Coal gasification ash water vacuum flash evaporation descaling system

A vacuum and flash evaporation technology, which is applied in the direction of water pollutants, water/sewage treatment, chemical instruments and methods, etc., can solve the problems of large area of settlement tank, easy scaling of equipment and pipelines, unstable operation, etc., to achieve The effect of reducing investment and floor area, shortening the settlement time, and ensuring operation stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

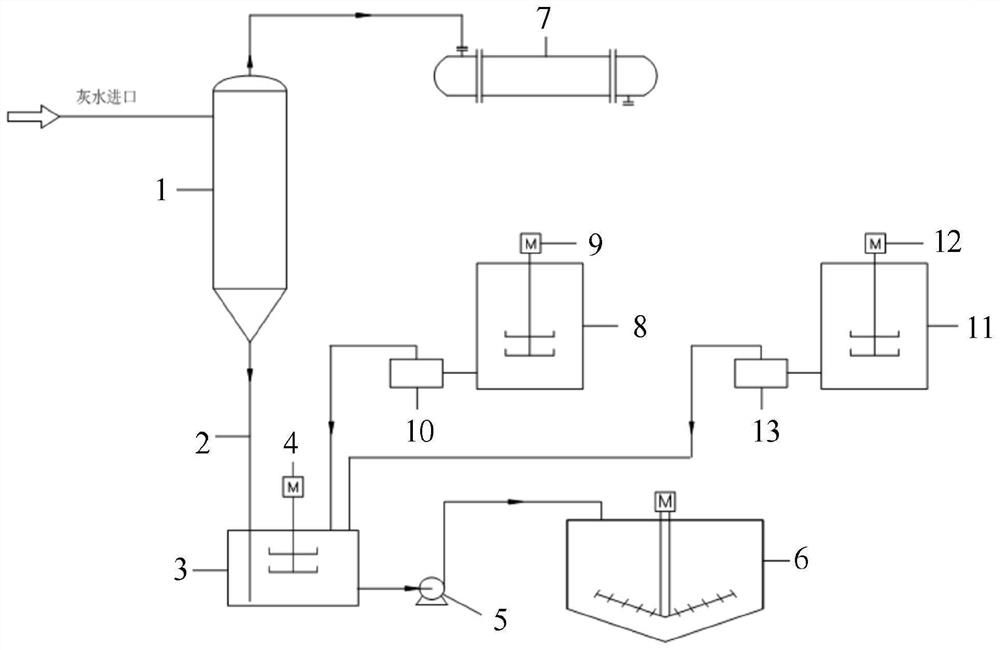

[0031] like figure 1 As shown, a coal gasification gray water vacuum flash descaling system in this embodiment includes a vacuum flash tank 1, a mixed dosing tank 3, a settling tank 6, a vacuum flash condenser 7, a flocculant tank 8 and Descaling agent tank 11, the gas phase outlet of vacuum flash tank 1 is communicated with the inlet of vacuum flash condenser 7 through pipeline, and the liquid phase outlet of vacuum flash tank 1 is communicated with the inlet of mixing dosing tank 3 through pipeline, mixing and adding The outlet of the medicine tank 3 is connected with the inlet of the settling tank 6 through a pipeline, the outlet of the flocculant tank 8 is connected with the inlet of the mixed dosing tank 3 through a pipeline, and the outlet of the descaling agent tank 11 is connected with the inlet of the mixed dosing tank 3 through a pipeline connected.

[0032] The technical effect achieved by this embodiment is: the mixing and dosing tank 3 of this embodiment can be u...

Embodiment 2

[0034] like figure 1 As shown, a kind of coal gasification gray water vacuum flash descaling system in this embodiment includes all the technical features in Embodiment 1, in addition, it also includes a settling feed pump 5, a mixing dosing tank 3 and The pipeline between the settling tanks 6 is provided with a settling feed pump 5; it also includes a flocculant pump 10, and the pipeline between the flocculant tank 8 and the mixing dosing tank 3 is provided with a flocculant pump 10; it also includes a descaling agent Pump 13, the pipeline between the descaling agent tank 11 and the mixing dosing tank 3 is provided with a descaling agent pump 13.

[0035]The beneficial effects of this embodiment are: the inlet of the subsidence feed pump 5 in this embodiment is set at the bottom of the mixing and dosing tank 3, and the pressure of the mixing and dosing tank 3 is normal pressure during normal operation, and the requirements for the NPSH of the pump Generally, ordinary chemica...

Embodiment 3

[0037] like figure 1 As shown, a coal gasification gray water vacuum flash descaling system in this embodiment includes all the technical features in Embodiment 2, in addition, it also includes a mixing and dosing agitator 4, a mixing and dosing tank 3 A mixing and dosing agitator 4 is provided inside; a flocculant agitator 9 is provided in the flocculant tank 8; a descaling agent agitator 12 is provided in the descaling agent tank 11 Agent agitator 12, wherein, mixing dosing agitator 4, flocculant agitator 9 and descaling agent agitator 12 all realize its rotation stirring by electric motor.

[0038] In some optional embodiments, the settling tank 6 is also provided with a settling agitator, and the settling agitator is driven by a motor.

[0039] The beneficial effects of this embodiment are: by setting the flocculant agitator 9, the stirring of the materials in the flocculant tank 8 is realized; by setting the descaling agent agitator 12, the stirring of the materials in t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com