Measuring method and probe for three-dimensional vector sound intensity

A three-dimensional vector, measurement method technology, applied in the field of measurement probes, can solve the problems of tailing effect, difficult to ensure spatial positioning accuracy, measurement time and spatial positioning accuracy errors are not much improved, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

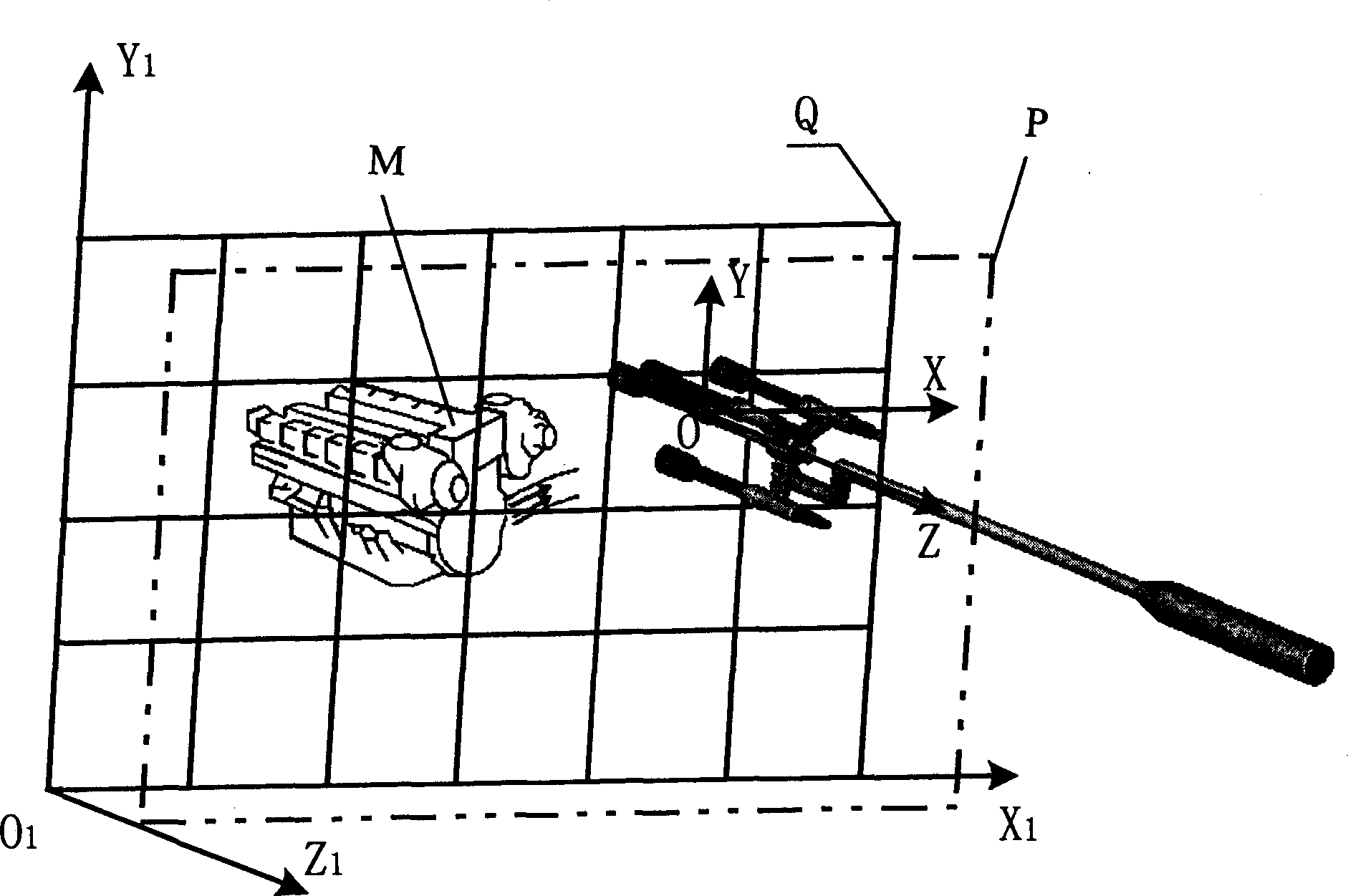

[0067] see figure 1 , Fig. 3, in the present embodiment, measured object M is engine, and its surface to be measured is plane, and concrete measurement process is:

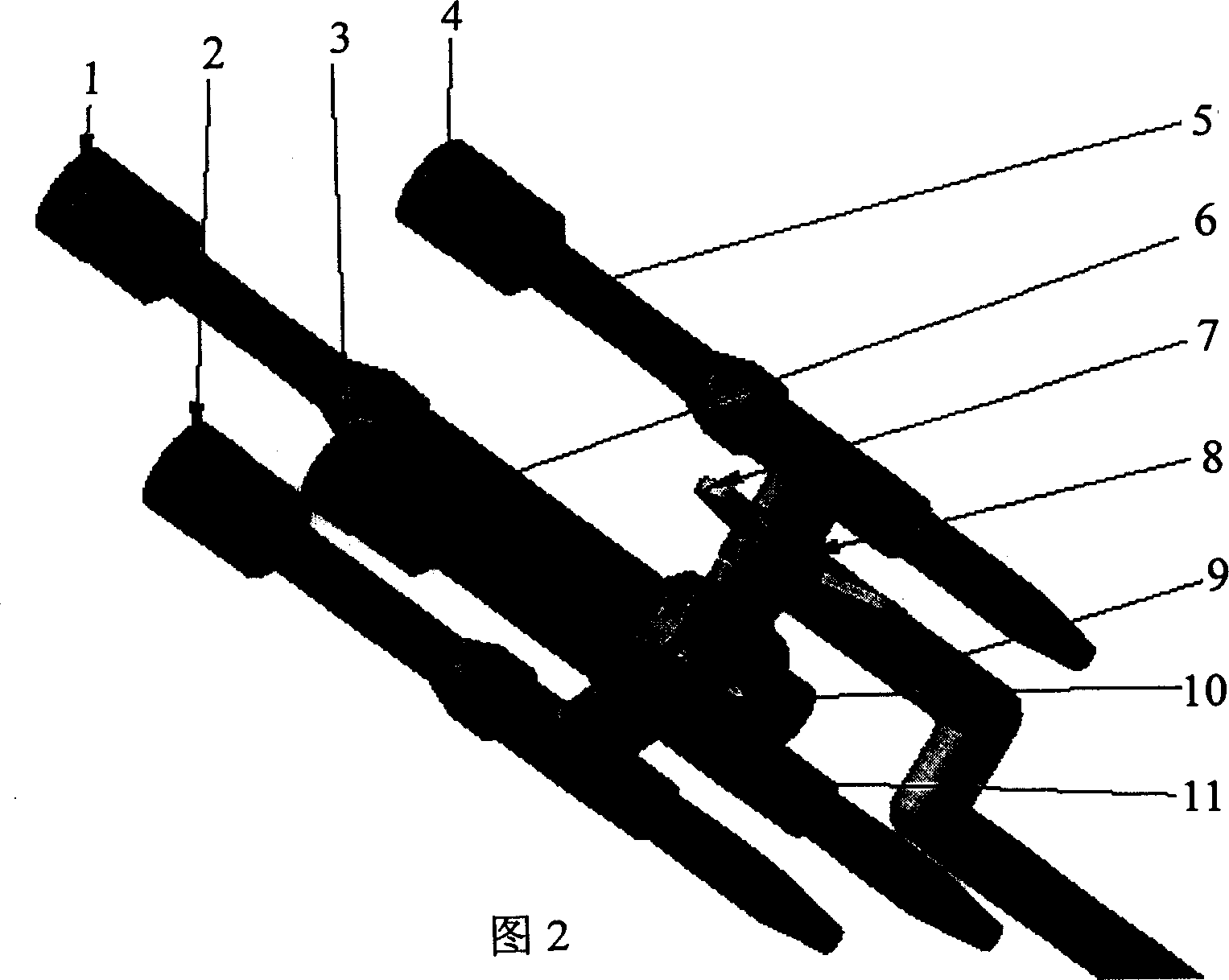

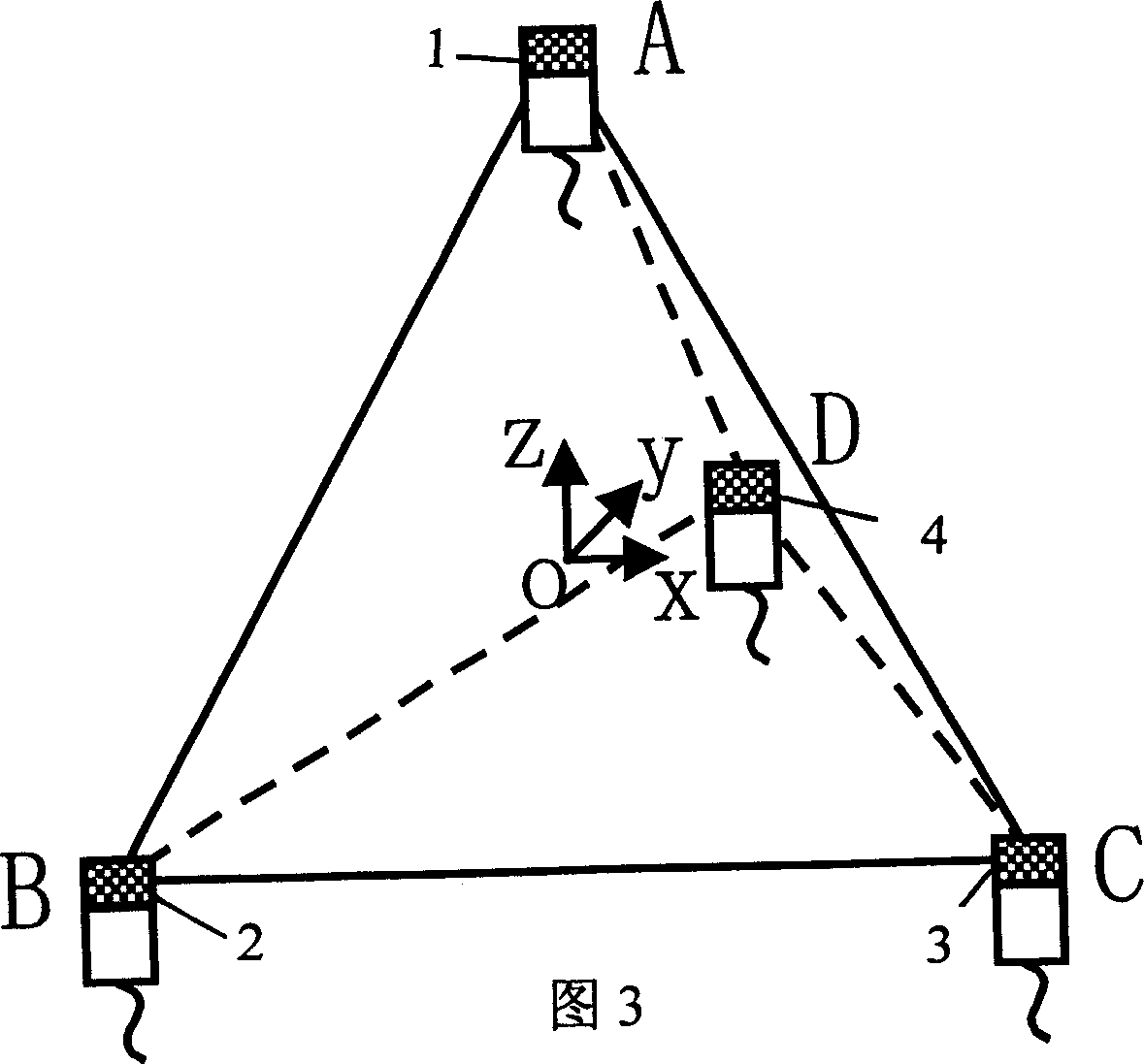

[0068] 1. Construct a geometric coordinate system O 1 -X 1 Y 1 Z 1 Used to determine the measurement positioning grid surface Q{Z 1 =0}; Construct the regular tetrahedron (ABCD) that is used for space vector sound intensity measurement, take the center point (O) of regular tetrahedron as the origin to set up the measurement coordinate system O-XYZ (this measurement coordinate system is a dynamic coordinate system), The vertex (A) on the top of the regular tetrahedron is located on the grid point of the measurement positioning grid surface Q. As the vertex (A) moves on the grid point, the moving track of the center point O (that is, the measurement point) constitutes the measurement Surface P, the distance between the measurement surface P and the measurement positioning grid surface Q is r; the Z-axis directi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com