Method for evaluating high sound intensity characteristics of sound intensity measuring instrument

An evaluation method, measuring instrument technology, applied in the measurement of ultrasonic/sonic/infrasonic waves, measuring devices, instruments, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

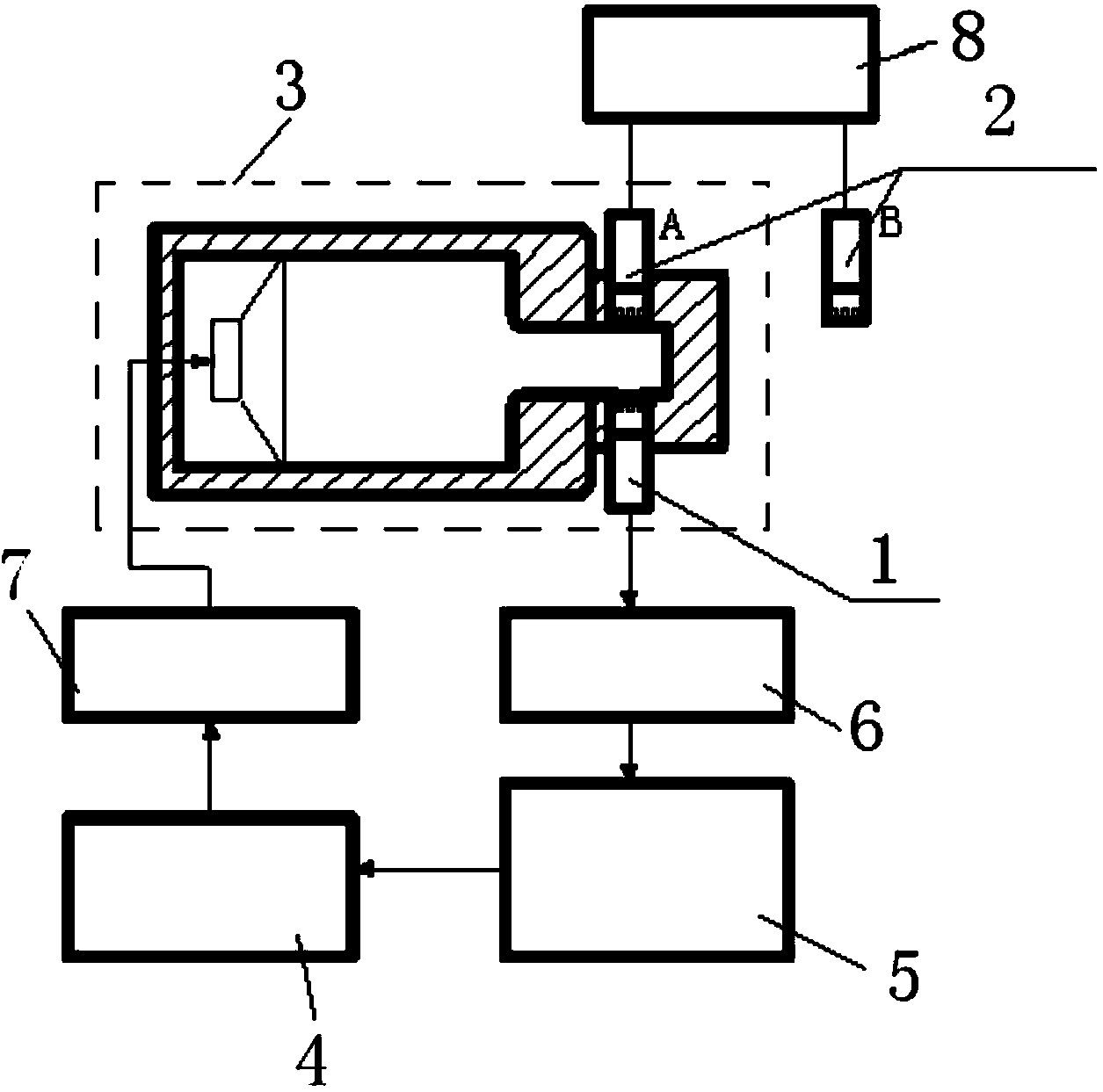

[0045] Such as figure 2 As shown, a method for evaluating the high sound intensity characteristics of a sound intensity measuring instrument according to the present invention is used for the evaluation of the upper limit of the dynamic range of the sound intensity level of the sound intensity measuring instrument. The sound intensity probe of the sound intensity measuring instrument has Two sound intensity probe microphones 2, both of which are connected to the sound intensity analyzer 8; one sound intensity probe microphone 2A of the sound intensity measuring instrument and the high sound pressure standard microphone 1 are axially symmetrically installed in the sound intensity level calibration On the device 3; the method comprises the steps of:

[0046] (a) The signal of a sound intensity probe microphone 2A is output to the sound intensity analyzer 8, and the sound intensity analyzer 8 outputs the sound pressure level measured to the data acquisition analyzer 5;

[0047]...

Embodiment 2

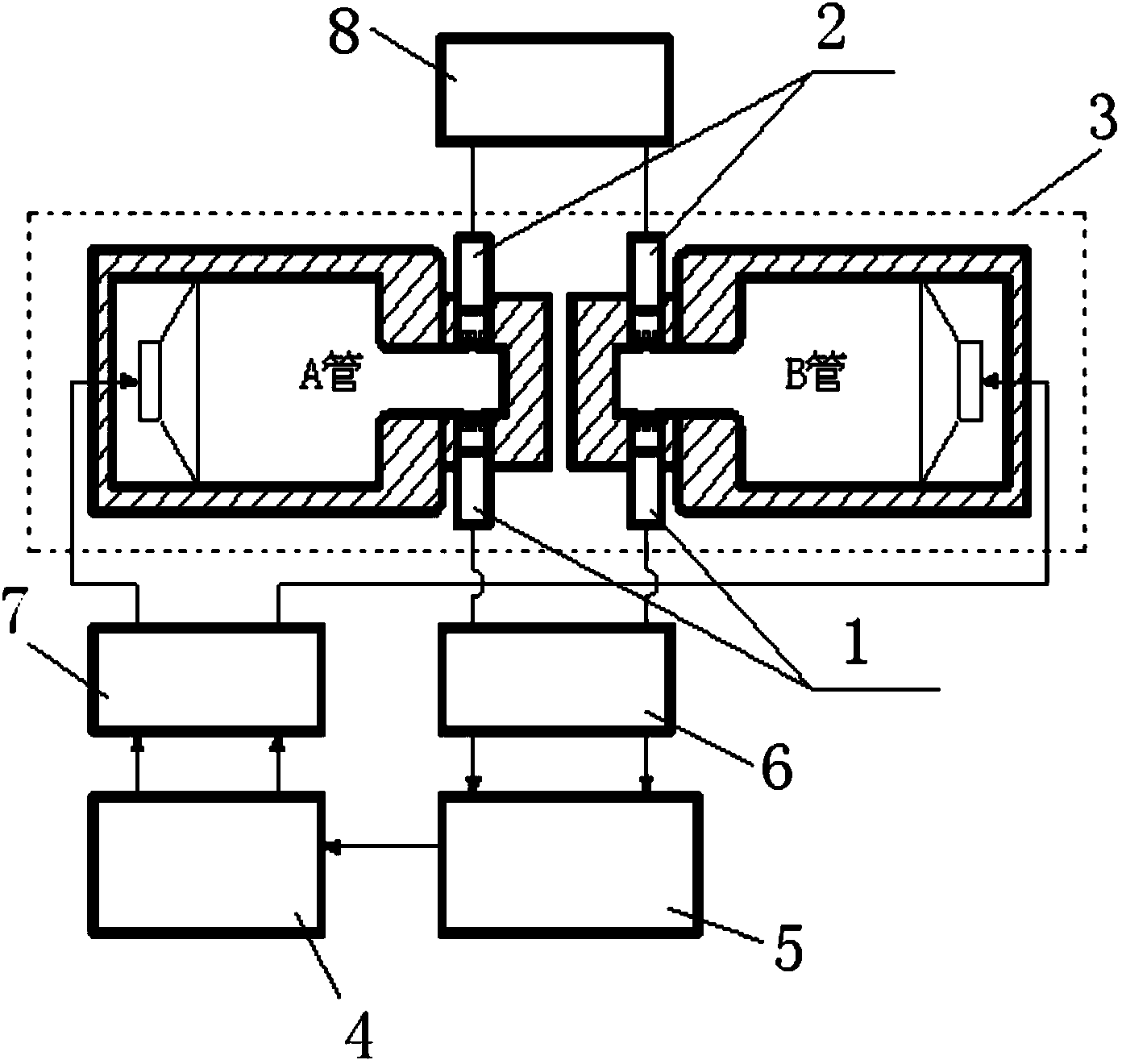

[0067] Such as image 3 As shown, a method for evaluating the high sound intensity characteristics of a sound intensity measuring instrument according to the present invention is used for sound intensity level deviation calibration, and the sound intensity probe of the sound intensity measuring instrument to be calibrated has two sound intensity probe microphones 2, The two sound intensity probe microphones 2 are connected to the sound intensity analyzer 8; the two sound intensity probe microphones 2A, 2B of the sound intensity measuring instrument and the two high sound pressure standard microphones 1 are axially symmetrically installed on the sound intensity level calibration device 3; The method comprises the steps of:

[0068] (a) the nominal spacing of two sound intensity probe microphones 2A, 2B of the sound intensity measuring instrument is set to be 50mm; the sound intensity analyzer 8 outputs the sound pressure level measured to the data acquisition analyzer 5;

[00...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com