Sound intensity full-automatic measurement bracket and measurement method thereof

A measurement method and fully automatic technology, applied in measurement devices, measuring ultrasonic/sonic/infrasonic waves, instruments, etc., can solve problems such as high work intensity and inability to achieve fully automatic measurement, achieve convenient operation, reduce measurement costs, guarantee The effect of accuracy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

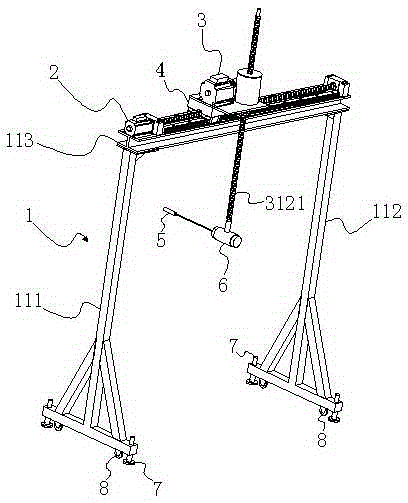

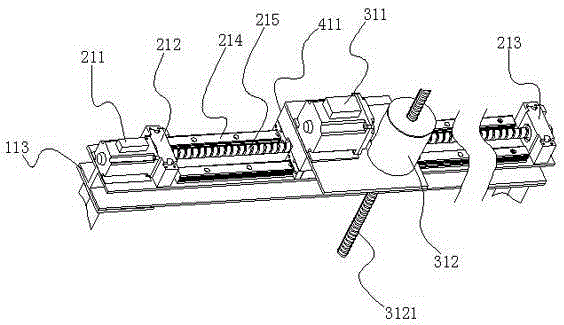

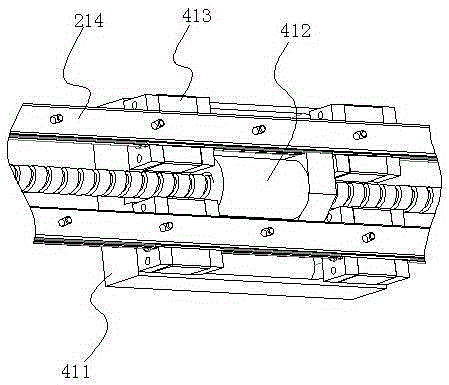

[0054] Embodiment 1: as figure 1 As shown, a sound intensity full-automatic measuring support includes a gantry support 1, a horizontal motor drive assembly 2, a lifting motor drive assembly 3, a horizontal slide table 4 and a probe holder 6 for fixing a sound intensity probe 5; The motor drive assembly 2 is arranged on the top of the gantry support 1, and the horizontal slide table 4 is slidably connected on the top of the gantry support 1. Driven by the horizontal motor drive assembly 2, the horizontal slide table 4 can move along the top of the gantry support 1. Sliding back and forth in the horizontal direction, the lifting motor driving assembly 2 is arranged on the horizontal slide table 4, the probe fixing clip 6 is connected to the lifting motor driving assembly 2, driven by the lifting motor driving assembly 2, the probe fixing clip 6 The sound intensity probe 5 can move up and down vertically. In this embodiment, the horizontal and vertical positions of the sound in...

Embodiment 2

[0076] Embodiment 2: as Figure 6 and Figure 7 As shown, compared with Embodiment 1, the difference is that in the measurement method of this embodiment, in order to further improve the accuracy of the measurement results, the vertical path and the horizontal path are improved, that is, the vertical path includes A plurality of vertical paths 9 parallel to each other and a semicircular path 11 between one end of the adjacent vertical path 9, the opening of the semicircular path 11 in the vertical path faces the vertical direction; the horizontal path includes a plurality of parallel paths. The horizontal path 10 and the semicircular path 11 between one end of the adjacent horizontal path 10, the opening of the semicircular path 11 in the horizontal path faces the horizontal direction. This embodiment only needs to be programmed according to the scanning path, and the above-mentioned measurement path containing a semicircular path can be completed by simultaneously opening an...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com