STAR OPTOELECTRONICS TECH CO LTD

Euro gray low-E (low-emissivity) coated glass

Owner:SICHUAN NANBO ENERGY SAVING GLASS CO LTD

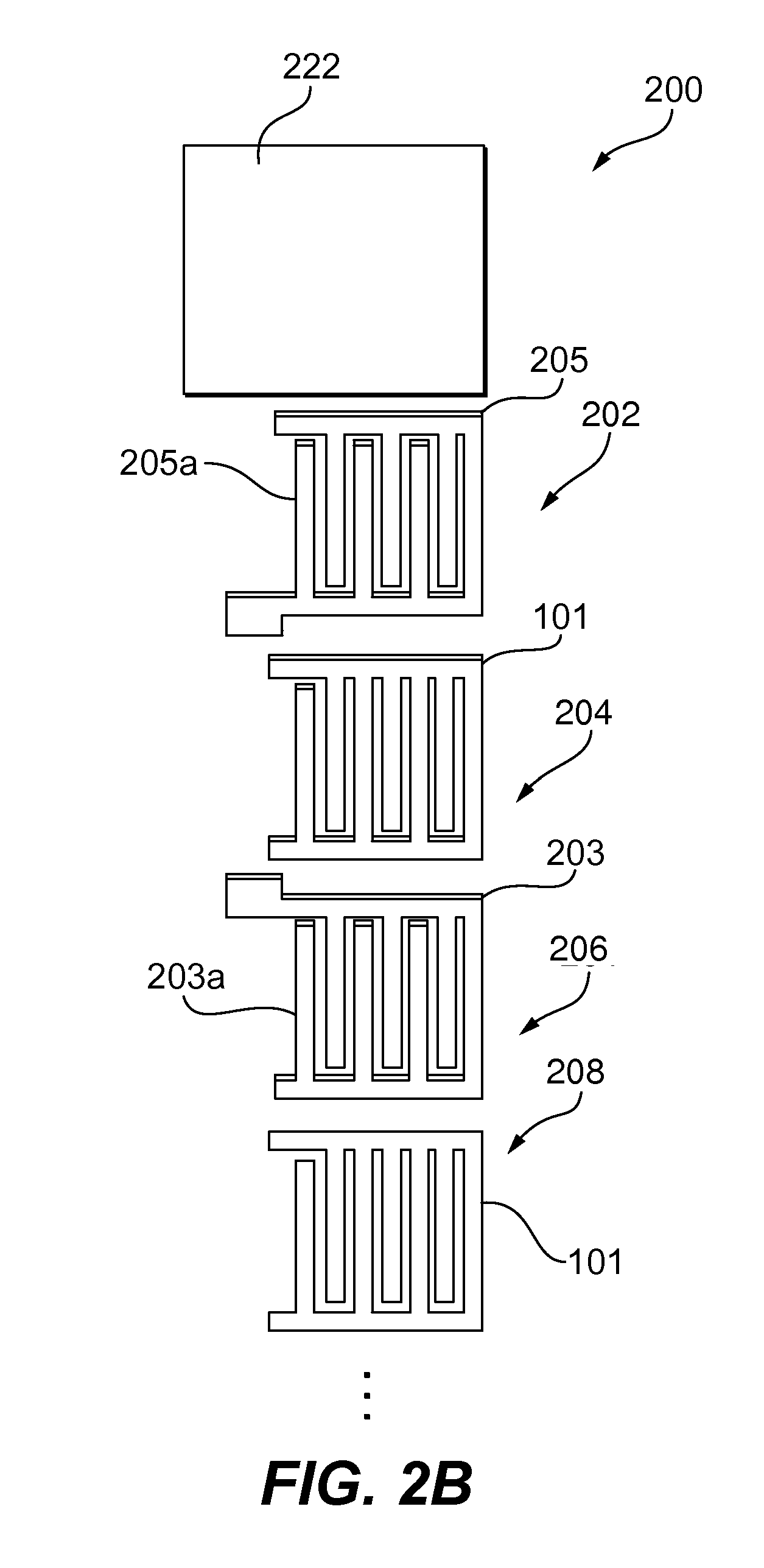

Radiation sensors

ActiveUS20170030768A1Great absorbanceMaterial is often sensitivePhotometry for measuring UV lightZinc tin oxideUltraviolet

In accordance with at least one aspect of this disclosure, an ultraviolet radiation (UV) sensor includes a UV sensitive material and a first electrode and a second electrode connected in series through the UV sensitive material such that UV radiation can reach the UV sensitive material. The UV sensitive material can include at least one of zinc tin oxide, magnesium oxide, magnesium zinc oxide, or zinc oxide. The electrodes can be interdigitated comb electrodes.

Owner:CARRIER CORP

Conductive film and electronic device having conductive film

ActiveUS20160086683A1Little changeImprove featuresConductive layers on insulating-supportsSynthetic resin layered productsZinc tin oxideWater vapor

Provided are a conductive film which is excellent in hygrothermal characteristics and has excellent bending performance, and an electronic device having such a conductive film.A conductive film is obtained by forming, on one surface or both surfaces of a substrate, a zinc tin oxide (ZTO) layer and a transparent conductive film that is formed of zinc oxide other than zinc tin oxide sequentially from the substrate side, in which a thickness of the zinc tin oxide layer is 5 to 500 nm, a thickness of the zinc oxide-based transparent conductive film is 5 to 1000 nm, and a water-vapor transmittance rate of the zinc tin oxide (ZTO) layer is 0.1 g / (m2·day) or less.

Owner:LINTEC CORP

Flexible nanofiber zinc tin oxide field effect transistor and preparation method thereof

PendingCN110534568ALow costEasy to operateSemiconductor/solid-state device manufacturingSemiconductor devicesZinc tin oxideNanofiber

The invention discloses a flexible nanofiber zinc tin oxide field effect transistor and a preparation method thereof. The flexible nanofiber zinc tin oxide field effect transistor comprises a top source electrode layer, a top drain electrode layer, a carrier channel layer of a nanofiber structure, a dielectric layer, a bottom gate electrode layer and a substrate which are arranged from top to bottom, wherein the carrier channel layer of the nanofiber structure is a zinc tin oxide filament cluster which is prepared by a sol method and has the diameter of about 100-300 nm. The preparation methodcomprises the following steps of: a) cleaning the substrate; b) preparing the bottom gate electrode layer, c) preparing a hafnium oxide dielectric layer, d) preparing a carrier channel layer with a nanofiber structure, and e) preparing a top source electrode layer and a top drain electrode layer. According to the scheme, the nanofiber (NF) filaments are prepared by adopting a sol method, the operation is simple and convenient, the distribution and direction are easy to control, the cost is low, the uniformity is relatively high, and large-scale industrial application can be realized; the advantages of environmental protection, high mobility and the like are achieved; the method can be applied to the field of flexible wearable circuits; and the whole device is transparent, and has good application potential in the optical field.

Owner:XIAN JIAOTONG LIVERPOOL UNIV

Thin film transistor, display substrate and method of manufacturing a thin film transistor

A thin film transistor includes a gate electrode, a channel overlapped with the gate electrode, a source electrode contacting the channel, and a drain electrode spaced apart from the source electrode and contacting the channel. The channel includes indium-zinc-tin oxide sourced from a source including a single phase indium-zinc-tin oxide.

Owner:SAMSUNG DISPLAY CO LTD

Thin film transistor, display substrate and method of manufacturing a thin film transistor

A thin film transistor includes a gate electrode, a channel overlapped with the gate electrode, a source electrode contacting the channel, and a drain electrode spaced apart from the source electrode and contacting the channel. The channel includes indium-zinc-tin oxide sourced from a source including a single phase indium-zinc-tin oxide.

Owner:SAMSUNG DISPLAY CO LTD

Sputtering target of oxide semiconductors and the manufacturing methods of oxide semiconductor layers

A technique capable of forming an oxide semiconductor target with a high quality in a low cost is provided. In a step of manufacturing zinc tin oxide (ZTO target) used in manufacturing an oxide semiconductor forming a channel layer of a thin-film transistor, by purposely adding the group IV element (C, Si, or Ge) or the group V element (N, P, or As) to a raw material, excessive carriers caused by the group III element (Al) mixed in the step of manufacturing the ZTO target are suppressed, and a thin-film transistor having good current (Id)-voltage (Vg) characteristics is achieved.

Owner:HITACHI METALS LTD

Display panel and preparation method thereof

ActiveCN112909200AImprove reliabilityQuality improvementSolid-state devicesSemiconductor/solid-state device manufacturingIndiumSilver electrode

The invention discloses a display panel and a preparation method thereof, and the display panel comprises the components of a substrate layer which comprises a display area and a non-display area which is arranged around the display area; a passivation layer which is arranged on one side of the substrate layer, wherein a first opening is formed in the passivation layer, and the first opening is located in the non-display area; a first electrode layer which is arranged on one side, close to the substrate layer, in the first opening of the passivation layer; and a second electrode layer which is arranged on the surface of one side, far away from the substrate layer, of the first electrode layer, wherein the second electrode layer comprises a second electrode, and the material of the second electrode comprises at least one of indium gallium tin oxide, indium gallium zinc tin oxide and gallium tin oxide. According to the invention, the second electrode layer is arranged, the first electrode layer is prevented from making contact with oxygen to generate oxidation reaction, meanwhile, the silver electrode is etched away, oxidation reaction of the silver electrode is also avoided, and then the reliability and the product quality of the display panel are improved.

Owner:SHENZHEN CHINA STAR OPTOELECTRONICS SEMICON DISPLAY TECH CO LTD

Manufacturing method for array substrate

InactiveUS20190013334A1Improve device performanceImprove performanceTransistorSolid-state devicesIndiumZinc tin oxide

The present disclosure discloses a method for manufacturing an array substrate comprising: forming a gate electrode on a substrate; forming a gate insulating layer on one side of the substrate facing the gate electrode, the gate insulating layer covering the gate electrode; depositing an indium gallium zinc tin oxide layer and an indium gallium zinc oxide layer on one side of the gate insulating layer away from the gate electrode; patterning the indium gallium zinc oxide layer and the indium gallium zinc tin oxide layer by a first yellow light process to form a protective layer and an active layer, the protective layer covering the active layer; depositing a metal layer on one side of the protective layer away from the active layer; and patterning the metal layer and the protective layer by a second yellow light process to form a source electrode, a drain electrode, and a separation region.

Owner:SHENZHEN CHINA STAR OPTOELECTRONICS TECH CO LTD

Durable low emissivity window film constructions

In certain embodiments, the present disclosure relates to low emissivity films and articles comprising them. Other embodiments are directed to methods of reducing emissivity in an article comprising the use of low emissivity films. In some embodiments, the low emissivity films comprise a metal layer and a pair of layers, one comprising a metal oxide such as zinc tin oxide and the other layer comprising a silicon compound, adjacent each of the two sides of the metal layer. This type of assembly may serve various purposes, including being used as a sun control film. These constructions may be used, for example, as window films on glazing units for reducing transmission of infrared radiation across the film in both directions.

Owner:3M INNOVATIVE PROPERTIES CO

Durable low emissivity window film construction

In certain embodiments, the present disclosure relates to low-E films and articles comprising the same. Other embodiments relate to methods of reducing the emissivity of an article comprising the use of low emissivity films. In some embodiments, the low emissivity film includes a metal layer and a pair of layers, one layer comprising a metal oxide such as zinc tin oxide and the other layer comprising a silicon compound adjacent to each of two sides of the metal layer. This type of assembly can be used for a variety of purposes, including as a solar insulation film. These constructions are useful, for example, as window films on glazing units for reducing the trans-film transmission of infrared radiation in both directions.

Owner:3M INNOVATIVE PROPERTIES CO

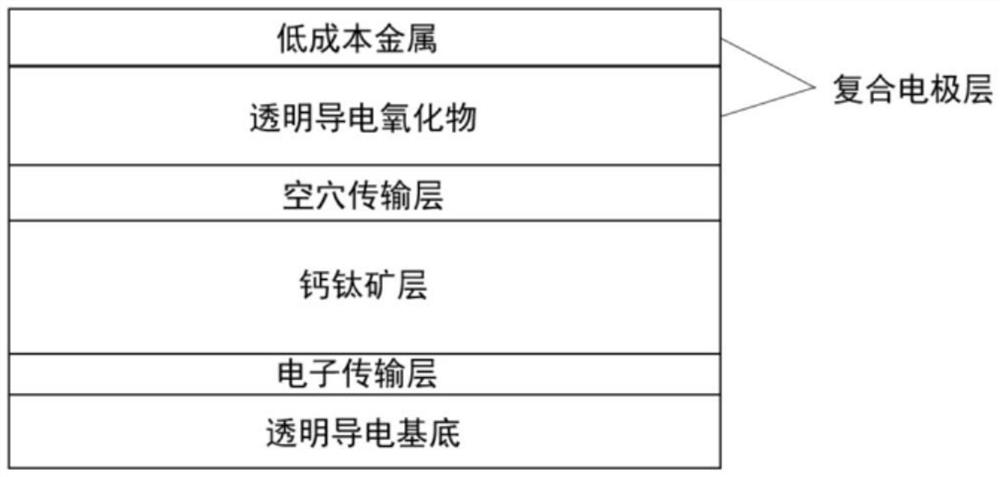

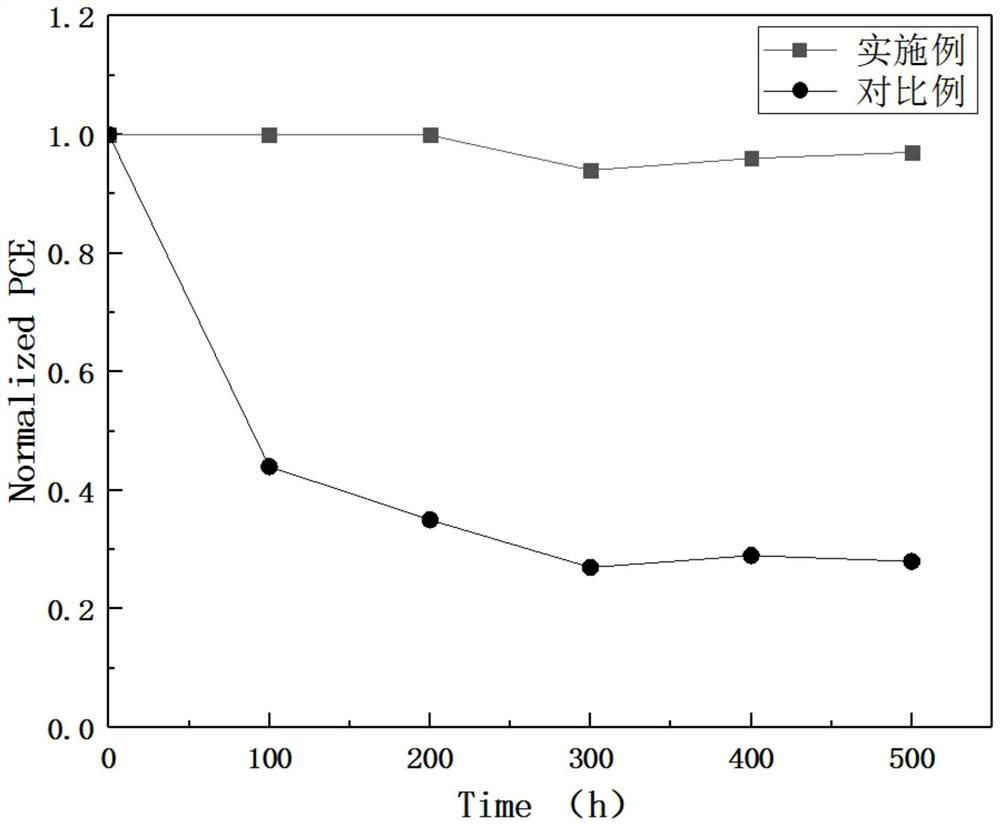

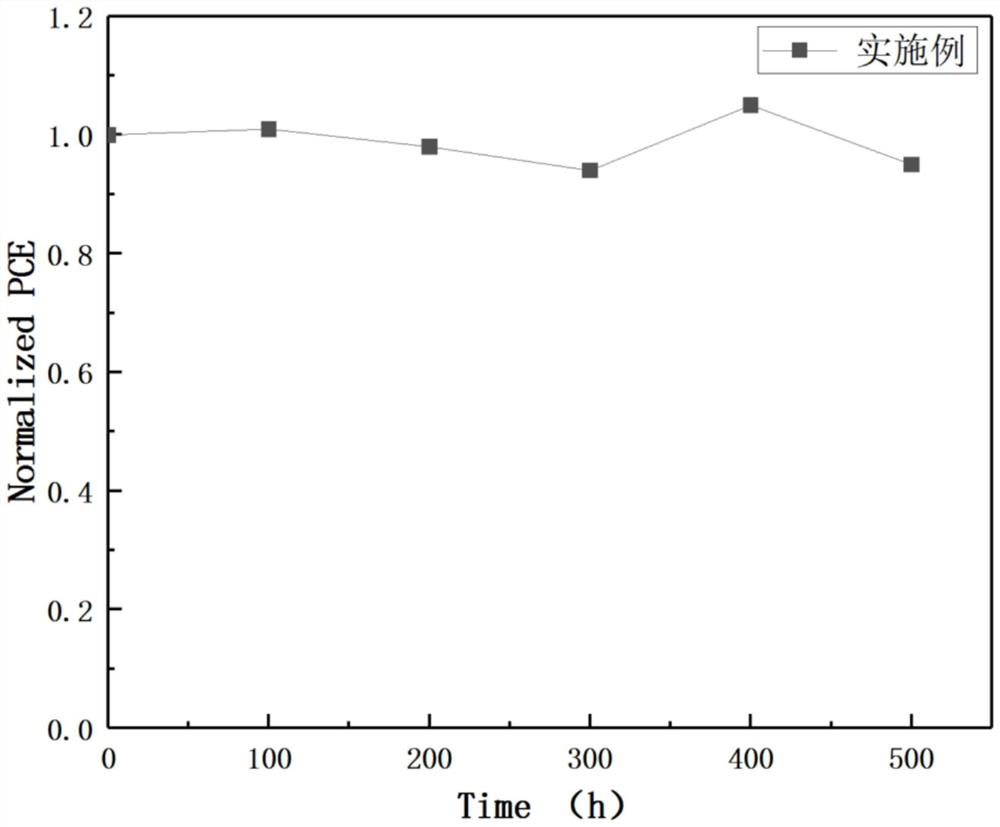

Composite film electrode based on low-cost metal and transparent conductive oxide and application of composite film electrode in perovskite photoelectric device

PendingCN113488594AImprove conductivityImprove stabilitySolid-state devicesSemiconductor/solid-state device manufacturingComposite filmIndium zinc oxide

The invention discloses a composite film electrode and application thereof in a perovskite photoelectric device. The composite film electrode comprises a transparent conductive oxide layer and a low-cost metal layer which are sequentially compounded, and the transparent conductive oxide layer is made of any one or combination of indium tin oxide, fluorine-doped tin oxide, tungsten-doped indium oxide, indium zinc oxide, aluminum-doped zinc oxide and zinc tin oxide. The low-cost metal layer is made of any one of copper, aluminum, nickel, zinc, tin, iron and silver and alloy and combination of the copper, the aluminum, the nickel, the zinc, the tin, the iron and the silver. The invention provides the composite film electrode based on the low-cost metal and the transparent conductive oxide, and the composite film electrode is successfully applied to a perovskite photoelectric device represented by a perovskite solar cell, so that the comprehensive stability of the perovskite photoelectric device is greatly improved on the basis of realizing relatively high photoelectric conversion efficiency of the perovskite photoelectric device.

Owner:深圳无限光能技术有限公司

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com