Crushed coal pressurized gasification gas-water separation and recycling system and method

A pressurized gasification of crushed coal, gas-water technology, applied in chemical instruments and methods, heating water/sewage treatment, degassed water/sewage treatment, etc., can solve the problem of gas-water separation and recovery processes that cannot meet modern requirements, pollution There are many discharge points and harsh on-site environment to achieve the effects of small footprint, short treatment process and low operating cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

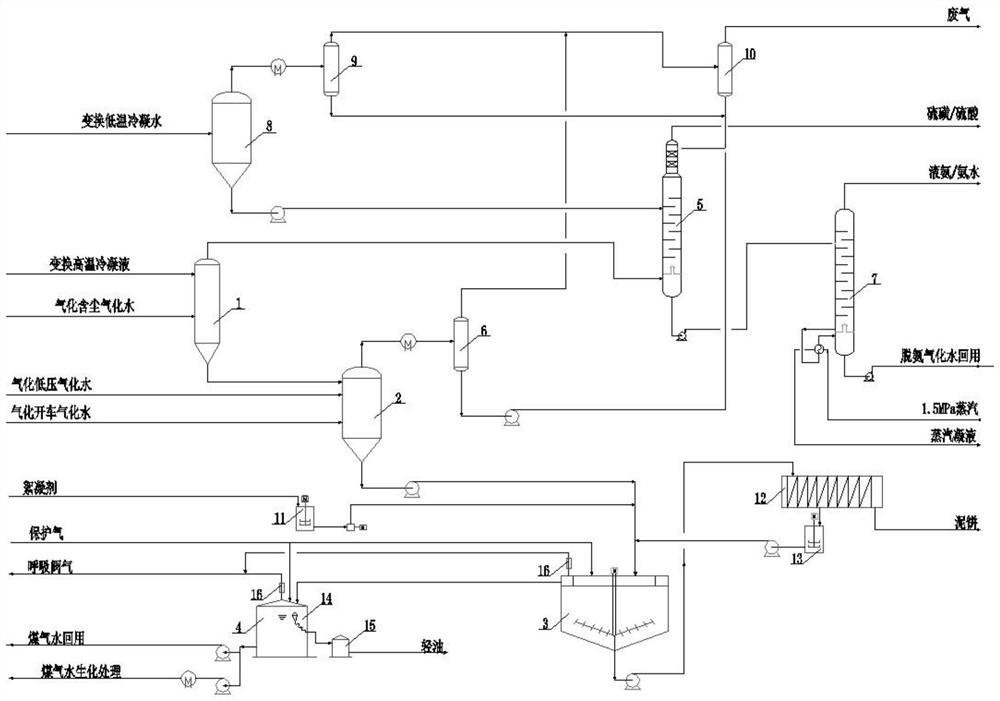

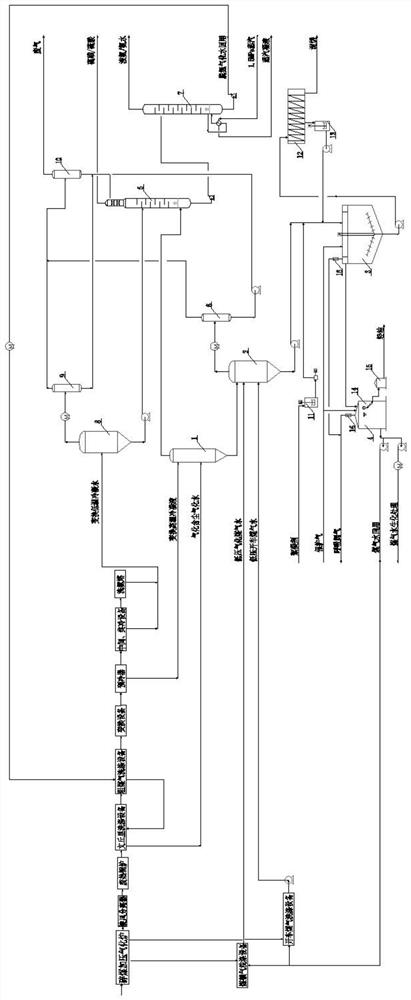

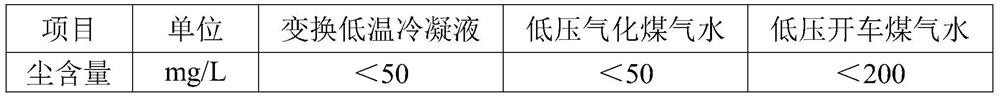

[0051] The crushed coal in this example is Jincheng anthracite with a water content of 5%. The coal sample is crushed and sieved to obtain a coal sample with a particle size of 5-50 mm, which is loaded into a crushed coal pressurized gasifier for pressurized gasification of the crushed coal , the gasification pressure is 4.0MPa, and the gasification temperature is 1250°C. The crude gas produced by gasification is divided into high-temperature gas water and low-temperature gas water according to the dust content, temperature and pressure in the water during washing. The high-temperature gas water is based on the dust content, The temperature and pressure are divided into transformed high-temperature condensate and gasified dust-containing gasified water. The low-temperature gas water is divided into transformed low-temperature condensate, low-pressure gasified gas water and low-pressure start-up gas water according to the dust content, temperature and pressure. The gas and water...

Embodiment 2

[0067] The crushed coal in this example is Jincheng anthracite with a water content of 6%. The coal sample is crushed and sieved to obtain a coal sample with a particle size of 5-50mm, which is loaded into a crushed coal pressurized gasifier for pressurized gasification of the crushed coal , the gasification pressure is 5.0MPa, and the gasification temperature is 1250°C. The crude gas produced by gasification is divided into high-temperature gas water and low-temperature gas water according to the dust content, temperature and pressure in the water during washing. The high-temperature gas water is based on the dust content, The temperature and pressure are divided into transformed high-temperature condensate and gasified dust-containing gasified water. The low-temperature gas water is divided into transformed low-temperature condensate, low-pressure gasified gas water and low-pressure start-up gas water according to the dust content, temperature and pressure. The gas and water ...

Embodiment 3

[0072] The crushed coal in this example is Yangquan anthracite with a water content of 8%. The coal sample is crushed and sieved to obtain a coal sample with a particle size of 5-50mm, which is loaded into a crushed coal pressurized gasifier for pressurized gasification of the crushed coal , the gasification pressure is 7.0MPa, and the gasification temperature is 1350°C. The crude gas produced by gasification is divided into high-temperature gas water and low-temperature gas water according to the dust content, temperature and pressure in the water during washing. According to the dust content, temperature and pressure, it is divided into transformed high-temperature condensate and gasified dust-containing gasified water. Low-temperature gas water is divided into transformed low-temperature condensate, low-pressure gasified gas water and low-pressure driving gas water according to dust content, temperature and pressure. The gas and water of different classifications are separat...

PUM

| Property | Measurement | Unit |

|---|---|---|

| density | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com