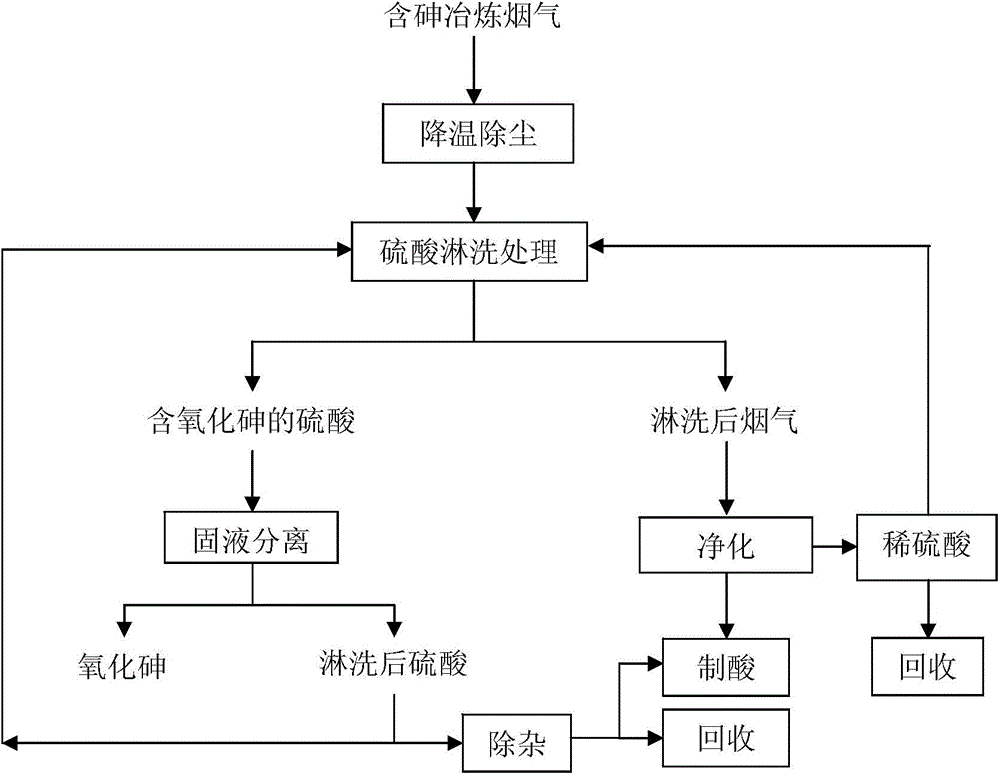

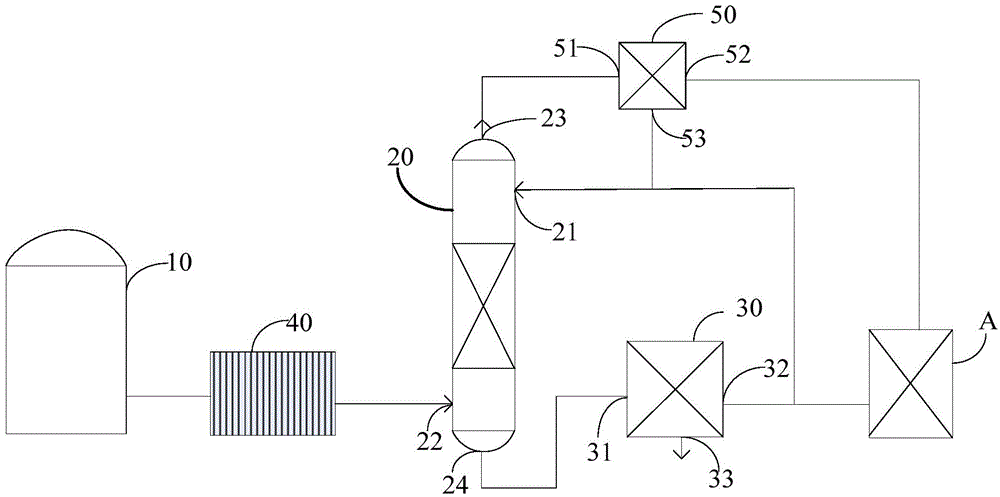

Method and system for treating arsenic-containing metallurgical off-gas

A technology for smelting flue gas and treatment methods, which is applied in the field of smelting flue gas treatment, and can solve problems such as strong dust binding ability, high dust concentration, and bag corrosion

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0035] Generally, when smelting arsenic-containing concentrates, especially when smelting arsenic-containing concentrates, in order to control the stability of smelted products, the amount of arsenic-containing concentrates added will be adjusted, resulting in large fluctuations in smelting flue gas. And the smelting of arsenic-containing concentrates, especially the smelting, usually adopts oxygen-enriched smelting, and the content of water vapor and sulfur trioxide in the smelting flue gas produced is significantly higher than that of roasting flue gas or even higher than other smelting flue gases. Furthermore, the flue gas from copper concentrate smelting has the characteristics of high dust concentration, large fluctuations in flue gas composition and concentration, strong dust binding ability, and high sulfur (especially sulfur trioxide) content in the flue gas. It is difficult to deal with the smelting flue gas.

[0036] For this reason, the present invention proposes a ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com