Technology for high-transmittance, high-performance and low-emissivity glass

A low-radiation glass and high transmittance technology, applied in the field of coated glass manufacturing process, can solve the problems of low radiation and processing resistance, low processing performance, low transmittance of coated glass, etc., to solve low processing performance, Low-radiation processing resistance, the effect of improving photothermal selectivity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment approach

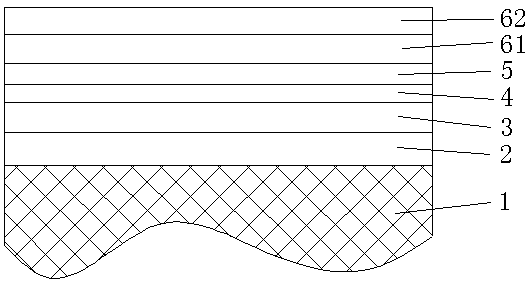

[0020] In the first embodiment of the present invention, please continue to refer to figure 1 shown. The above-mentioned silicon nitride (Si3N4) dielectric layer 2 is deposited under the conditions that the ratio of nitrogen to argon is 1:1.2 to 1.5 and the vacuum sputtering pressure is between 2.0E-3mbar and 6.0E-3mbar, And the power is between 15KW and 50KW, so that the deposited film thickness of the silicon nitride (Si3N4) dielectric layer 2 is between 16nm and 30nm.

[0021] In the second embodiment of the present invention, the above-mentioned zinc oxide dielectric layer 3 adopts the conditions that the ratio of oxygen to argon is 1.2 to 1.5:1 and the vacuum sputtering pressure is between 2.0E-3mbar and 3.0E-3mbar The deposition is carried out under the power of 15KW to 50KW, so that the zinc oxide dielectric layer 3 is deposited with a film thickness of 16nm to 30nm.

[0022] In the third embodiment of the present invention, the above-mentioned silver (Ag) layer is us...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com