Mobile-type sensor installation auxiliary platform for measuring sound intensity level of equal-height curved surface

A technology of installation assistance and sound intensity level, which is applied in the direction of measuring devices, measuring ultrasonic/sonic/infrasonic waves, instruments, etc., can solve the problems that the measurement of the microphone and the surface of the machine cannot be realized, and achieve low noise, low production cost and convenient operation. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

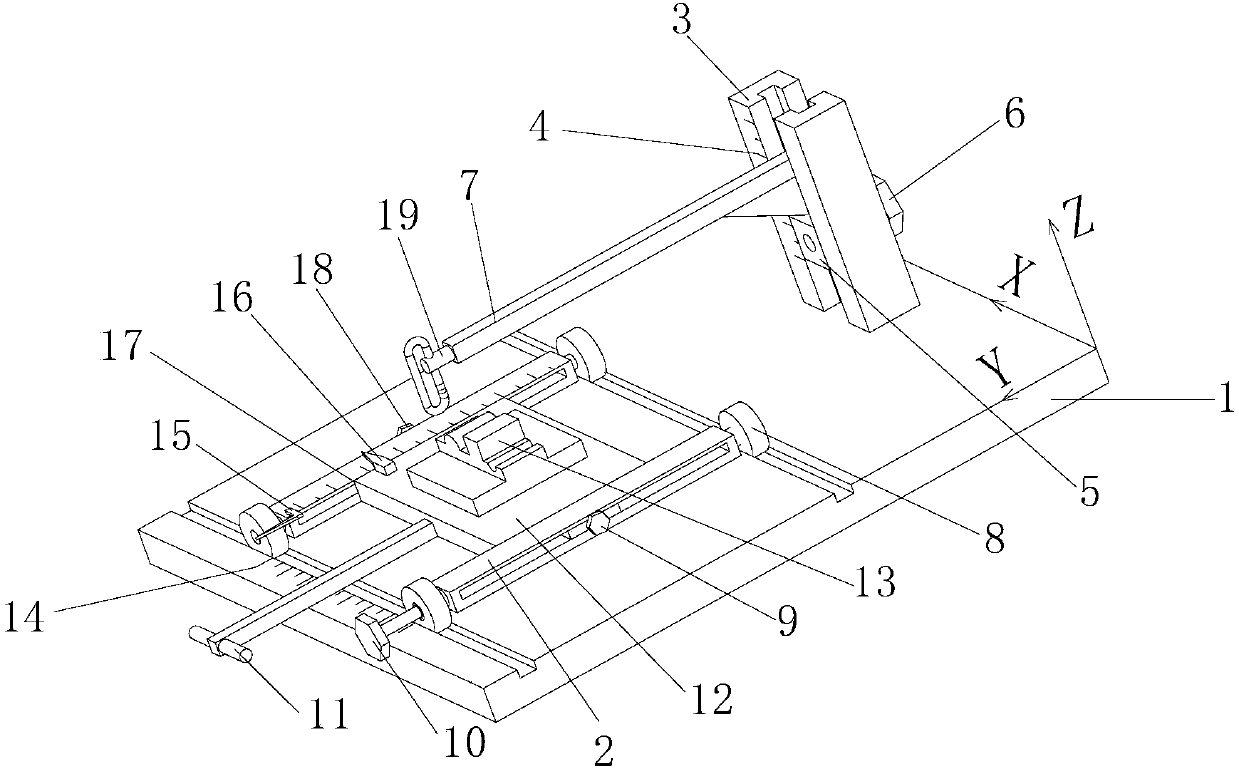

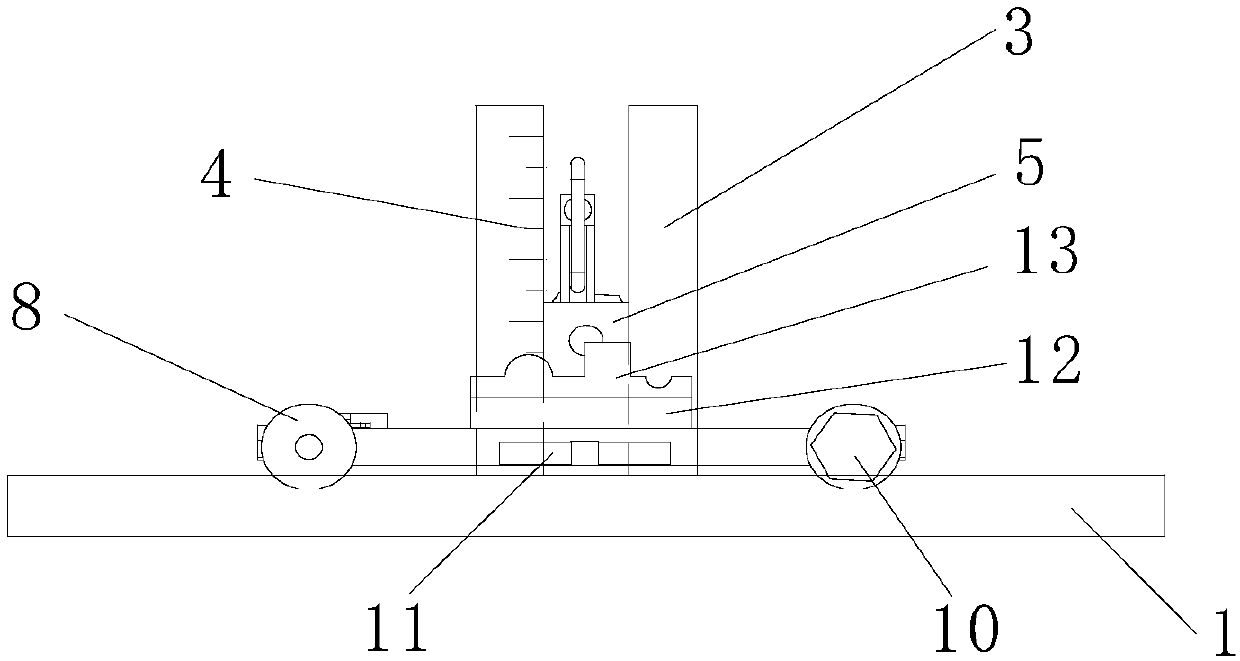

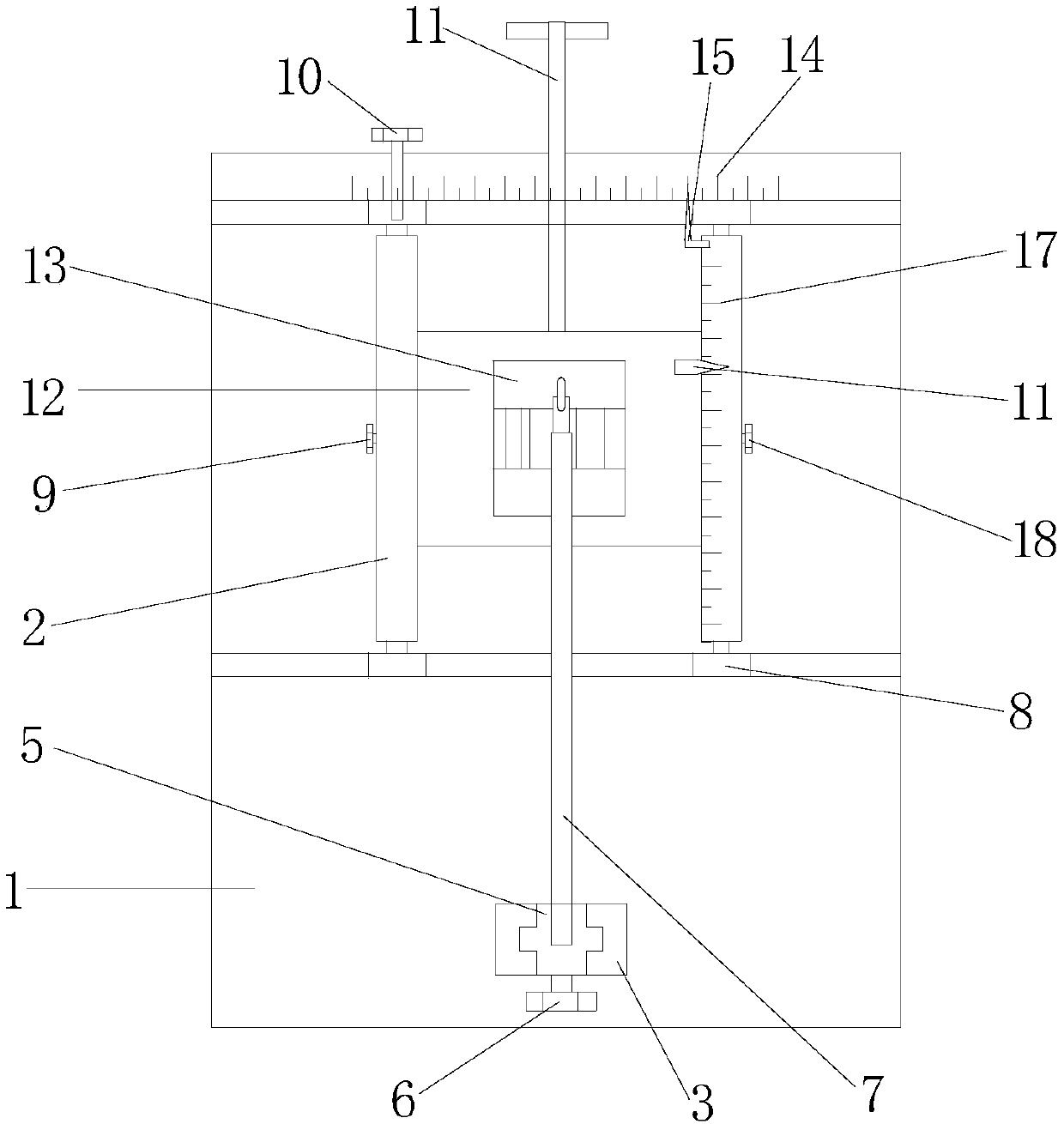

[0023] The present invention will be further described below in conjunction with the accompanying drawings.

[0024] Such as Figure 1-Figure 4 As shown, the present invention comprises base plate 1, working plate 12, two guide rails 2 and cantilever beam 7; Described base plate 1 is provided with two guide grooves 1-1 that are arranged in parallel, and the two ends of guide rail 2 are provided with roller 8, and guide rail 2 The rollers 8 at both ends are placed in the two guide grooves 1-1 respectively. The base plate 1 is provided with a scale II14 close to a guide groove 1-1, one of the two guide rails 2 is provided with a pointer I15 corresponding to the scale II14, and the other end of the guide rail is provided with a limit bolt III10, which is used to realize that the guide rail 2 is relative to the base plate. 1 fixed.

[0025] The guide rail 2 is provided with a long straight hole, and the sliders at both ends of the working plate 12 are embedded in the long straig...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com