Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

44 results about "Smoke composition" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

A smoke composition is a pyrotechnic composition designed primarily to generate smoke. Smoke compositions are used as obscurants or for generation of signaling smokes. Some are used as a payload of smoke bombs and smoke grenades.

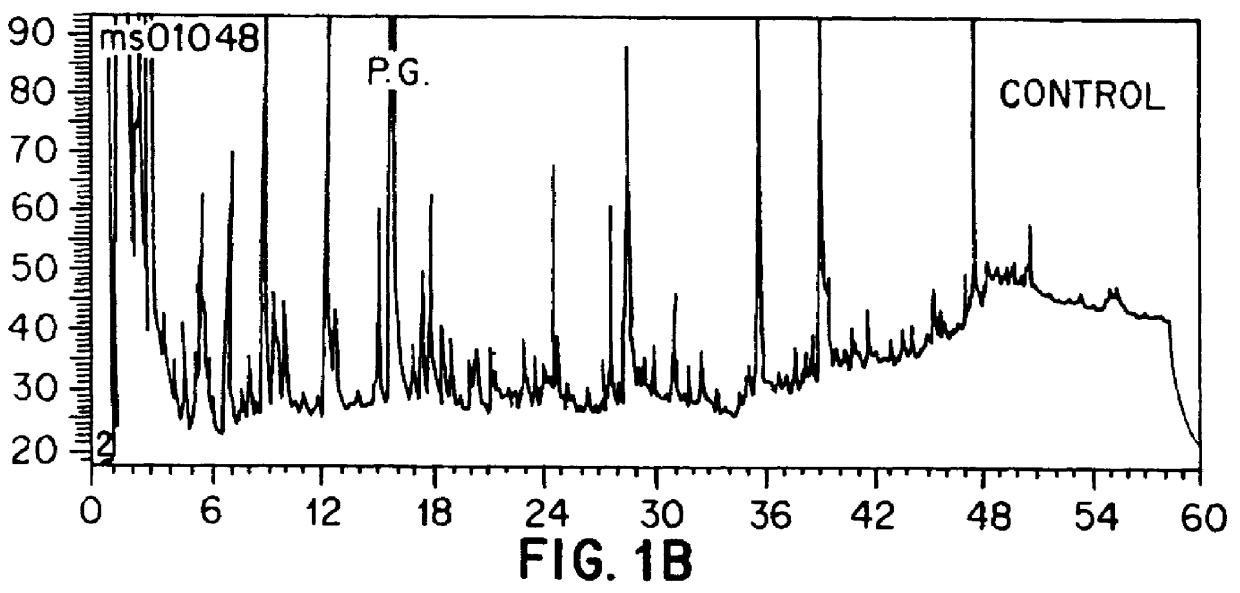

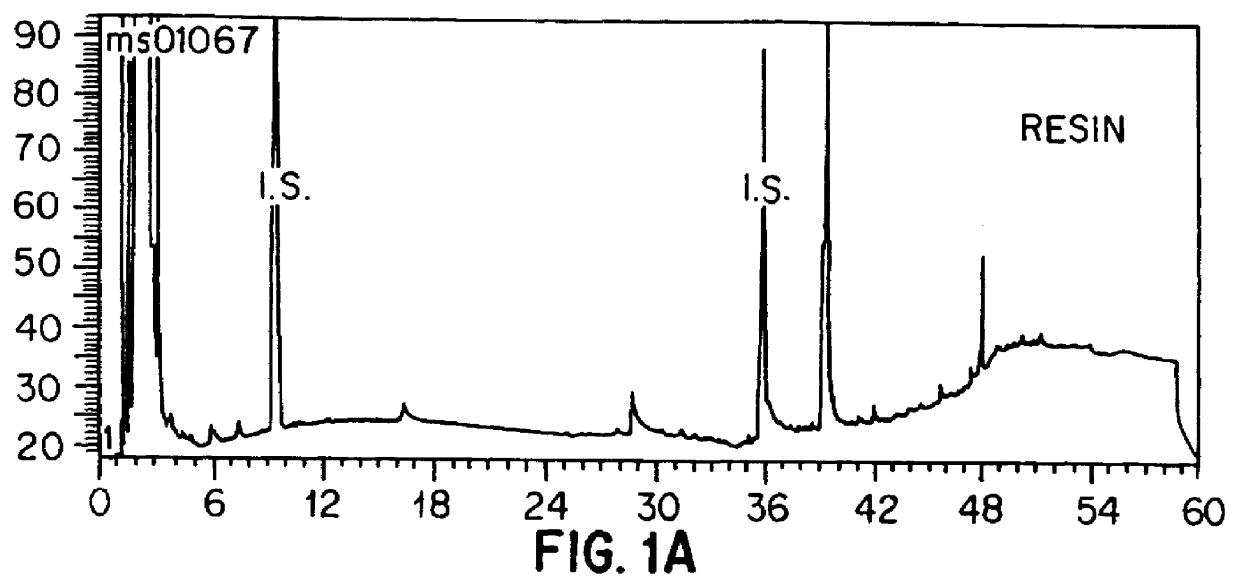

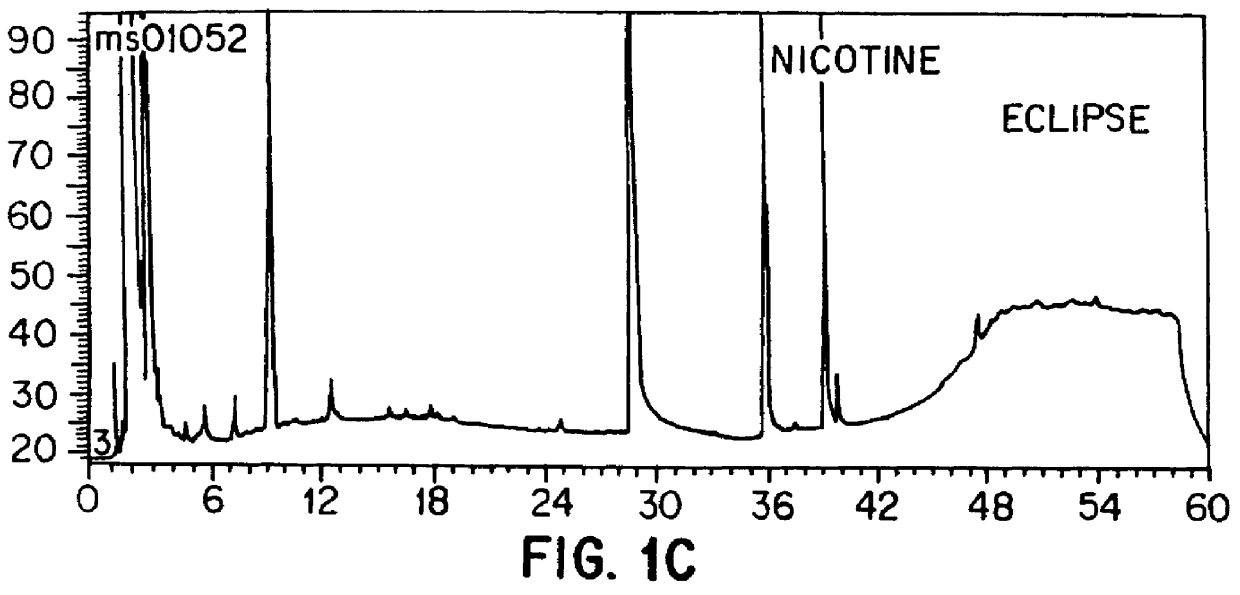

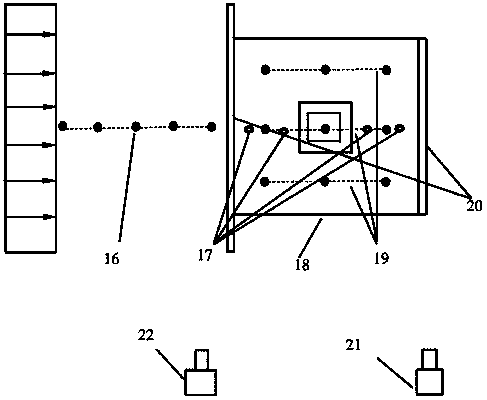

Method and apparatus for the selective removal of specific components from smoke condensates

InactiveUS6119699AHigh capacity bonded phaseEasy to useTobacco treatmentCigar manufactureLow affinitySmoke composition

A smoking article capable of delivering a regulated smoke composition to a smoker, includes: a) a combustible filler wrapped in a combustible sheath; and b) at least one affinity chromatographic filter unit designed to preferentially remove specific targeted components from the smoke disposed within the sheath adjacent the combustible filler. The filter unit includes a mass of silica or resin particles having chemically bonded to their surfaces functional groups which exhibit preferential affinity for the targeted components and which reversibly bind the targeted components to elute components having a lower affinity than a previously bound component.

Owner:SUNG MICHAEL T

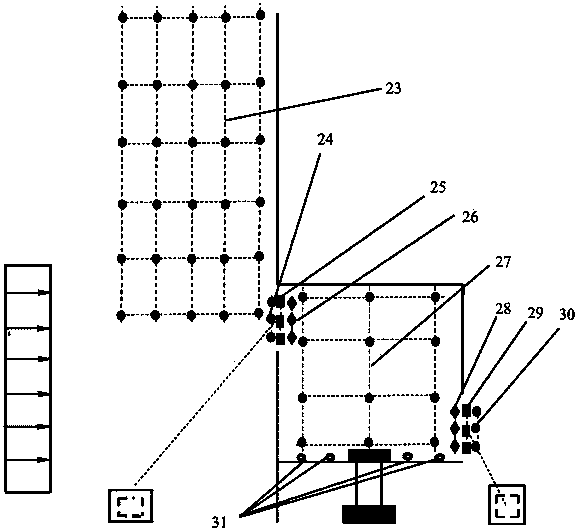

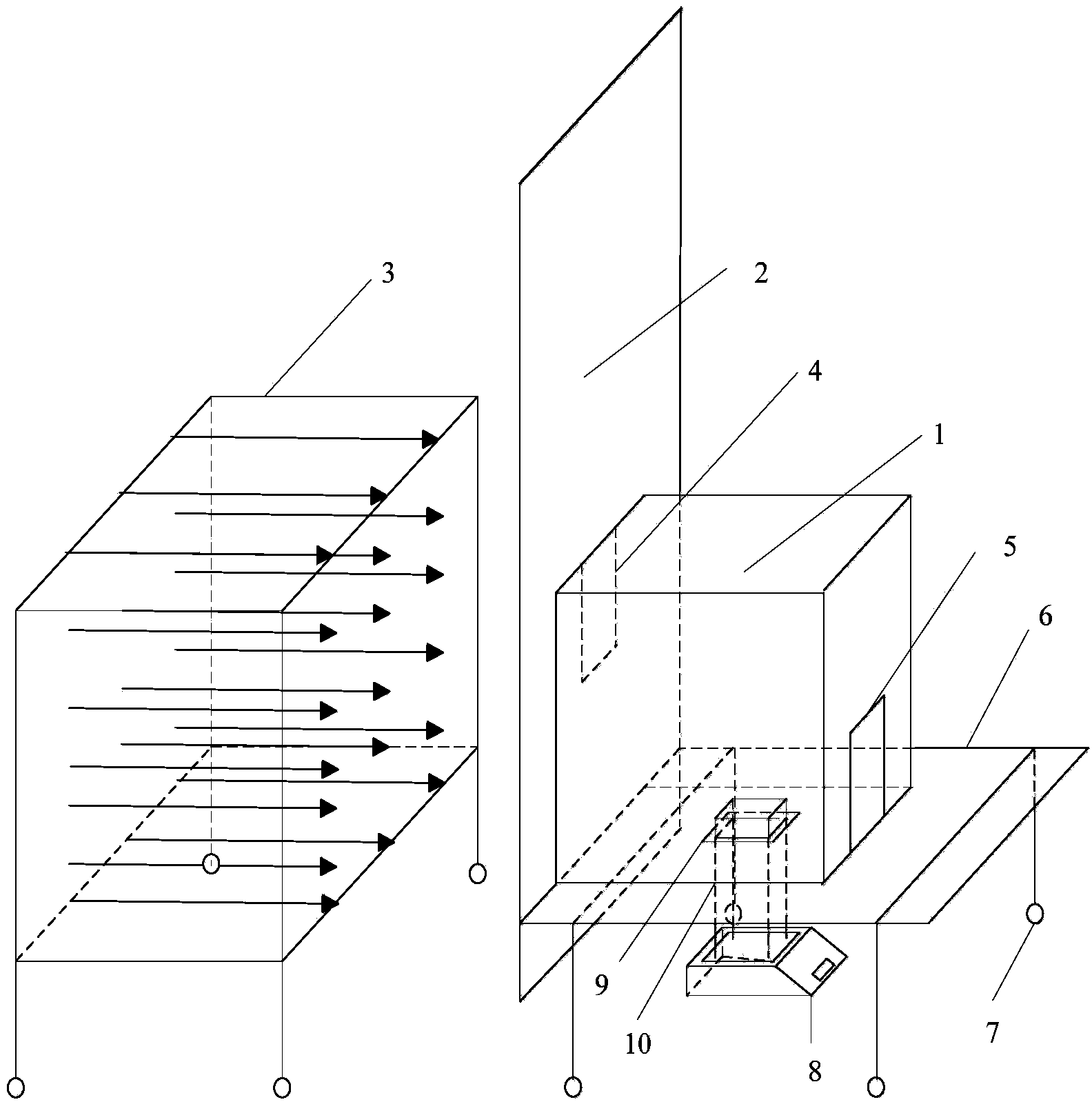

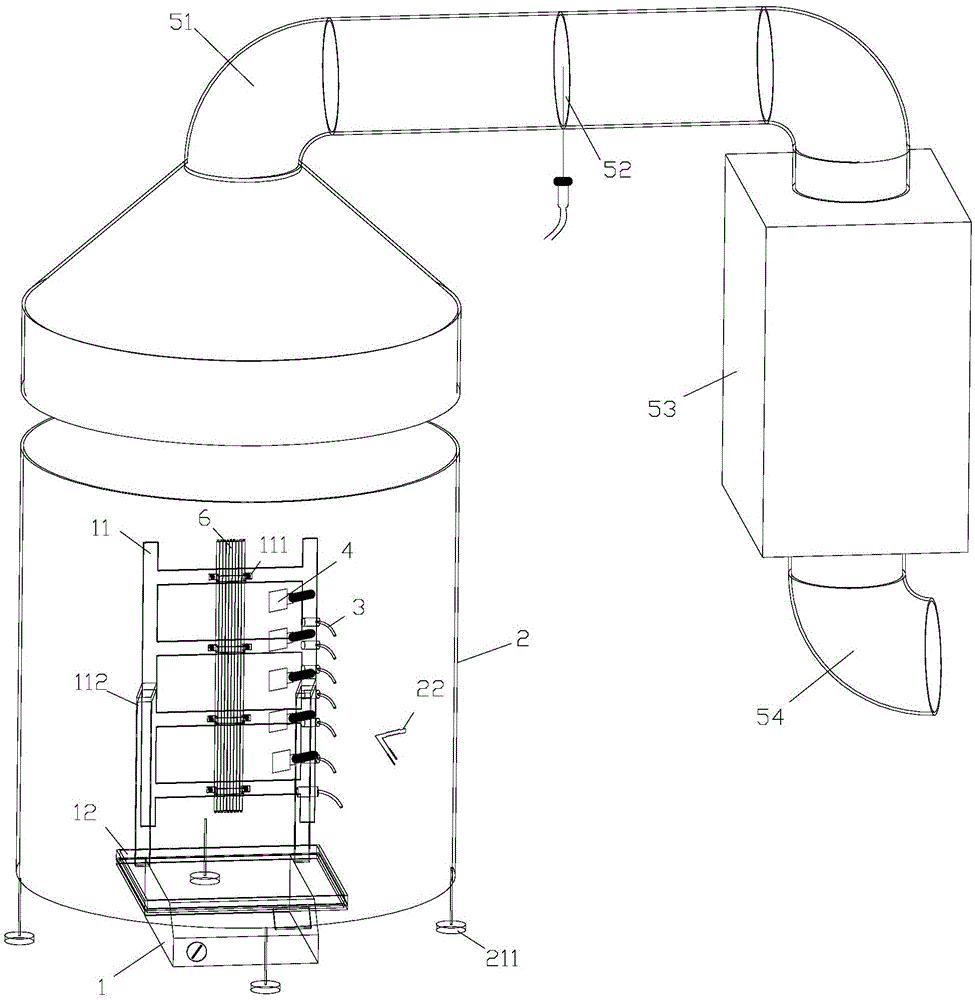

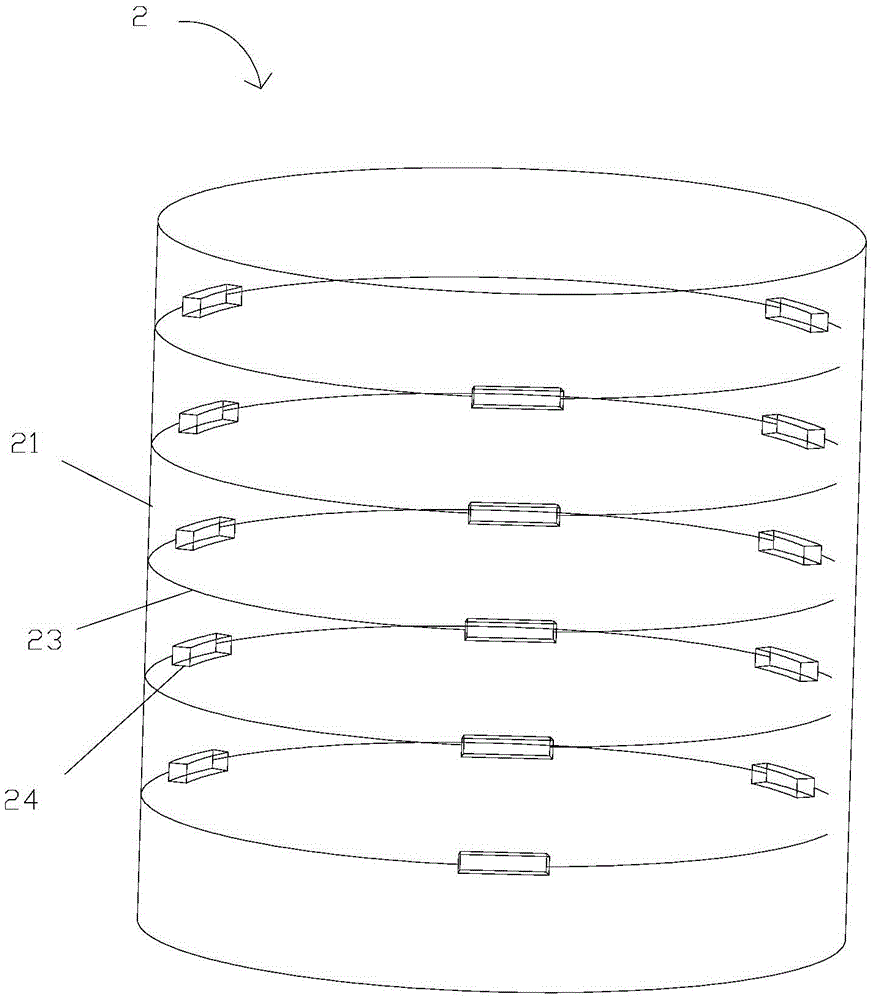

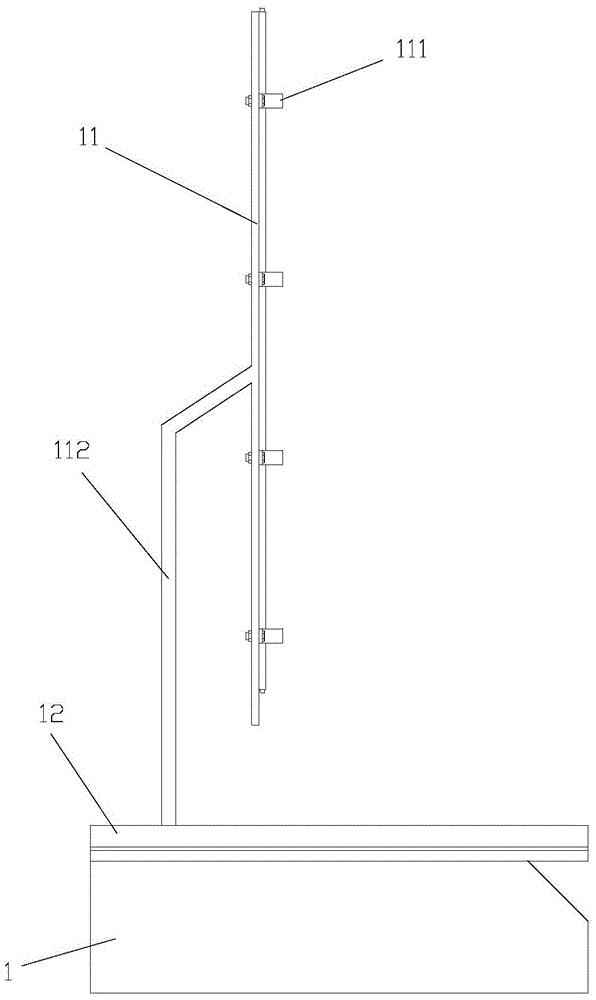

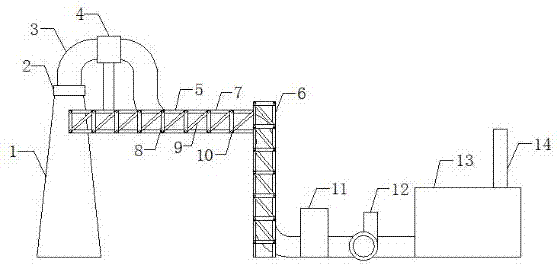

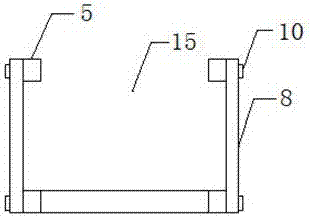

Chamber fire simulation experiment device under action of external wind

The invention provides a chamber fire simulation experiment device under the action of external wind. The device can simulate chamber fire combustion conditions in a laboratory under the action of the external wind and can be used for researching chamber fire development and windowsill overflow rules under the action of the external wind. The chamber fire simulation experiment device under the action of the external wind comprises an experiment table body, an outer vertical face, an external wind system and a matched measurement and control system. The device is designed according to a medium-size model proportion of 1:3 and is the first experimental device carrying out comprehensive and systematic study on the heat release rate, smoke flowing, temperature distribution, smoke compositions, the air supplement speed, thermal radiation flux, flame forms, sill overflowing and the like of a chamber fire under the action of the external wind. On the basis of previous experimental bases, the defects that a full-scale experiment is high in cost and a numerical simulation tool is not precise enough are overcome, repeatability of the experiment is guaranteed, and the device has great application value and important guiding significance in conducting laboratory scientific research and influences of actual external wind on the chamber fire.

Owner:UNIV OF SCI & TECH OF CHINA

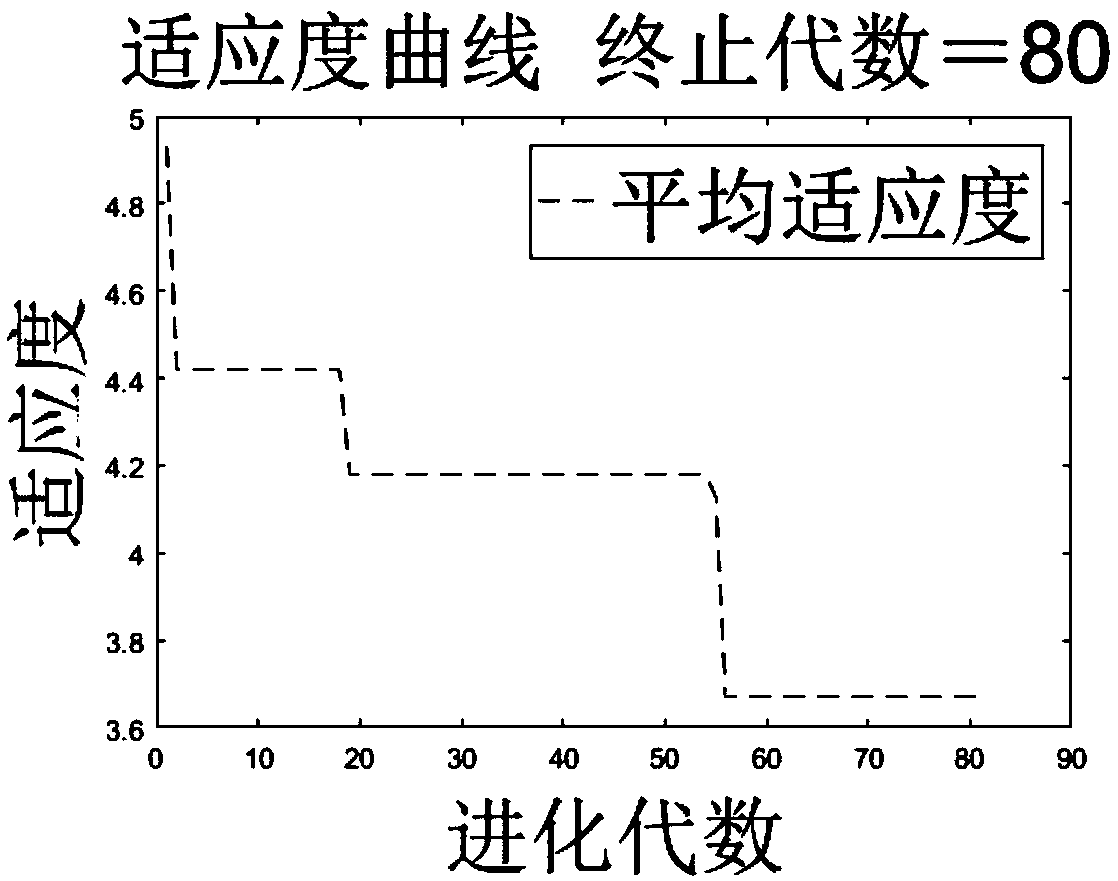

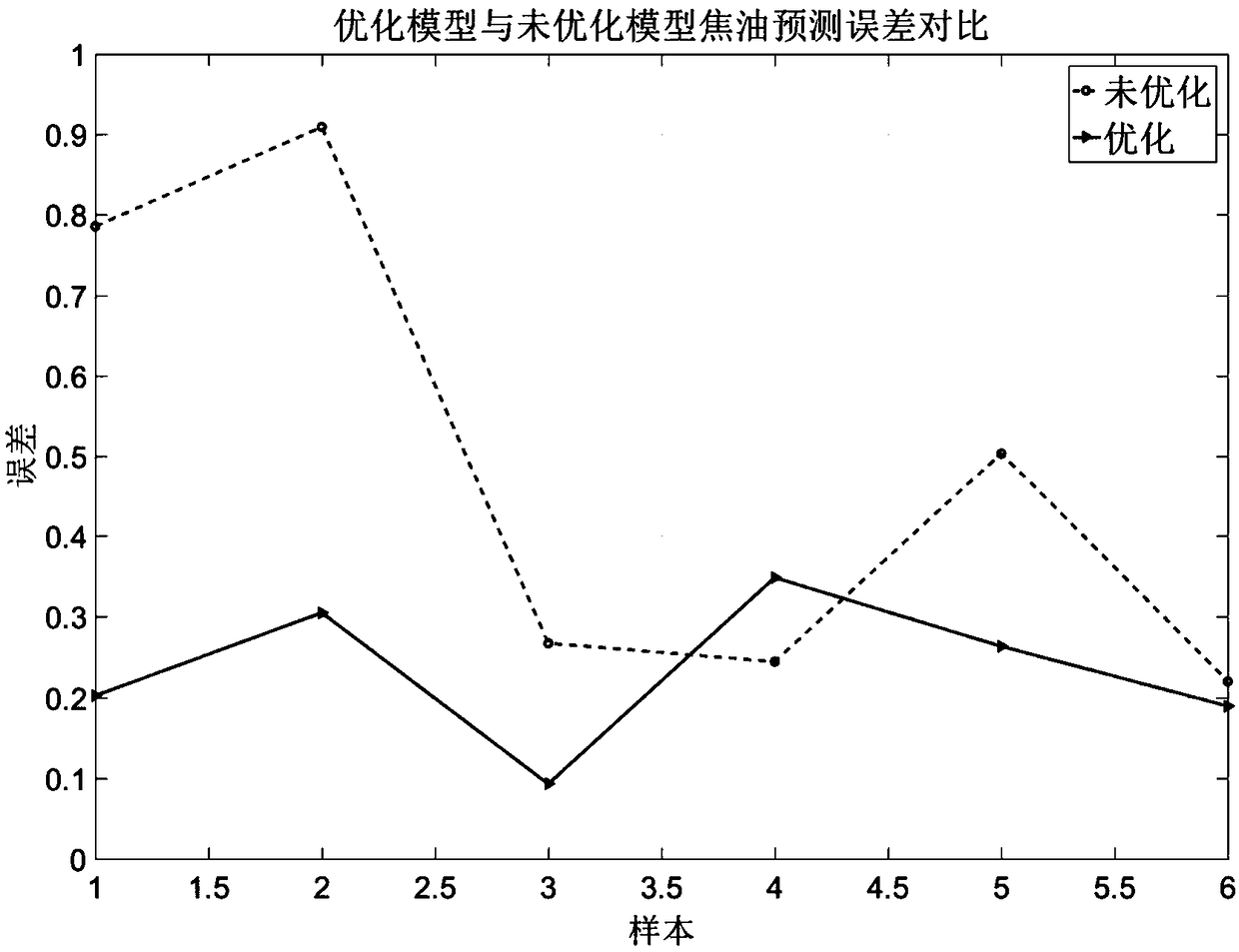

Prediction model of cigarette material and mainstream smoke composition based on genetic algorithm optimized neural network

A prediction model of cigarette material and mainstream smoke composition based on genetic algorithm optimized neural network comprises the following steps: sample pretreatment; obtaining the optimalweights and threshold parameters of neural network based on genetic algorithm; constructing and training the neural network based on the optimal weights and thresholds obtained by genetic algorithm. The trained neural network model is verified and the evaluation model is applied to the actual effect. Compared with the neural network without optimization algorithm, the neural network model based ongenetic algorithm firstly uses genetic algorithm to select the weights and thresholds to minimize the model error as the initial parameters of the training neural network, which can avoid the model falling into the local optimal solution, but can not get the global optimal solution.

Owner:HUBEI CHINA TOBACCO IND

Microcrystalline Nitrocellulose Pyrotechnic Compositions

InactiveUS20070068610A1Degradation of combustionHard and durableNitrocellulose explosive compositionsExplosive working-up apparatusNitrocellulosePyrotechnic composition

Owner:NICKEL RUSSELL R

Training rocket for smoke development

A training rocket for smoke development. The training rocket includes a rocket tube which contains powder and constitutes a propulsion motor for the rocket. The rocket includes a forward training head which contains a smoke composition adapted to emit visible smoke upon impact. An igniter charge, such as a tracer charge, which can be ignited by the propellant powder is situated in the rearmost of the training head, behind a bursting charge which can be ignited by the igniter charge. The igniter charge and the bursting charge are situated behind the smoke composition in the training head, for igniting the smoke composition, in a capsule which can be forced rearwardly from the training head due to the increased pressure caused by combustion of the smoke composition, whereby an aperture is formed for passage of smoke gases rearwardly in the rocket, through the rocket tube and out of it.

Owner:NAMMO RAUFOSS

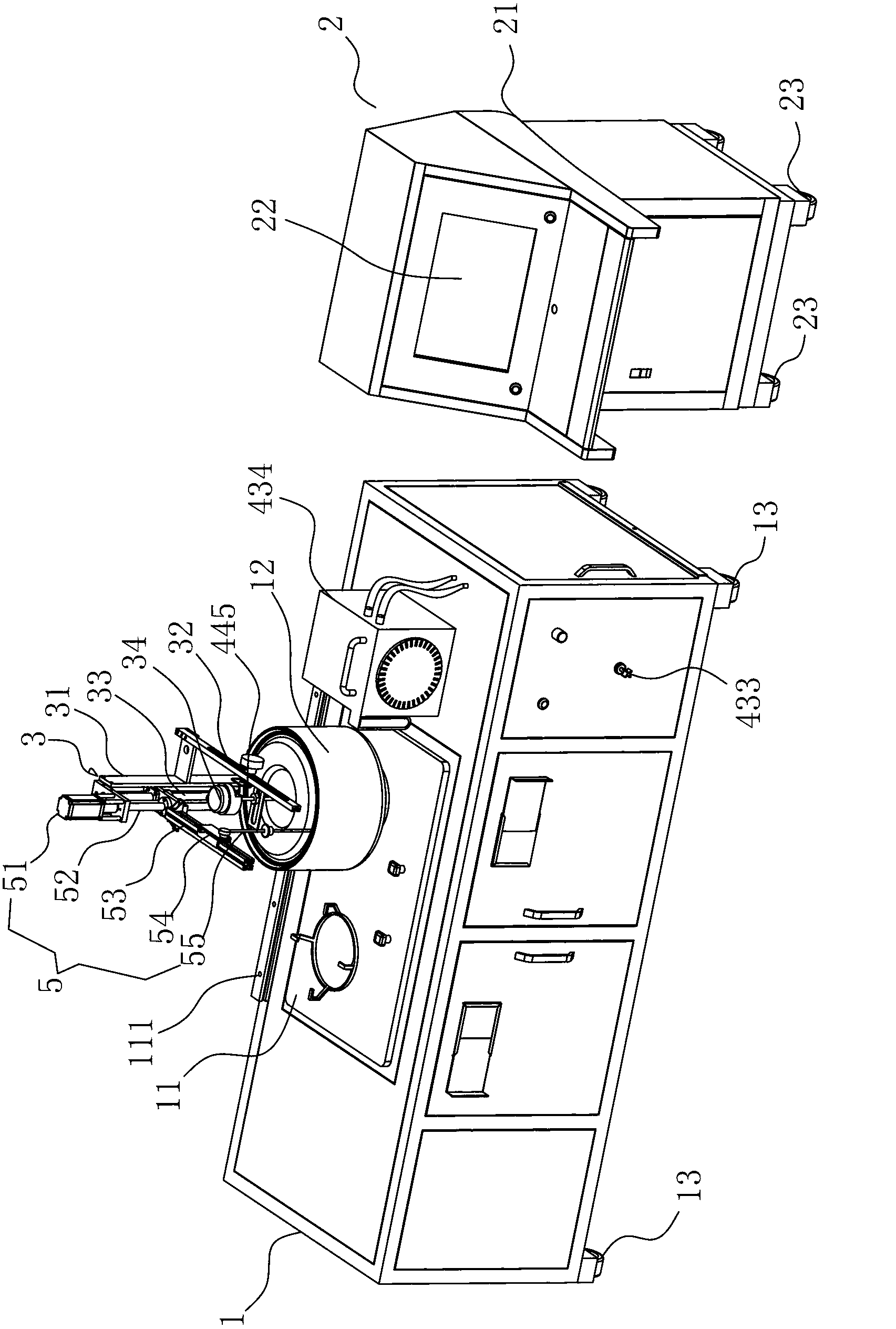

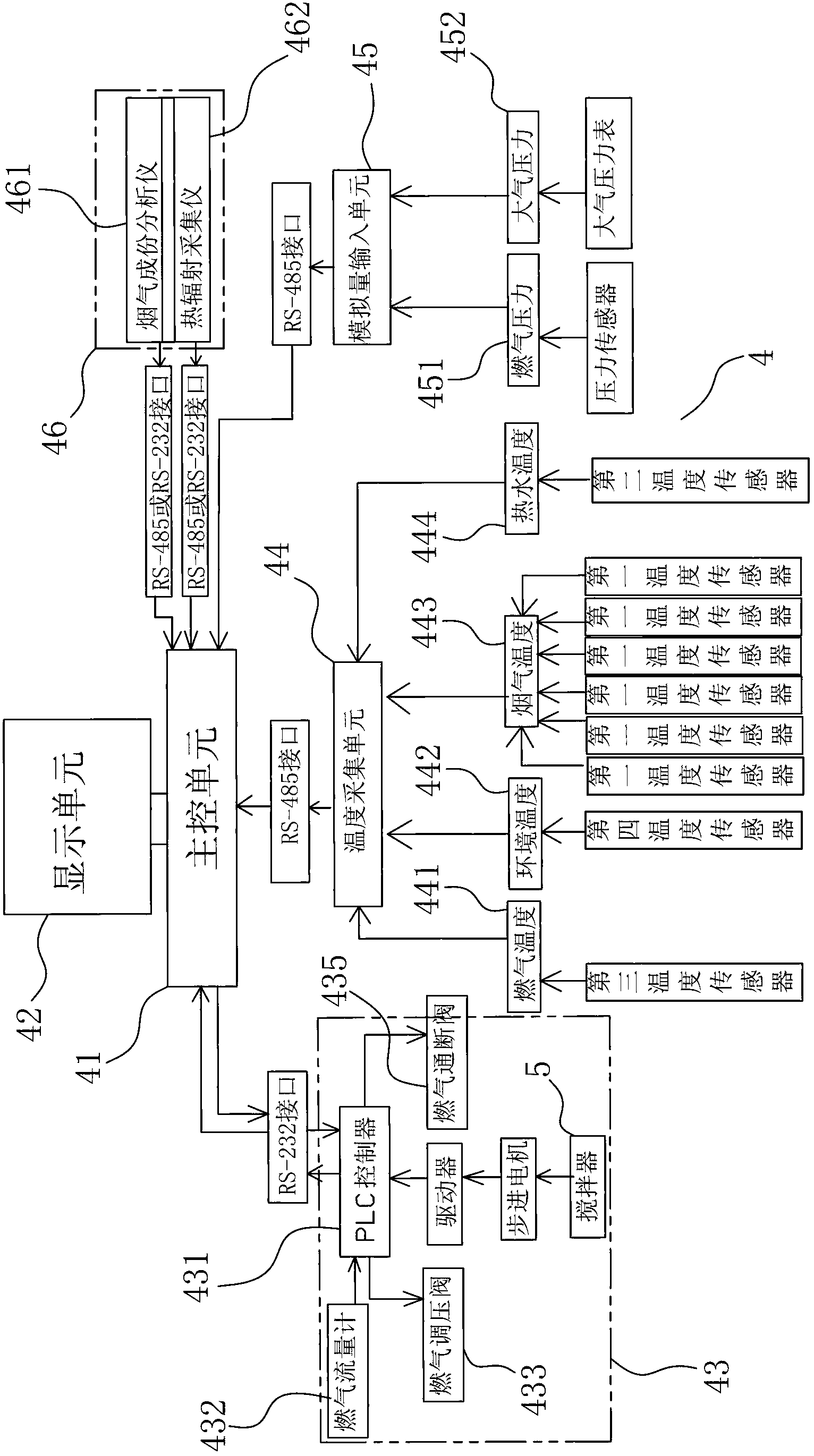

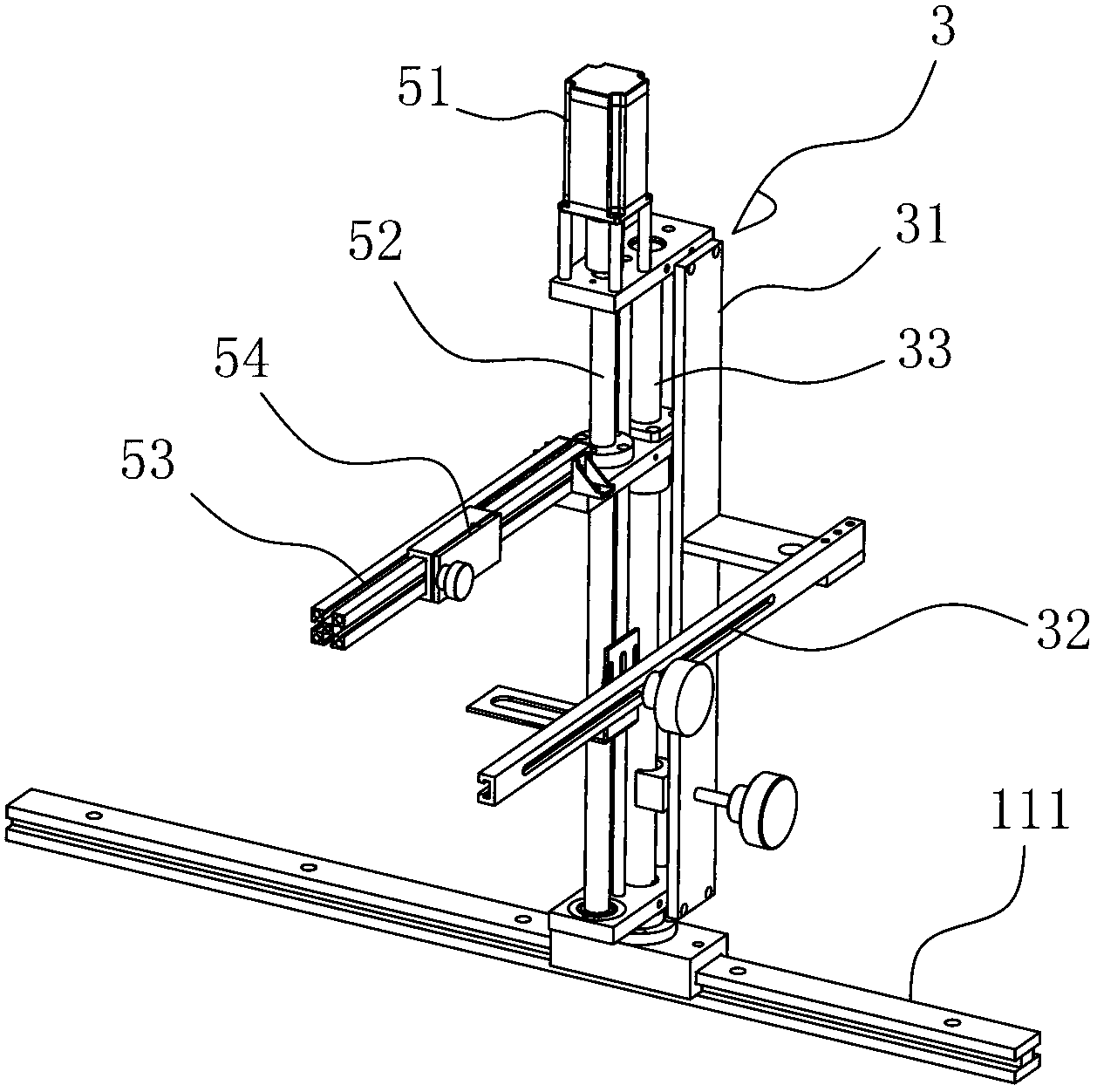

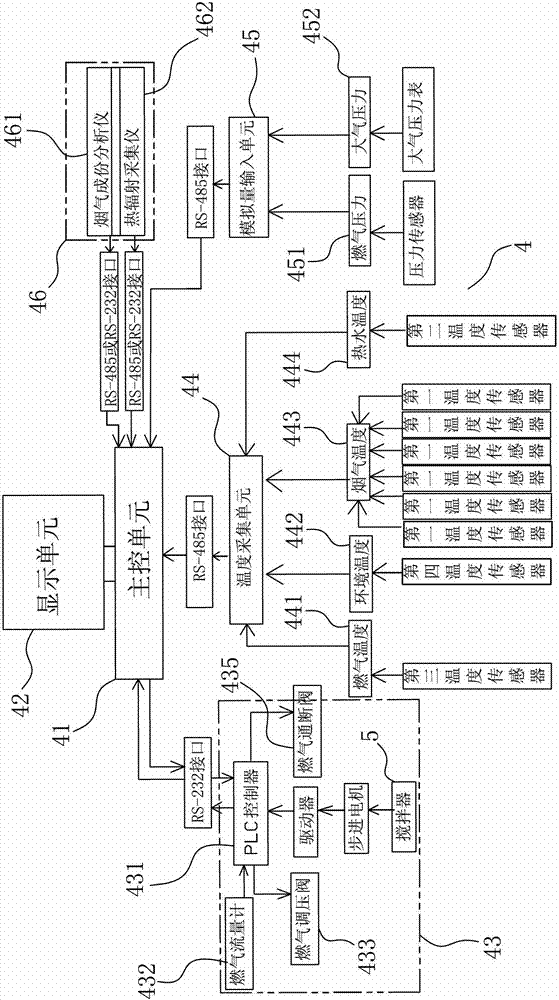

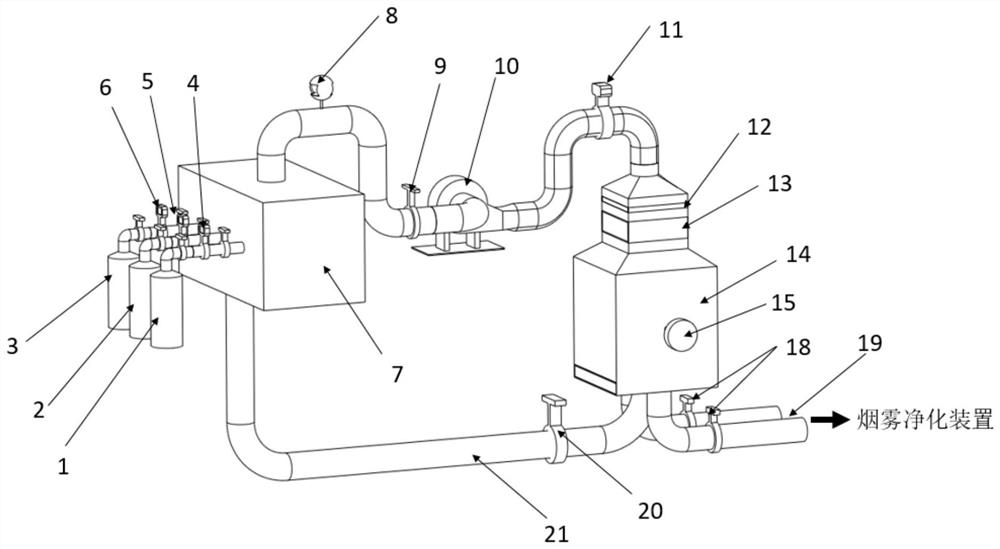

Automatic control test device of gas cooker

InactiveCN102706636ASimple and fast operationThe test effect is goodStructural/machines measurementAutomatic controlSmoke composition

The invention discloses an automatic control test device of a gas cooker. A working circuit of the device comprises a main control unit, and a display unit, a control unit, a temperature collection unit, an analog input unit and an analysis processing unit, which are respectively and electrically connected with the main control unit, wherein the control unit comprises a program logic controller (PLC), a gas flow meter which is electrically connected with the PLC, a gas pressure regulating valve, a stirrer and a gas on-off valve; the temperature collection unit comprises a gas temperature collection unit, an ambient temperature collection unit, a smoke temperature collection unit and a hot water temperature collection unit; the analog input unit comprises a gas pressure input unit and an atmosphere pressure input unit; and the analysis processing unit comprises a smoke composition analyzer and a heat radiation collection instrument. The automatic control test device of the gas cooker has advantages of compactness in structure, high safety, simpleness and convenience in testing, good test effect, reliability in test data and the like.

Owner:DONGGUAN HAIDE TESTING INSTR

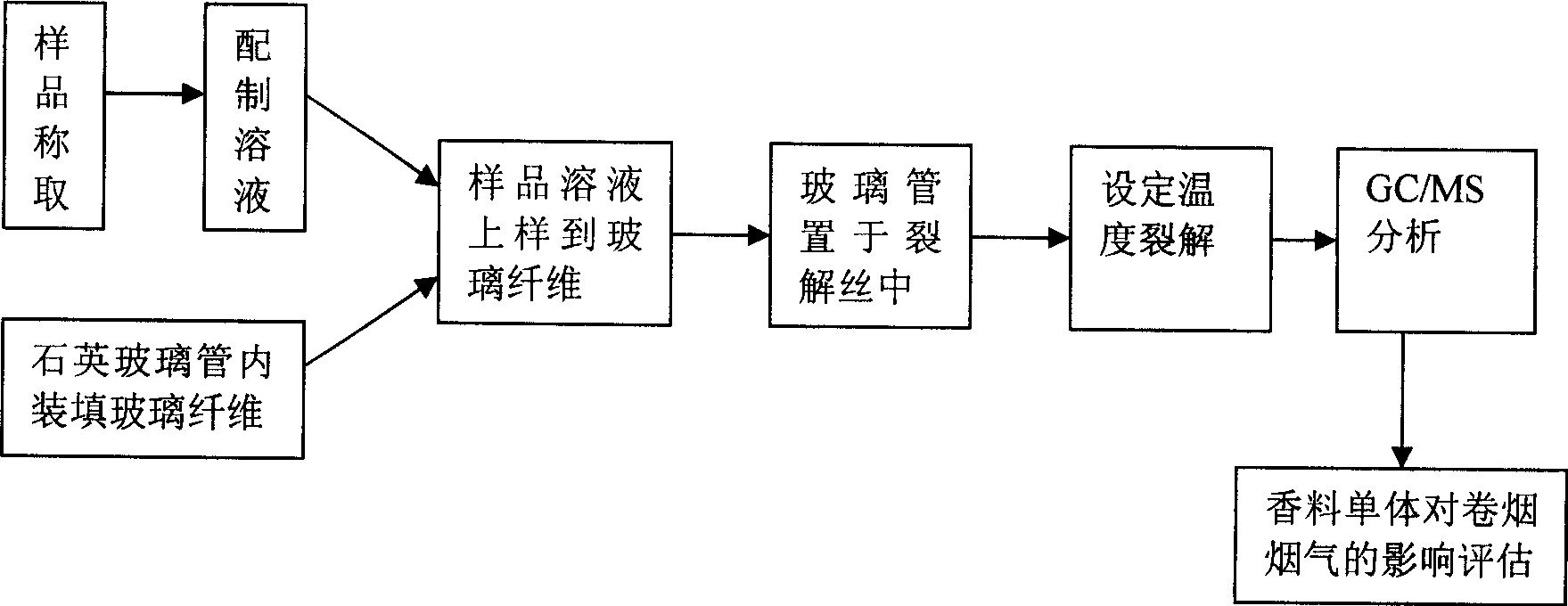

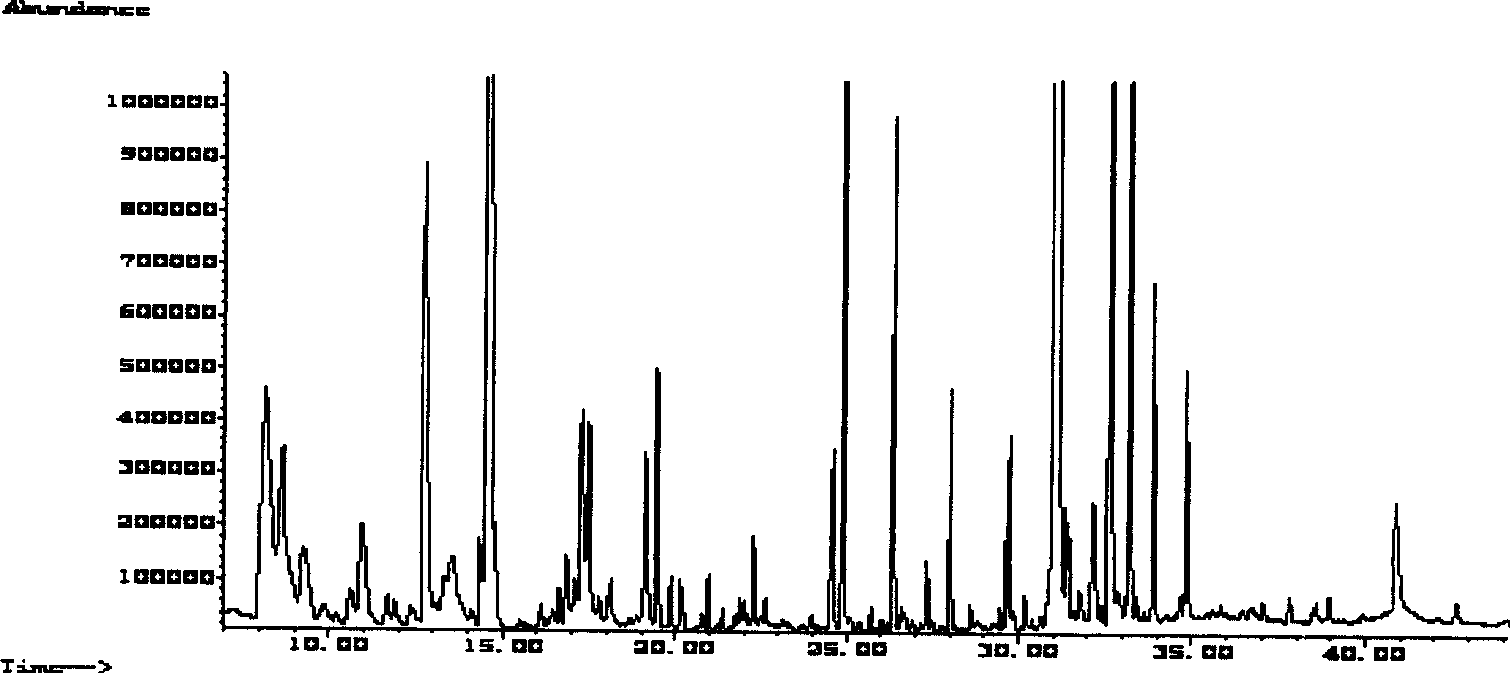

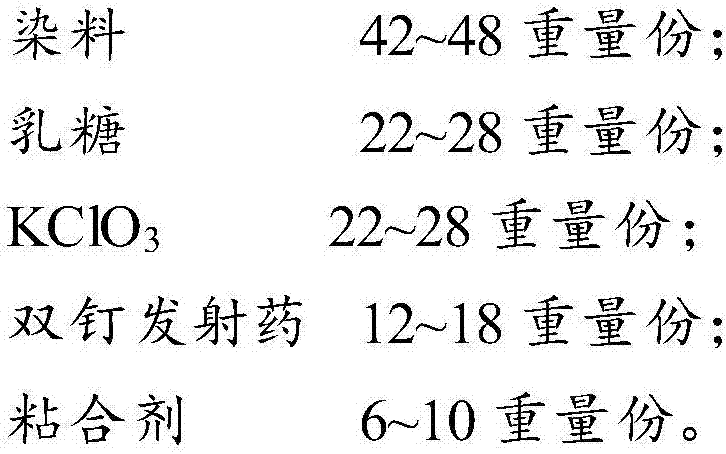

Method for assessing function of spices monomer to cigarette by pyrolysis experiment

The invention discloses a method for evaluating the influence of the perfume monomer on cigarettes by adopting the thermal pyrolysis experiments, which is characterized by comprising the following steps: perfume monomer samples of a certain amount are sampled, dissolved by solvent and volume-limited, the sample solution is injected in the glass fiber of a quartz glass tube by a sampling needle, then pyrolysis is carried out in a pyrolysis apparatus, the generated pyrolyzate is carried out GC / MS analysis, and the influence of the perfume monomer on the cigarette smoke after the perfume monomer is added into the cigarette is evaluated according to the analytic determination result of the pyrolyzate. The invention has the advantages that: the perfume monomer is carried out thermal pyrolysis by simulating the temperature condition in the cigarette combustion process, and GC / MS is adopted to carry out analysis on the pyrolyzate, thus evaluating the influence of the perfume monomer on the smoke composition after the perfume monomer is added into the cigarette for combustion, and the method has simple operation and low cost. The method can comprehensively evaluate the influence of the perfume monomer on the flavor components in the smoke composition and the burst size of harmful ingredients after the perfume monomer is added into the cigarette for combustion, and has important guidance meaning for the application of the perfume monomer on the cigarette.

Owner:ZHENGZHOU TOBACCO RES INST OF CNTC

Experiment system for simulating cable burning under fire environment and method thereof

InactiveCN105489103AAvoid pollutionQualitatively accurateEducational modelsHeat flowSmoke composition

The invention discloses an experiment system for simulating cable burning under the fire environment and a method thereof. The experiment system for simulating cable burning under the fire environment comprises a weighing device which is provided with a sample frame used for fixing cable samples; a heating device which comprises a radiation heating shell and an igniter, wherein the radiation heating shell covers the weighing device, and the igniter is arranged in the cavity of the radiation heating shell and used for igniting the cable samples fixed on the sample frame; multiple thermocouples and heat flow meters; and a smoke collection device which comprises a smoke collection hood and a smoke composition analyzer, wherein the smoke collection hood is connected with the radiation heating shell of the heating device, and smoke emitted by burning of the cable samples is guided to the smoke composition analyzer through the smoke collection hood. According to the experiment system for simulating cable burning under fire environment and the method thereof, more accurate nature determination and classification of the burning characteristics of the cables are facilitated so that deeper research and analysis can be performed in the aspect of cable fire dynamics.

Owner:INST OF IND TECH GUANGZHOU & CHINESE ACADEMY OF SCI +1

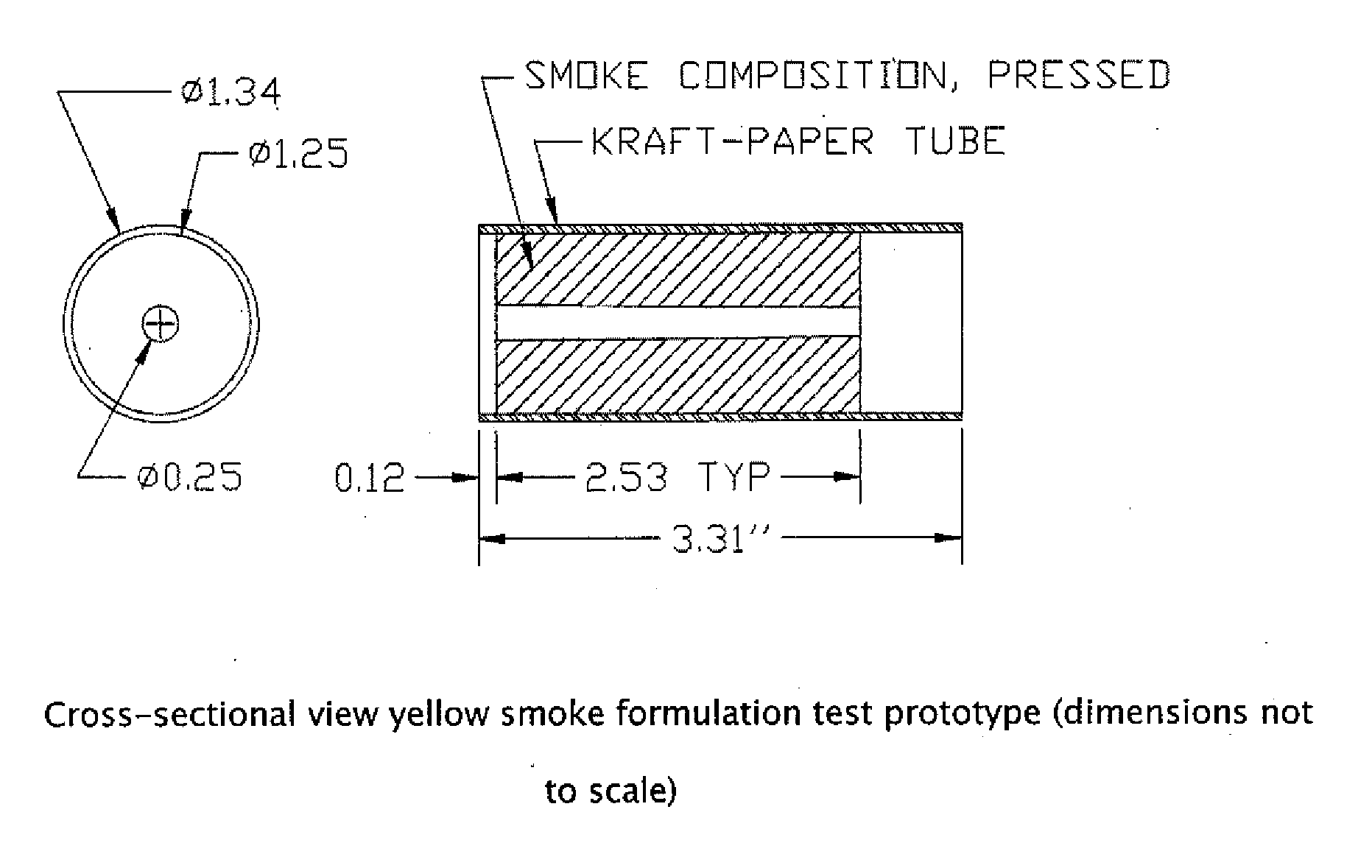

Pyrotechnic yellow smoke compositions based on solvent yellow 33

InactiveUS20160115090A1Aid flowabilityAmmunition projectilesAlkali metal salt explosive compositionsCardboardSmoke composition

A yellow smoke composition useful in hand held signals, such as the U.S. Army M194 yellow smoke parachute signal; which composition contains the nontoxic, environmentally safe, quinoline solvent yellow 33 color agent and critically exhibits the requisite dense yellow smoke for the requisite 9 to 18 second burn time upon use. Further, this inventive yellow smoke composition can be used in current metal tubes and in other media, such as biodegradable cardboard tubes.

Owner:UNITED STATES OF AMERICA THE AS REPRESENTED BY THE SEC OF THE ARMY

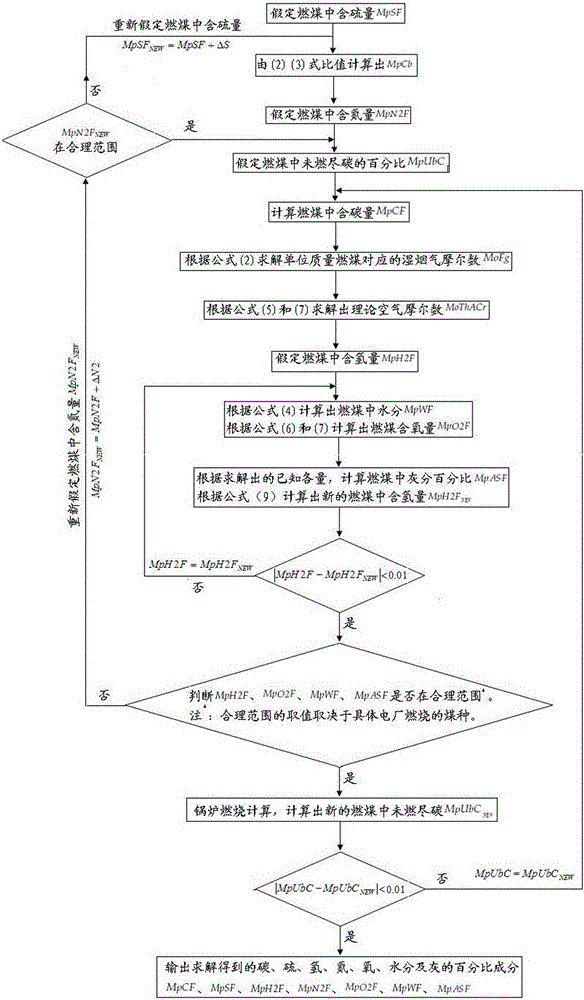

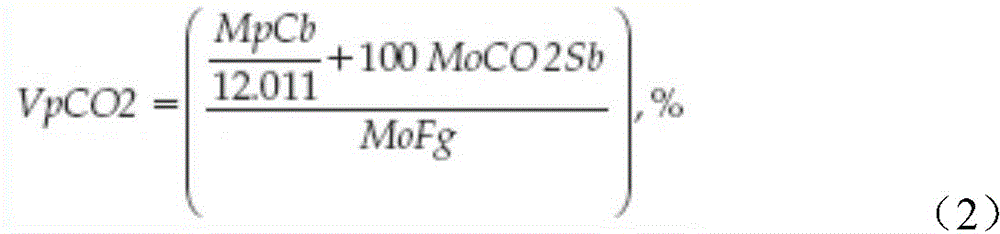

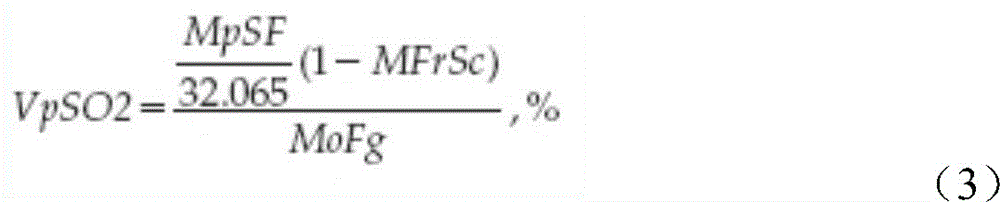

Method for analyzing the coal quality for boiler combustion based on monitoring of smoke compositions of boiler

The invention discloses a method for analyzing the coal quality for boiler combustion based on monitoring of smoke compositions of a boiler. The concentration analysis data based on the smoke compositions in the entry of an air pre-heater comprises oxygen amount, sulfur dioxide, carbon dioxide, moisture and nitrogen. Combined with the ash data of the on-site coal quality for boiler combustion, by means of a specific calculating method and steps, the composition of each element for the burning coal quality during the normal operation can be determined and the problem that how to accurately monitor the coal quality for boiler combustion during the normal operation can be solved. The monitoring method provided by the invention is simple and convenient, and provides a possible selection for monitoring the coal quality for boiler combustion accurately for a power plant.

Owner:STATE GRID CORP OF CHINA +2

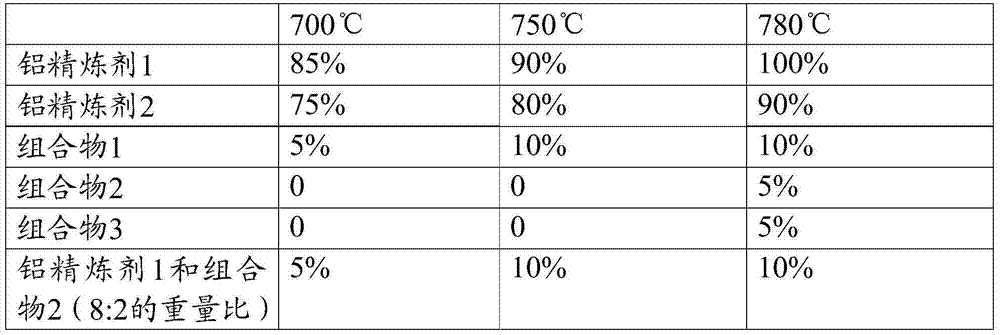

Refining composition and smelting method of aluminum or aluminum alloy

The invention discloses a refining composition for smelting aluminum or an aluminum alloy, and a method for smelting aluminum or the aluminum alloy by utilizing the refining composition. The refining composition comprises a low-smoke composition formed by KCl, MgCl2 and CaF2, wherein the weight ratio of KCl to MgCl2 is 1:1; the total weight of KCl and MgCl2 accounts for 65wt% to 50wt% of the total weight of the low-smoke composition; the weight of CaF2 accounts for 35wt% to 50wt% of the total weight of the low-smoke composition. The refining composition can be used for eliminating or obviously reducing black smoke generated during the smelting of aluminum or the aluminum alloy.

Owner:SMC CHINA +2

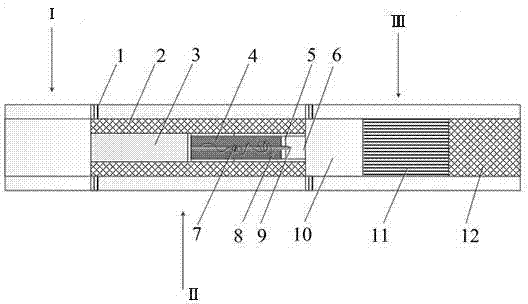

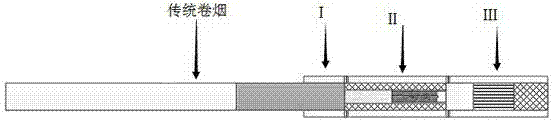

Cigarette tip filtering device with atomized smoke releasing and mixing functions

The invention relates to the technical field of cigarette smoke filtering devices, in particular to a filter tip device which is provided with an atomized smoke releasing device and can be used for mixing atomized smoke and cigarette smoke. The filter tip device is used for smoking of traditional cigarettes and comprises a cigarette tip section, an atomization device section and a smoke mixing and filtering section, wherein the cigarette tip section is connected with a filter tip of a traditional cigarette; the atomization device comprises an electronic smoke atomization device wrapped by a flue channel; the smoke mixing and filtering section comprises a smoke primary mixing cavity, a smoke secondary guiding and mixing section and a filtering section which are connected in sequence. According to the filter tip device disclosed by the invention, liquid spray smoke generated by electronic atomization and the traditional smoke are mixed, so that the smoke composition and the smoking mouthfeel can be adjusted and changed, and the smoking mouthfeel of smoke is well considered while harmful components are filtered and adsorbed more sufficiently. The filter tip device disclosed by the invention is novel and unique in development idea and has better promotion, application and protection value.

Owner:CHINA TOBACCO HENAN IND

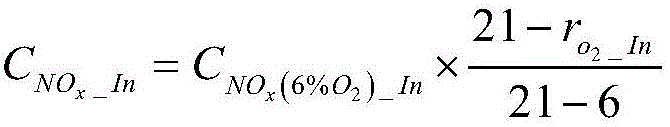

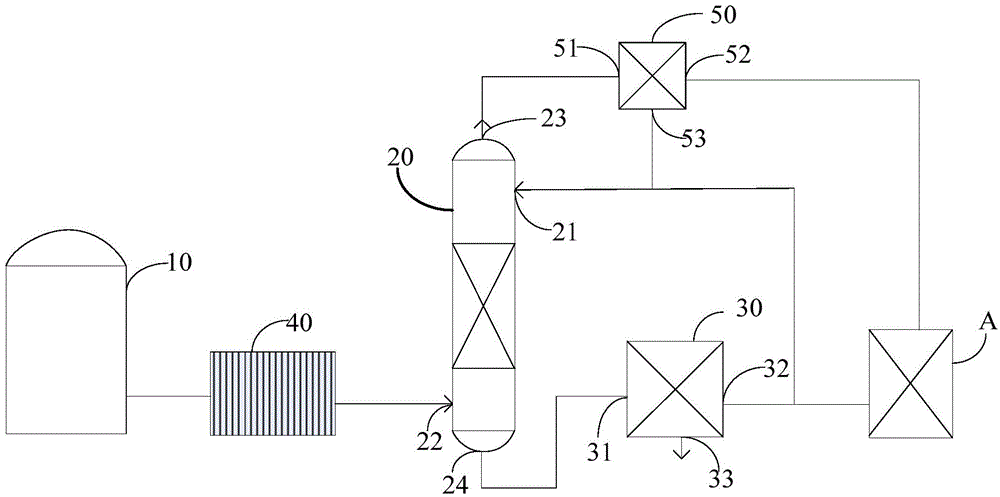

Ammonia-escaping-rate online obtaining method for desulfurization and denitrification control

InactiveCN105975789AGuaranteed real-timeImprove accuracyData processing applicationsChemical processes analysis/designEscape rateSmoke composition

The invention discloses an ammonia-escaping-rate online obtaining method for desulfurization and denitrification control. According to the technical scheme, the ammonia-escaping-rate online obtaining method includes the steps that when an SCR denitrification system of a coal firing unit is in the running state, oxygen content conversion is carried out on NOx concentration data, given by a smoke composition analyzer, of an inlet and an outlet of an SCR reactor of the denitrification system, the NO content and the NO2 content of the smoke of the inlet and the outlet of the reactor under the practical oxygen content are obtained, and then the ammonia escaping rate is calculated according to the conversion result and data of the ammonia spraying amount and the smoke flow of the inlet of the SCR reactor. According to the ammonia-escaping-rate online obtaining method, the ammonia escaping rate of the SCR denitrification system is online calculated according to the practical denitrification effect; in the flow processing process, nitric oxide is subdivided into NO and NO2 for analysis and calculation, and the accuracy of the calculation result is greatly improved; the ammonia spraying amount and the smoke flow of the inlet of the SCR reactor are collected in real time, and therefore the real-time performance of calculation of the ammonia escaping rate is guaranteed.

Owner:NORTH CHINA ELECTRIC POWER UNIV (BAODING)

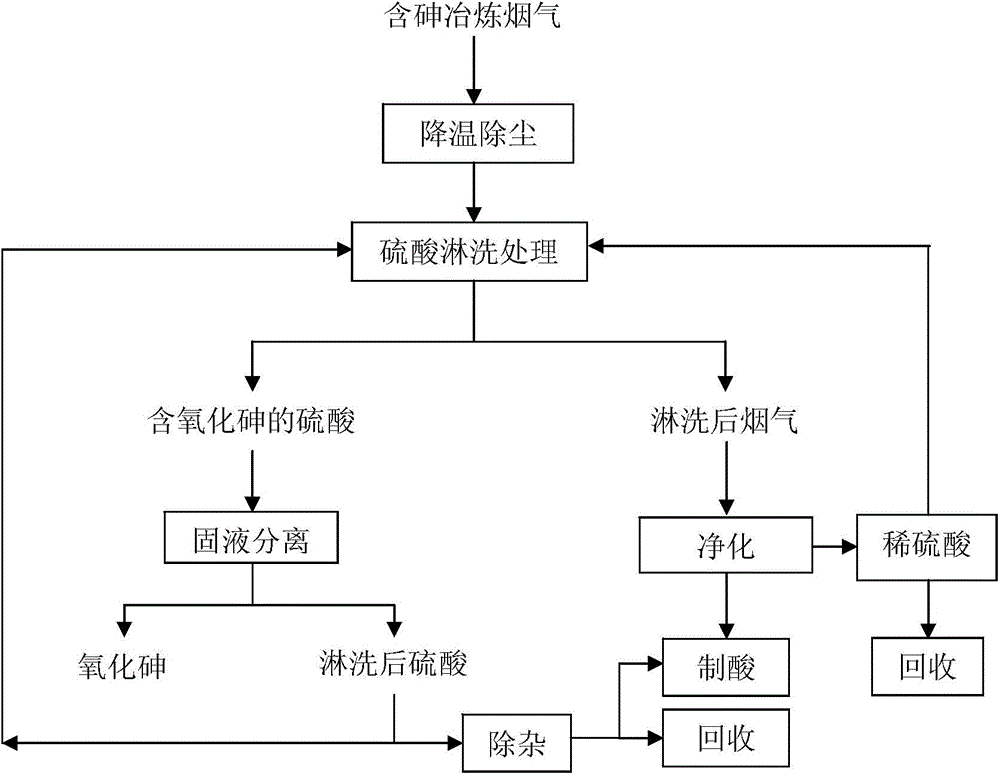

Method and system for treating arsenic-containing metallurgical off-gas

ActiveCN104548823AEfficient removalReduce processing costsUsing liquid separation agentTreatment effectArsenic oxide

The invention discloses a method and a system for treating arsenic-containing metallurgical off-gas. The method comprises the following steps: smelting arsenic-containing concentrate to obtain a smelted product and the metallurgical off-gas; adopting sulfuric acid with a mass concentration of 55-63% to elute the metallurgical off-gas, so as to absorb arsenic oxide in the metallurgical off-gas; when the arsenic oxide is supersaturated and separated out, performing solid-liquid separation to the sulfuric acid containing arsenic oxide, so as to obtain arsenic oxide and the eluted sulfuric acid. The method disclosed by the embodiment of the invention can be used for treating the arsenic-containing metallurgical off-gas with high dust concentration, high smoke composition and concentration fluctuation, high dust cementation capacity, and high sulfur content in the off-gas, so as to improve the treatment effect in the prior art.

Owner:CHINA ENFI ENGINEERING CORPORATION

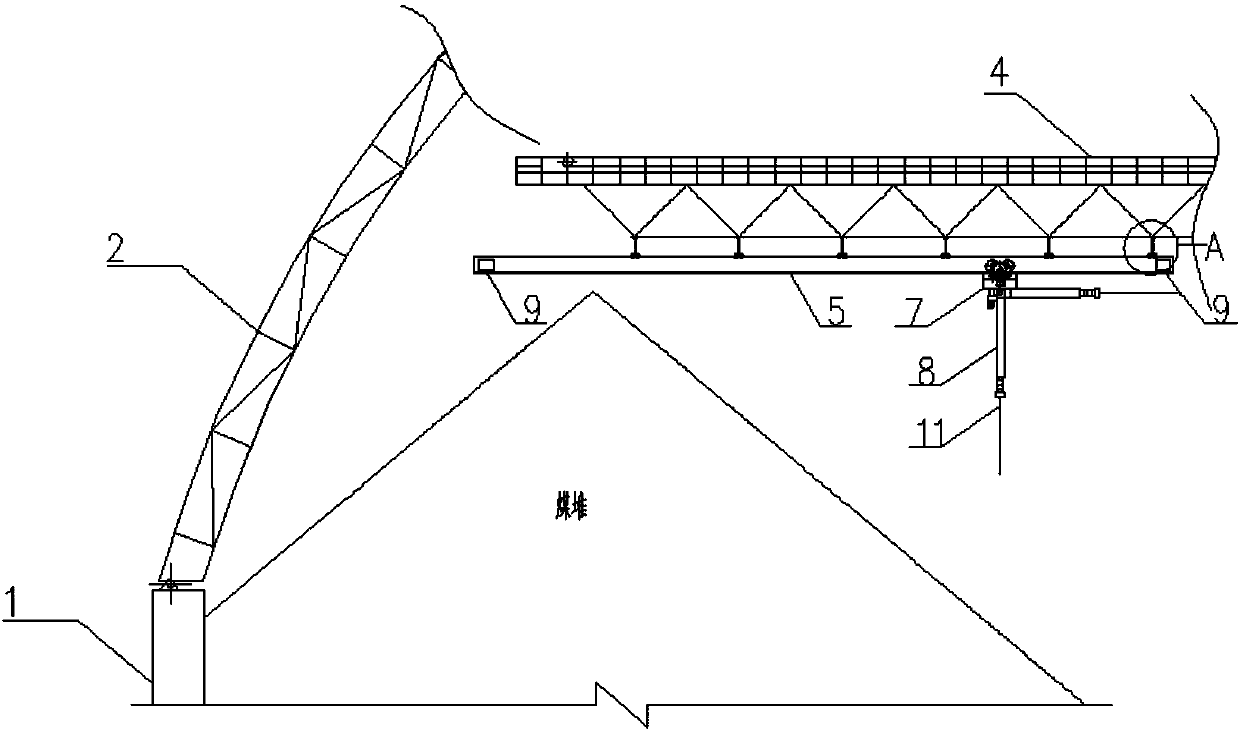

Round coal yard with coal pile spontaneous combustion preventing and controlling function

PendingCN107870613APrevention of spontaneous combustionEasy to detectMeasurement devicesTotal factory controlSpontaneous combustionSmoke composition

The invention relates to a round coal yard with a coal pile spontaneous combustion preventing and controlling function and solves the problem of difficulty in preventing spontaneous combustion of a coal pile in the prior art. The round coal yard further comprises an inversely-hung guide rail, a plurality of connecting members are mounted at the bottom of a cantilever, the top of the inversely-hungguide rail is mounted at the bottoms of the connecting members, a stopper is fixedly mounted on each of two sides of the inversely-hung guide rail, rollers of an electric-control walking vehicle arehung on the inversely-hung guide rail, an electric extensible rod is mounted below the electric-control walking vehicle, and a spontaneous combustion preventive detection device is mounted on the electric extensible rod. The electric-control walking vehicle can reach space above a coal pile at any area of the round coal yard, and temperature (smoke composition) of the surface of the coal pile at any point can be conveniently and accurately detected to accurately judge whether spontaneous combustion of the coal pile at the point occurs or not, so that spontaneous combustion of the coal pile isprevented.

Owner:ANHUI ELECTRIC POWER DESIGN INST CEEC

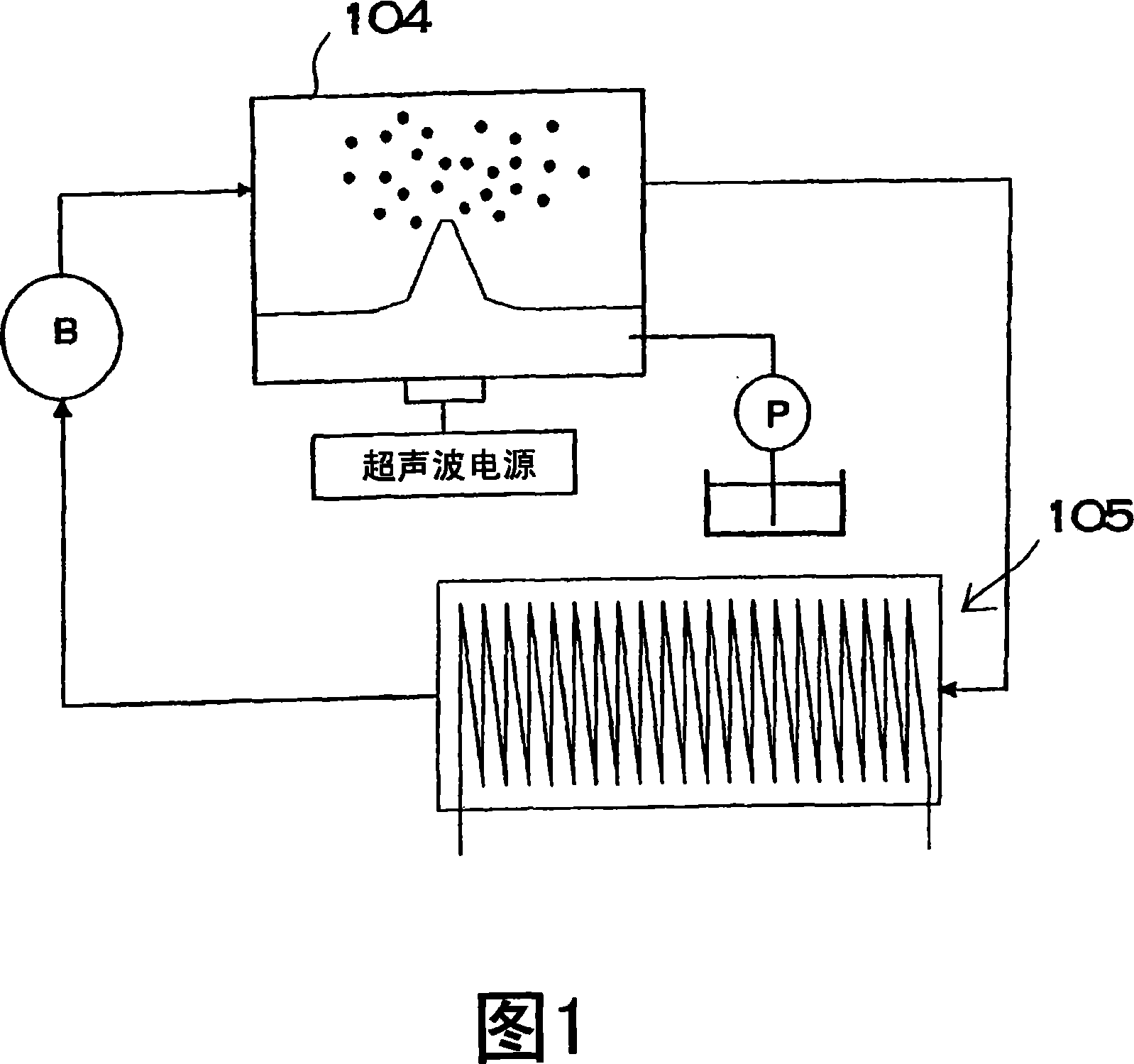

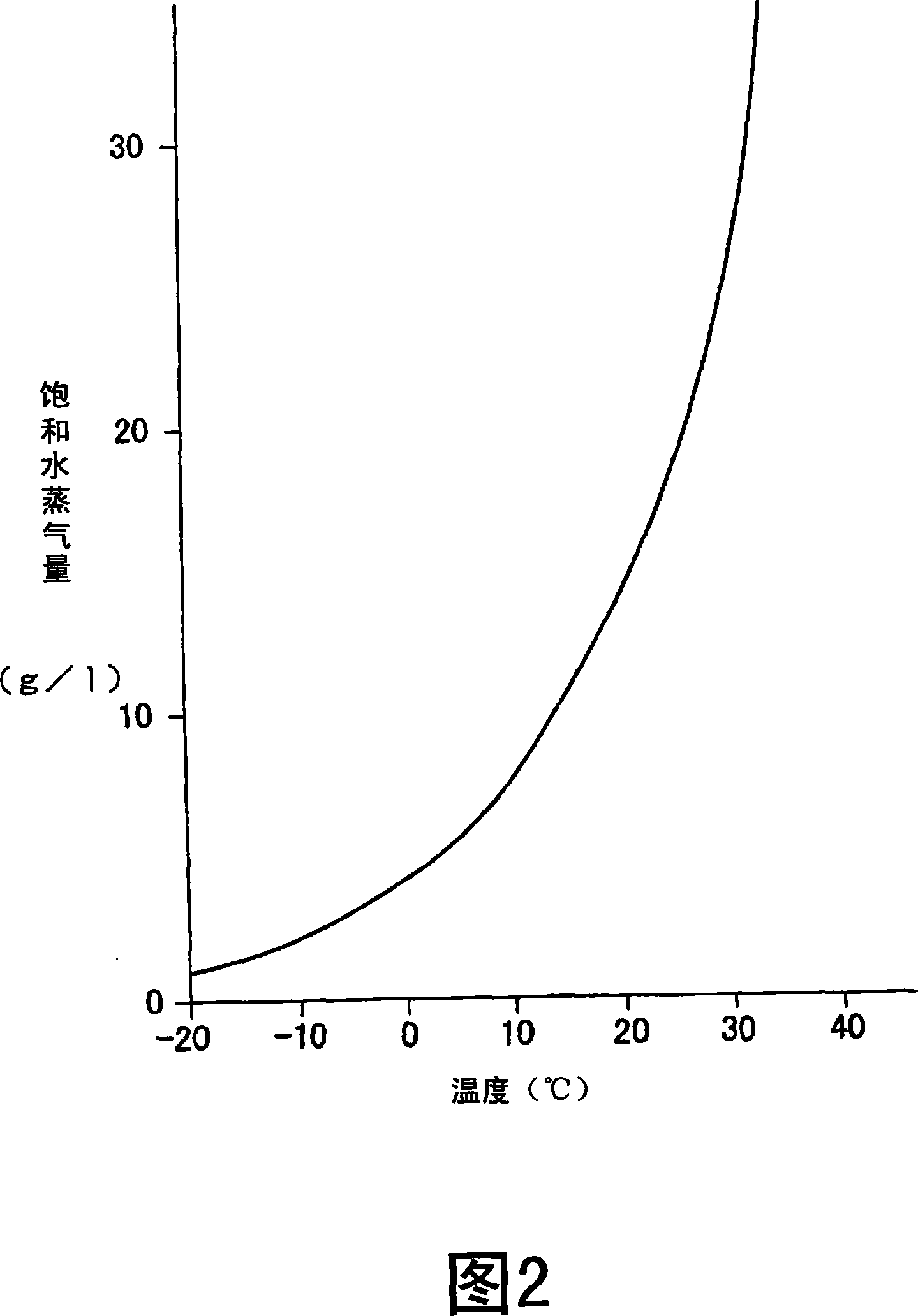

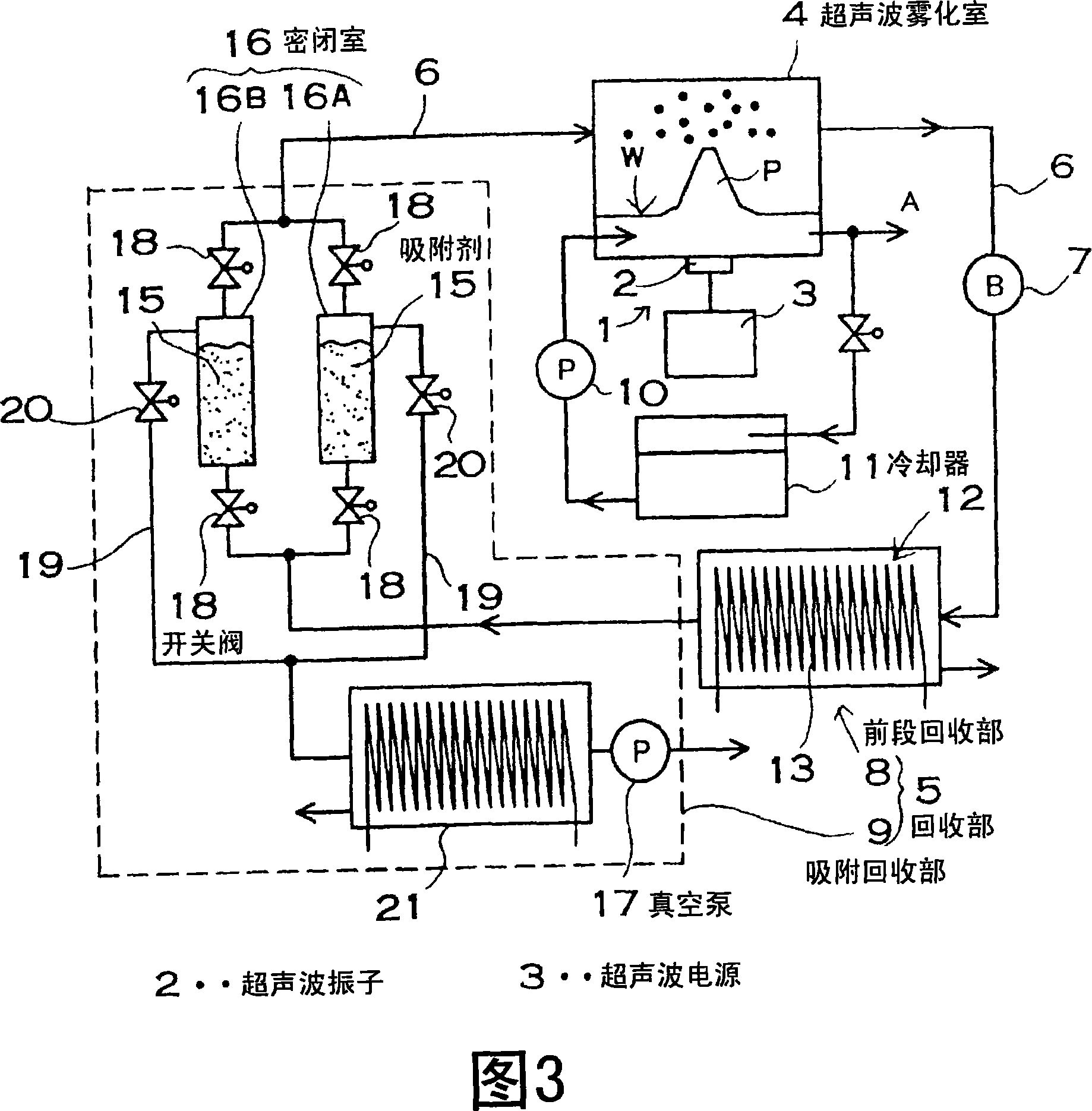

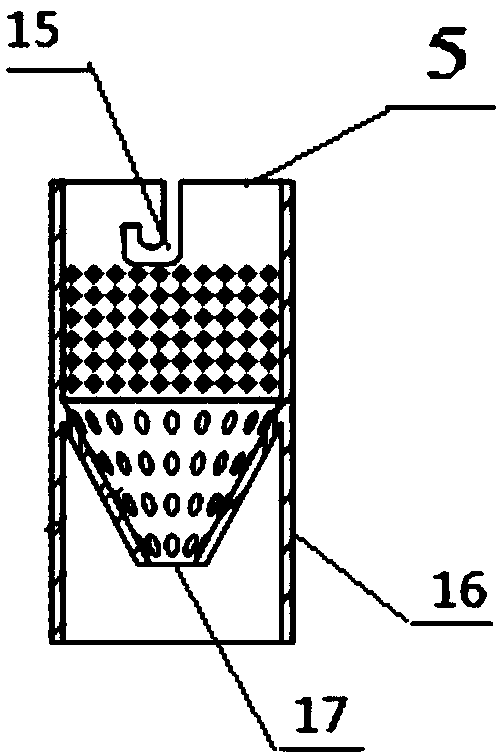

Ultrasonic solution separating method and ultrasonic separating apparatus used in this method

InactiveCN101094711AEfficient recyclingLarge adsorption capacityFermented solutions distillation/rectificationDistillation by vibrationSorbentSmoke composition

A method for the ultrasonic separation of a solution, wherein the solution is subjected to the ultrasonic vibration in an ultrasonic atomization chamber (4) and atomized into a mist in a conveying gas, the conveying gas containing the atomized mist is transported to a recovering section (5), and a mist component having been atomized to a mist is separated from the conveying gas and recovered in the recovering section (5), which comprises, in the recovering section (5), an adsorption step of contacting the conveying gas containing the mist component with an adsorbing agent (15) to allow the adsorbing agent (15) to adsorb the mist component and a separation step of separating the mist component having been adsorbed on the adsorbing agent (15) in the adsorption step from the adsorbing agent (15) and then recovering it, and separates the mist component from the conveying gas by the absorbing and separation steps and by setting the pressure in the separation step at a value lower than that in the adsorbing step.

Owner:ULTRASOUND BREWERY

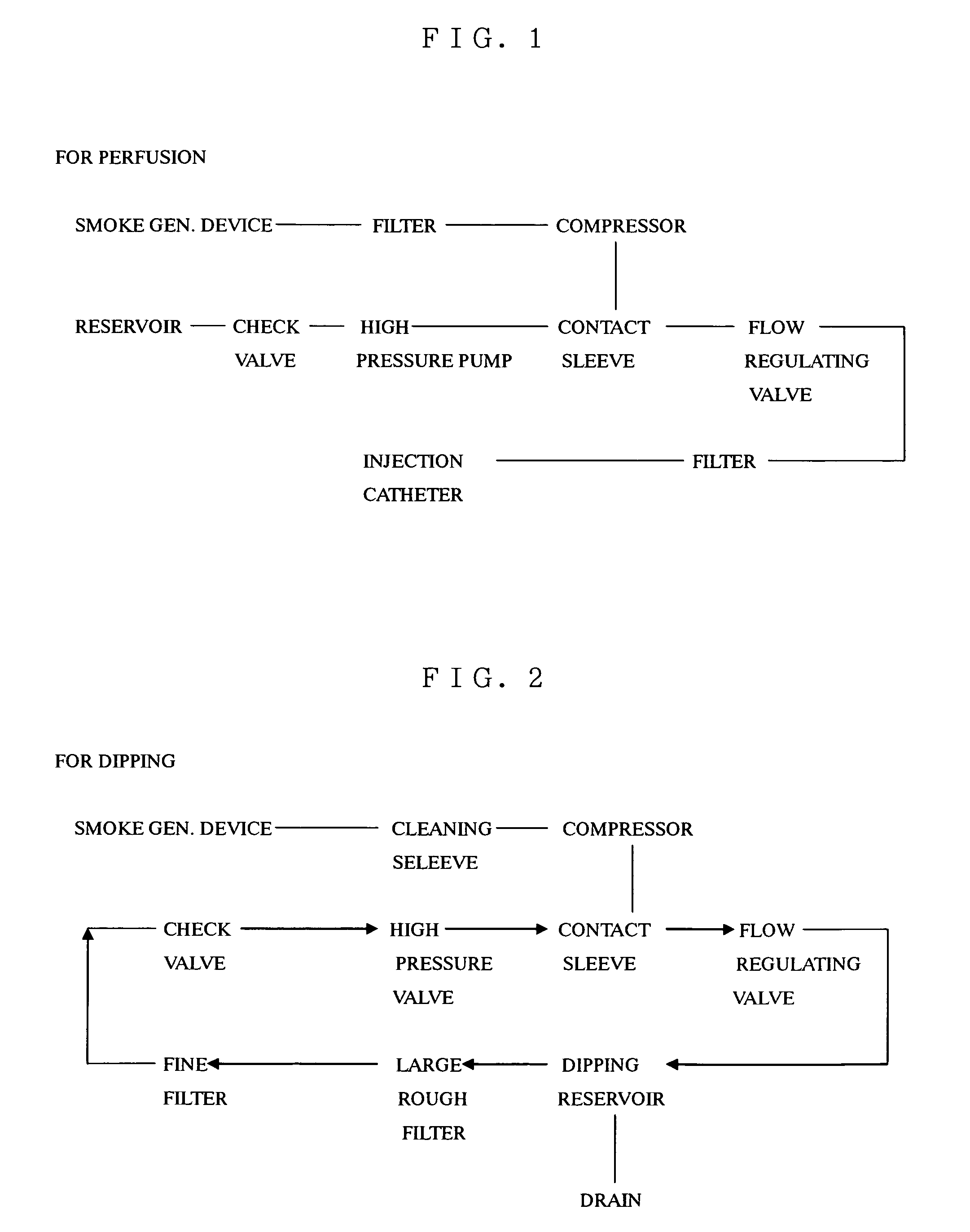

Fish processing method using smoking liquid into which smoke-dry components are dissolved

ActiveUS7595071B2Easy to handleEasy to mass produceMilk preparationFood preparationFlavorAntioxidant

A fish processing method using a smoking liquid into which a smoke component is dissolved in which a so-called smoke-dry (smoke dry component) is liquefied and the smoking liquid is applied to the fish meat so that the product that is similar to that produced through a smoke dry process is produced with this liquid (smoking liquid), and it is possible to produce the product that is similar to that produced through the smoke dry process without performing the smoke-dry process in which the product should be brought into contact with gas. In addition, since not only the step for applying the flavor but also the smoke-dry components of the liquid and gas is contained in this smoking liquid, the same effect as that of the smoke dry process such as preservation is exhibited, with the smoking liquid which is easy to handle and superior in mass production, it is possible and easy to handle the smoke dried product which has been conventionally difficult to handle and has a disadvantage in mass production. A fish processing method using a smoking liquid into which a smoke dry component is dissolved is disclosed in which a smoking material from which at least one unnecessary substance such as soot and tar is removed is brought into contact with at least one of a water, a solution and a solution into which at least one necessary additive such as an antioxidant, a pH adjuster and a condiment so that the smoking liquid into which a smoking component is dissolved is applied to fish to produce a smoke dried product.

Owner:ONSUI

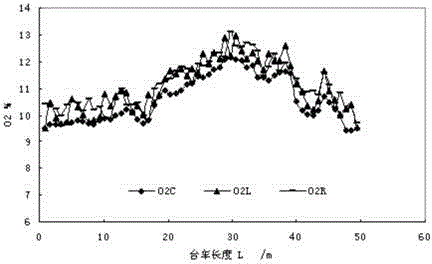

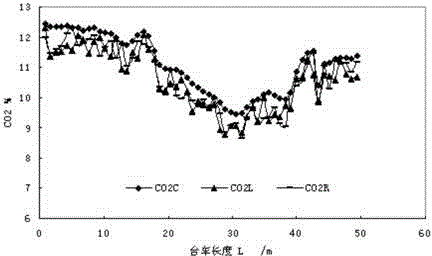

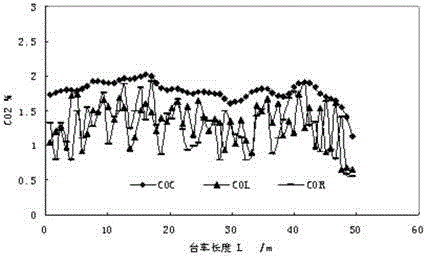

Device and method for detecting sintering homogeneity

InactiveCN105628866AAccurately judge the horizontalAccurately judge the longitudinal homogeneityFurnace typesMaterial analysisCombustionGas composition

The invention relates to a device and a method for detecting sintering homogeneity. The device comprises sampling guns, a hose, a vacuum pump and a gas analyzer, wherein the suction end of the vacuum pump is connected to joints of the sampling guns through the hose, and the other end of the vacuum pump is connected with the gas analyzer. The method comprises the following steps: the three sampling guns with different lengths are placed at positions of grate bars at the bottom part of a sintering trolley respectively, and travel with the sintering trolley; when the sintering trolley runs to an initial ignition section, the hose connected with the vacuum pump is connected to the three sampling guns, combustion exhaust gas is pumped into the gas analyzer for detection of the volume concentrations of CO, CO2 and O2, the symmetry and the continuity of the combustion exhaust gas are analyzed, and the transverse homogeneity and the longitudinal homogeneity of sintering of the trolley are judged. By online detection of sintering smoke composition, the device and the method have the advantages that the magnitude of the transverse homogeneity and the magnitude of the longitudinal homogeneity of the sintering trolley can be accurately judged, and non-dead-angle gas composition analysis of the whole trolley is achieved; besides, the sintering operation process and the ore blending scheme can be improved and optimized in real time based on detection and judgment results, therefore, the quality of sintered ore is improved.

Owner:ANGANG STEEL CO LTD

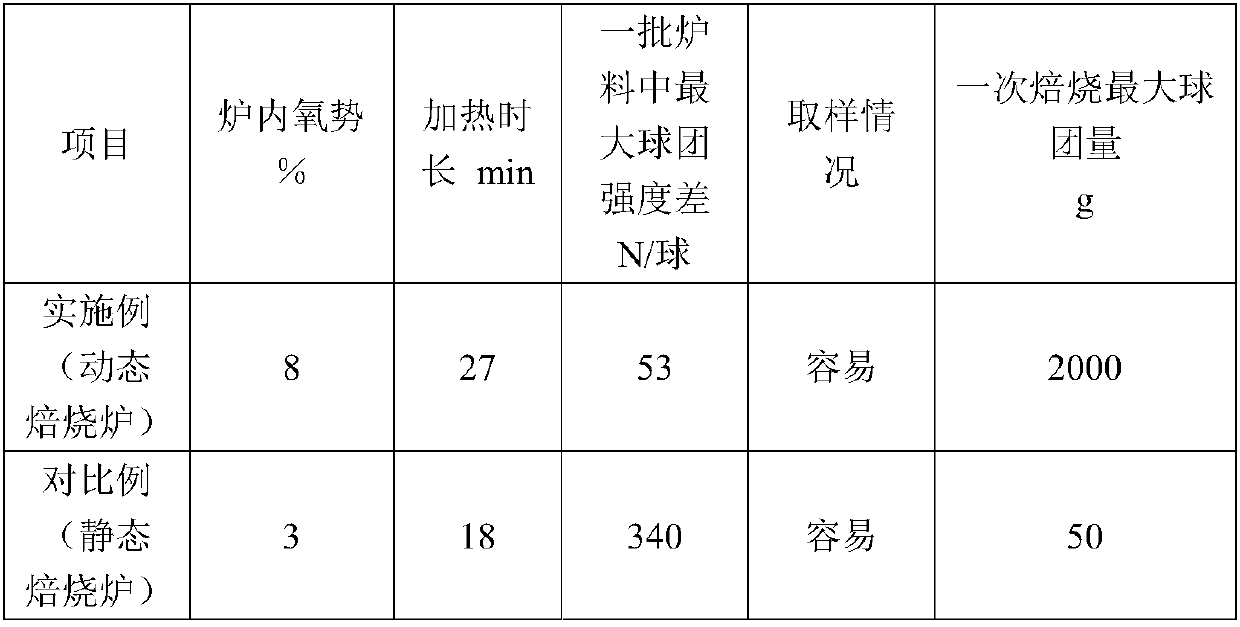

Dynamic pellet roaster and using method thereof

InactiveCN107557566ASolve the problem of oxidation roastingSolve the difficulty of retrieving materialsCold airBrick

The invention discloses a dynamic pellet roaster which comprises a roaster body, an air feeding air pump, a transmission lead screw, a computer real-time monitoring and controlling system and a material cage. The transmission lead screw driven by a motor is connected with the material cage filled with pellets through an upper support and a supporting rod, and the transmission lead screw can move up and down and enter a hearth in the roaster body. Heating elements are located on the lower portion of the roaster body, located on the periphery of the hearth and evenly distributed, and the heightof the heating elements is not larger than 2 / 3 of the dimension of the whole hearth. Porous heat storage bricks or high-aluminum balls with the diameter being 4-20 mm are arranged at the bottom insidethe hearth, and the upper edges of the porous heat storage bricks or the high-aluminum balls are not higher than the 1 / 2 positions of the heating elements. The material cage is in a downward conicalshape, a hole with the diameter being 10-12 mm is formed in the middle of the bottom of the material cage, and small holes with the diameter being smaller than 10 mm are evenly distributed in the sidewall of the material cage. Cold air blown from the air feeding air pump passes through a flowmeter and then enters the hearth from the bottom, the upper edge of the interior of the material cage andthe upper edge of the hearth are provided with a thermocouple and a smoke composition collecting system correspondingly, a collected temperature signal and a collected smoke composition signal are transmitted to the computer real-time monitoring and controlling system, and meanwhile, the computer real-time monitoring and controlling system can control the motor and the flowmeter according to the signals.

Owner:ANGANG STEEL CO LTD

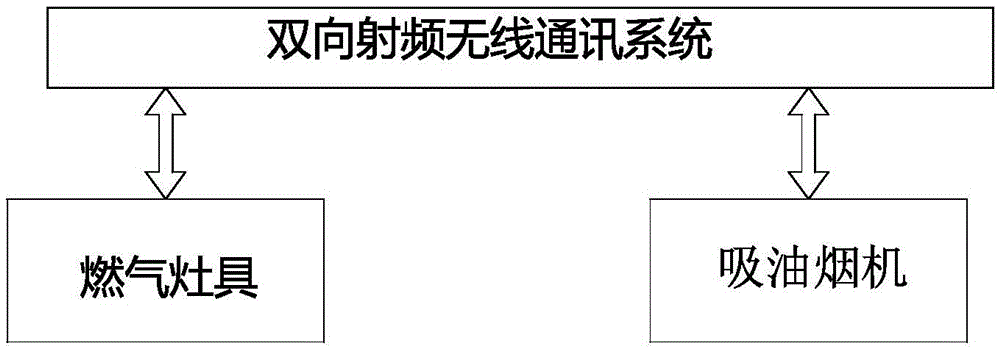

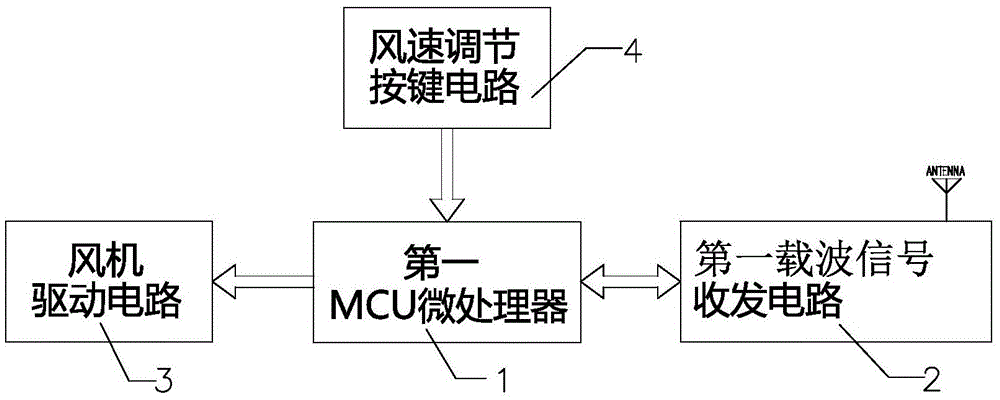

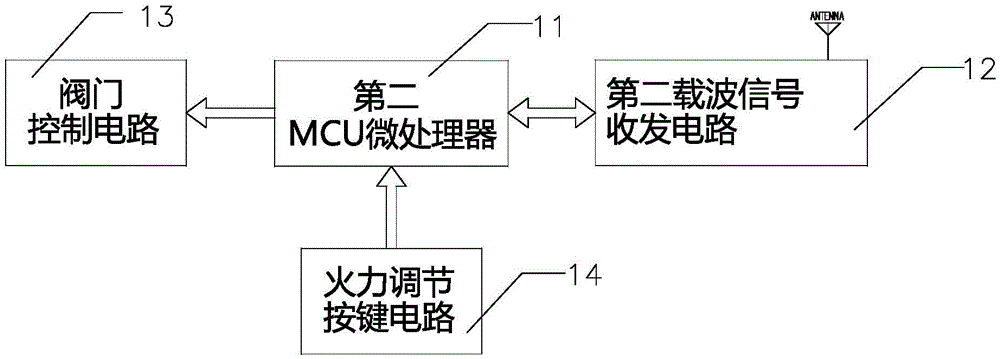

A smoke stove combination with a two-way radio frequency wireless communication system

ActiveCN104296185BIntelligentEnable two-way communicationDomestic stoves or rangesLighting and heating apparatusSmoke compositionRadio frequency

The invention relates to the field of intelligent cooking utensils and particularly relates to a smoke stove combination with a two-way radio frequency wireless communication system. The smoke stove combination comprises a gas stove, a range hood and the two-way radio frequency wireless communication system for two-way communication between the gas stove and the range hood, wherein the two-way radio frequency wireless communication system comprises a gas stove RF signal transceiving control unit arranged in the gas stove and a range hood RF signal transceiving control unit arranged in the range hood; the range hood responds to corresponding wind force aiming at different firepower of the gas stove and similarly responds to the corresponding firepower according to the different wind force of the range hood; and on the basis of realizing intelligentization of equipment in a kitchen, the smoke stove combination also saves energy and is safe and convenient.

Owner:ZHEJIANG SHUAIKANG ELECTRIC

Chimney purification system

The invention discloses a chimney purification system comprising a chimney, a smoke barrel, a horizontal mounting frame, a vertical mounting frame and a smoke filter chamber. The horizontal mounting frame and the vertical mounting frame are each formed by fixedly assembling four long guiding rods and a plurality of evenly-distributed short guiding rods through screws, and are each internally provided with a mounting trough with one side open. One end of the horizontal mounting frame is fixedly connected with the upper end of the chimney, the other end of the horizontal mounting frame is fixedly connected with the upper end of the vertical mounting frame, and the bottom of the vertical mounting frame is fixedly connected with the ground. A smoke outlet of the top of the chimney is connected with one end of the smoke barrel, the smoke barrel is laid in the mounting troughs of the horizontal mounting frame and the vertical mounting frame, and the other end of the smoke barrel is connected with the smoke filter chamber. According to the chimney purification system, a smoke outlet of the chimney is connected with the smoke filter chamber positioned on the ground through the smoke barrel, filters, such as an acid-alkaline spraying tower and a heavy metal purifier, corresponding to smoke compositions can be conveniently installed in the smoke filter chamber, and smoke can be efficiently filtered and then discharged.

Owner:厦门辉煌赵工环保科技有限公司

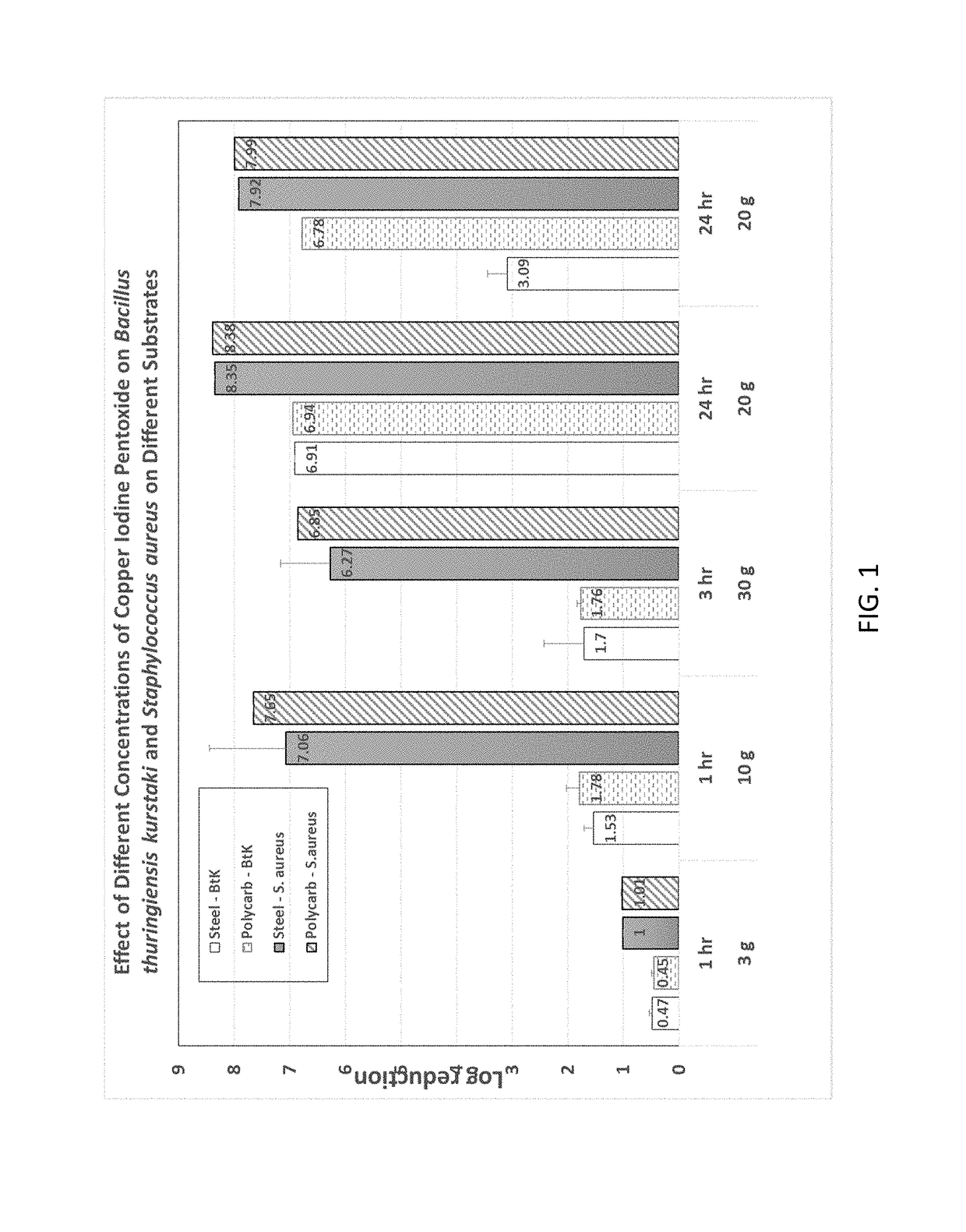

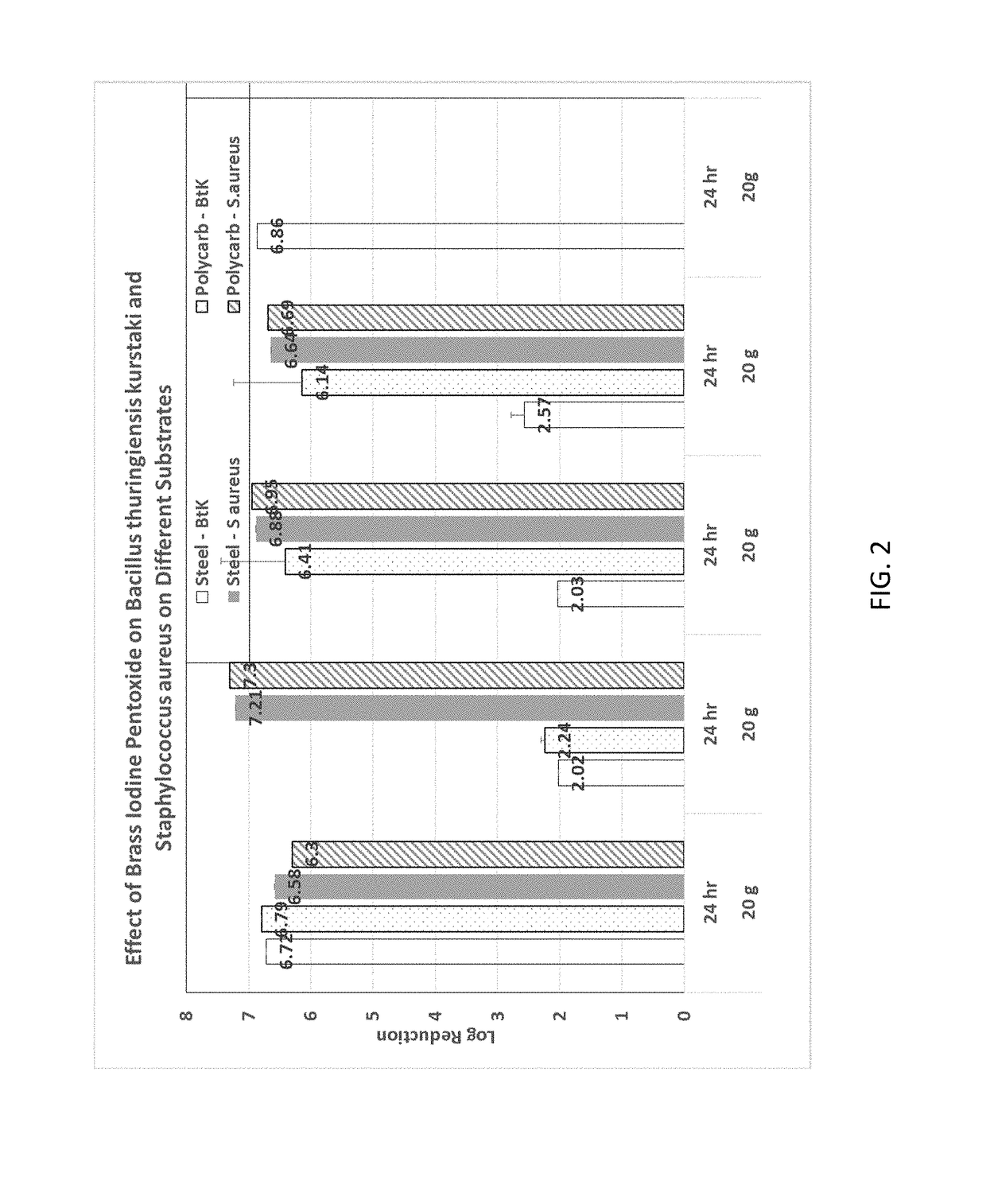

Pyrotechnic iodine smoke generation for counter biological application

A biocidal and sporicidal smoke composition(s) using iodine oxide and metal powder is provided. This composition generates iodine gas or smoke as the primary biocidal agent, as well as metal oxides that provide additional biocidal properties. The smoke producing composition is suitable for pressing into canisters of compacted powder at a load pressure range of 1500 to 7500 psi and can be used for decontamination of spaces believed to be contaminated with biological agents. The composition is also suitable for use in hand grenades, smoke pots, rifle grenades, mortars, multiple launch grenades, shoulder fired missiles, and artillery rounds, as well as first responder and commercial biological decontamination applications.

Owner:UNITED STATES OF AMERICA

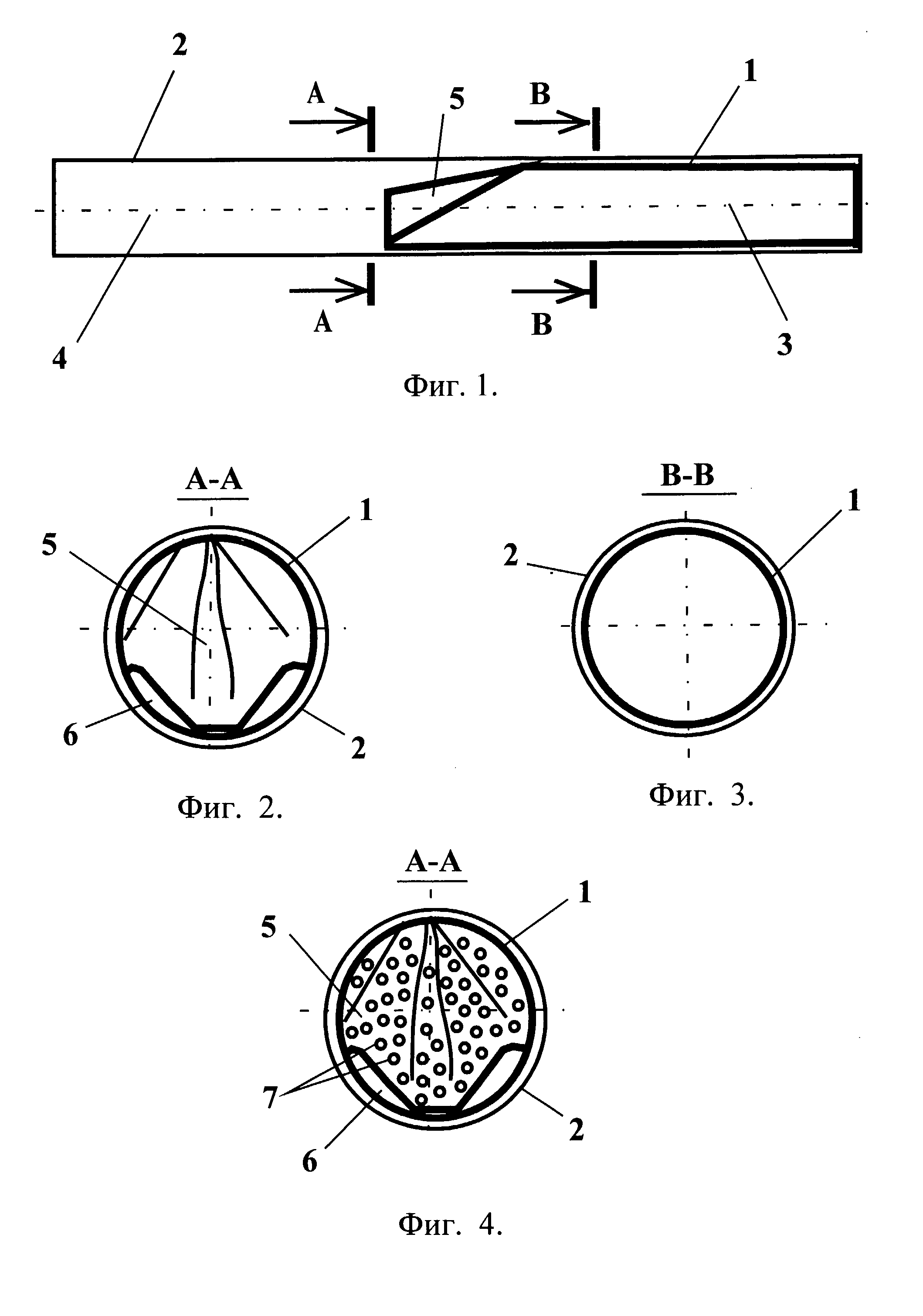

Sleeve for a russian cigarette

InactiveUS20070119466A1High propertyImprove adsorption capacityTobacco preparationCigarette manufactureSmoke compositionStructural engineering

The invention is a cigarette casing, which is intended for independent making of a <<Russian>> cigarette (papirosy) by a smoker or for bulk production. The casing of the <<Russian>> cigarette has an empty mouthpiece (1) and a connected empty envelope (2) at least a part of the cavity (4) of which is intended for the allocation of the smoking material. It contains a separating partition being selectively penetrable for the smoke, installed so that at least a part of the cavity (3) of the mouthpiece (1) could be detached from at least a part of the cavity (4) of the envelope (2) and so that it is possible to overlap at least a part of the cross section of the cavity (3) of the mouthpiece (1). Its design impedes, making minor changes in the composition of the smoke, the penetration of the particles of the smoking material located in the cavity (4) of the envelope (2) into the cavity (3) of the mouthpiece (1) while filling the casing with this smoking material and into the mouth of the smoker during smoking. The casing of the <<Russian>> cigarette has an empty mouthpiece (1) and a connected empty envelope (2), the length of the mouthpiece (1) not less than the length of the envelope (2), the envelope (2) overlaps the mouthpiece (1) with all its length, the mouthpiece (1) and the envelope (2) are installed so that it is possible to move them relative to each other along the common longitudinal axis. The mouthpiece (1) impedes the deformation of the part of the cavity (4) of the envelope (2) intended for the allocation of the smoking material before the placing of this smoking material.

Owner:BILIVITIN YURIY SERGEYEVICH +1

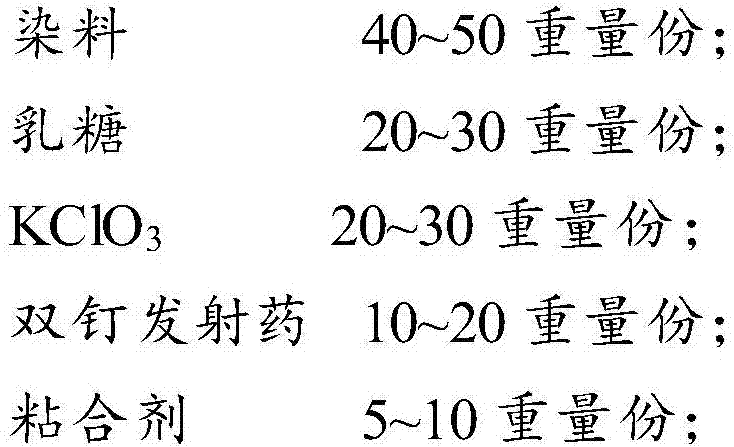

Smoke composition, preparation method thereof and smoke cartridge

InactiveCN107501022ARapid smoking processRaw materials are easy to getAmmunition projectilesSmoke/mist generationThermal energyNitroguanidine

The invention provides a smoke composition. The smoke composition is prepared from the following components in parts by weight: 40-50 of dye, 20-30 of lactose, 20-30 of KClO3, 10-20 of double-nail propellant powder, and 5-10 of adhesive, wherein the double-nail propellant powder comprises collodion and nitroguanidine. The double-nail propellant powder serves as the main energy source of the smoke composition, the lactose serves as a combustible agent, and the dye serves as a coloring agent. Due to external stimulation, the double-nail propellant powder burns furiously, generating sound and releasing a large quantity of heat so as to enable KClO3 and lactose to react to produce a lot of gas and energy, the heat sublimates the dye quickly, gas fuel scatters in air along with CO1, CO2, vapor and other gases produced by the reaction between KClO3 and lactose and condenses into solid dye particles when being cooled in air, and the solid dye particles are reflected by sunshine so as to form visible smoke. The smoke composition provided in the invention is non-toxic and harmless and produces smoke rapidly, the raw materials are easy to get, and the preparation method is simple.

Owner:重庆长江电工工业集团有限公司

A heating furnace emergency interlock control method, device and system

Owner:大庆华展石油科技有限公司

Cigarette tip filter device with atomized smoke release and mixing functions

The invention relates to the technical field of cigarette smoke filtering devices, in particular to a filter tip device which is provided with an atomized smoke releasing device and can be used for mixing atomized smoke and cigarette smoke. The filter tip device is used for smoking of traditional cigarettes and comprises a cigarette tip section, an atomization device section and a smoke mixing and filtering section, wherein the cigarette tip section is connected with a filter tip of a traditional cigarette; the atomization device comprises an electronic smoke atomization device wrapped by a flue channel; the smoke mixing and filtering section comprises a smoke primary mixing cavity, a smoke secondary guiding and mixing section and a filtering section which are connected in sequence. According to the filter tip device disclosed by the invention, liquid spray smoke generated by electronic atomization and the traditional smoke are mixed, so that the smoke composition and the smoking mouthfeel can be adjusted and changed, and the smoking mouthfeel of smoke is well considered while harmful components are filtered and adsorbed more sufficiently. The filter tip device disclosed by the invention is novel and unique in development idea and has better promotion, application and protection value.

Owner:CHINA TOBACCO HENAN IND

Method for assessing function of spices monomer to cigarette by pyrolysis experiment

The invention discloses a method for evaluating the influence of the perfume monomer on cigarettes by adopting the thermal pyrolysis experiments, which is characterized by comprising the following steps: perfume monomer samples of a certain amount are sampled, dissolved by solvent and volume-limited, the sample solution is injected in the glass fiber of a quartz glass tube by a sampling needle, then pyrolysis is carried out in a pyrolysis apparatus, the generated pyrolyzate is carried out GC / MS analysis, and the influence of the perfume monomer on the cigarette smoke after the perfume monomeris added into the cigarette is evaluated according to the analytic determination result of the pyrolyzate. The invention has the advantages that: the perfume monomer is carried out thermal pyrolysis by simulating the temperature condition in the cigarette combustion process, and GC / MS is adopted to carry out analysis on the pyrolyzate, thus evaluating the influence of the perfume monomer on the smoke composition after the perfume monomer is added into the cigarette for combustion, and the method has simple operation and low cost. The method can comprehensively evaluate the influence of the perfume monomer on the flavor components in the smoke composition and the burst size of harmful ingredients after the perfume monomer is added into the cigarette for combustion, and has important guidance meaning for the application of the perfume monomer on the cigarette.

Owner:ZHENGZHOU TOBACCO RES INST OF CNTC

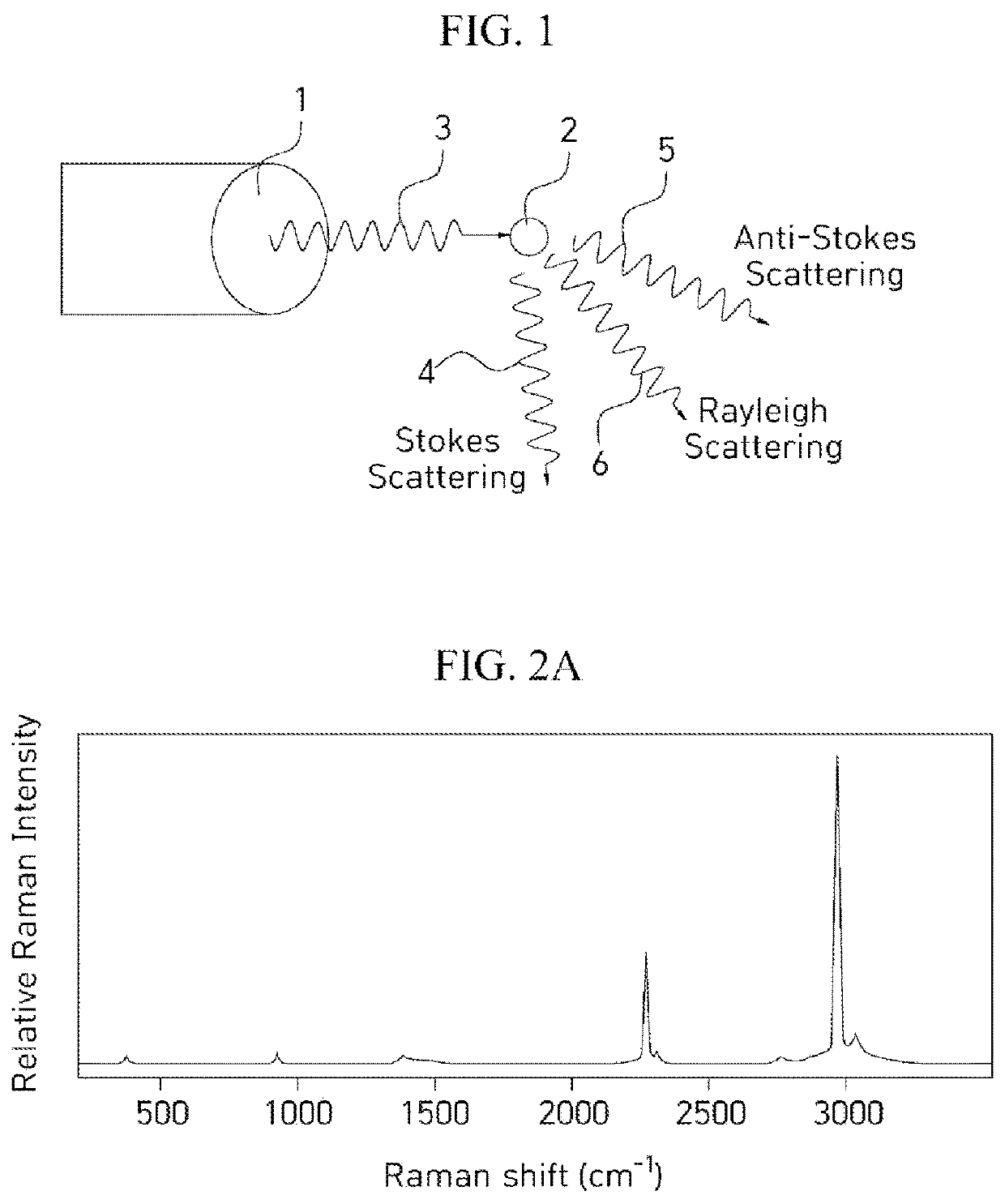

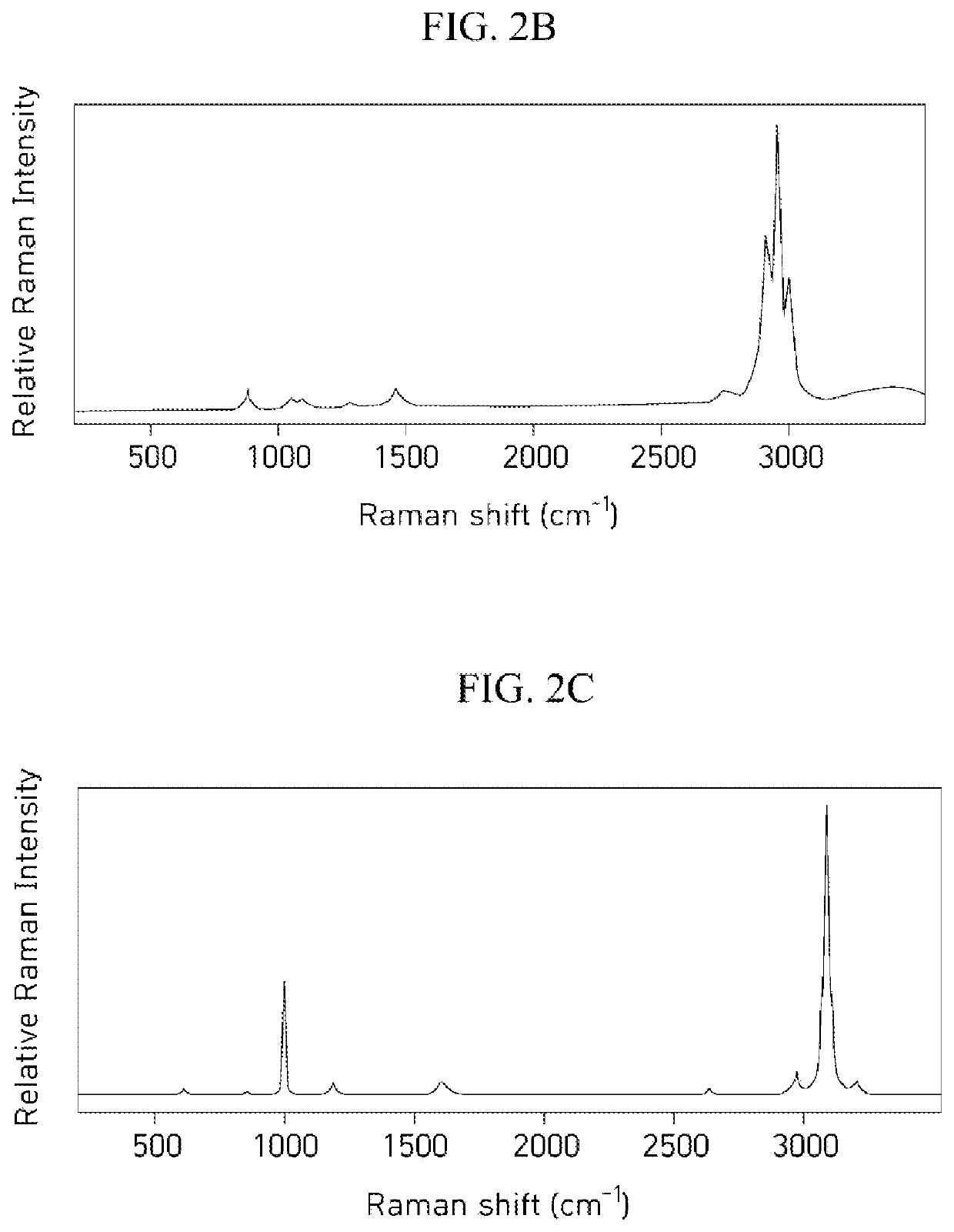

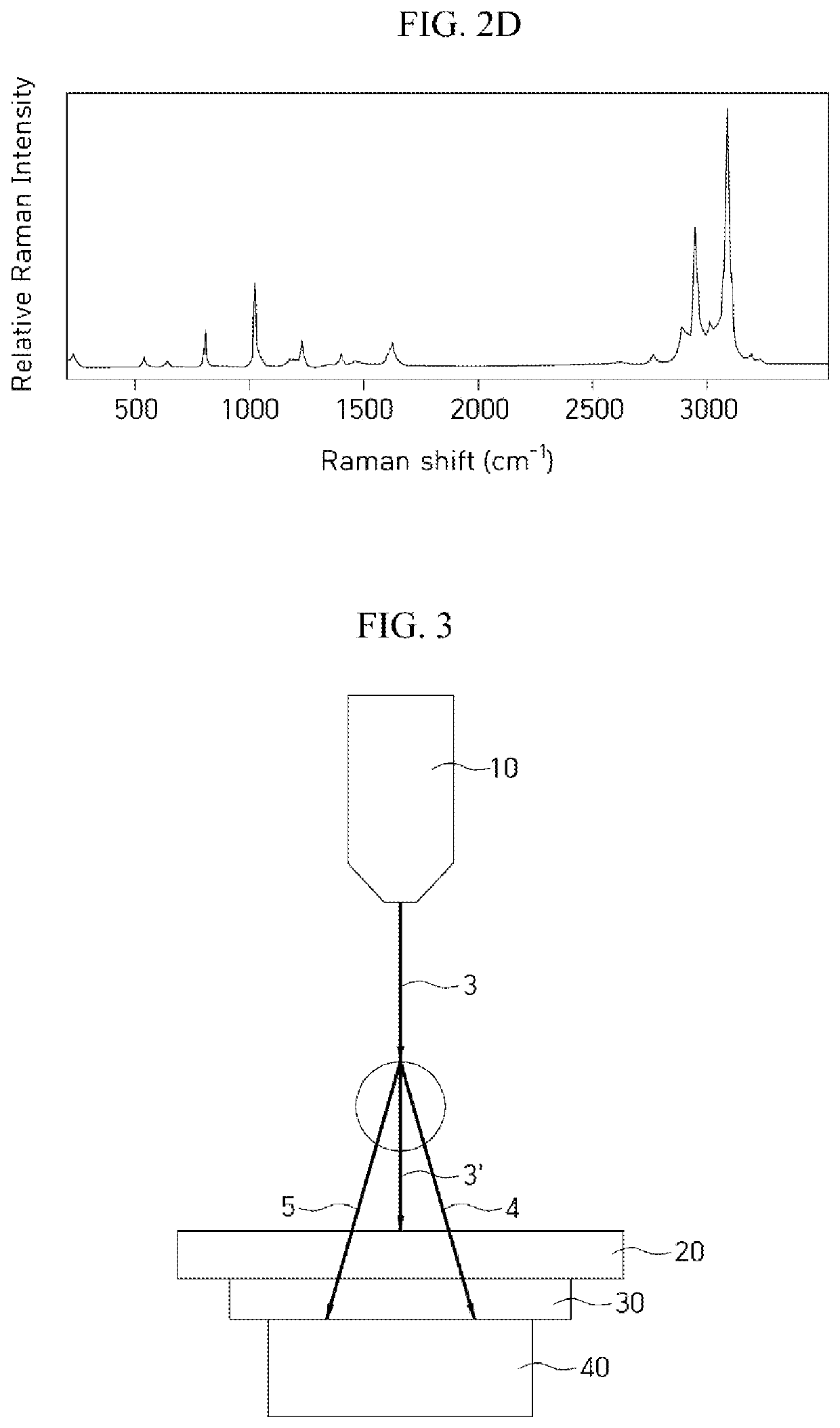

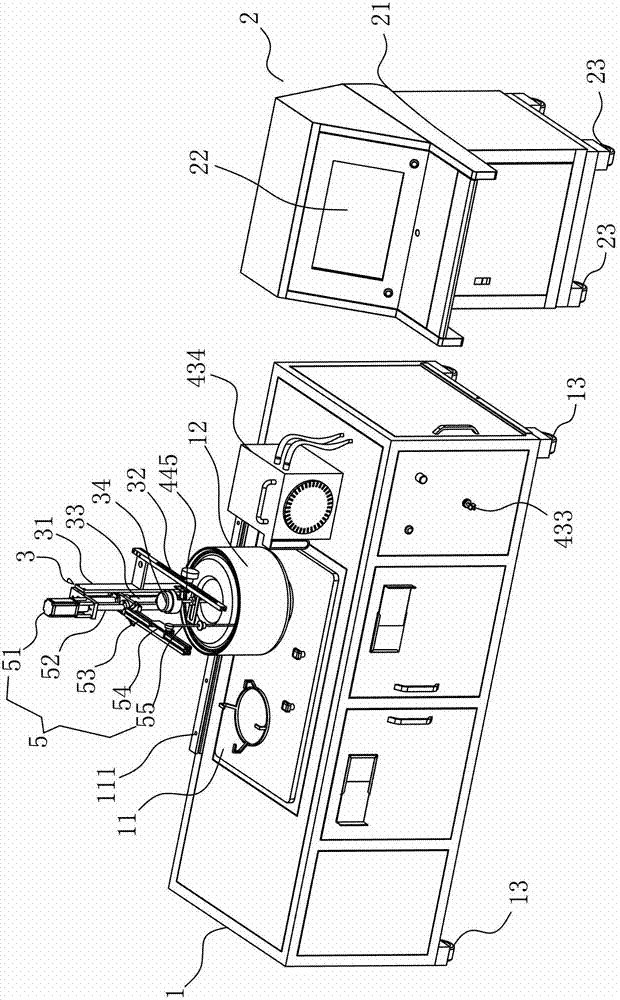

Apparatus for measuring raman scattering, and apparatus and method for determining true fire using the apparatus

PendingUS20220099579A1Reduce the number of timesScattering properties measurementsRaman scatteringPhotodetectorSmoke composition

Provided is a Raman scattering measurement apparatus including a light source which emits light to smoke particles, a filter configured to block light which is incident to the smoke particles and passes through the particle and to allow Raman scattered light to pass therethrough, and a photodetector which detects the Raman scattered light passing through the filter in order to distinguish fire smoke generated due to a true fire from non-fire smoke generated due to daily life or industrial activity. The present invention also provides a fire determination apparatus including a unit which reads a Raman shift from Raman scattered light detected by the photodetector of the Raman scattering measurement apparatus, estimates a smoke component from the read Raman shift, and determines fire / non-fire from the estimated smoke component and a method thereof.

Owner:ELECTRONICS & TELECOMM RES INST

Automatic control test device of gas cooker

InactiveCN102706636BSimple and fast operationThe test effect is goodStructural/machines measurementAutomatic controlSmoke composition

The invention discloses an automatic control test device of a gas cooker. A working circuit of the device comprises a main control unit, and a display unit, a control unit, a temperature collection unit, an analog input unit and an analysis processing unit, which are respectively and electrically connected with the main control unit, wherein the control unit comprises a program logic controller (PLC), a gas flow meter which is electrically connected with the PLC, a gas pressure regulating valve, a stirrer and a gas on-off valve; the temperature collection unit comprises a gas temperature collection unit, an ambient temperature collection unit, a smoke temperature collection unit and a hot water temperature collection unit; the analog input unit comprises a gas pressure input unit and an atmosphere pressure input unit; and the analysis processing unit comprises a smoke composition analyzer and a heat radiation collection instrument. The automatic control test device of the gas cooker has advantages of compactness in structure, high safety, simpleness and convenience in testing, good test effect, reliability in test data and the like.

Owner:DONGGUAN HAIDE TESTING INSTR

Animal chronic obstructive disease test device and method capable of recycling smoke

PendingCN113069240AProvide accuratelyAvoid the problem of inaccurate regulationBiological testingVeterinary instrumentsDiseaseAnimal science

Owner:XIAN PEIHUA UNIV

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com