Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

43 results about "Sound intensity probe" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

A sound intensity probe is a probe capable of measuring sound intensity. The sound intensity is the product of sound pressure and particle velocity. Common probes measure the sound intensity using two microphones. Another type measures the sound intensity using a microphone and a particle velocity probe.

Method for sound field separation by pressure velocity method

InactiveCN101403634AGood calculation stabilityImprove calculation accuracyVelocity propogationEquivalent source methodSound sources

The invention discloses a pressure speed method sound field separation method, a measured sound field is provided with a measuring surface S; a sound pressure sensor is adopted to measure the sound pressure on the measuring surface S, and a particle velocity sensor or a sound intensity probe is adopted to measure the particle speed on the measuring surface S; both sides of the measuring surface S are provided with the imaginary source surfaces S1 <*> and S2 <*> which are provided with the equivalent sources; the transfer relationship between the equivalent sources and the sound pressure and the particle speed on the measuring surface S is constructed; the separation of sound source radiation sound pressure and the particle speed of both sides on the measuring surface according to the transfer relationship is realized; the sound field separation is realized by measuring the speed relation of sound pressure and particle on each surface; and the equivalent source method is adopted as the sound field separation arithmetic, the calculation stability is good, the calculation precision is high, and the implement is simple. The method can be widely applicable to the near-field acoustic holography measurement in the environments of internal sound field or noisy sound, the sound intensity method sound source identification in the noisy environment, the material reflection coefficient measurement, and the separation of the scattering sound field.

Owner:HEFEI UNIV OF TECH

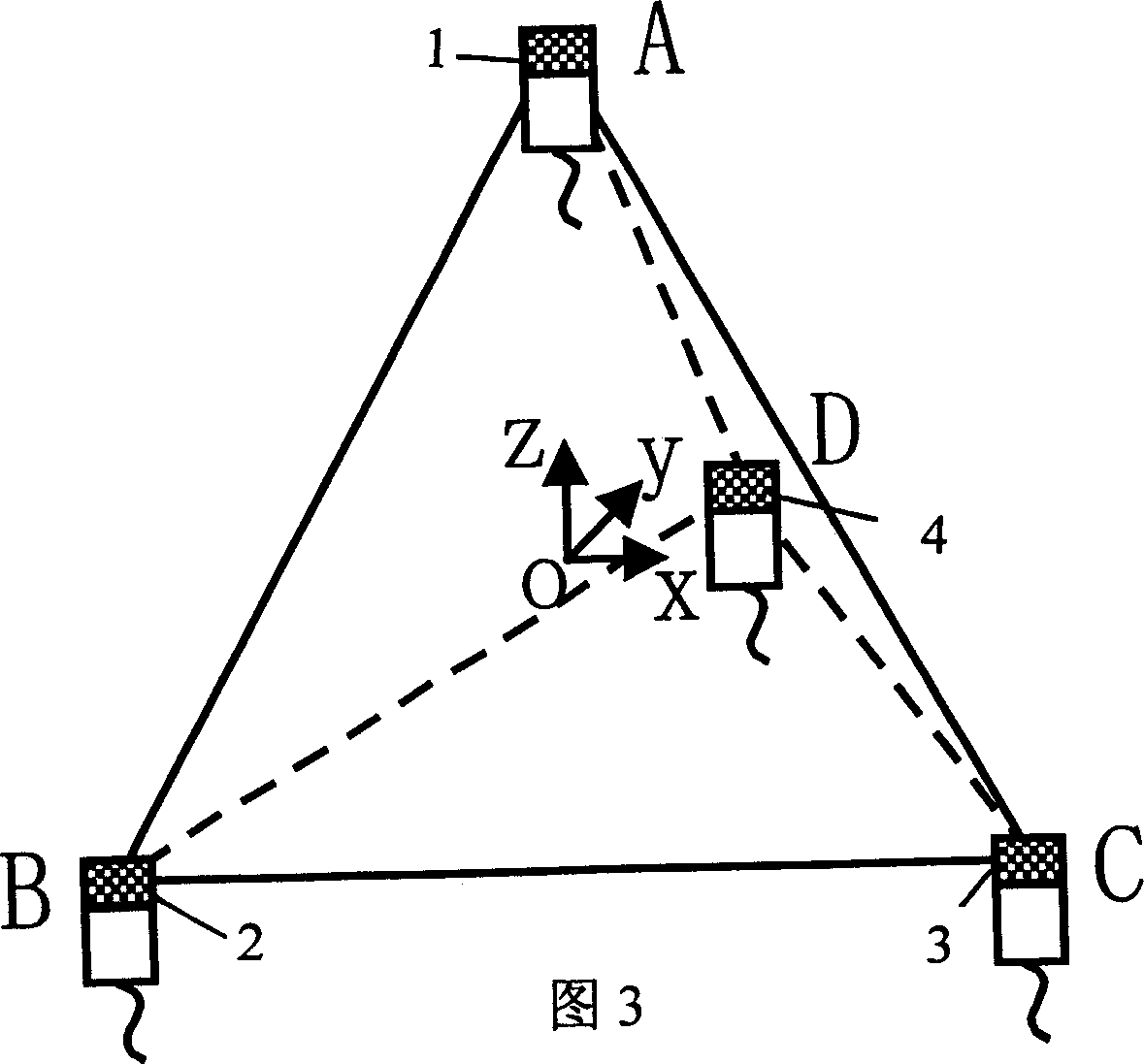

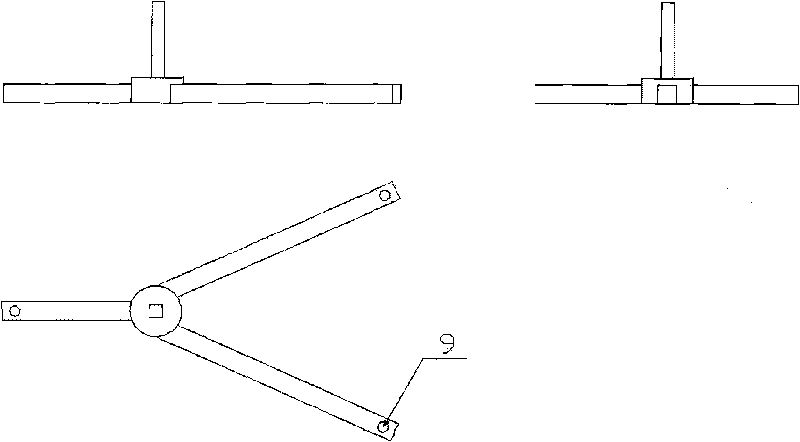

Measuring method and probe for three-dimensional vector sound intensity

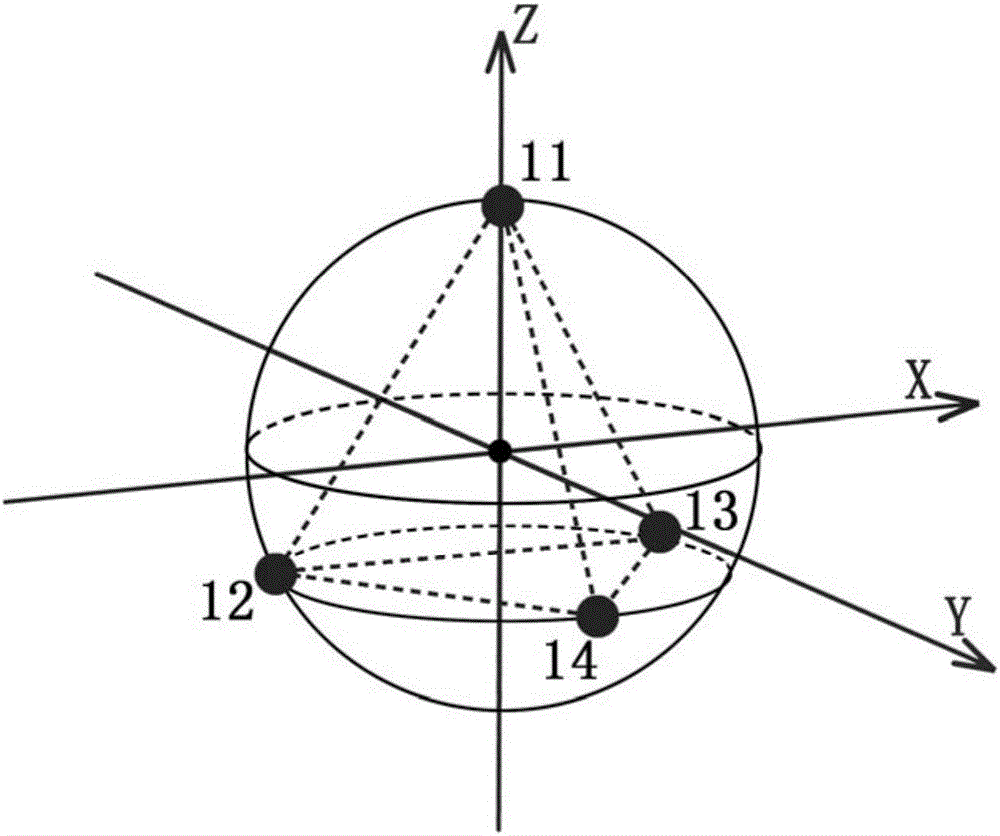

InactiveCN1553154AGuaranteed spatial positioning accuracyEasy to measureSubsonic/sonic/ultrasonic wave measurementUsing electrical meansSpatial positioningMathematical model

A measuring probe is structured in regular tetrahedron to be carried on for space vector sound indensity meaurement and sound pressure at four top positions is measured so sound iontensity component at six ridges is calculated out according to measurement principle of double sound transmitted having coross-power sound intensity, mathematical model is established between three-dimensional sound intensity at measuring point and sound intensity component for calculating out three-dimensional vector sound intensity. The probe is formed by four sound pressure transducers located on four top positions of regular tetrahedron.

Owner:HEFEI UNIV OF TECH

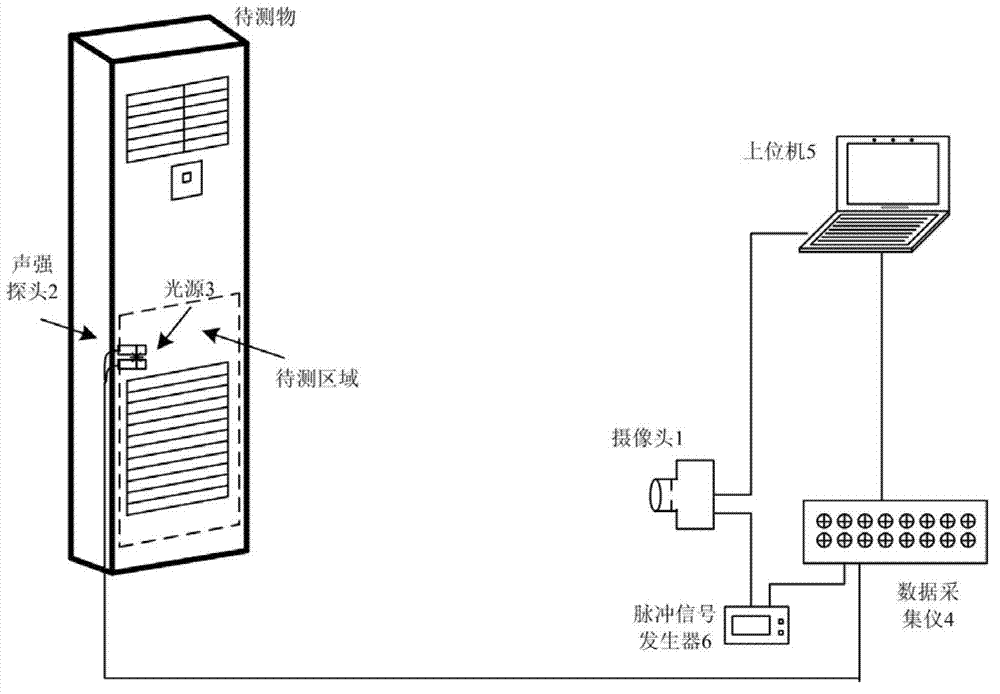

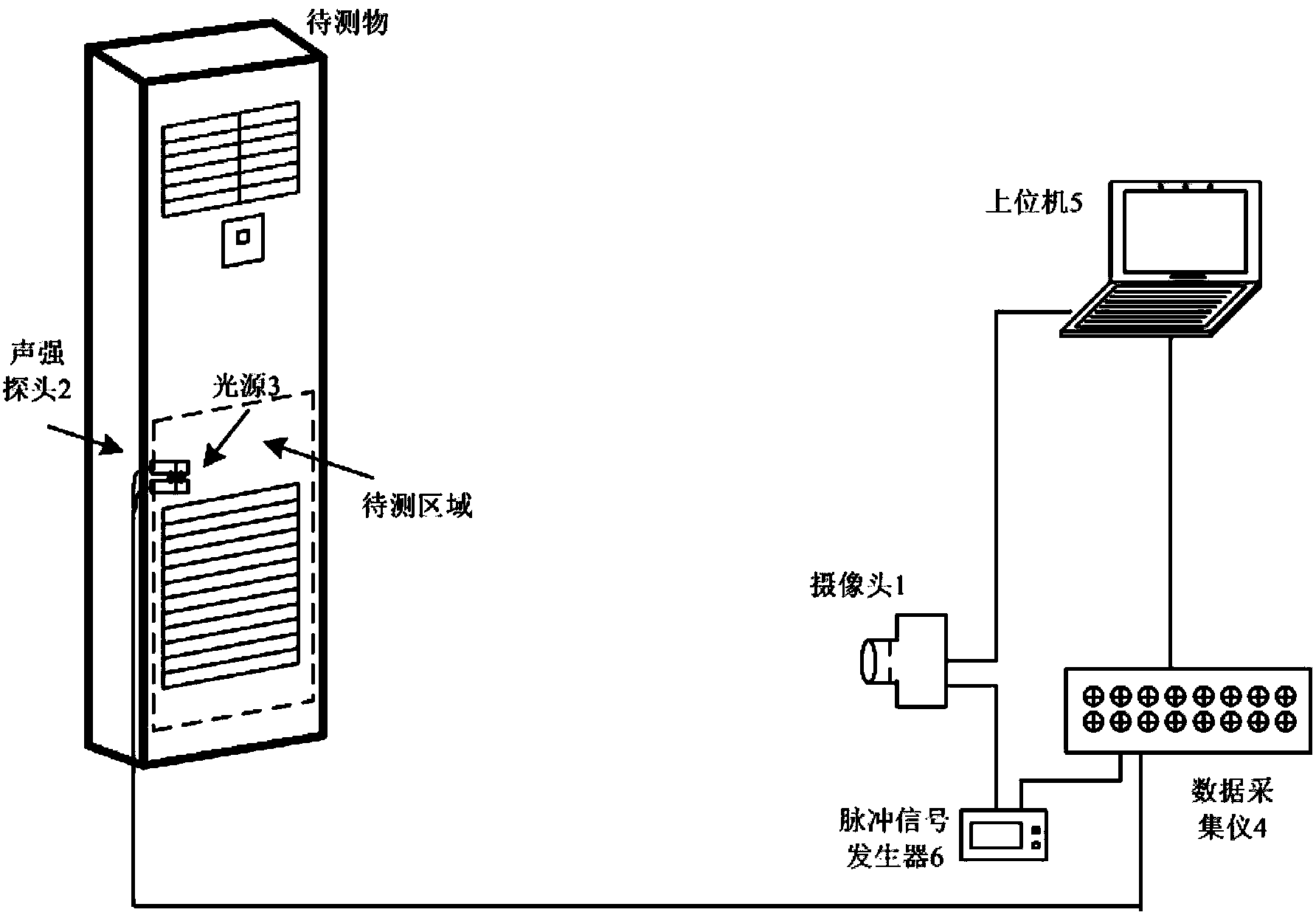

System and method for quickly positioning noise source through image identification and sound intensity scanning

InactiveCN102879763ARapid positioningAvoid interferencePhotogrammetry/videogrammetryPosition fixationNoiseData acquisition

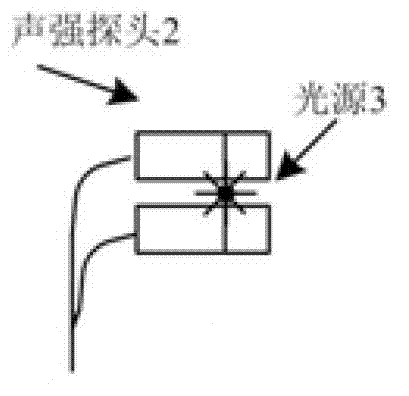

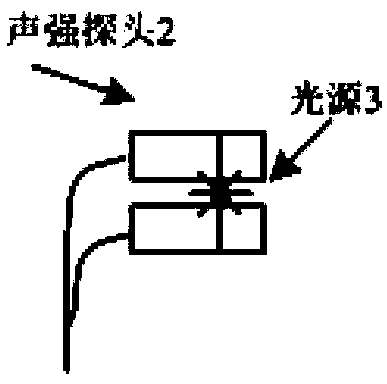

The invention discloses a system and a method for positioning a noise source. The method comprises the following steps of: adjusting the position and focal length of a camera until a taken image comprises a region to be detected, and storing an image which is taken as a background image into an upper computer; fixing a light source on a sound intensity probe which is connected with a data acquirer; endowing the image which is taken by the camera with the color of a light source by filtering; moving the sound intensity probe, and scanning on the surface of the region to be detected at constant speed; outputting a trigger signal by a pulse signal generator, continuously taking images by the camera, recording a motion image of the light source, recording the trigger signal and an acoustic signal by the data acquirer, and synchronizing the acoustic signal and image taking time; after detection is finished, processing the image, and thus obtaining the position of the light source in a picture; extracting the acoustic signal, and thus obtaining acoustic physical quantity information at a corresponding moment; dividing the region to be detected into triangular units, wherein nodes are the positions of the light source, which are acquired at all moments, and the acquired acoustic physical quantity serves as a cloud picture measuring value; and acquiring a sound field cloud picture, and displaying the sound field cloud picture. The invention has the advantages of quick positioning, accurate measurement and high accuracy.

Owner:SHANGHAI JIAO TONG UNIV

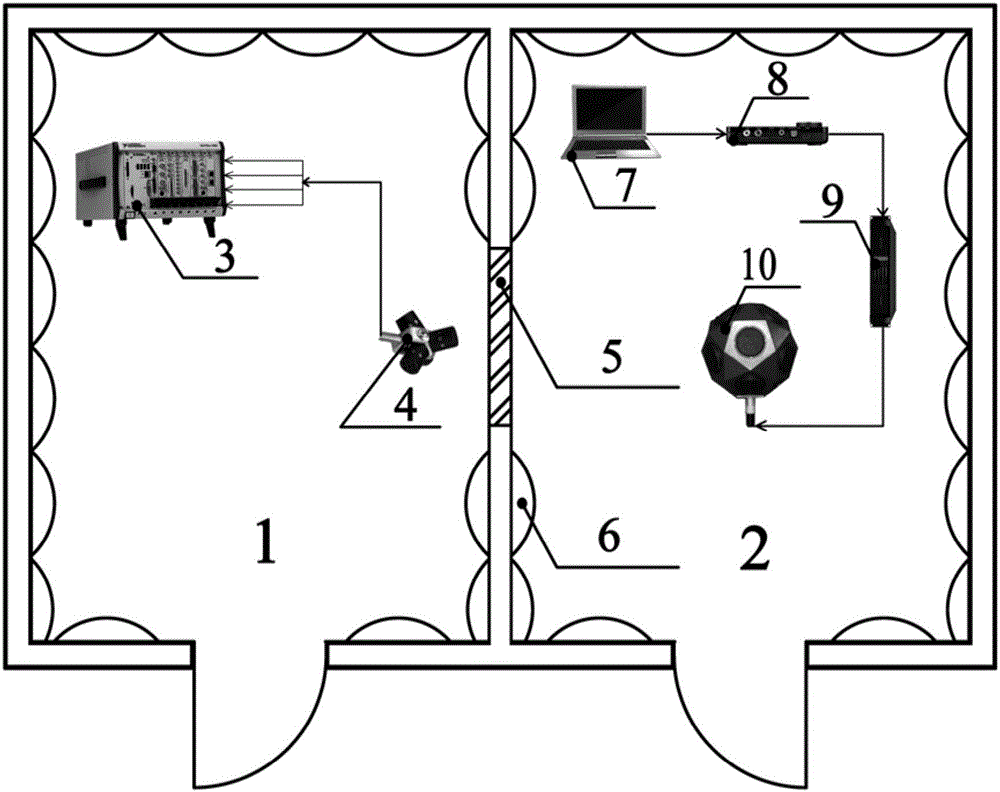

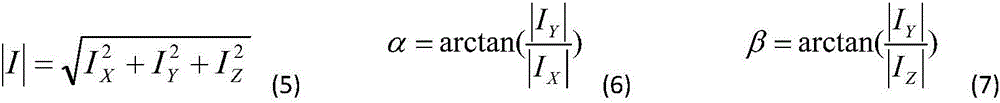

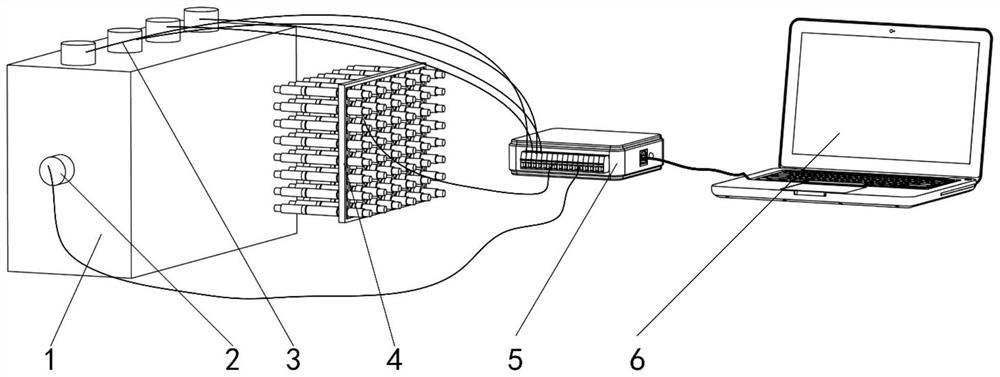

Sound insulation measurement system and measurement method based on three-dimensional sound intensity array

PendingCN106680376ALocating Acoustic DefectsSuppresses lateral sound transmissionAnalysing solids using sonic/ultrasonic/infrasonic wavesResponse signal detectionSound sourcesDodecahedron

The invention discloses a sound insulation measurement system and a measurement method based on a three-dimensional sound intensity array. According to the sound insulation measurement system, a measurement platform based on Labview and a regular tetrahedron sound intensity probe are arranged inside a sound receiving chamber; a PC (Personal Computer), a sound card, a power amplifier and a dodecahedron loudspeaker are arranged inside a sound source chamber; the PC, the sound card, the power amplifier and the dodecahedron loudspeaker are connected in sequence; the dodecahedron loudspeaker is positioned in the central position of the sound source chamber; a test part to be measured and a reflection plate are arranged between the sound receiving chamber and the sound source chamber; the test part to be measured is arranged in the center of a wall surface; the reflection plate is positioned at the periphery of the test part to be measured; the sound receiving chamber is completely isolated from the sound source chamber through the test part to be measured and the reflection plate; the PC, the sound card, the power amplifier and the dodecahedron loudspeaker form an original signal output module. Sound intensity vectors tested by using the sound insulation measurement system comprise information such as amplitude and phase, and not only is an air sound insulation index of a building part tested, but also the direction of a noise source can be predicted by calculating directions.

Owner:SOUTH CHINA UNIV OF TECH

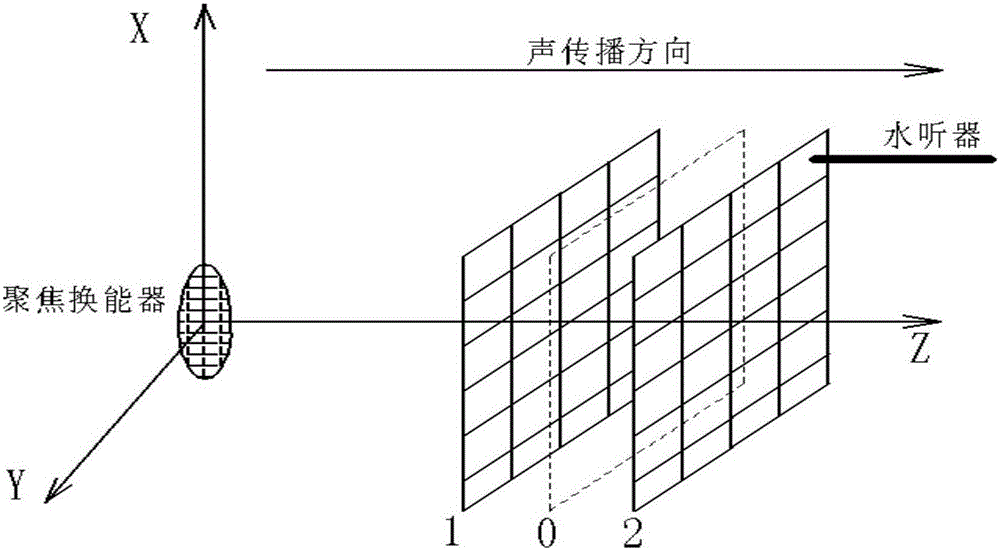

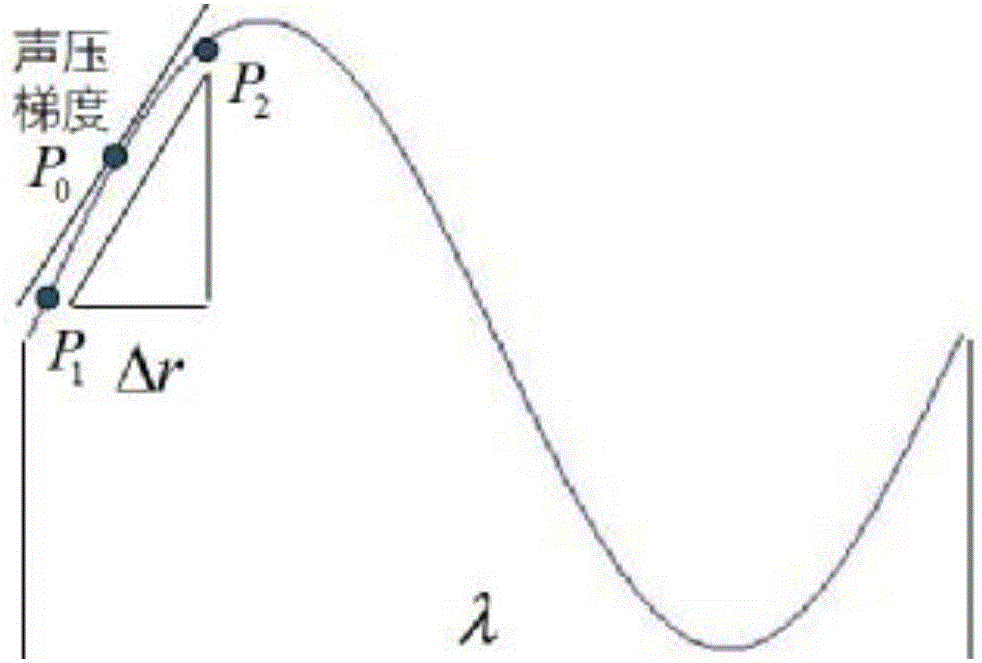

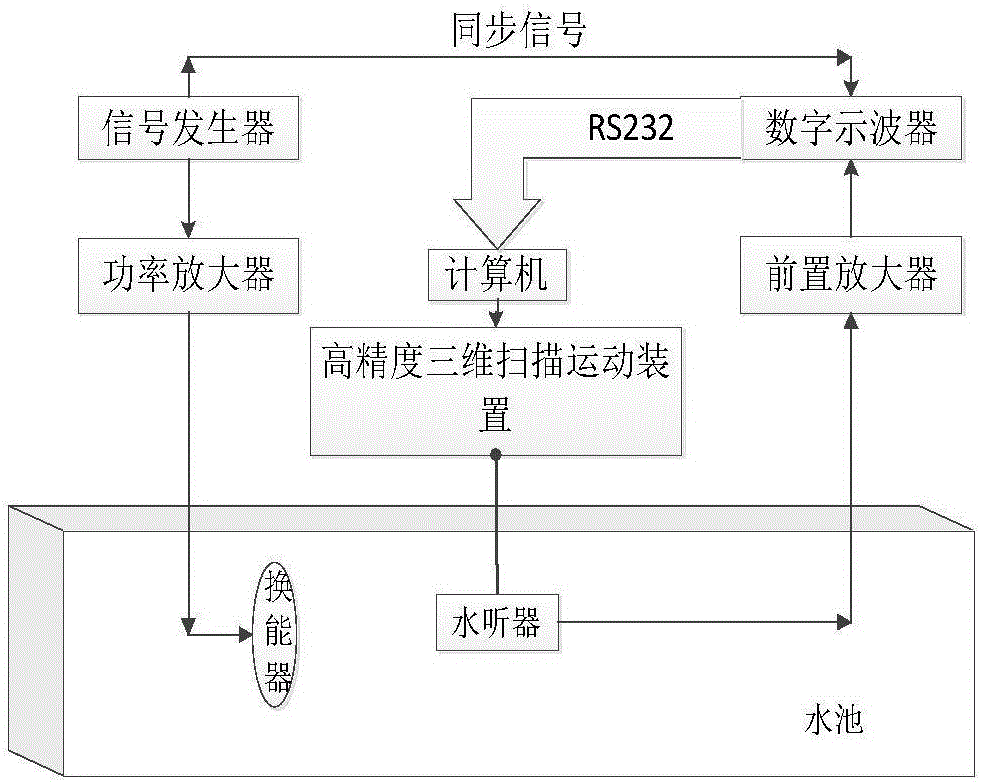

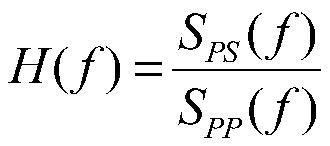

Sound intensity and acoustical power measurement method of high-strength focused ultrasound

PendingCN106813774AEasy to implementComputationally efficientSubsonic/sonic/ultrasonic wave measurementFocus ultrasoundHydrophone

The present invention relates to a sound intensity and acoustical power measurement method of the high-strength focused ultrasound. The sound intensity and acoustical power measurement method of the present invention is characterized by selecting two mutually parallel first and second planes in a pre-focusing area of the high-strength focused ultrasound to measure, and using a PC to control a hydrophone to scan the sound pressure data on the first plane, and then using a servo motor to control the hydrophone to move along a Z direction accurately, repeating the above control and acquisition processes, and obtaining the sound pressure data on the second plane. The sound intensity and acoustical power measurement method of the high-strength focused ultrasound of the present invention has the remarkable characteristics of being simple and convenient to implement, efficient and accurate to calculate, etc., avoids measuring in a focusing area, can protect a sensor furthest, can obtain a plurality of parameters, such as the sound intensity distribution, etc., while obtaining the acoustical power, facilitates evaluating the performances of a focusing transducer comprehensively, and is suitable for measuring the radiation acoustical powers of various focusing transducers.

Owner:CHINA JILIANG UNIV

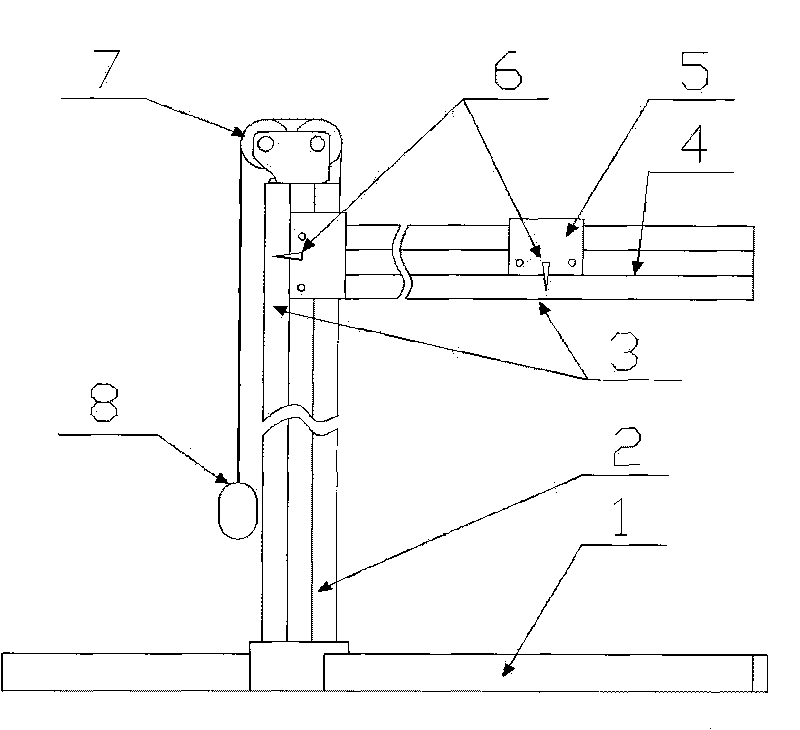

Sound intensity testing bracket

ActiveCN101709996AEasy to operateLow costSubsonic/sonic/ultrasonic wave measurementEngineeringSound intensity probe

The invention relates to a sound intensity testing bracket, which comprises a bracket base, a vertical rail, a horizontal rail and a sound intensity probe, wherein the vertical rail is vertically arranged on the bracket base; the horizontal rail is vertically arranged on the vertical rail and is arranged horizontally; and the sound intensity probe is movably arranged on the horizontal rail.

Owner:CHERY AUTOMOBILE CO LTD

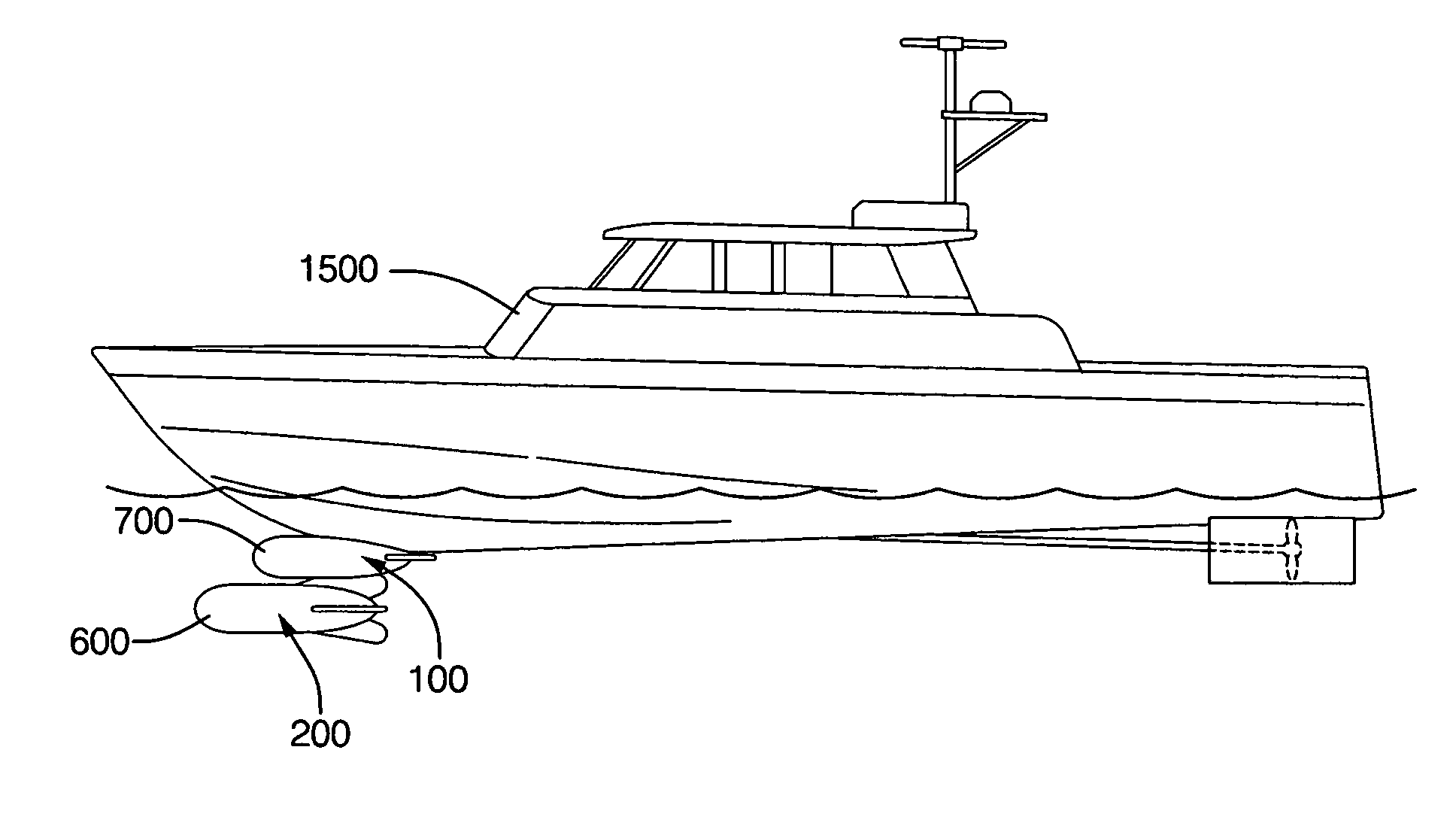

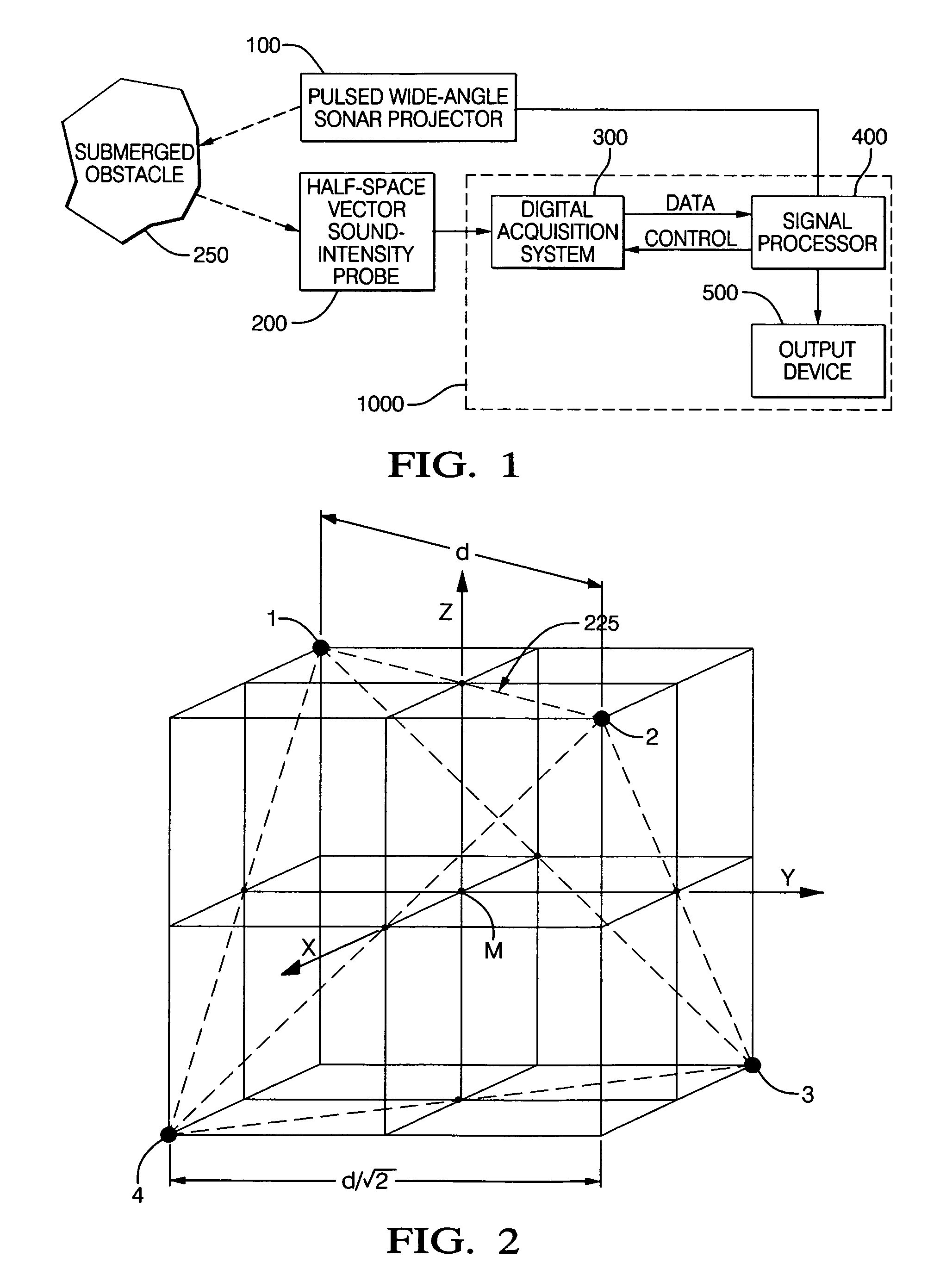

Forward-looking sonar for ships and boats

InactiveUS8203909B1Analysing solids using sonic/ultrasonic/infrasonic wavesResponse signal detectionSonarOn board

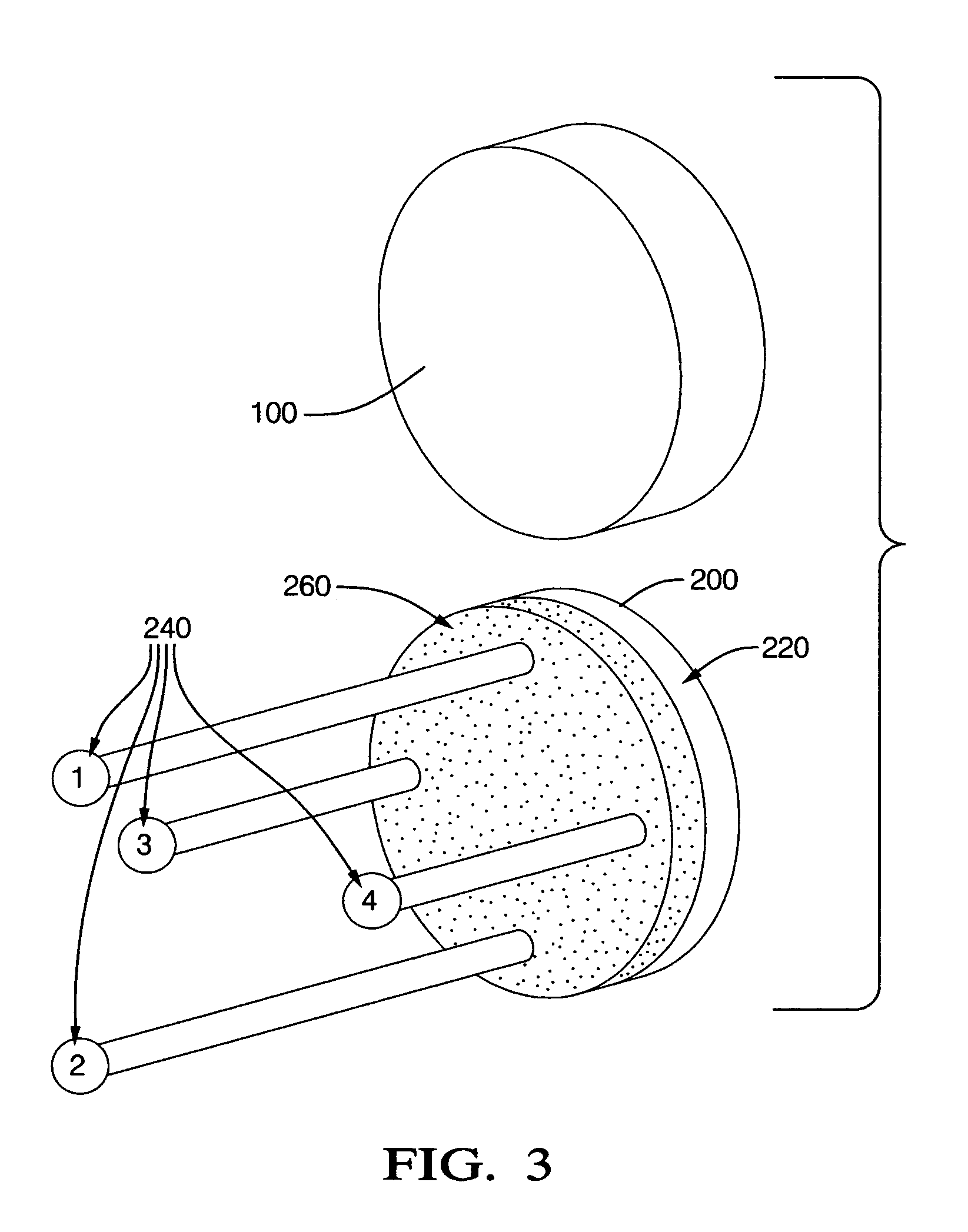

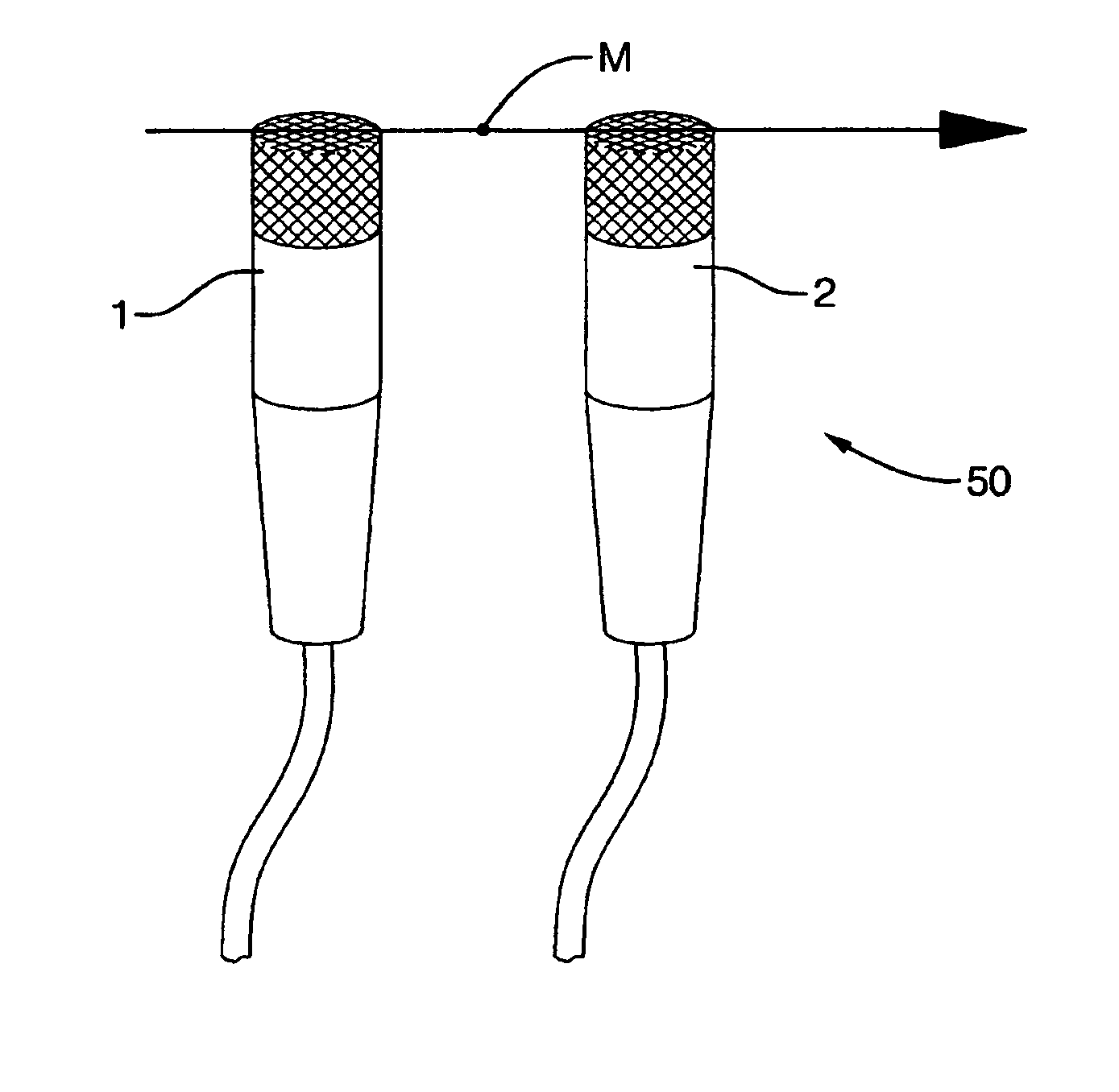

Method and apparatus for detecting and locating underwater obstacles in the path of a ship or boat. The apparatus includes a pulsed wide-angle sonar projector (100) controlled by a digital signal processor (400) that emits sound pulses at frequencies of 30 kHz and less that can penetrate sediment-laden water hundreds of meters or more ahead of the ship or boat. The projector generates echoes from submerged objects. A vector sound-intensity probe (200) receives the echoes and transmits them to the digital signal processor. The digital signal processor determines the location of submerged obstacles ahead of the ship or boat from the echoes received by the probe. This information is displayed on an output device (500). The sonar projector and vector sound-intensity probe are contained separately in streamlined housings aimed in the forward direction under the bow of the ship or boat. The processor, output device and other electronics are located on board the ship or boat.

Owner:HICKLING ROBERT

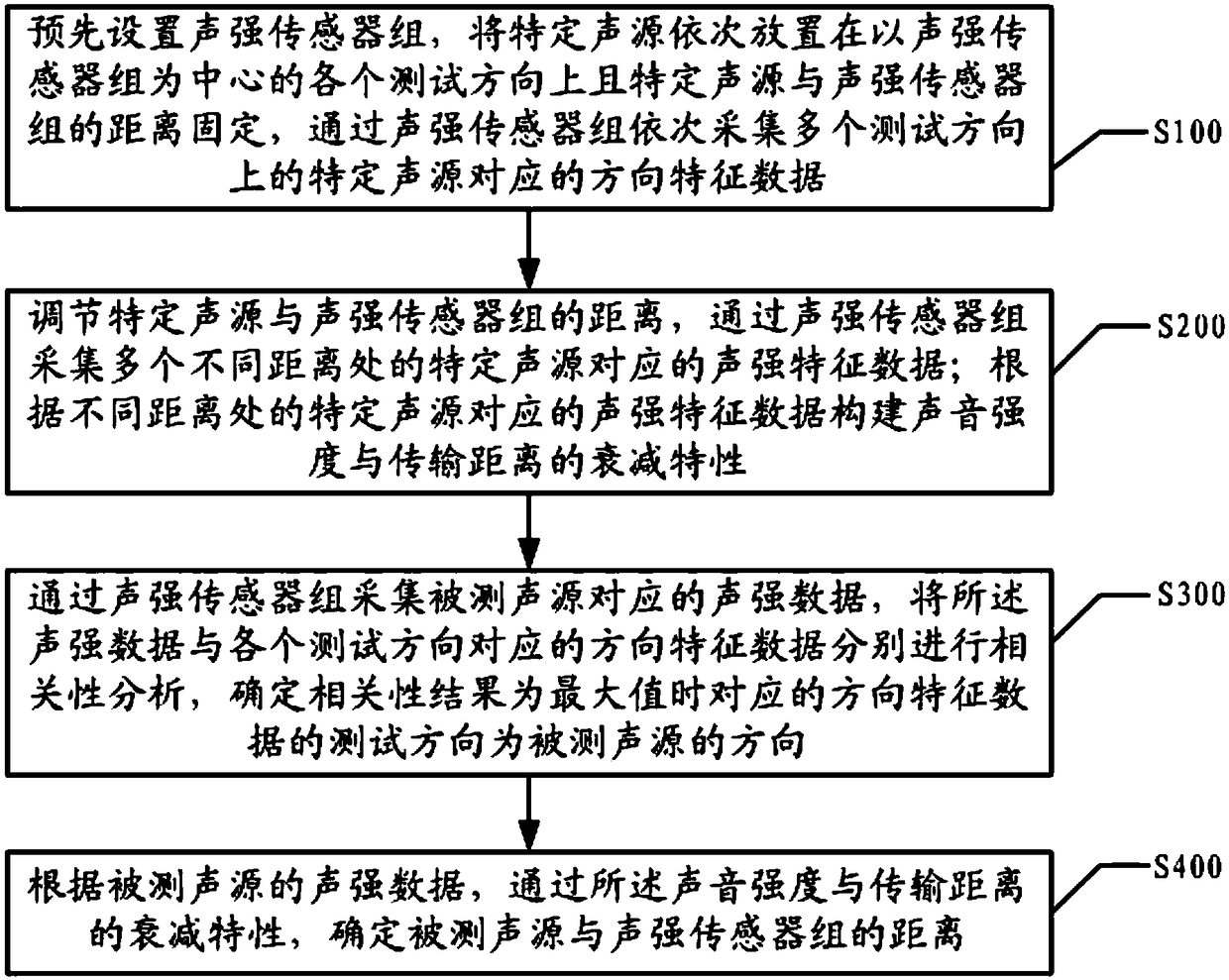

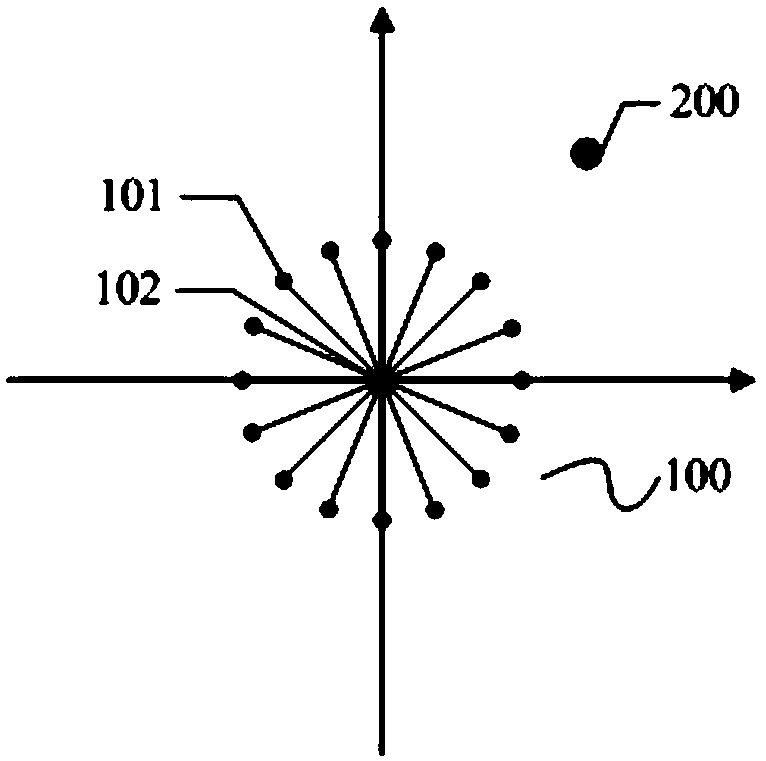

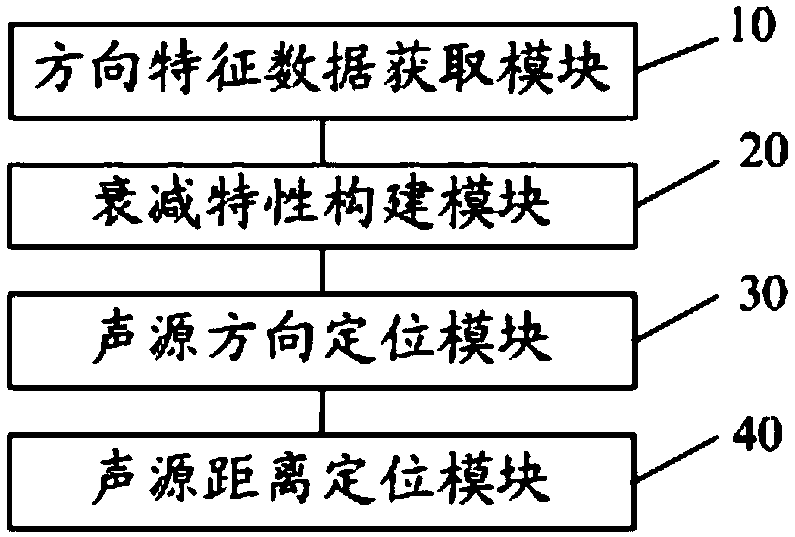

Sound source positioning method and system

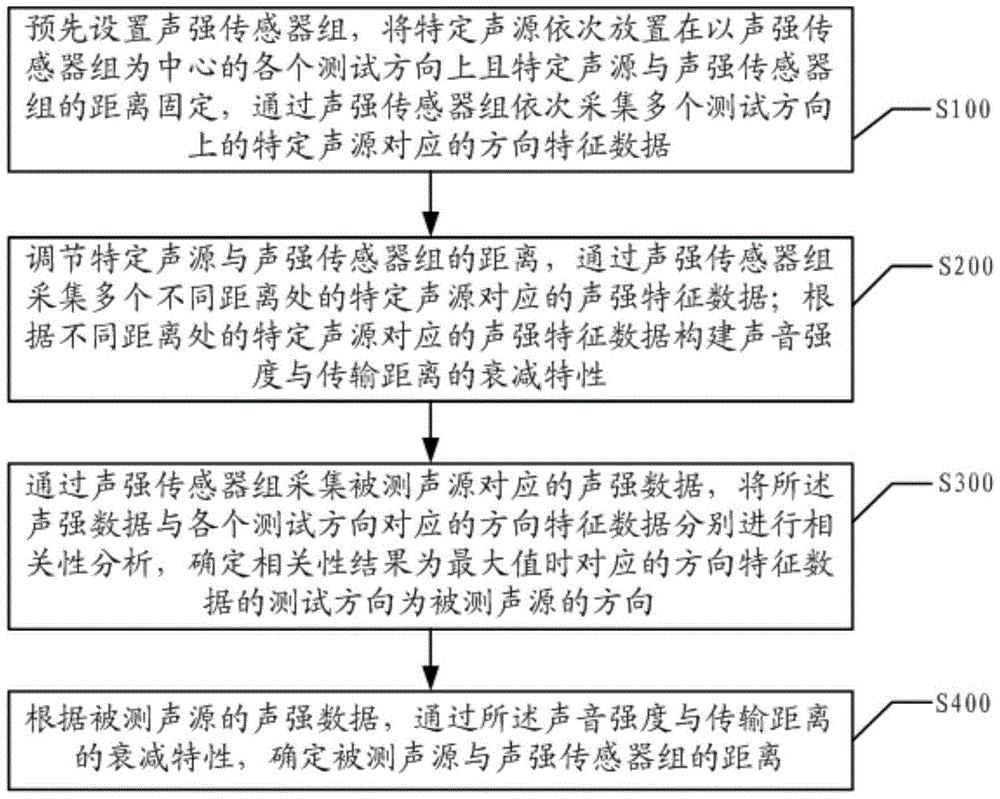

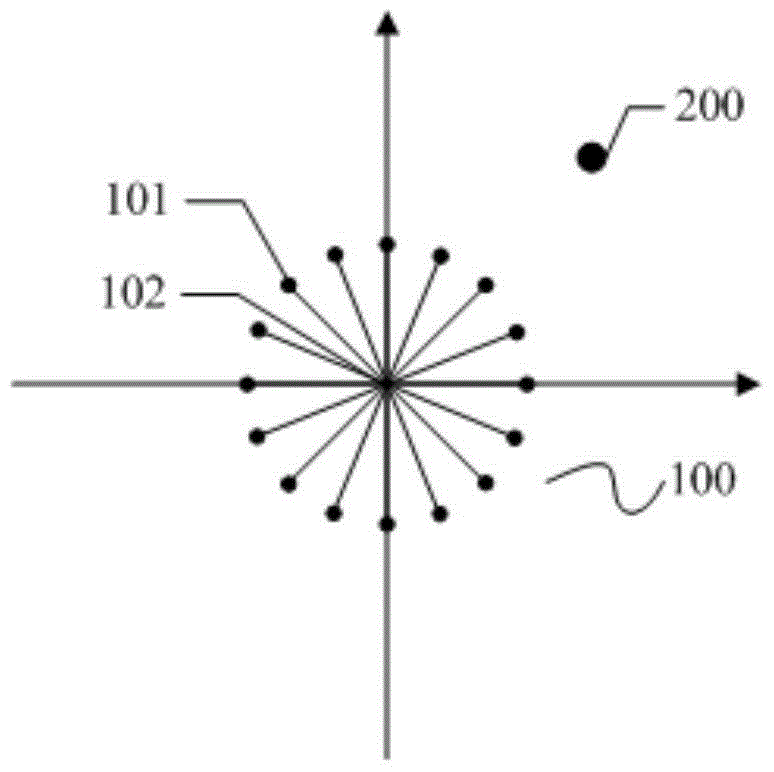

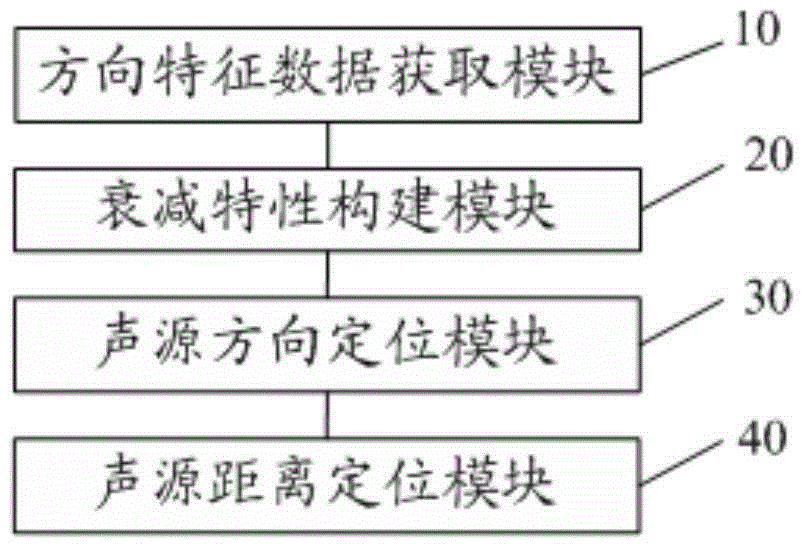

ActiveCN105204002AReduce the difficulty of implementationHigh positioning accuracyPosition fixationUltrasound attenuationSound sources

The invention discloses a sound source positioning method and system. Through the arrangement of a sound intensity sensor group in advance, specific sound sources are arranged in various testing directions with fixed intervals by taking the sound intensity sensor group as the center in sequence, and direction feature data corresponding to the specific sound sources in the various testing directions is collected; sound intensity feature data corresponding to the specific sound sources at different distances is collected to establish the attenuation characteristic of sound intensity and transmission distance; sound intensity data corresponding to a sound source to be tested is collected, the sound intensity data and the direction feature data corresponding to the testing directions are respectively subjected to correlation analysis, and the testing direction corresponding to the maximum value of correlation results is determined as the direction of the sound source to be tested; according to the sound intensity data and the attenuation characteristic, the distance between the sound source to be tested and the sound intensity sensor group is determined. The sound source positioning is realized by adoption of methods of feature matching of the sound source direction and the attenuation characteristic of the sound source distance, the implementation difficulty of sound source positioning is reduced, and meanwhile the positioning accuracy and the stability are improved.

Owner:TCL CORPORATION

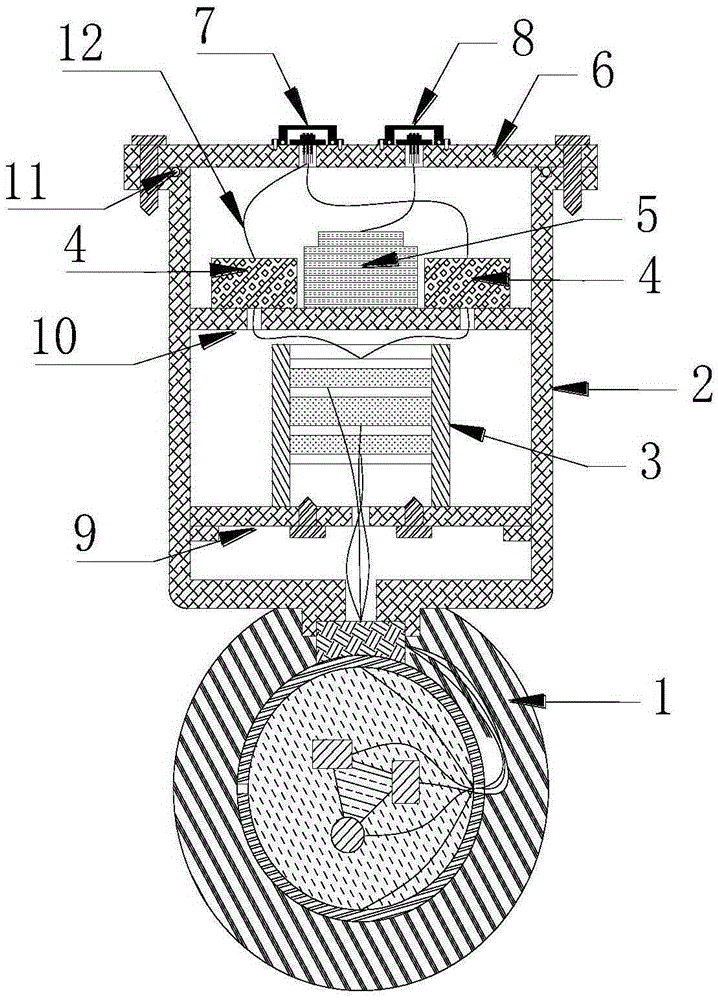

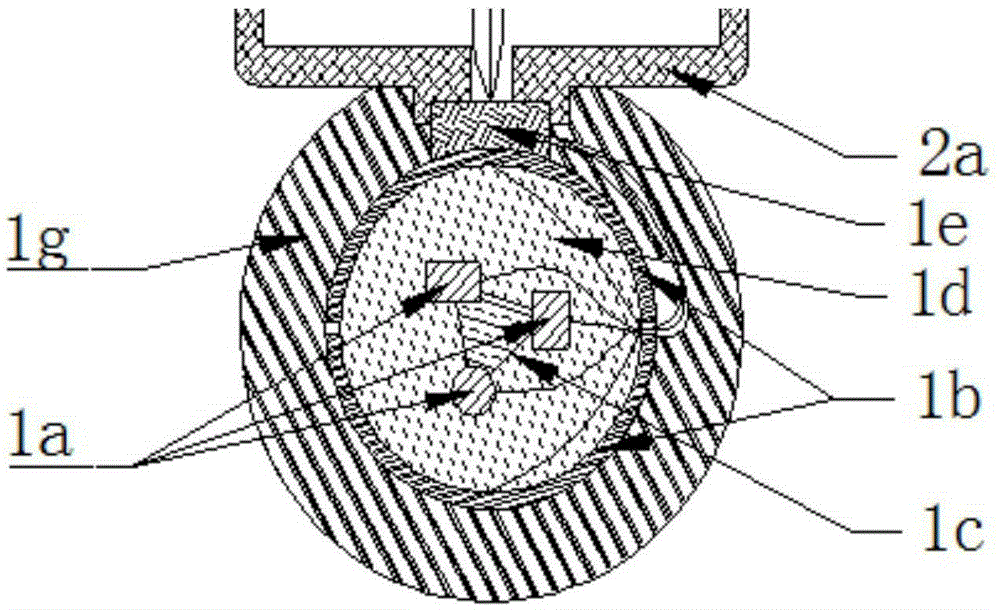

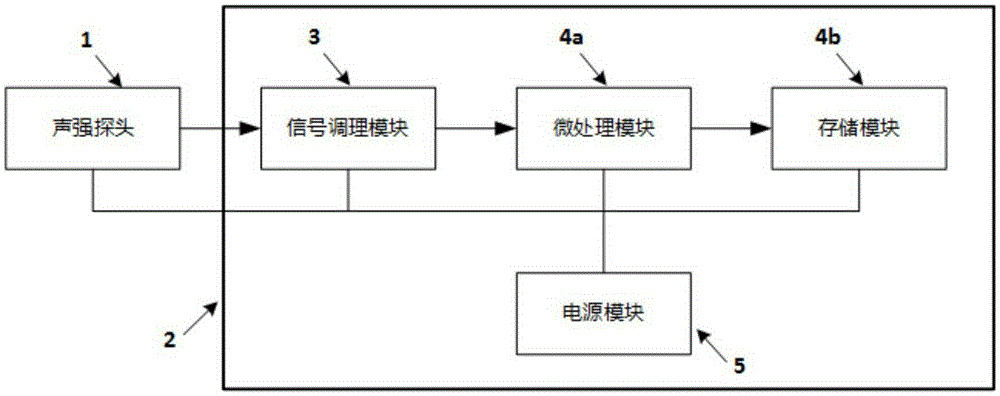

Underwater self-contained sound intensity instrument and sound intensity measurement method

InactiveCN105424167AReduce usageReduce distractionsSubsonic/sonic/ultrasonic wave measurementUsing electrical meansBattery chargeSignal conditioning

The invention discloses an underwater self-contained sound intensity instrument and a sound intensity measurement method. A sound intensity probe is installed at the lower end of a storage bin bottom seat, and the interior of a storage bin is provided with a lower partitioning plate and an upper partitioning plate. A signal conditioning module is disposed on the lower partitioning plate, and a microprocessing and storage module and a power module are disposed on the upper partitioning plate. A data reading interface and a storage battery charging interface are disposed on an upper cover plate of the storage bin, and are sealed through O-shaped rings. An output end of the sound intensity probe is connected with an input end of the signal conditioning module. An output end of the signal conditioning module is connected with the microprocessing and storage module. The power module supplies power to the sound intensity probe, the signal conditioning module and the microprocessing and storage module at the same time. The data reading interface is connected with the microprocessing and storage module, and the storage battery charging interface is connected with the power module. The instrument can enable the instant sound intensity, mean sound intensity and complex sound intensity data to be stored in an instrument without a cable.

Owner:HARBIN ENG UNIV

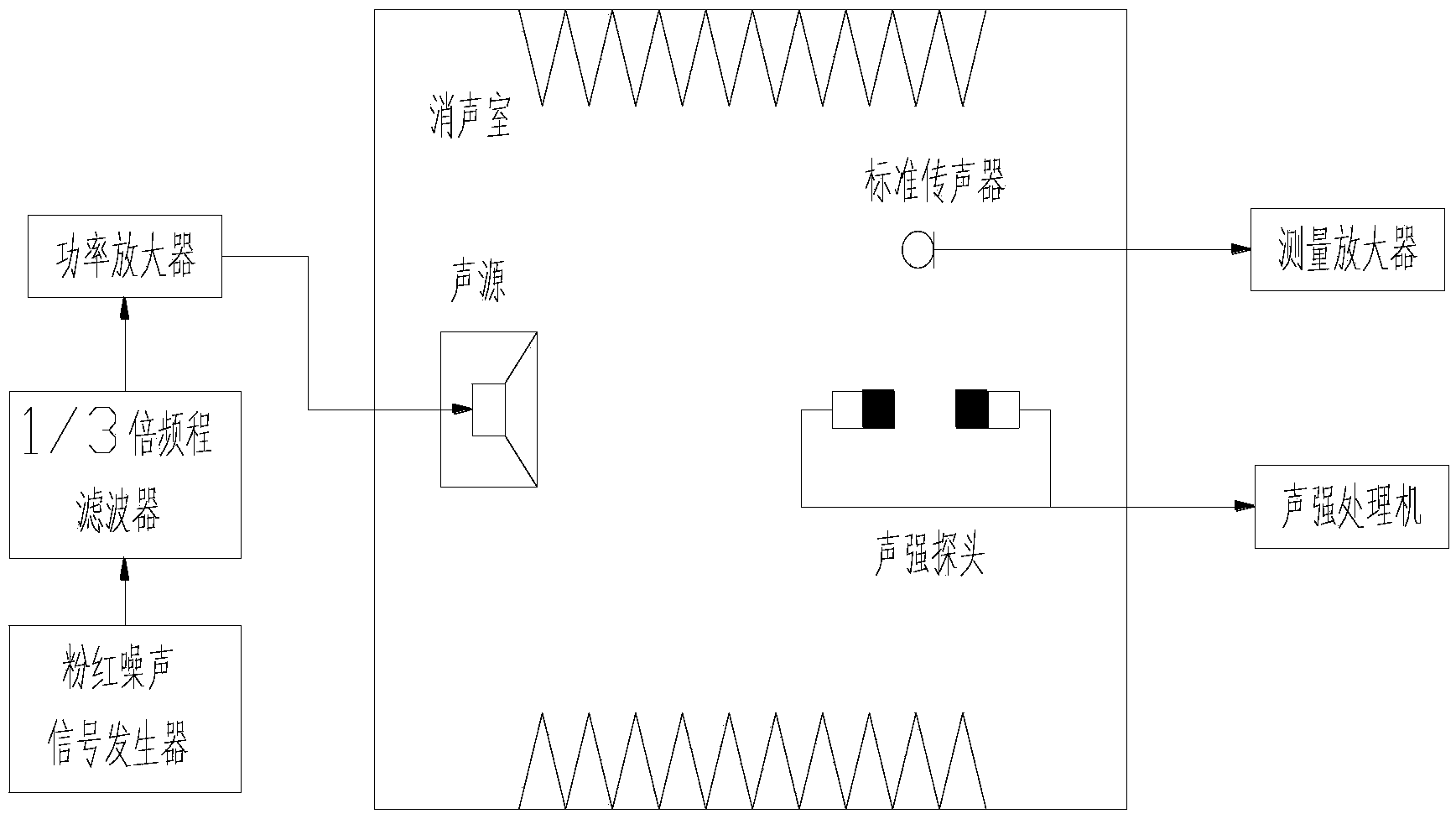

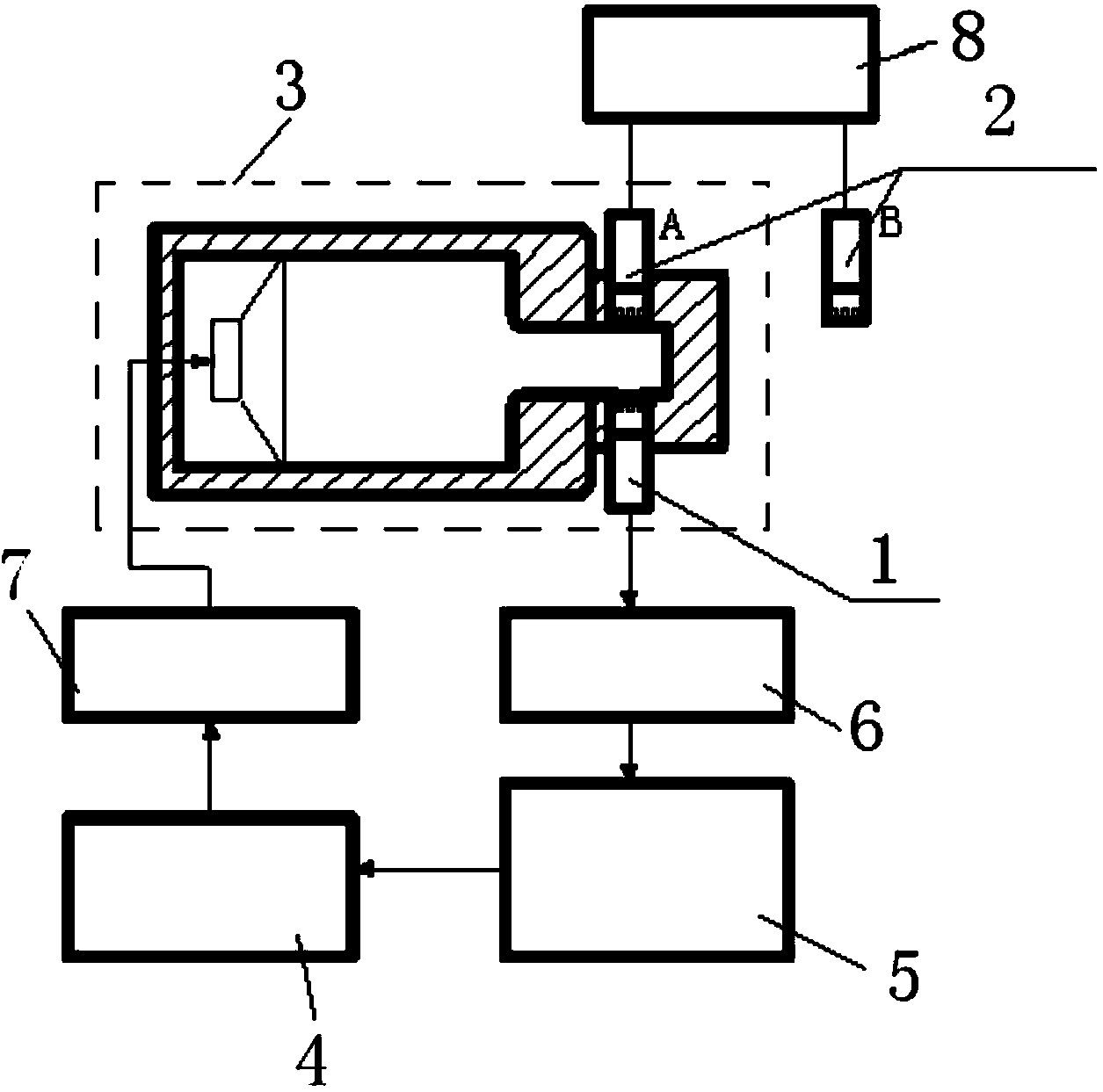

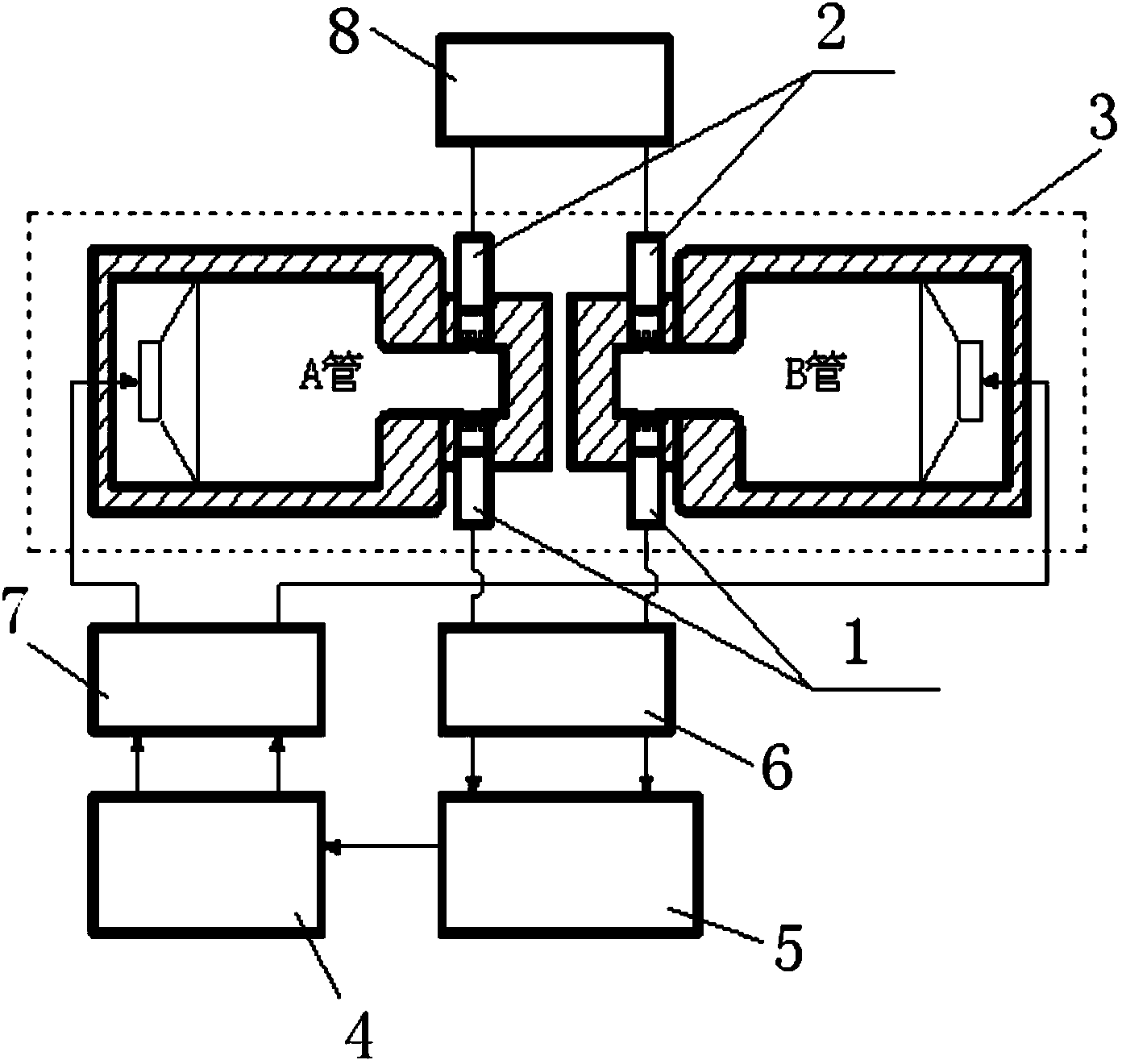

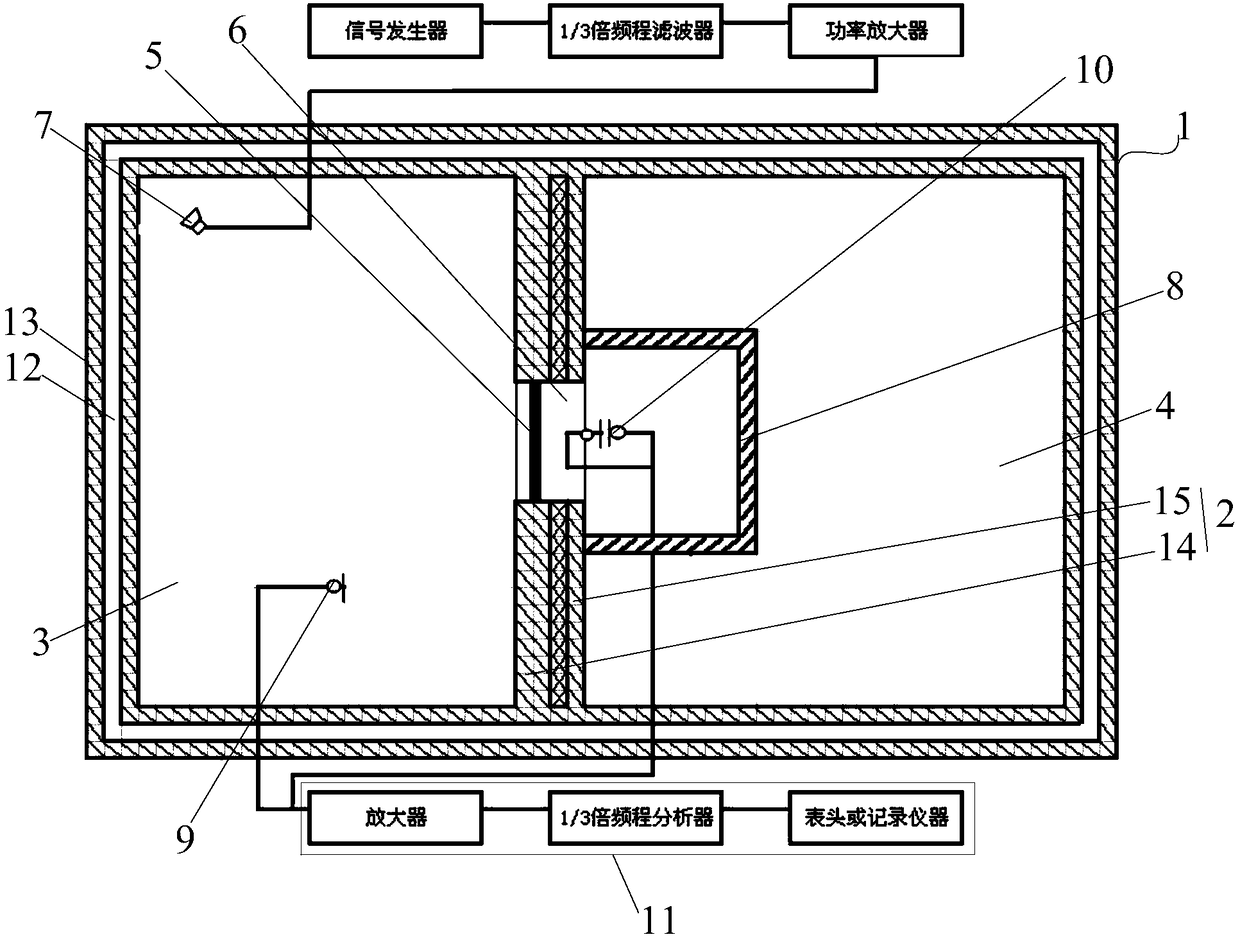

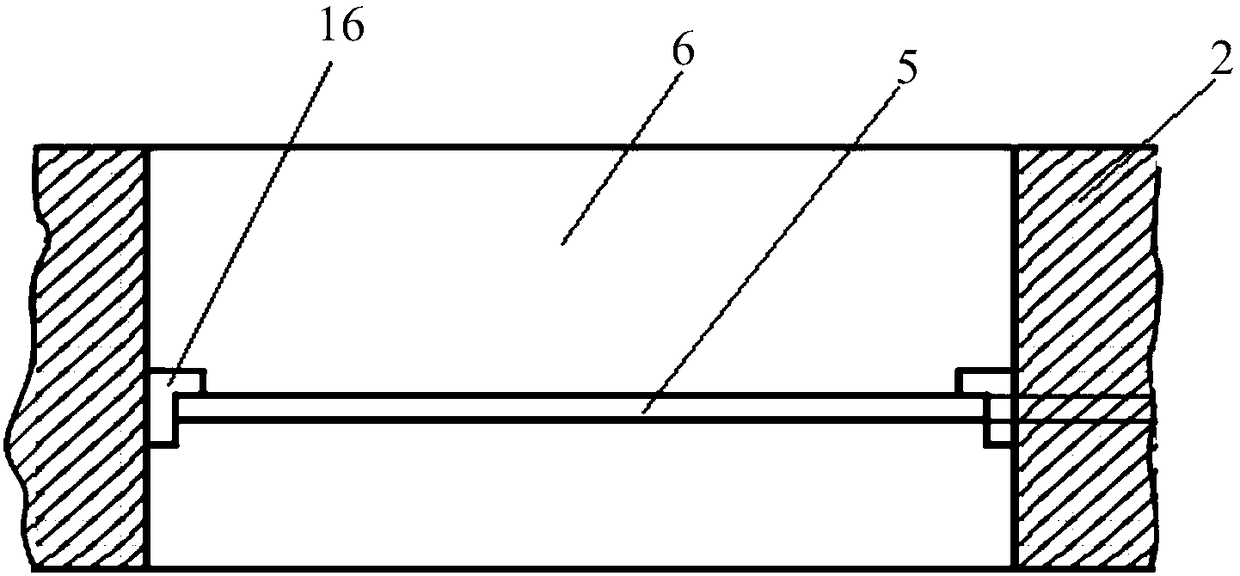

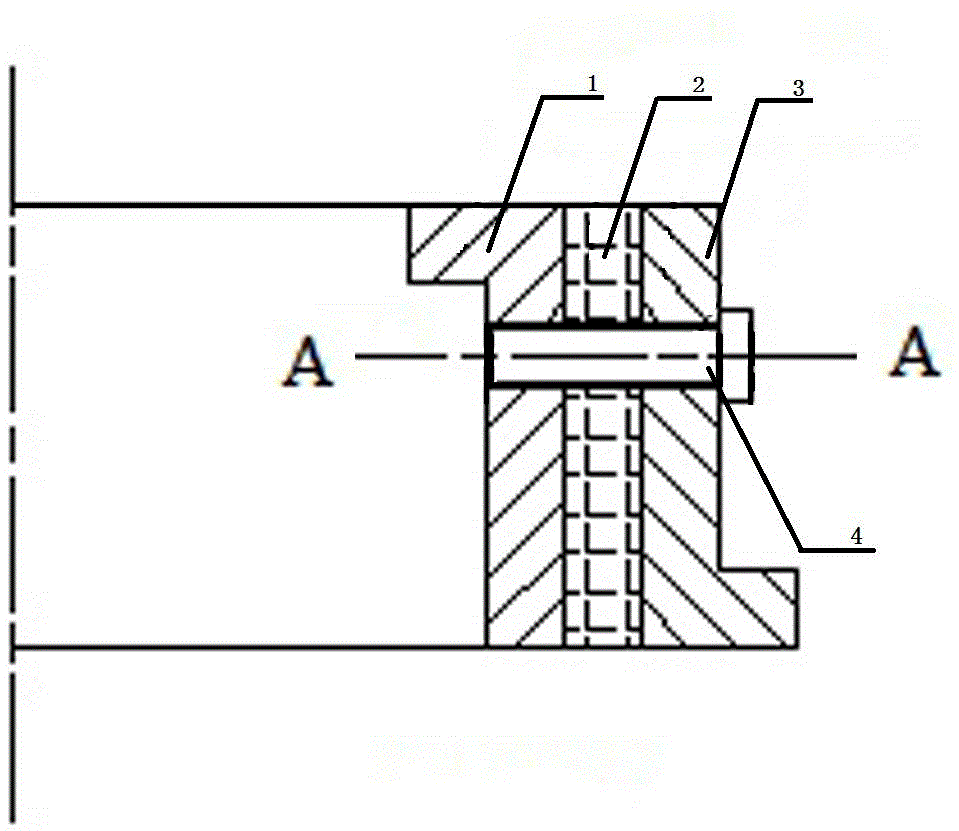

Method for evaluating high sound intensity characteristics of sound intensity measuring instrument

The invention provides a method for evaluating high sound intensity characteristics of a sound intensity measuring instrument. The method is used for evaluating sound intensity level dynamic range upper limit of the sound intensity measuring instrument, and calibrating sound intensity level deviation; a sound intensity probe of the to-be-calibrated sound intensity measuring instrument is provided with two sound intensity probe microphones; the two sound intensity probe microphones are both connected with a sound intensity analysis meter; the intensity probe microphones of the sound intensity measuring instrument and a high sound pressure standard microphone are arranged on a sound intensity level calibration device in axial symmetry. Through the method, the standard sound intensity level is simulated through a standing wave tube sound wave generation technology based on the double resonance sound wave amplitude-phase control principle; the evaluation of sound intensity measuring instrument calibration with measurement range of 100-150dB can be realized.

Owner:BEIJING AEROSPACE INST FOR METROLOGY & MEASUREMENT TECH +1

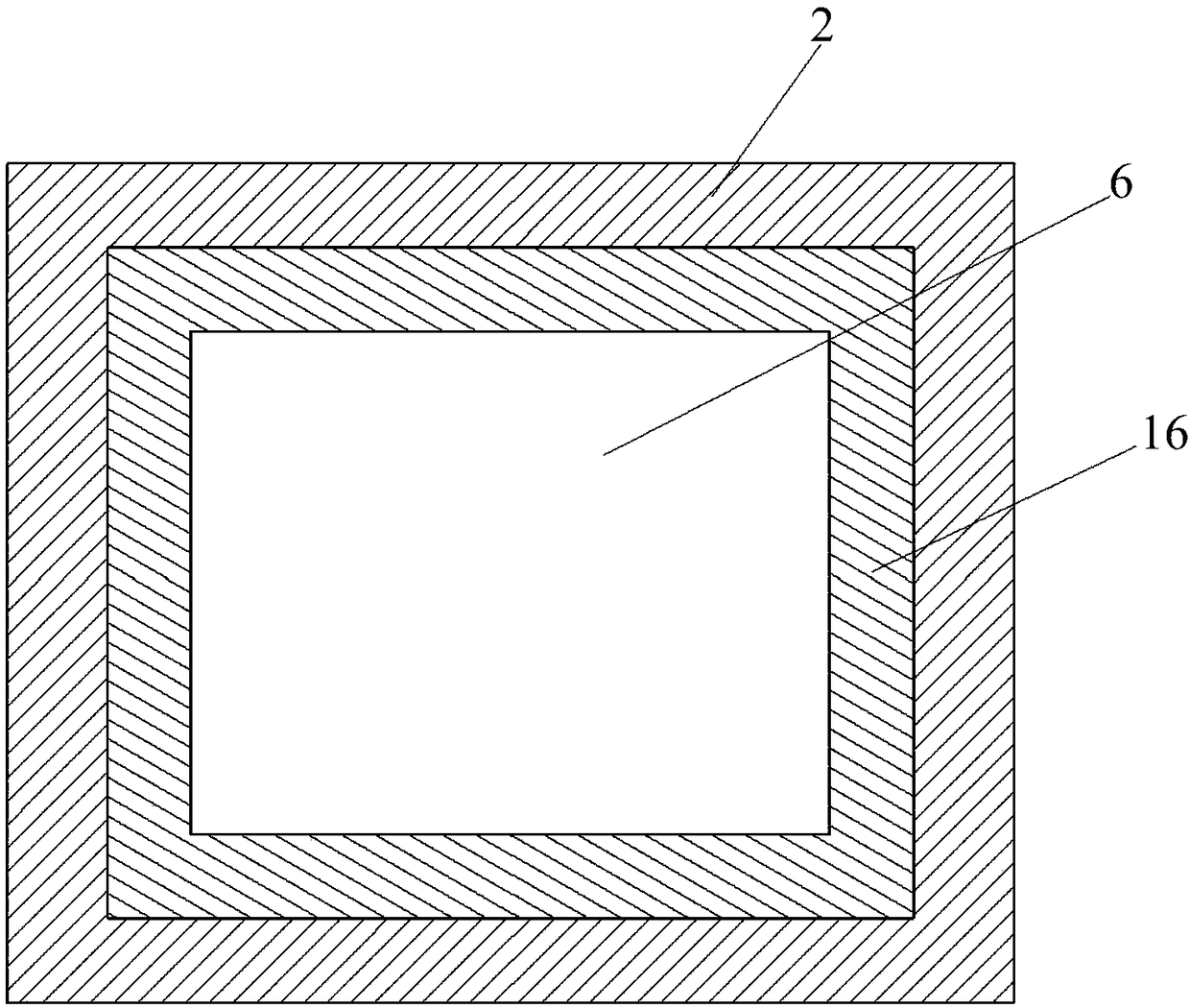

Testing device for automobile front windshield

ActiveCN108333257AGet the sound insulation effectAnalysing solids using sonic/ultrasonic/infrasonic wavesElectricitySound sources

The invention discloses a testing device for an automobile front windshield. The testing device comprises a detection chamber, a sound insulation wall, a loudspeaker, a signal generator, a sound transmitting device, a sound intensity probe and a sound intensity processing unit. The sound insulation wall is arranged in the detection chamber and is used for separating the detection chamber into a sound source chamber and a receiving chamber; the sound insulation wall is provided with a detection hole for placing a test sample; the loudspeaker is arranged in the sound source chamber; the signal generator is electrically connected with the loudspeaker; the sound transmitting device is arranged in the sound source chamber; the sound intensity probe is arranged in the receiving chamber and is located at an opening of the detection hole; the sound transmitting device and the sound intensity probe are electrically connected with the sound intensity processing unit; the sound intensity processing unit is used for obtaining detection results of the sound transmitting device and the sound intensity probe and calculating sound transmission loss. According to the testing device disclosed by theinvention, the sound transmission loss can be calculated according to sound intensity detected by the sound source chamber and the receiving chamber, so that a sound insulation effect of a test sample is obtained.

Owner:ANHUI JIANGHUAI AUTOMOBILE GRP CORP LTD

Sound insulation measurement system based on hand-held sound intensity probe suite

PendingCN109187759ASimple structureEasy to testAnalysing solids using sonic/ultrasonic/infrasonic wavesResponse signal detectionHand heldData acquisition

The invention discloses a sound insulation measurement system based on a hand-held sound intensity probe suite. The sound insulation measurement system based on the hand-held sound intensity probe suite comprises a complete elimination chamber and a reverberation room which are separated through a wall surface, the center of the wall surface is provided with a window which divides the complete elimination chamber and the reverberation room completely through sealing installation of a sample piece to be tested, and the reverberation room is internally and uniformly provided with a plurality oflow-frequency loudspeakers, high-frequency loudspeakers and microphones. The complete elimination chamber is provided with the hand-held sound intensity probe suite, a data acquisition system and hardware and a test computer. The data acquisition system and hardware is in circuit connection with the low-frequency loudspeakers and the high-frequency loudspeakers through an audio control unit to constitute an original signal output module. The hand-held sound intensity probe suite and the microphones are separately connected with the data acquisition system and hardware, and the data acquisitionsystem and hardware is connected with the test computer. According to the sound insulation measurement system based on the hand-held sound intensity probe suite, the structure is simple, the test process is easy to adjust, the sound insulation measurement system is convenient to move, meanwhile, sound insulation measurement results are reliable, and the cost is low.

Owner:SOUTH CHINA UNIV OF TECH

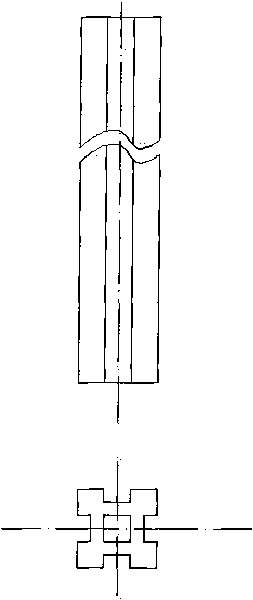

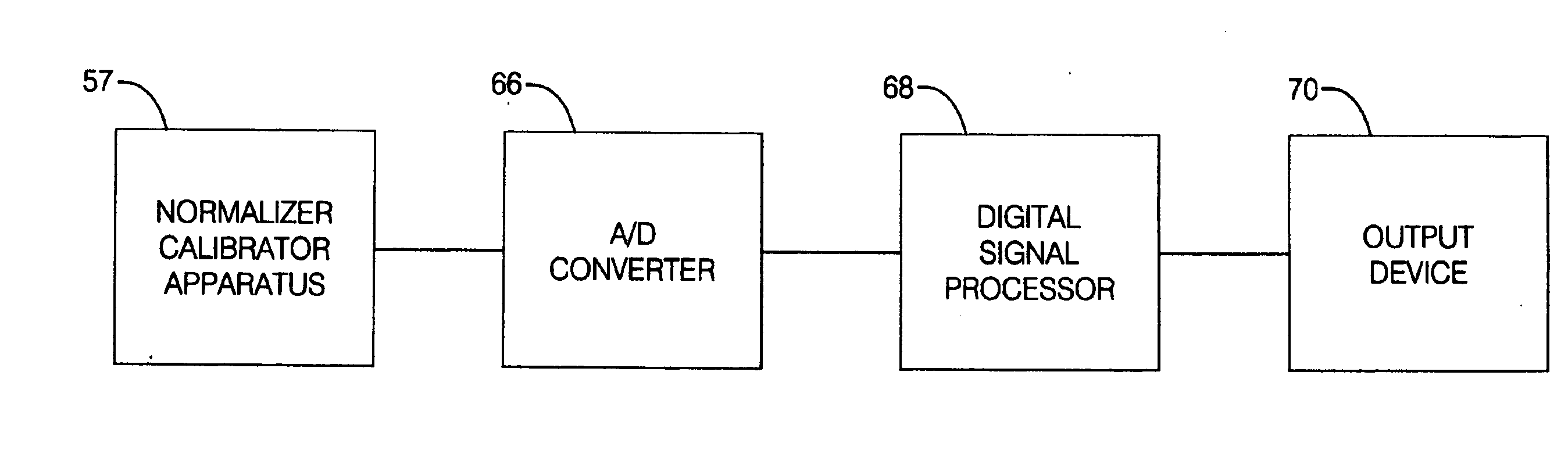

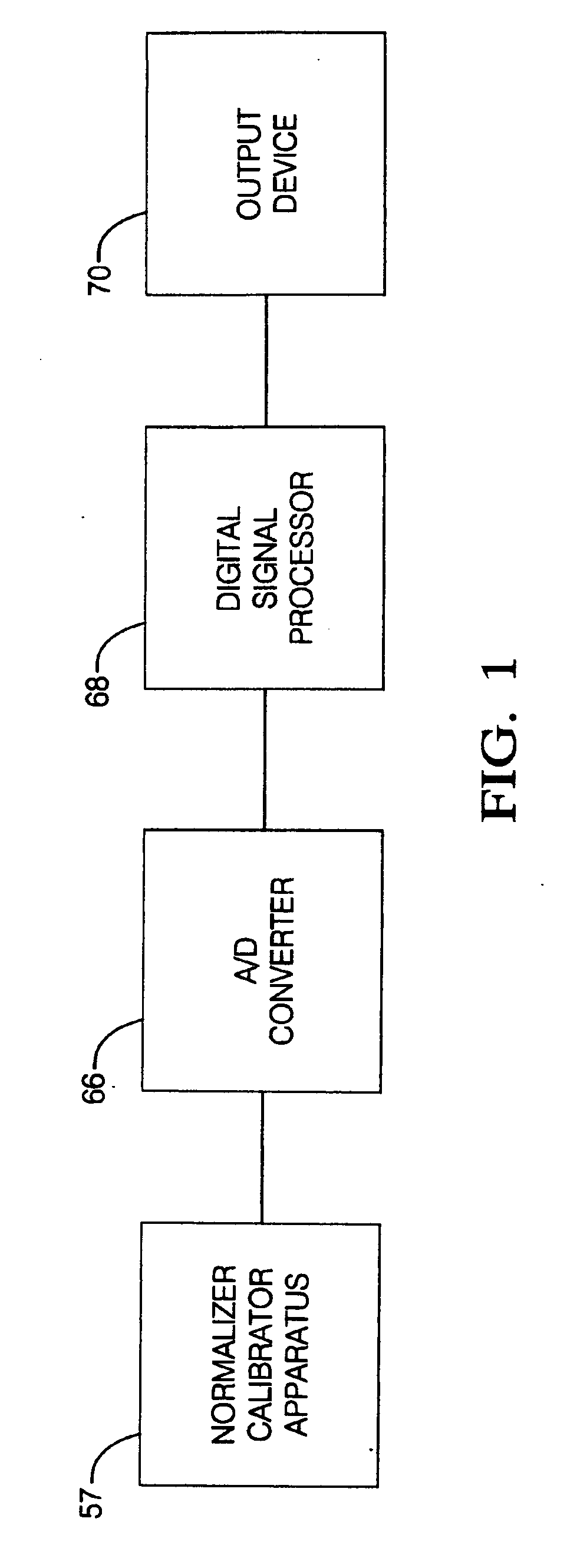

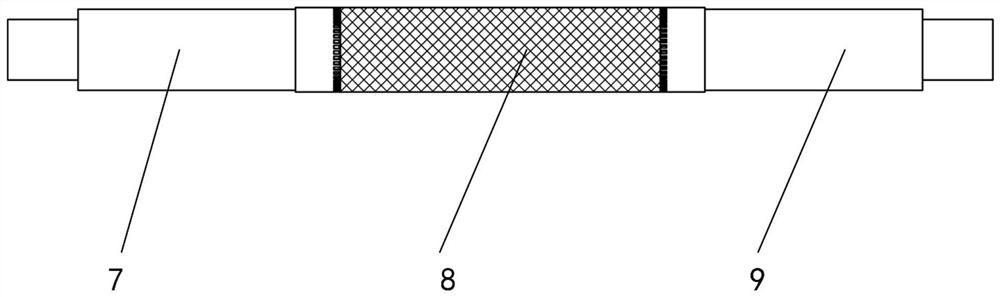

Normalization and calibration of microphones in sound-intensity probes

InactiveUS20070223730A1Accurate measurementImprove accuracyFrequency response correctionElectrostatic transducersSound sourcesEngineering

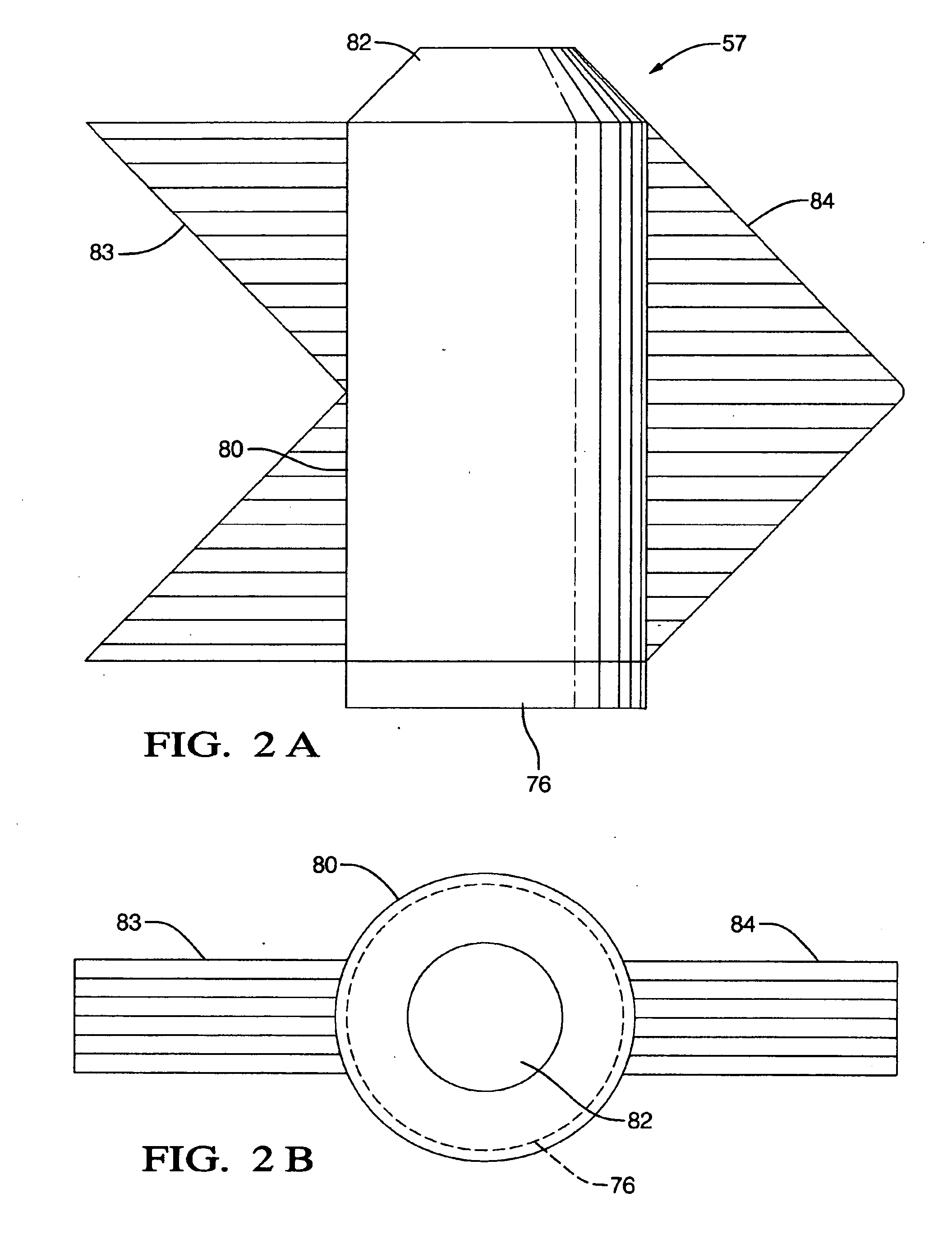

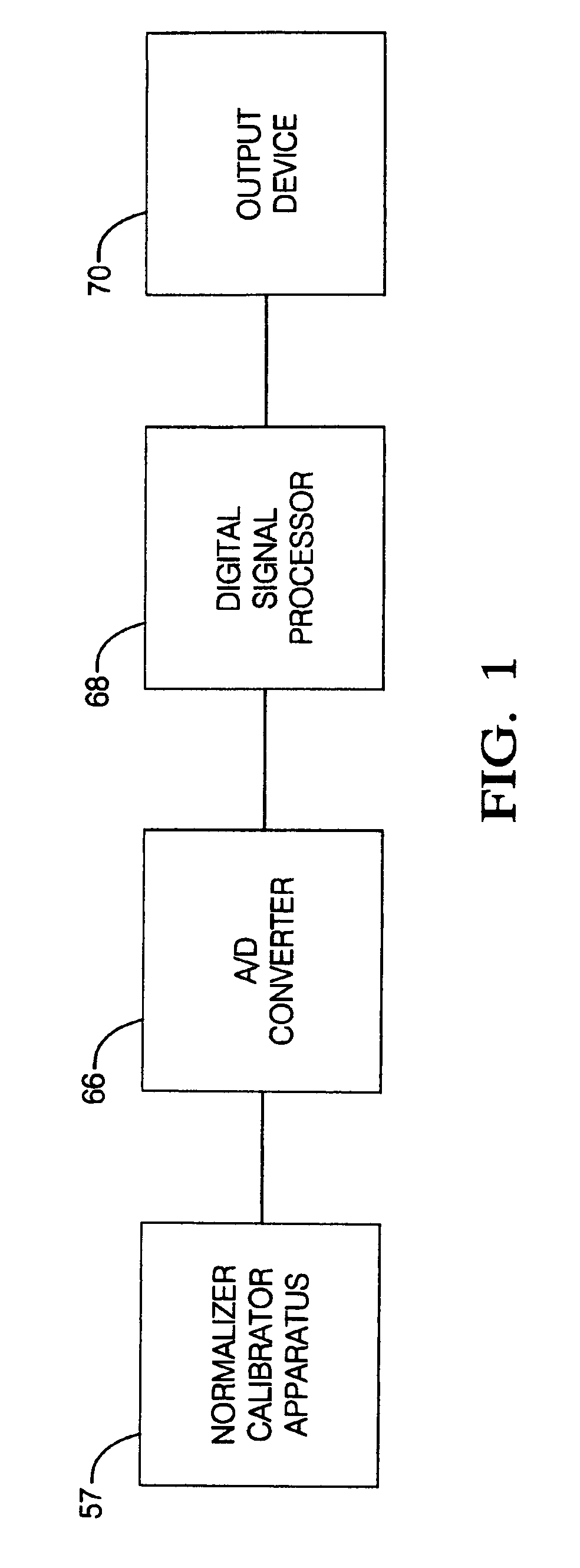

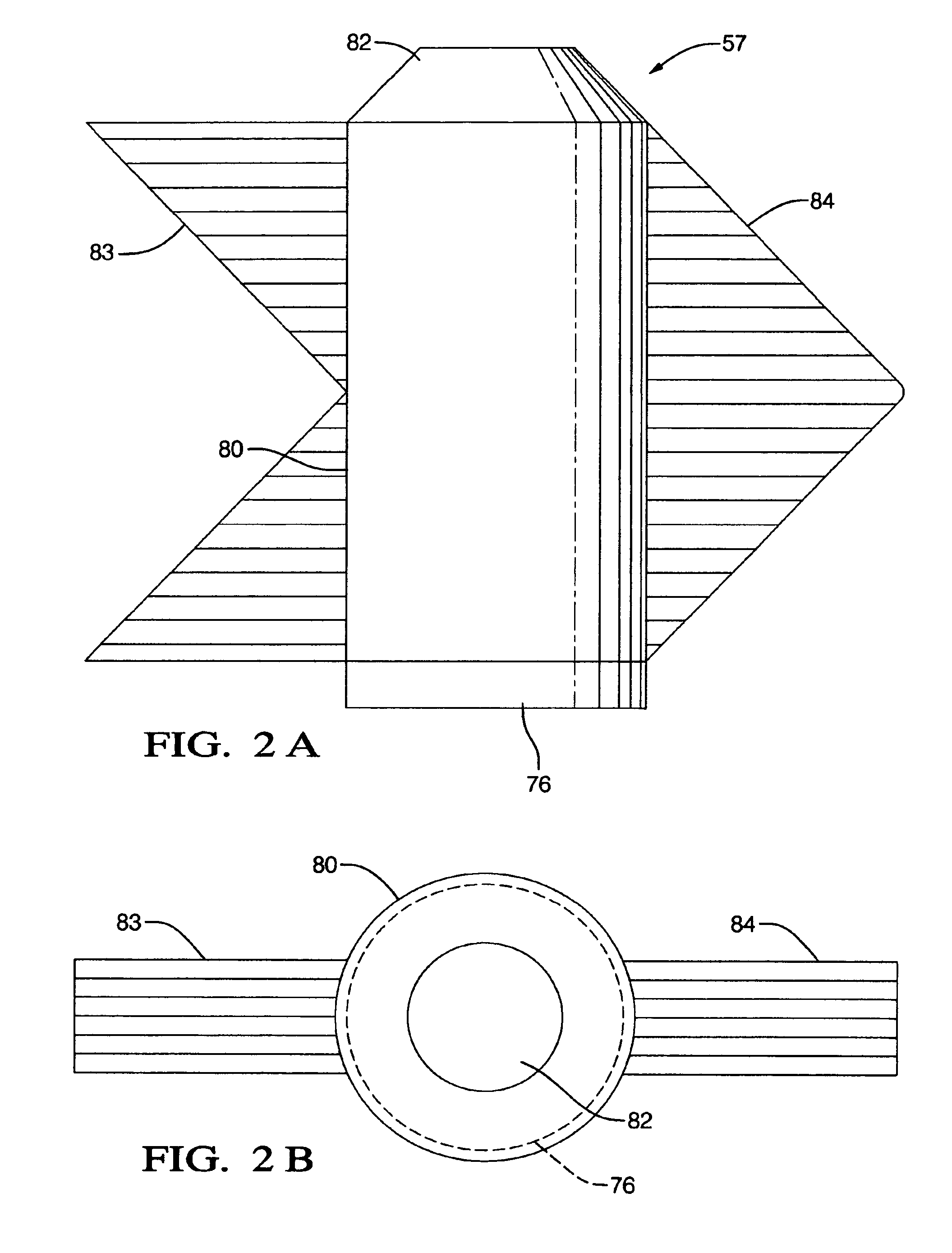

A system for normalizing and calibrating the microphones of a sound-intensity probe or a composite of such probes, with respect to a stable comparison microphone with known acoustical characteristics. Normalizing and calibrating are performed using an apparatus 57 consisting of a tube with a loudspeaker inserted in one end and a fixture for holding the microphones of the probe together with the comparison microphone in the other end. The comparison microphone has known acoustical characteristics supplied by the manufacturer. Two banks of quarter-wave resonators 83 and 84 are attached to the side of the tube to absorb standing waves. The sound-intensity probe can be either a two-microphone probe used for measuring a single component of the sound-intensity vector or a probe with four microphones in the regular tetrahedral arrangement used for measuring the full sound-intensity vector. The microphones in the probe are made to have a substantially identical response with the comparison microphone by determining the transfer functions between the microphones and the comparison microphone. The transfer functions and known acoustical characteristics of the comparison microphone are then used to correct the pressure measurements by the microphones, when they are used to measure sound intensity. This ensures that the sound-intensity measurements are accurate and that there is essentially no bias in determining the direction to a sound source from the direction of the sound-intensity vector.

Owner:HICKLING ROBERT

Normalization and calibration of microphones in sound-intensity probes

InactiveUS7526094B2Improve accuracyAccurate measurementFrequency response correctionElectrostatic transducersSound sourcesEngineering

A system for normalizing and calibrating the microphones of a sound-intensity probe or a composite of such probes, with respect to a stable comparison microphone with known acoustical characteristics. Normalizing and calibrating are performed using an apparatus 57 consisting of a tube with a loudspeaker inserted in one end and a fixture for holding the microphones of the probe together with the comparison microphone in the other end. The comparison microphone has known acoustical characteristics supplied by the manufacturer. Two banks of quarter-wave resonators 83 and 84 are attached to the side of the tube to absorb standing waves. The sound-intensity probe can be either a two-microphone probe used for measuring a single component of the sound-intensity vector or a probe with four microphones in the regular tetrahedral arrangement used for measuring the full sound-intensity vector. The microphones in the probe are made to have a substantially identical response with the comparison microphone by determining the transfer functions between the microphones and the comparison microphone. The transfer functions and known acoustical characteristics of the comparison microphone are then used to correct the pressure measurements by the microphones, when they are used to measure sound intensity. This ensures that the sound-intensity measurements are accurate and that there is essentially no bias in determining the direction to a sound source from the direction of the sound-intensity vector.

Owner:HICKLING ROBERT

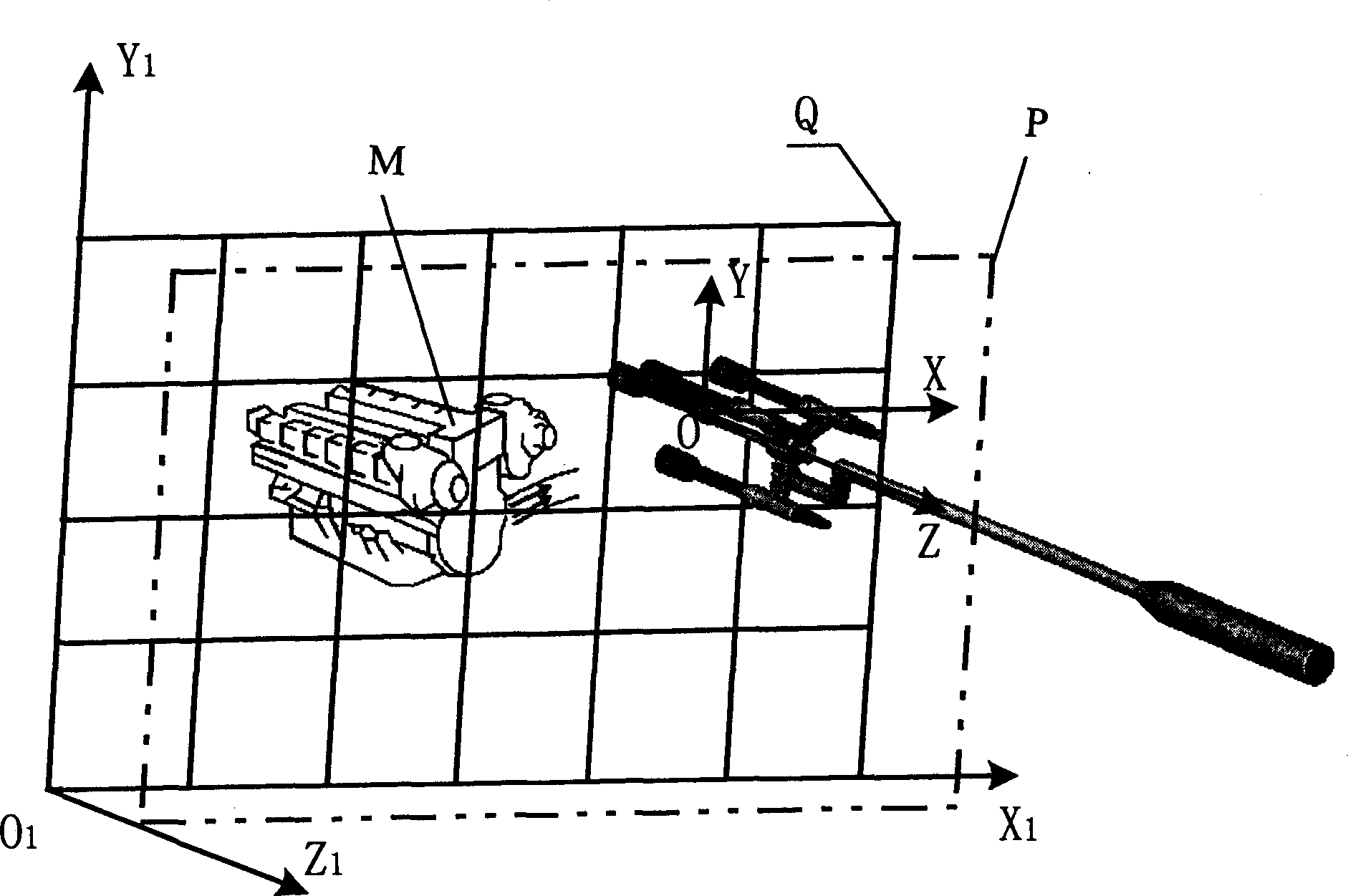

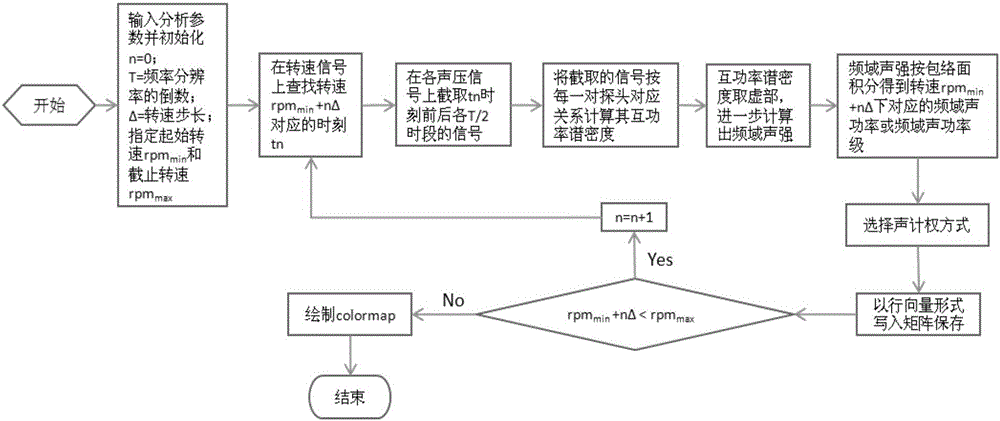

Engine air inlet noise sound power test system and test method thereof

The invention provides a test system of measuring engine air inlet noise sound power and a method thereof. In the invention, assembling of an installation support and a sound intensity probe is specially designed. The test system is constructed, and a scientific sound intensity and sound power algorithm is used to process a test signal. Through using a characteristic that a sound intensity vector carries out integral along a closed curved surface, an engine air inlet noise is completely isolated and extracted from an integral and complex noise field of an engine mathematically so as to be served as a reliable basis of evaluating the engine air inlet noise. Compared to sound power measurement by using an existing traditional sound pressure method, by using the method in the invention, a test result is irrelevant with a peripheral sound field, which means that there is no requirement to a sound field test environment and the test does not need to be performed in a specific acoustic environment, such as an anechoic chamber and a live room. Based on a mathematics principle, a characteristic of an air inlet noise source can be extracted from the complex engine noise field. Tool equipment, such as a big barrier board, an air inlet extension tube and the like, does not need to be designed and made.

Owner:CHONGQING CHANGAN AUTOMOBILE CO LTD

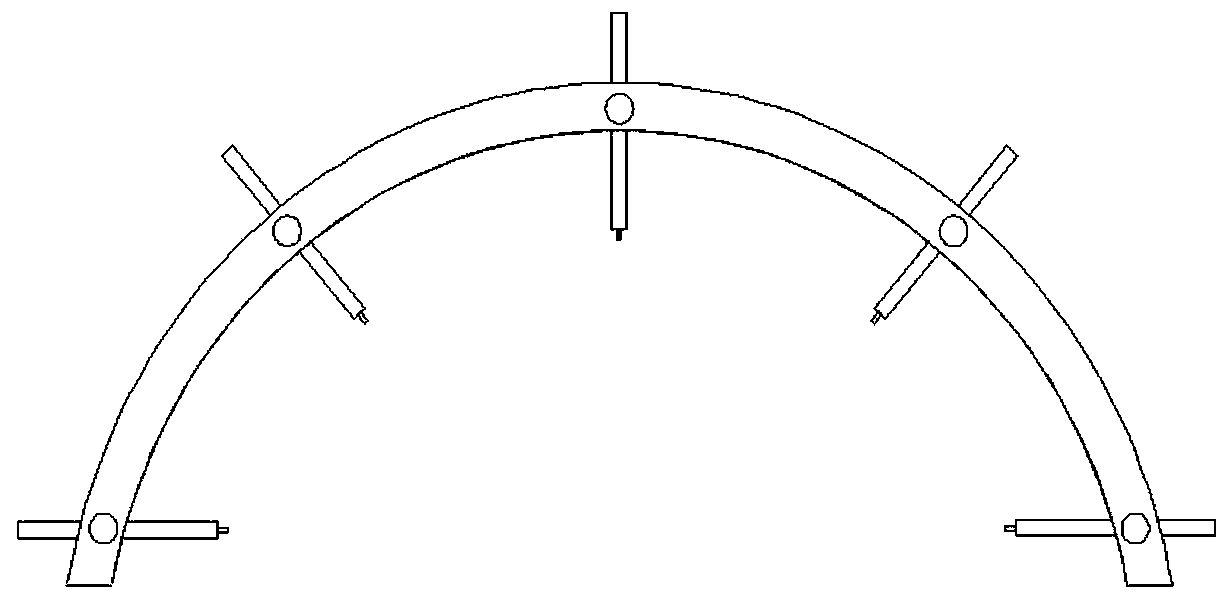

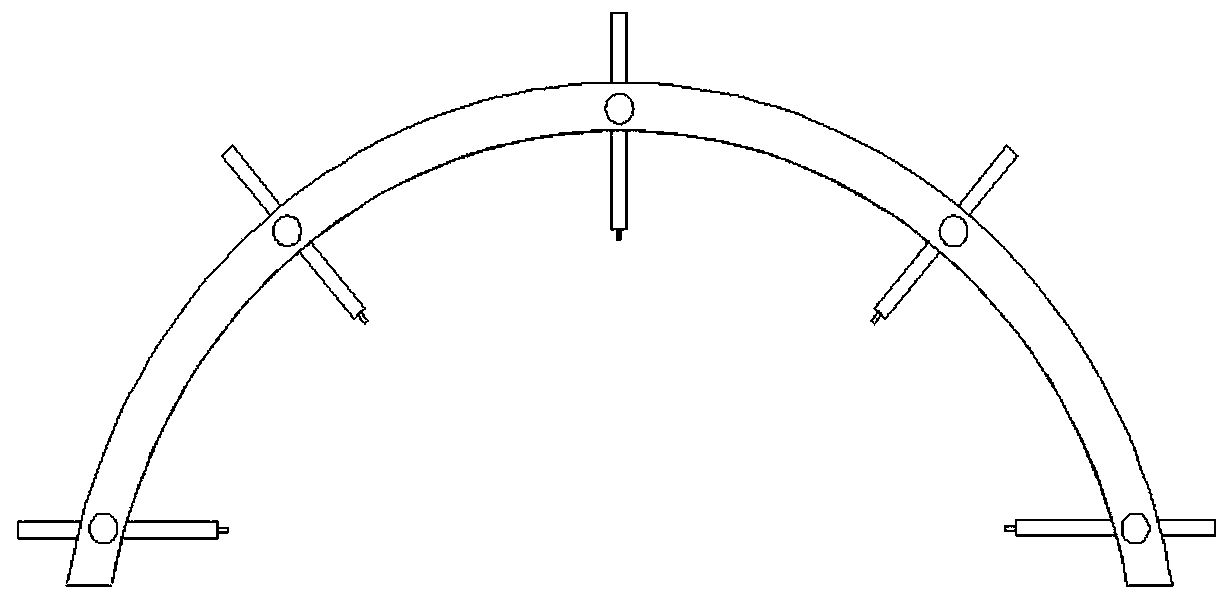

GIS mechanical fault live detection system based on acoustic imaging

PendingCN109916612AImplement fault diagnosisMachine part testingIndicating presence of current/voltageSound intensity probeMetal

The invention relates to a GIS mechanical fault live detection system based on acoustic imaging. The system comprises a sound intensity measuring unit, an acquisition module and a test host which aresuccessively connected. The sound intensity measuring unit comprises a semicircular metal rack. The semicircular metal rack is provided with five groups of sound intensity probes along a circumferencedirection. Each group of sound intensity probe is a P-P type sound intensity probe formed by two sound intensity microphone sensors. After trial, through using the method of the invention, a state ofan operated GIS device can be assessed and fault diagnosis can be given.

Owner:ELECTRIC POWER RESEARCH INSTITUTE OF STATE GRID NINGXIA ELECTRIC POWER COMPANY +2

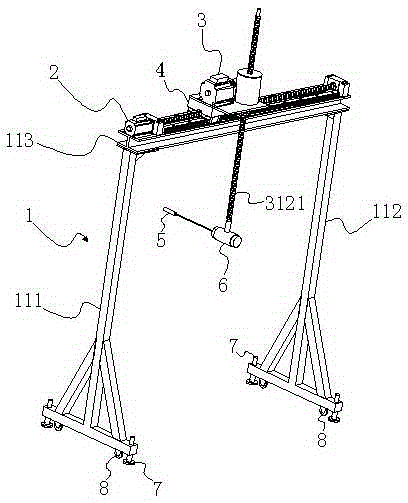

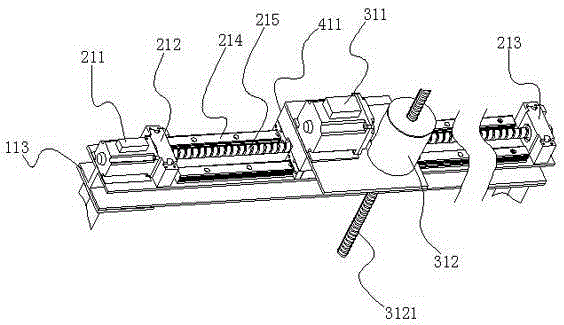

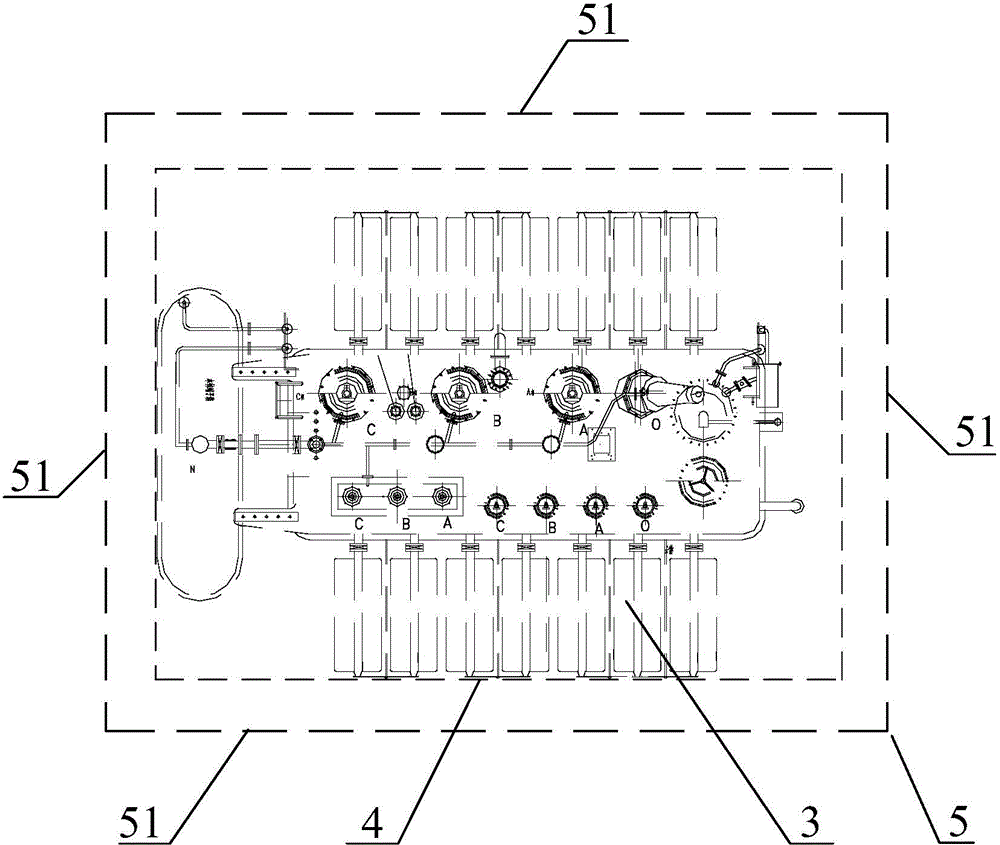

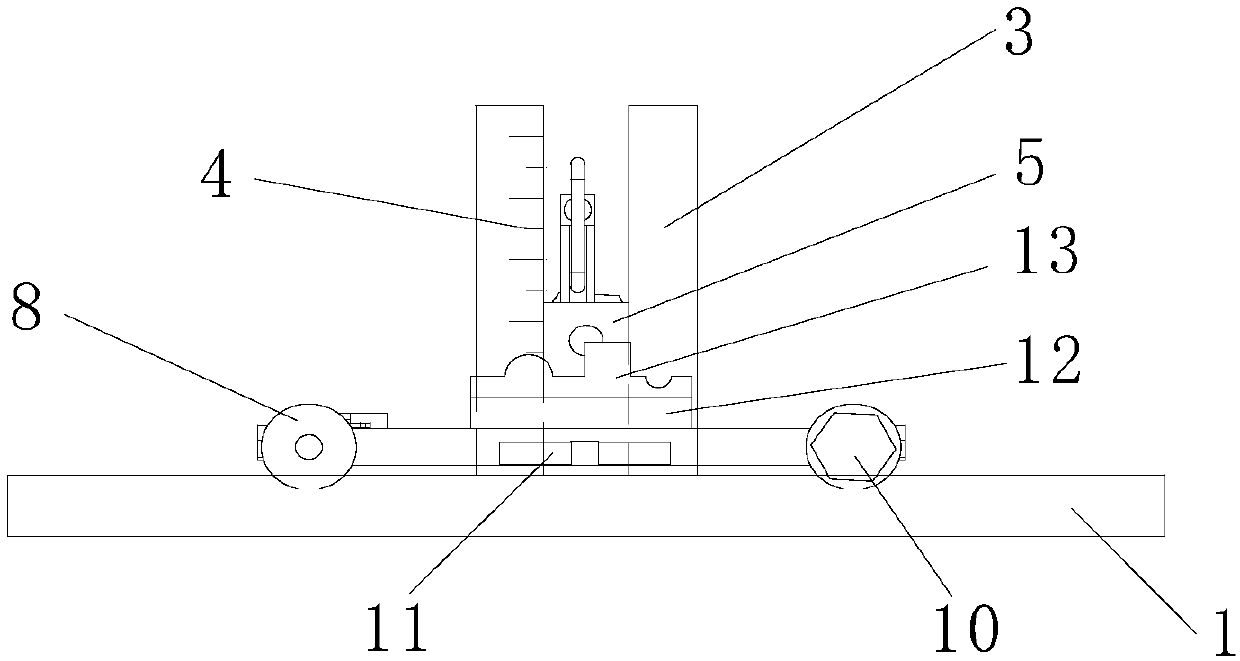

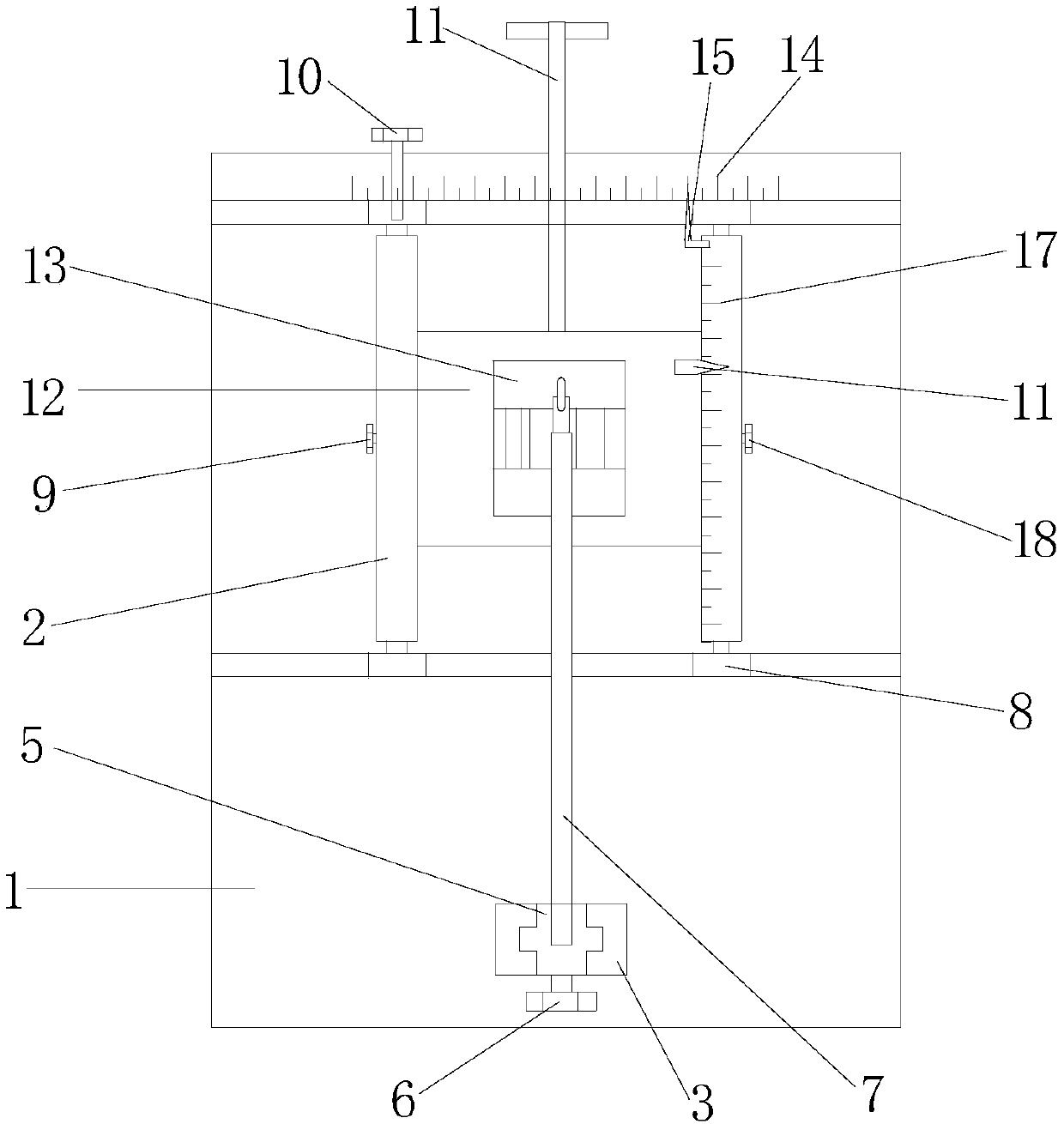

Sound intensity full-automatic measurement bracket and measurement method thereof

InactiveCN106644046AReduce work intensityImprove accuracySubsonic/sonic/ultrasonic wave measurementMotor driveEngineering

The invention discloses a sound intensity full-automatic measurement bracket and measurement method thereof. The sound intensity full-automatic measurement bracket comprises a gantry bracket, a horizontal motor driving component, an elevating motor driving component, a horizontal slide table and a probe fixing clamp which is used for fixing a sound intensity probe. The horizontal motor driving component is arranged on the top part of the gantry bracket. The horizontal slide table is slidably connected on the top part of the gantry bracket. The horizontal slide table can slide back and forth on the horizontal direction along the top part of the gantry bracket under driving of the horizontal motor driving component. The elevating motor driving component is arranged on the horizontal slide table. The probe fixing clamp is connected on the elevating motor driving component. The probe fixing clamp and the sound intensity probe can move back and forth on the vertical direction under driving of the elevating motor driving component. The sound intensity full-automatic measurement bracket can perform full-automatic sound intensity measurement on the tested component according to the actual state of the tested component through cooperation with the sound intensity probe so that the working intensity of measurement personnel can be reduced and the accuracy of the measurement result can be enhanced.

Owner:ZHUZHOU TIMES NEW MATERIALS TECH

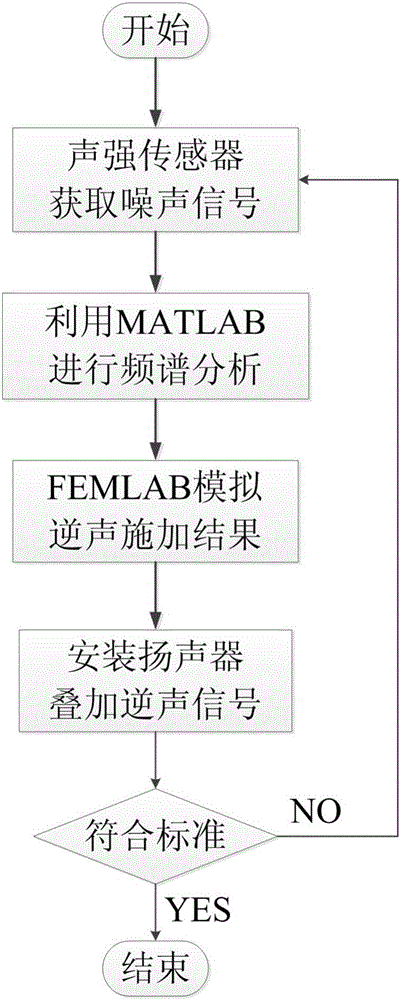

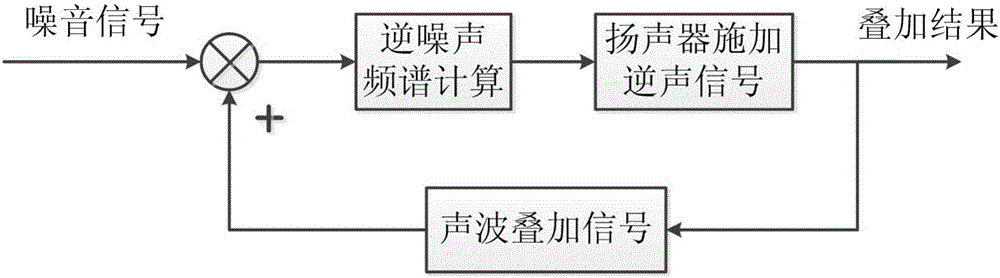

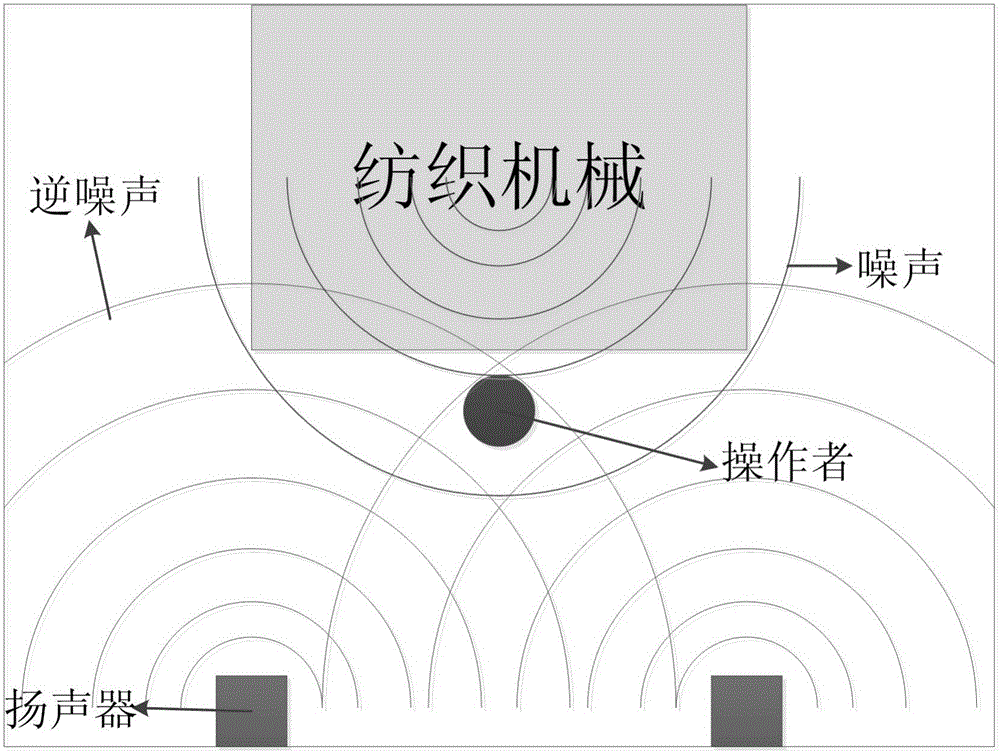

Textile machinery reverse noise noise reduction method

The invention relates to a textile machinery reverse noise noise reduction method. The textile machinery reverse noise noise reduction method comprises the steps that a sound intensity probe is used to acquire noise signals during a working process of textile machinery; the noise signals are analyzed and processed, and the spectrum maps of the noises are acquired; reverse noise spectrum maps required by the noise reduction are acquired according to the spectrum maps of the noises, analogue simulation is carried out to acquire slicing results; an amount and positions of loudspeakers are determined according to the slicing results, and reverse noise signals are transmitted by the loudspeakers to cancel the noises. The noise cancellation is completed by applying the reverse noises opposite to the spectrums of the noises, and therefore the working requirement of reducing the noises during the working process of the textile machinery is satisfied.

Owner:DONGHUA UNIV

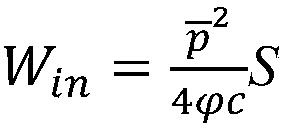

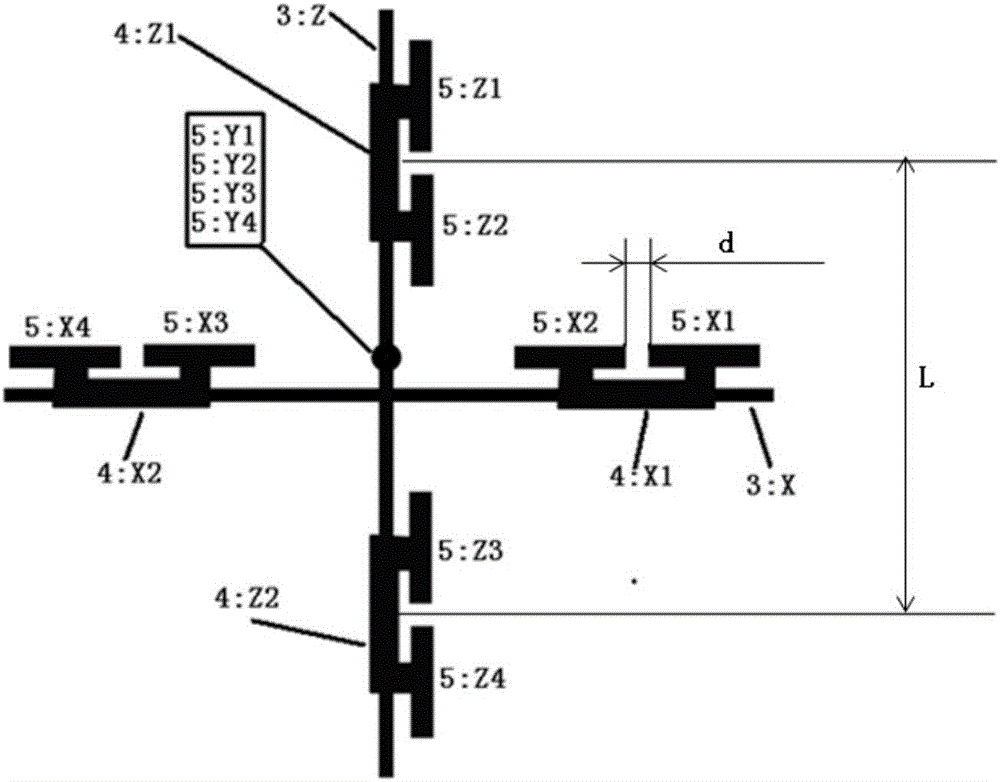

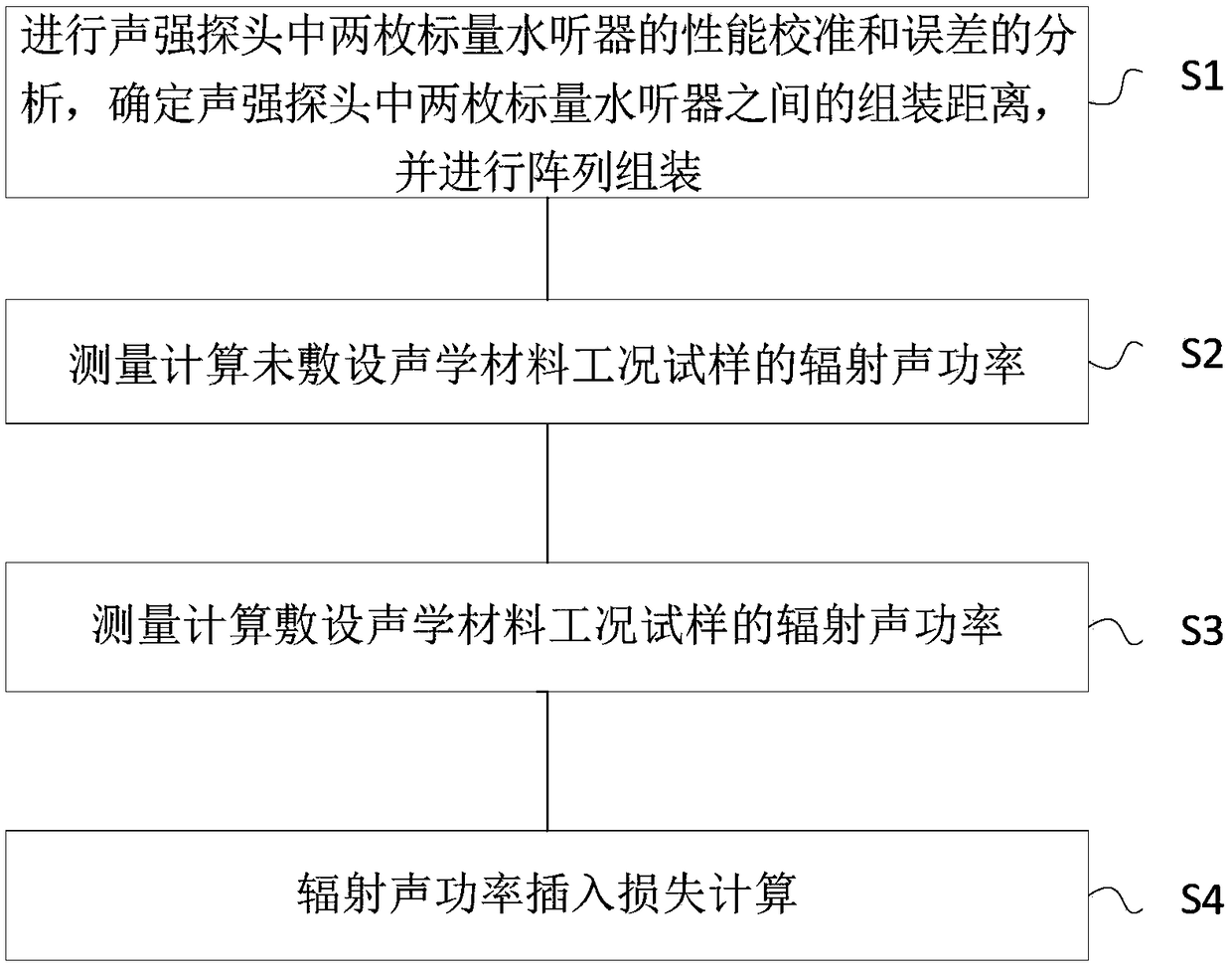

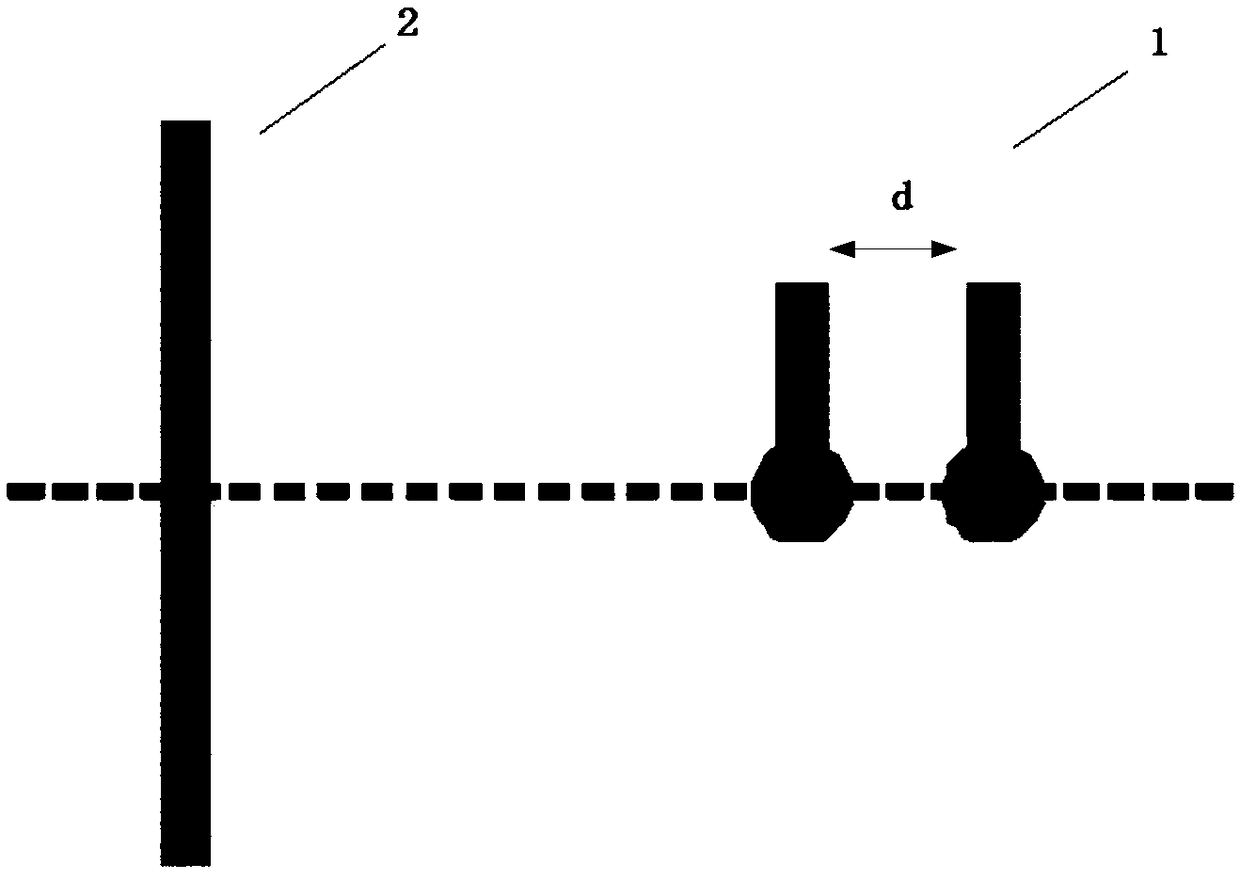

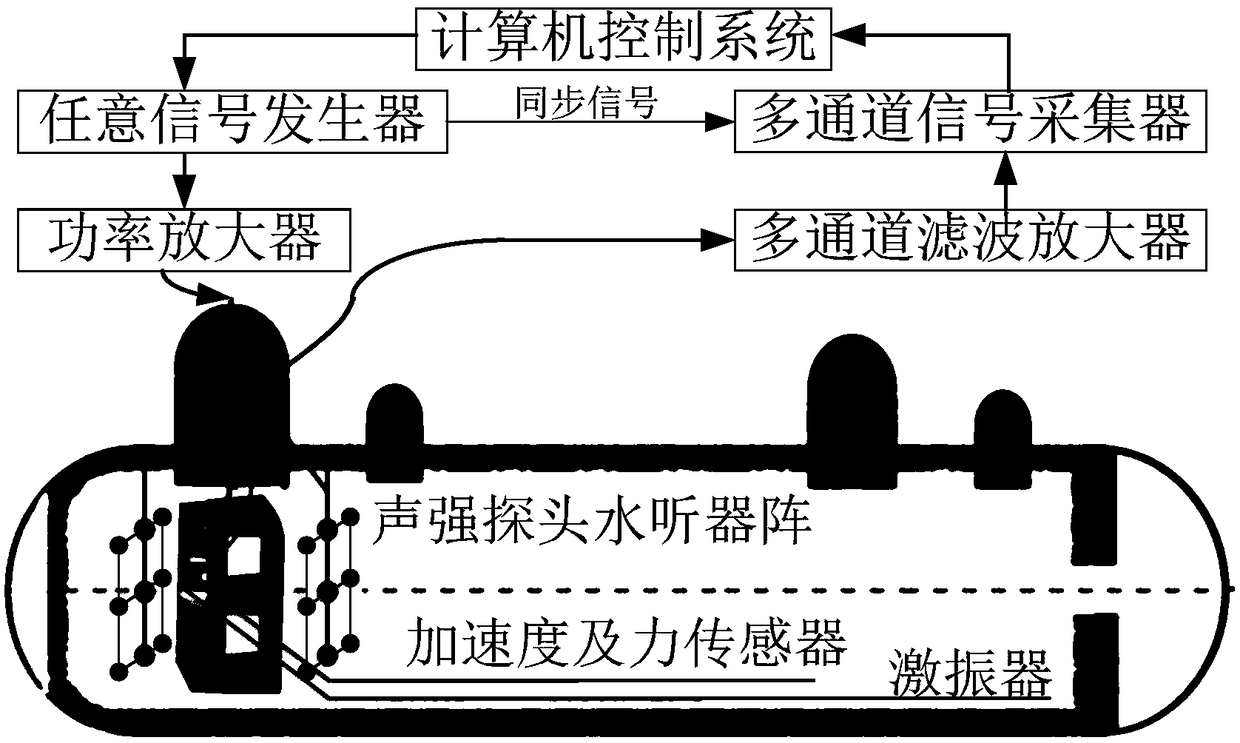

Automatic measurement method for radiated sound power insertion loss of sound intensity probe

The embodiment of the invention relates to an automatic measurement method for the radiated sound power insertion loss of a sound intensity probe. The automatic measurement method comprises the stepsthat the assembly distance d between two scalar hydrophones in the sound intensity probe is determined and meets a formula (please see the specifications for the formula), wherein lambda is the wavelength of a sound wave in water; the mounting positions of the two scalar hydrophones in the sound intensity probe are determined to enable the connecting line direction of the two scalar hydrophones topoint to a tested structure object, and the positions of all sound intensity probe array elements are determined according to the main lobe direction of the sound intensity probe; the radiated soundpower of a sample under the work condition without laying acoustic materials is measured and calculated; the radiated sound power of the sample under the work condition of laying the acoustic materials is measured and calculated; and the radiated sound power insertion loss is calculated. According to the automatic measurement method for the radiated sound power insertion loss of the sound intensity probe, the influence of an interface on test results during radiated sound power measurement in a large pressure muffler water tank can be reduced, and meanwhile, the structure radiated sound powerinsertion loss can be automatically measured.

Owner:CSSC SYST ENG RES INST

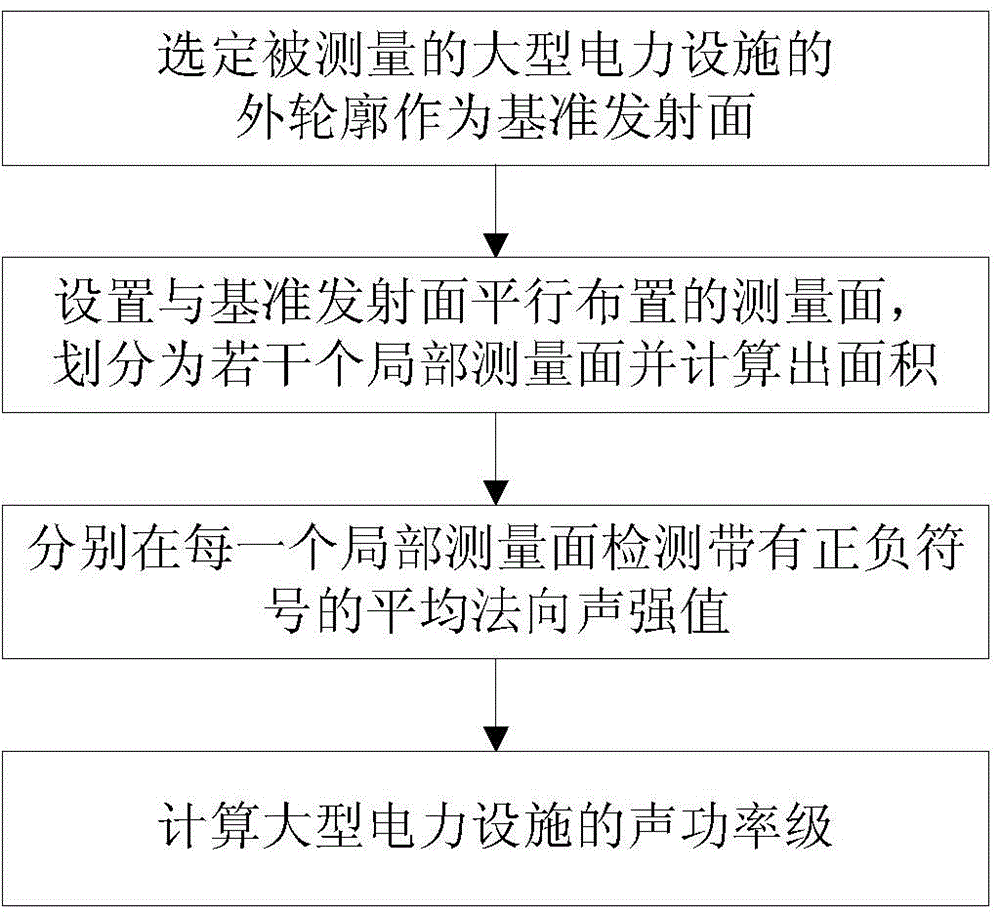

Large power facility sound power level field measurement method and device thereof

InactiveCN104062000AGuaranteed accuracyAccurate measurementSubsonic/sonic/ultrasonic wave measurementFast measurementComputer module

The invention discloses a large power facility sound power level field measurement method and a device thereof. The method comprises a step of selecting the outer profile of a measured large power facility as a reference emission surface, a step of setting a measurement surface which is parallel to the reference emission surface, dividing the measurement surface into a plurality of local measurement surfaces, and calculating the areas of the local measurement surfaces, a step of detecting a mean normal sound intensity value with positive and negative symbols at each local measurement surface, and a step of calculating the sound power level of the large power facility. The device comprises a guide rail assembly and a constant speed moving mechanism which is slidingly arranged on the guide rail assembly. The constant speed moving mechanism is provided with a sound intensity probe, an analog-to-digital conversion module, a data transmission module and a power supply module. The sound intensity probe, the analog-to-digital conversion module and the data transmission module are connected in sequence. The method and the device have the advantages of fast measurement speed, accurate and reliable measurement data, less investment and convenient implementation and are suitable for large power facility sound power level field rapid and accurate measurement.

Owner:STATE GRID CORP OF CHINA +2

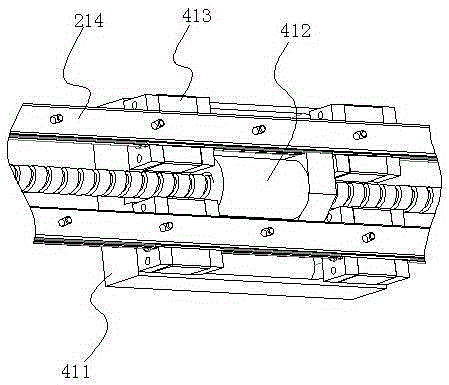

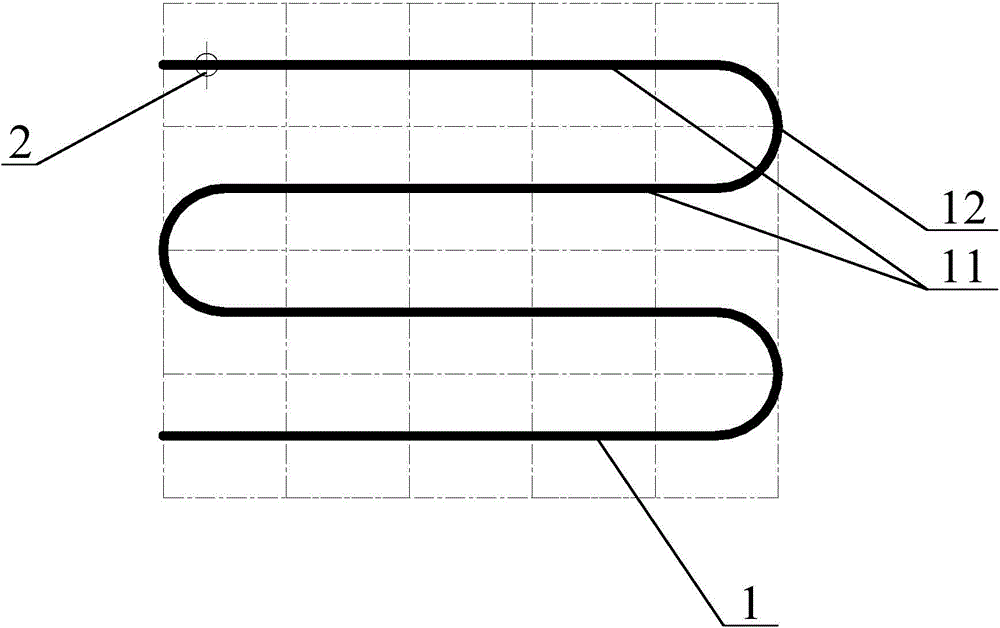

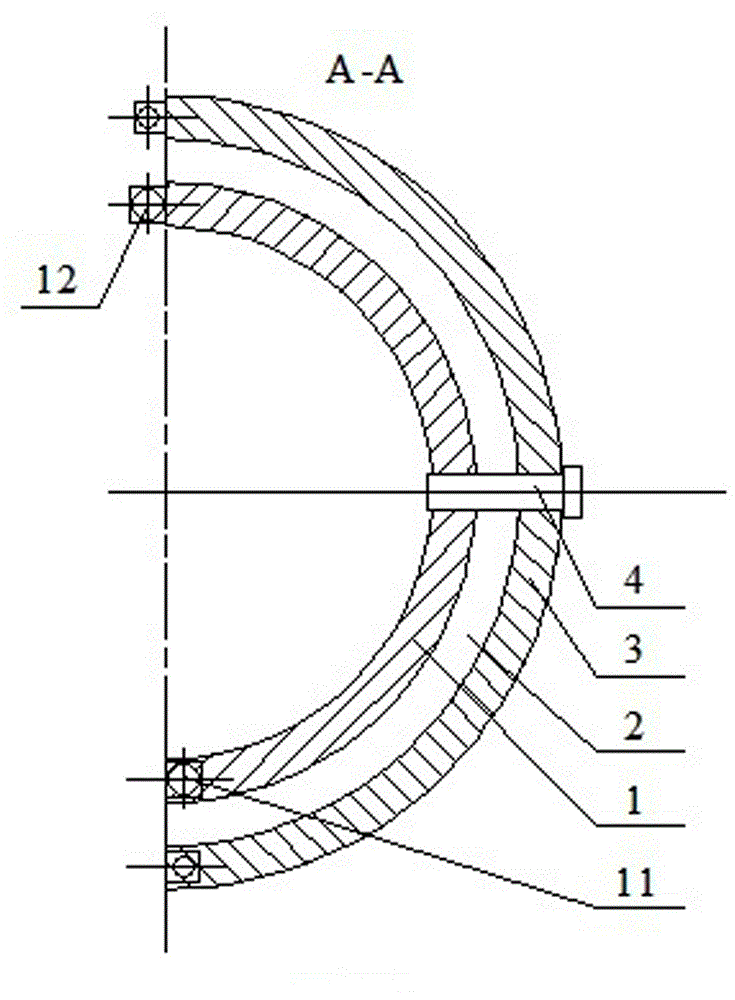

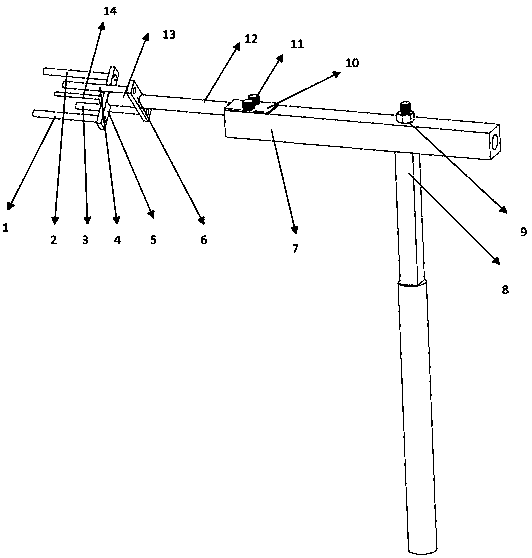

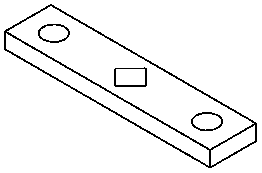

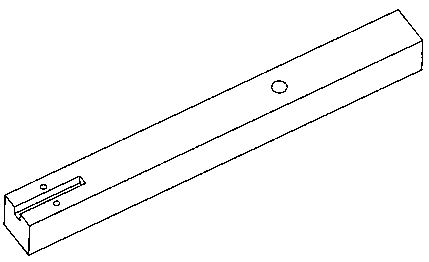

Combined type cavitation sound field measuring device for ultrasonic honing

InactiveCN104875112ALevel of precisionPrecise vertical movementSubsonic/sonic/ultrasonic wave measurementGrinding feed controlCavitationSonification

The invention provides a combined type cavitation sound field measuring device for ultrasonic honing. The combined type cavitation sound field measuring device comprises a sound field measurement auxiliary clamp and a sound intensity probe. The sound field measurement auxiliary clamp comprises a combined type vibration damper, a combined type outer sleeve, a horizontal connecting rod, a vertical connecting rod and a sound intensity probe clamping mechanism. The horizontal connecting rod is connected with the combined type outer sleeve and the vertical connecting rod, the other end of the vertical connecting rod is connected with the sound intensity probe clamping mechanism to make the sound intensity probe horizontally move, and the movement value can be read from the horizontal scale. Clearance fits are provided between two semicircular sleeves of the combined type outer sleeve and two semicircular outer spindle sleeves of the combined type vibration damper, to make the sound intensity probe to rotate, and the rotational angle can be read from the angle scale. The measuring device can be used for accurately and quantitatively measuring the cavitation sound field in areas around oilstone wall. The combined type cavitation sound field measuring device is convenient to disassemble, and the device can measure cavitation sound fields of a plurality of oilstones at the same through adding a plurality sets of horizontal connecting rods, vertical connecting rods and probe clamping mechanisms.

Owner:ZHONGBEI UNIV

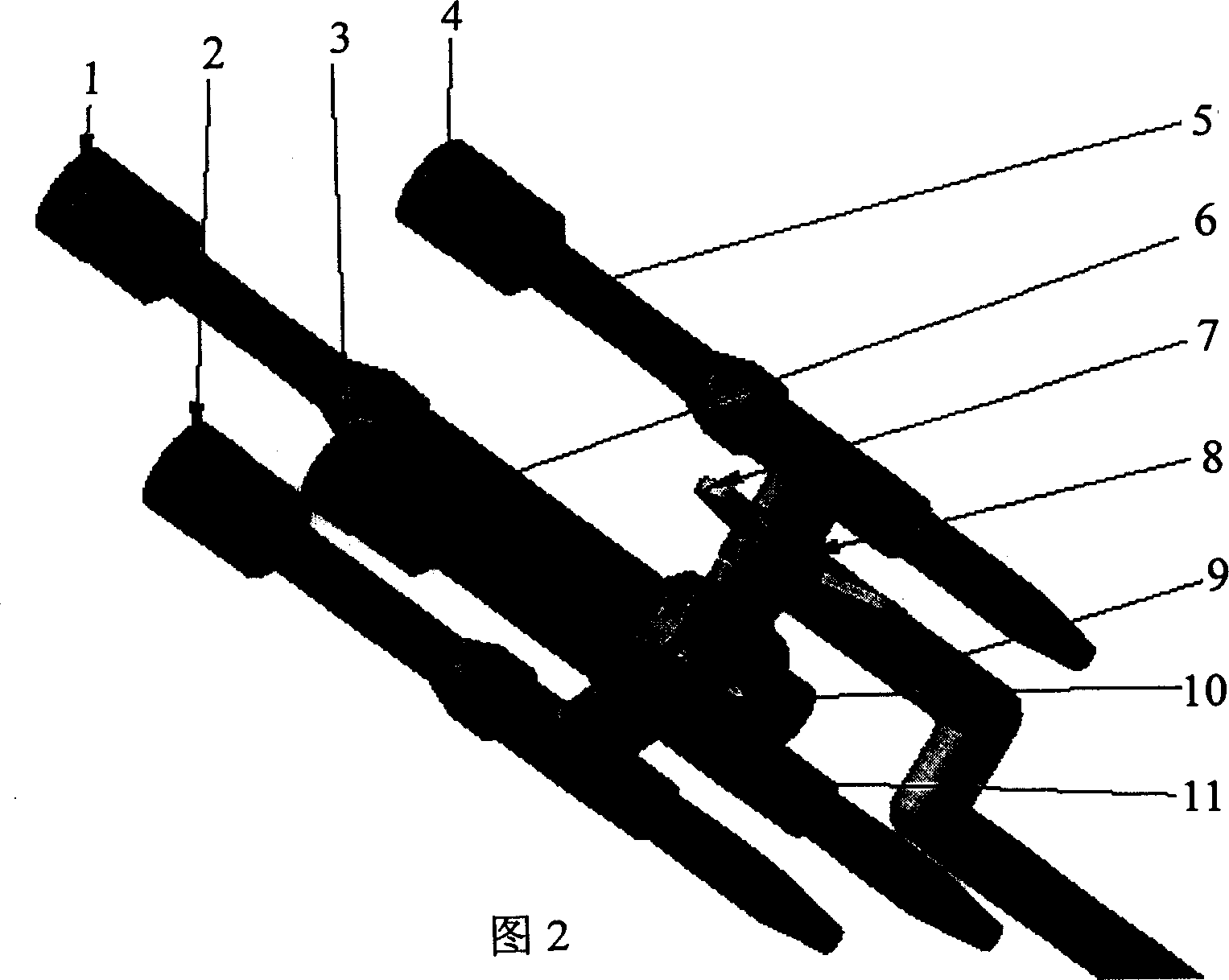

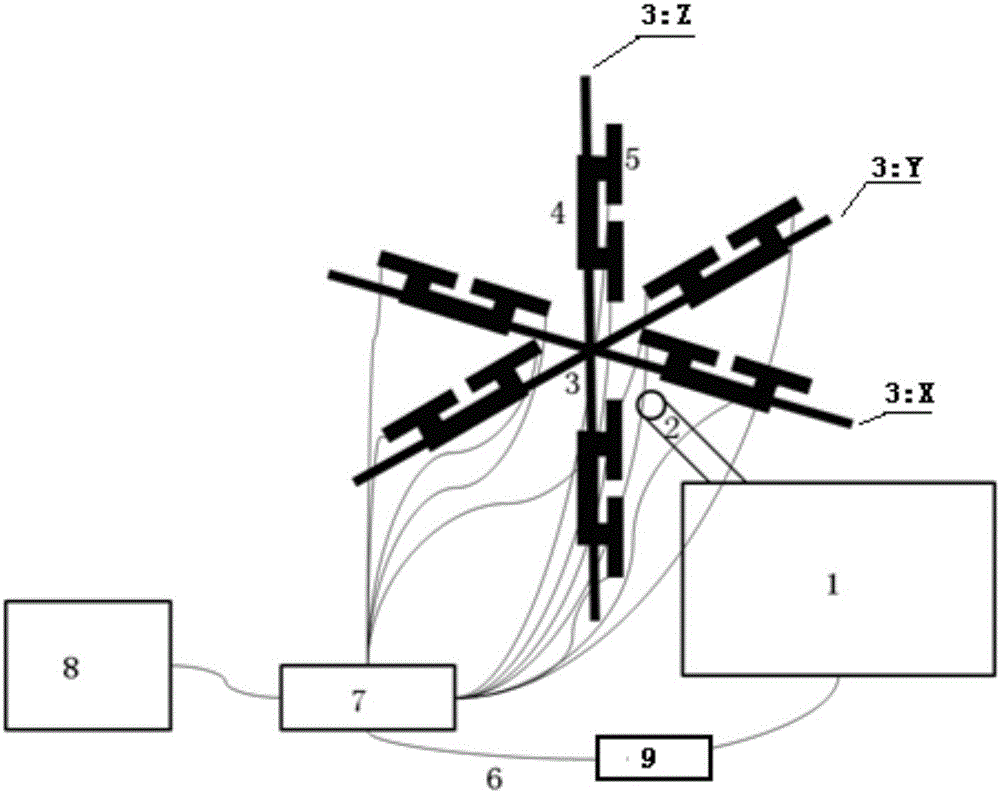

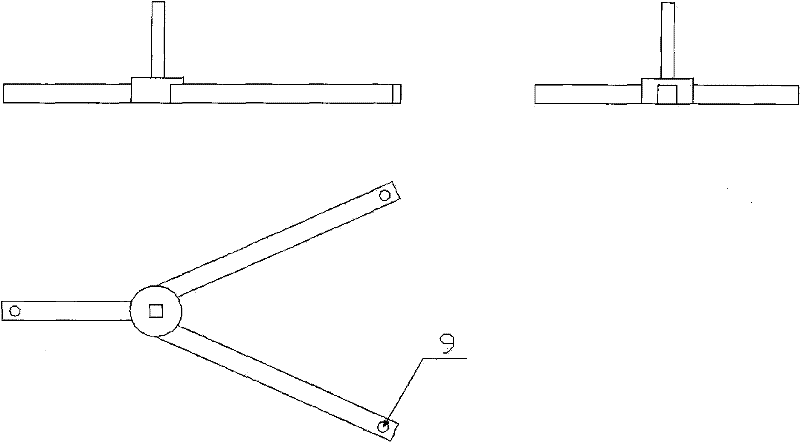

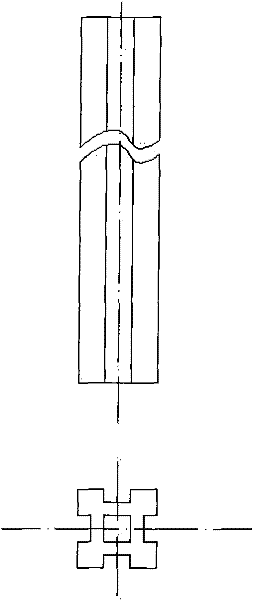

Three-dimensional vector sound intensity probe

InactiveCN107389183AGuaranteed spatial positioning accuracyEasy to measureSubsonic/sonic/ultrasonic wave measurementEngineeringSound intensity probe

The invention discloses a three-dimensional vector sound intensity probe comprising a microphone set, an arrangement frame set, a supporting rod, a handle, a locking nut, a baffle plate, locking screws, a fixed column, a spacing column, a center rod and a center square rod. The microphone set includes a microphone I, a microphone II, a microphone III and a microphone IV. The arrangement frame set includes an arrangement frame I and an arrangement frame II. The sound intensity components of three directions of the measuring points in a sound field can be acquired through one time of measurement so that the space positioning precision can be guaranteed, the measurement process can be simplified and the measurement time can be saved; and the probe only uses four microphones so that the structure is simple and use is convenient, and the probe can be widely used for the field of noise source identification and control.

Owner:KUNMING UNIV OF SCI & TECH

Random distribution microphone array

ActiveCN109471069AVersatileSubsonic/sonic/ultrasonic wave measurementSustainable transportationFar distancePositioning technology

The invention discloses a random distribution microphone array. The random distribution microphone array comprises an array frame, an array fixing support, an acoustic camera and three-dimensional sound intensity probe supports. Microphone measuring points are optimized by means of mixed Gaussian distribution so that the array can be used for not only medium-low-frequency medium-far-distance near-field acoustic holographic positioning but also a medium-high-frequency medium-far-distance beam forming positioning technology. At the same time, three-dimensional sound intensity probes can also beinstalled on the array frame for performing three-dimensional sound intensity measurement. Compared with a conventional single-form array frame structure, a random distribution microphone array framedevice has the advantages of having more functions and a wider application range.

Owner:KUNMING UNIV OF SCI & TECH

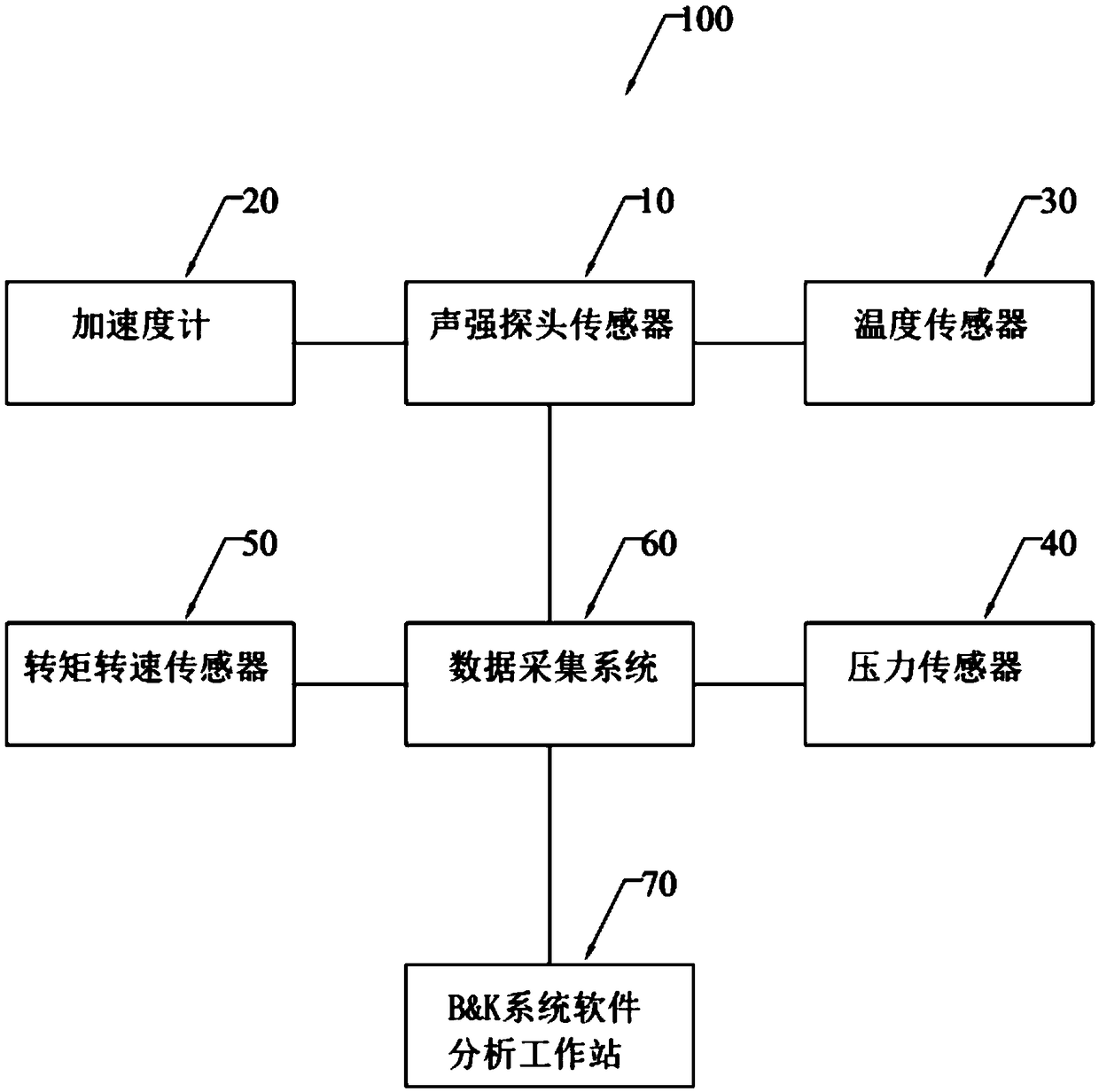

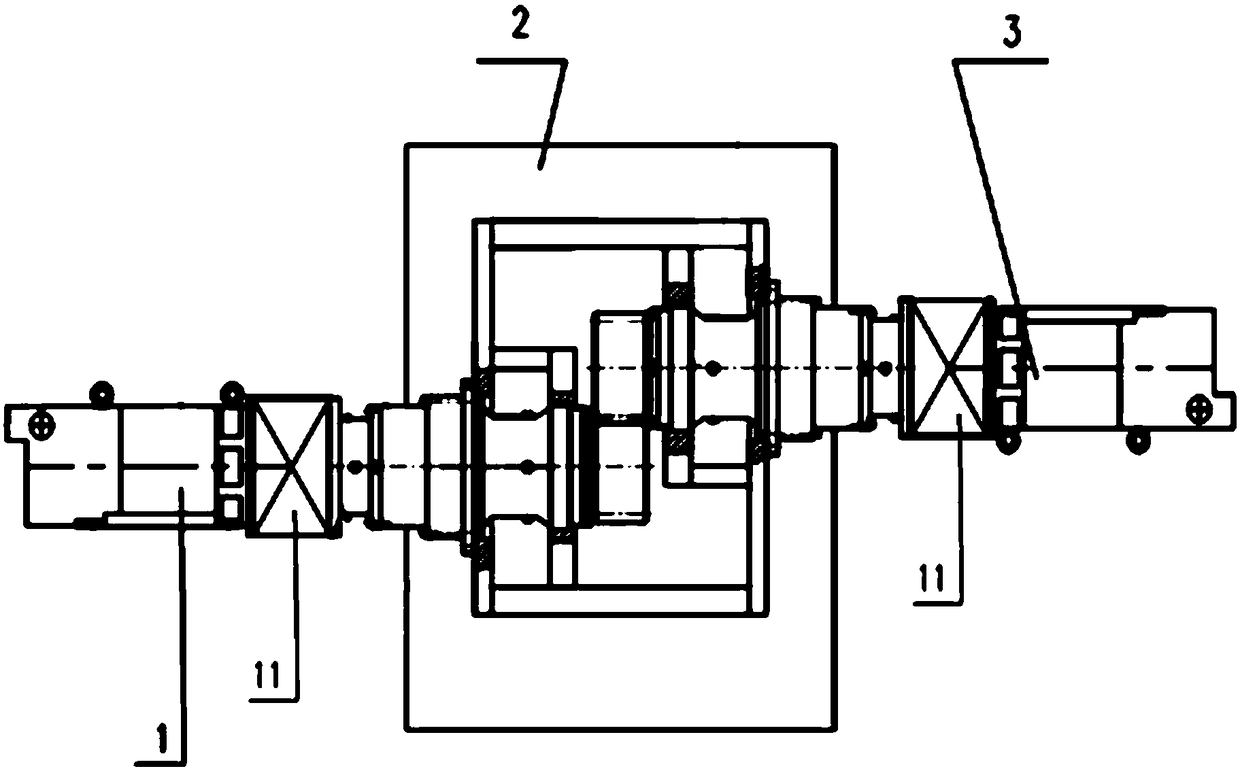

Analysis system for online detection of performance and fault of gearbox

InactiveCN109357865AImprove reliabilityRealize fully automated online testingMachine gearing/transmission testingAccelerometerData acquisition

The invention relates to an analysis system for online detection of performance and fault of a gearbox, comprising: a sound intensity probe sensor for collecting noise data during operation of the gearbox, an accelerometer for collecting vibration data during operation of the gearbox, a temperature sensor for collecting temperature data during operation of the gearbox, a pressure sensor, a torqueand speed sensor, a data acquisition system and a B&K system software analysis workstation; the data acquisition system forms a communication connection with the sound intensity probe sensor, the accelerometer, the temperature sensor, the pressure sensor, and the torque and speed sensor; the data acquisition system is in a communication connection with the B&K system software analysis workstation.The analysis system for online detection of performance and fault of the gearbox has the advantages that the data of each sensor can be centralized, and the operation performance of the gearbox undera specific working condition can be detected online for comprehensive analysis and diagnosis of the fault of the gearbox.

Owner:NANJING HIGH SPEED GEAR MFG

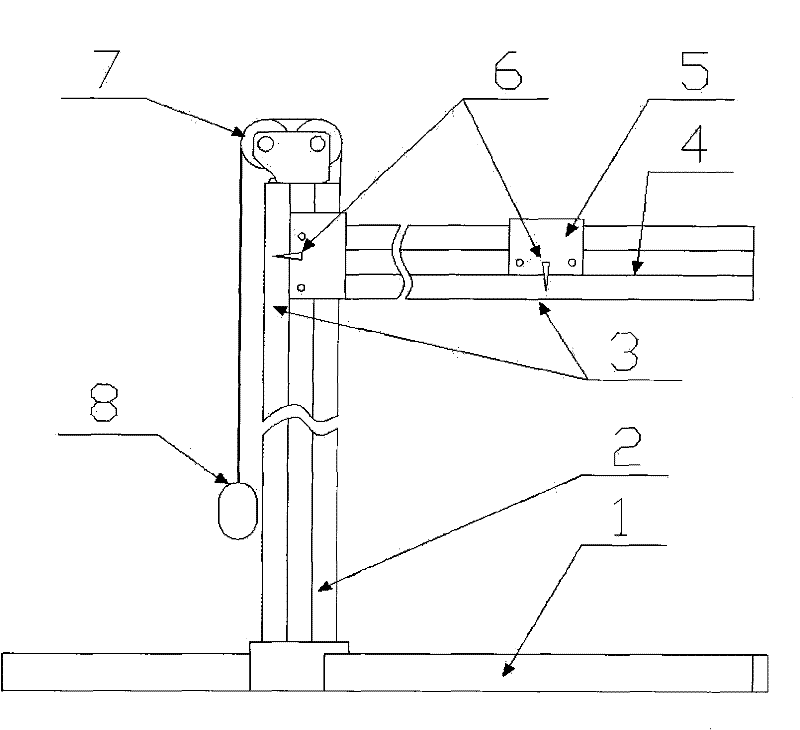

Sound intensity testing bracket

ActiveCN101709996BEasy to operateLow costSubsonic/sonic/ultrasonic wave measurementEngineeringSound intensity probe

The invention relates to a sound intensity testing bracket, which comprises a bracket base, a vertical rail, a horizontal rail and a sound intensity probe, wherein the vertical rail is vertically arranged on the bracket base; the horizontal rail is vertically arranged on the vertical rail and is arranged horizontally; and the sound intensity probe is movably arranged on the horizontal rail.

Owner:CHERY AUTOMOBILE CO LTD

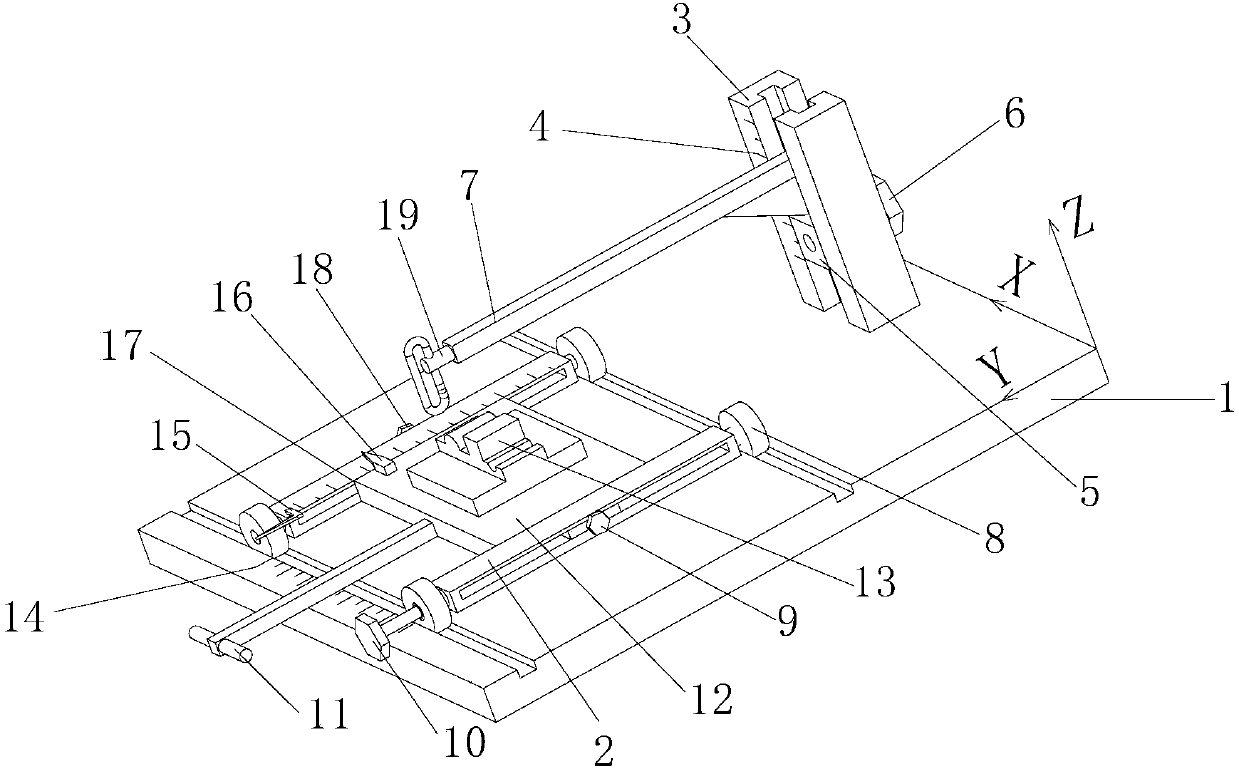

Mobile-type sensor installation auxiliary platform for measuring sound intensity level of equal-height curved surface

PendingCN108020315AReduce mistakesSimple structureSubsonic/sonic/ultrasonic wave measurementUsing electrical meansCantilevered beamEngineering

The invention discloses a mobile-type sensor installation auxiliary platform for measuring the sound intensity level of an equal-height curved surface, and the platform comprises a bottom plate, a work panel, two guide rails, and a cantilever beam. The bottom plate is provided with two parallel guide grooves, and two ends of the guide rails are provided with rollers. The rollers at two ends of theguide rails are disposed in the two guide grooves. Two ends of the work panel are respectively placed on two guide rails through sliding blocks, and a positioning device is disposed between the sliding blocks and the guide rails. The height of the cantilever beam can be adjusted, and an end part of the cantilever beam is provided with a clamping head. The clamping head is connected with a sound intensity probe, and the sound intensity probe is located above the work panel. The platform can independently move in three directions: X, Y and Z, achieves the precise measurement of the sound intensity levels of equal-height curved surfaces of measured objects in different surface shapes, is simple in structure, is low in manufacturing cost, is convenient to use, and is high in measurement precision.

Owner:HUNAN UNIV OF SCI & TECH

Engine mechanical noise testing method and device

ActiveCN113029330AEliminate the effects ofEliminate distractionsSubsonic/sonic/ultrasonic wave measurementEngine testingCombustion noiseNoise

The invention provides an engine mechanical noise testing method which overcomes the defect that mechanical noise testing is interfered by other noise sources in the prior art. A cylinder pressure sensor and a sound intensity probe are used for synchronously testing cylinder pressure and sound pressure signals of an engine, combustion noise components are separated from the sound pressure signals, mechanical noise components are obtained, and the sound intensity value of the mechanical noise is calculated according to the mechanical noise components in two microphones in the sound intensity probe. Compared with the prior art, the mechanical noise test device and method provided by the invention have the advantages that the precision of the measured mechanical noise is higher, and the result can indicate the direction for the optimization of the mechanical noise of the engine.

Owner:JIANGSU UNIV +1

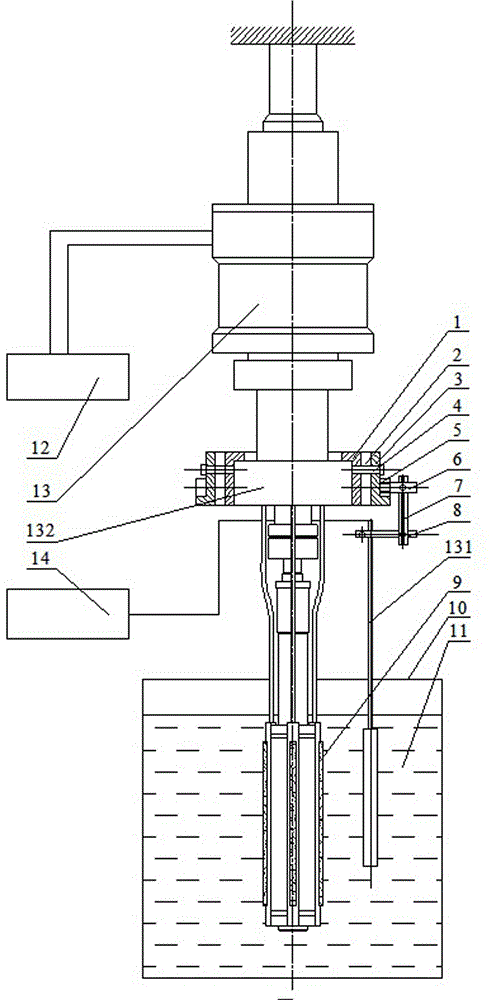

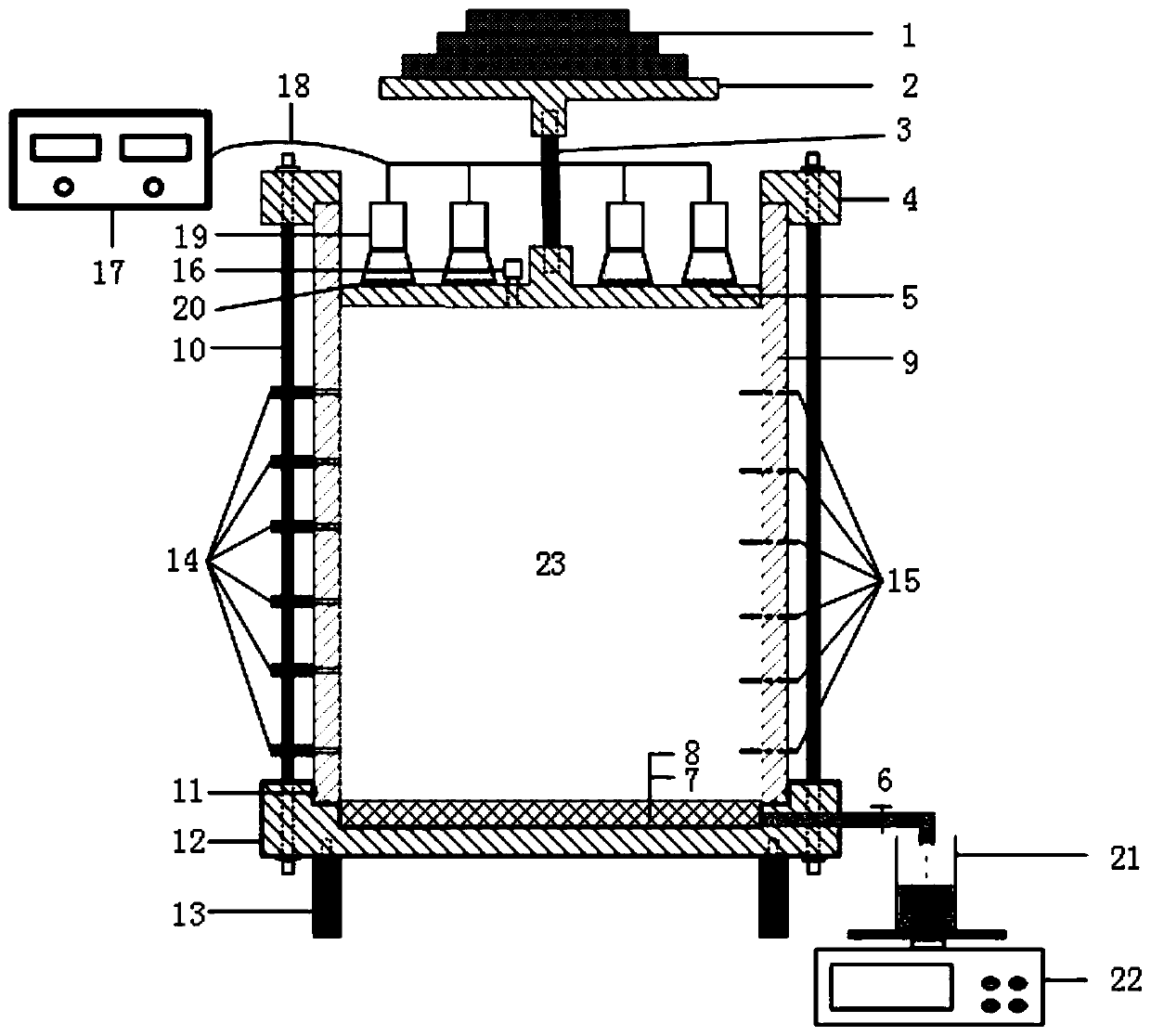

Testing device for promoting soft clay drainage consolidation through ultrasonic waves

The invention discloses a testing device for promoting soft clay drainage consolidation through ultrasonic waves. The testing device comprises a soil sample chamber, a pressure system, an ultrasonic transmitting system and a measuring system; the soil sample chamber comprises a base and an organic glass barrel, and the base is provided with a filter layer, a permeable layer, a drainage pipe and adrainage valve, wherein the drainage pipe and the drainage valve communicate with the permeable layer; the pressure system comprises a force applying assembly and a force transferring plate making contact with the top surface of a soil sample, and an exhaust valve is further arranged on the force transferring plate; the ultrasonic transmitting system comprises an ultrasonic generator and a plurality of ultrasonic transducers connected with the ultrasonic generator, and the ultrasonic transducers are evenly distributed on the force transferring plate; the measuring system comprises a pluralityof sound intensity probes, a plurality of hole pressure gauges, an electronic scale and a drainage vessel; and a plurality of holes and mounting frames for mounting the sound intensity probes and thehole pressure gauges are further arranged on the side wall of the organic glass barrel in the height direction, and the electronic scale is used for weighing the amount of water in the drainage vessel. The testing device has the characteristics of convenient use and reliable data.

Owner:HOHAI UNIV

Sound source localization method and system

ActiveCN105204002BReduce the difficulty of implementationHigh positioning accuracyPosition fixationUltrasound attenuationSound sources

The invention discloses a sound source positioning method and system. Through the arrangement of a sound intensity sensor group in advance, specific sound sources are arranged in various testing directions with fixed intervals by taking the sound intensity sensor group as the center in sequence, and direction feature data corresponding to the specific sound sources in the various testing directions is collected; sound intensity feature data corresponding to the specific sound sources at different distances is collected to establish the attenuation characteristic of sound intensity and transmission distance; sound intensity data corresponding to a sound source to be tested is collected, the sound intensity data and the direction feature data corresponding to the testing directions are respectively subjected to correlation analysis, and the testing direction corresponding to the maximum value of correlation results is determined as the direction of the sound source to be tested; according to the sound intensity data and the attenuation characteristic, the distance between the sound source to be tested and the sound intensity sensor group is determined. The sound source positioning is realized by adoption of methods of feature matching of the sound source direction and the attenuation characteristic of the sound source distance, the implementation difficulty of sound source positioning is reduced, and meanwhile the positioning accuracy and the stability are improved.

Owner:TCL CORPORATION

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com