Climbing robot walking along overhead line

An overhead line and robot technology, applied in the direction of overhead line/cable equipment, manipulators, manufacturing tools, etc., can solve the problems affecting the inspection efficiency of the robot, the complex structure of the tension tower head, and the practical restriction of the robot, so as to improve the obstacle crossing. Efficiency, light weight, short obstacle clearance time

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0075] Below in conjunction with accompanying drawing and specific embodiment the present invention is described in further detail:

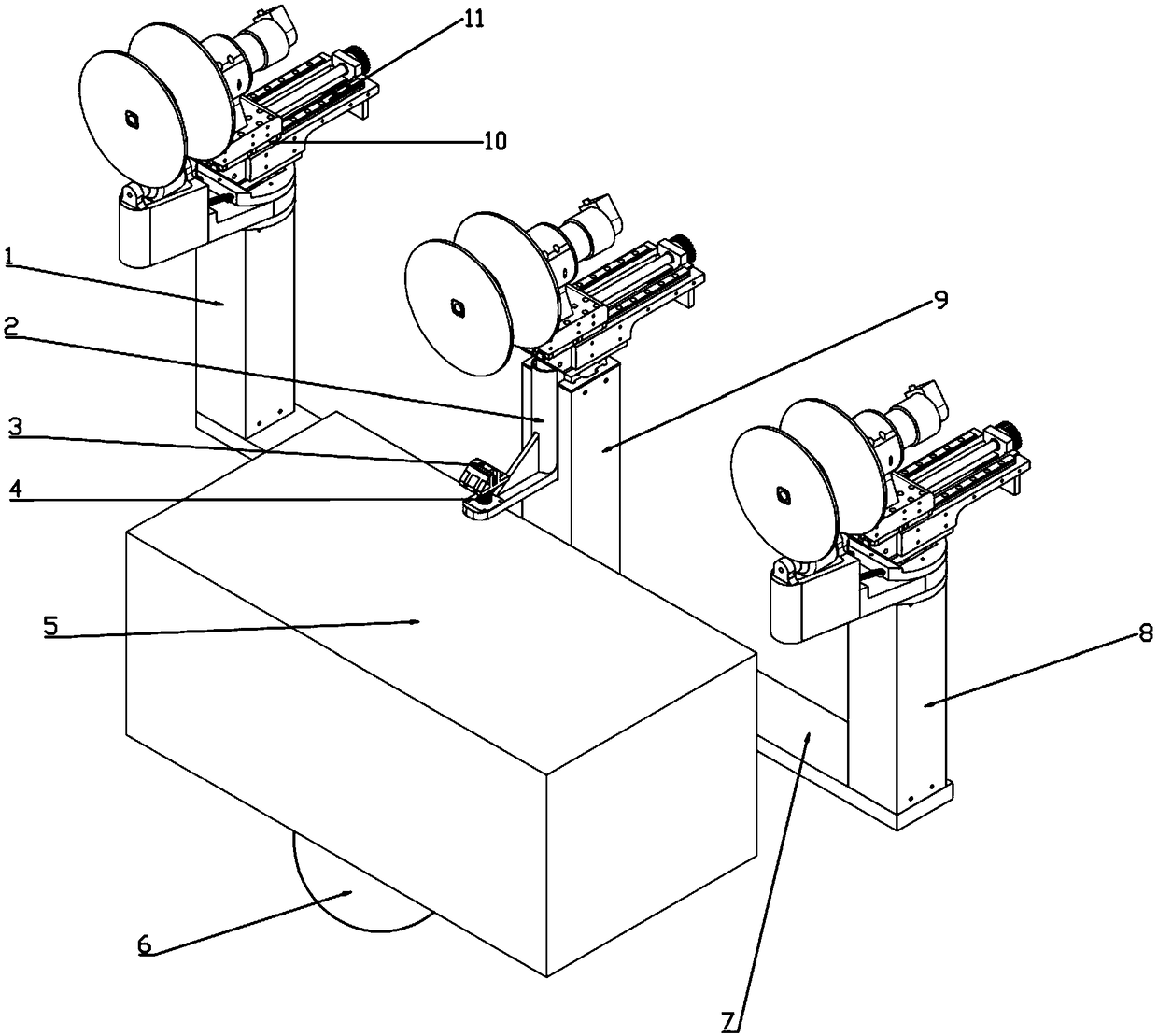

[0076] combine figure 1 with figure 2 As shown, a walking and climbing robot along an overhead line includes a support structure 5, a cantilever device base 7 and three cantilever devices. in:

[0077] The supporting structure 5 in this embodiment may adopt a box structure, for example.

[0078] A controller (not shown) is provided inside the support structure 5 for automatic control of other mechanisms.

[0079] In addition, inspection equipment 6 is also provided on the supporting structure 5 , including, for example, a camera, an infrared detector, and a wireless signal transceiver. Wherein, the camera and the infrared detector are respectively connected with the wireless signal transceiver through lines.

[0080] The wireless signal transceiver is connected to the base station control center on the ground through wireless signals.

[...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com