Automatic measurement method for radiated sound power insertion loss of sound intensity probe

A technology of sound intensity probe and measurement method, which is applied in the direction of vibration measurement in fluid, measurement vibration, measurement device, etc., and can solve the problem that the anechoic pool cannot simulate the deep sea pressure environment, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

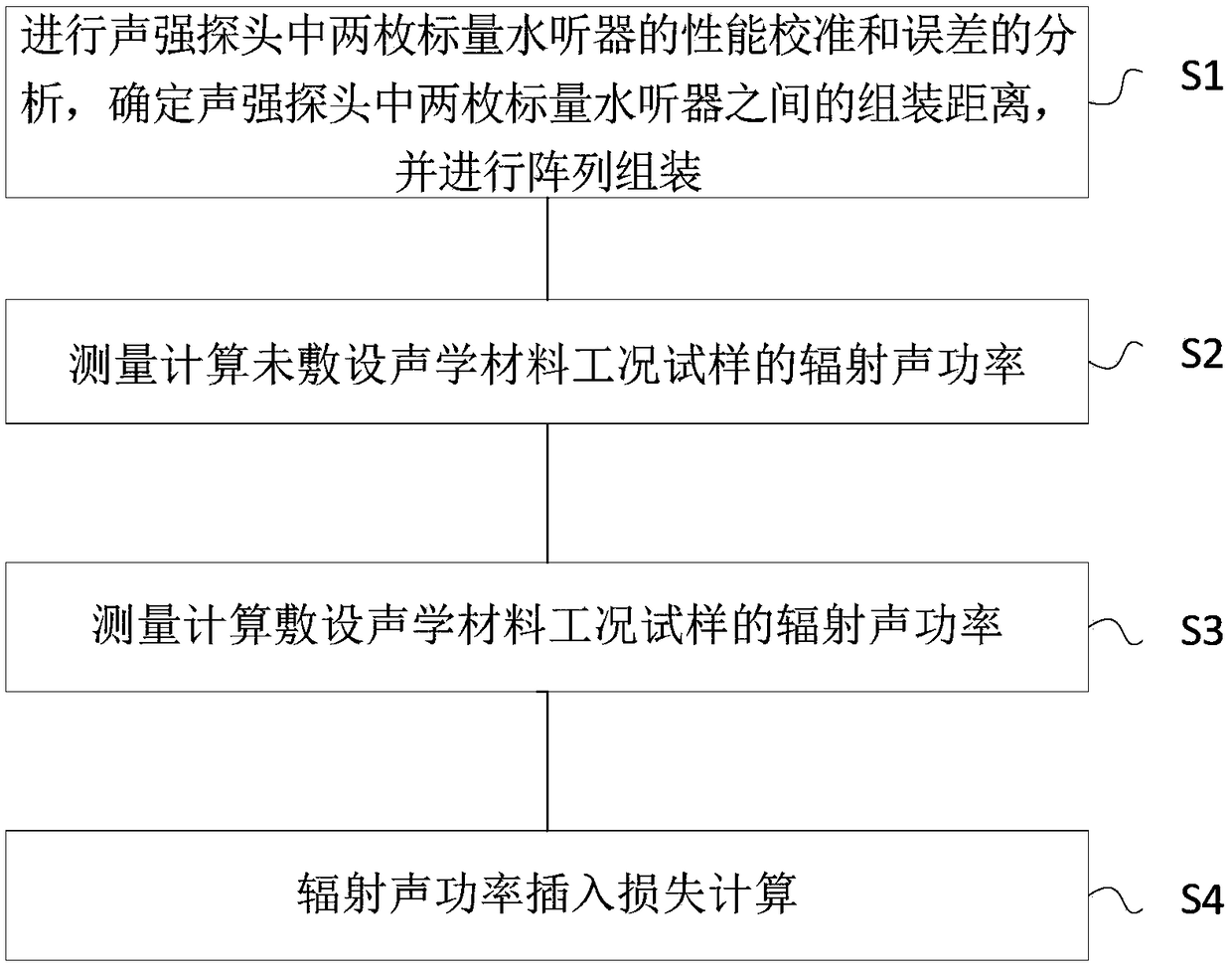

[0079] figure 1 A flowchart showing an automatic measurement method for insertion loss of radiated sound power based on a sound intensity probe provided by an embodiment of the present invention, the method may be executed by an electronic device, such as a terminal device or a server device. In other words, the method can be executed by software or hardware installed on the terminal device or the server device. The server includes, but is not limited to: a single server, a server cluster, and the like. As shown in the figure, the method includes the following steps.

[0080] Step S1: Perform performance calibration and error analysis of the two scalar hydrophones in the sound intensity probe, determine the assembly distance between the two scalar hydrophones in the sound intensity probe, and perform array assembly

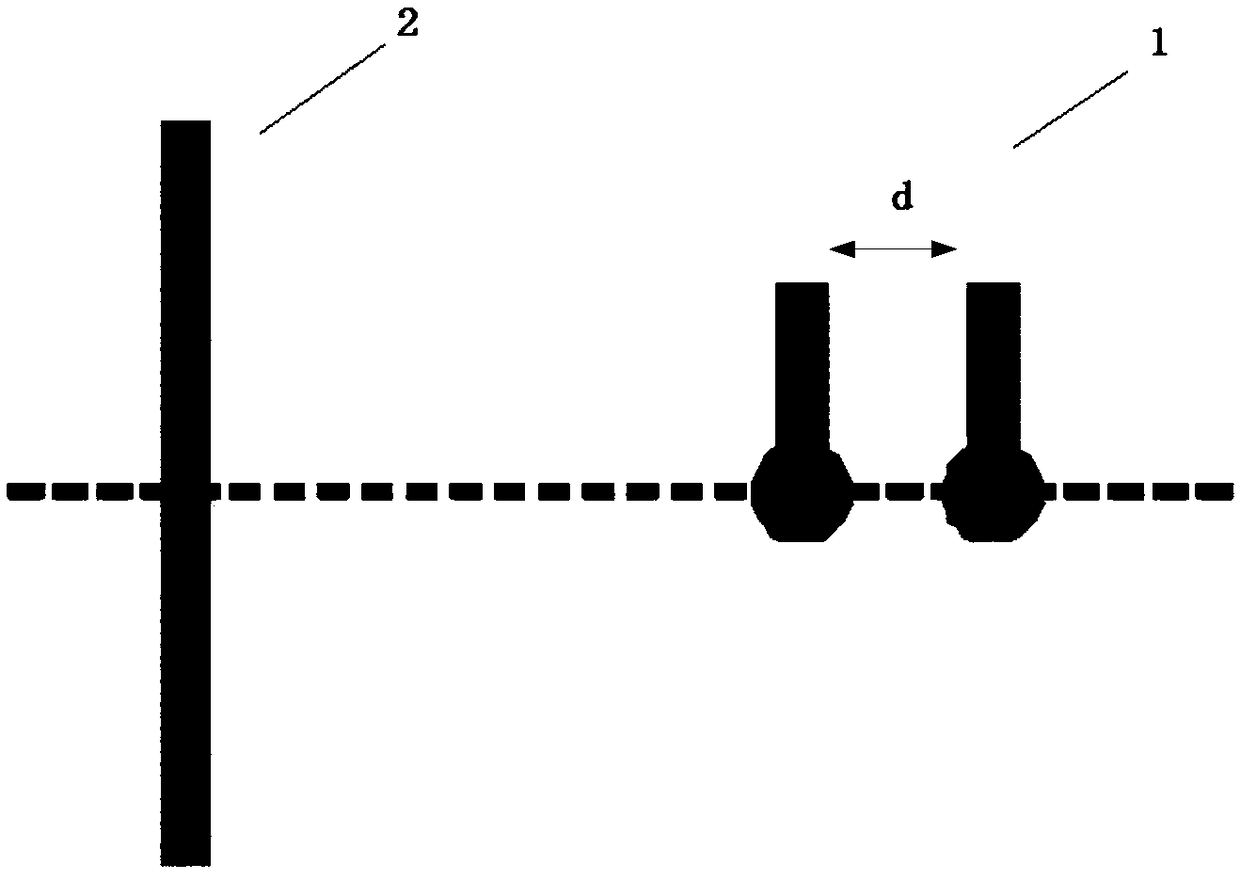

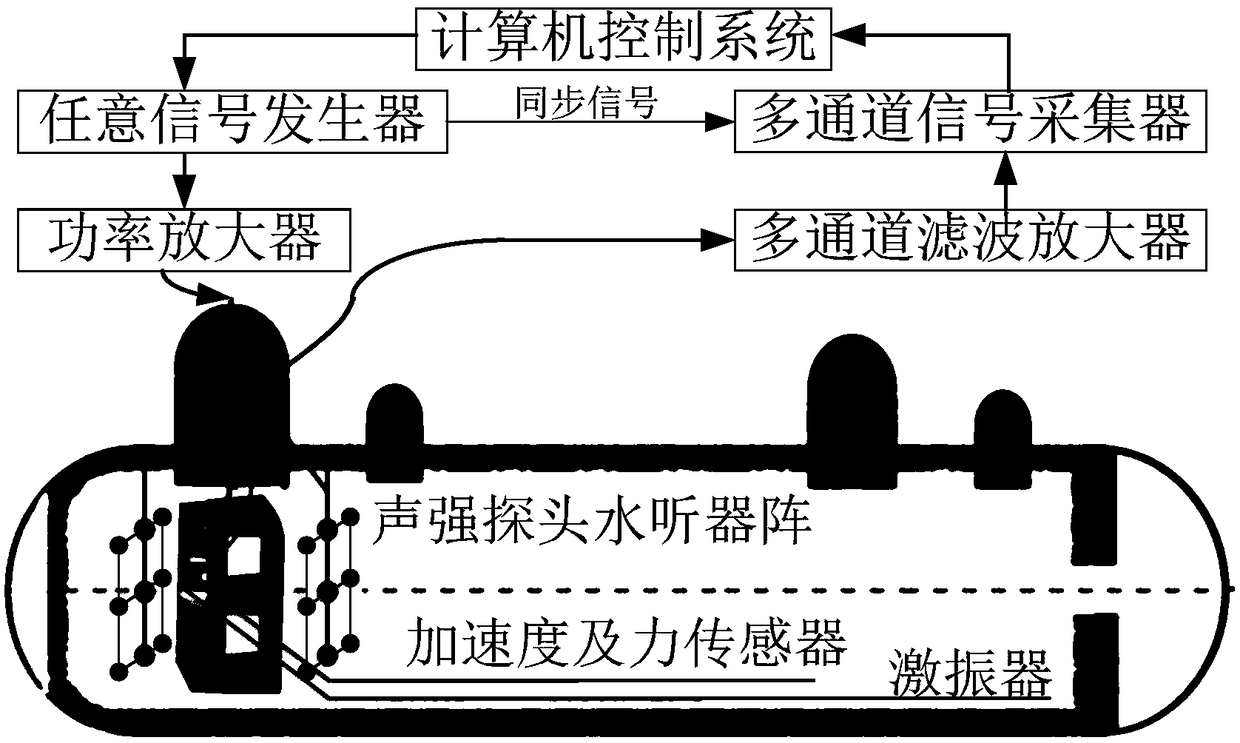

[0081] Sound intensity probe assembly and sound intensity probe array installation, including the assembly of each sound intensity probe by two pressure-resista...

Embodiment 2

[0160] An embodiment of the present invention provides a non-transitory (non-volatile) computer storage medium, the computer storage medium stores computer-executable instructions, and the computer-executable instructions can execute the method in any of the above-mentioned method embodiments, and achieve the same technical effect.

Embodiment 3

[0162] An embodiment of the present invention provides a computer program product, the computer program product includes a computer program stored on a non-transitory computer-readable storage medium, the computer program includes program instructions, and when the program instructions are executed by a computer , causing the computer to execute the methods described in the above aspects, and achieve the same technical effect.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com