Three-dimensional vector sound intensity probe

A sound intensity probe and three-dimensional vector technology, which is applied to the measurement of ultrasonic/sonic/infrasonic waves, measuring devices, instruments, etc., can solve the problems of difficult to ensure the accuracy of spatial positioning, time-consuming measurement process, high cost, etc., to save measurement time , simple structure, and the effect of ensuring the accuracy of spatial positioning

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

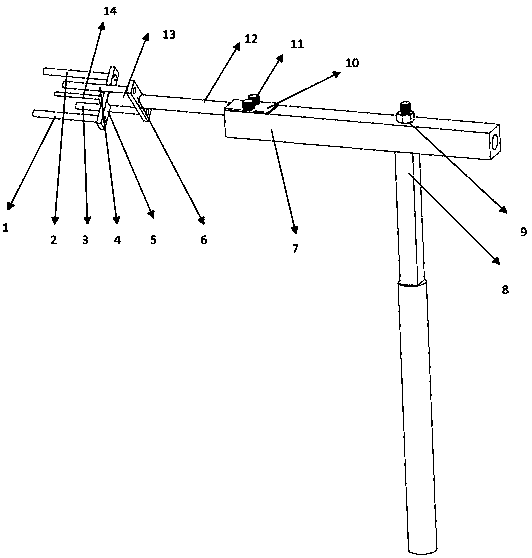

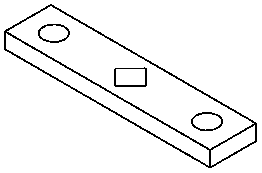

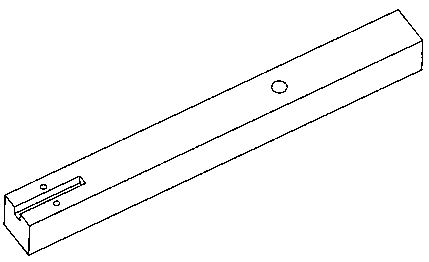

[0029] Embodiment 1: as Figure 1-7 As shown, a three-dimensional vector sound intensity probe includes a microphone group, a layout frame group, a support rod 7, a handle 8, a lock nut 9, a baffle 10, a lock screw 11, a fixed column 12, a distance column 13, a center Rod 14 and central square rod 15, the microphone group includes microphone I1, microphone II2, microphone III3, and microphone IV4, and the arrangement frame group includes arrangement frame I5 and arrangement frame II6;

[0030] The microphone I1 and microphone II2 are fixed in the circular holes at both ends of the arrangement frame I5, the microphone III3 and the microphone IV4 are fixed in the circular holes at both ends of the arrangement frame II6, and the end of the central square rod 15 without threaded hole is inserted into the front end of the support rod 7. In the groove, and attach the baffle plate 10 on the upper surface of the groove of the front end of the support rod 7 and lock it by the locking s...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com