Sound intensity testing bracket

A technology of sound intensity and sound intensity probe, which is used in measuring devices, measuring ultrasonic/sonic/infrasonic waves, instruments, etc., can solve problems such as hearing damage, danger, and loud engine noise, and achieve easy popularization, simple operation and low cost. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

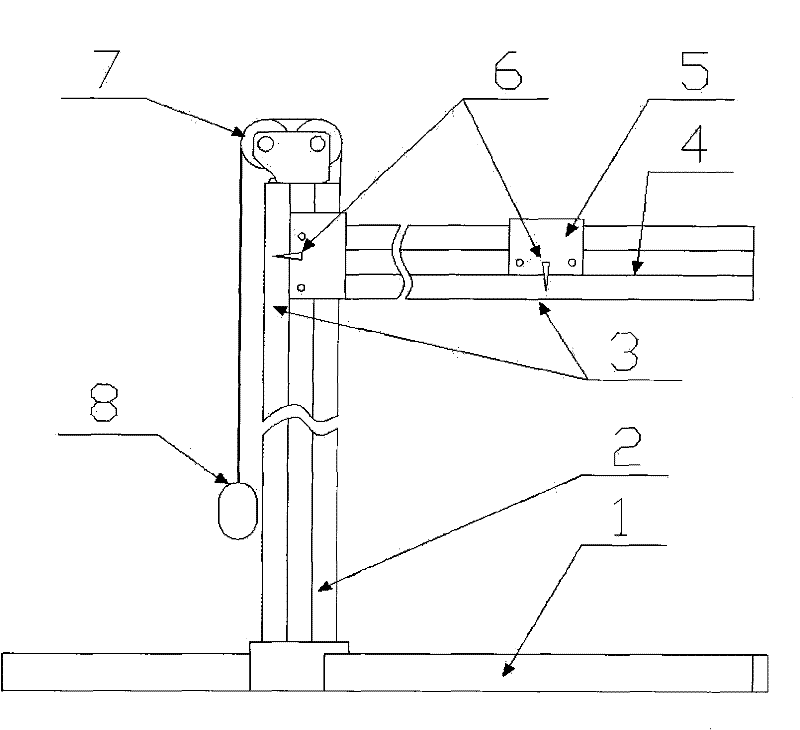

[0025] The present invention will be described in detail below according to the accompanying drawings, which is a preferred embodiment of the various embodiments of the present invention.

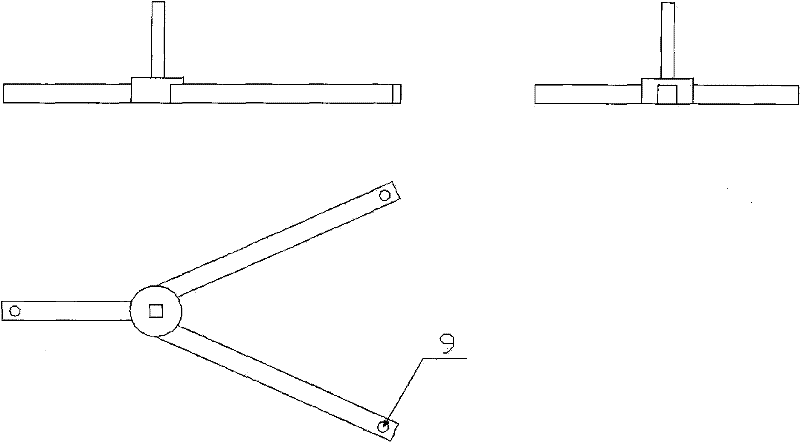

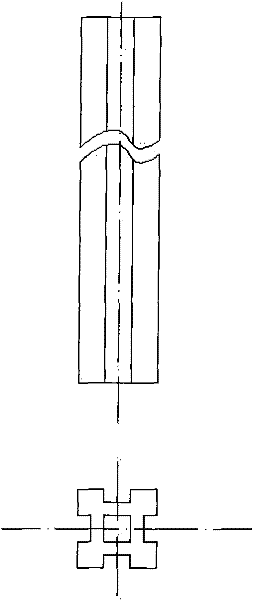

[0026] The operation method of the present invention: place the bracket base 1 on the position of the sound intensity to be measured, insert the vertical rail 2 into the bracket base 1, and fix it; slide the horizontal rail 4 into the rail from the top of the vertical rail 2; insert the pulley group 7 into the vertical rail The top of the track 2 is fixed; after the balance weight and the rope 8 are connected to the hanging hole of the traction rope to 13, they bypass the pulley block, and adjust the bracket base 1 to be horizontal through the vertical condition of 8 and the horizontal plane; after adjusting the level, put the horizontal trolley 5 Slide into the track from the outside of the horizontal track 4, and fix the sound intensity probe to the horizontal trolley 5. The sound intensi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com