Device and method for producing synthetic gas by multi-nozzle gasification furnace

A gasifier and synthesis gas technology, which is applied in the field of coal gasification, can solve the problems of low combustion temperature, water in the synthesis gas, and low heat flux, and achieves the effects of high temperature, reduced labor cost, and increased heat flux

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

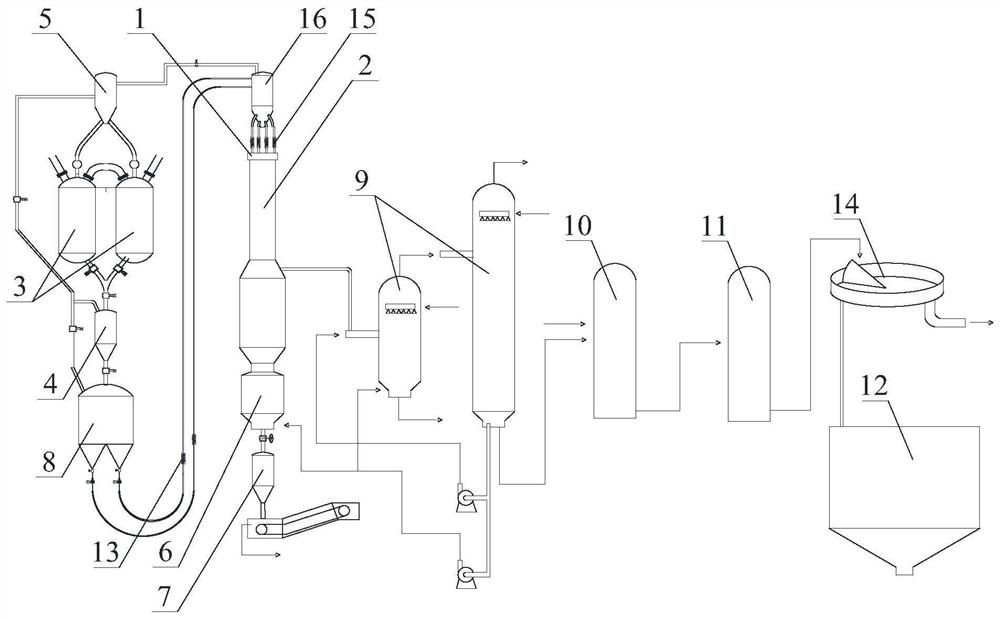

[0087] Such as Figure 4 As shown, the process condition of "single burner + ultra-dense phase coal transportation" is adopted. The single burner is the traditional three-channel pulverized coal burner. The flow of pulverized coal is adjusted by the pressure difference. From above the slag water level, it is sprayed with chilled water and enters the water washing tower. The synthesis gas that removes most of the fine slag enters the torch, and the black water in the gasifier enters the high-pressure flash tank, the vacuum flash tank, and finally the sedimentation tank. Tank, in the settling tank, by adding flocculant, the coal slime settles at the bottom of the tank, pumped into the filter press for solid-liquid separation.

[0088] The startup process is as follows:

[0089] (1) Pulverized coal is ground and conveyed under pressure, and the pulverized coal is produced by CO 2 After the gas is brought into the bag filter, it enters the pulverized coal atmospheric pressure pu...

Embodiment 2

[0099] Such as Figure 5 As shown, the flow of pulverized coal driven by differential pressure has the disadvantage of unstable flow. By adding a frequency conversion magnetic screw conveyor to the pulverized coal transportation pipeline, the temperature control of the pulverized coal flow can be achieved.

[0100] The advantage of adopting frequency conversion magnetic screw conveyor is that on the one hand, it can ensure the stability of pulverized coal flow, and on the other hand, there is no waste of pulverized coal in differential pressure transportation, so that there is no excessive pulverized coal in the gasifier before ignition. Table 5 is the pulverized coal flow rate using the magnetic screw conveyor.

[0101] Table 5 Embodiment 2 Pulverized coal transportation process parameters

[0102]

[0103] The startup process is as follows:

[0104] (1) Pulverized coal is ground and conveyed under pressure. After the pulverized coal is brought into the bag filter by CO2...

Embodiment 3

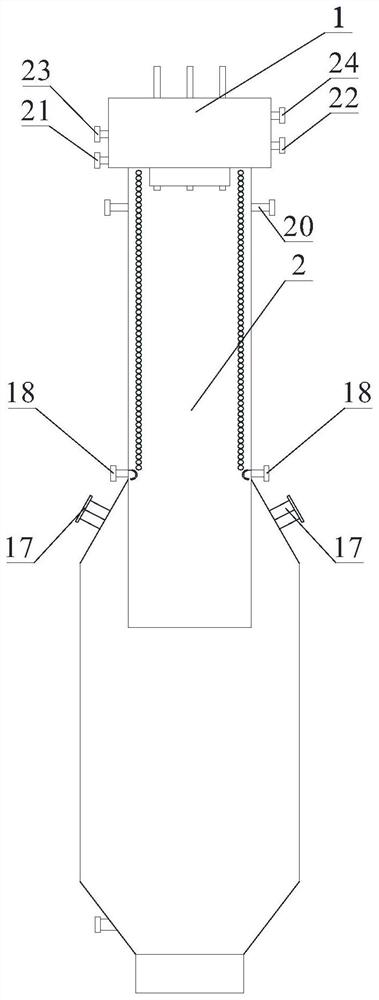

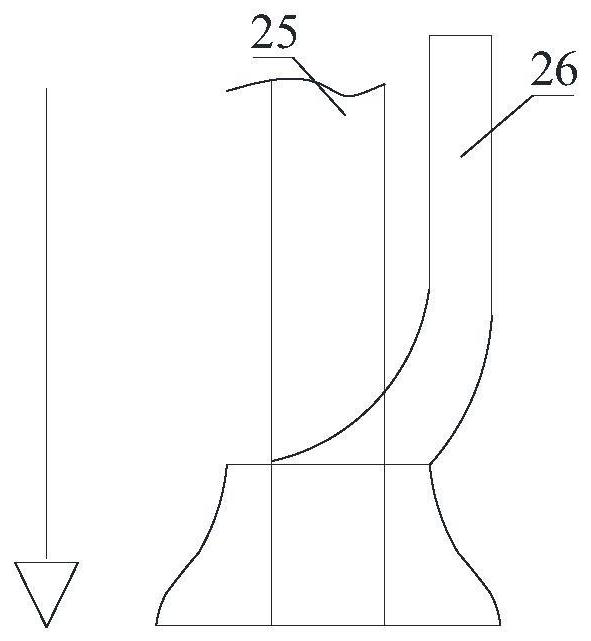

[0113] Such as Figure 6 As shown, in order to increase the heat flux of the gasifier and improve the production capacity of the gasifier, the heat flux of the gasifier installed with a single burner burner is insufficient. The burners of the gasifier have been modified, and three The burner is integrated and installed on the burner plate, and at the same time, one water washing tower is transformed into two water washing towers, which reduces the dust content of the syngas.

[0114] Three burners and one ignition burner are installed on the burner plate, and screw conveyors are installed on the coal conveying pipeline. The speed parameters of the three screw conveyors are incorporated into the start-up program and the shutdown SIS program, Table 7 It is the relationship between the conveyor speed and the coal flow.

[0115] Table 7 Embodiment 3 Pulverized coal conveying process parameters

[0116]

[0117] The startup process is as follows:

[0118] (1) Pulverized coal ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| density | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com