Coal gasification ash water treatment process and equipment

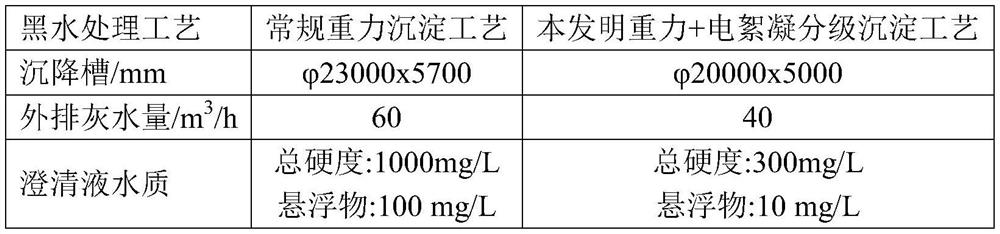

A treatment process, coal gasification technology, applied in water/sewage treatment equipment, water/sewage treatment, water treatment parameter control, etc., can solve the problem of reducing total hardness, increasing the risk of scaling equipment and pipelines, and large external drainage of clarified liquid, etc. problems, to achieve the effect of reducing the total hardness, reducing the amount of gray water discharged, and reducing the amount of fresh water

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

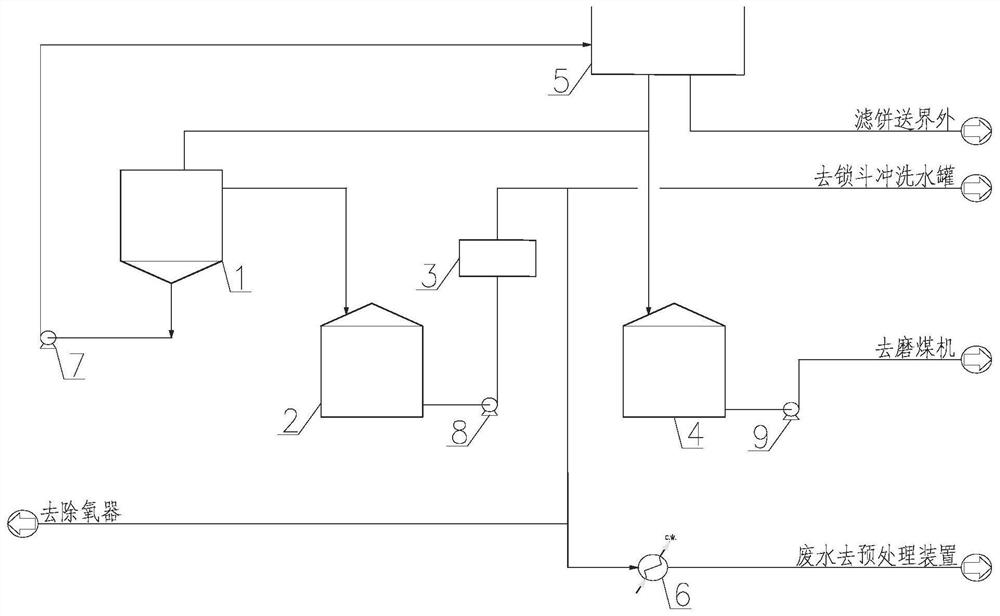

[0033] The present invention will be further described in detail below with reference to the embodiments of the accompanying drawings.

[0034] like figure 1 As shown, the treatment process of coal gasification ash water in this embodiment includes the following steps:

[0035] (1) 0.1-0.2MPaG, 45°C black water with high ammonia nitrogen, high suspended solids and high hardness from the black water flash distillation and grey water treatment process of the upstream coal gasification unit is subjected to coarse gravity liquid-solid separation in sedimentation tank 1 , the clarified liquid overflows into the gray water tank 2, and the settled solid phase is pressurized to 0.2-0.3 MPaG by the sedimentation tank bottom flow pump 7 and transported to the vacuum filter 5 for forced liquid-solid separation;

[0036] (2) the filtrate flows into the sedimentation tank 1 or the filtrate tank 4 by gravity flow, and the filtrate in the filtrate tank 4 is pressurized to 0.3~0.4MPaG by the...

PUM

| Property | Measurement | Unit |

|---|---|---|

| hardness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com