Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

37 results about "Subsidence trough" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Determining and estimating method for surface subsidence characteristic parameters caused by subway tunnel construction

InactiveCN104965994AConcrete conclusionSpecial data processing applicationsFeature parameterSubsidence

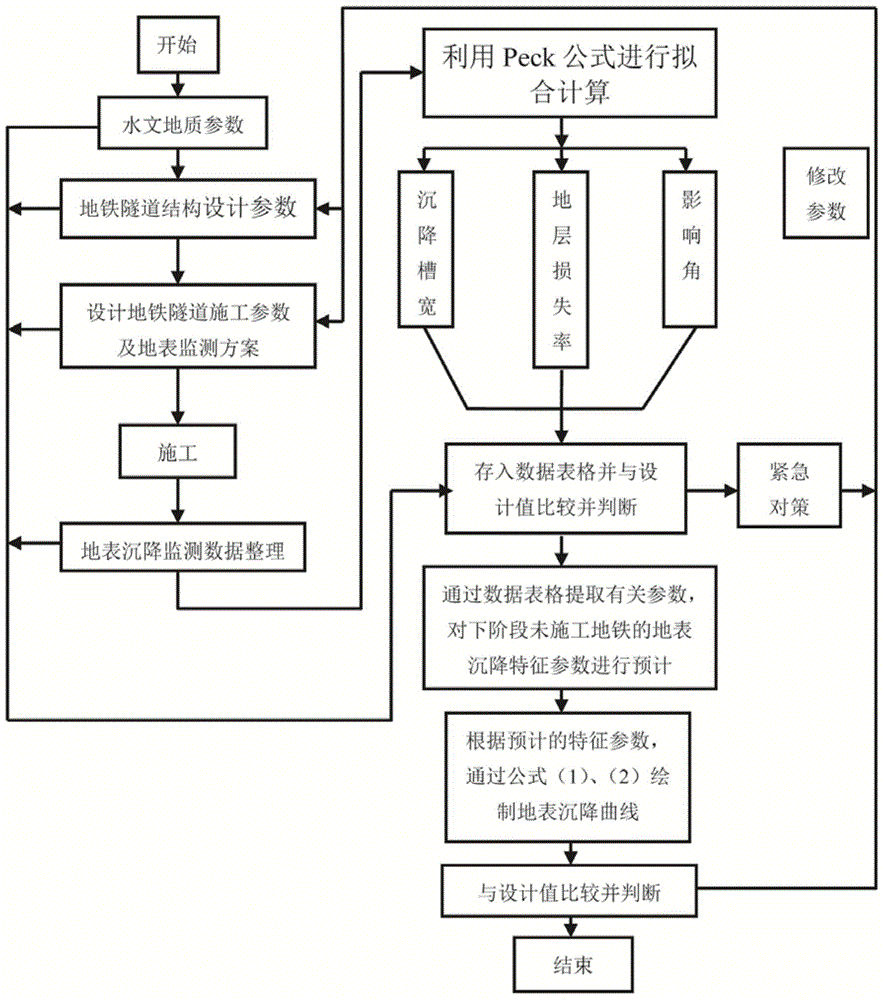

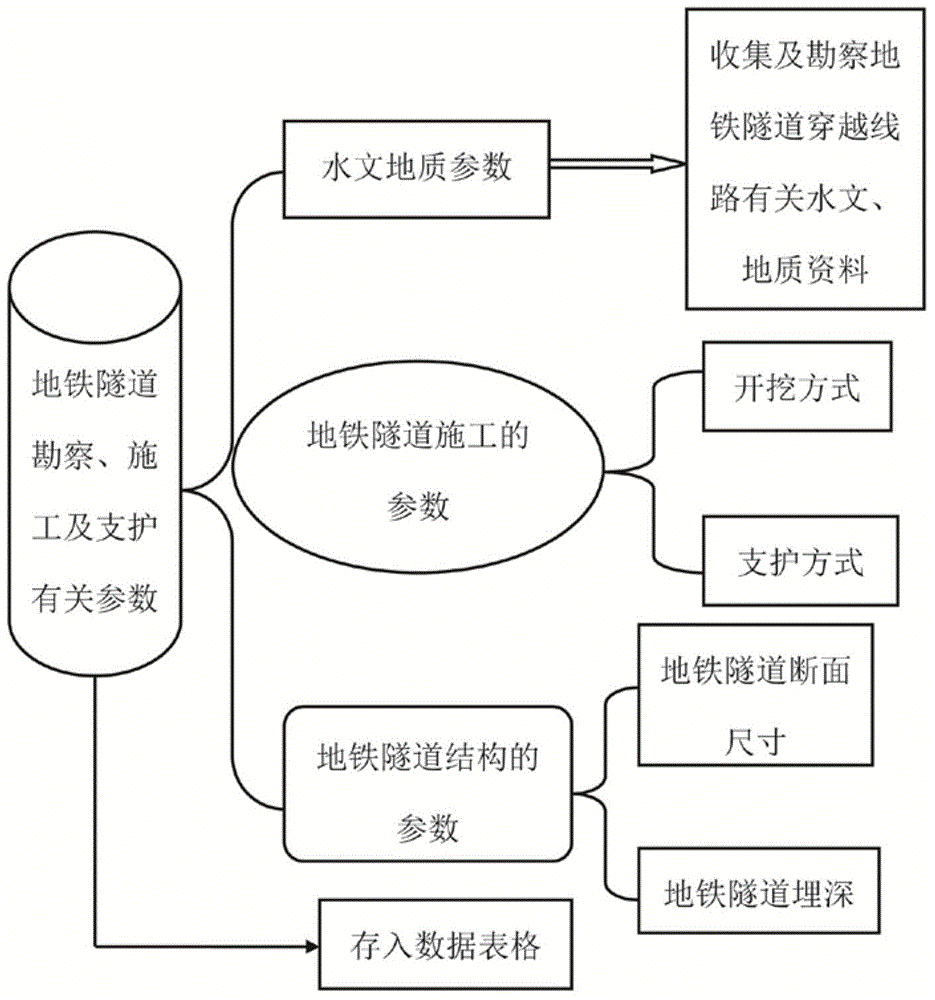

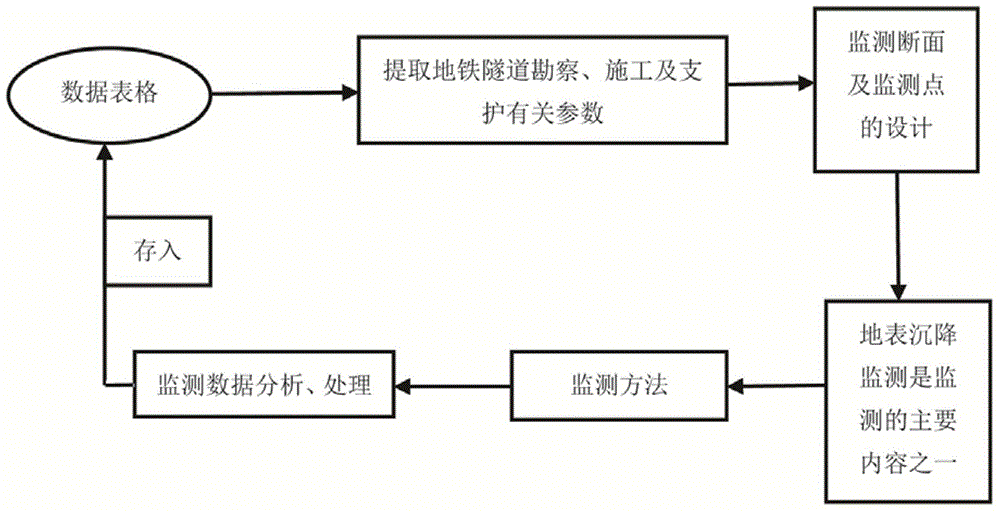

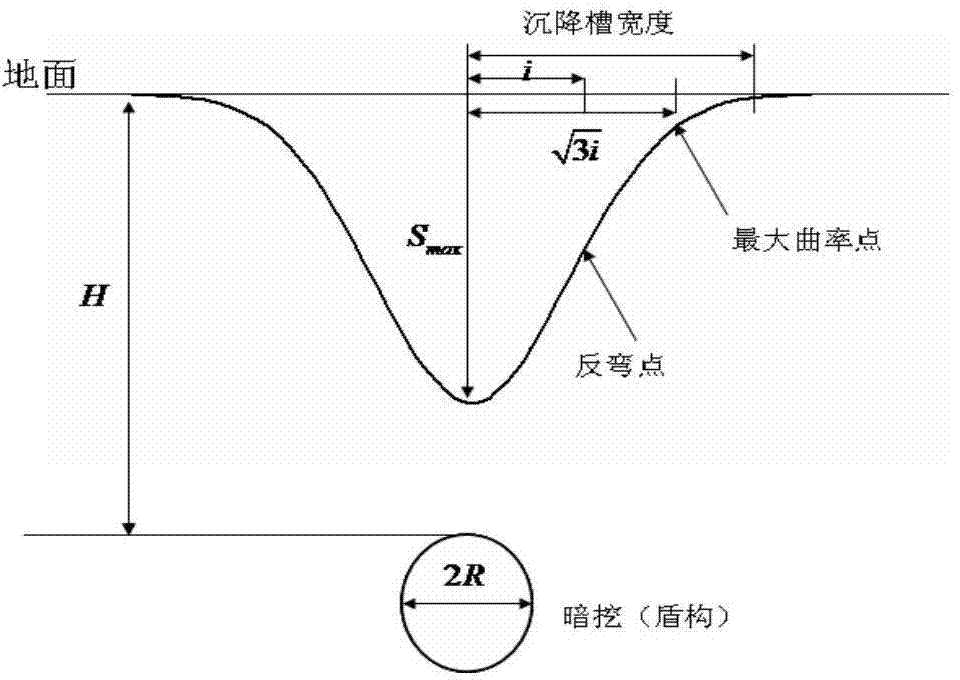

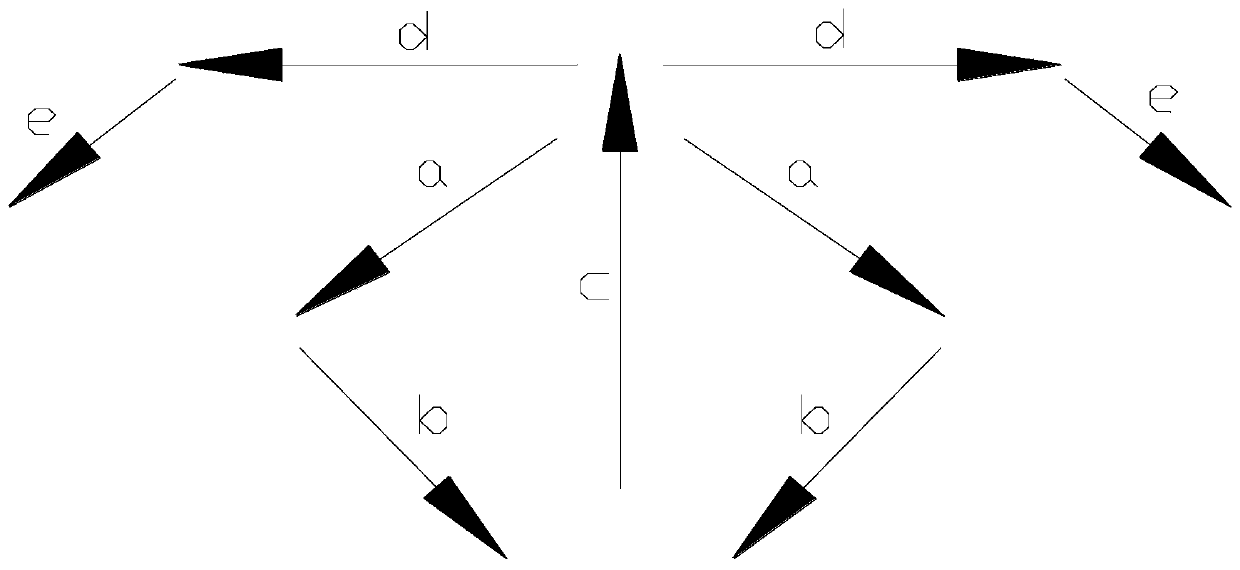

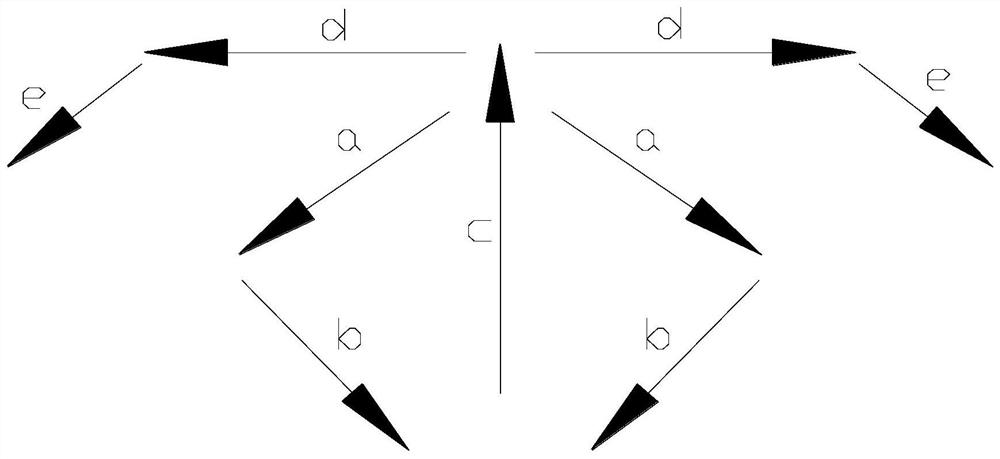

The present invention relates to a determining and estimating method for surface subsidence characteristic parameters caused by subway tunnel construction. The determining and estimating method comprises the following steps of: (1) determining related parameters for investigating, constructing and supporting a dug subway tunnel; (2) observing surface subsidence of the dug subway tunnel, and recording subsidence data; (3) calculating the surface subsidence characteristic parameters of the dug subway tunnel, including the width of a subsidence tank, the ground loss ratio, a width coefficient of the subsidence tank and an influence angle; (4) inputting data parameters and monitoring data of the dug subway tunnel and the fitted surface subsidence characteristic parameters in various conditions into a data table, and searching the relationships and the laws among the data; and (5) determining the related parameters for investigating, constructing and supporting a to-be-dug subway tunnel, searching parameters that are consistent with or generally similar to the existing parameters from the data table, estimating the surface subsidence characteristic parameters of the to-be-dug subway tunnel, drawing a surface subsidence tank curve by substituting a Peck formula through the estimated characteristic parameters, estimating the influence range, and regulating a construction scheme.

Owner:QINGDAO TECHNOLOGICAL UNIVERSITY

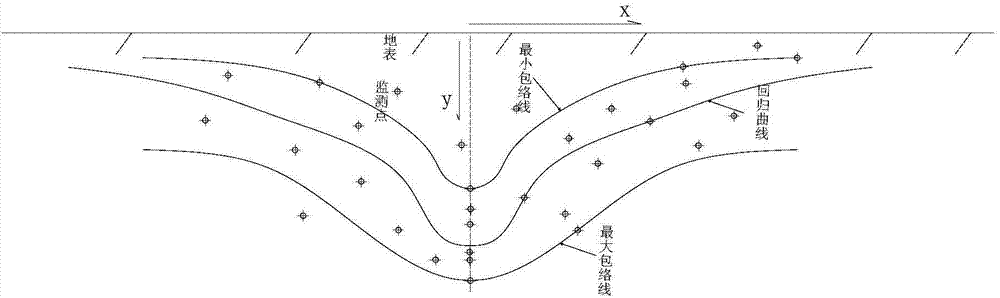

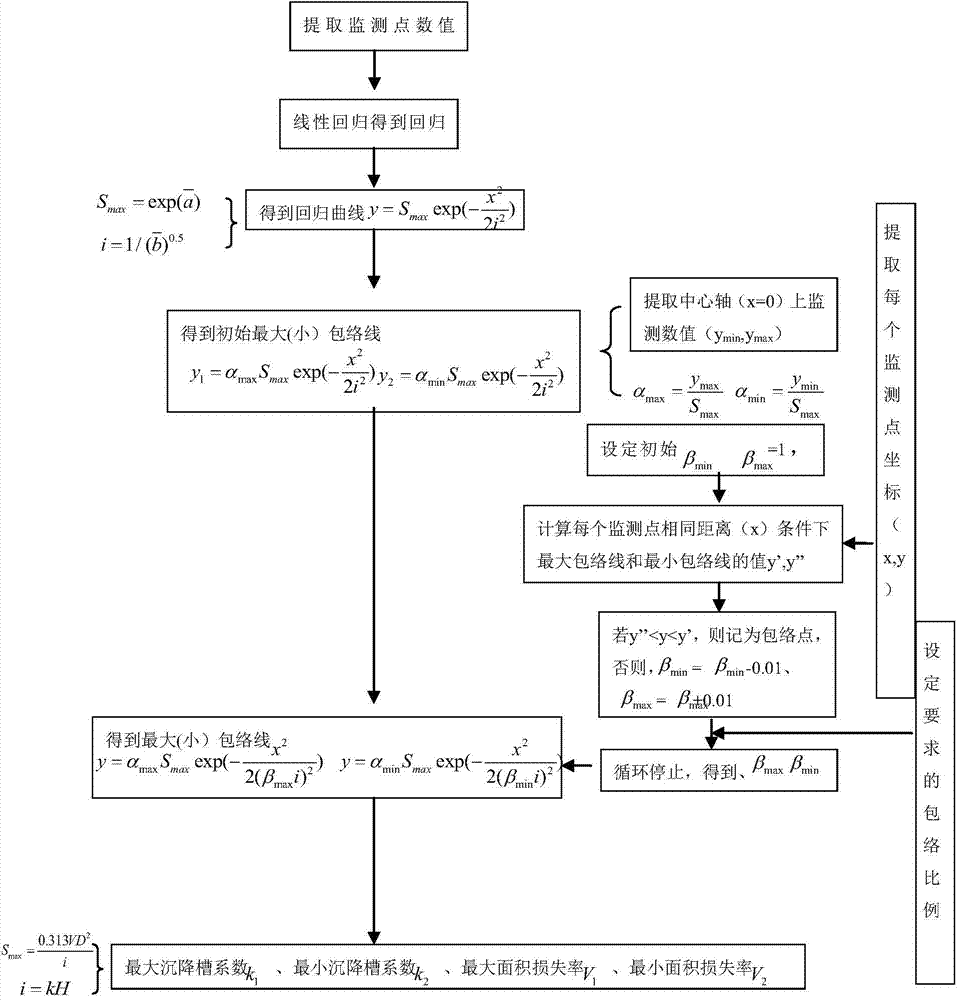

Subway tunnel subsider production method capable of achieving different sedimentation distribution guarantee rates

The invention belongs to the technical field of civil engineering, and discloses a subway subsider production method used for generating and predicting ground surface subsider curves caused by subway underground excavation or shield tunnels. The subway subsider production method mainly includes the steps of subsider curve generation, subsider envelop curve generation and sedimentation prediction parameter calculation, and specifically includes the steps of obtaining the distances between all monitoring points and the central line of a tunnel, obtaining the sedimentation values of the monitoring points, calculating a regression subsider curve, setting the envelop ratios of the monitoring points, conducting adjustment with the regression subsider curve as the foundation to obtain the maximum envelop curve and the minimum envelop curve, setting the diameter and the burial depth of the tunnel, and calculating the maximum subsider coefficient, the minimum subsider coefficient, the regression subsider coefficient, the maximum area loss rate, the minimum area loss rate and the regression area loss rate of each of the three curves. According to the method, the distribution rule and the distribution range of the ground surface sedimentation caused by underground excavation or shield tunnels are formed by taking actual monitoring data as the foundation and considering the probability distribution of settlement, the prediction parameter of the distribution range is formed, and the method is high in practicability, convenient to use and wide in application prospect.

Owner:BEIJING URBAN CONSTR GROUP

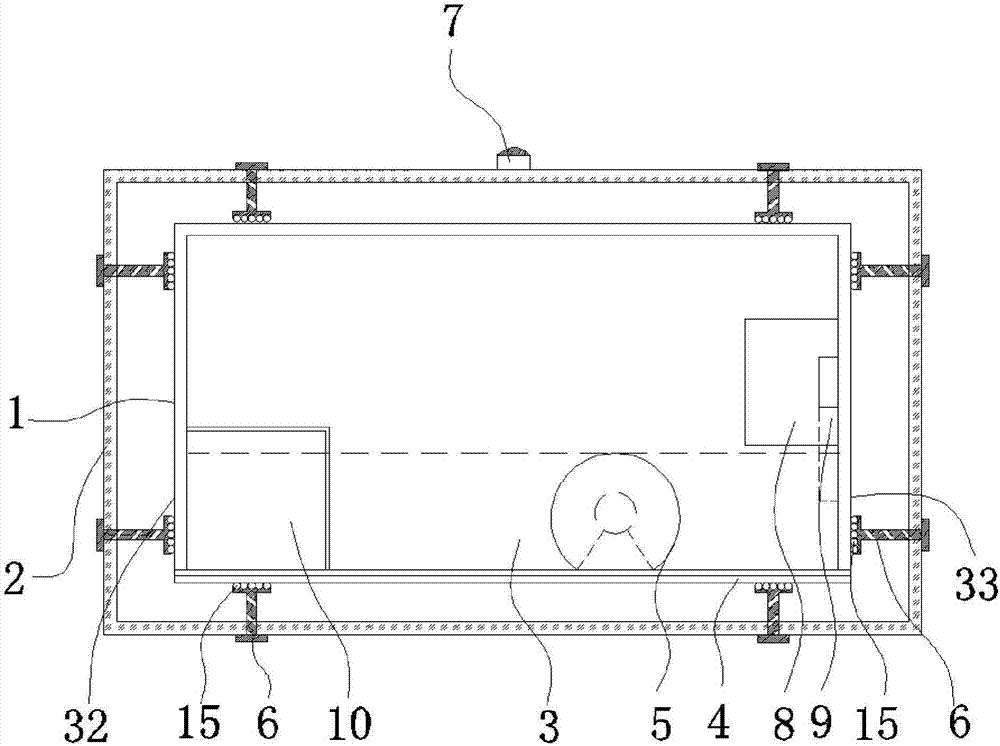

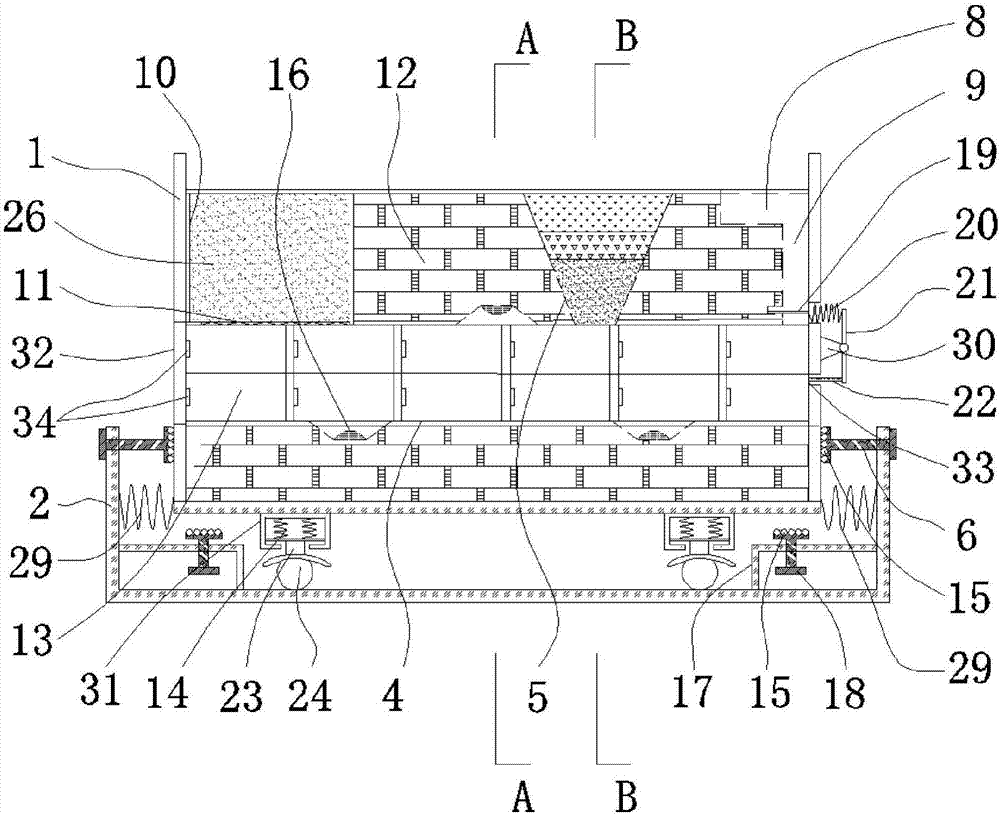

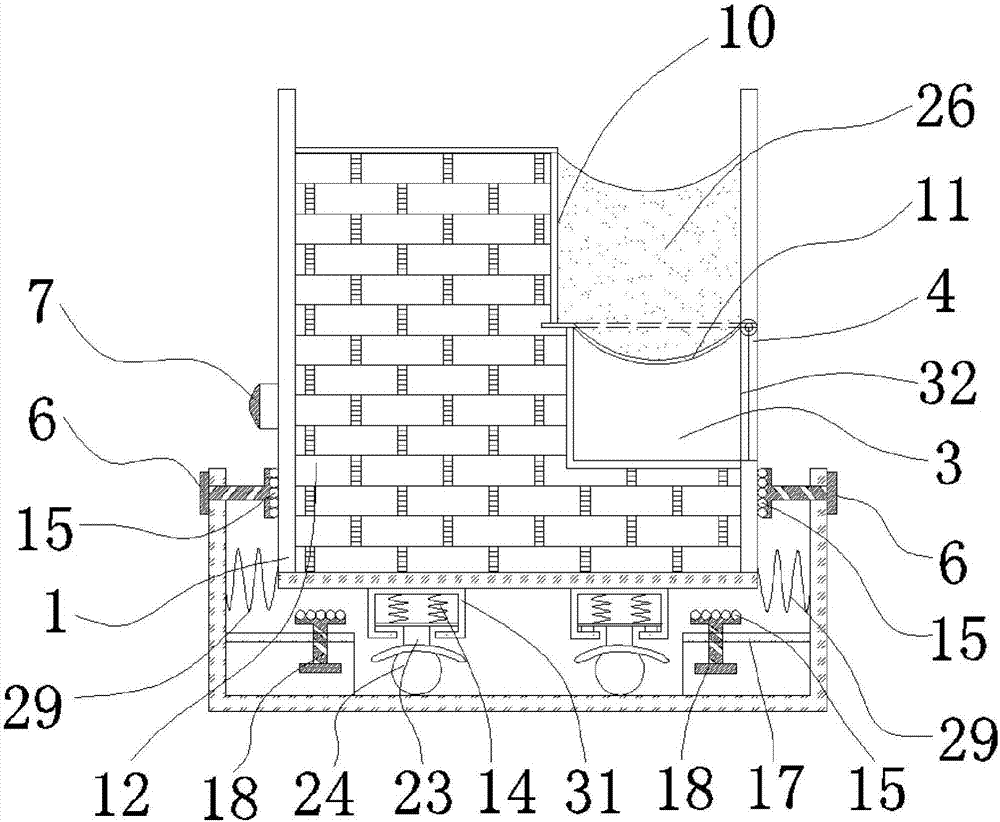

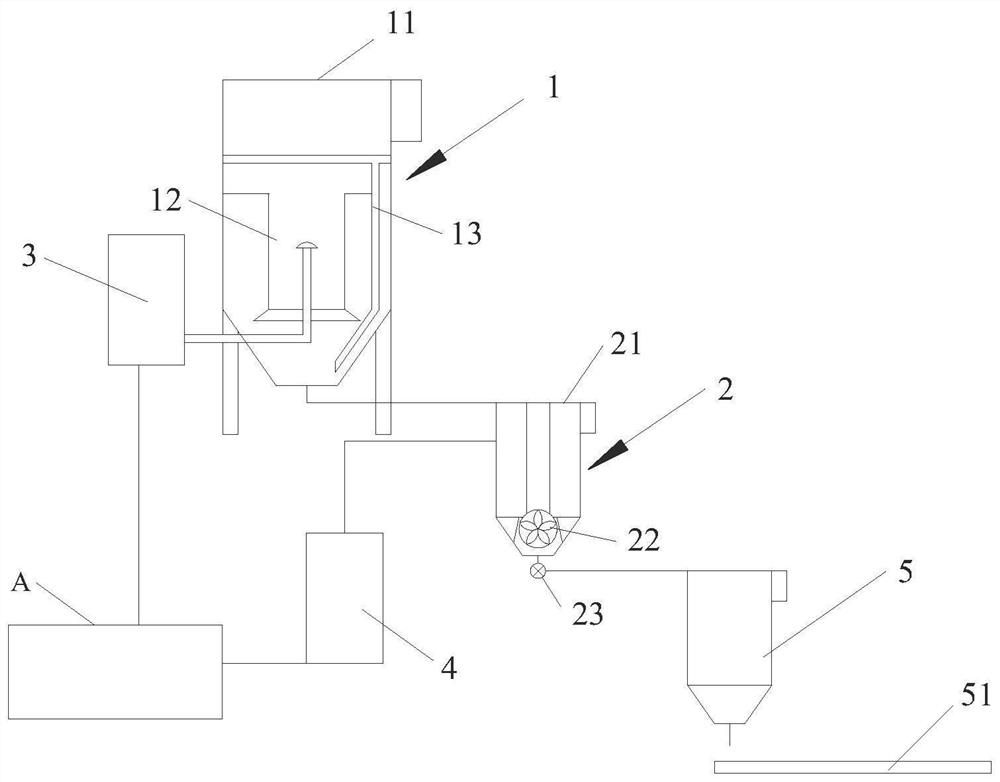

Apparatus and method for teaching demonstration of underground engineering geological disasters

PendingCN107884548AEasy to operateIncrease visibilityEarth material testingEducational modelsVibration controlBedrock

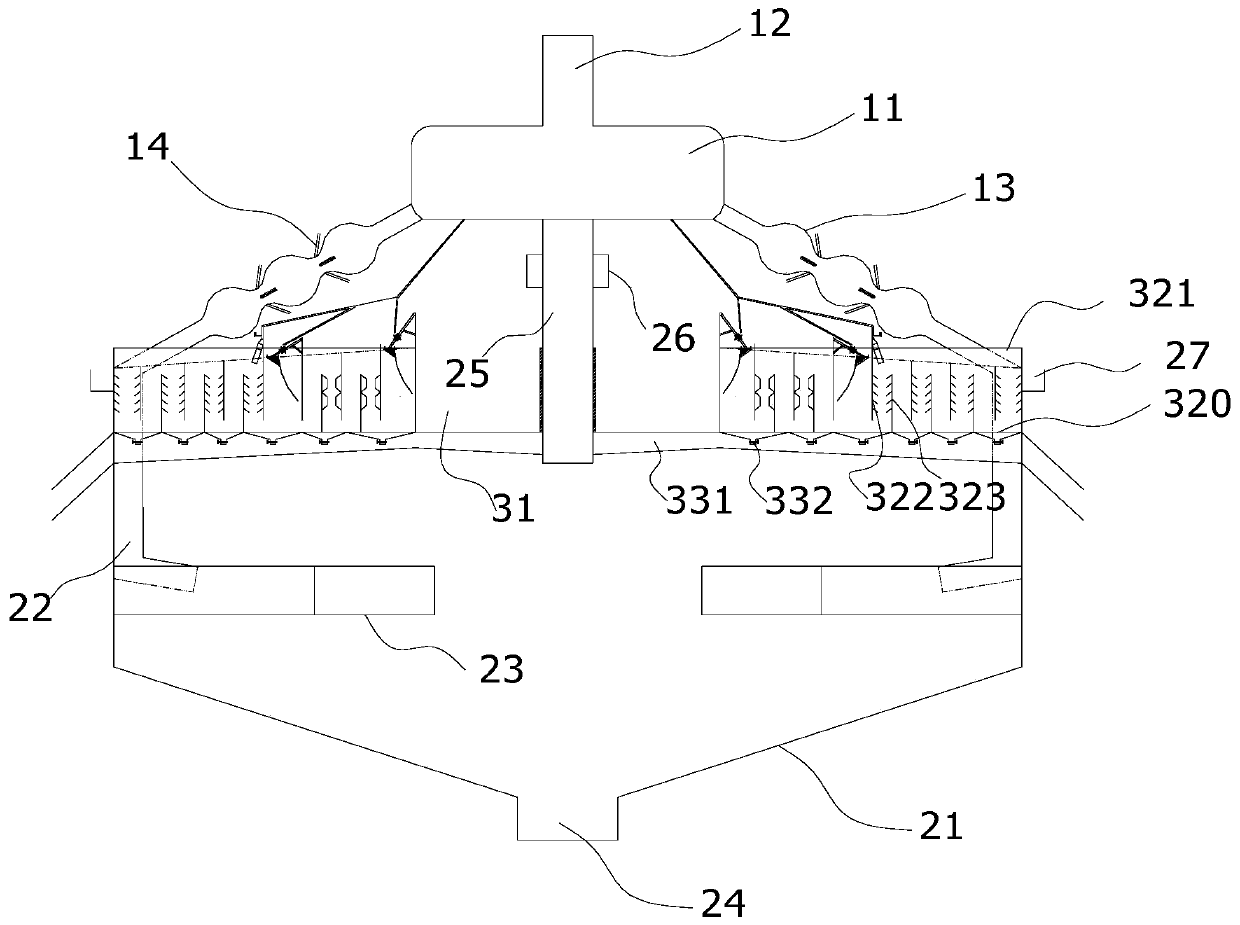

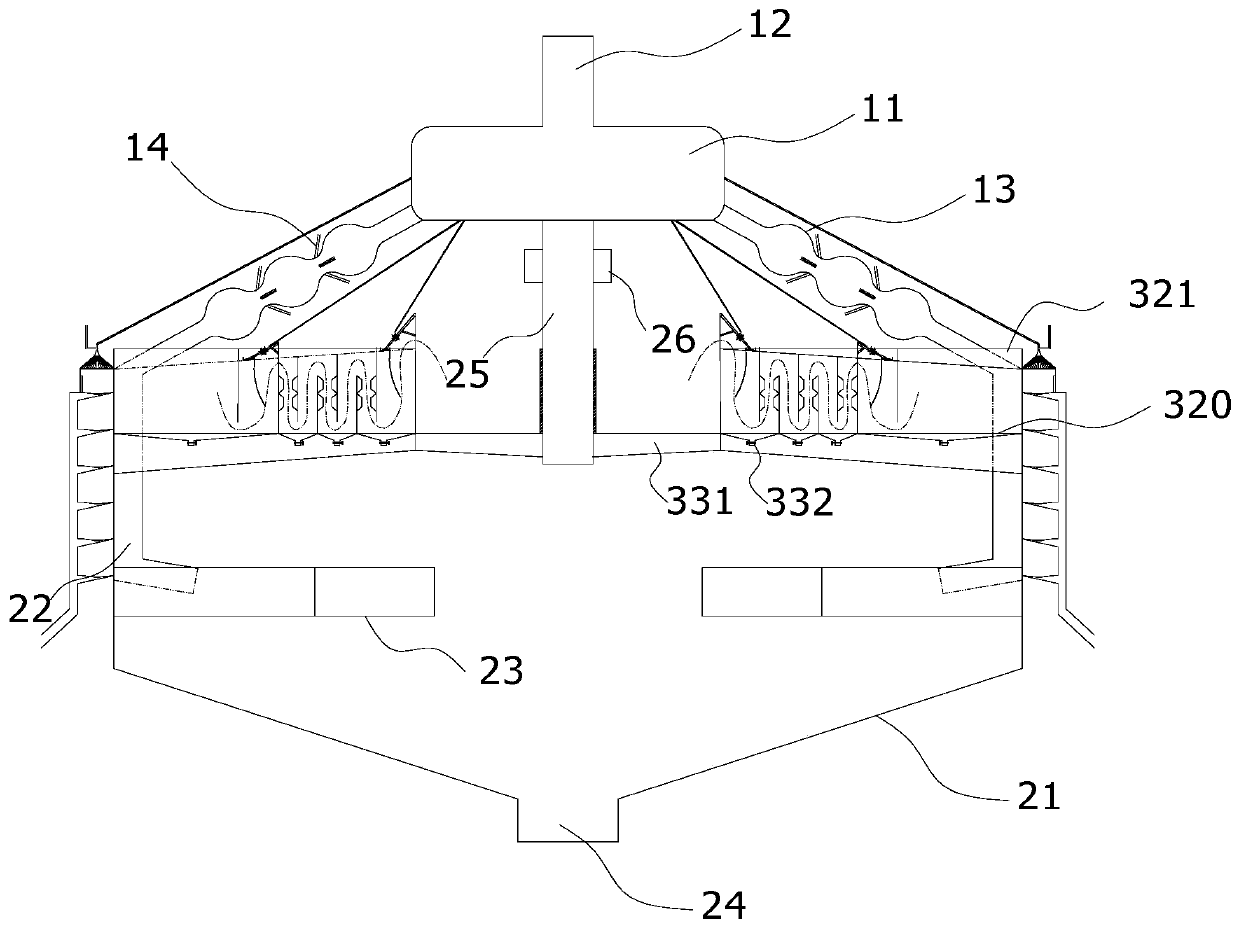

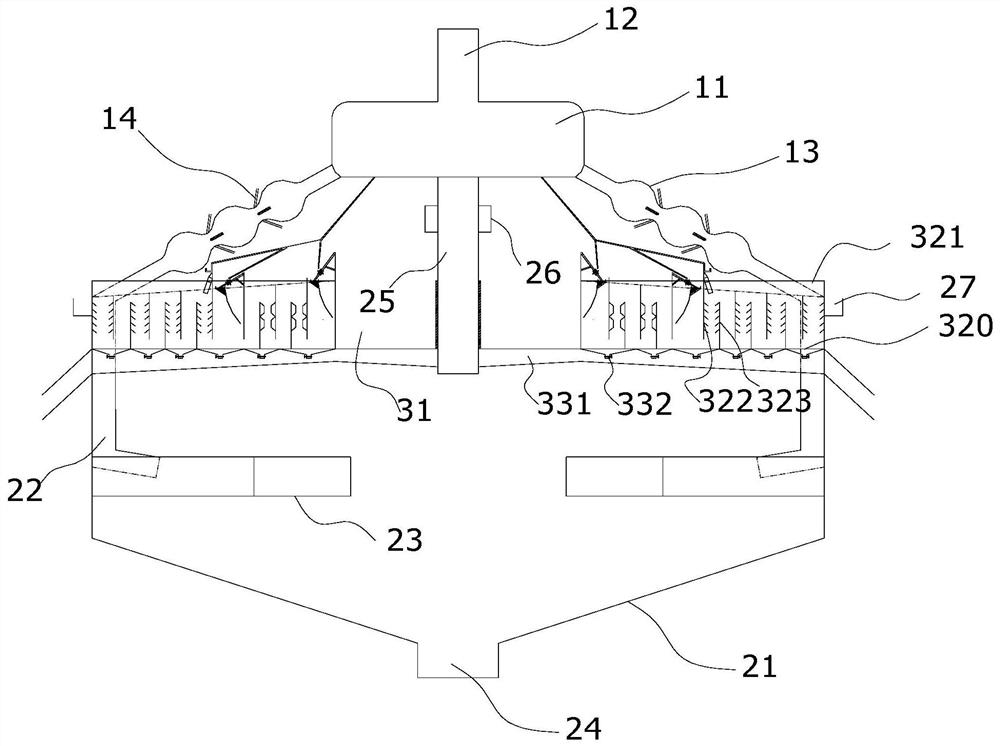

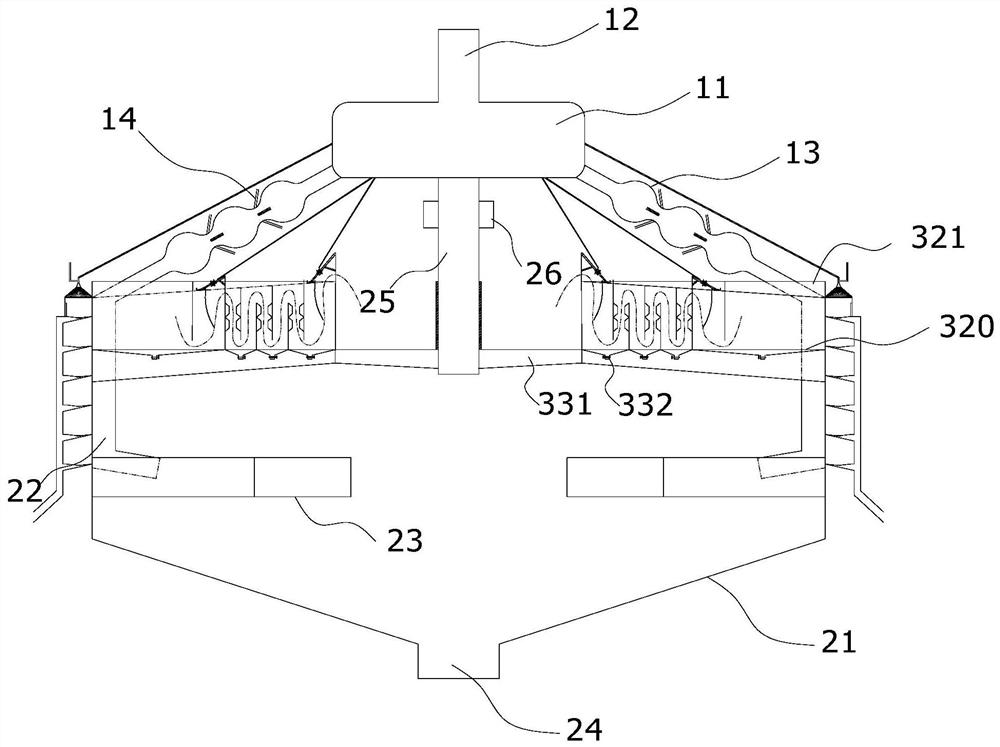

The invention relates to an apparatus and a method for teaching demonstration of underground engineering geological disasters. The apparatus includes a steel plate box of which the top is provided with an opening. A simulation box body is arranged in the steel plate box. A vibration control device is arranged between the steel plate box and the simulation box body. The simulation box body is filled with a base rock simulating pack. A long-bar-shaped groove is arranged in the side wall of the simulation box body. A glass plate is arranged on the side wall of the simulation box body. A settlement groove, a funnel-like groove, a mud water trough and a mud water transportation channel are arranged above the long-bar-shaped groove. A steel wire net is arranged between the bottom of the settlement groove and the long-bar-shaped groove. Gypsum bulks are arranged in the long-bar-shaped groove. During demonstration of geological disaster in underground engineering, specific damage status, suchas deformation displacement slump, surface subsidence, surface collapse, water and mud inrush in a Karst zone and the like, can be obviously observed. The apparatus can show the process of formation and movement of the underground engineering geological disasters.

Owner:SOUTHWEST PETROLEUM UNIV

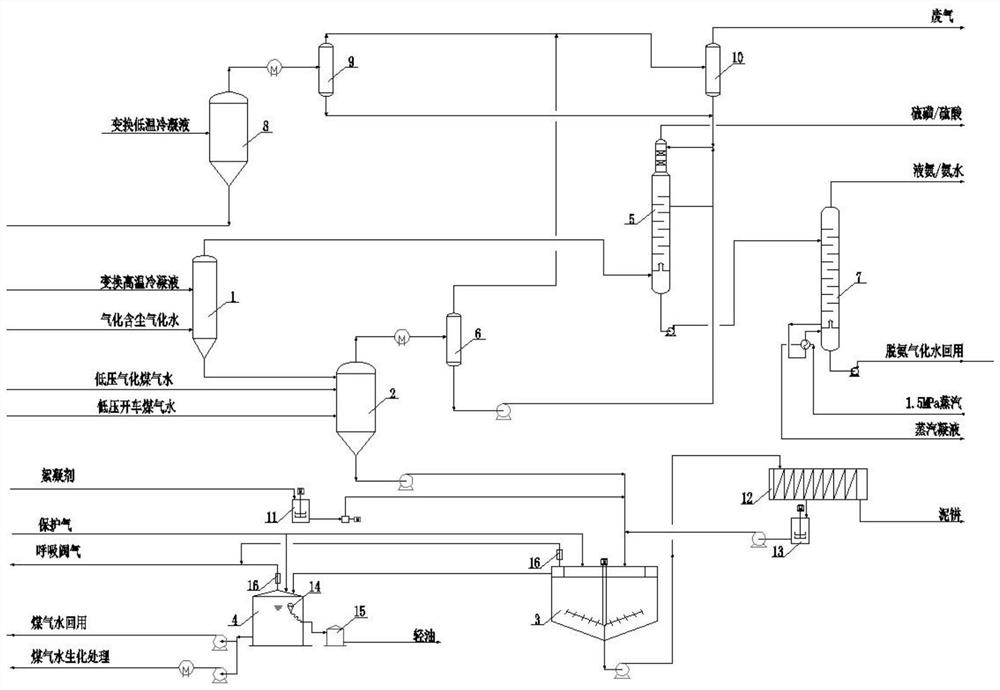

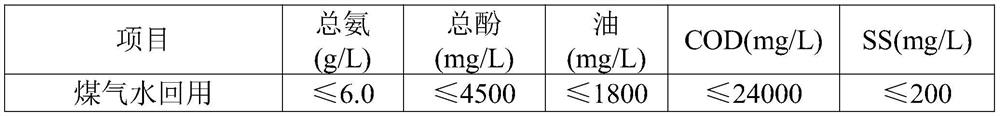

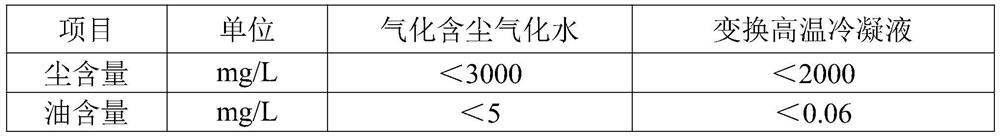

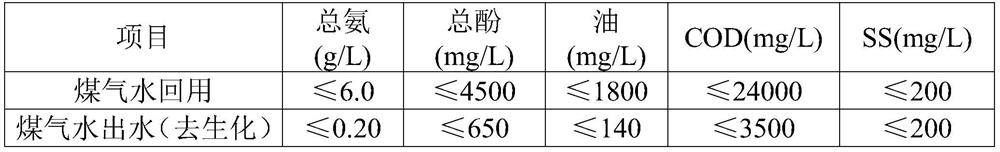

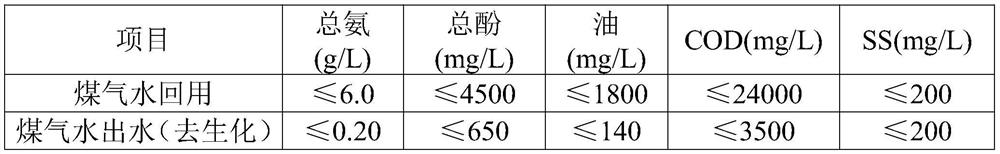

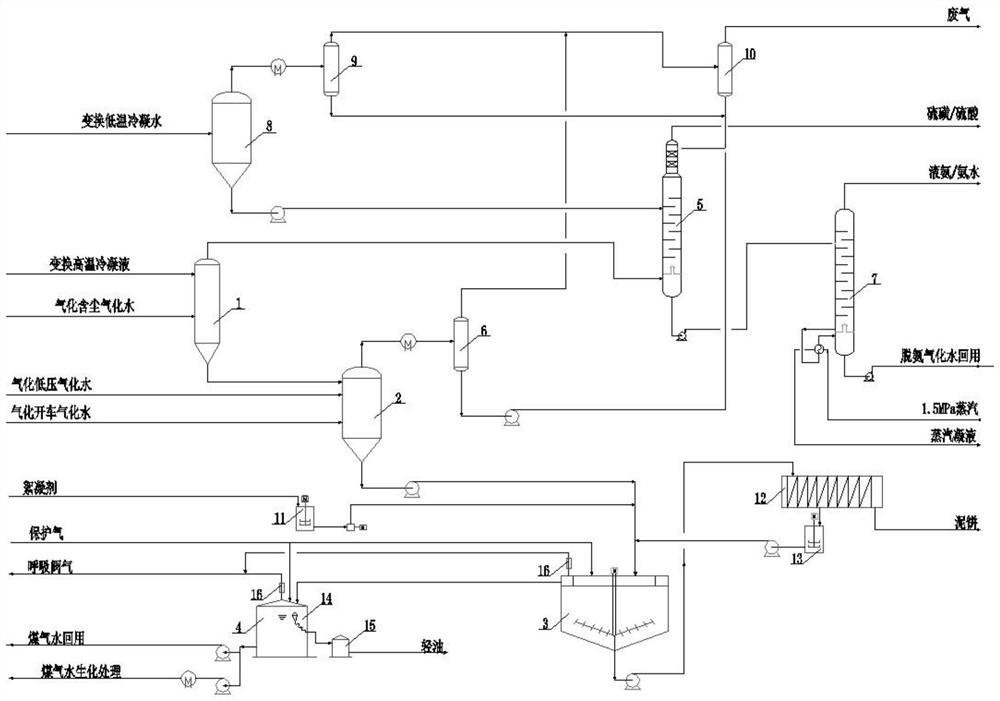

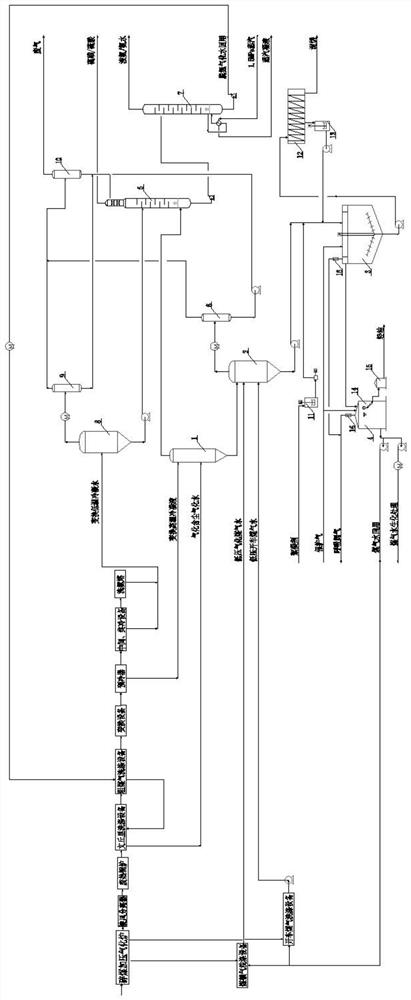

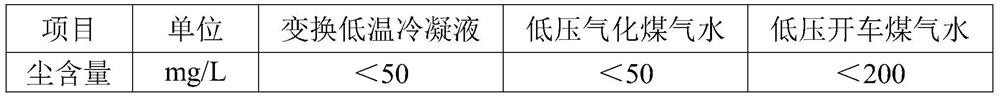

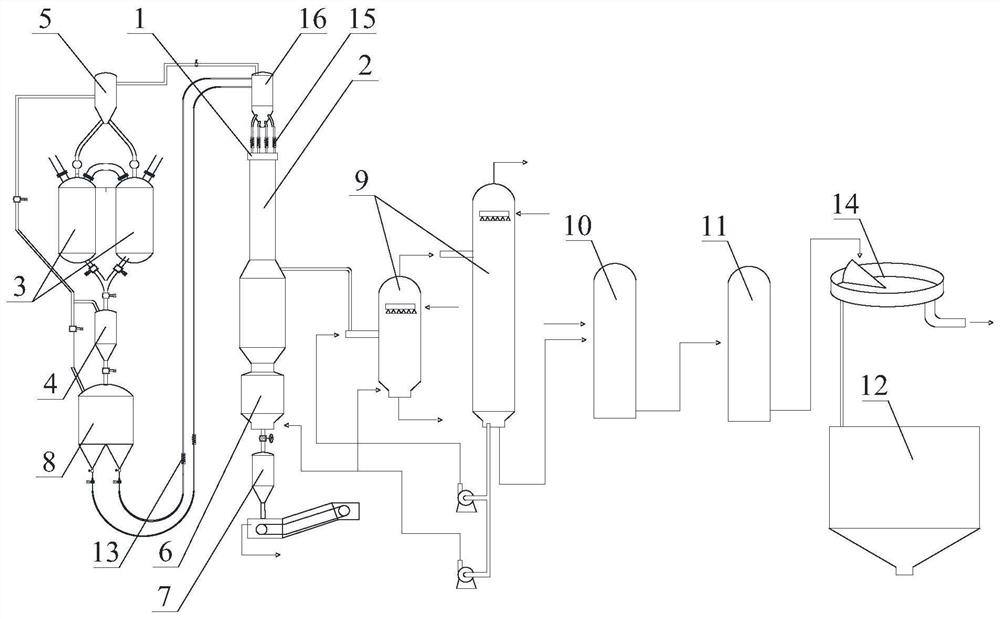

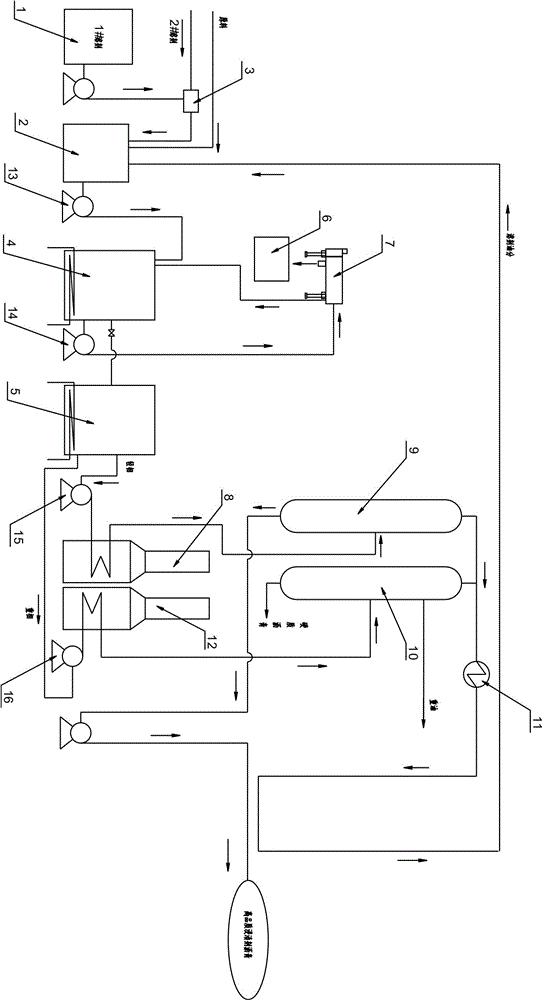

Crushed coal pressurized gasification gas-water separation and recycling system and method capable of recycling sewage

InactiveCN112408709ALess emissionsNot easy to cause pollutionSludge treatmentFatty/oily/floating substances removal devicesOutfallEngineering

The invention provides a crushed coal pressurized gasification gas-water separation and recycling system and method capable of recycling sewage, and belongs to the field of gas separation and recycling. According to the invention, different types of coal gas water are respectively separated and recycled, so that the whole system is small in occupied area, low in investment, low in operation cost,short in treatment flow, less in equipment, less in pollutant discharge points and not easy to cause environmental pollution. By arranging a medium-pressure flash evaporator, a vacuum flash evaporator, a vacuum flash separator, an ammonia distillation tower and other devices and arranging a settling tank and the top of a coal gas water tank to be connected with an inert gas pipeline in a sealed mode, the whole system and the separation and recycling process keep micro-positive-pressure operation larger than 0.2 kPa, and therefore it can be guaranteed that VOCs and odor exhausted from the system can be treated in a centralized mode. The water outlet of the second vacuum flash evaporator is connected with the water inlet of the heat exchanger connected with the waste heat boiler through thepipeline and the water pump, so that recycling of waste water is realized; therefore, the amount of waste water going to biochemical treatment equipment can be reduced, and heat in the waste water canbe fully utilized.

Owner:SEDIN ENG

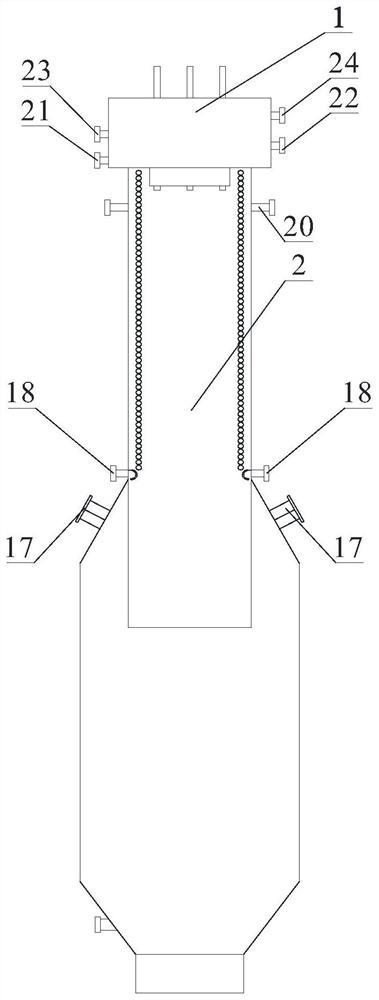

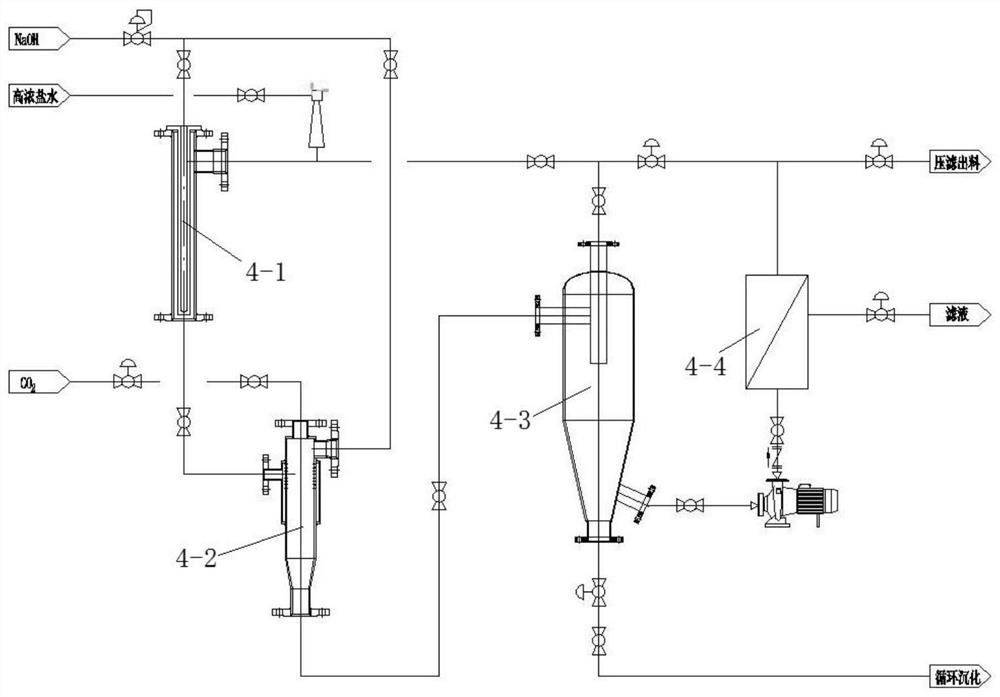

Entrained-flow coal gasification black ash water settling and dispersing system and black ash water settling method thereof

InactiveCN110665260AReduce dosageReduce usageTreatment involving filtrationSettling tanks feed/dischargeFlocculationBlackwater

The invention belongs to the technical field of entrained-flow coal gasification, and provides an entrained-flow coal gasification black ash water settling and dispersing system and a black ash watersettling method thereof in order to improve the settling efficiency of entrained-flow coal gasification black water. A primary flocculant adding device is that a flocculation tank I is connected witha mixer I through a flocculation pump I; a secondary flocculant adding device is that a flocculation tank II is connected with a mixer II through a flocculation pump II; the mixer I and the mixer II are connected with a black water pipeline of a settling tank, the bottom of the settling tank is connected with a drainage pump, and the top of the settling tank is connected with the water inlet of abaffling clarifier through an overflow weir; the bottom of the baffle clarifier is provided with a drain outlet, the top is provided with a drain pipe, and the end of the drain pipe is connected withan ash water tank; the baffle clarifier and the ash water tank are connected with a dispersant tank through a dispersant pump. By adding different kinds of flocculants in the two-stage device, the purpose of reducing the total dosage of chemicals on the one hand and better settling treatment effect on the black water on the other hand can be achieved.

Owner:SHANXI JINCHENG ANTHRACITE COAL MINING GRP CO LTD

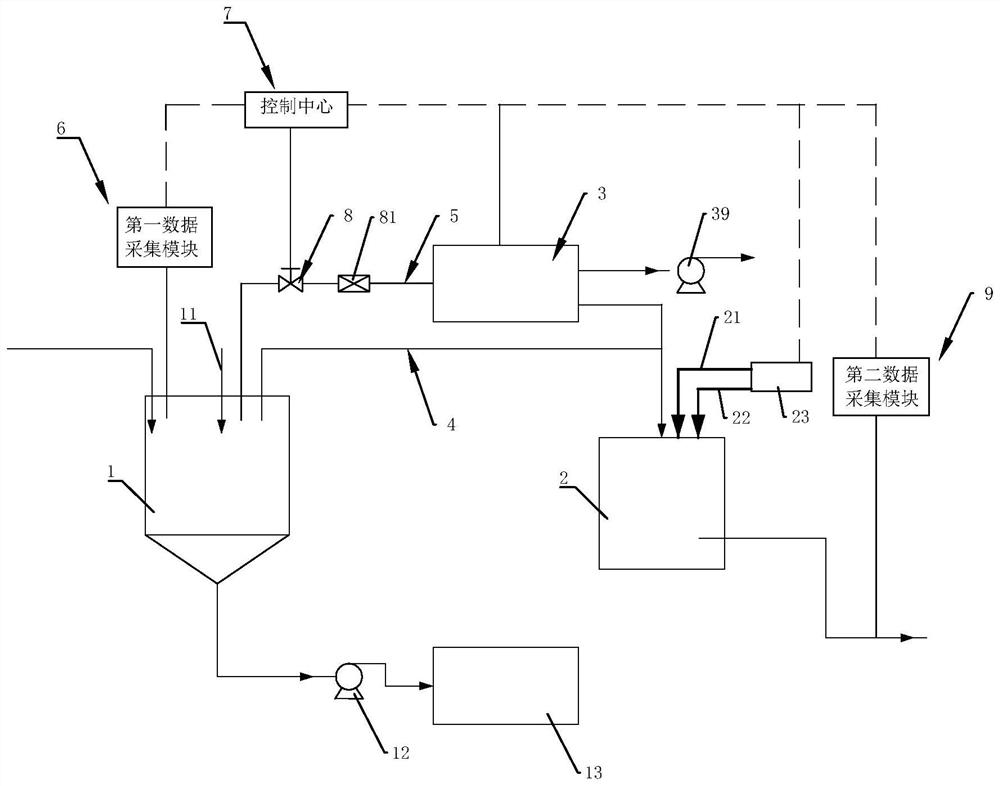

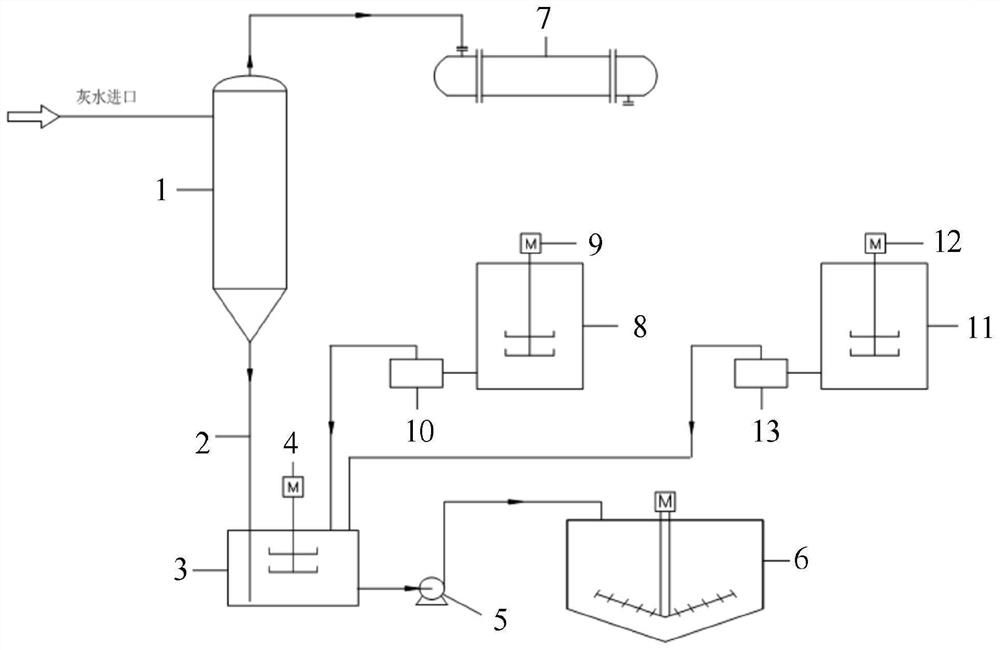

Automatic continuous dosing system for treating coal gasification black water

InactiveCN111762856AWater treatment parameter controlWater/sewage treatment by flocculation/precipitationEngineeringDrainage tubes

The invention discloses an automatic continuous dosing system for treating coal gasification black water. The system comprises a settling tank, a grey water tank and a dissolving tank, the settling tank is connected with a black water pipe, a flocculating agent dosing branch pipe is arranged on the black water pipe, the flocculating agent dosing branch pipe is connected with the dissolving tank, aconnecting pipe is arranged between the settling tank and the grey water tank, the grey water tank is connected with a dispersing agent dosing pipe, the bottom of the grey water tank is provided witha purified water pipe, and the purified water pipe is provided with two branches, namely an outer water drainage pipe and a recycled water pipe. In actual use, flow monitoring and online data signalanalysis are added to the whole dosing system, and detection signals are transmitted to a central control room, so that flow regulation and continuous and automatic dosing of a medicament can be ensured, and the treated water quality is ensured to meet the requirements of discharge and gasification cyclic utilization.

Owner:宁夏神耀科技有限责任公司

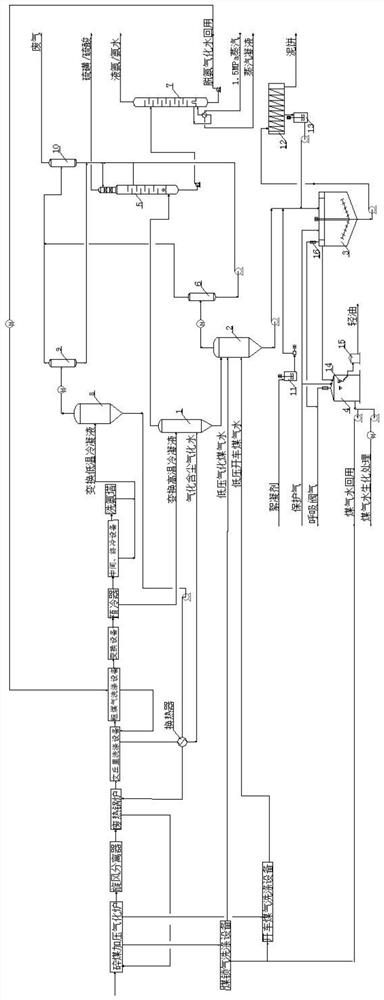

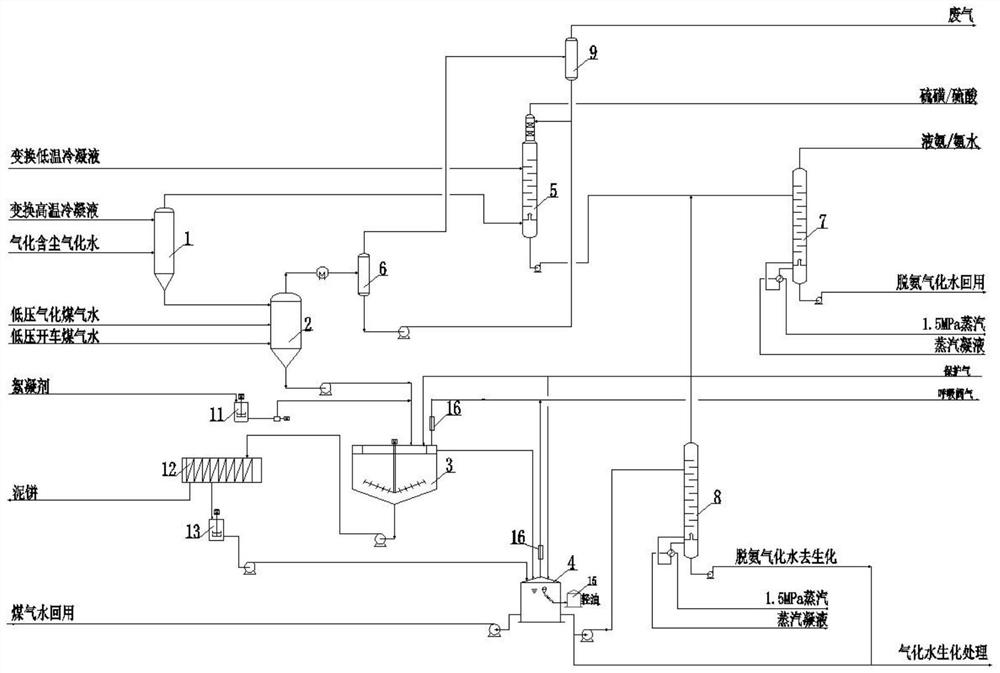

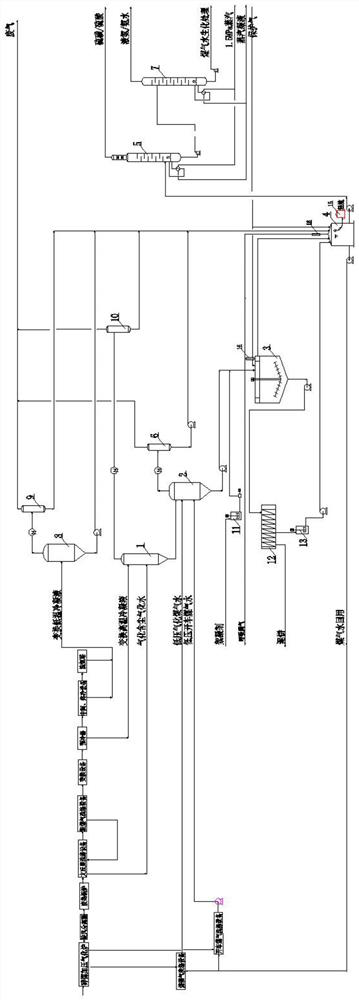

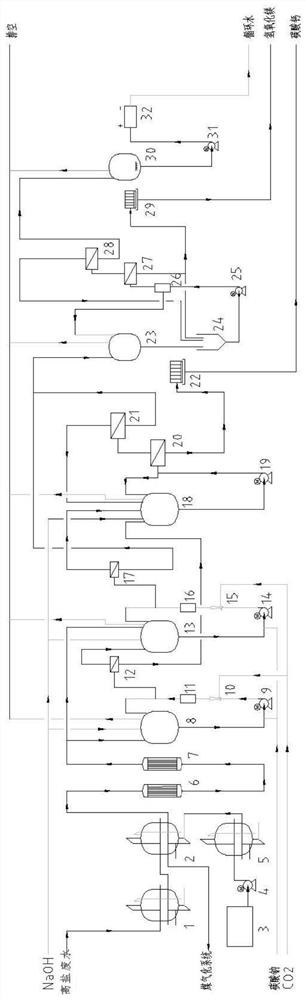

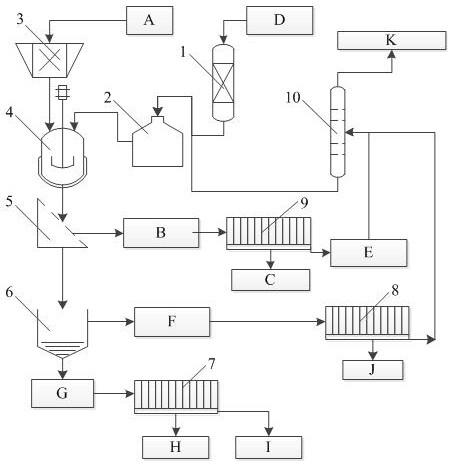

Crushed coal pressurized gasification gas-water separation and recycling system and method

PendingCN112299665ALow emission pointLess emissionsSludge treatmentFatty/oily/floating substances removal devicesPollutant emissionsProcess engineering

The invention provides a crushed coal pressurized gasification gas-water separation and recycling system and method, and belongs to the field of coal gas separation and recycling. According to the invention, different types of coal gas water are respectively separated and recycled, so that the whole system is small in occupied area, low in investment, low in operation cost, short in treatment flow, less in equipment, less in pollutant discharge points and not easy to cause environmental pollution. By arranging a medium-pressure flash evaporator, a vacuum flash evaporator, a vacuum flash separator, an ammonia distillation tower and other devices and arranging a settling tank and the top of a coal gas water tank to be connected with an inert gas pipeline in a sealed mode, and the whole system and the separation and recycling process keep micro-positive-pressure operation greater than 0.2 kPa, thereby being capable of guaranteeing that VOCs and odor exhausted from the system can be treated in a centralized mode. The coal gas water tank is connected with a second ammonia distillation tower, so that coal gas water going to biochemical treatment equipment can be completely or partially subjected to ammonia distillation through the ammonia distillation tower, and the problem that a biochemical system is difficult to operate stably due to change of different feed coals is solved.

Owner:SEDIN ENG

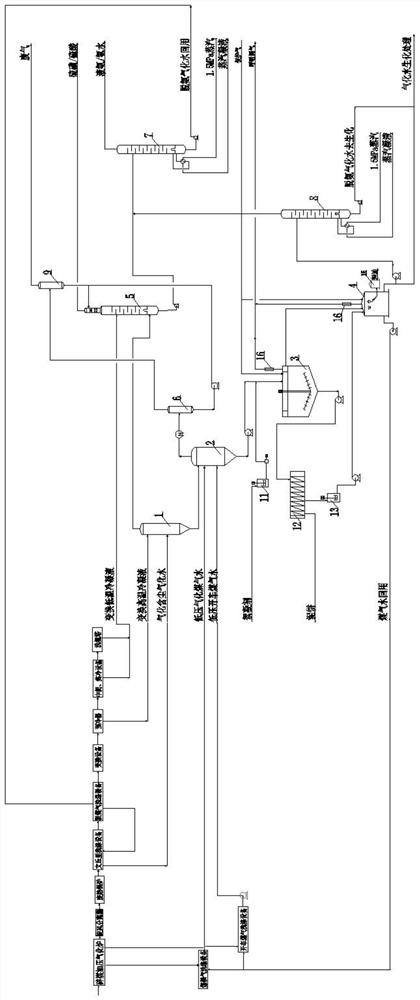

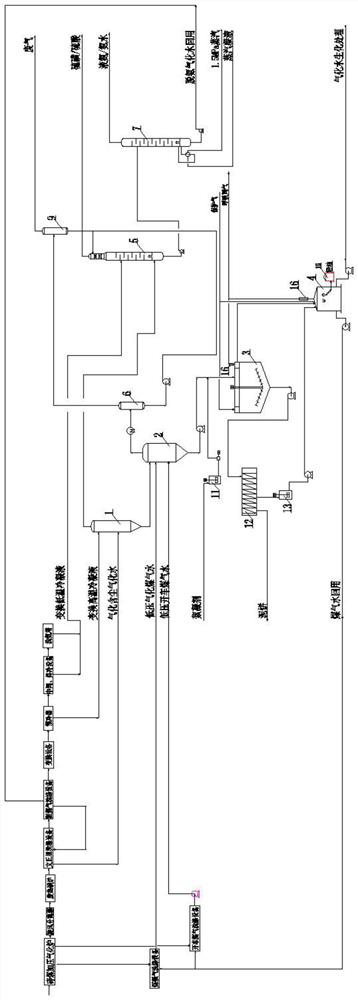

Crushed coal pressurized gasification gas-water separation and recycling system and method

PendingCN112299664ALow emission pointLess emissionsSludge treatmentFatty/oily/floating substances removal devicesPollutant emissionsProcess engineering

The invention provides a crushed coal pressurized gasification gas-water separation and recycling system and method, and belongs to the field of coal gas separation and recycling. According to the invention, different types of coal gas water are respectively separated and recycled, so that the whole system is small in occupied area, low in investment, low in operation cost, short in treatment flow, less in equipment, less in pollutant discharge points and not easy to cause environmental pollution. By arranging a medium-pressure flash evaporator, a vacuum flash evaporator, a vacuum flash separator, an ammonia distillation tower and the like and arranging a settling tank and the top of a coal gas water tank to be connected with an inert gas pipeline, and the whole system and the separation and recycling process keep micro-positive pressure operation greater than 0.2 kPa, thereby being capable of guaranteeing that VOCs and odor exhausted from the system can be treated in a centralized mode. The coal gas water treated by a deacidification tower is fed into the ammonia distillation tower, so that the coal gas water going to the biochemical treatment equipment can be subjected to ammoniadistillation, the ammonia content in the coal gas water going to the biochemical treatment equipment can be reduced, and the problem that a biochemical system is difficult to operate stably due to change of different feed coals is solved.

Owner:SEDIN ENG

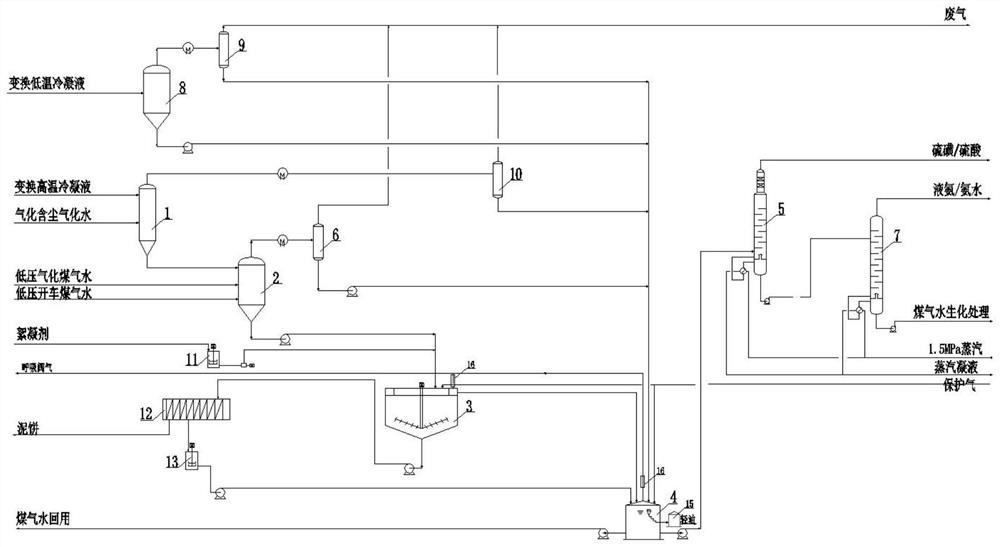

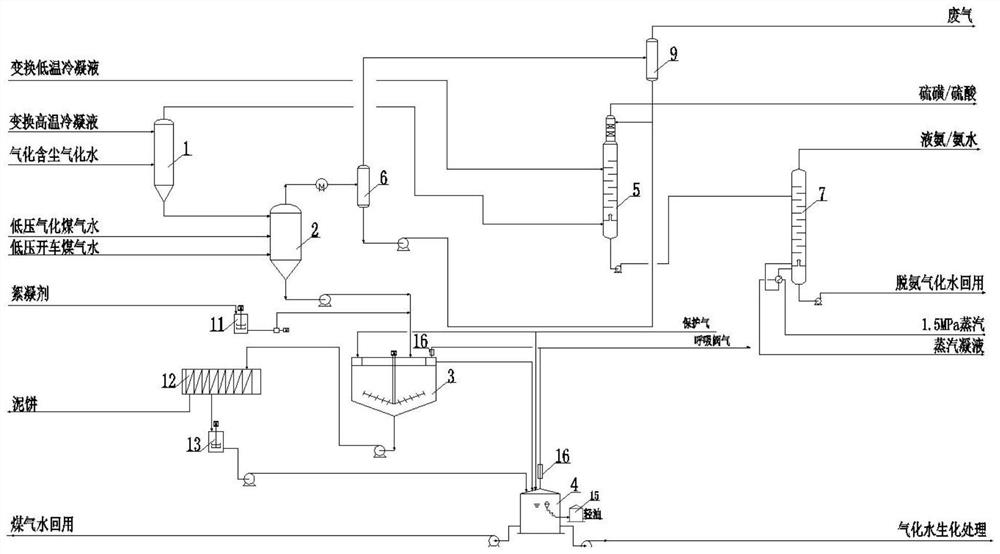

Simple crushed coal pressurized gasification gas-water separation and recycling system and method

InactiveCN112299666ALow emission pointLess emissionsSludge treatmentFatty/oily/floating substances removal devicesPollutant emissionsProcess engineering

The invention provides a simple crushed coal pressurized gasification gas-water separation and recycling system and method, and belongs to the field of coal gas separation and recycling. According tothe invention, different types of coal gas water are respectively separated and recycled, so that the whole system is small in occupied area, low in investment, low in operation cost, short in treatment flow, less in equipment, less in pollutant discharge points and not easy to cause environmental pollution. By arranging a medium-pressure flash evaporator, a vacuum flash evaporator, a vacuum flashseparator, an ammonia distillation tower and other devices and arranging a settling tank and the top of a coal gas water tank to be connected with an inert gas pipeline in a sealed mode, the whole system and the separation and recycling process keep micro-positive-pressure operation greater than 0.2 kPa, thereby being capable of guaranteeing that VOCs and odor exhausted from the system can be treated in a centralized mode. The whole system uses less and simple equipment, so that the whole system is safe and stable in operation, and the gas water treatment cost can be effectively reduced.

Owner:SEDIN ENG

Crushed coal pressurized gasification gas-water separation and recycling system and method

InactiveCN112299667ALow emission pointLess emissionsSludge treatmentFatty/oily/floating substances removal devicesPollutant emissionsProcess engineering

The invention provides a crushed coal pressurized gasification gas-water separation and recycling system and method, and belongs to the field of gas separation and recycling. According to the invention, different types of coal gas water are respectively separated and recycled, so that the whole system is small in occupied area, low in investment, low in operation cost, short in treatment flow, less in equipment, less in pollutant discharge points and not easy to cause environmental pollution. By arranging a medium-pressure flash evaporator, a vacuum flash evaporator, a vacuum flash separator,an ammonia distillation tower and other devices and arranging a settling tank and the top of a coal gas water tank to be connected with an inert gas pipeline in a sealed mode, the whole system and theseparation and recycling process keep micro-positive-pressure operation larger than 0.2 kPa, and therefore it can be guaranteed that VOCs and odor exhausted from the system can be treated in a centralized mode.

Owner:SEDIN ENG

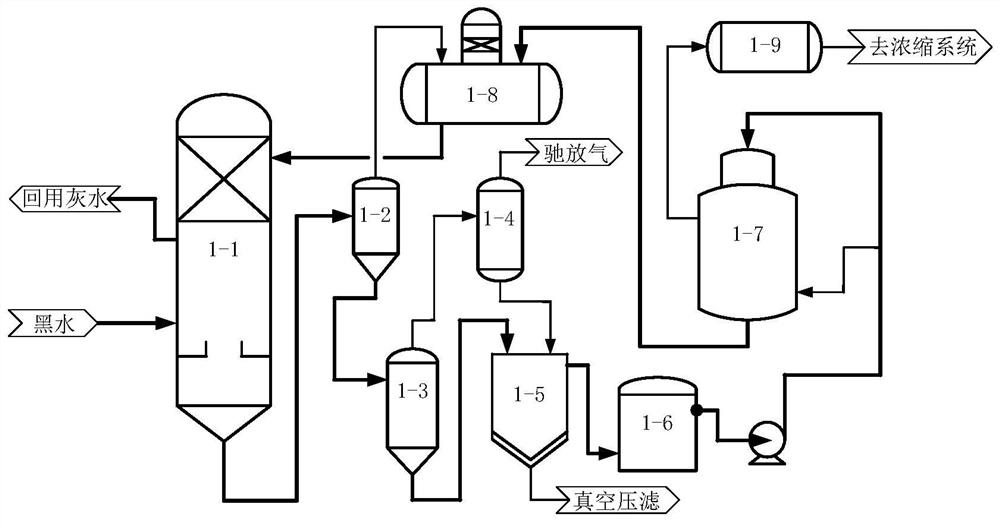

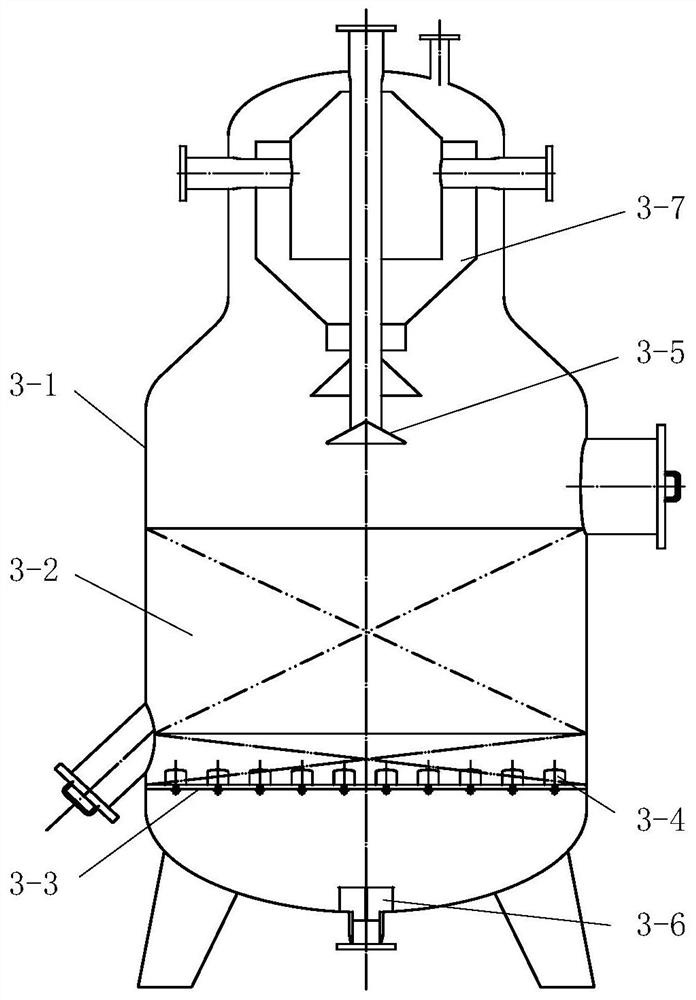

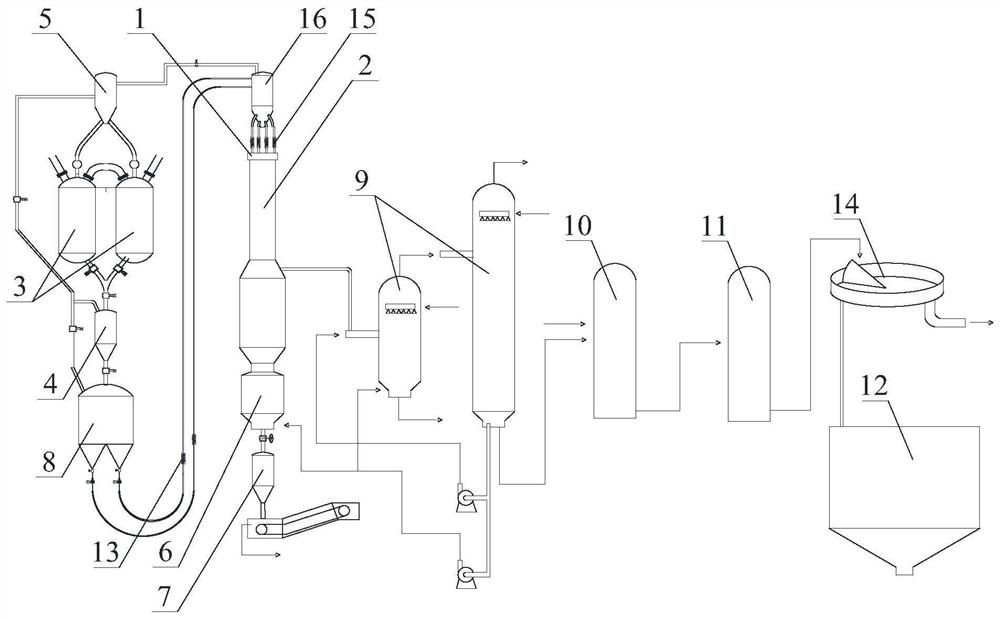

Flash evaporation-sedimentation-fluidized bed separation combined purification method and device for coal gasification black water

PendingCN112624472AMake up for the problem of insufficient separation efficiencySolve the problem of deep purificationTreatment involving filtrationMultistage water/sewage treatmentFine particulateDeaerator

The invention relates to a flash evaporation-sedimentation-fluidized bed separation combined purification method and device for coal gasification black water. The flash evaporation-sedimentation-fluidized bed separation combined purification method for the coal gasification black water comprises the following steps: (i) carrying out flash evaporation treatment on the coal gasification black water; (ii) feeding the coal gasification black water having been subjected to flash evaporation treatment into a sedimentation tank, conducting sedimentation and separating, feeding bottom concentrated suspended matters into a vacuum filter pressing system, and feeding a supernatant of the sedimentation tank, namely coal gasification ash water, into an ash water tank; (iii) pumping the coal gasification ash water out of the ash water tank, and sending the coal gasification ash water to a fluidized bed separator to deeply remove fine particles in the coal gasification ash water; (iv) sending the coal gasification ash water purified by the fluidized bed separator to a deaerator for deoxygenation; and (v) after the fluidized bed separator is operated for a period of time and a pressure difference is 0.3 MPa, mixing the coal gasification ash water and nitrogen, and reversely feeding the obtained mixture to regenerate a separation medium of the fluidized bed separator. The invention further provides the flash evaporation-sedimentation-fluidized bed separation combined purification device for coal gasification black water.

Owner:EAST CHINA UNIV OF SCI & TECH

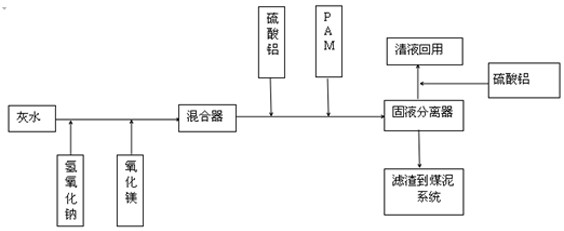

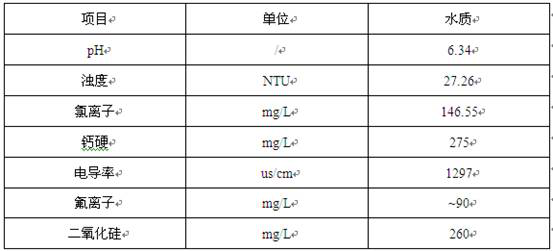

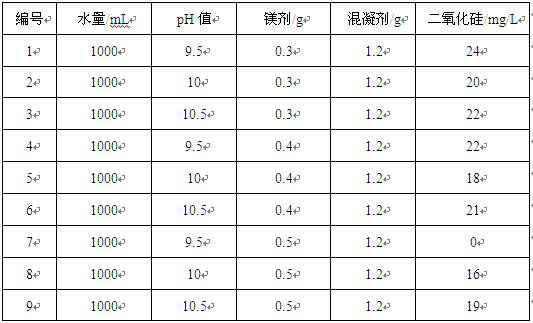

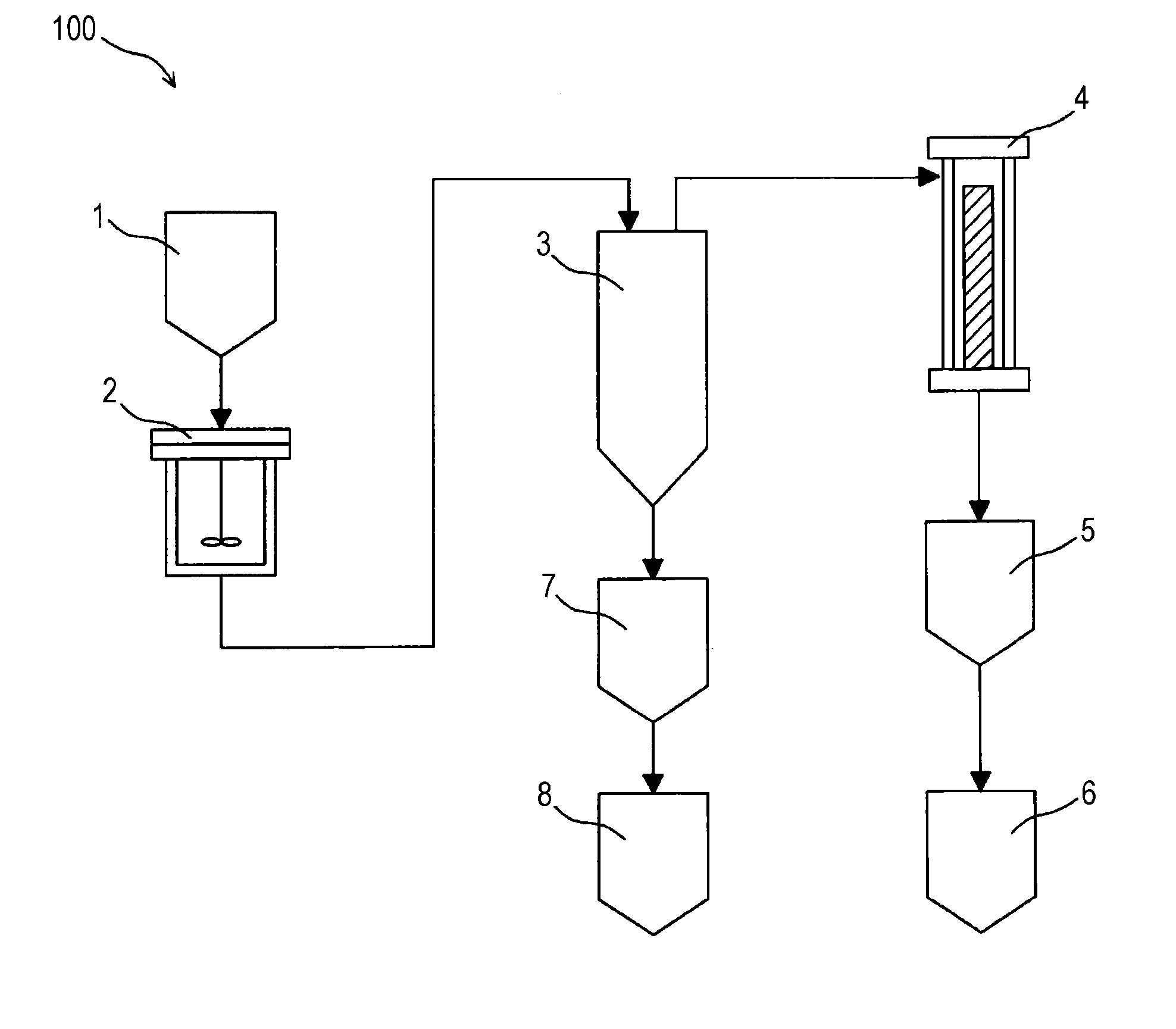

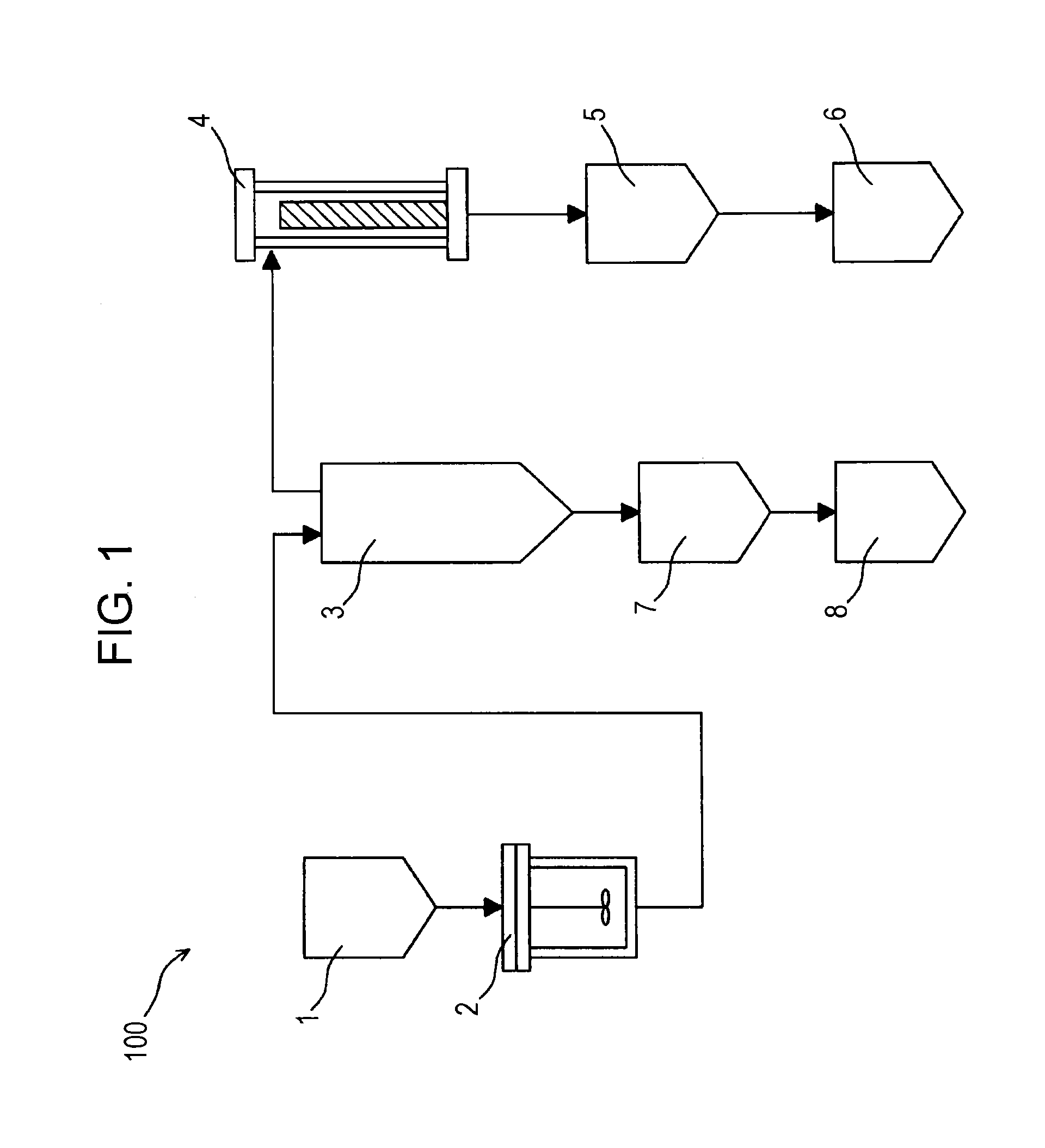

Silicon removal method for wastewater discharged by aerospace furnace gasification process

PendingCN112573708AEfficient removalReducing processing costs requiresMultistage water/sewage treatmentWater/sewage treatment by neutralisationWater useSludge

The invention relates to a silicon removal method for wastewater discharged by an aerospace furnace gasification process, belongs to the technical field of coal liquefaction sewage treatment, and solves the problem that the total silicon of the wastewater discharged by the aerospace furnace gasification process in the prior art does not reach the standard and the long-period operation of a systemcannot be ensured. A method combining magnesium agent silicon removal, aluminum salt coagulation and a solid-liquid separator is adopted, under the conditions that the sludge discharge amount is reduced and a settling tank with a large occupied area is not used, soluble silicon dioxide and part of colloidal silicon in water are effectively removed, and the concentration of silicon dioxide in recycled water is controlled to be 20 mg / L. The method is obvious in effect, simple in technological process, small in occupied area and convenient and reliable to control, the requirement of industrial enterprises for reducing the sewage treatment cost can be met, silicon dioxide influencing long-period operation of the system is effectively removed, and the requirements of environmental protection, production and operation of the enterprises are met.

Owner:SHANXI JINCHENG ANTHRACITE COAL MINING GRP CO LTD

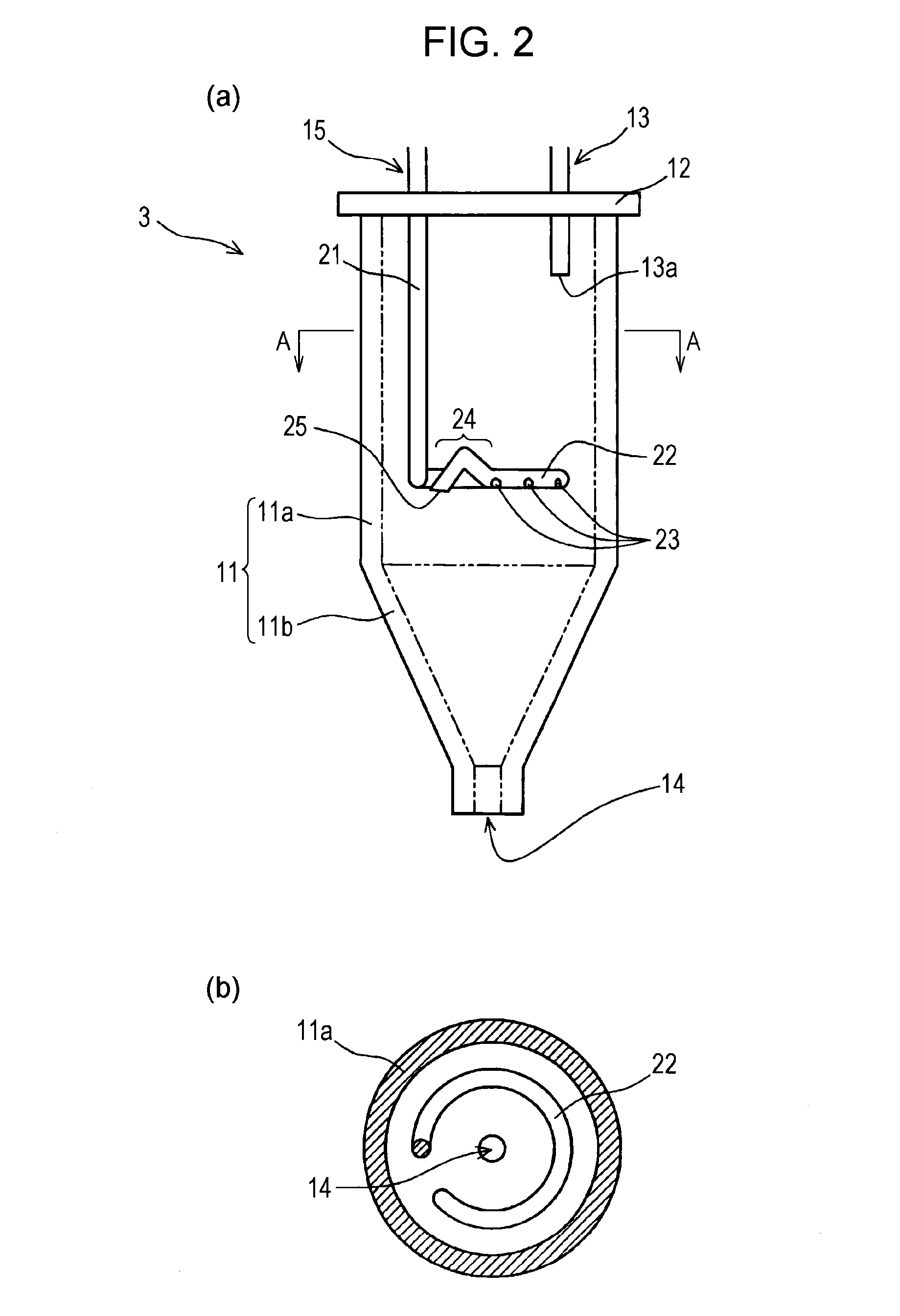

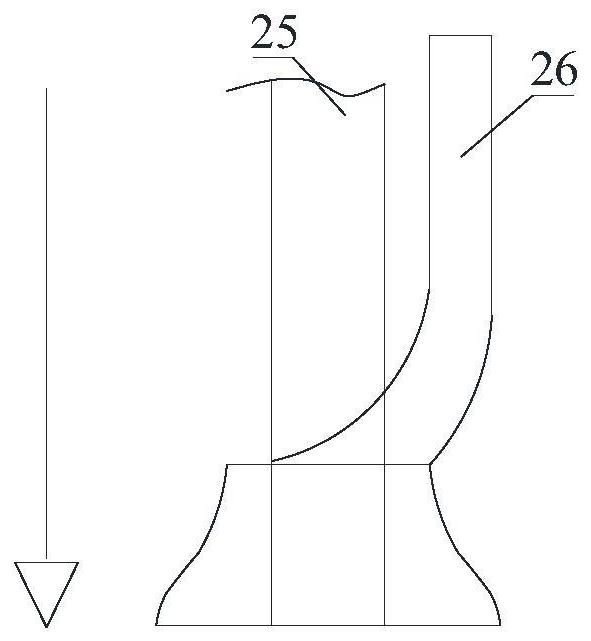

Gravitational settling tank and method for producing ash-free coal

ActiveUS20140115957A1Avoid agitationEfficient productionSettling tanks feed/dischargeSolid fuelsSolid componentSlurry

A gravitational settling tank including a pressure vessel which precipitates solid content contained in slurry in which coal and solvent are blended, and separates the solid-content concentrated liquid from the supernatant liquid, and a supply pipe which supplies the pressure vessel with the slurry. A main body part and a nozzle part which is connected on the downstream side of the main body part and extends horizontally are provided in the supply pipe. A plurality of holes are provided in the nozzle part. By virtue of this, agitation of the solid-content concentrated liquid which has settled in the bottom is inhibited.

Owner:KOBE STEEL LTD

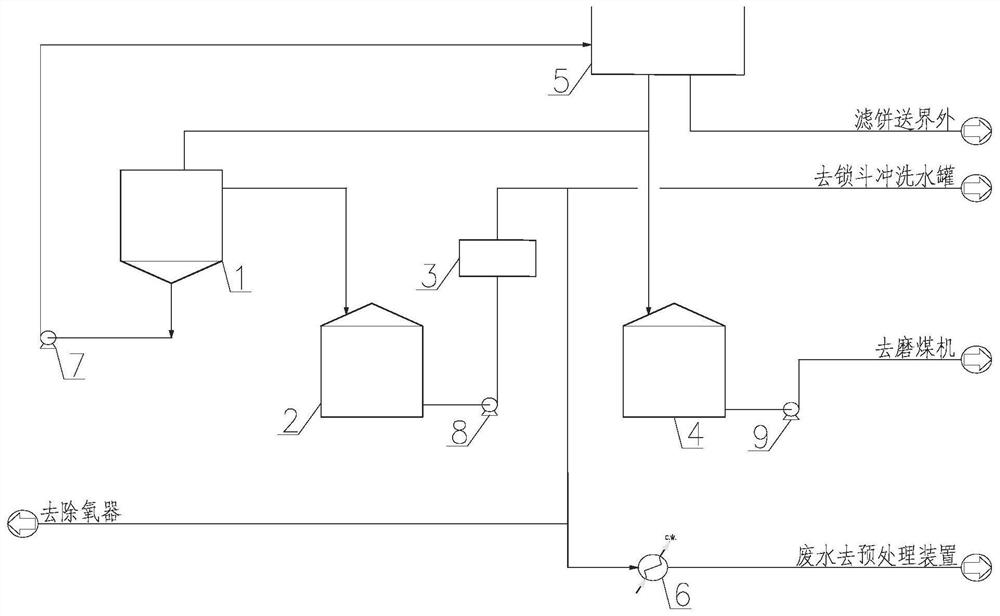

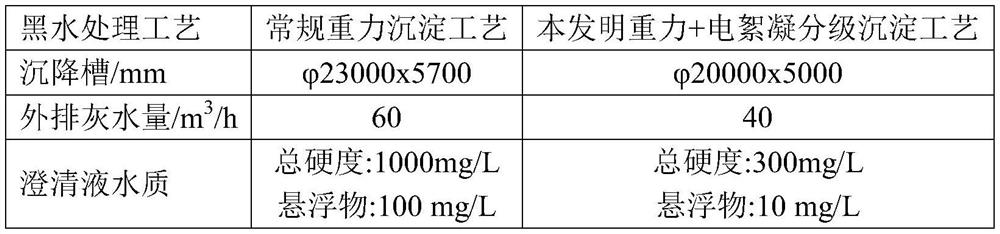

Coal gasification ash water treatment process and equipment

PendingCN112479445ASmall sizeReduce hardnessWater treatment parameter controlSludge treatmentElectro flocculationSuspended matter

The invention relates to a coal gasification ash water treatment process and equipment. Firstly, black water generated by coal gasification firstly enters a settling tank for coarse separation to achieve the purpose of removing most suspended matter, and clear liquid of the settling tank is pumped to electric flocculation integrated equipment by using an ash water pump for fine separation. Al<3+>or Fe<2+> obtained by ionizing of an iron plate or an aluminum plate and OH<-> generated by a cathode plate are complexed to generate a high-activity hydroxyl complex, suspended matter and calcium andmagnesium ions in the ash water are subjected to hardness removal treatment, meanwhile, the suspended matter in clarified liquid can be removed, the removal rate of the calcium and magnesium ions inthe ash water passing through the electric flocculation integrated equipment can reach 70% or above, and the removal rate of the suspended matter can reach 99% or more. Due to the fact that the waterquality of the ash water passing through the electric flocculation integrated equipment is improved, on one hand, the amount of discharged ash water can be reduced, and on the other hand, due to the fact that the hardness and the suspended matter of the ash water returned to the system are reduced, the risk of scaling of the equipment and pipelines can be reduced, and the operation safety of the device is improved.

Owner:SINOPEC NINGBO ENG +2

Coal water slurry gasification system and coal water slurry gasification process based on phase-change-free heat exchange and black water heating

InactiveCN109054904ASolve the problem that latent heat cannot be recycledTake advantage ofChemical industryGranular/pulverulent flues gasificationEnergy recoveryEngineering

The invention discloses a coal water slurry gasification system. The coal water slurry gasification system comprises a gasification furnace, a washing tower, an ash water tank, a sedimentation tank, afirst coal water slurry / black water heat exchanger and a second coal water slurry / black water heat exchanger; the gasification furnace, the washing tower, the ash water tank and the sedimentation tank are sequentially arranged and connected through pipelines; the black water input end of the first coal water slurry / black water heat exchanger is connected with the black water output ends of the gasification furnace and the washing tower; the black water input end of the second coal water slurry / black water heat exchanger is connected with the black water output end of the first coal water slurry / black water heat exchanger; the black water output end of the second coal water slurry / black water heat exchanger is connected with the black water input end of the sedimentation tank. The coal water slurry gasification system has the advantages that high-temperature black water from the gasification furnace and the washing tower preheats and heats coal water slurry through the second coal water slurry / black water heat exchanger and the first coal water slurry / black water heat exchanger for two-time heat exchange, no phase change exists, low-grade heat energy can be recovered, and the energy recovery efficiency is greatly improved; complex flashing systems are omitted, and the equipment investment cost is reduced.

Owner:KUNSHAN UNITED ENERGY TECH CO LTD

Device and method for producing synthetic gas by multi-nozzle gasification furnace

ActiveCN112708470AIncrease temperatureTreatment involving filtrationGasification processes detailsHeat fluxSlag

The invention discloses a device and a method for producing synthetic gas by a multi-nozzle gasification furnace. The device sequentially comprises a normal-pressure pulverized coal storage tank, a lock hopper and a feeding tank. A buffer tank and a spiral conveyor are sequentially connected between a discharging pipe at the bottom of the feeding tank and a burner. The spiral conveyor is sequentially connected with the burner and a gasification furnace. The gasification furnace is respectively connected with a water scrubber and a slag breaker. The bottom of the slag breaker is connected with a slag lock hopper. The water scrubber is sequentially connected with a high-pressure flash tank and a vacuum flash tank. The vacuum flash tank is connected with a tilting pan filter, and the tilting pan filter is connected with a settling tank. The pulverized coal heat can be concentrated, the pulverized coal flow can be quantitatively controlled, the pulverized coal conveying amount is increased, meanwhile, the heat flux and the combustion temperature are higher, and the water carrying amount of synthetic gas is effectively reduced.

Owner:HUAYANG NEW MATERIAL TECH GRP CO LTD +1

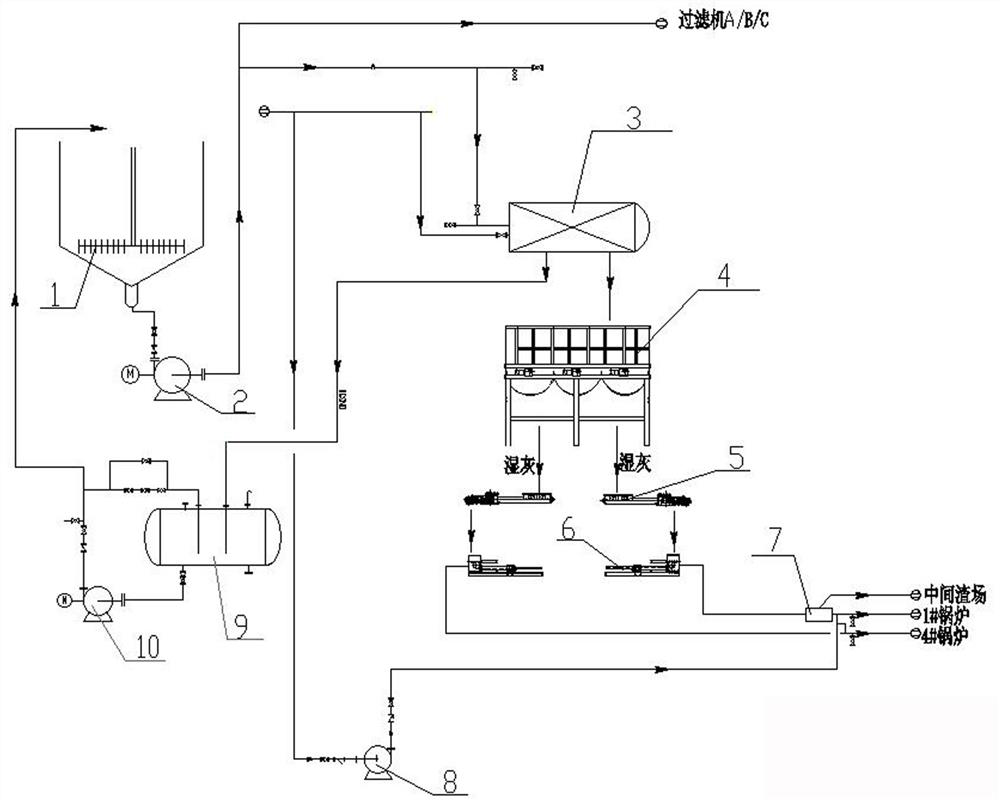

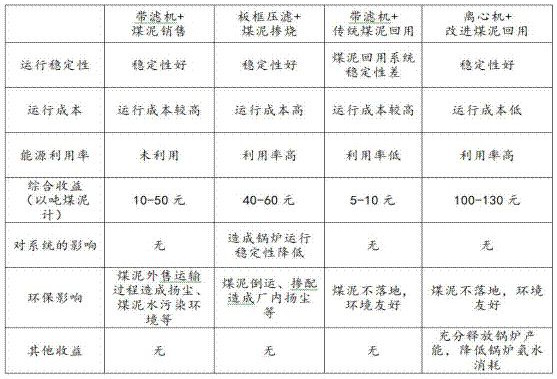

Comprehensive recycling process for gasification fine slag

PendingCN113562809AImprove the state of combustionTake advantage ofWater/sewage treatment by centrifugal separationTreatment involving filtrationWet ashingCombustion

The invention discloses a comprehensive recycling process for gasification fine slag. The process comprises the following steps: firstly, high-solid-content black water of gasification fine slag is conveyed to a centrifugal machine from a settling tank through a settling tank underflow pump for solid-liquid separation, enters a wet ash conveying system after being discharged from the centrifugal machine, falls into a stirring bin and is stirred; then the ash is conveyed to a spiral feeder after passing through a hydraulic gate valve control outlet; and finally, after being pressurized by a wet ash conveying pump, the wet ash is conveyed to a composite coal slime pipeline and then is conveyed to a boiler for blending combustion and utilization; filtrate of the centrifugal machine flows into a filtrate tank by itself, and the filtrate in the filtrate tank is conveyed back to the settling tank by a filtrate pump through a pipeline. The process solves the problems of low utilization rate, high recovery cost and environmental pollution of the existing gasification fine slag. The horizontal spiral centrifugal machine and a coal slime pump are combined, feeding is conducted in a dense-phase area of the boiler, efficient and clean comprehensive recycling of gasification fine slag is achieved, and meanwhile low-nitrogen combustion of the boiler is achieved.

Owner:晋能控股装备制造集团华昱能源化工山西有限责任公司

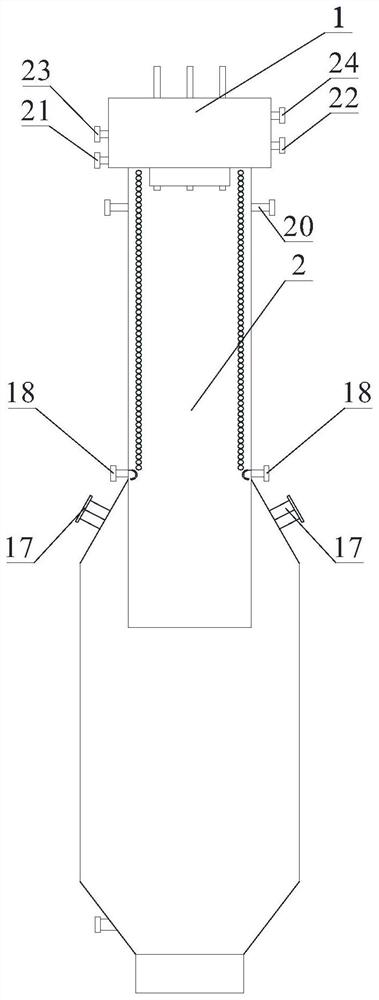

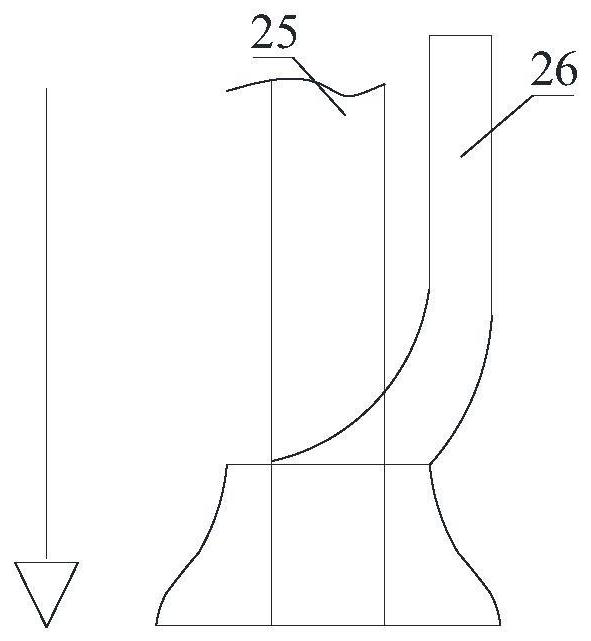

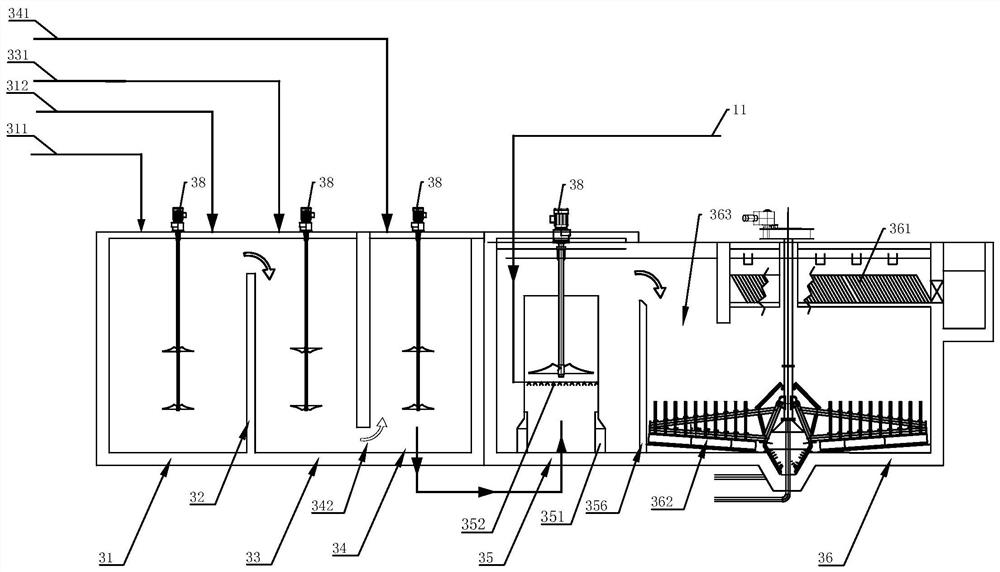

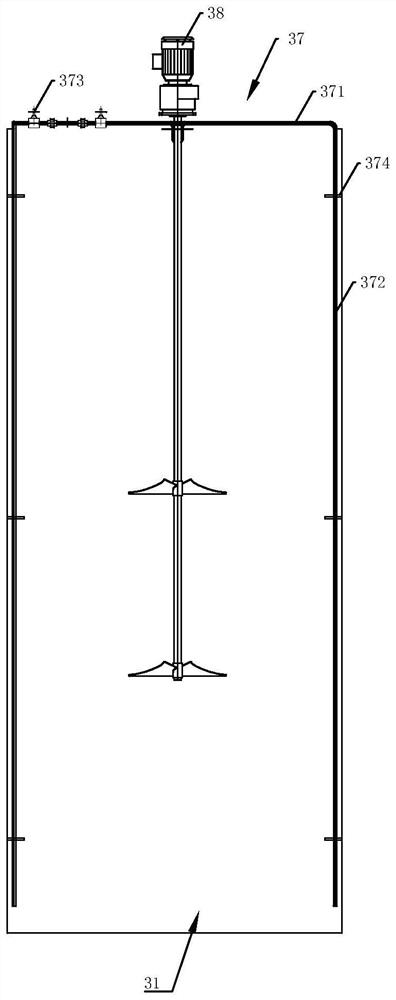

Multi-stage sedimentation rake-free concentration device comprising layer-drop diversion sedimentation screen

ActiveCN110935205AAchieving step-by-step settlingAchieve enrichmentSludge treatment by de-watering/drying/thickeningSettling tanks feed/dischargeSprayerWater flow

The invention relates to a multi-stage sedimentation rake-free concentration device comprising a layer-drop diversion sedimentation screen. The device comprises a central tank body, a diversion settling area is arranged on the outer side of the central tank body, the diversion settling area comprises a layer-drop diversion sedimentation screen and a magnetism gathering sprayer, the layer-drop diversion sedimentation screen comprises a plurality of third diversion settling subgroups which are sequentially arranged downwards along the outer wall of the central tank body, in every two adjacent settling tanks, slime water flowing out from the settling tank at the upper portion is flown into the settling tank at the lower portion, each third diversion settling subgroup comprises a settling tank, the bottom plates of the settling tanks are provided with third underflow discharge ports for discharging settled fine coal slime, and completely settled water is output from a third overflow discharge pipe at the output end of the bottommost third diversion settling subgroup. According to the invention, the diversion settling area uses the layer-drop diversion sedimentation screen and sequentially passes through all the third diversion settling subgroups, so that step-by-step settling is achieved, fine coal slime and settled water are discharged from different pipes, and concentration is achieved.

Owner:ANHUI UNIV OF SCI & TECH

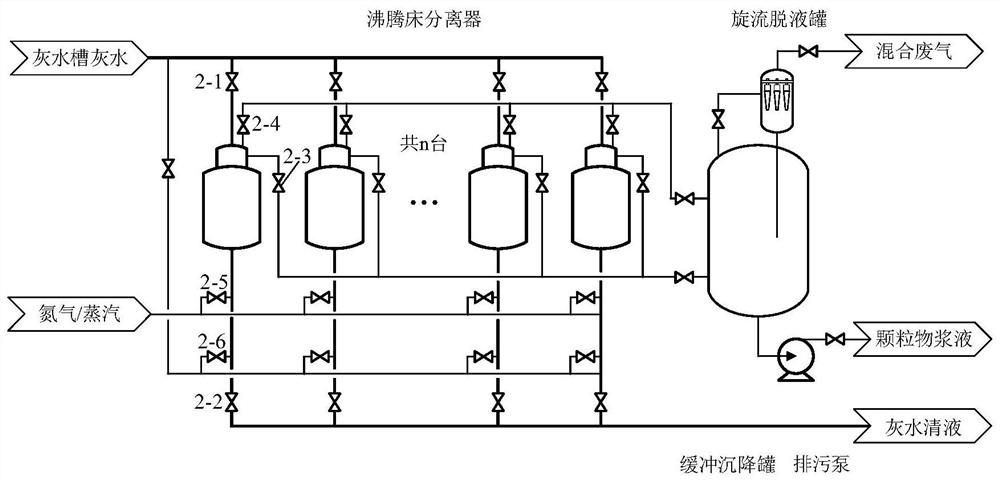

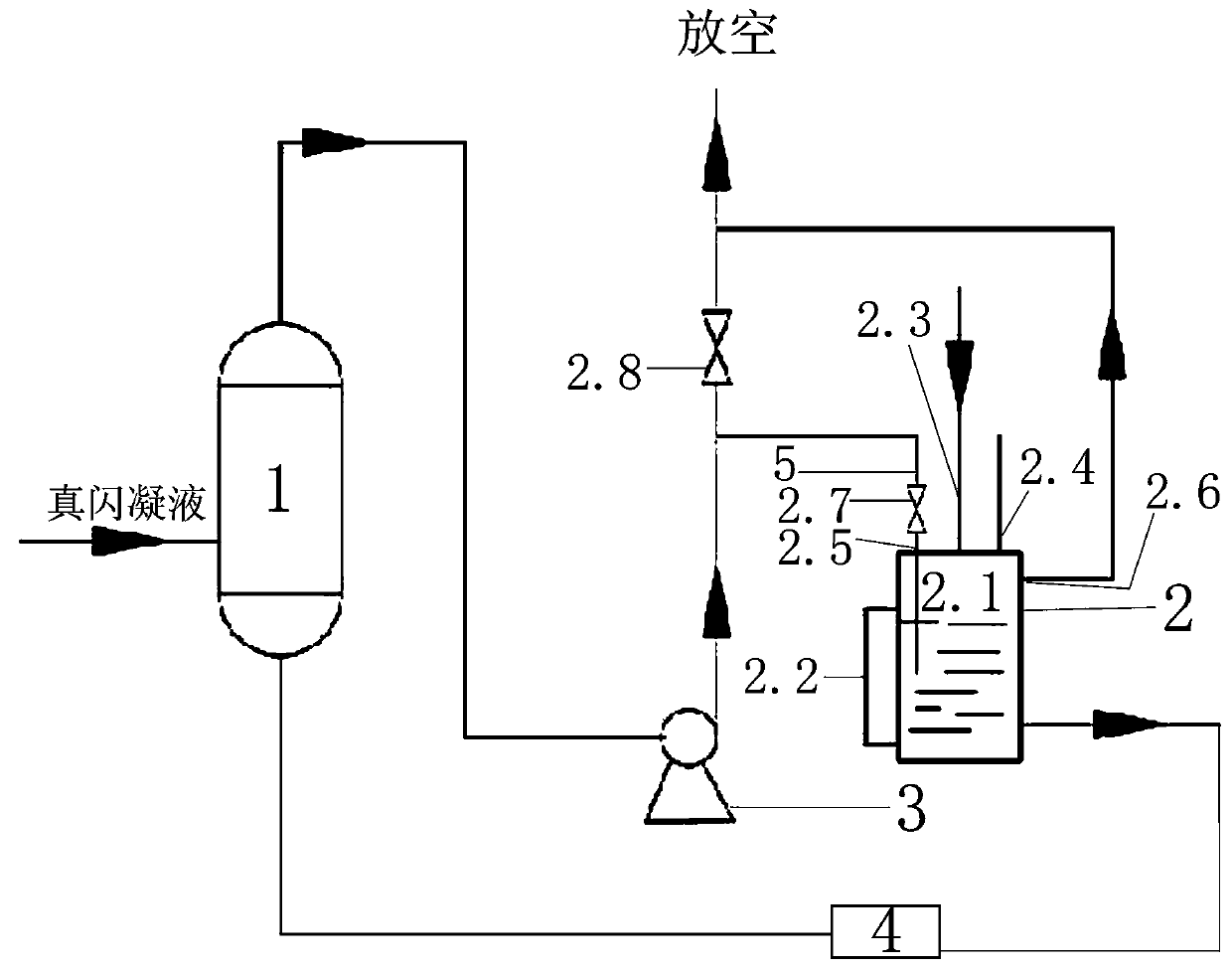

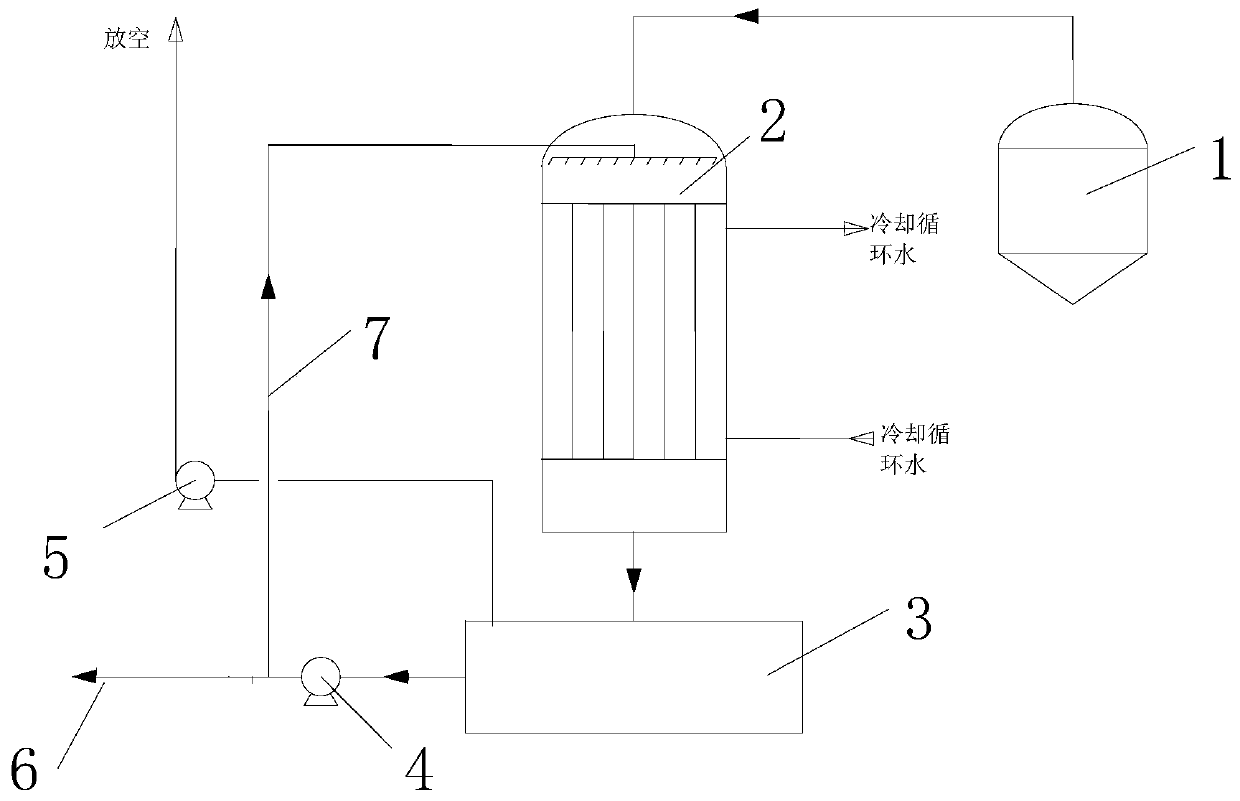

Entrained-flow bed coal gasification flashing noncondensable gas purification system and method

InactiveCN110760341AEliminate the surrounding odorGeneral water supply conservationDispersed particle separationSubsidence troughVacuum pump

The invention belongs to the technical field of coal gasification of entrained-flow beds, and provides an entrained-flow bed coal gasification flashing noncondensable gas absorption and purification system and method in order to improve the environment, purify and treat noncondensable gas in the production and operation processes of coal gasification of an entrained-flow bed, and prevent environmental pollution. A vacuum flashing separation tank is connected with an absorption device through a vacuum pump; the bottom of the vacuum flashing separation tank is connected with a subsider, and thetop of the vacuum flashing separation tank is connected with the vacuum pump; the other end of the vacuum pump is connected with the absorption device; as for the absorption device, the bottom of an absorption tank is connected with the subsider, a level meter is mounted on the side wall of the lower part of the absorption tank, the top of the absorption tank is provided with a desalted water inlet, a caustic soda flake adding opening and a noncondensable gas inlet, and the side wall of the upper part of the absorption tank is provided with a noncondensable gas exhaust opening; and the noncondensable gas inlet is connected with an outlet of the vacuum pump through a gas inlet pipe, a pipe opening of the gas inlet pipe is inserted below the liquid surface in the absorption tank, a noncondensable gas discharging valve is arranged at the position, on the noncondensable gas inlet, of the gas inlet pipe, the gas inlet pipe extends outwards to be provided with a blow-down pipeline, and a noncondensable gas blow-down valve is arranged between the gas inlet pipe and the blow-down pipeline. The effect of removing unpleasant odors around a factory is achieved.

Owner:SHANXI JINCHENG ANTHRACITE COAL MINING GRP CO LTD

Coal gasification black grey water treatment method and system

PendingCN111995114AReduce addReduce maintenanceWater treatment parameter controlWater contaminantsGreywaterPollution

Owner:北京翰祺环境技术有限公司

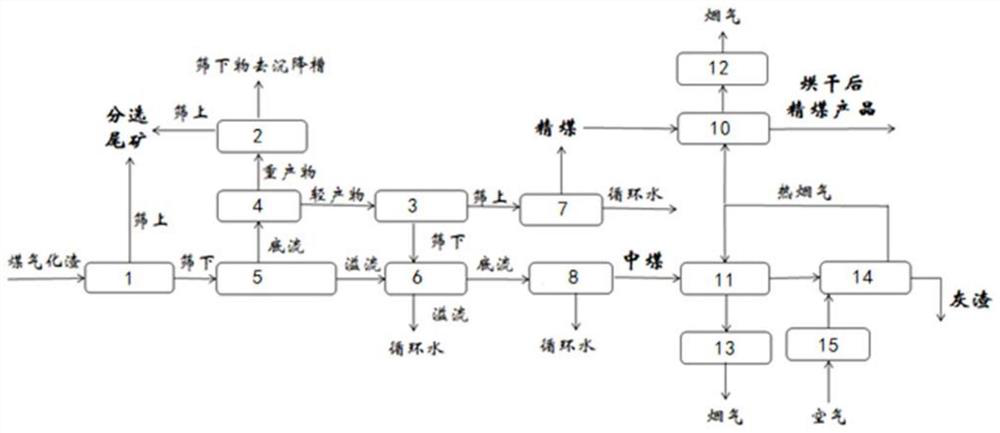

Self-drying quality-divided utilization system and method for coal gasification slag

PendingCN114849895AImplement hierarchical extractionReduce landfillTransportation and packagingVortex flow apparatusSlagProcess engineering

The invention discloses a coal gasification slag self-drying quality-divided utilization system and method, and the method comprises the steps: carrying out preliminary separation on a coal gasification slag raw material through a screening machine, taking a high-ash-content oversize product as a tailing product, and enabling an undersize product to continuously pass through a grading cyclone to realize carbon-ash separation; overflow of the grading cyclone is fed into a settling tank for treatment, bottom flow of the grading cyclone is separated by a separator to obtain a heavy product and a light product, the heavy product is screened to obtain an oversize product as a tailing product, and an undersize product is fed into the settling tank; screening the light product to obtain an oversize product, dehydrating the oversize product as clean coal, and feeding an undersize product into a settling tank; feeding underflow of the settling tank into a dehydrator for dehydration to obtain middling coal; and the low-quality middling coal is directly combusted to deeply dehydrate the clean coal, and a final high-quality clean coal product is obtained. According to the technical scheme provided by the invention, graded and quality-divided large-scale resource utilization of the coal gasification slag can be realized, and energy recycling can be realized while environmental pollution can be effectively reduced.

Owner:XI AN JIAOTONG UNIV

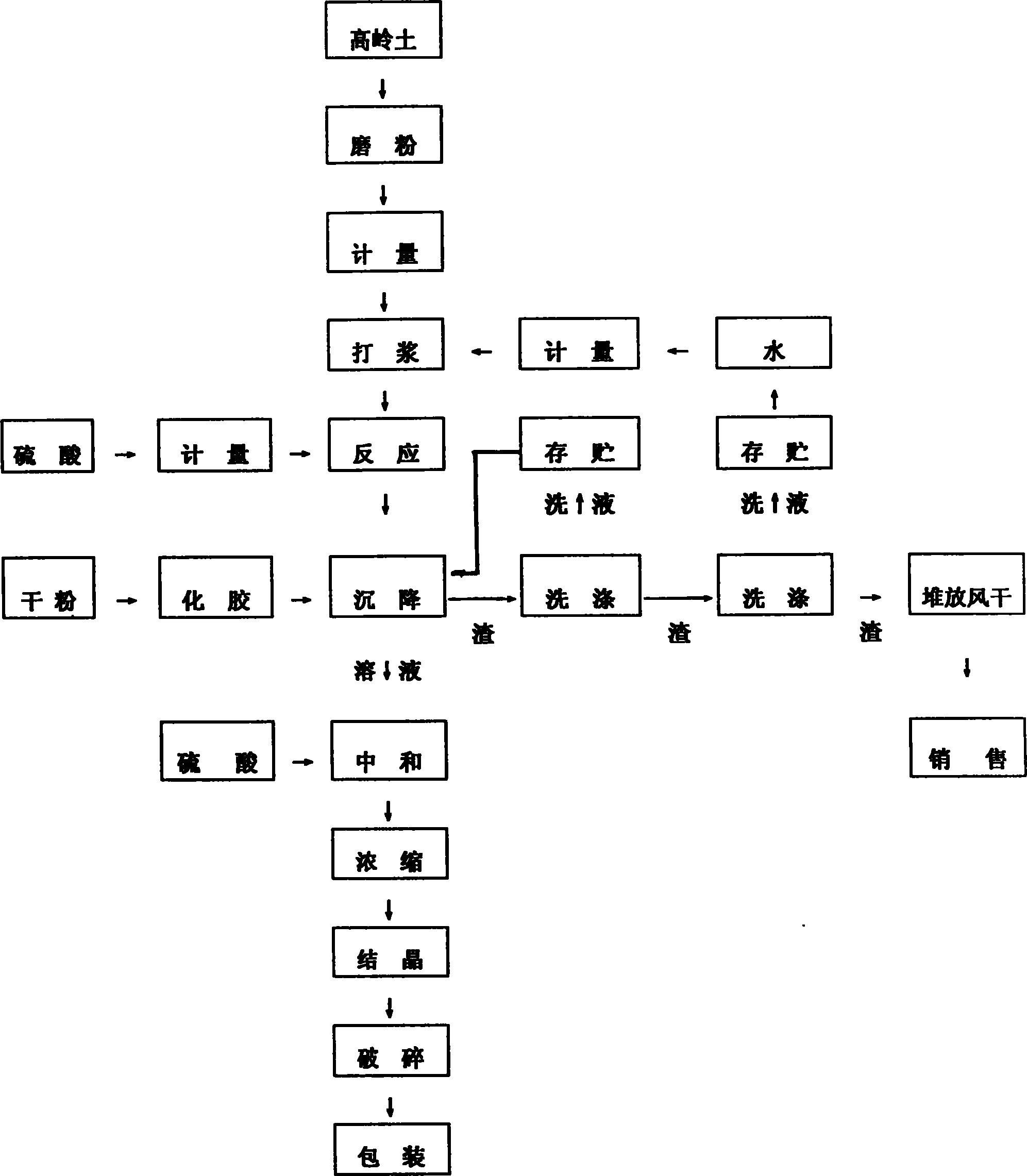

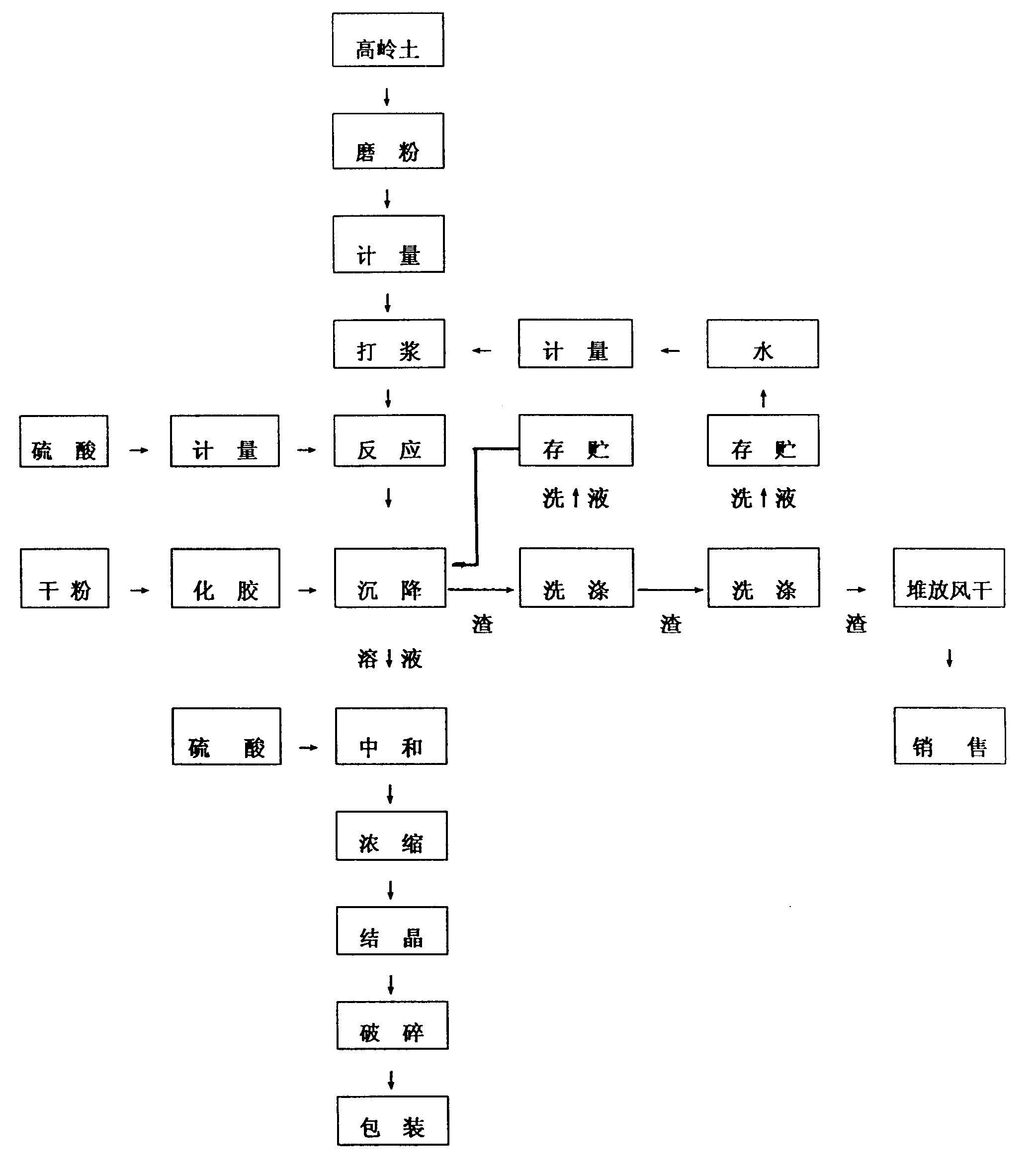

Low pressure leaching process of coal-bearing kaolin powder for producing industrial aluminum sulfate

InactiveCN1986412BProcess technology scienceAdvanced process technologyAluminium sulfatesAluminum sulphatePhysical chemistry

The technological process of low pressure leaching coal-bearing kaolin powder to produce industrial aluminum sulfate includes the following steps: crushing and grinding coal-bearing kaolin to 150-200 mesh powder, metering and adding water to compound 55-65 wt% concentration slurry and reaction; mixing the ore slurry with sulfuric acid in the ratio of 0.55 kg to 610 kg to react at the temperature of 140+ / -2 deg.c and pressure of 0.33+ / -0.02Mpa for 4-5 hr; relieving pressure and adding water to dilute; depositing separation in a settling tank; neutralizing the solution via adding acid to pH 3-3.5 in a neutralizing tank; evaporating to concentrate and drum crystallizing to obtain product. The process is reasonable, reliable, low in production cost and high in leaching rate, and is used in developing aluminum salt resource.

Owner:赵振民 +1

A pulverized coal gasification flash condensation system and process

ActiveCN108795506BAvoid depositionGuaranteed heat transfer efficiencyVapor condensationGasification processes detailsEngineeringProcess engineering

Owner:LUXI CHEM GRP

Coal gasification ash water vacuum flash evaporation descaling system

PendingCN111646621AGuaranteed running stabilityLess investmentWater contaminantsMultistage water/sewage treatmentWater treatment systemFluid phase

The invention discloses a coal gasification ash water vacuum flash evaporation descaling system. A gas phase outlet of a vacuum flash tank is communicated with an inlet of a acuum flash condenser through a pipeline; a liquid phase outlet of the vacuum flash tank is communicated with an inlet of a mixing and dosing tank through a pipeline, an outlet of the mixing and dosing tank is communicated with an inlet of a settling tank through a pipeline, an outlet of a flocculating agent tank is communicated with an inlet of the mixing and dosing tank through a pipeline, and an outlet of a descaling agent tank is communicated with an inlet of the mixing and dosing tank through a pipeline. The coal gasification ash water vacuum flash evaporation descaling system has the effects that coal gasification ash water is treated by the method; the ash water from the vacuum flash tank, a descaling agent and a flocculating agent are uniformly mixed in the mixing and dosing tank and then are conveyed to the settling tank to be clarified and settled, and fine ash and silicon, aluminum, calcium and magnesium ion precipitates contained in the water are removed, so that scaling of pipelines and equipment of the ash water treatment system can be slowed down, and the service life of the equipment is prolonged. Equipment operation period and stability of the ash water treatment system are improved, and investment of the ash water treatment system is reduced.

Owner:BEIJING QING CHUANG JIN HUA TECH CO LTD

Device and method for producing synthesis gas in a multi-nozzle gasifier

ActiveCN112708470BIncrease temperatureTreatment involving filtrationGasification processes detailsHeat fluxSlag

The present invention discloses a device and method for the production of a multi -nozzle gas gas production furnace. The device includes normally pressure coal powder storage tanks, buckets and feed tanks, and the bottom out of the material tube of the tank and the burning mouth.There are buffer tanks and spiral conveyors. The spiral conveyor connects the burning mouth and gasification furnace in turn.High -pressure flash steaming tanks and vacuum flash steaming tanks, vacuum flash steaming tanks are connected to a turning filter, and the turning filter is connected to a settlement slot.The present invention can concentrate the heat of the coal, and can quantitatively control the flow of the coal, increase the amount of coal transportation. At the same time, the heat flux and the burning temperature are higher and effectively reduce the amount of synthetic gas.

Owner:HUAYANG NEW MATERIAL TECH GRP CO LTD +1

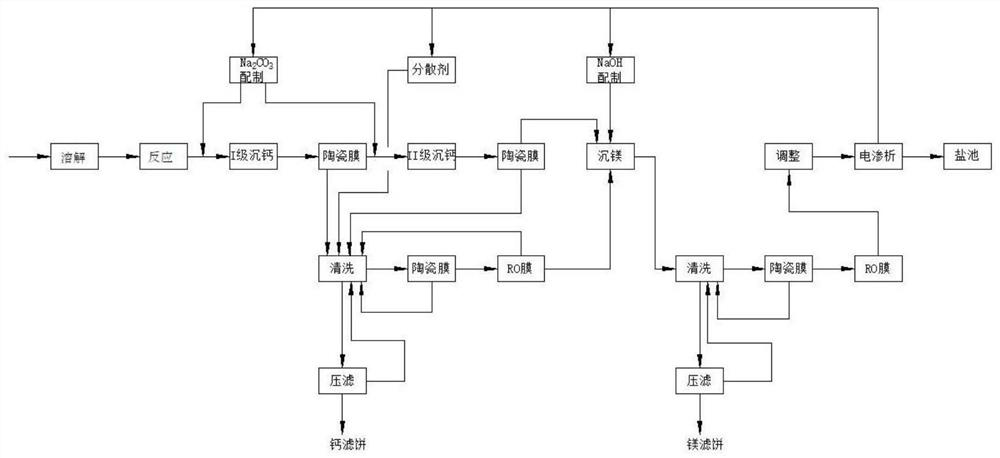

A zero-discharge process for coal chemical high-salt wastewater

ActiveCN112694201BAchieve recyclingAvoid badCalcium/strontium/barium carbonatesSpecific water treatment objectivesProcess engineeringPre treatment

The invention discloses a coal chemical industry high-salt wastewater zero-discharge process, comprising: the wastewater in the coal chemical industry wastewater settling tank is pumped into a pretreatment tank by a raw water pump, and after pretreatment, its produced water enters an adsorption tank; After the adsorber is saturated with adsorption, the system is automatically cut off, and the analysis tank is used for analysis; the analysis waste liquid generated after the analysis of the adsorber by the analysis tank is sent to the calcium recovery device through the first-stage heat exchanger and the second-stage heat exchanger. Processing, using a dispersant to produce nano-scale calcium carbonate, which is separated and solidified in a calcium-precipitated ceramic membrane and a calcium filter press to produce a nano-calcium carbonate product; after being separated by a class II ceramic membrane, the clear liquid enters the magnesium recovery device and passes through the magnesium-precipitated ceramic membrane. Magnesium products are produced after separation from magnesium and magnesium filter presses, and the clear liquid is recovered and reused as analytical liquid to achieve zero discharge and resource utilization of waste liquid. According to the characteristics of water quality, this application designs a process plan to realize standardization and resource utilization, to make waste from waste, to realize waste water recycling and zero discharge of waste water.

Owner:大连东道尔膜技术有限公司

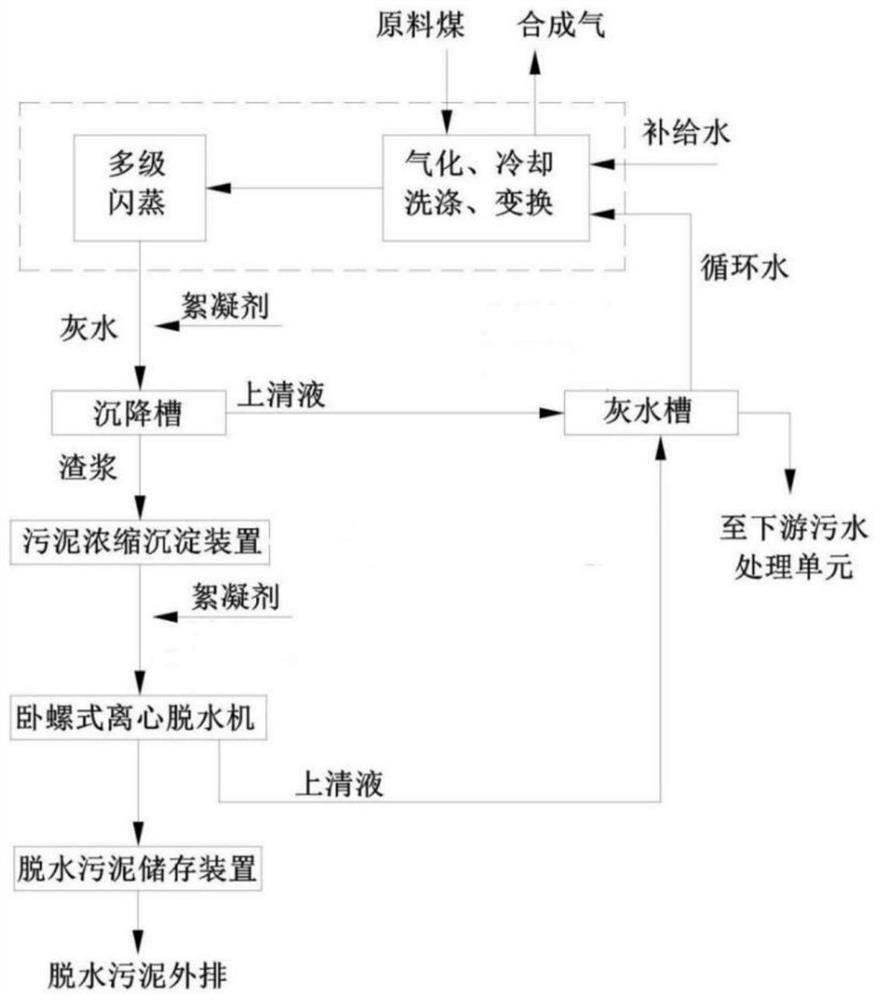

Coal gasification fine slag water treatment device and process

PendingCN113582406ALow running costGuaranteed uptimeWater/sewage treatment by centrifugal separationMultistage water/sewage treatmentSlagEngineering

The invention discloses a coal gasification fine slag water treatment device and process, and belongs to the technical field of coal gasification device fine slag water treatment. The coal gasification fine slag water treatment device comprises a sludge concentration and precipitation device and a horizontal screw type centrifugal dehydrator. The sludge concentration and precipitation device is communicated with the horizontal screw type centrifugal dehydrator through a first blow-off pipe. The sludge concentration and precipitation device is further communicated with a settling tank. The settling tank is further communicated with a grey water tank. The grey water tank is communicated with a centrifugal dewatering device. The centrifugal dewatering device is further communicated with a dewatered sludge storage tank. The process for treating coal gasification fine slag water by the device comprises the following steps of: S1, settling fine slag water in the settling tank; S2, carrying out primary treatment by the sludge concentration and precipitation device; and S3, carrying out secondary treatment by the centrifugal dewatering device. A treatment process based on a sludge concentration and precipitation device and a centrifugal dehydrator is adopted, the operation effect is met when the change space of solid contained in fine slag water is too large, and precipitation and concentration facilities provide stable operation conditions for the centrifugal machine and enable the centrifugal machine to stably operate for a long time.

Owner:刘现海

A multi-stage sedimentation non-rake thickening device including a laminar diversion sedimentation screen

ActiveCN110935205BAchieving step-by-step settlingAchieve enrichmentSludge treatment by de-watering/drying/thickeningSettling tanks feed/dischargeSprayerWater flow

The invention relates to a multi-stage sedimentation rakeless concentrating device comprising a layered sedimentation diversion screen. A diversion sedimentation screen and a magnetic gathering sprinkler, the laminar diversion sedimentation screen includes a plurality of third diversion sedimentation subgroups arranged downwards along the outer wall of the central tank, and in the two adjacent sedimentation tanks, The lower settling tank obtains the coal slime water flowing out of the previous settling tank, and each third diversion settling subgroup includes a settling tank, and the bottom plate of the settling tank is provided with a third underflow discharge port for discharging the settled fine coal slime, and complete settlement The final water is output from the third overflow discharge pipe at the output end of the lowermost third flow settling subgroup. In the diversion settlement area of the present invention, layered diversion diversion sedimentation sieves are used to sequentially pass through all the third diversion settlement subgroups, thereby realizing step-by-step settlement, and the fine coal slime and settled water are discharged from different pipes. achieve concentration.

Owner:ANHUI UNIV OF SCI & TECH

A process and device for upgrading waste oil by boiling coal

ActiveCN111534354BNew ways to develop and utilizeHigh calorific valueFatty oils/acids recovery from wasteSolid fuelsOil and greaseBrown coal

Owner:TAIYUAN UNIV OF TECH

High-quality impregnant asphalt production process

InactiveCN103242880BHigh yieldWorking-up pitch/asphalt/bitumen by distillationWorking-up pitch/asphalt/bitumen by selective extractionKeroseneDistillation

The invention discloses a high-quality impregnant asphalt production process. The high-quality impregnant asphalt production process is characterized by comprising the following steps of: mixing first solvent coal oil and second solvent washing oil for extraction by using a pipeline mixer, and then feeding the mixture into a stirring tank; feeding raw material coal asphalt into the stirring tank for stirring; pumping the stirred raw material coal asphalt into a first settling tank through an oil pump; pumping a heavy phase part in the first settling tank into a quinoline insoluble centrifugal removal device through the oil pump, and centrifugally removing quinoline insoluble residue; returning a material from which the quinoline insoluble residue is removed into the first settling tank; when the storage amount of mixed liquid in the first settling tank reaches the limit, enabling the mixed liquid to enter into a second settling tank, and standing; after lamination occurs in the second settling tank, heating a light phase component in the second settling tank through a first heating furnace, and pumping the light phase component into a first depressurizing distillation tower for depressurizing distillation; and removing a solvent, and thus obtaining a target product, namely high-quality impregnant asphalt. The high-quality impregnant asphalt production process is used for producing the high-quality impregnant asphalt. The product yield is high and can exceed 60 percent. The temperature of a softening point of a product is 70 to 90 DEG C. The ash content can be controlled to be 0.01 to 0.1 percent.

Owner:武汉钢铁有限公司

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com