Silicon removal method for wastewater discharged by aerospace furnace gasification process

A waste water and process technology, which is applied in chemical instruments and methods, water/sewage treatment, water/sewage multi-stage treatment, etc., can solve the problems that the long-term operation of the system cannot be guaranteed, and the total silicon in the discharged waste water does not meet the standard, so as to meet the requirements Environmental protection and production management, reducing sewage treatment costs, and obvious effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

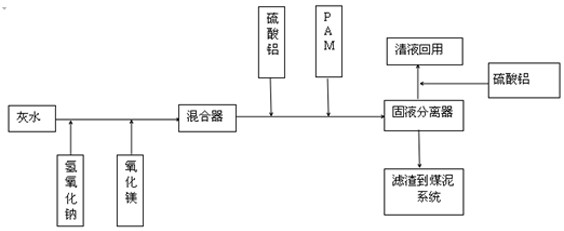

Method used

Image

Examples

Embodiment 1

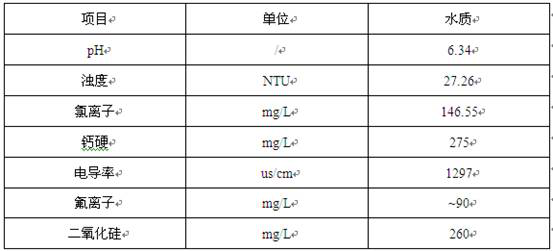

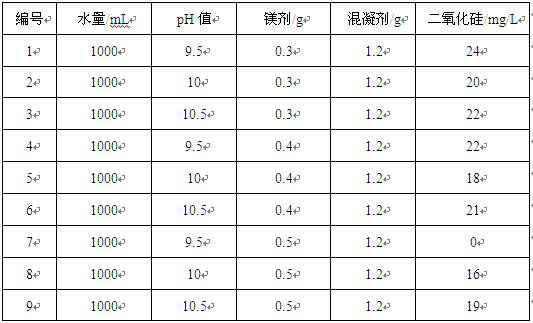

[0043] The ash water from the gasification unit of the aerospace furnace has a temperature of 75°C and a total silicon content of 260mg / L. Add liquid caustic soda to the wastewater in the pipeline to adjust the pH to 10, and then transfer the alkali-adjusted water to Reactor 1 for the reaction of adding magnesium agent, the reaction time is 30 minutes; add a coagulant with a concentration of 10wt% to the discharged wastewater The aluminum salt is 1200mg / L, and the two are reacted in the reactor 2 together with the waste water for 25 minutes. After the reaction, they enter the solid-liquid separator for solid-liquid separation. The residence time is 10 minutes. The dosage of cationic polyacrylamide is 3mg / L; the stirring speed is adjusted according to the size of the sludge alum flower and the sedimentation rate. The supernatant is discharged from the system, and 1% of the sludge discharged from the bottom is returned to the secondary reaction coagulation tank, and the rest is ...

Embodiment 2

[0045] The ash water from the gasification unit of the aerospace furnace has a temperature of 75°C and a total silicon content of 260mg / L. Add liquid caustic soda to the wastewater in the pipeline to adjust the pH to 10.50, and then transfer the alkali-adjusted water to Reactor 1 for the reaction of adding magnesium agent. The reaction time is 30 minutes; add a coagulant with a concentration of 10wt% to the discharged wastewater The aluminum salt is 1200mg / L, and the two are reacted in the reactor 2 together with the waste water for 25 minutes. After the reaction, they enter the solid-liquid separator for solid-liquid separation. The residence time is 10 minutes. The dosage of cationic polyacrylamide is 3mg / L; the stirring speed is adjusted according to the size of the sludge alum flower and the sedimentation rate. The supernatant is discharged from the system, and 1% of the sludge discharged from the bottom is returned to the secondary reaction coagulation tank, and the rest ...

Embodiment 3

[0047] The ash water from the gasification unit of the aerospace furnace has a temperature of 75°C and a total silicon content of 260mg / L. Add liquid caustic soda to the wastewater in the pipeline to adjust the pH to 9.50, and then transfer the alkali-adjusted water to Reactor 1 for the reaction of adding magnesium agent. The reaction time is 30 minutes; add a coagulant with a concentration of 10wt% to the discharged wastewater The aluminum salt is 1200mg / L, and the two are reacted in the reactor 2 together with the waste water for 25 minutes. After the reaction, they enter the solid-liquid separator for solid-liquid separation. The residence time is 10 minutes. The dosage of cationic polyacrylamide is 3mg / L; the stirring speed is adjusted according to the size of the sludge alum flower and the sedimentation rate. The supernatant is discharged from the system, and 1% of the sludge discharged from the bottom is returned to the secondary reaction coagulation tank, and the rest i...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com