Driving guide-rail pair for tabouret of computerized embroidery machine

A technology for driving guide rails and embroidery machines, used in embroidery machines, embroidery machine mechanisms, metal processing machinery parts, etc. The effect of improving operating life and ensuring operating stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

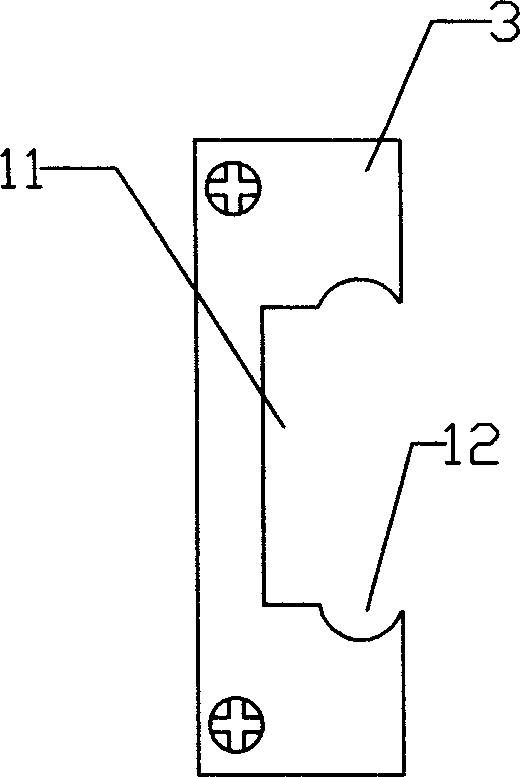

Embodiment Construction

[0021] Depend on Figure 5 As can be seen in the figure, the slider 2 of the existing computerized embroidery machine embroidery frame driving guide rail pair is provided with two rows of convex guide rail wheels 13, and the upper end of the guide rail wheels of the same row is provided with a guide rail wheel connecting plate 14, and the slide block 2 and the guide rail (not shown in the figure) after matching, this convex surface guide rail wheel 13 is connected with the groove that is set on the both sides of guide rail, and convex surface guide rail wheel 13 can axially slide on the groove. The guide rail is made of aluminum alloy, and the convex guide rail wheel 13 is made of stainless steel. The hardness of the two is quite different. During the operation of the drive guide rail pair, the grooves are easy to be worn, which will lead to The deviation of the running position of the embroidery frame connected with the slider 2 will cause an error between the embroidered pat...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com