Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

34 results about "Rapid compression machine" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

A Rapid compression machine (RCM) is an experimental device used to simulate a single compression stroke of an internal combustion engine. A rapid compression machine can be used for chemical kinetics studies. It is often used as an alternative to a shock tube for understanding specifically low-to-intermediate temperature autoignition chemistry under idealized automotive engine conditions.

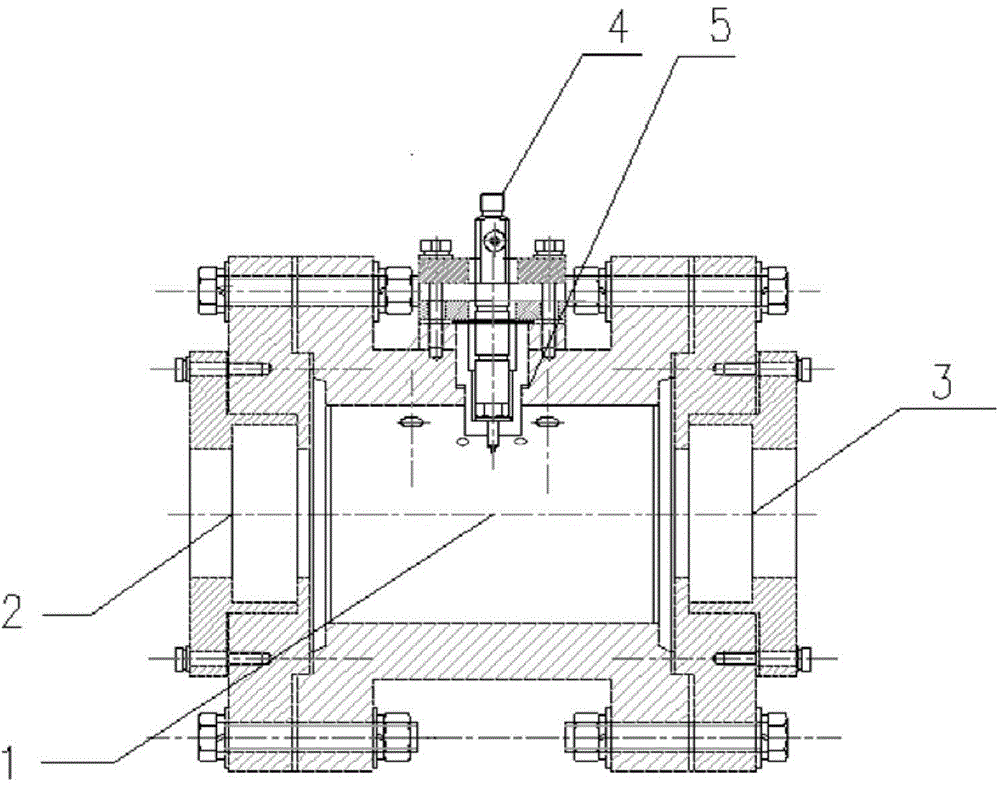

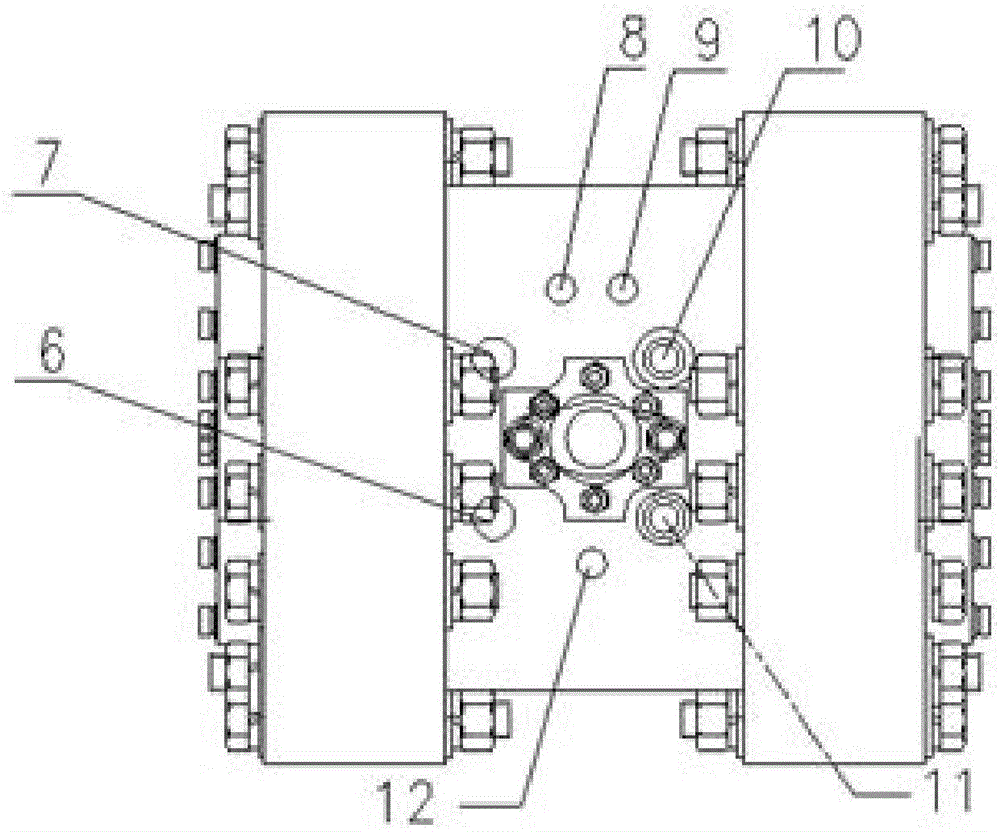

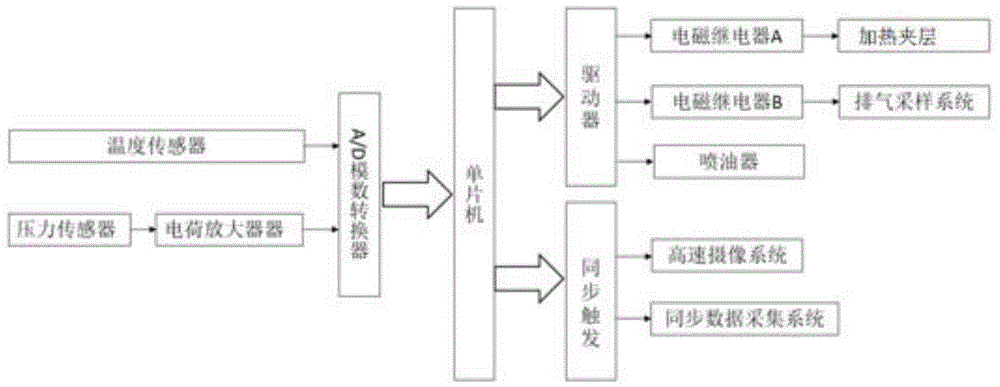

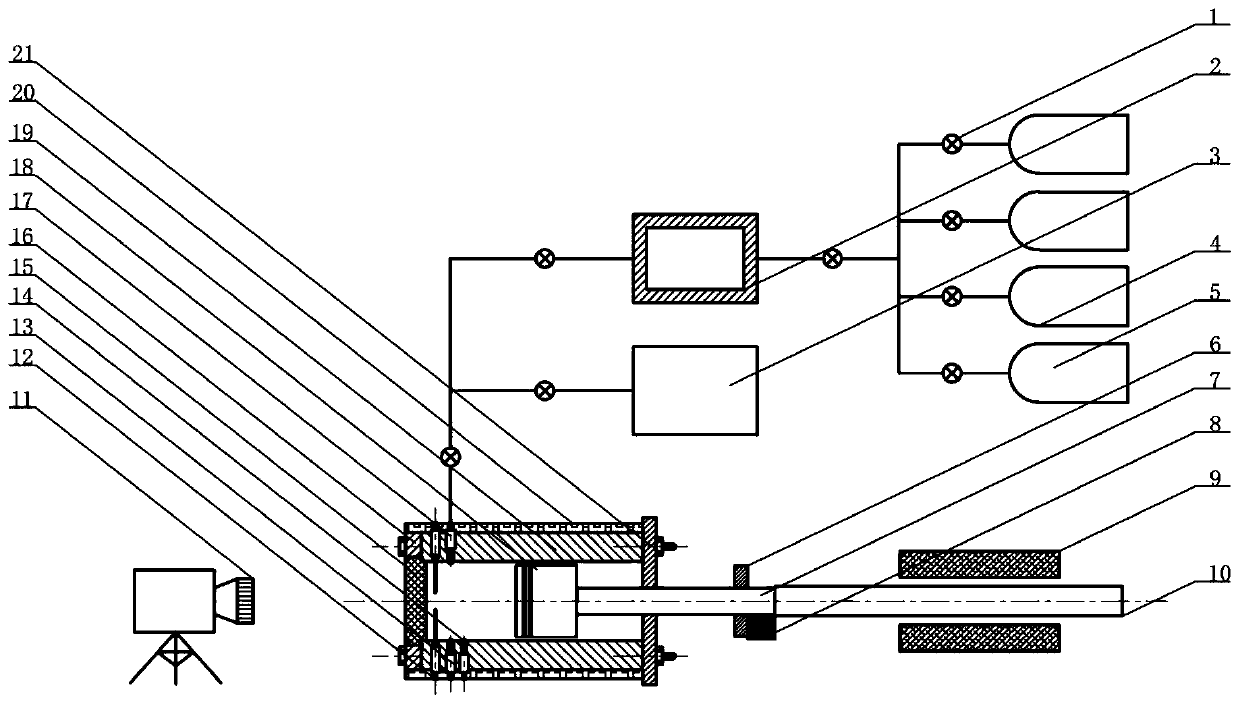

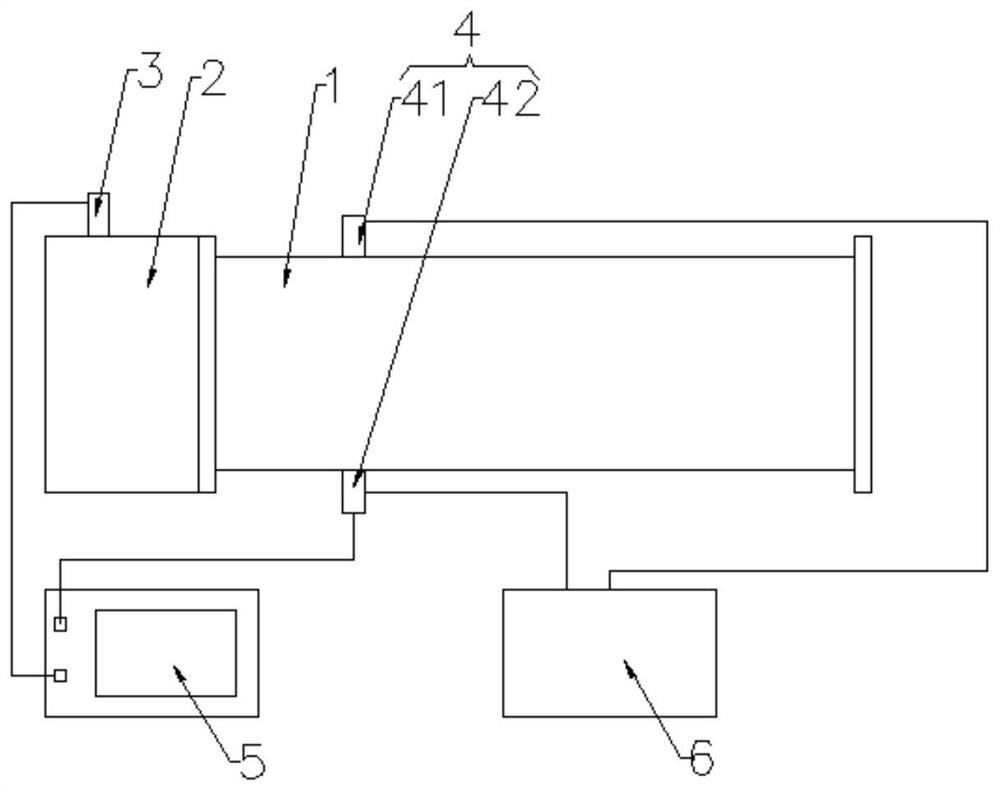

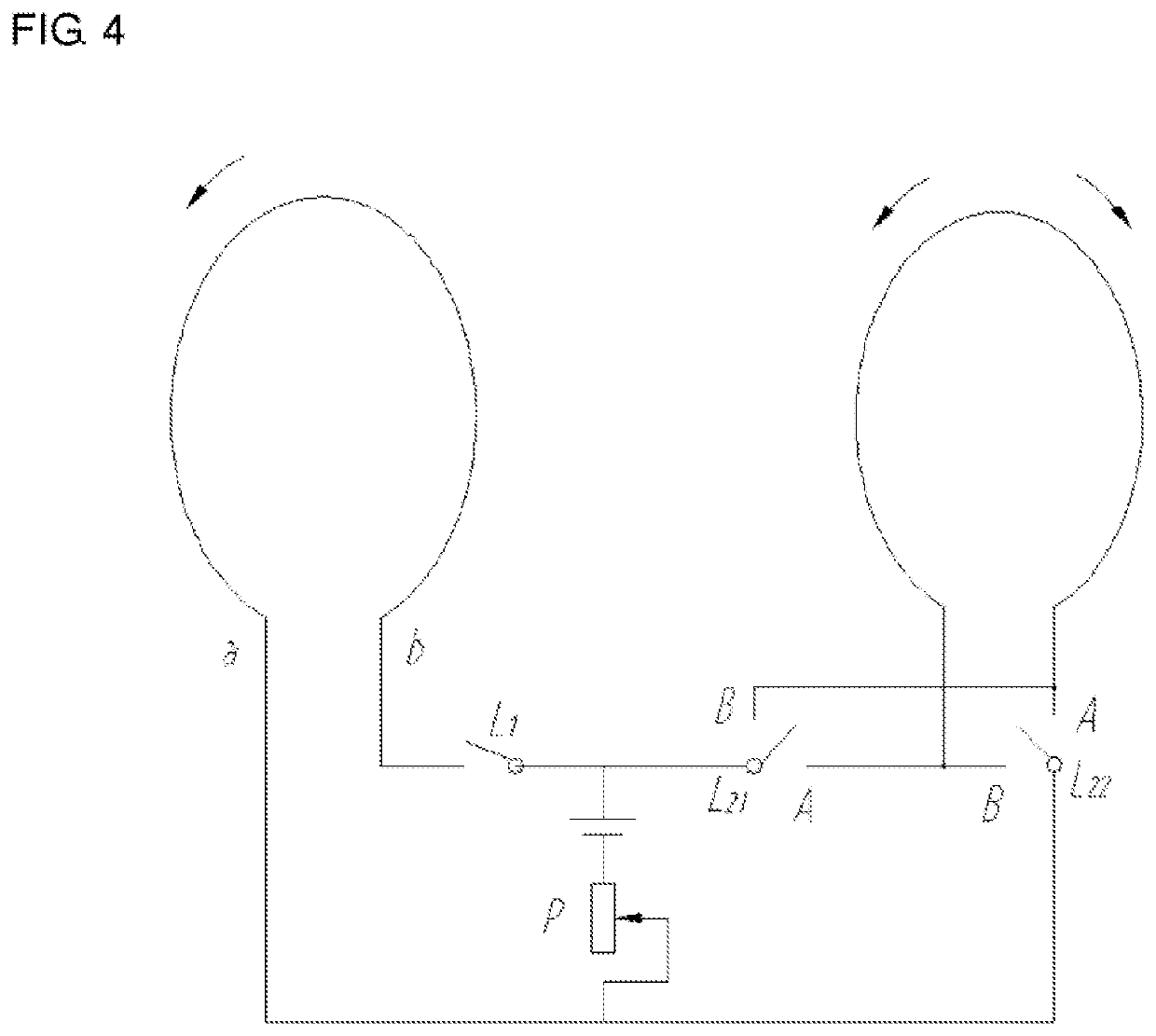

Constant-volume firebomb system for simulating combustion of engine

InactiveCN104819850AEasy to controlAvoid interactionInternal-combustion engine testingMicrocontrollerData acquisition

The invention relates to a constant-volume firebomb system for simulating combustion of an engine, for solving the technical problems of difficult observation of a flame combustion process in an actual engine, difficult evaluation and determination of a charcoal smoke generation amount at certain time in the combustion process and difficult realization of real-time sampling analysis of combustion products under the condition of a single variable. The constant-volume firebomb system for simulating the combustion of the engine comprises the following components: a firebomb body with a cylindrical cavity; a heating interlayer nested in the periphery of the firebomb body; a fuel injector; a pressure sensor; a temperature sensor; an air inlet channel; an exhaust sampling system; a high-pressure injection fuel oil supply system; a synchronization data acquisition system; a highs-speed shooting system; and a single-chip microcomputer control system. The constant-volume firebomb system provided by the invention has the following advantages: compared to a specially reconstructed single-cylinder machine or a rapid compressor, the cost is lower, and accurate control of the single variable is easily realized.

Owner:TIANJIN UNIV

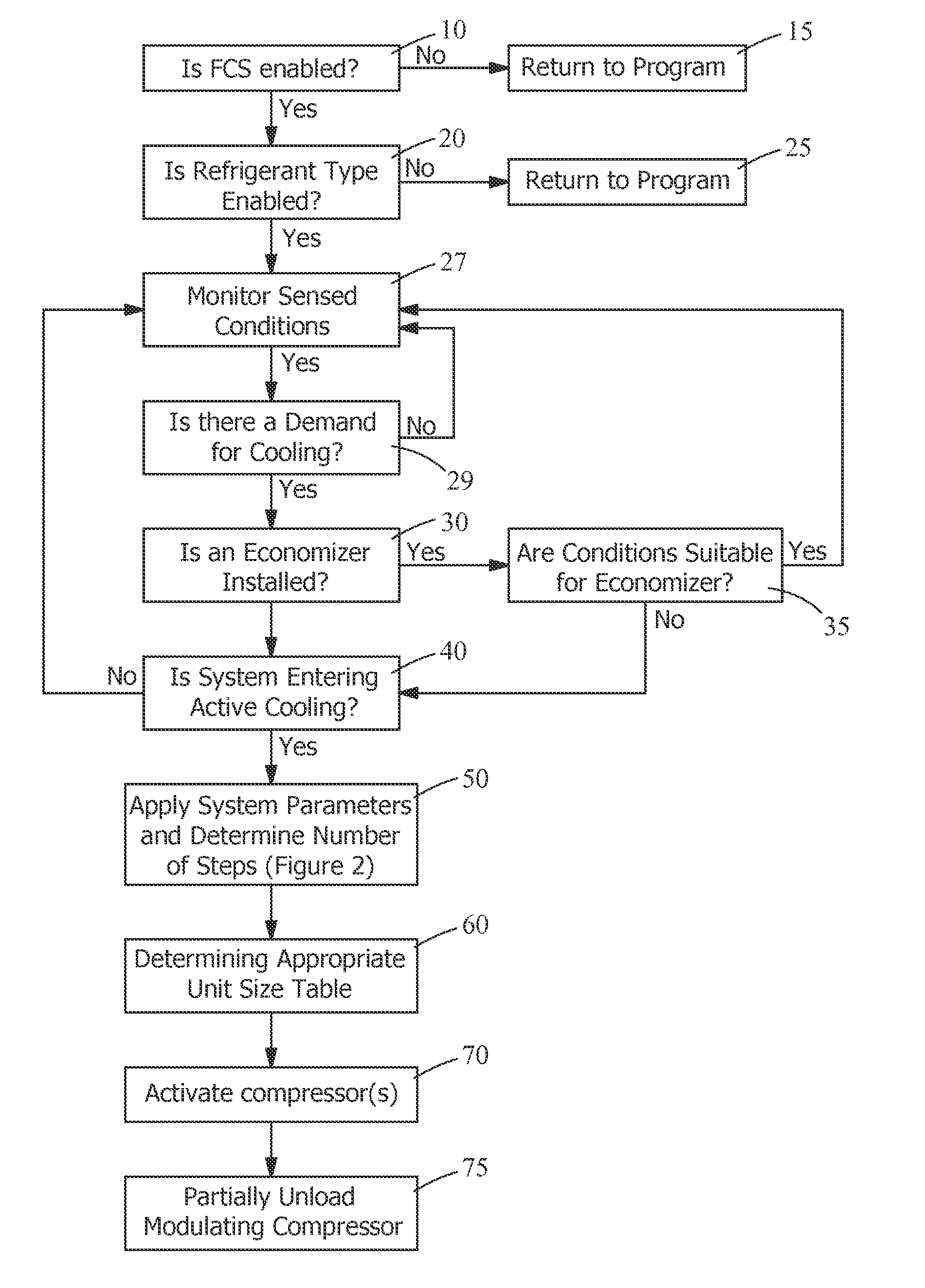

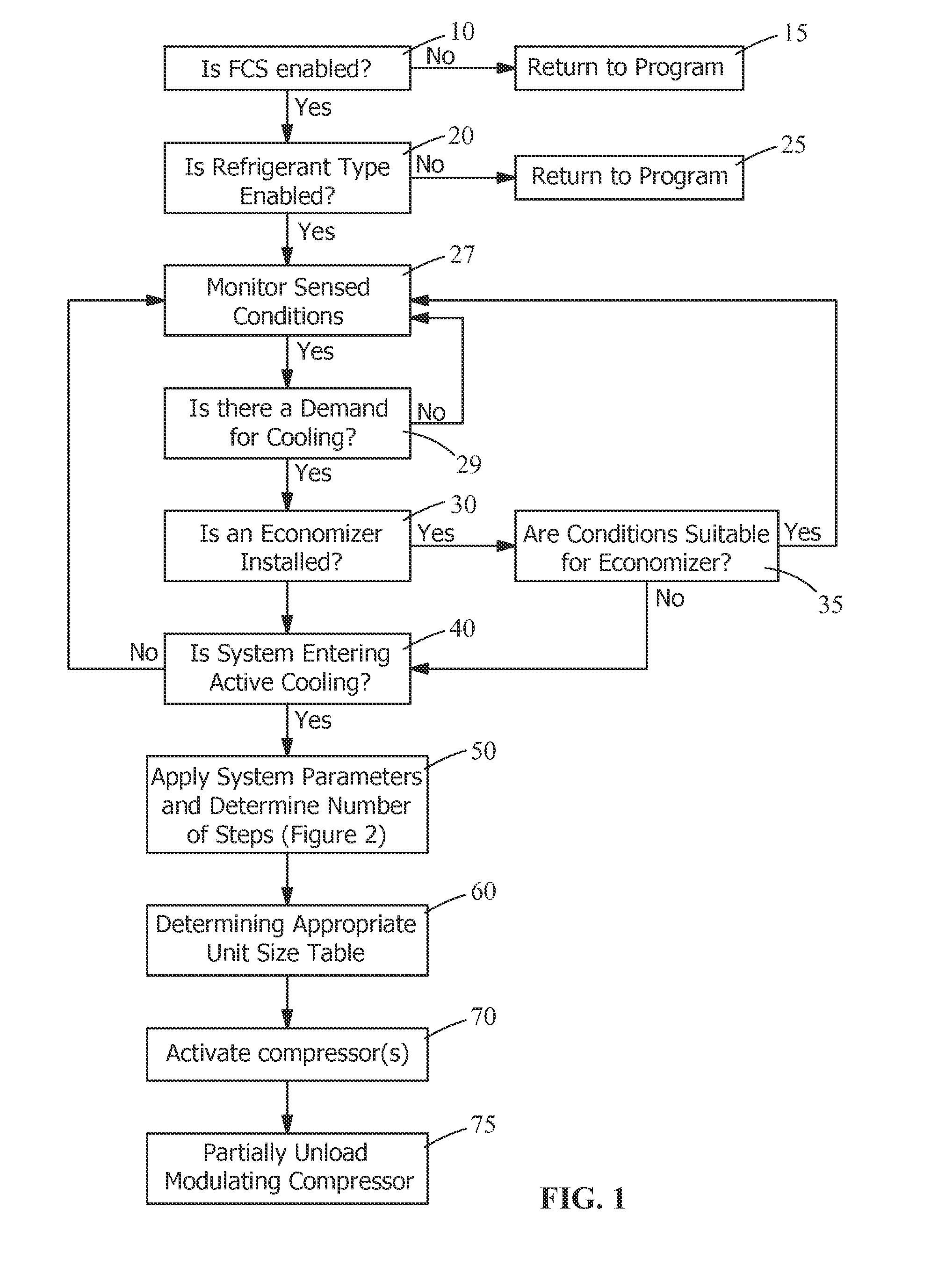

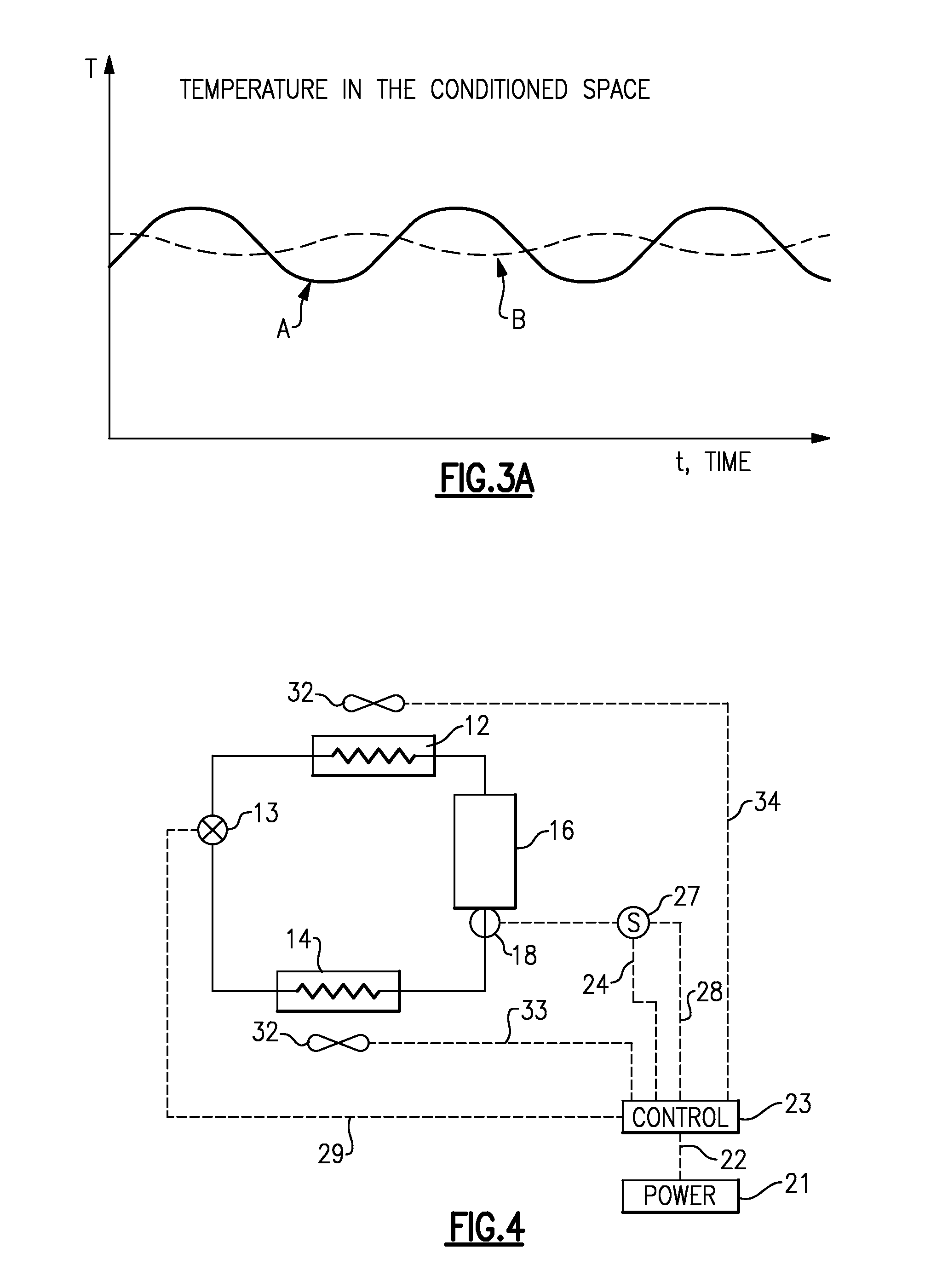

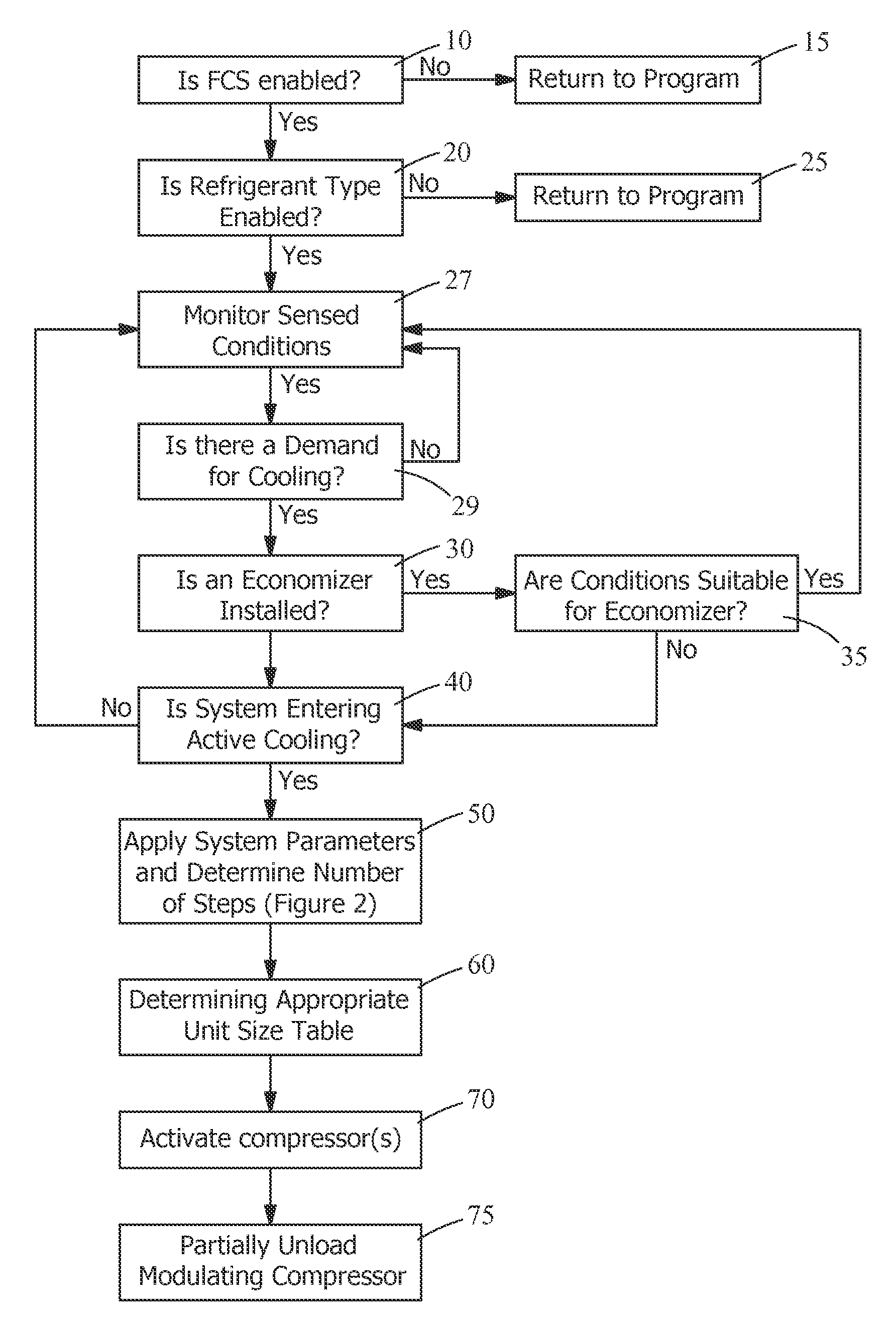

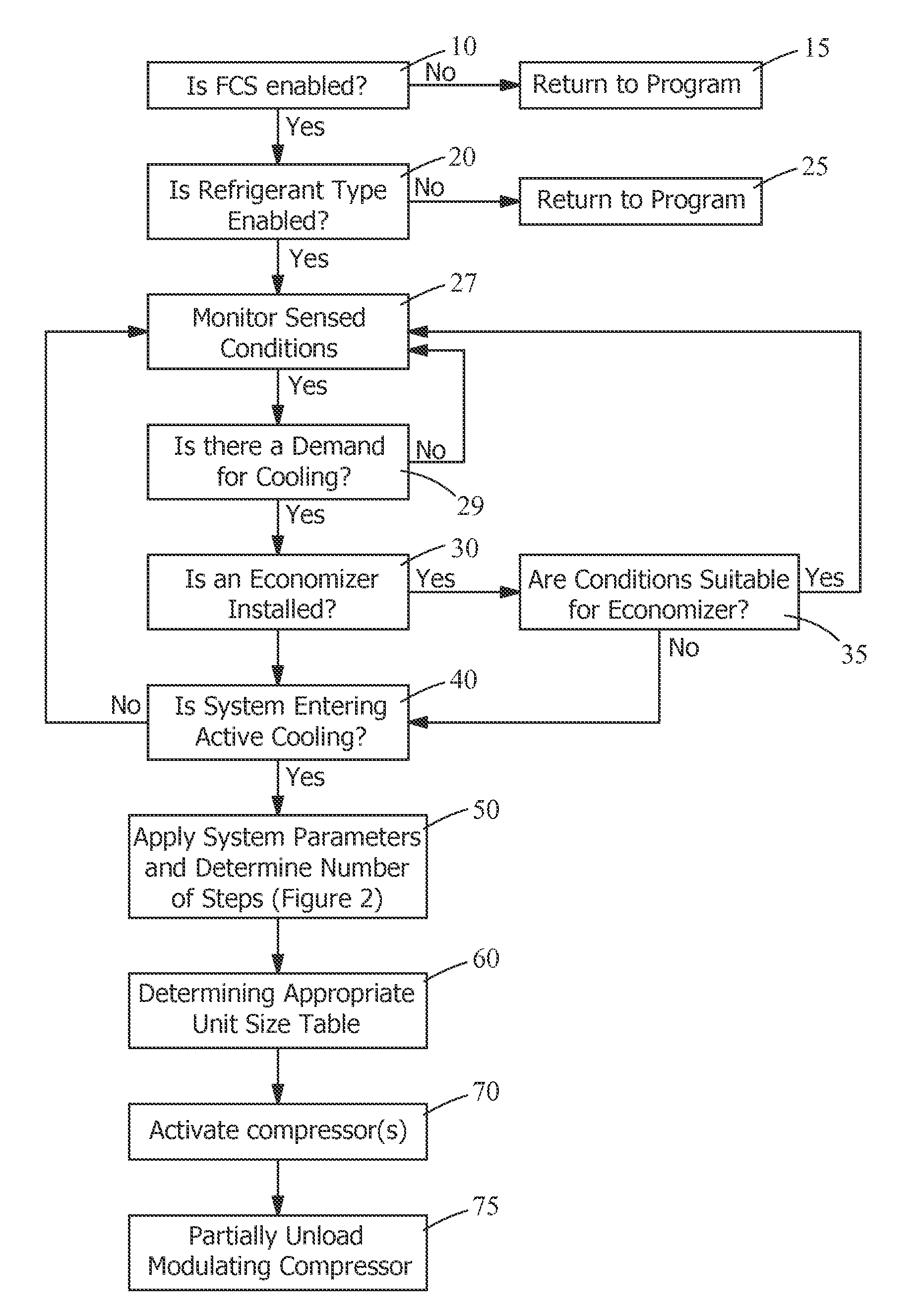

Staging active cooling start-up

ActiveUS20150007595A1Shortens time to operationFast equalizationCompression machines with non-reversible cycleRefrigeration safety arrangementActive coolingAir conditioning

A novel process for activating available compressors in multiple compressor air conditioning systems, using an Optimum Stage-Up Process. This process is programmed into a controller as an algorithm, to provide a process for fast compressor start. This process shortens the time to initiate operation of compressors in a multi-compressor air conditioning system required to meet the demand call under any load condition, and hence shortens the time required for the actual sensed interior region air temperature to reach the interior region temperature set point. The Optimum Stage-up Algorithm estimates the number of compressor stages or steps that must be initiated, based on sensed or measured values, to meet the demand at any load condition. These measured values include the sensed temperature of the interior region being cooled, which is compared to the temperature set point of this interior region as well as measured mixed air temperature and supply air temperature.

Owner:JOHNSON CONTROLS TYCO IP HLDG LLP

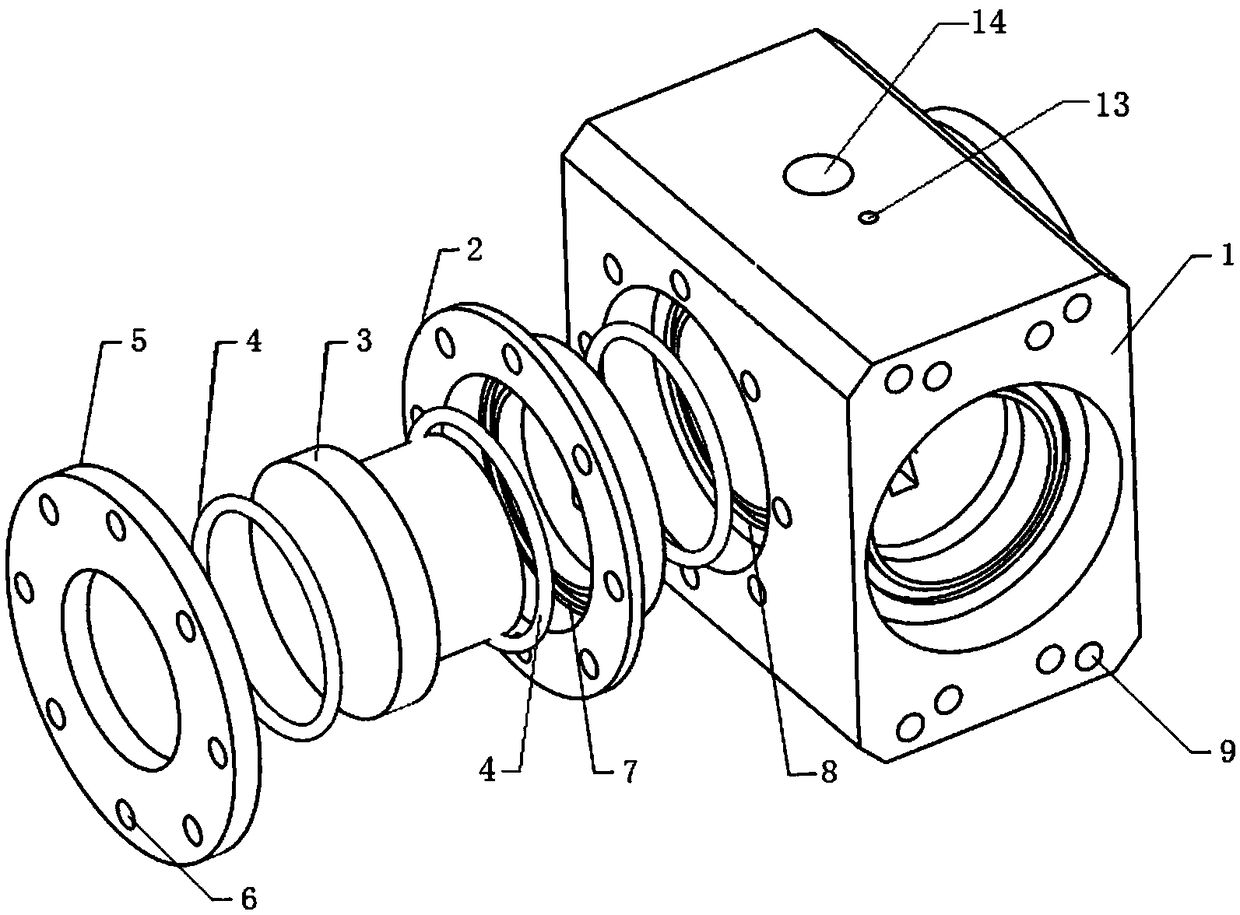

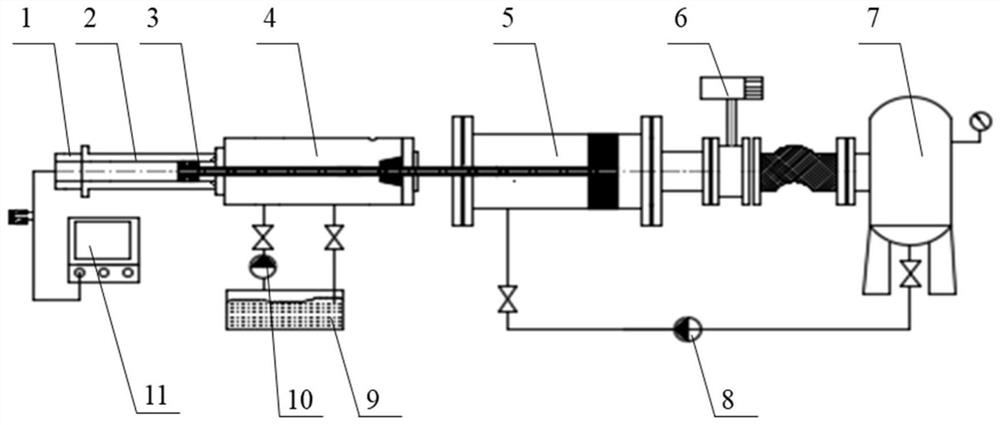

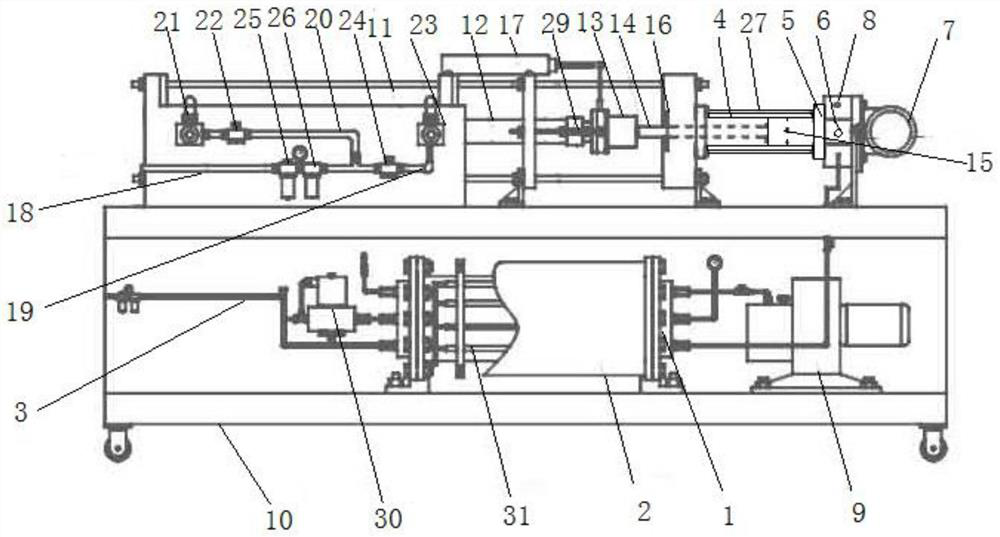

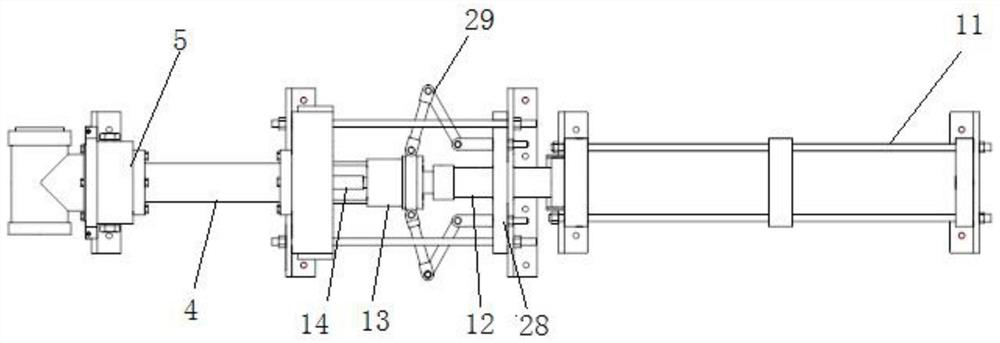

Rapid compressor experimenting platform for laboratory and compression ratio adjusting method

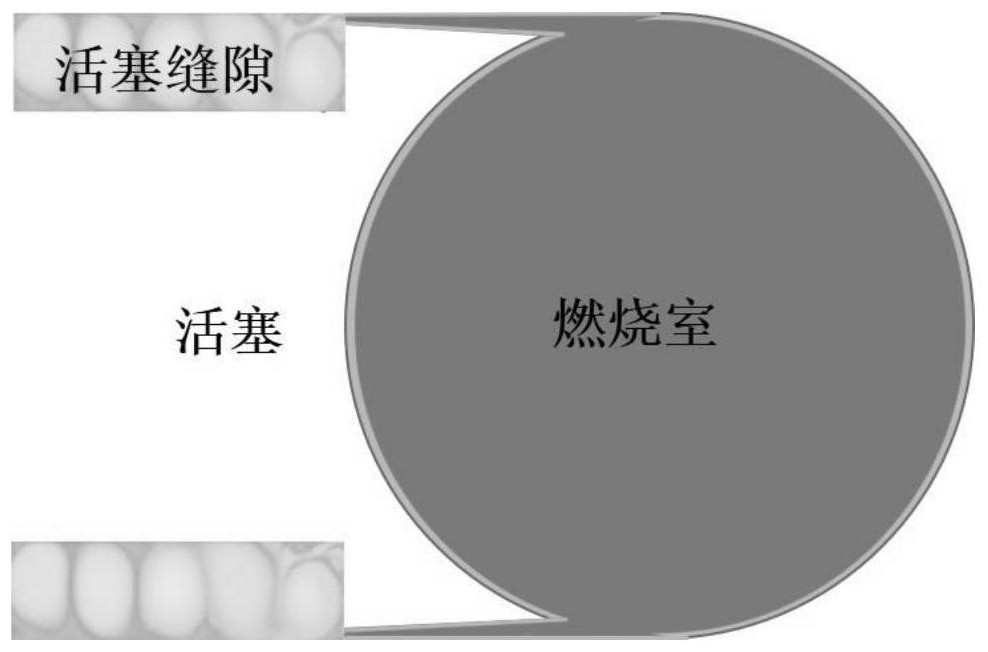

ActiveCN106089676ARealize compression ratio adjustmentAchieving a thermodynamic statePump testingPositive-displacement liquid enginesAxial compressorCombustion chamber

The invention discloses a rapid compressor experimenting platform for a laboratory. The rapid compressor experimenting platform comprises a combustion chamber unit, a brake cylinder unit and a driving cylinder unit. The brake cylinder unit comprises a brake cylinder body, a brake cylinder rear cover and a brake piston, a first connecting rod is connected between the brake piston and a combustion chamber piston, and the lower stop point position of the brake piston is determined by the position of the brake cylinder rear cover. The driving cylinder unit comprises a driving piston, and a second connecting rod is connected between the driving piston and the brake piston. A plurality of compression ratio adjusting gaskets capable of being arranged between the brake cylinder rear cover and the brake cylinder body are arranged. Each compression ratio adjusting gasket is composed of a pair of cohesive semicircular gasket bodies, and the total thickness of the arranged compression ratio adjusting gaskets is determined according to the lower stop point position of the combustion chamber piston under the premise that the upper stop point position of the combustion chamber piston is kept unchanged. According to the rapid compressor experimenting platform for the laboratory, the gaskets are additionally arranged at the brake cylinder rear cover to change the initial position of the combustion chamber piston and maintain the volume of a clearance unchanged so as to adjust the compression ratio.

Owner:TIANJIN UNIV

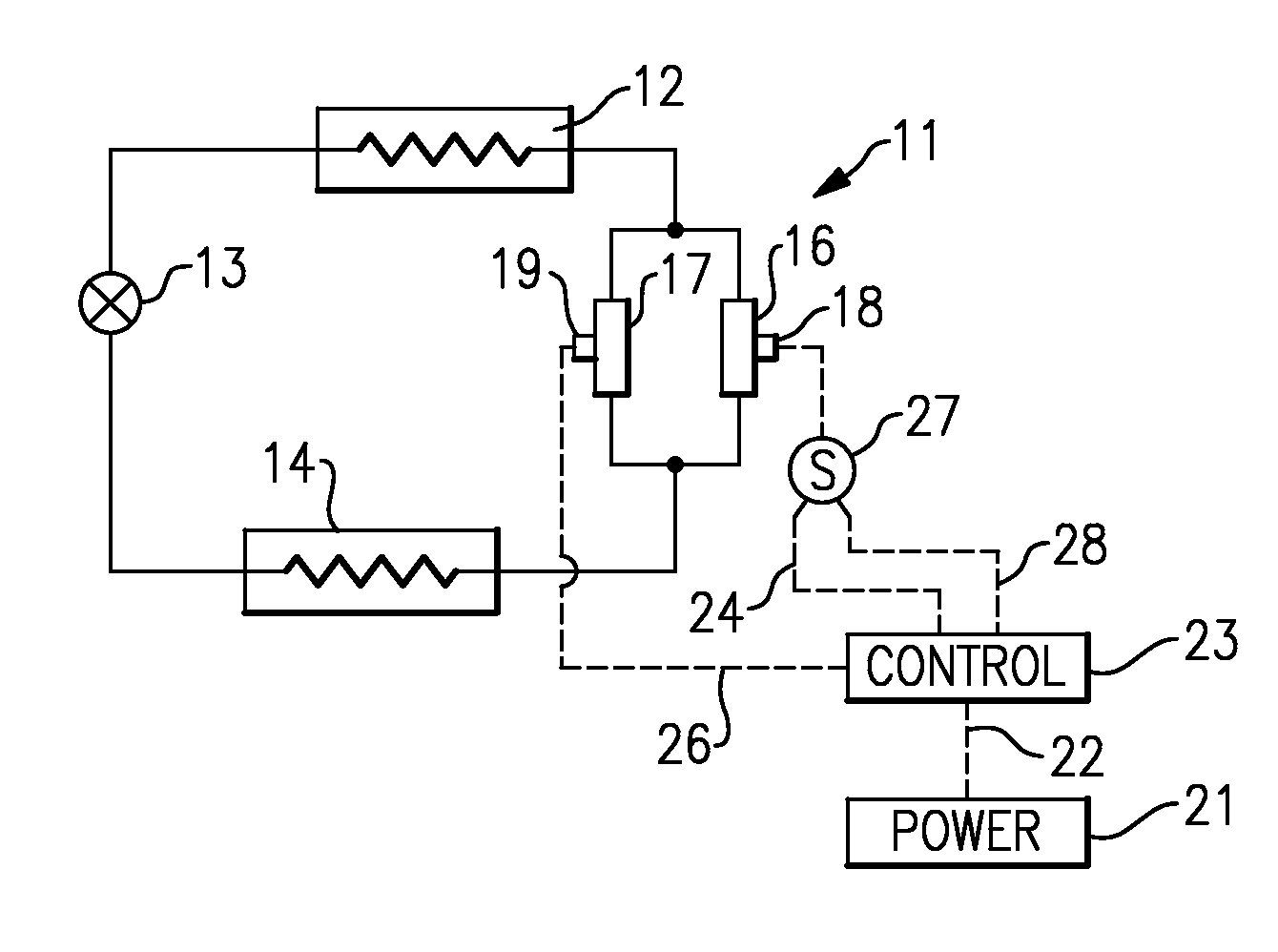

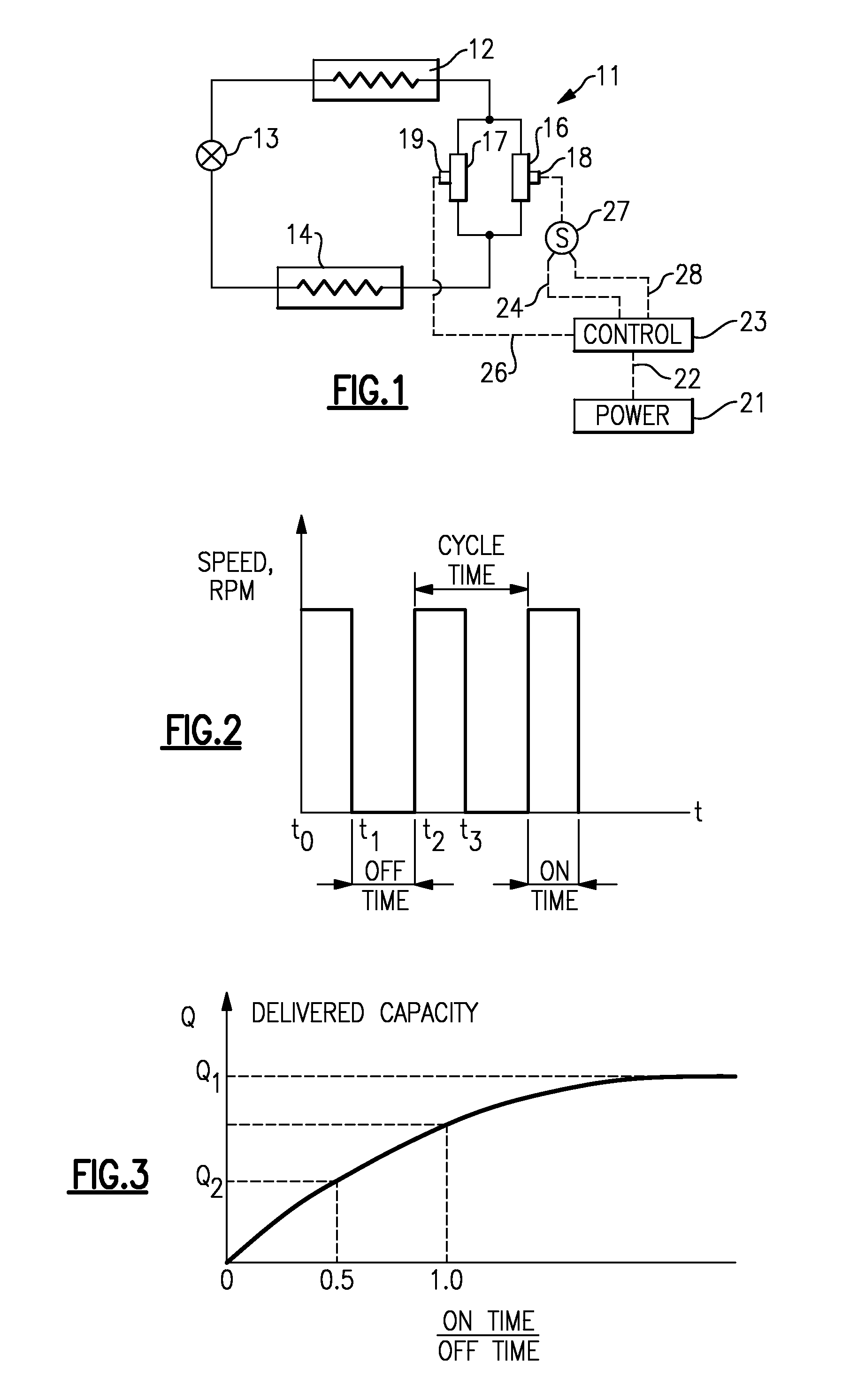

Rapid compressor cycling

InactiveUS20100307177A1Compression machines with non-reversible cycleEvaporators/condensersDrive motorCycle time

A single speed compressor is provided with a switching device and control for turning the compressor drive motor ON and OFF in repeated succession at a selected ON time / OFF time ratio within a selected cycle time interval. The ON / OFF ratio and cycle time interval are selected to maintain desired temperature and / or humidity control within a conditioned space.

Owner:CARRIER CORP

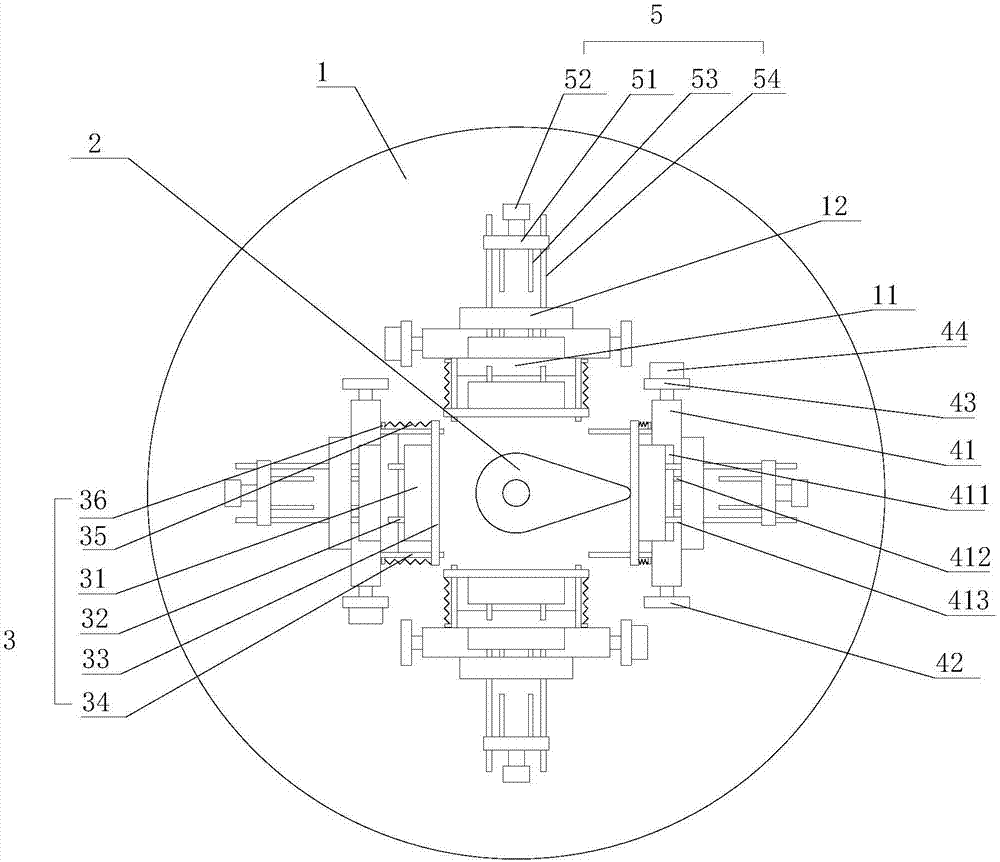

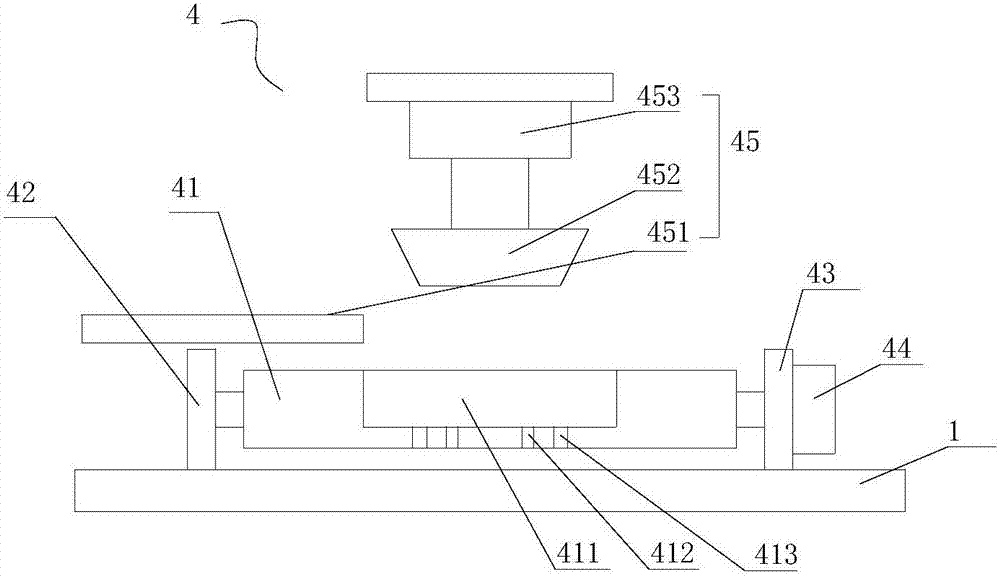

Efficient and quick compressor valve plate punching machining device

InactiveCN107052143AInhibit sheddingRealize automatic separation and blankingPerforating toolsPress ramPunchingEngineering

The invention provides an efficient and quick compressor valve plate punching machining device. Multiple punching machining mechanisms are installed on a circular truncated cone and circumferentially distributed by taking the center of the circular truncated cone as the center; each punching machining mechanism comprises a punching unit, a fixing unit and a discharging unit which are sequentially arranged in the direction from the portion close to the center of the circular truncated cone to the portion far away from the center of the circular truncated cone; a cam is installed on the circular truncated cone and located at the center of the circular truncated cone, a first driving mechanism is in transmission connection with the cam and drives the cam to rotate, and the cam rotates to drive punching dies of the punching machining mechanisms to move towards the fixing units of the punching machining mechanisms. According to the efficient and quick compressor valve plate punching machining device, efficient and quick punching machining on a workpiece is achieved through the first driving mechanism, the cam and the punching machining mechanisms, one-time punching molding of a product is achieved, automatic separated falling of punching waste materials and the product is achieved, the molded product is separated from a molding groove through the discharging units, collection is convenient, and the working efficiency is improved.

Owner:WUHU XIAOSHENG ELECTROMECHANICAL TECH CO LTD

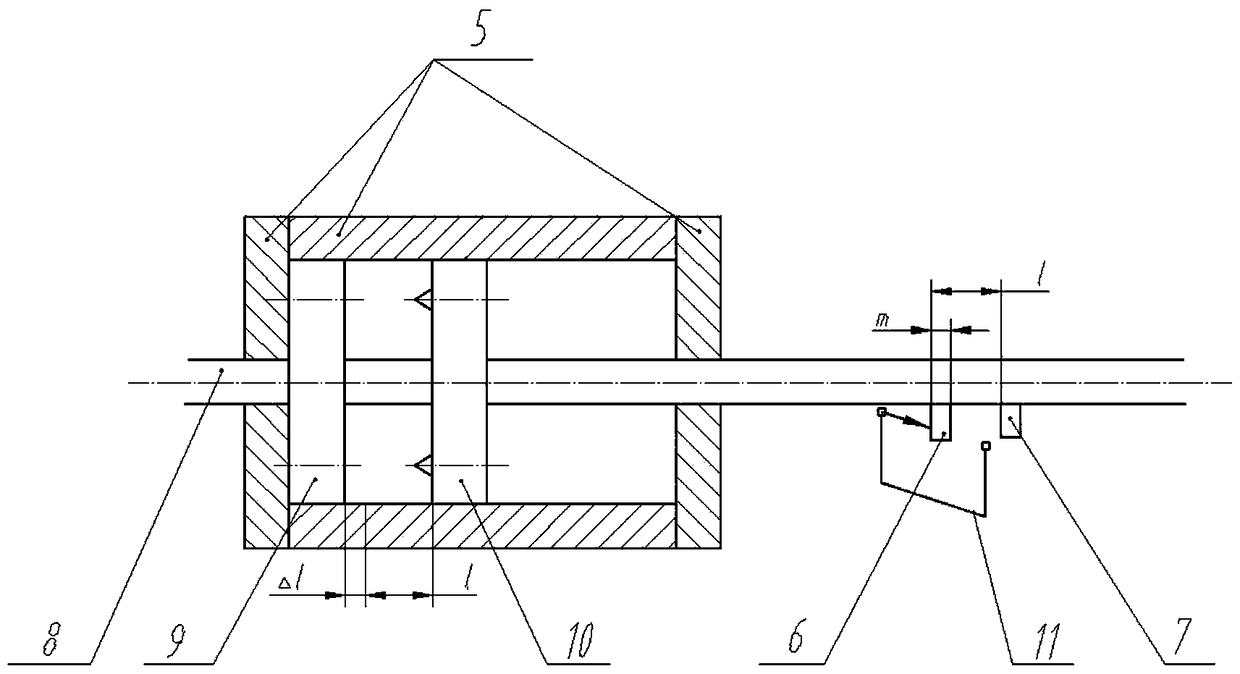

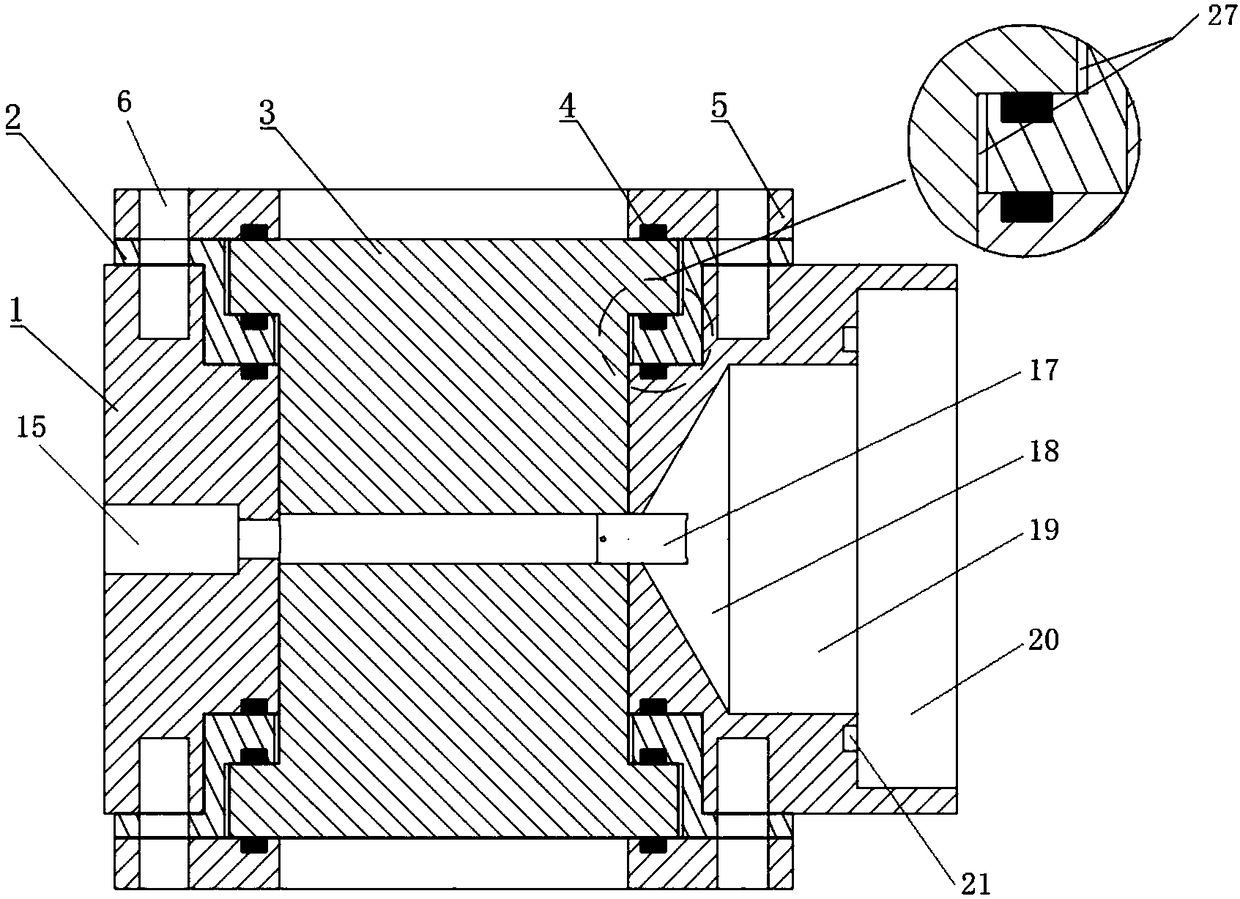

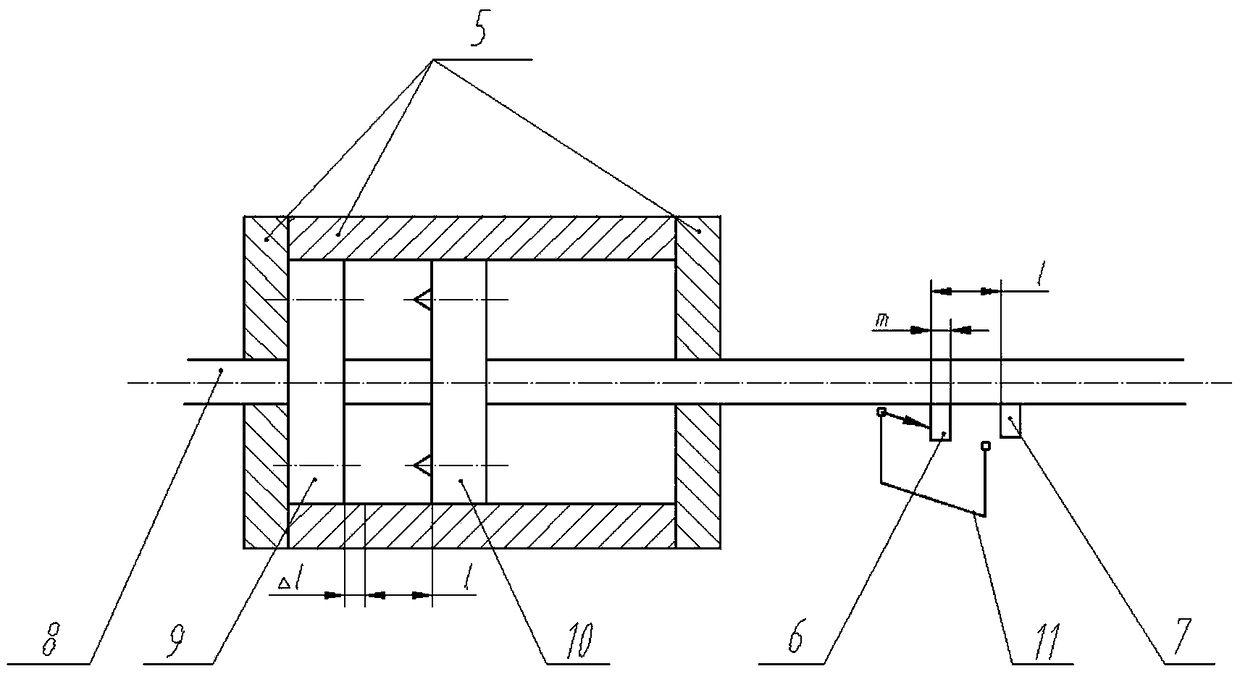

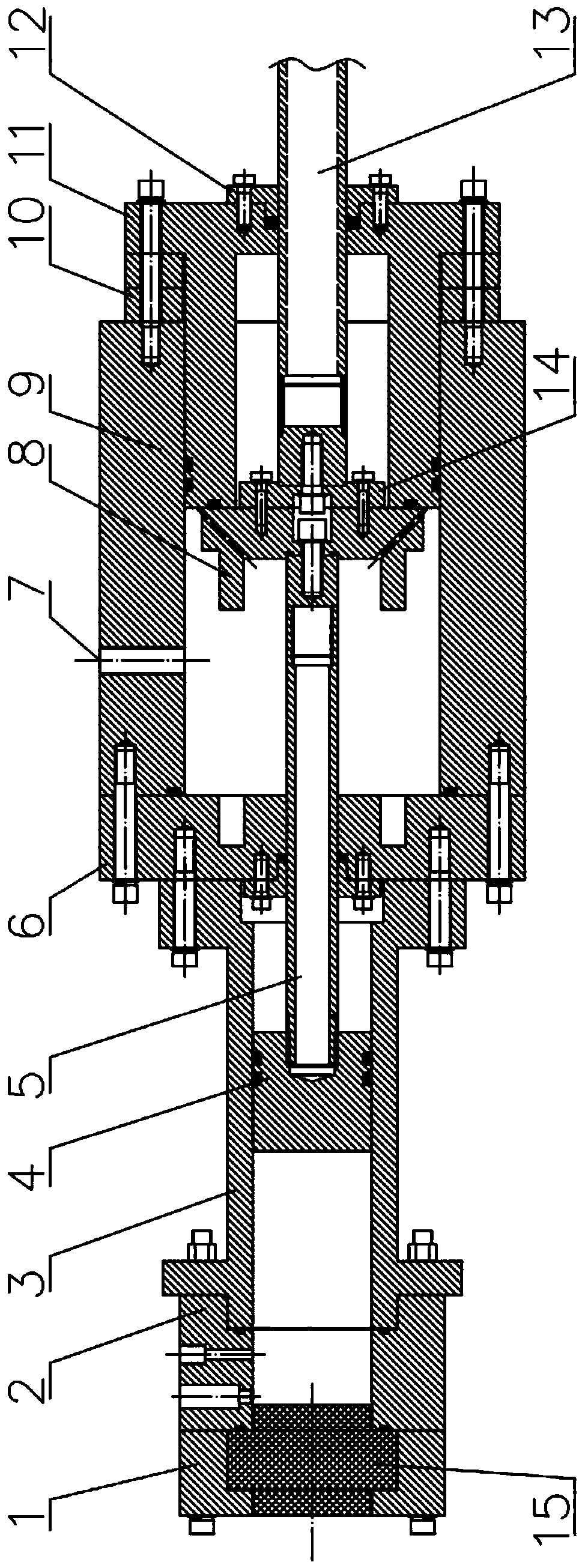

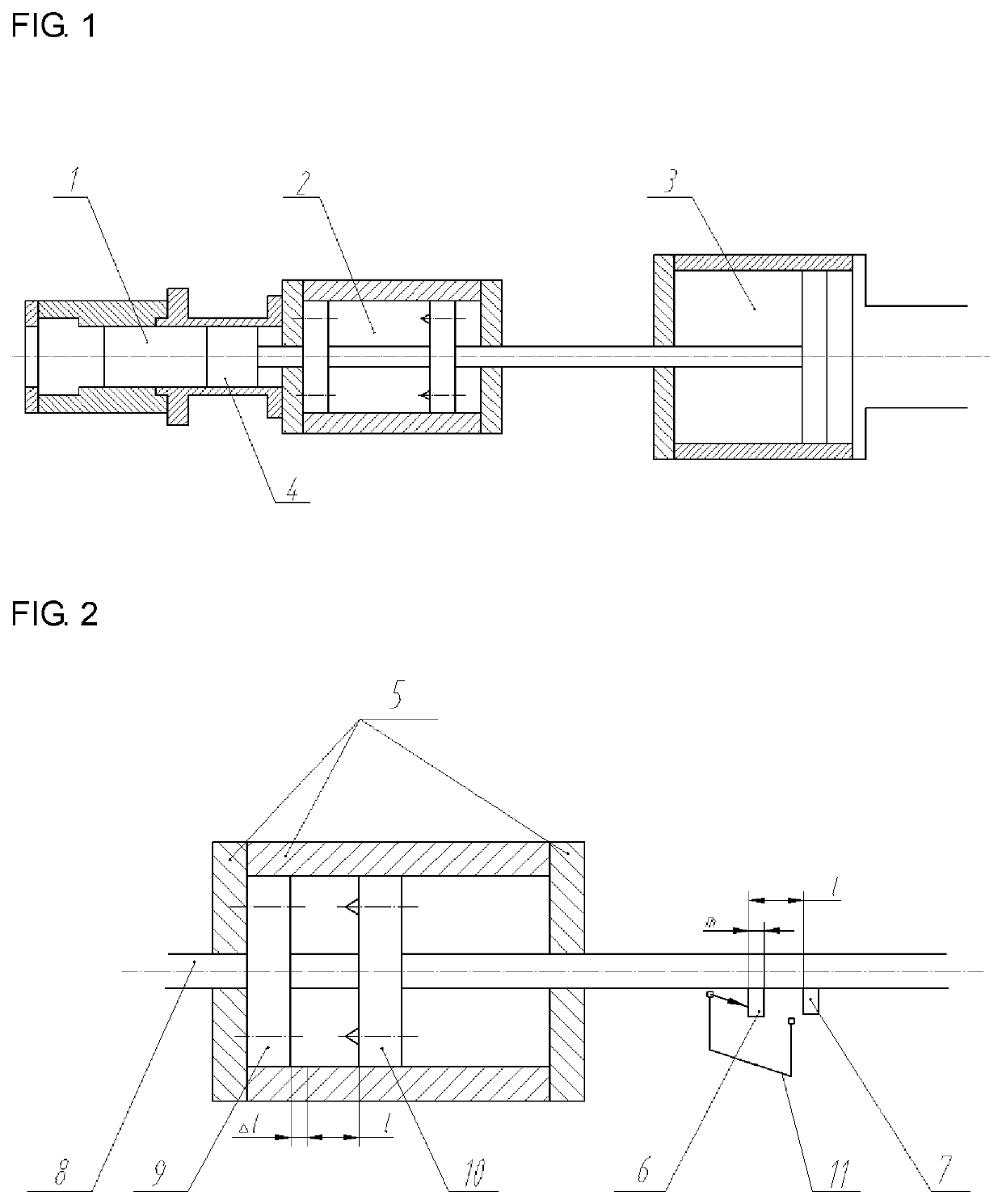

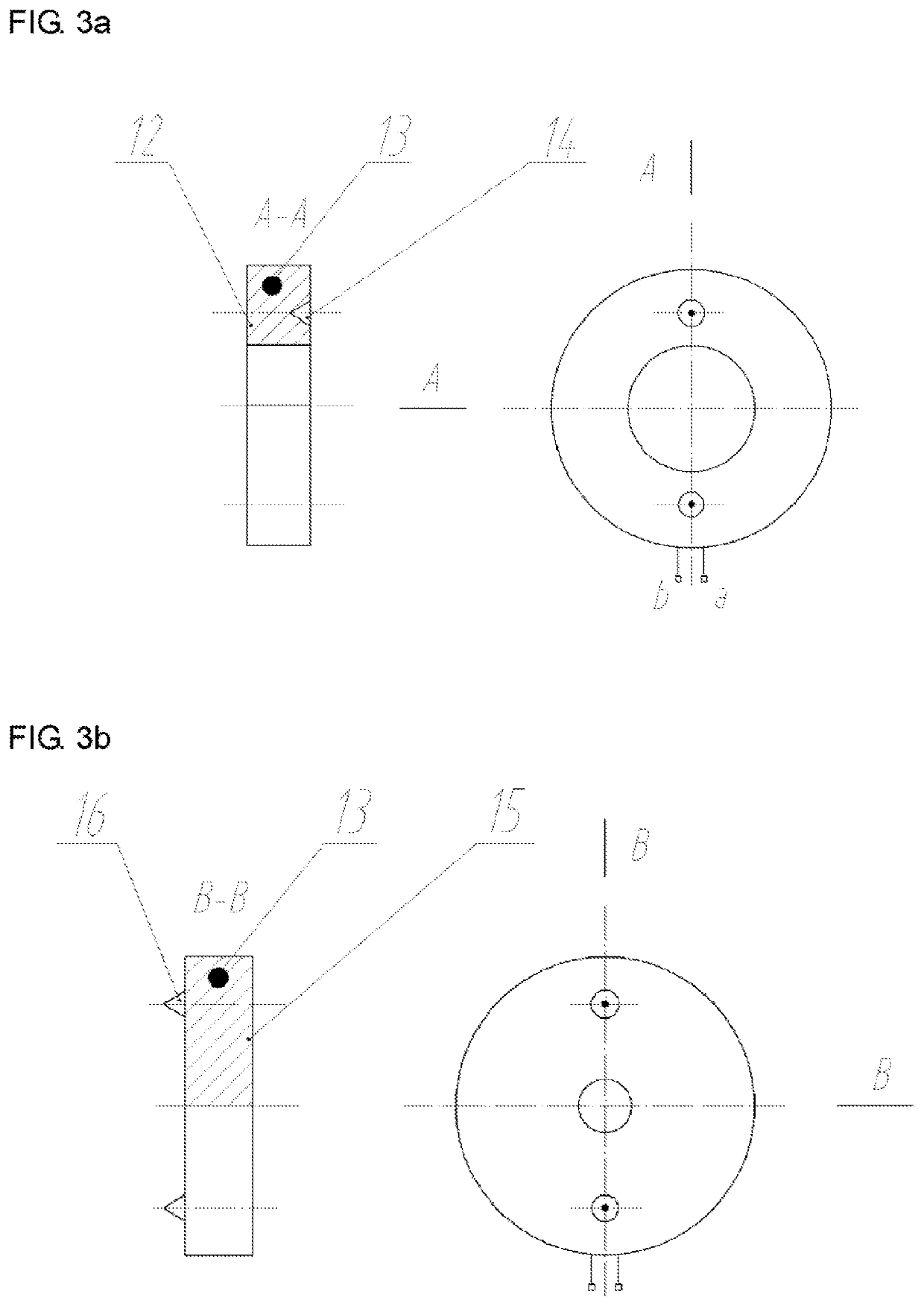

Control method based on electromagnetic braking system of fast compressor

The invention relates to a control method based on an electromagnetic braking system of a fast compressor. The applicative electromagnetic braking system of the fast compressor comprises a central control unit, a braking cylinder made of a magnetic separation material, a pushing rod penetrating through the braking cylinder, an electromagnetic braking circular ring fixed to the braking cylinder, anelectromagnetic braking piston fixed to the pushing rod, a first light shading plate, a second shading plate, a photoelectric sensor and an electromagnetic braking control circuit, wherein the firstlight shading plate and the second shading plate are fixed to the pushing rod, and the photoelectric sensor is fixed nearby the pushing rod. The control method comprises the following steps that the braking distance l is estimated preliminarily according to the magnitude of a current capable of being provided, electromagnetic force between two electromagnetic coils and the initial velocity v of apushing rod combination during braking, a small part of restore distance delta l is still formed between the piston and an upper stop point after braking is completed, the electromagnetic braking piston and the electromagnetic braking circular ring are further fastened, the two second shading plates and the photoelectric sensor are mounted, and when braking is started, the distance between the twoelectromagnetic coils meets the formula of L=l+delta l.

Owner:TIANJIN UNIV

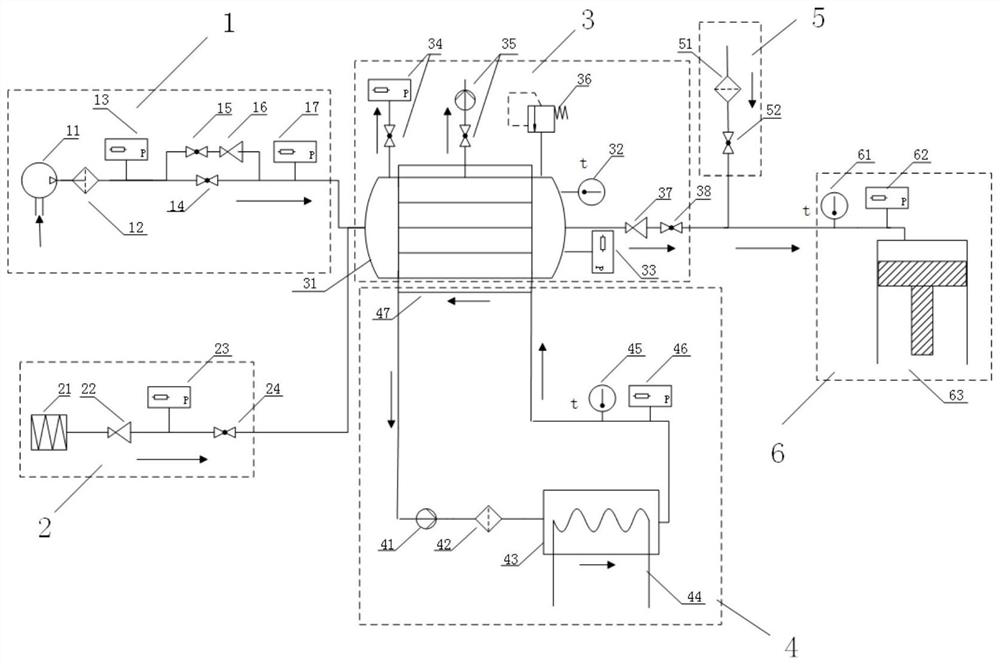

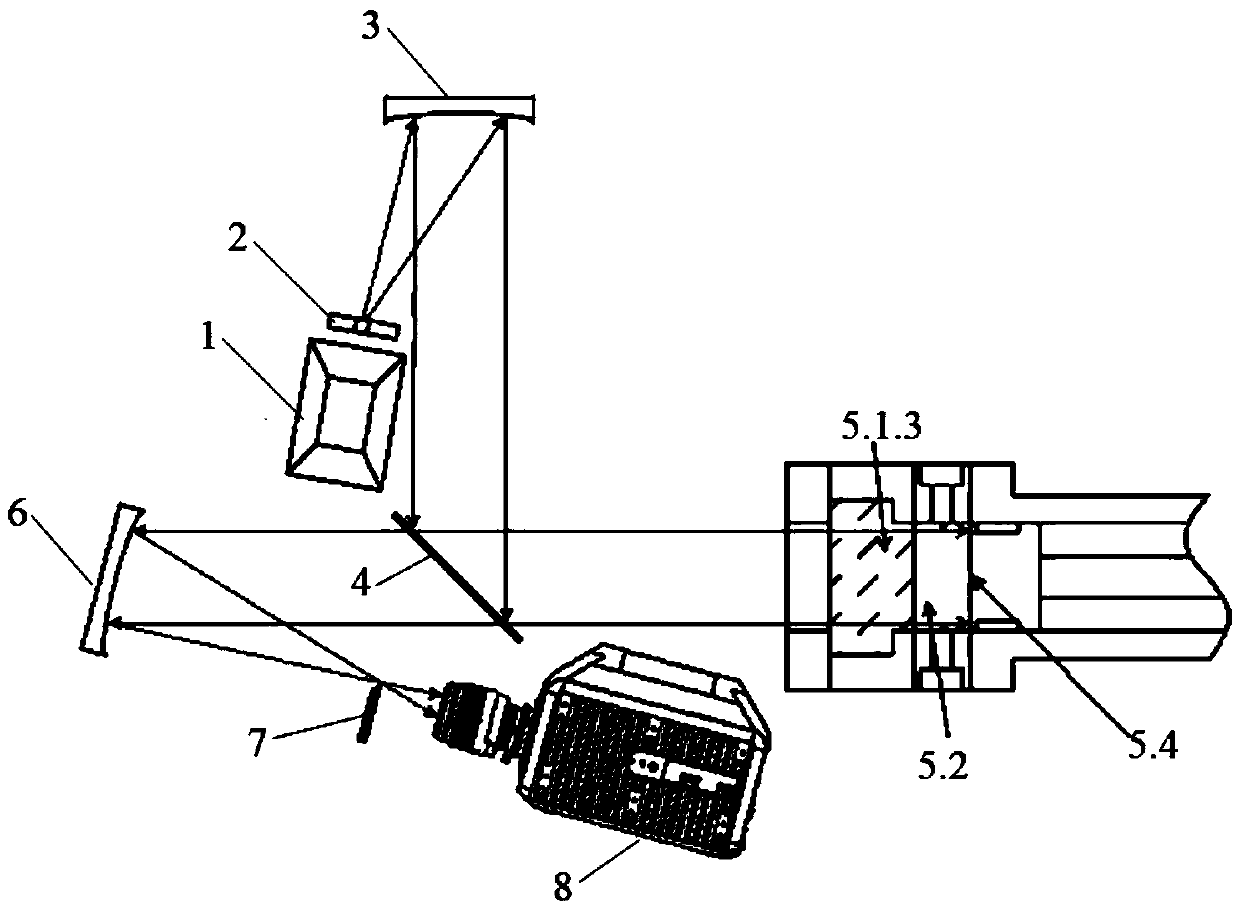

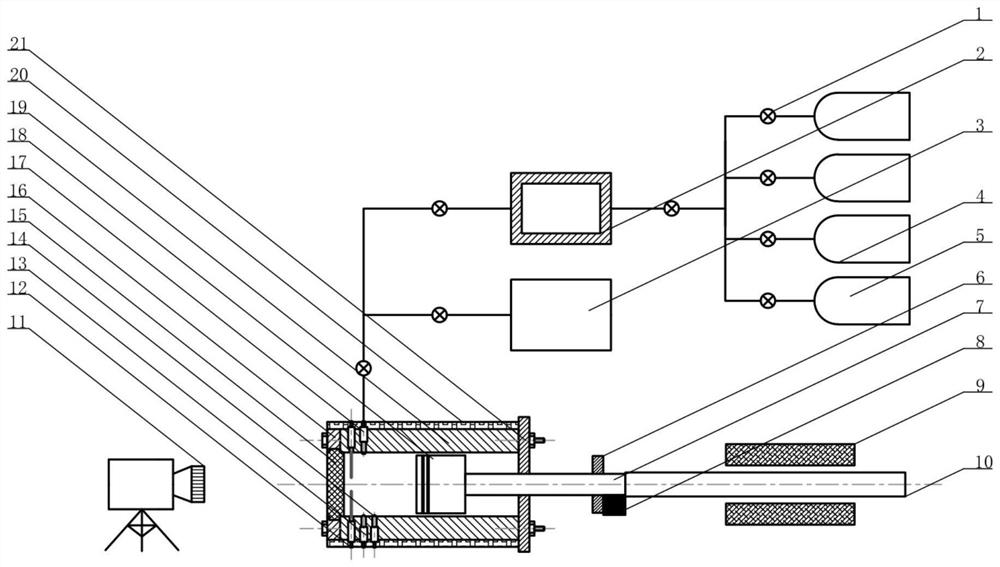

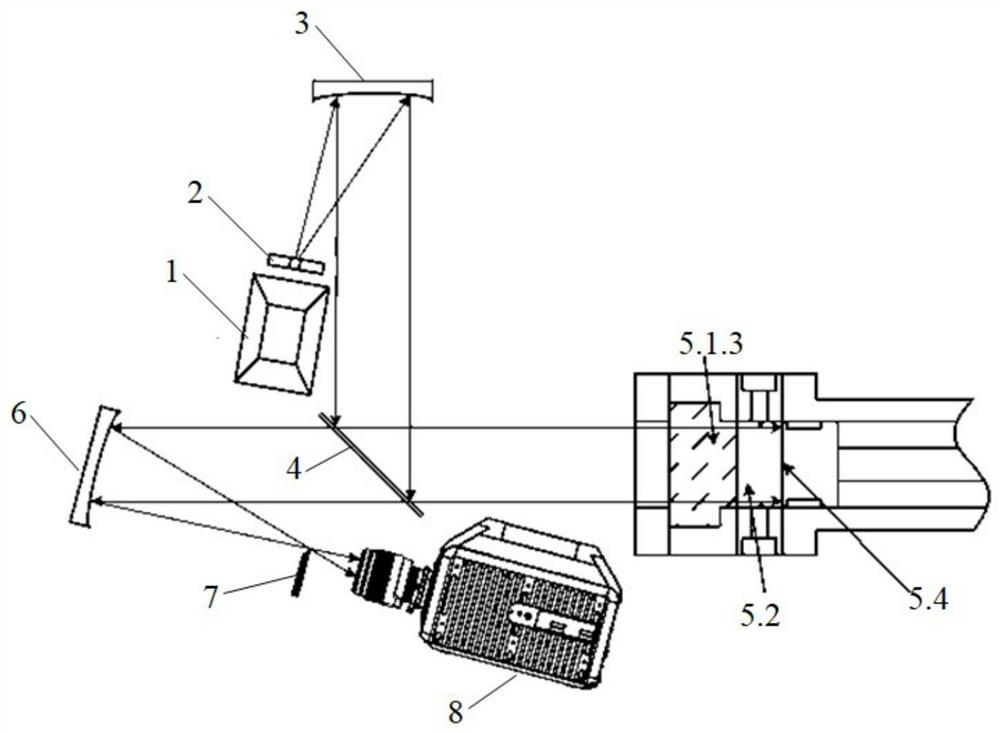

Optical experiment platform based on spray combustion visualization of rapid compressor

The invention discloses an optical experiment platform based on spray combustion visualization of a rapid compressor. The optical experiment platform is used for simulating the compression stroke of an engine and the spray development and combustion process. The platform comprises a rapid compressor system, a visual combustion chamber, a fuel supply system, a data acquisition system, a schlieren method optical system and the like. The rapid compressor and the visual combustion chamber can provide in-cylinder thermal conditions similar to those of an actual engine. The fuel injector and the fuel supply system can realize injection conditions of different pressures and pulse widths; in-cylinder pressure signals can be collected through the data acquisition system, and experiment images of the spraying development and combustion process are obtained through a schlieren method. The invention provides an experimental platform and method for researching spray development and combustion underthe in-cylinder thermal condition similar to that of an actual engine, provides a technical scheme for in-cylinder spray visualization research, and is beneficial to development of spray combustion mechanism research under high-temperature and high-pressure conditions.

Owner:XI AN JIAOTONG UNIV

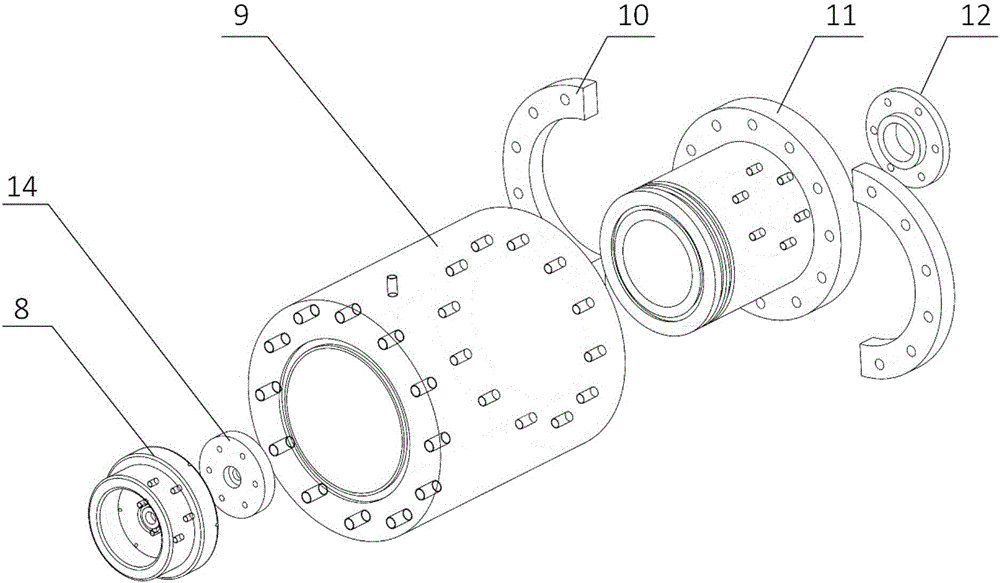

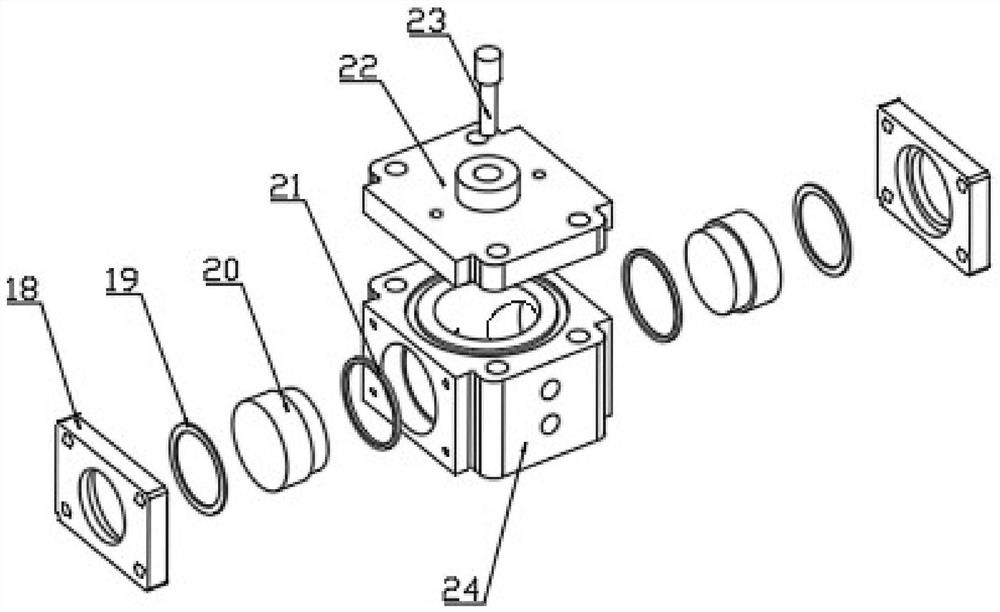

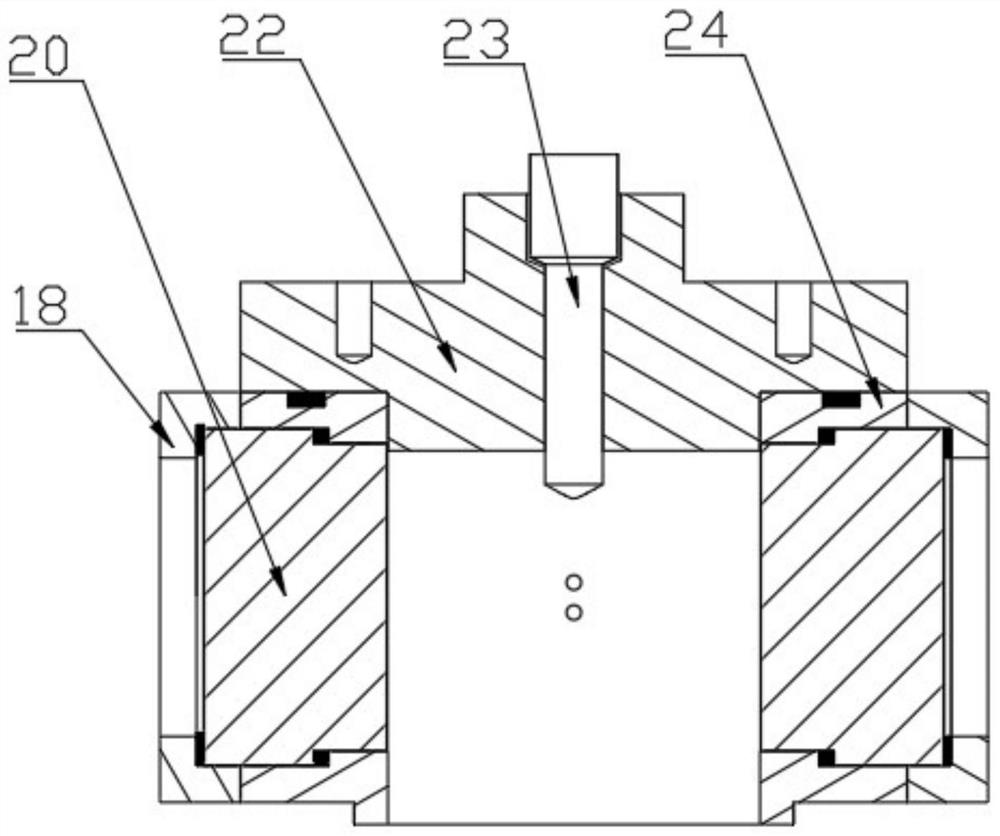

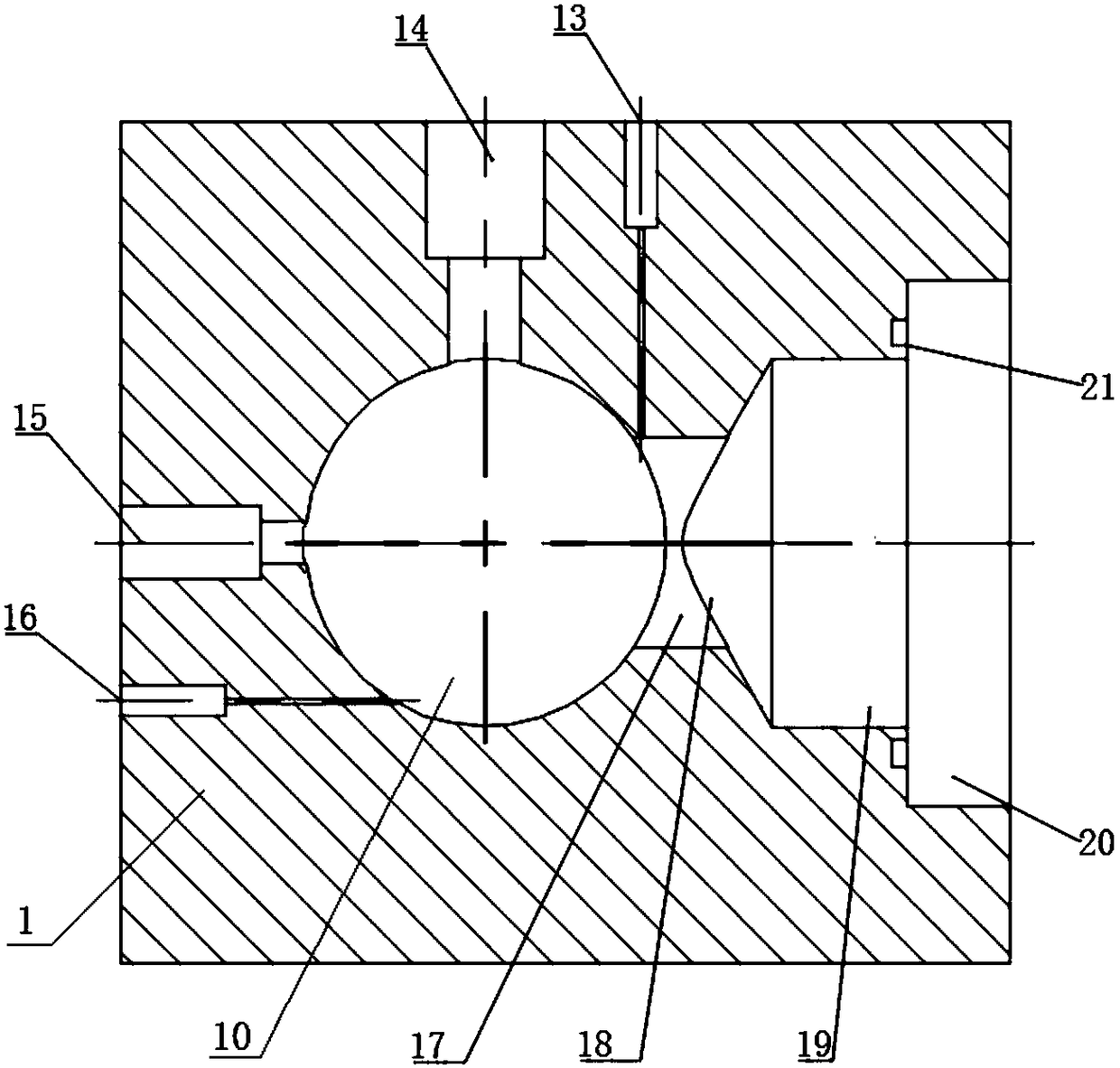

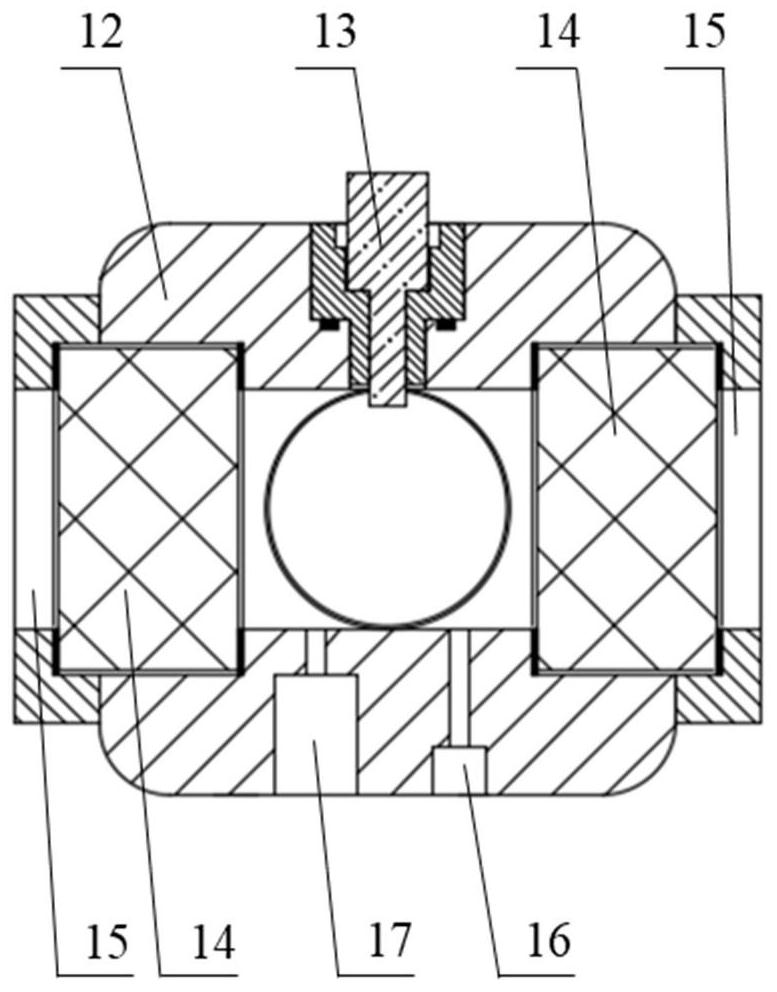

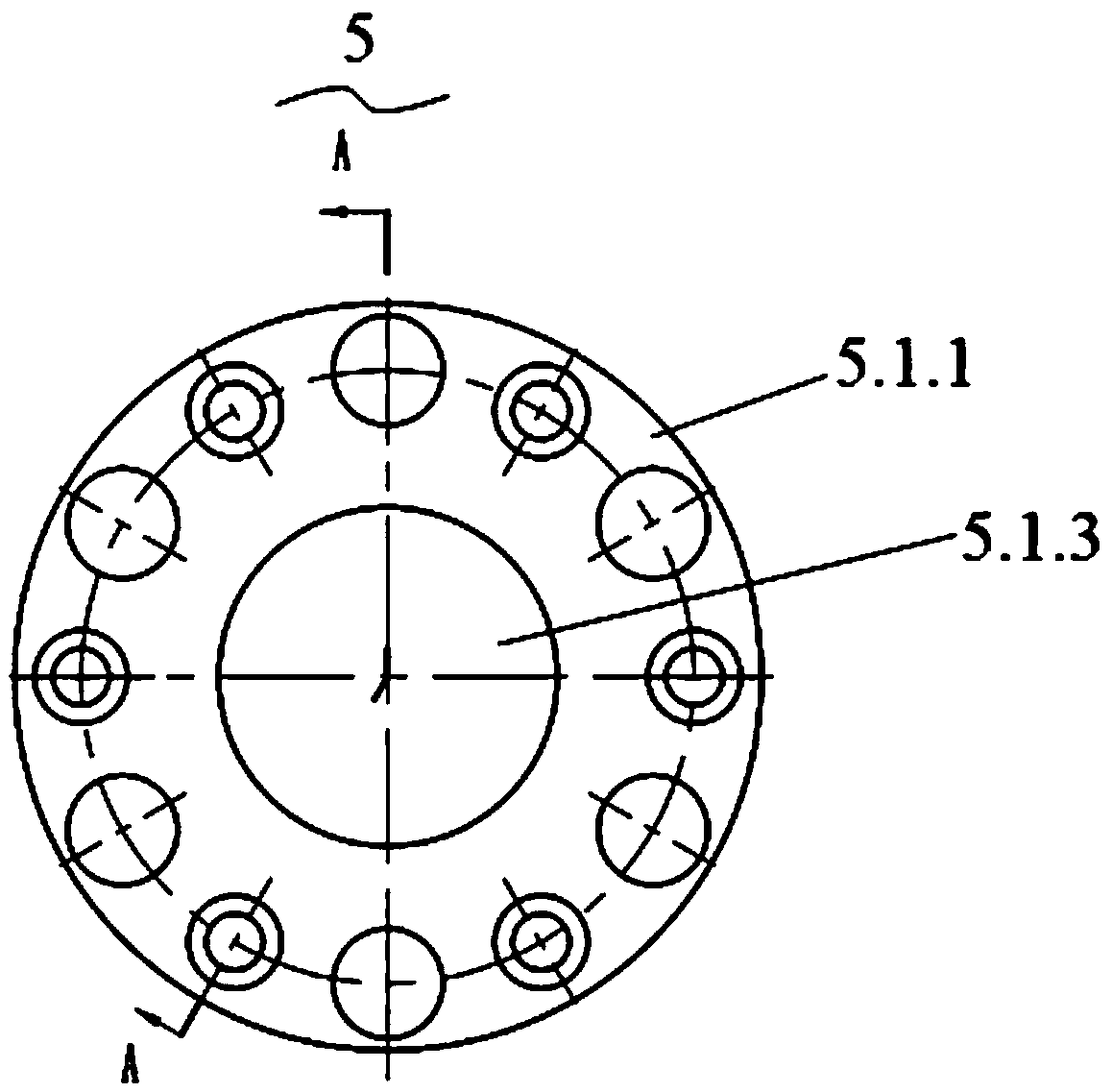

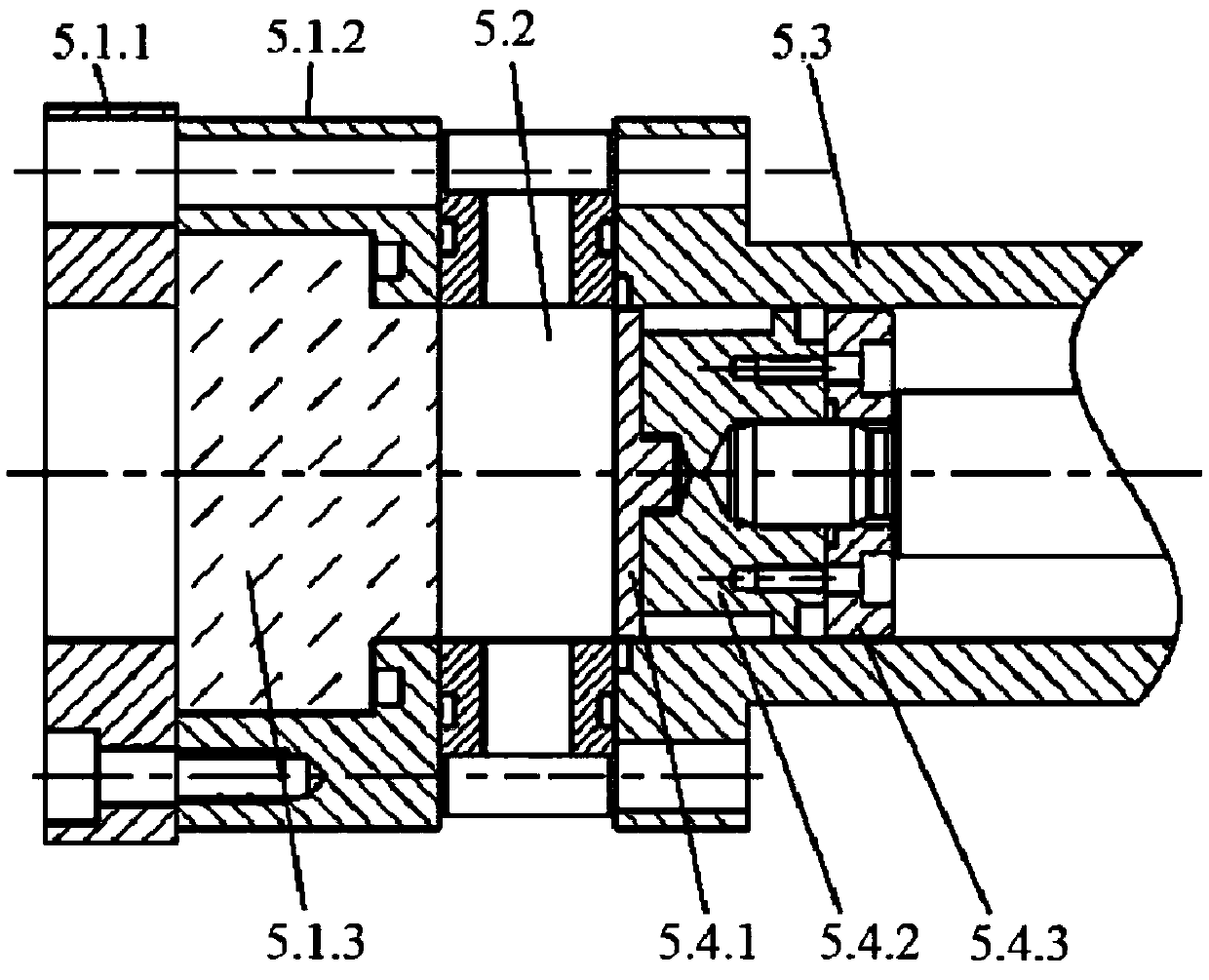

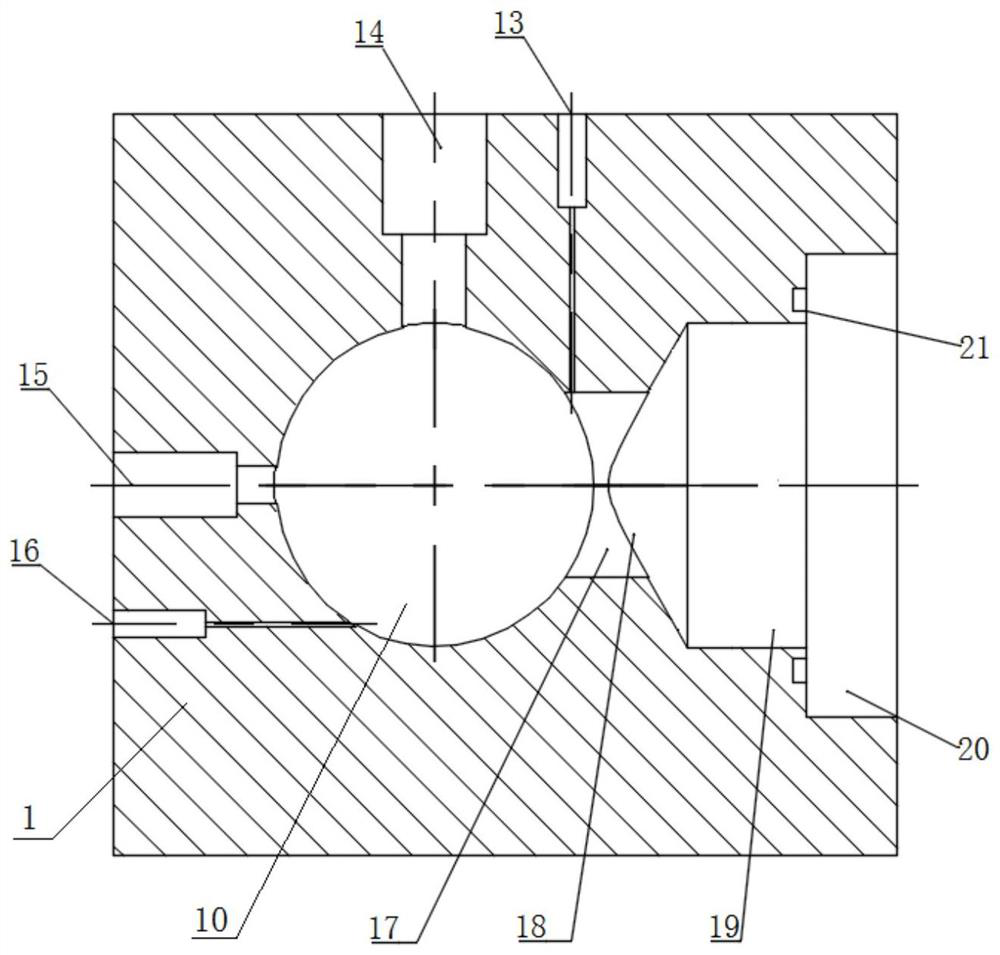

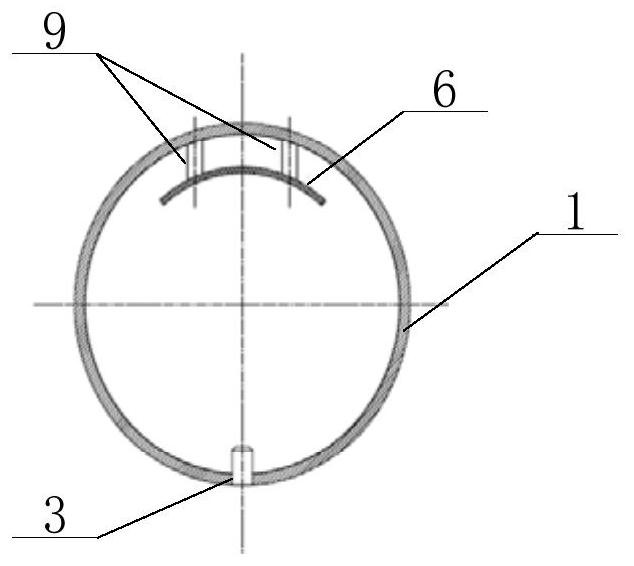

Optical rapid compression machine combustion cylinder capable of realizing shooting by schlieren method

ActiveCN108060972AMeet the layout requirementsRealize full visual shootingInternal-combustion engine testingInternal combustion piston enginesCombustion chamberEngineering

The invention discloses an optical rapid compression machine combustion cylinder capable of realizing shooting by a schlieren method. A combustion chamber cavity penetrates through the front end faceand the rear end face of a combustion cylinder body; the front end and the rear end of the combustion chamber cavity are respectively provided with window locating cavities; the left end face of the combustion cylinder body is provided with a cylinder pressure sensor mounting hole and a vent hole, the upper surface of the combustion cylinder body is provided with a sparking plug mounting hole andan air inlet, and the right end face of the combustion cylinder body is provided with a combustion cylinder locating cavity; a rectangular channel, a tapered transition section, and a compression section are sequentially arranged between the combustion cylinder locating cavity and the combustion chamber body from left to right; the front end and the rear end of the combustion chamber body are provided with silica glass, and the silica glass is fixed through glass baffles; a combustion chamber is reserved between the two pieces of silica glass; the combustion chamber communicates with the cylinder pressure sensor mounting hole, the vent hole, the rectangular channel, and the sparking plug mounting hole, and the rectangular channel communicates with the air inlet. The optical rapid compression machine combustion cylinder capable of realizing shooting by the schlieren method mainly changes the direction of the combustion chamber axis, so that the combustion chamber axis is perpendicular to the movement direction of a piston, and the requirements of the optical arrangement of the schlieren method are met.

Owner:TIANJIN UNIV

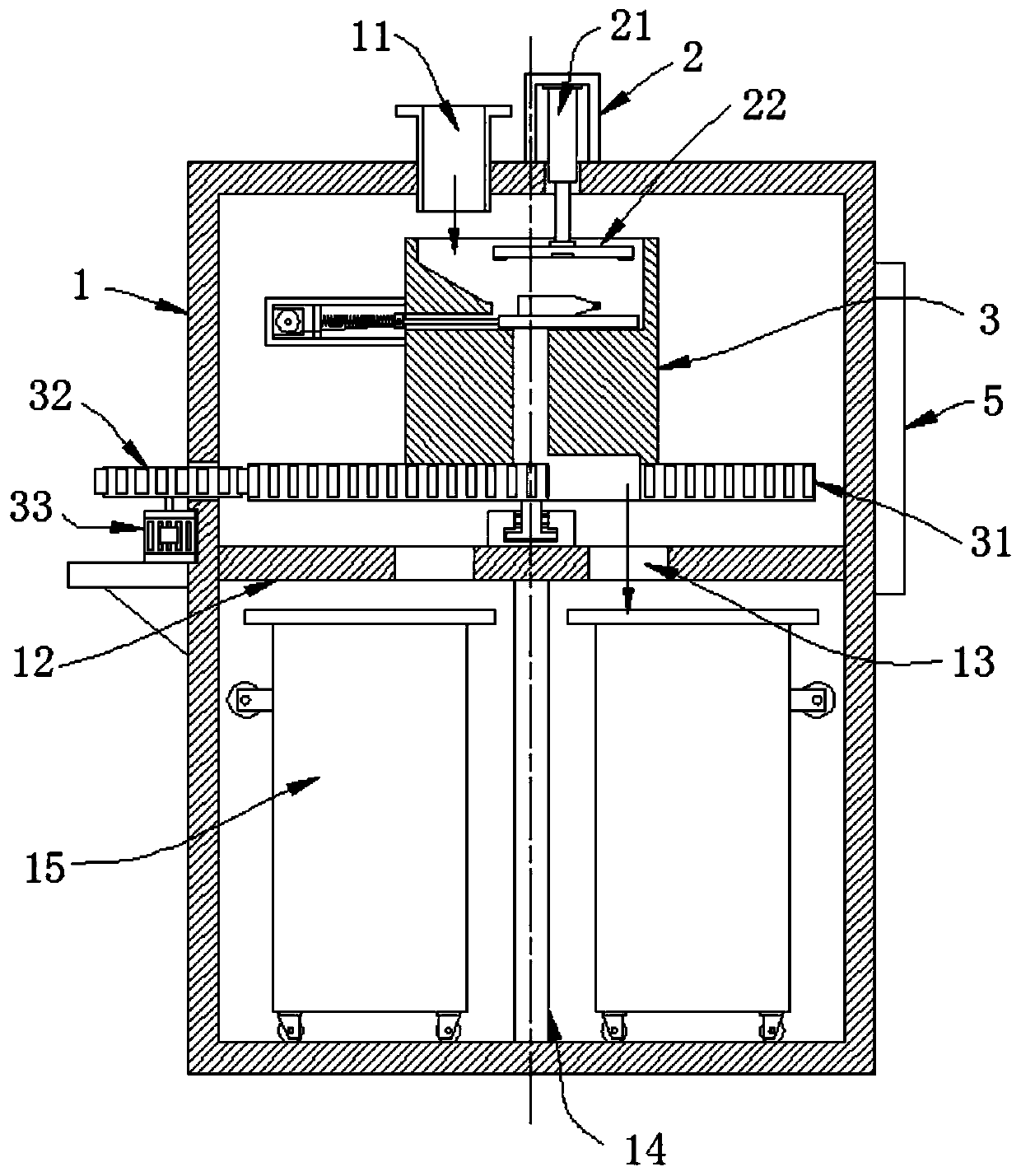

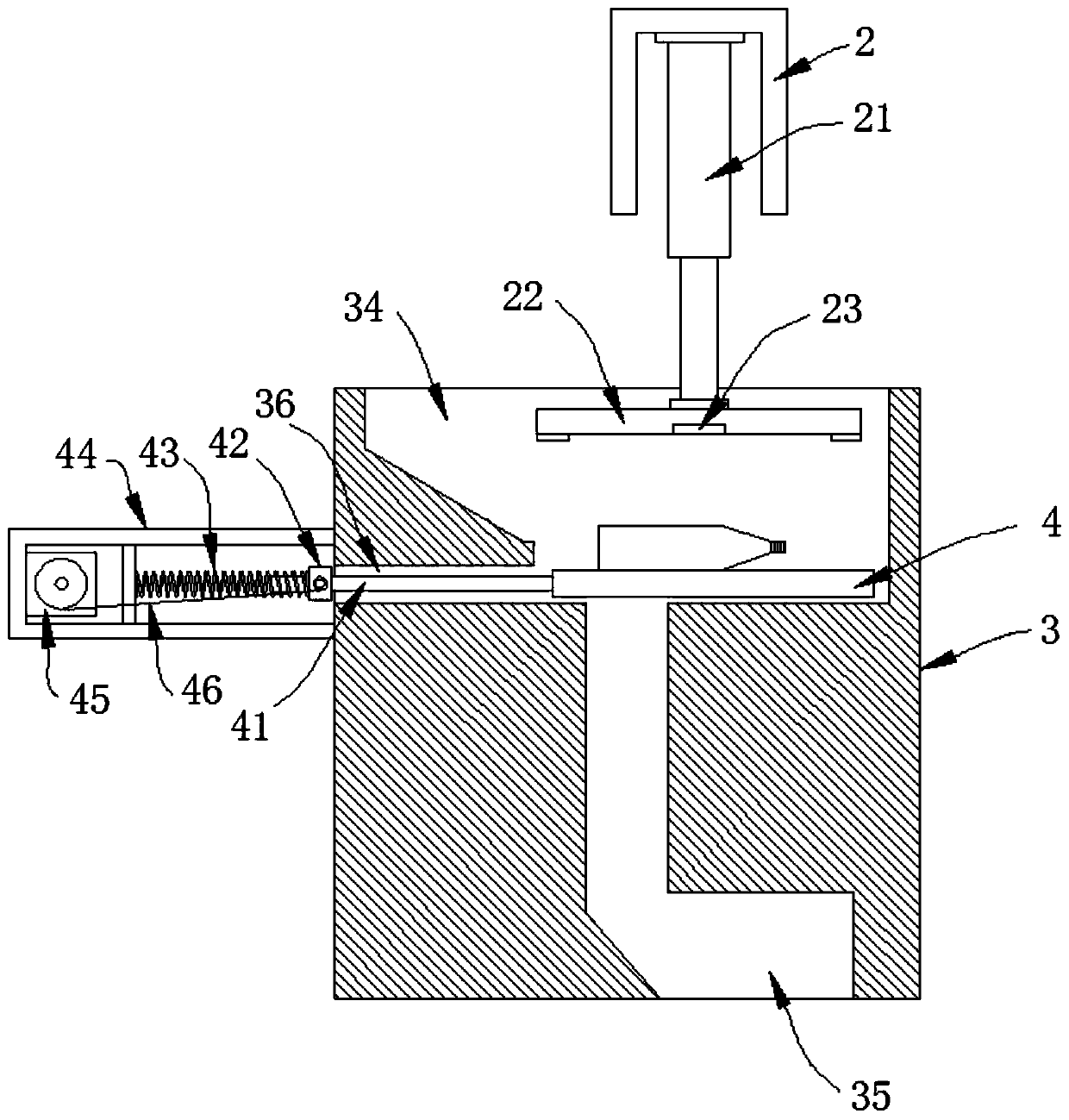

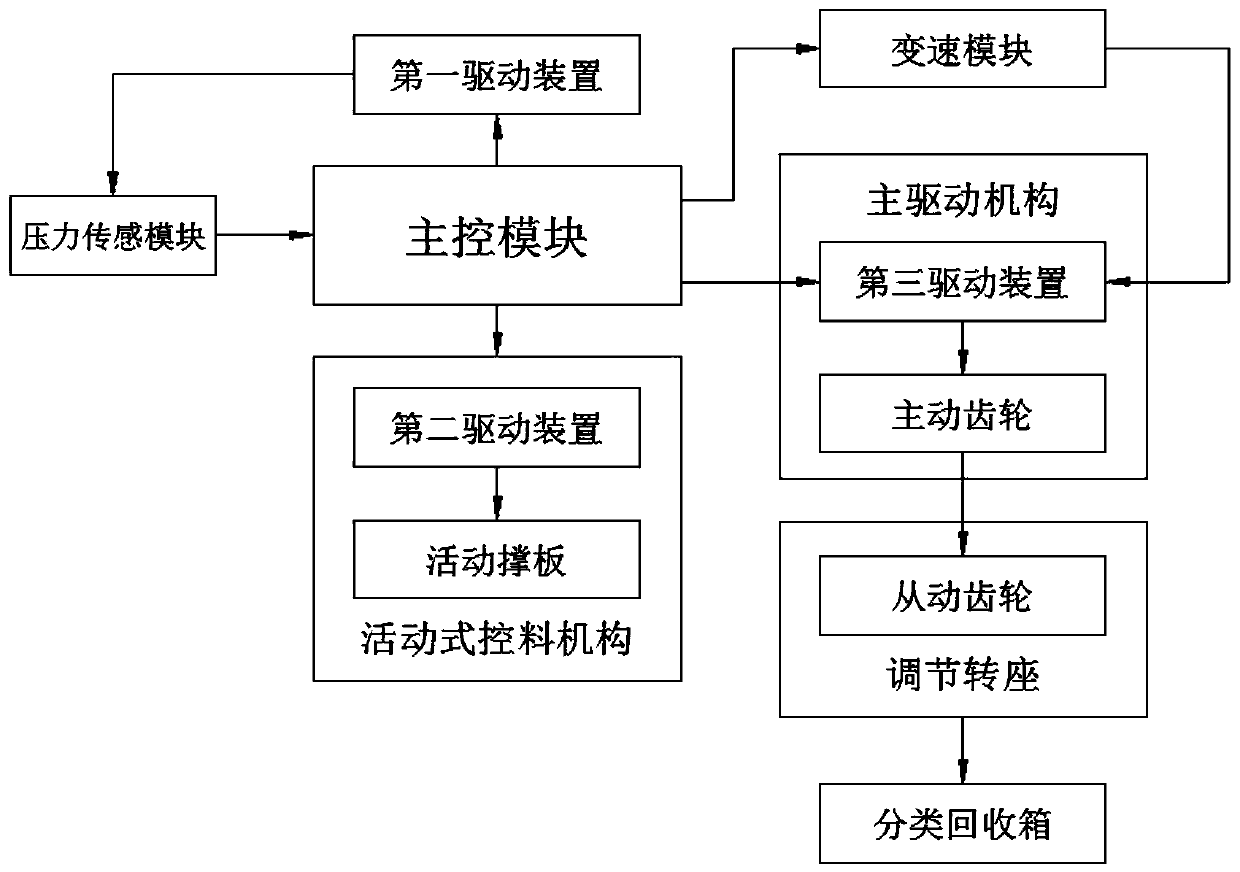

Automatic recycling and classifying device for beverage bottles and cans

ActiveCN109733763AFlexible and convenient discharge controlEasy dischargeRefuse receptaclesEngineeringBottle

The invention relates to the technical field of waste recycling, in particular to an automatic recycling and classifying device for beverage bottles and cans, and solves the technical problems that inthe prior art, the beverage bottles and cans are manually recycled, which is complex in recovery process and low in efficiency, and the beverage bottles and cans cannot be automatically classified. The automatic recycling and classifying device for the beverage bottles and cans comprises a device body, and further comprises an adjusting rotating seat which is arranged in the device body, a rapidcompression mechanism for pressing the beverage bottles and cans is arranged above the adjusting rotating seat, a movable material control mechanism is arranged inside the adjusting rotating seat, oneside of the adjusting rotating seat is provided with a main driving mechanism which is used for driving the adjusting rotating seat to do variable-speed circular motion, and the beverage bottles andcans are matched with the movable material control mechanism to complete compression moulding inside the adjusting rotating seat and then are automatically classified and recycled according the compressive strength of the beverage bottles and cans and under the action of the main driving mechanism. The an automatic recycling and classifying device for the beverage bottles and cans is ingenious indesign, and the beverage bottles and cans can be automatically recycled without workers, so that time and labor are saved, automatic classification is realized, and recovery efficiency of the beveragebottles and cans is effectively improved, which all make the eautomatic recycling and classifying device for the beverage bottles and cans be worthy of popularization.

Owner:XINCHANG COUNTY TAIRU TECH CO LTD

Staging active cooling start-up

ActiveUS9534822B2Shortens time to operationFast equalizationRefrigeration safety arrangementActive coolingAir conditioning

A novel process for activating available compressors in multiple compressor air conditioning systems, using an Optimum Stage-Up Process. This process is programmed into a controller as an algorithm, to provide a process for fast compressor start. This process shortens the time to initiate operation of compressors in a multi-compressor air conditioning system required to meet the demand call under any load condition, and hence shortens the time required for the actual sensed interior region air temperature to reach the interior region temperature set point. The Optimum Stage-up Algorithm estimates the number of compressor stages or steps that must be initiated, based on sensed or measured values, to meet the demand at any load condition. These measured values include the sensed temperature of the interior region being cooled, which is compared to the temperature set point of this interior region as well as measured mixed air temperature and supply air temperature.

Owner:JOHNSON CONTROLS TYCO IP HLDG LLP

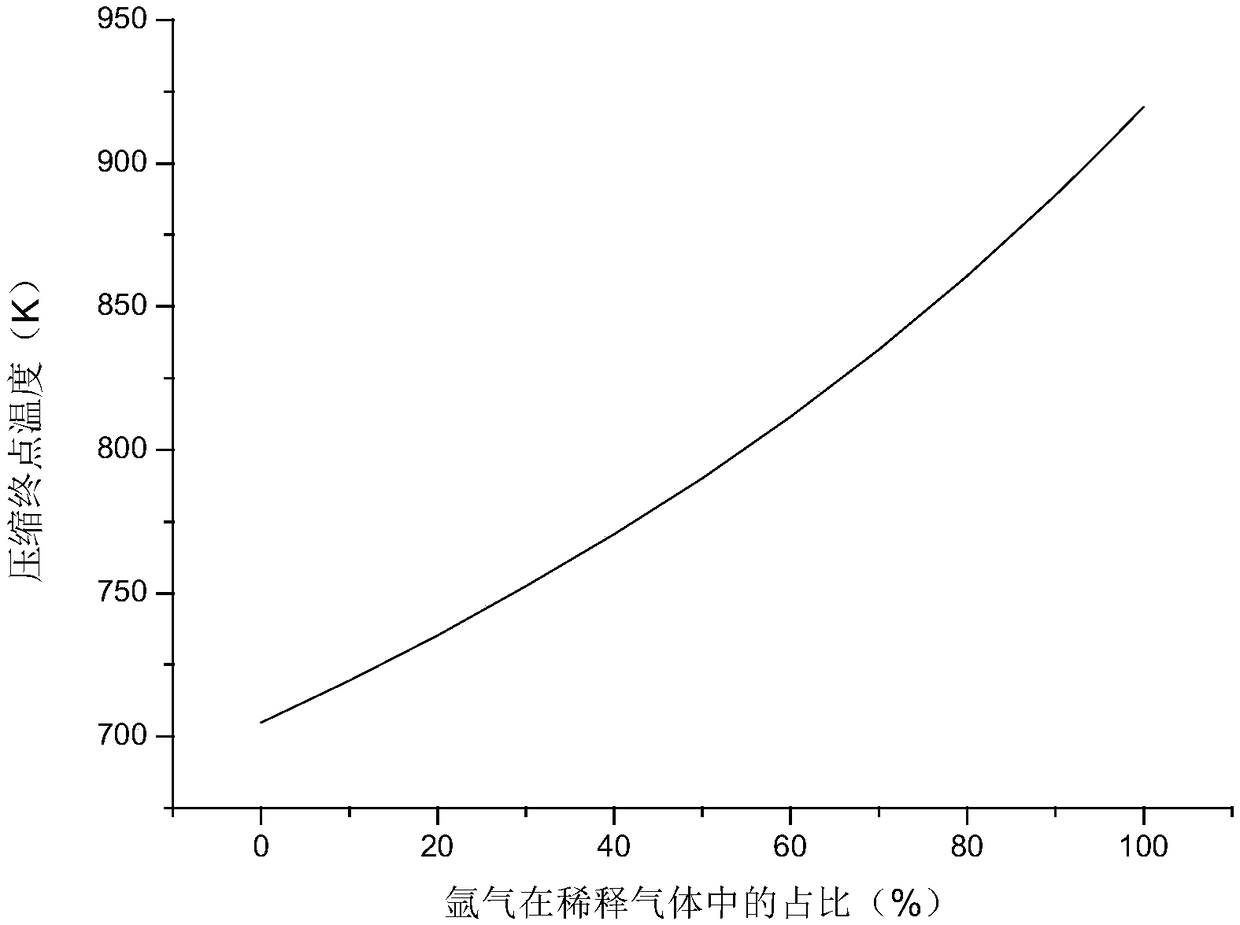

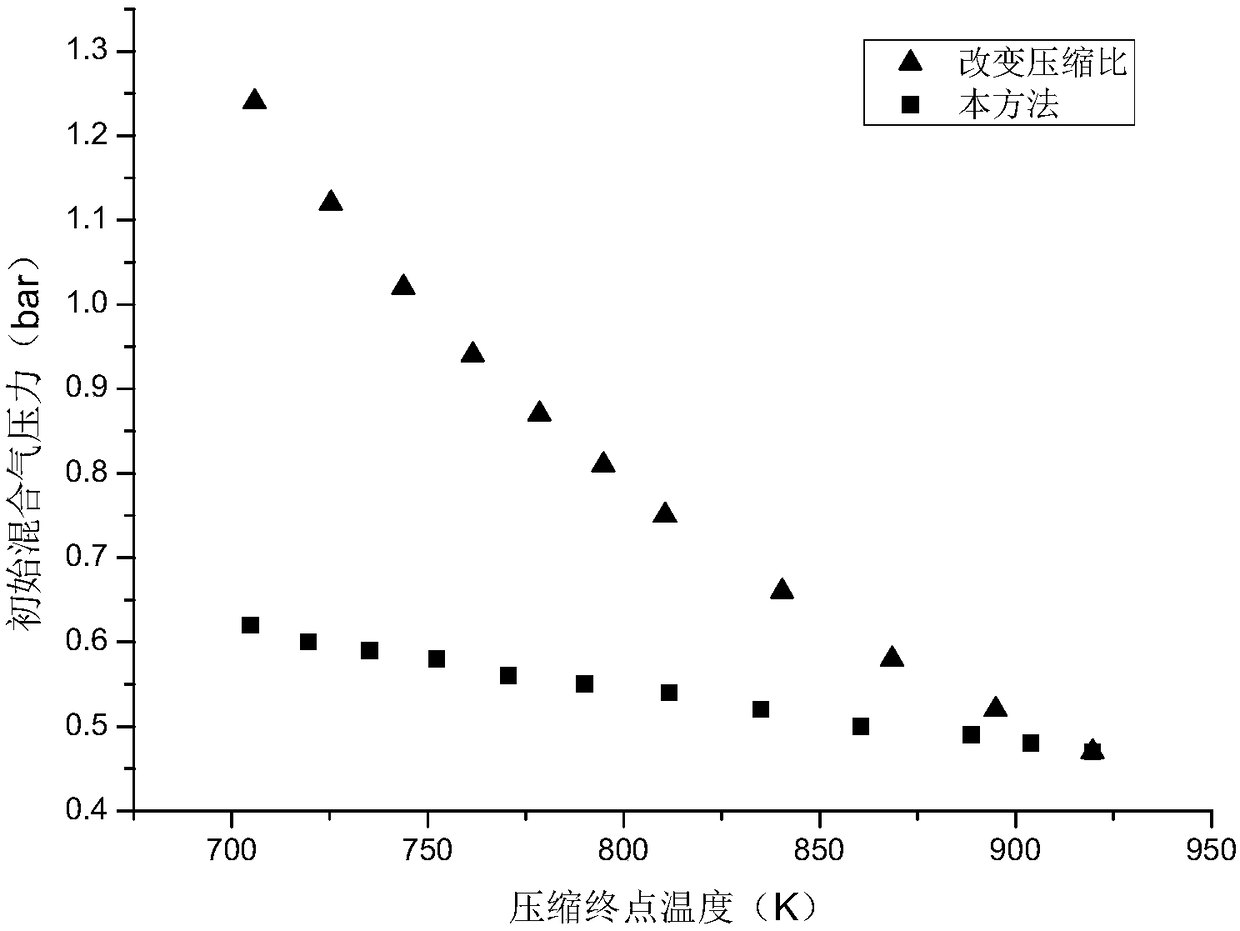

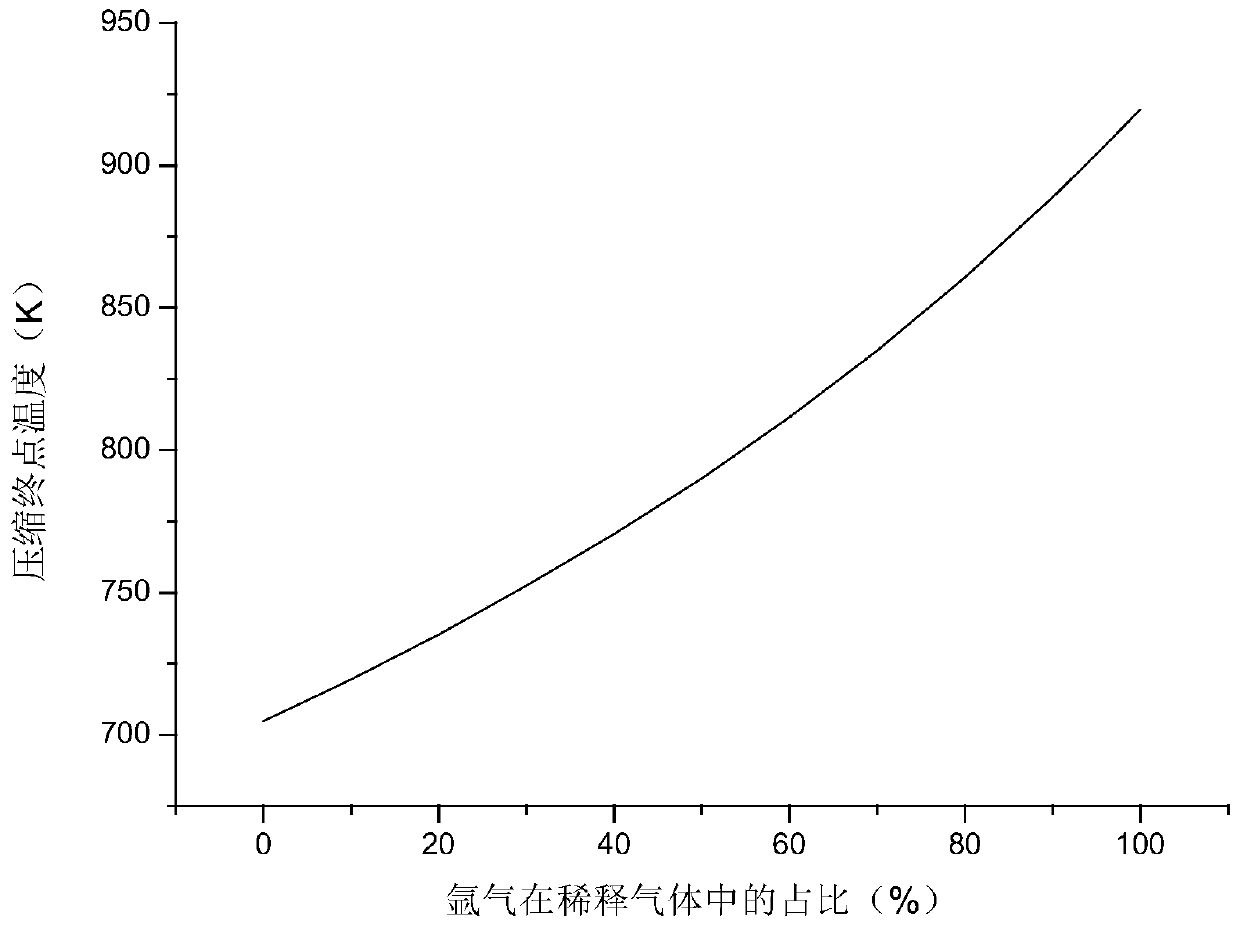

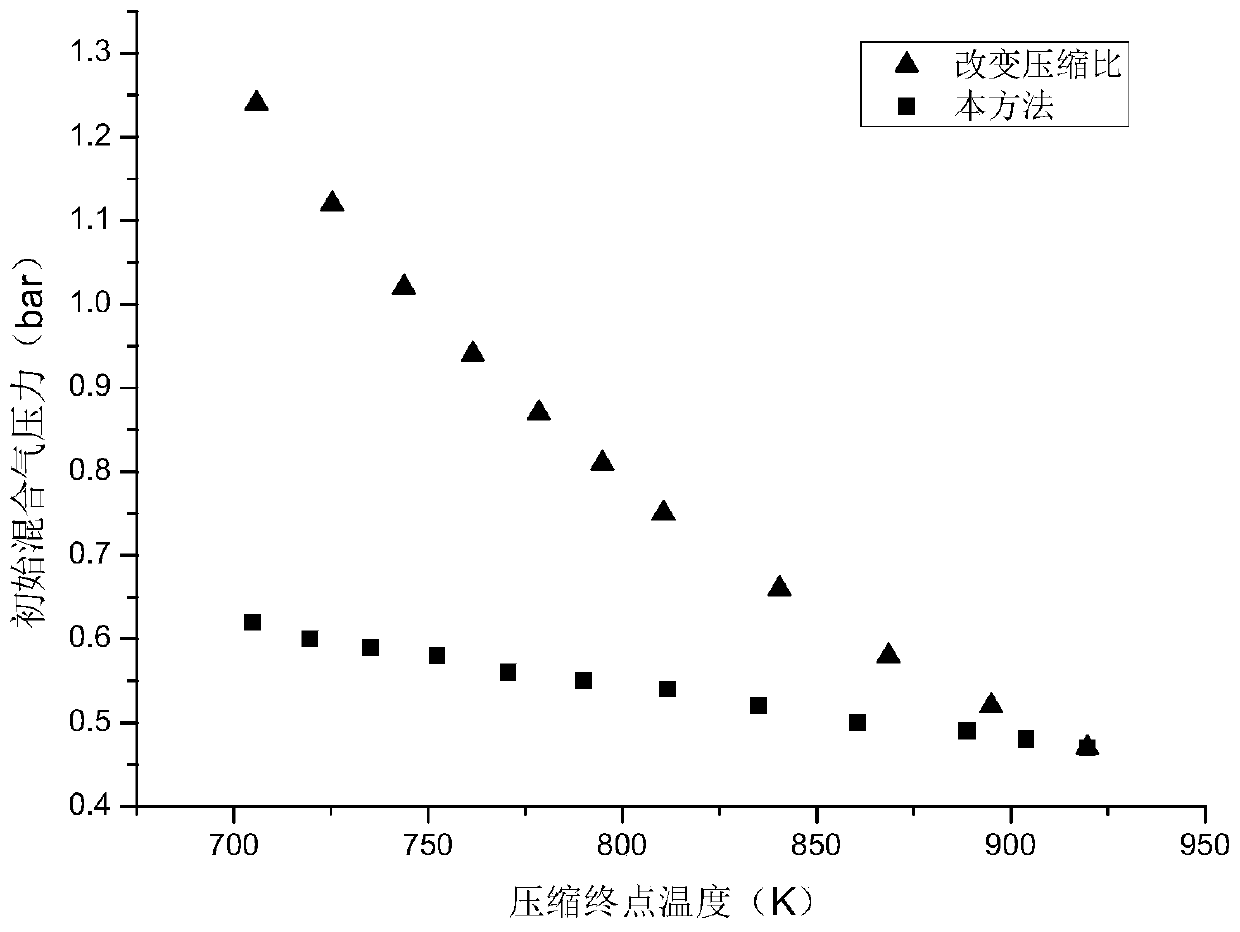

Compression end point temperature adjusting method for fast compressor in lab

ActiveCN109281826AAvoid disassemblyExtended service lifePump testingPositive-displacement liquid enginesCombustion chamberGas compressor

The invention discloses a compression end point temperature adjusting method for a fast compressor in a lab. The method comprises the following steps that 1 ) determining the components of combustiblemixed gas in an experiment of the fast compressor; 2 ) determining the total pressure of the combustible mixed gas in a combustion chamber to be P, and calculating the corresponding partial pressurePi = P * Xi according to volume fraction of each gas; 3 ) after evacuating a gas mixing tank, filling the gas sequentially according to the corresponding gas partial pressure to complete the configuration of the combustible gas mixture; 4 ) compressing the combustible mixed gas for one step, and recording the pressure change in the combustion chamber ; 5 ) calculating is carried out according to an ideal gas heat insulation formula to obtain the compression end point temperature Tc of the experiment; and 6 ) replacing a part of argon in diluent gas with nitrogen, repeating the steps 3 )-5 ), and obtaining a compression end point temperature which is lower than the first time. According to the method, under the condition that the structure of an existing experimental device is not changed,the compression end point temperature is changed by changing the diluent gas component in the mixed gas, so that the experimental working condition range is effectively widened.

Owner:永春县产品质量检验所福建省香产品质量检验中心国家燃香类产品质量监督检验中心福建

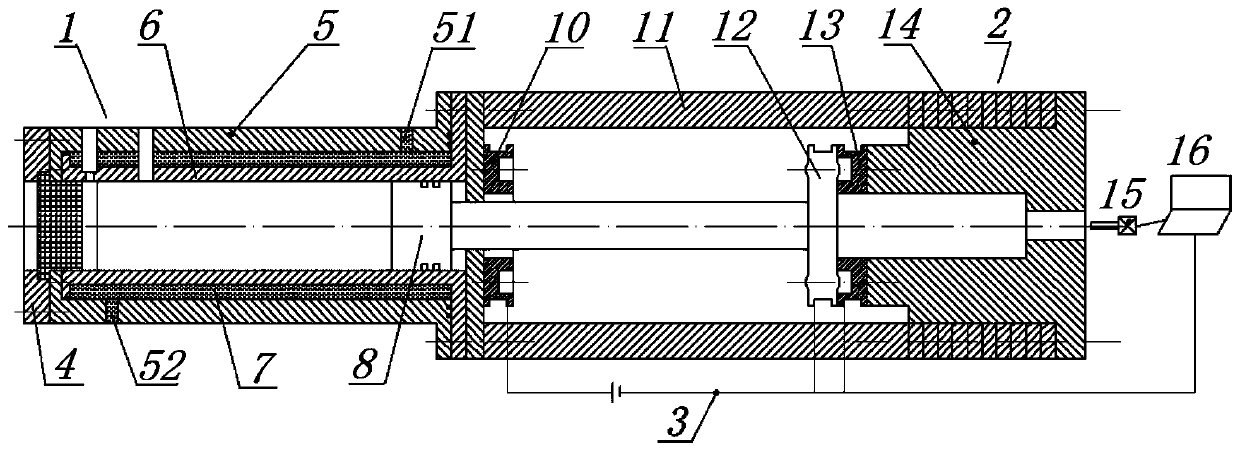

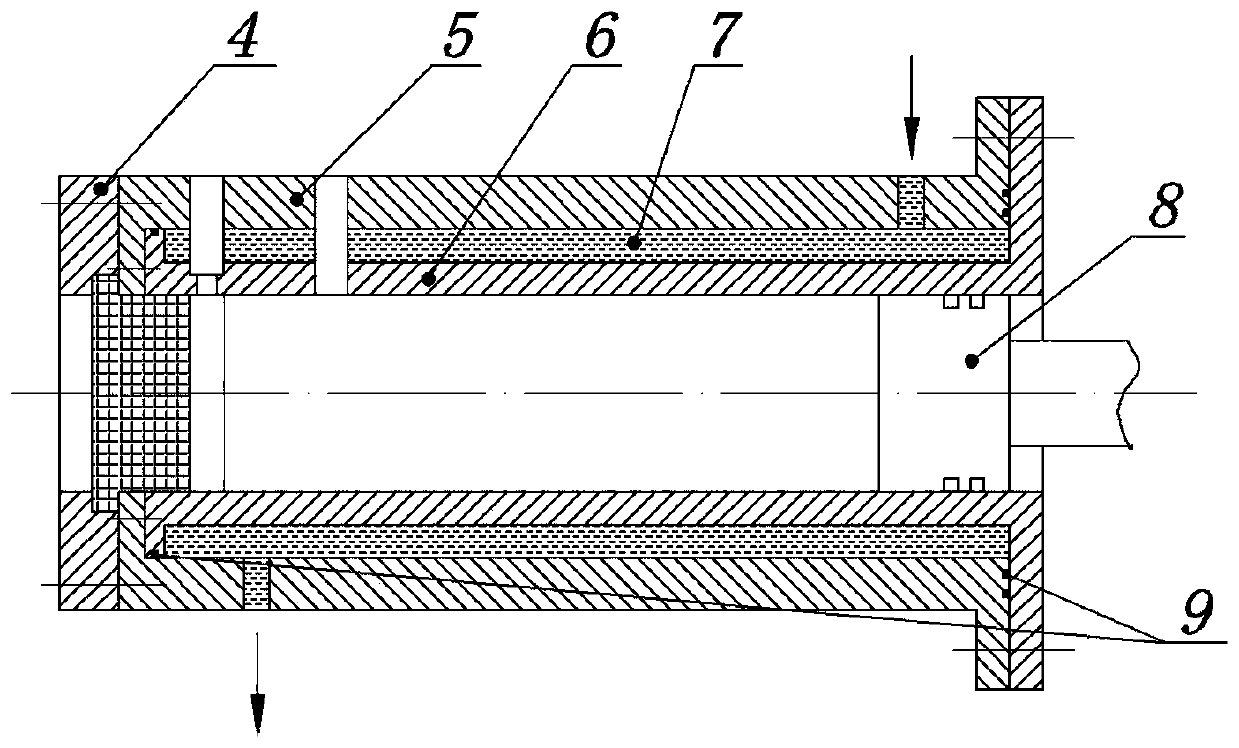

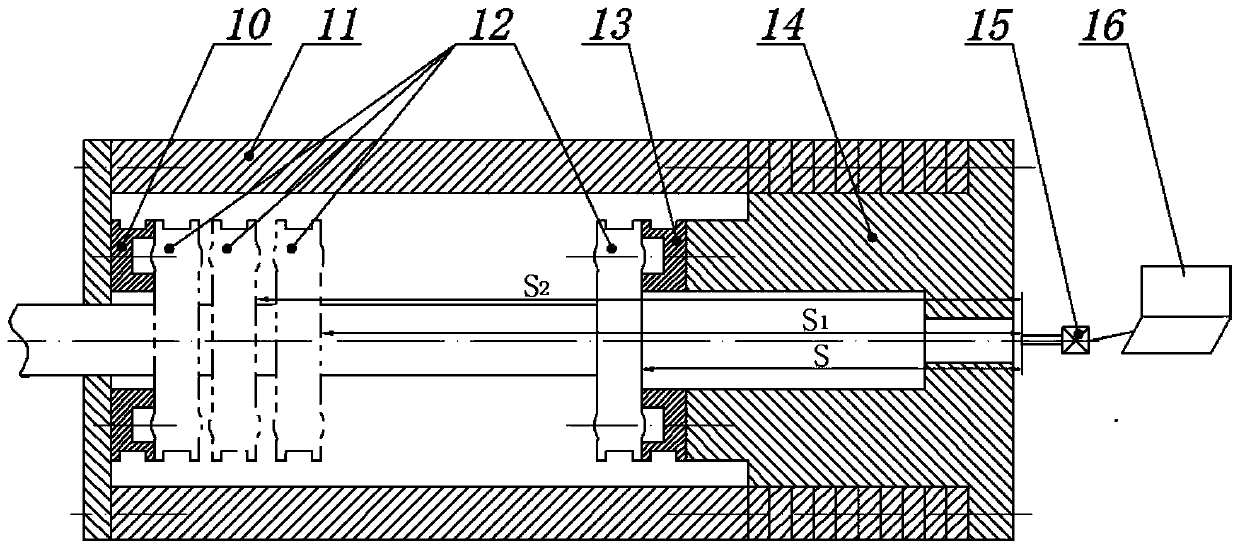

Rapid compression/compression expansion machine combustion performance test bench of internal combustion engine

ActiveCN110726559ASimple structureReduce complexityInternal-combustion engine testingControl systemElectric machinery

The invention relates to a rapid compression / compression expansion machine combustion performance test bench of an internal combustion engine, and belongs to the field of internal combustion engine test. The rapid compression / compression expansion machine combustion performance test bench comprises a rapid compressor and an air supply system. A linear motor is used as a power source, a piston is pushed to move, and the structure of the rapid compressor is greatly simplified; by changing a linear motor control strategy, the rapid compressor can work under two modes of rapid compressor (constant-volume combustion) and rapid compression expansion machine (free expansion), and the device is high in applicability; and the rapid compression / compression expansion machine combustion performance test bench has the advantages of adjustable compression-ratio characteristic, multi-fuel applicability and speed variability. By the rapid compression / compression expansion machine combustion performance test bench of the internal combustion engine, the bench structure is simplified, the integral volume is reduced, the complexity of the control system is reduced, and the applicability and the reliability of the internal combustion engine test bench are improved.

Owner:BEIJING INSTITUTE OF TECHNOLOGYGY

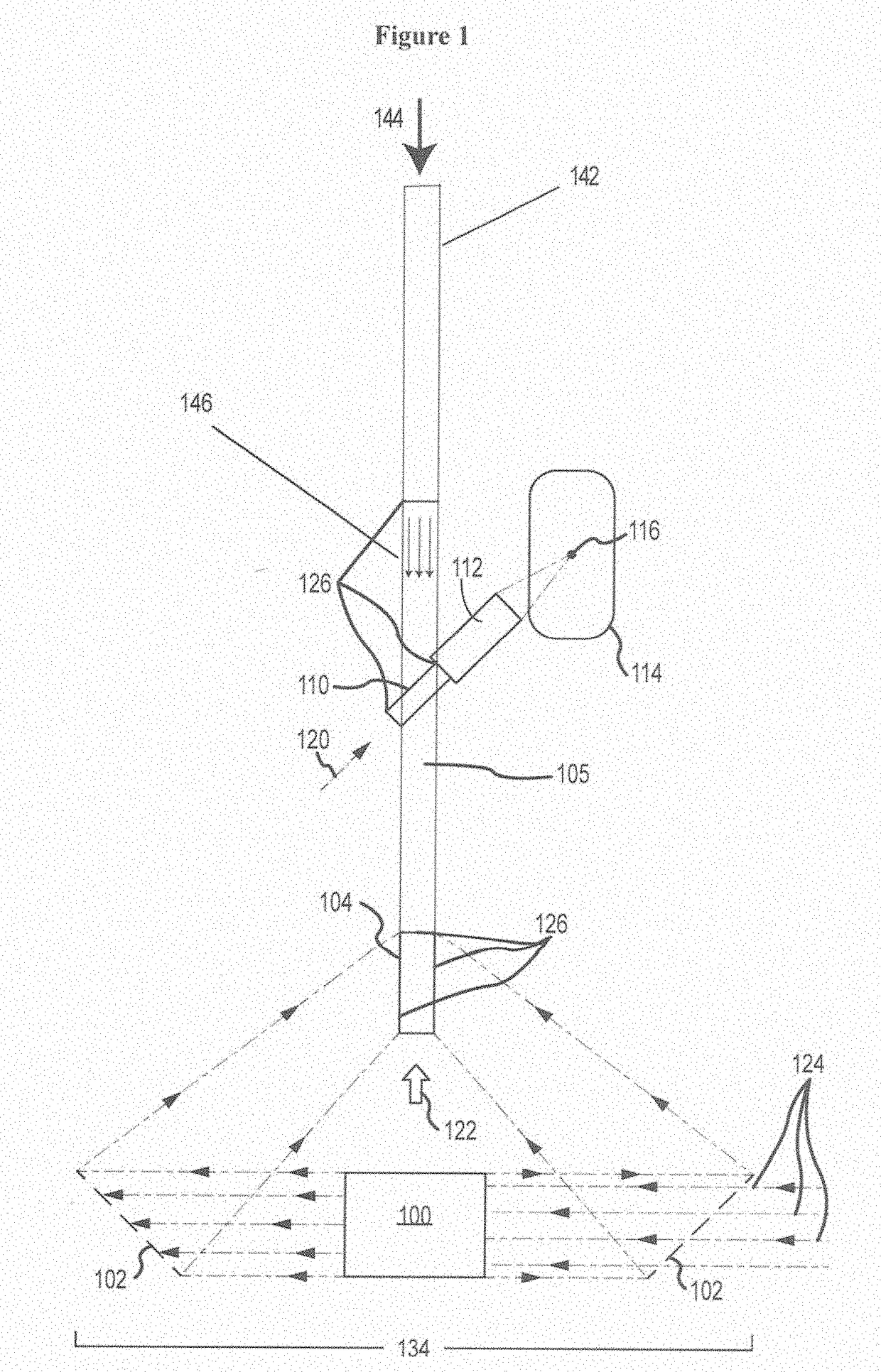

Integration of Direct Compressor with Primary Laser Source and Fast Compressor

ActiveUS20180191120A1High temporal compression ratioLow costNuclear energy generationLaser arrangementsMultiplexingGas compressor

The present architecture utilizes a Nonlinear Scattering Aperture Combiner that does not need to be optically multiplexed and then drives a Direct Compressor stage that produces a large temporal compression ratio to pump a Fast Compressor. This eliminates the need for a separate array of ATDMs, multiplexing optical elements, and, at the approximate 107 joule energy output required for ICF, reduces the number of mechanical elements and gas interfaces from the order of 103 to about 10. In addition, this provides a large reduction of the volume of the gas containment region. In order to accomplish this, a technique for transversely segmenting by color and / or polarization of the optical extraction beams of the Direct Compressor has been invented. In particular, it is directed towards the integration of the Direct Compressor with the Primary Laser Source and Fast Compressor. The embodiments describe how the high operating fluence are addressed in terms of avoiding optical damage and how to integrate the stages in fluid mechanical and optical aspects.

Owner:INNOVEN ENERGY

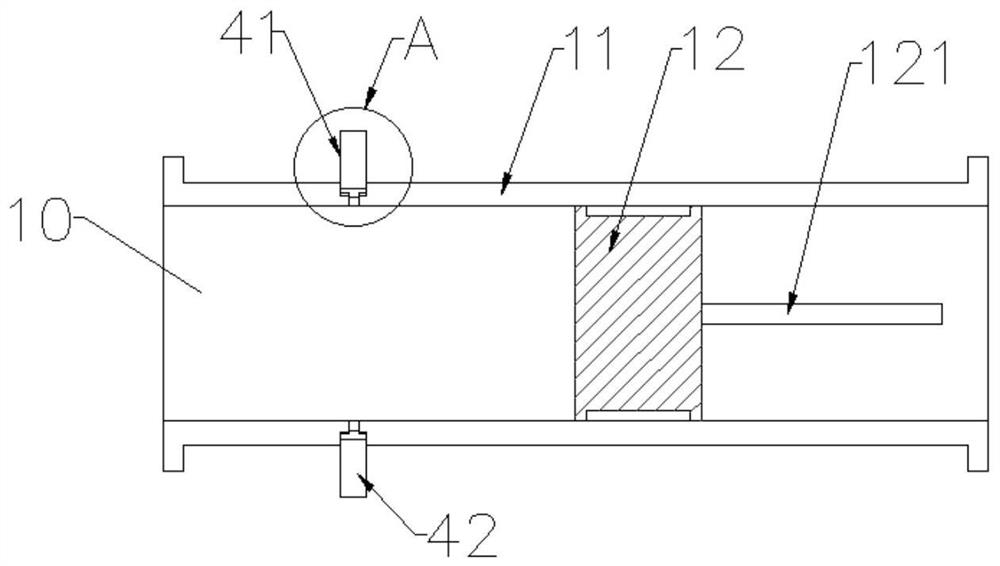

Experimental device for simulating evaporation and combustion of liquid drops of engine under high-temperature and high-pressure conditions

PendingCN114047287AThe experimental data is accurateInternal-combustion engine testingChemical analysis using combustionMicro imagingSpontaneous combustion

The invention discloses an experimental device for simulating evaporation and combustion of liquid drops of an engine under high-temperature and high-pressure conditions. The experimental device comprises a high-temperature and high-pressure visual rapid compressor experimental system, an oil sprayer liquid drop generation system, a signal generation and acquisition system and a microscopic imaging system. According to the high-temperature and high-pressure visual rapid compressor experiment system, hydraulic braking is driven by air pressure, a piston connecting rod mechanism is driven by compressed air to rapidly compress gas in a cylinder, and a uniform high-temperature and high-pressure environment is formed in a visual combustion chamber; the signal generation and acquisition system is used for controlling a quick compressor to act and giving a high-speed camera trigger signal and a combustion chamber dynamic pressure acquisition signal of the microscopic imaging system; the oil sprayer liquid drop generation system is used for supplying a certain number of submillimeter discrete liquid drops to the combustion chamber; and the microscopic imaging system is used for obtaining liquid drop process image information in the visual combustion chamber. The device is beneficial to research on evaporation characteristics and spontaneous combustion characteristics of liquid drops and establishment of a numerical model under high-temperature and high-pressure conditions.

Owner:XI AN JIAOTONG UNIV

Electromagnetic braking system for rapid compressor

The invention relates to an electromagnetic braking system for a rapid compressor. The electromagnetic braking system comprises a central control unit, a braking cylinder made of a magnetic separationmaterial, a pushing rod penetrating through the braking cylinder, an electromagnetic braking circular ring fixed to the braking cylinder, an electromagnetic braking piston fixed to the pushing rod, afirst light shading plate, a second shading plate, a photoelectric sensor and an electromagnetic braking control circuit, wherein the first light shading plate and the second shading plate are fixedto the pushing rod, and the photoelectric sensor is fixed nearby the pushing rod. Circumferentially-wound electromagnetic coils are embedded on the electromagnetic braking circular ring and the electromagnetic braking piston correspondingly; the two light shading plates are fixed to the corresponding positions on the pushing rod when baking needs to be started and needs to be completed, the distance between the two light shading plates is equal to the braking distance l, and the photoelectric sensor is arranged at the first light shading plate when braking is started; and the photoelectric sensor sends detection signals on the two light shading plates into the central control unit.

Owner:TIANJIN UNIV

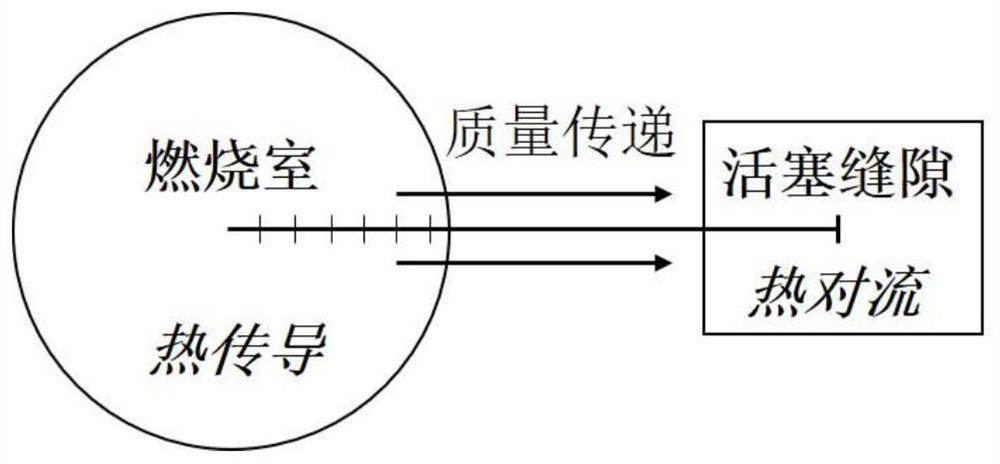

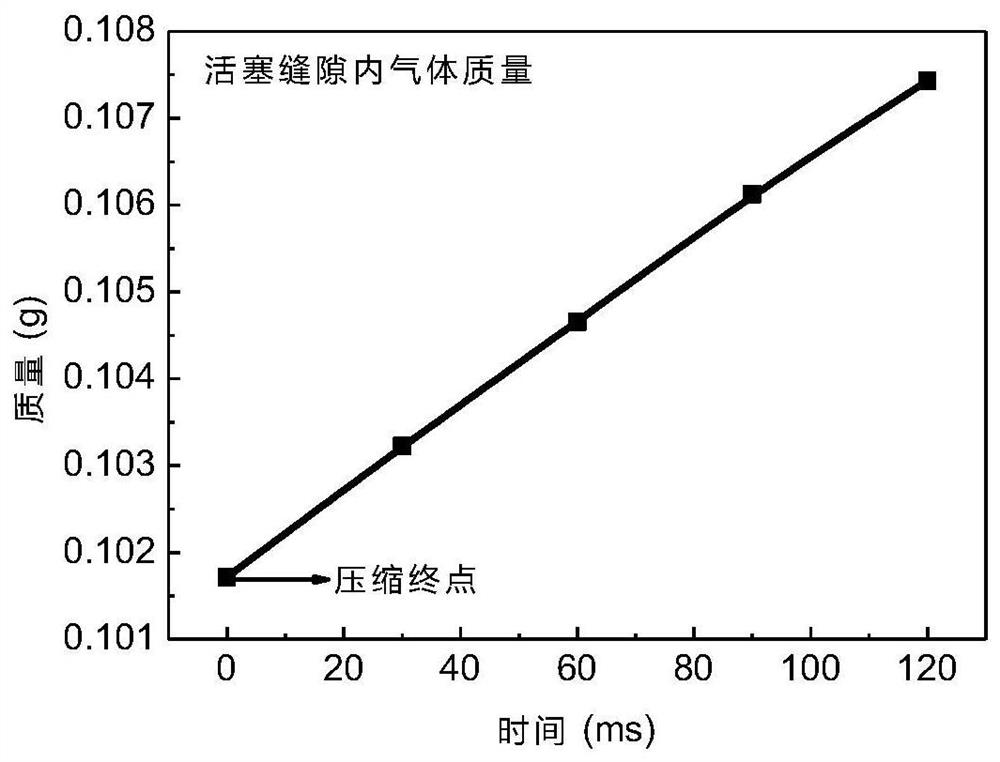

Thermal compensation method for combustion chamber of rapid compressor

ActiveCN113283080AThermal Compensation RealizedLong lastingChemical processes analysis/designDesign optimisation/simulationKineticsCombustion chamber

According to a thermal compensation method for a combustion chamber of a rapid compressor disclosed by the invention, under the condition of no thermal compensation, the heat dissipation model is used for obtaining a predicted value of a pressure decline curve caused by heat dissipation and mass transfer of the combustion chamber within a set time range, and the predicted value of the model is compared with a pressure curve measured value obtained by an experiment; model prediction and experimental measurement results are made to be the same by adjusting heat exchange coefficients, the number of calculation units and time steps of combustion chamber calculation units in the heat dissipation model, then adjusted parameters are input into the model to operate under the thermal compensation condition, and a piston motion curve needed by thermal compensation under the working condition is obtained. The piston movement speed of the rapid compressor is controlled according to the obtained piston movement speed curve, and the purpose of heat dissipating capacity compensation of a core area of a combustion chamber is achieved; according to the method, the heat loss of the combustion chamber of the rapid compressor is reduced, the maintaining time of a high-temperature and high-pressure environment is prolonged, and a more ideal thermodynamic environment is provided for research of the fuel oxidation ignition dynamics process.

Owner:XI AN JIAOTONG UNIV

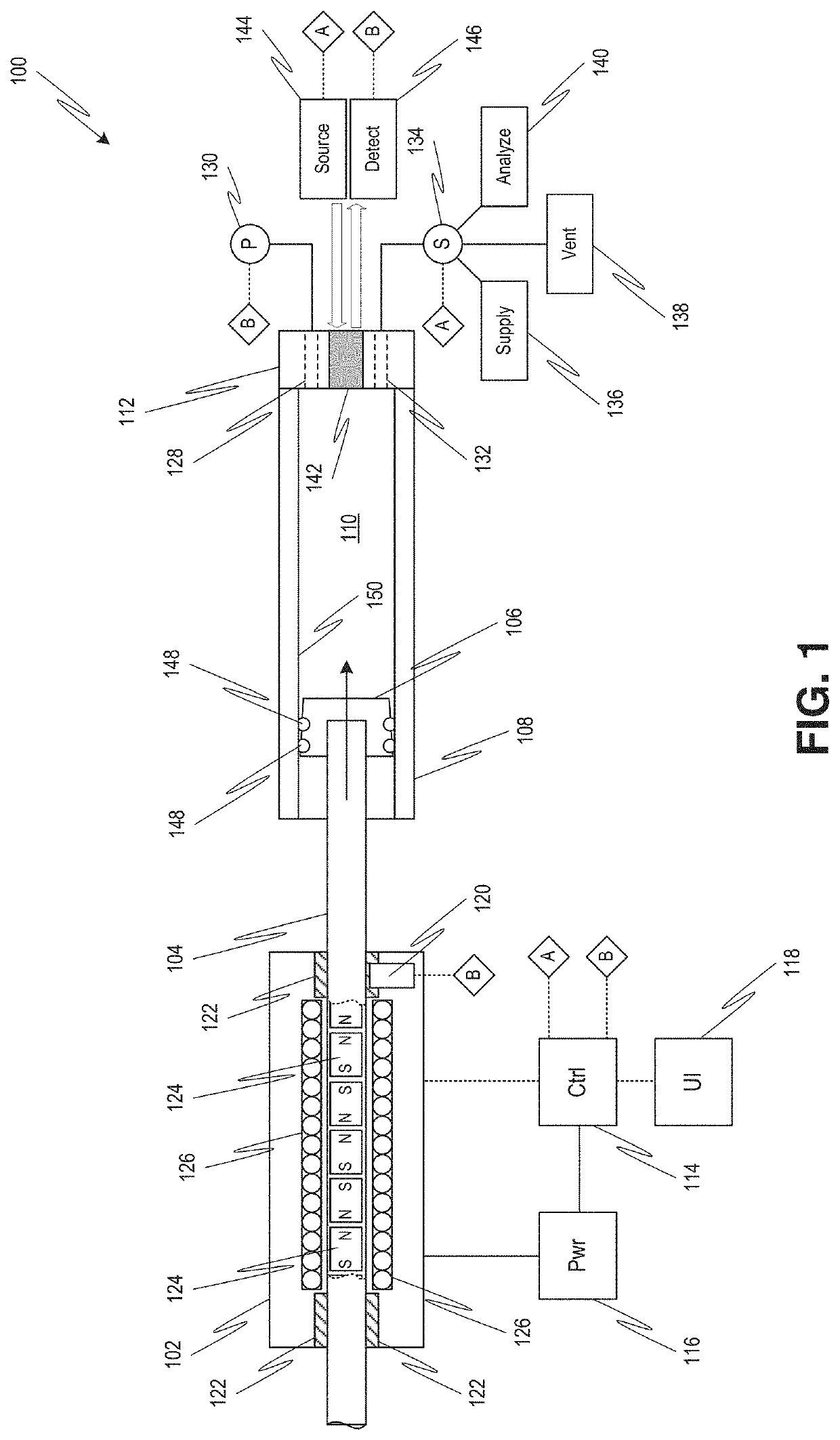

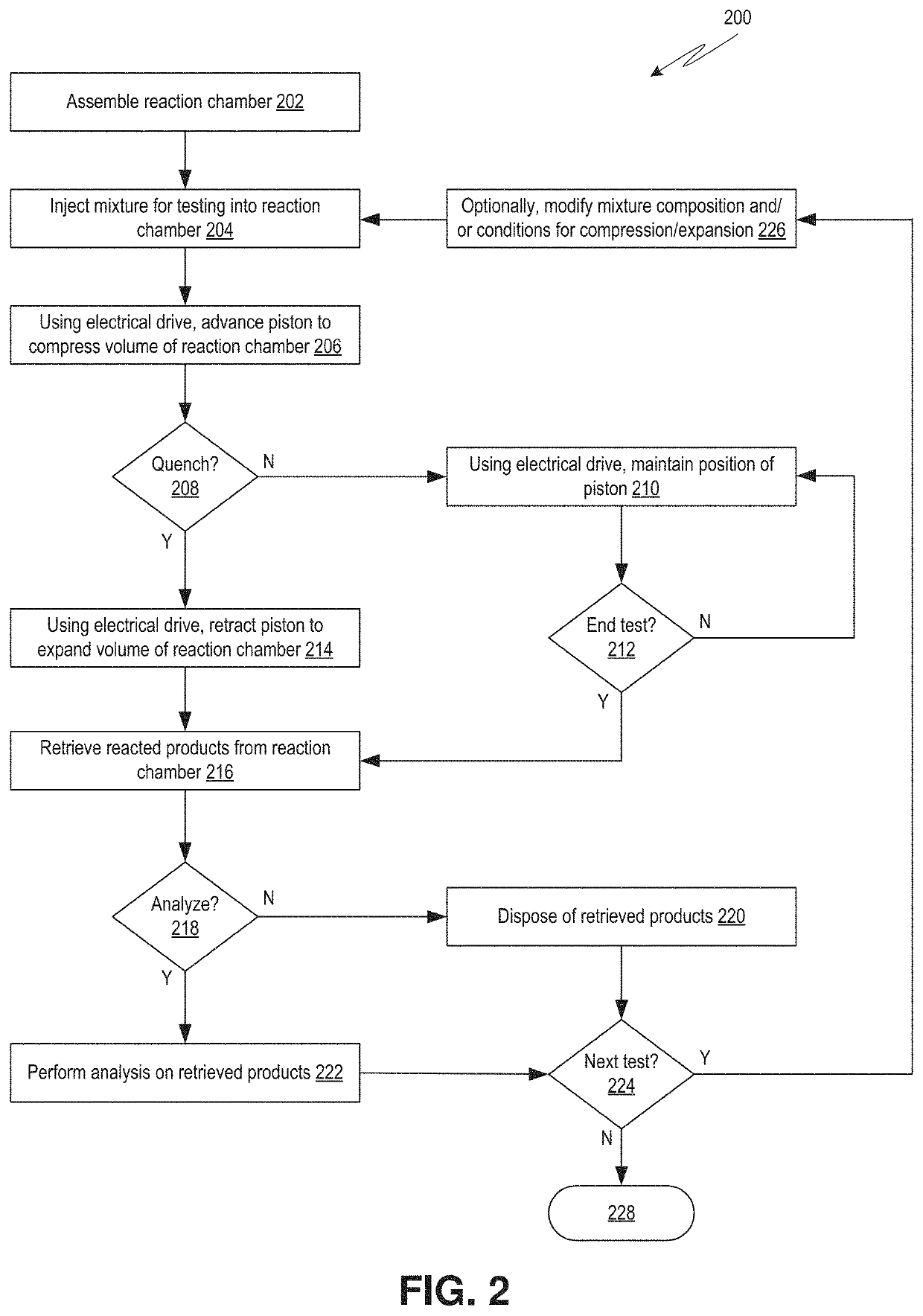

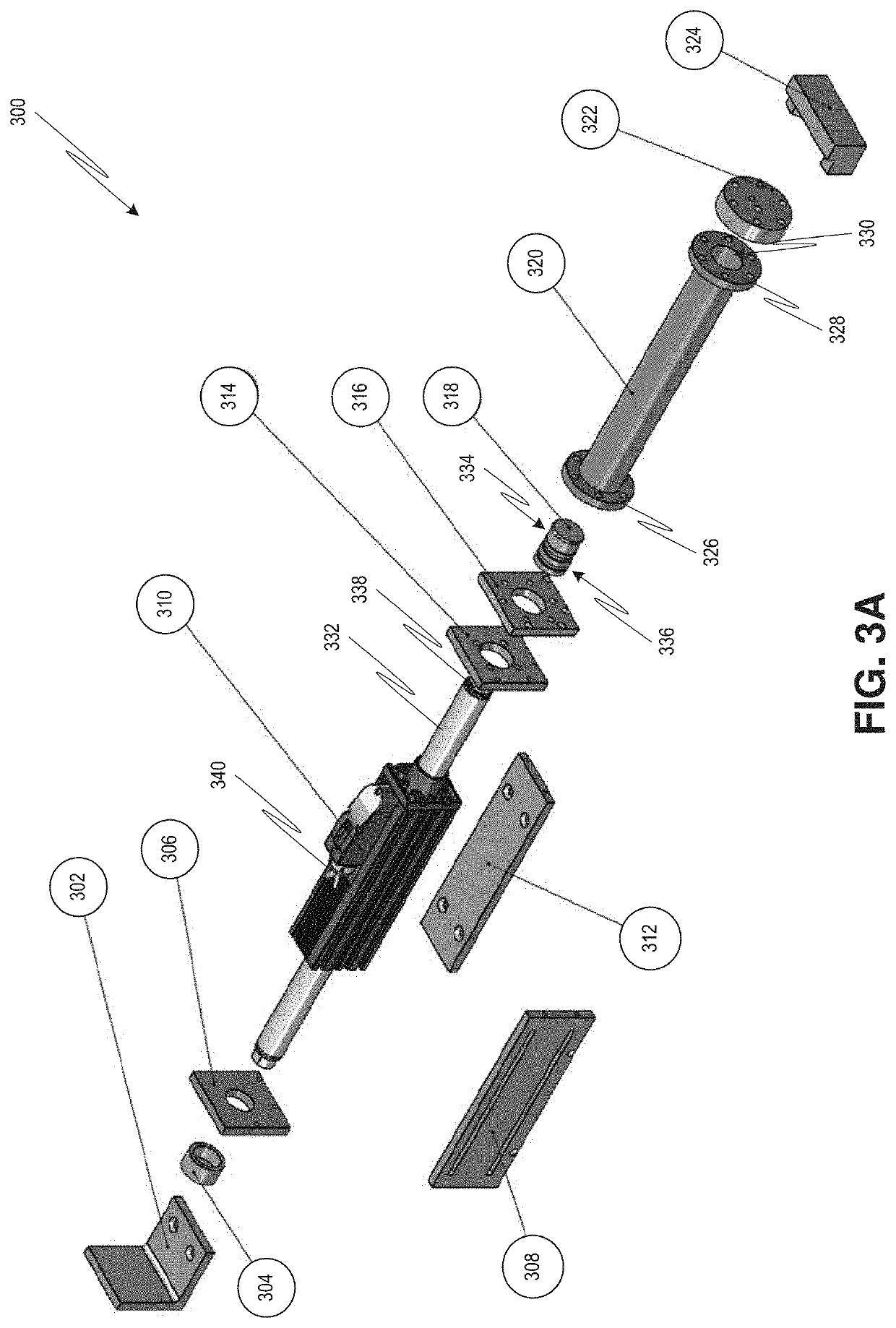

Rapid compression machine with electrical drive and methods for use thereof

PendingUS20220065752A1Increase pressureIncrease temperatureInternal-combustion engine testingLinear motionEngineering

A rapid compression machine (RCM) employs an electrical drive to move a piston disposed within a chamber housing. The electrical drive converts electrical power into linear motion of the piston, for example, to compress contents in a reaction chamber defined by the chamber housing and the piston. The temperature and pressure changes induced by the compression can cause reaction of contents within the chamber, for example, autoignition of the contents. The RCM can thus be used to study chemical kinetics. In some embodiments, the electrical drive can also rapidly move the piston in reverse to expand a volume of the reaction chamber, for example, to quench the compression-induced reaction therein. In such embodiments, the RCM may be considered a rapid compression-expansion machine (RCEM) and can be used for speciation studies.

Owner:UNIVERSITY OF IDAHO

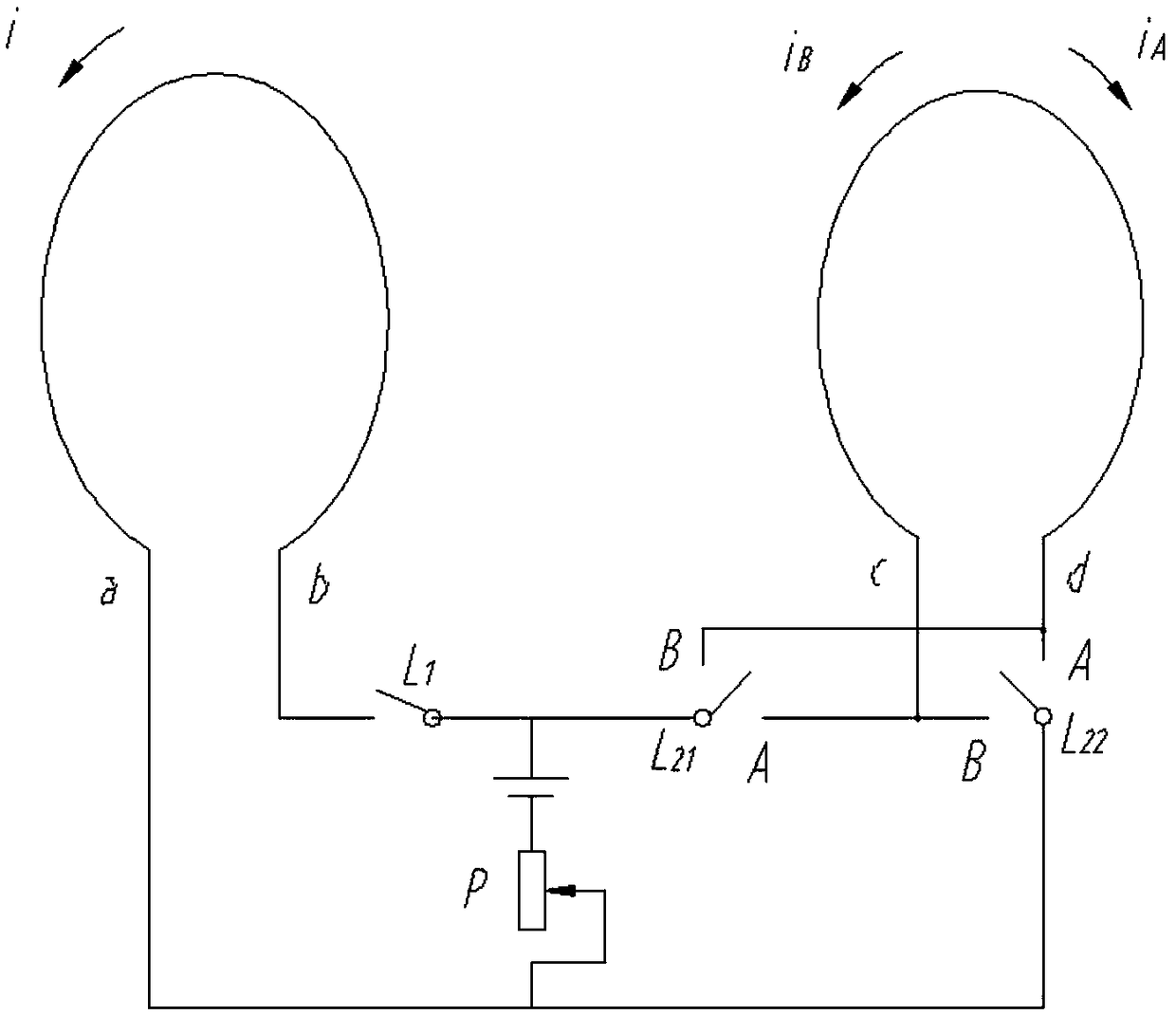

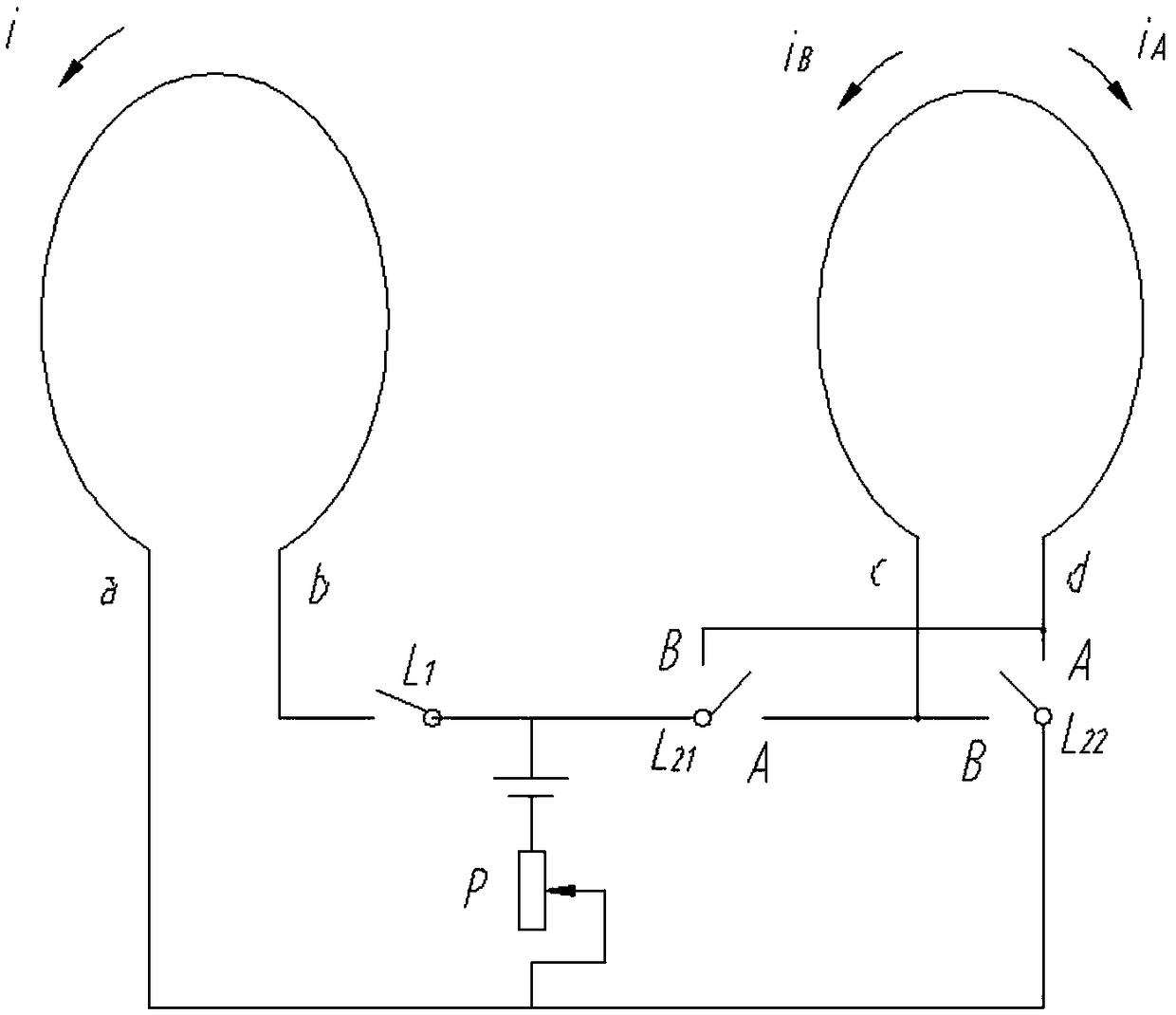

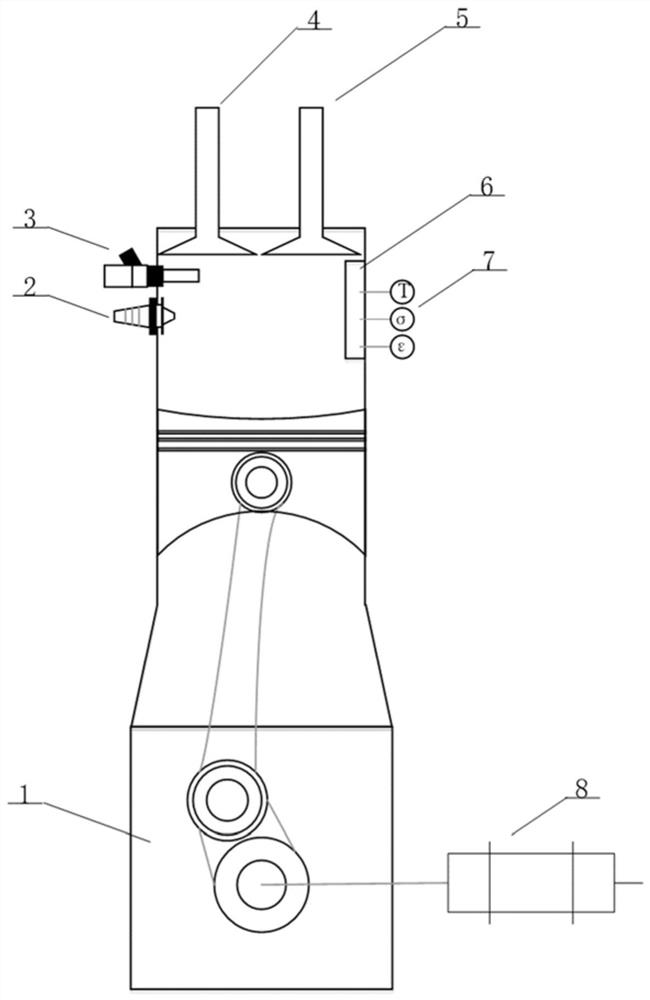

Small quick compressor based on electromagnetic control

ActiveCN110905764ASimple and fast operationSave time and costInternal combustion piston enginesPump controlLaser rangingCombustion chamber

The invention discloses a small quick compressor based on electromagnetic control. The small quick compressor is mainly composed of a main combustion chamber system, a power system and an electromagnetic control circuit. The main combustion chamber system is composed of a gland and two layers of sleeves. Heat conduction oil flows through a gap between the two sleeves to heat a combustion chamber.The power system comprises a cylinder body, a power cylinder gland, a braking circular ring, a power piston, a driving circular ring and a laser distance measuring sensor. The laser distance measuringsensor measures the distance through a center hole of the power cylinder gland, and therefore, control of the compression process is achieved. The electromagnetic control circuit comprises a direct-current power supply, a slide rheostat and five switches, wherein the direct-current power supply supplies current; the slide rheostat is used for adjusting the circuit current so as to change the electromagnetic force between the coils; three switches are used as on-off switches of a circuit, and the other two switches are jointly used as change-over switches and are responsible for changing the current flow direction in the coil, so that the direction of electromagnetic force is changed. The quick compressor is simpler and more compact in structure, and the working process is more efficient.

Owner:TIANJIN UNIV

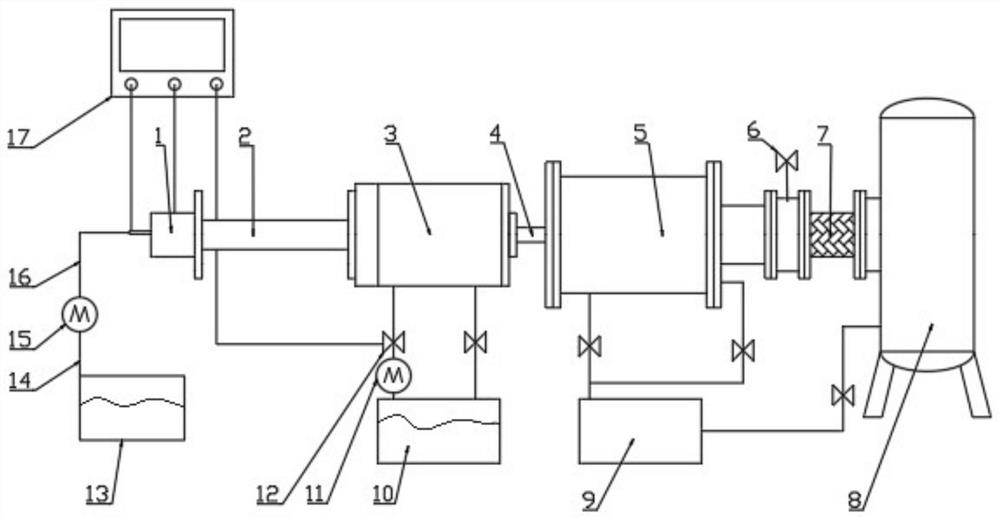

Engine simulation test device capable of achieving ultrahigh compression temperature and pressure

ActiveCN113654807AFlexible temperature changeFlexibility to change pressureInternal-combustion engine testingUltra high pressureSurge tank

The invention provides an engine simulation test device capable of achieving ultrahigh compression temperature and pressure, and belongs to the field of diesel engine high-temperature and high-pressure systems. The problems that an existing engine simulation test cannot achieve ultrahigh compression temperature and pressure, and the temperature and the pressure cannot be adjusted are solved. The device comprises a compressed air inlet mechanism, a nitrogen inlet mechanism, a pressure stabilizing mechanism, a circulating heating mechanism, an air inlet mechanism and a rapid compressor mechanism, and the compressed air inlet mechanism and the nitrogen inlet mechanism are both connected with the air inlet end of a pressure stabilizing tank in the pressure stabilizing mechanism, the compressed air inlet mechanism and the nitrogen inlet mechanism respectively introduce air and nitrogen into the surge tank, the surge tank is connected with the cyclic heating mechanism, the cyclic heating mechanism heats the air in the surge tank, the air outlet end of the surge tank is connected with the rapid compressor mechanism, and an air inlet mechanism is connected between the surge tank and the quick compressor mechanism. The device is mainly used for engine simulation tests.

Owner:HARBIN ENG UNIV

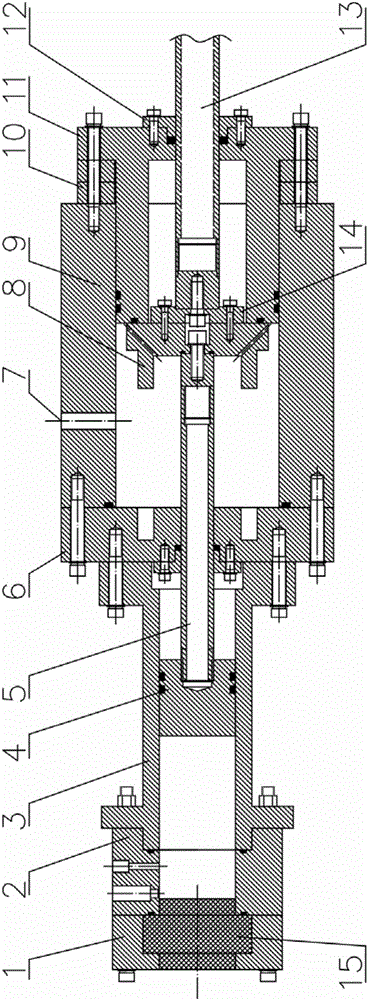

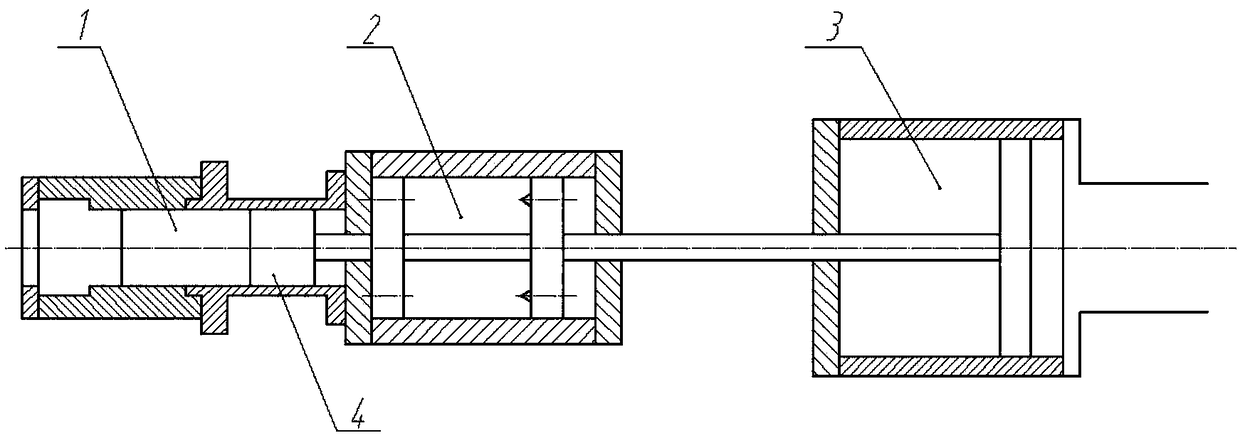

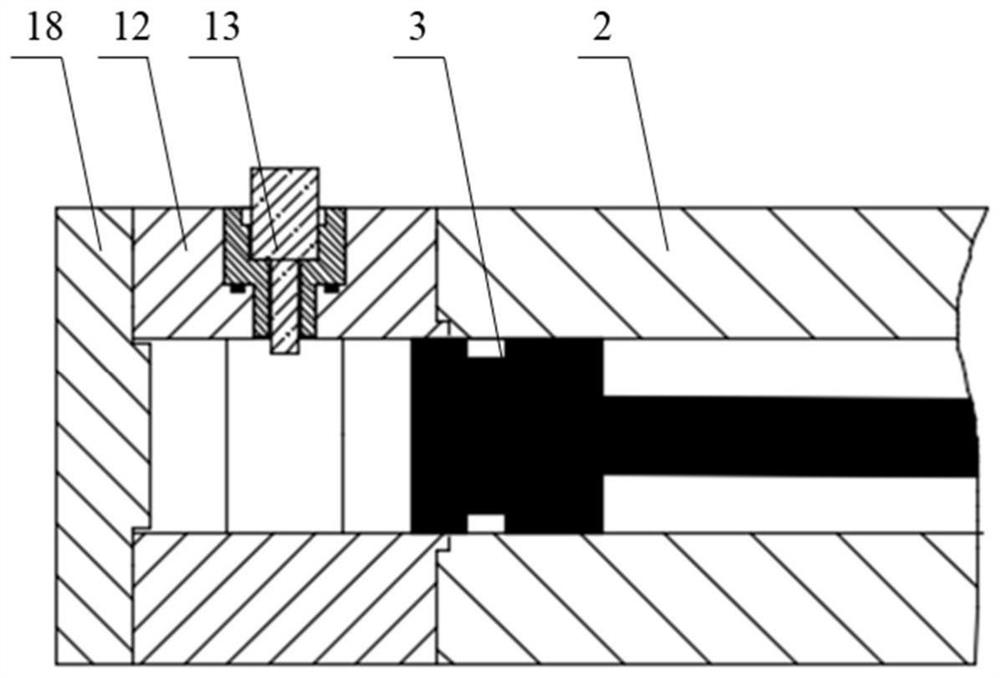

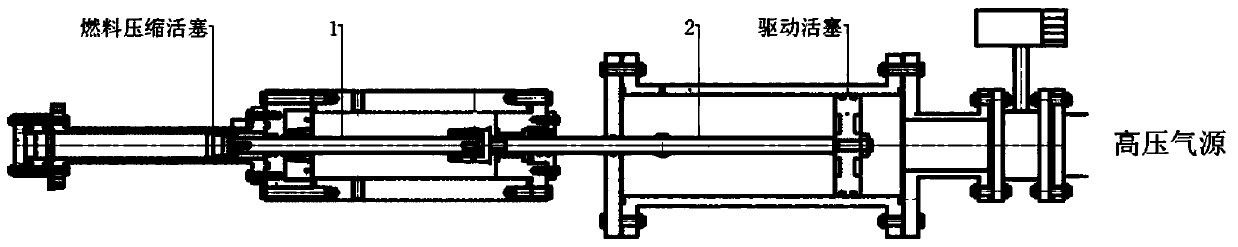

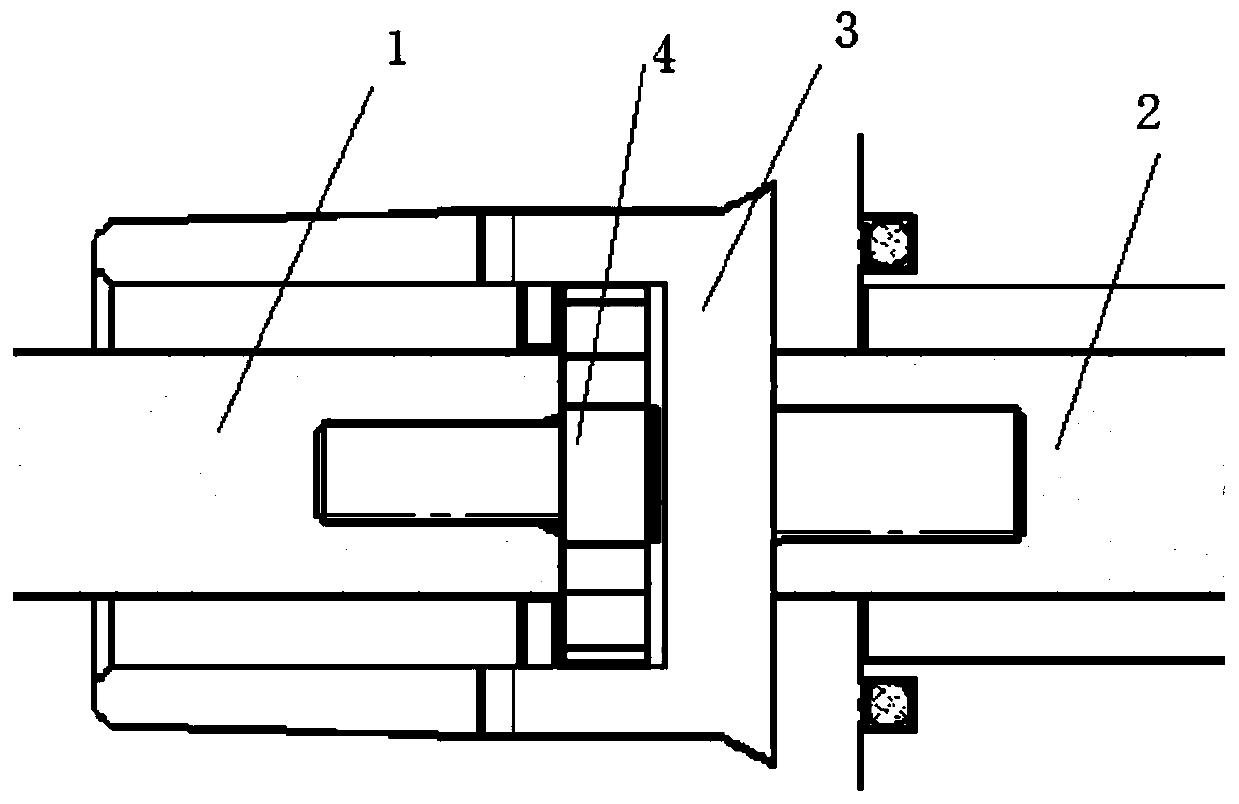

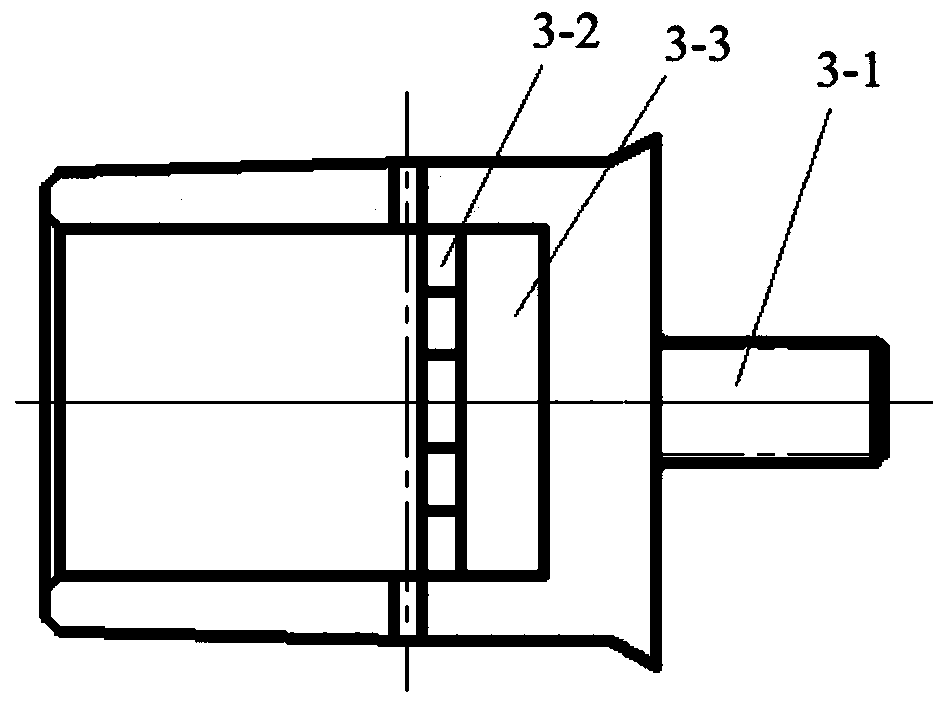

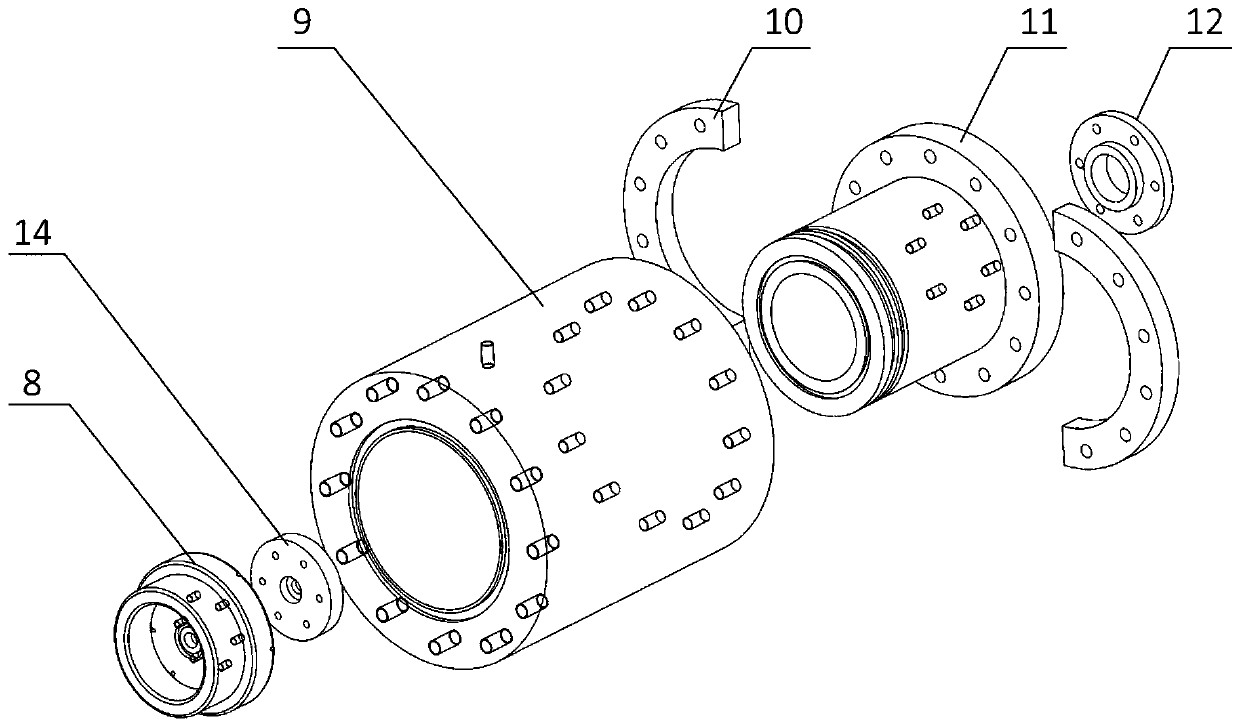

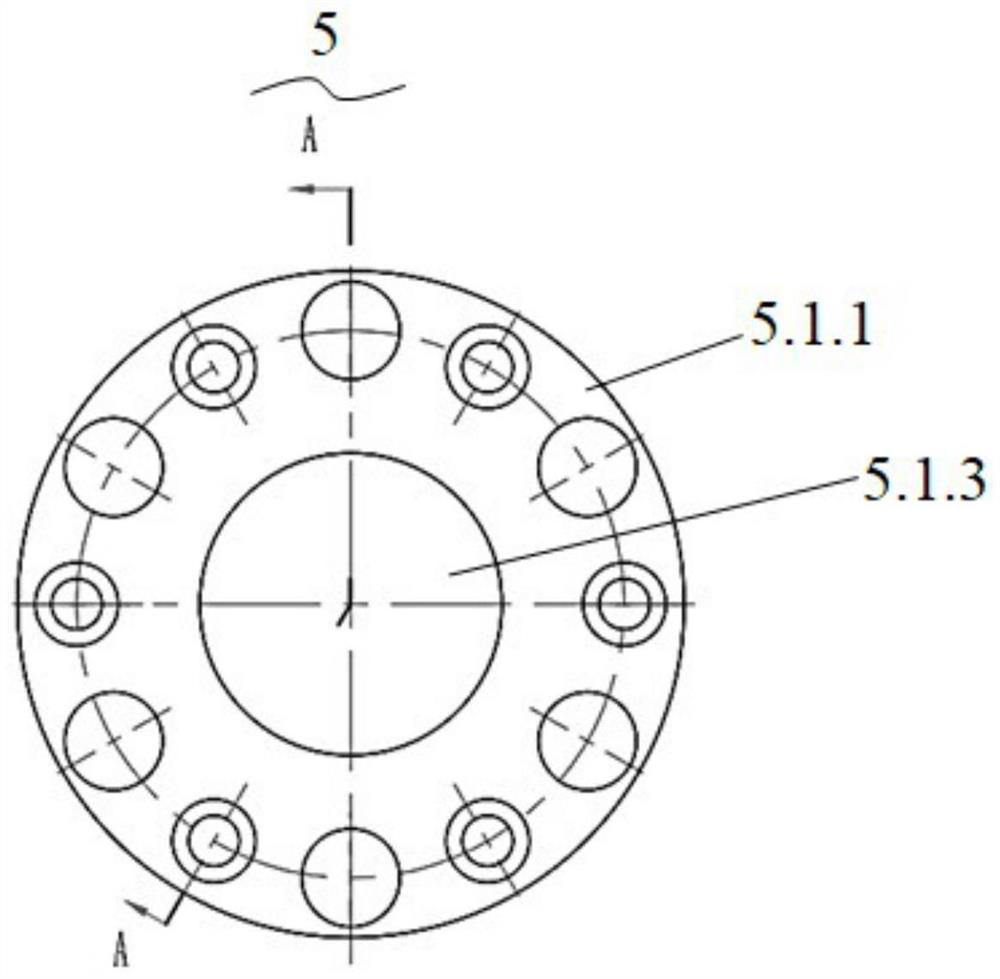

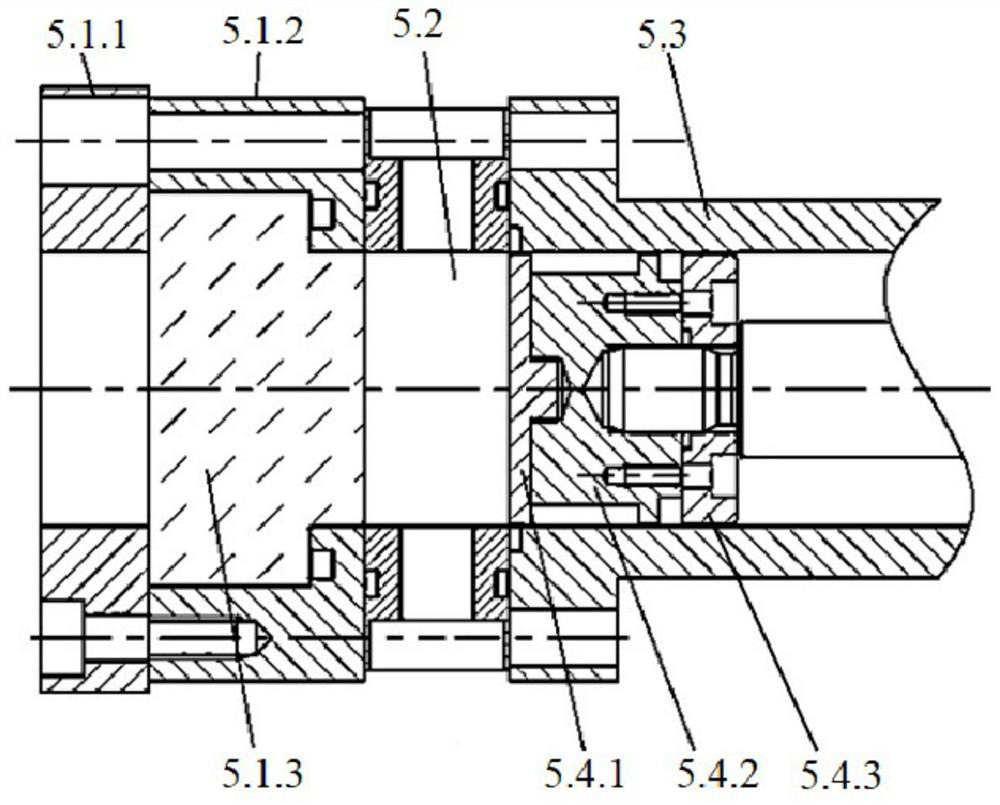

A quick compressor connecting rod connecting device

ActiveCN107387538BReduce machining accuracyReduce the requirements for coaxiality accuracyConnecting rod bearingsConnecting rodsStructural engineeringMechanical engineering

The invention discloses a connecting rod connecting device of a rapid compression machine. The rapid compression machine comprises a fuel compression piston connecting rod and a driving piston connecting rod, and the fuel compression piston connecting rod is connected with the driving piston connecting rod through the connecting device. The connecting device comprises a connecting piston and a spline shaft which are connected with each other in a buckling mode and are capable of moving mutually in a connected state. The fuel compression piston connecting rod is movably connected with the driving piston connecting rod through the connecting device, the mounting positions of both the fuel compression piston connecting rod and the driving piston connecting rod are adaptively adjusted during assembly, the requirement for the machining accuracy of the two connecting rods and the requirement for the coaxiality accuracy of the two connecting rods during assembly are lowered, and the production cost is reduced.

Owner:XI AN JIAOTONG UNIV

Rapid compressor simulation experiment device for studying combustion process of internal combustion engine

The invention discloses a rapid compressor simulation experiment device for studying the combustion process of an internal combustion engine, which comprises a fuel supply device, a combustion cylinder, a vacuum pump, an impact cylinder and an impact cylinder control assembly, a fuel mixing chamber is arranged on the fuel supply device, a combustion chamber is formed in the combustion cylinder, and the combustion chamber is communicated with the fuel mixing chamber; the combustion cylinder is provided with a laser incidence hole and a visual observation window, an impact piston rod on the impact cylinder is connected with an impact head, and the impact head is connected with a combustion cylinder connecting rod to drive a combustion cylinder piston to extrude the combustion chamber; the impact air cylinder control assembly comprises an inflation header pipe, a front cavity branch pipe, a rear cavity branch pipe, a front cavity electromagnetic valve, a front cavity pressure regulating valve, a rear cavity electromagnetic valve and a rear cavity pressure regulating valve, the front cavity branch pipe is communicated with the front cavity, the rear cavity branch pipe is communicated with the rear cavity, the front cavity electromagnetic valve and the front cavity pressure regulating valve are connected to the front cavity branch pipe, and the rear cavity electromagnetic valve and the rear cavity pressure regulating valve are connected to the rear cavity branch pipe. The inflation header pipe is connected with the front cavity branch pipe and the rear cavity branch pipe to supply air.

Owner:上海保烁航空科技有限公司

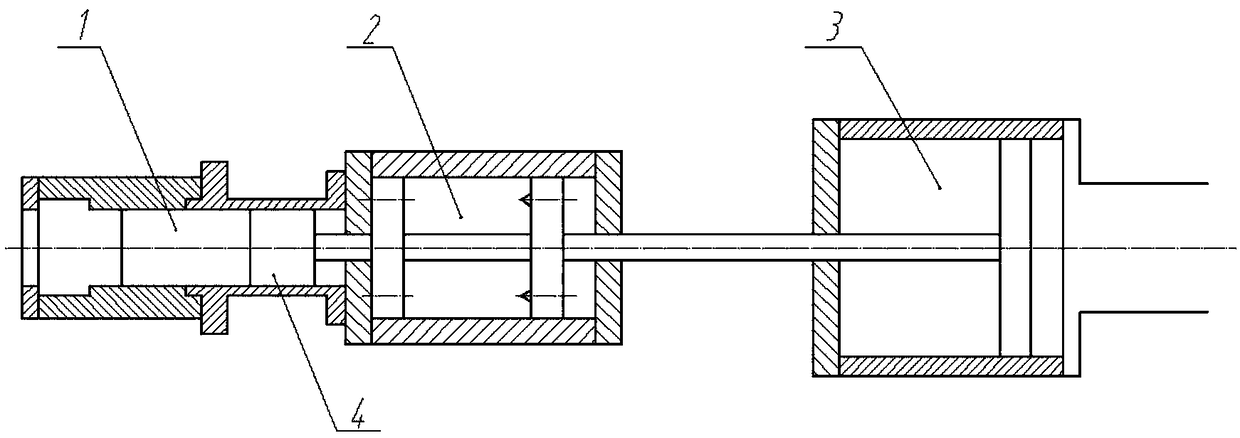

Rapid compressor test platform for laboratory and adjustment method of compression ratio

ActiveCN106089676BRealize compression ratio adjustmentAchieving a thermodynamic statePump testingPositive-displacement liquid enginesCombustion chamberCylinder block

The invention discloses a rapid compressor experimenting platform for a laboratory. The rapid compressor experimenting platform comprises a combustion chamber unit, a brake cylinder unit and a driving cylinder unit. The brake cylinder unit comprises a brake cylinder body, a brake cylinder rear cover and a brake piston, a first connecting rod is connected between the brake piston and a combustion chamber piston, and the lower stop point position of the brake piston is determined by the position of the brake cylinder rear cover. The driving cylinder unit comprises a driving piston, and a second connecting rod is connected between the driving piston and the brake piston. A plurality of compression ratio adjusting gaskets capable of being arranged between the brake cylinder rear cover and the brake cylinder body are arranged. Each compression ratio adjusting gasket is composed of a pair of cohesive semicircular gasket bodies, and the total thickness of the arranged compression ratio adjusting gaskets is determined according to the lower stop point position of the combustion chamber piston under the premise that the upper stop point position of the combustion chamber piston is kept unchanged. According to the rapid compressor experimenting platform for the laboratory, the gaskets are additionally arranged at the brake cylinder rear cover to change the initial position of the combustion chamber piston and maintain the volume of a clearance unchanged so as to adjust the compression ratio.

Owner:TIANJIN UNIV

Schlieren system based on rapid compressor

ActiveCN110763479ASimple structureEasy to installInternal-combustion engine testingShock waveCombustion chamber

The invention relates to equipment for researching shock wave and flame propagation characteristics in a fuel combustion process, and provides a schlieren system based on a rapid compressor. The system comprises a light source, a high-speed camera, a knife edge, a spectroscope, a first concave mirror, a second concave mirror and the rapid compressor; the rapid compressor comprises a combustion chamber and a compression chamber, wherein one end of the combustion chamber is covered with a visual end cover, and the other end of the combustion chamber is communicated with the compression chamber;a mirror surface is arranged at the end, facing the visual end cover, of a piston in the compression chamber; a light source and a diaphragm are arranged on an incident light path of the first concavemirror, and the spectroscope is arranged on a reflected light path; the rapid compressor is arranged on a reflected light path of the spectroscope, and the visual end cover is located on the reflected light path of the spectroscope, and the second concave mirror is arranged on a transmitted light path of the spectroscope; the knife edge and the high-speed camera are sequentially arranged on the reflected light path of the second concave mirror. By means of the visual end cover and the mirror surface arranged at one end of the piston, flame and shock wave structures in the combustion chamber can be obtained in real time, and flow field distribution can be captured.

Owner:TSINGHUA UNIV

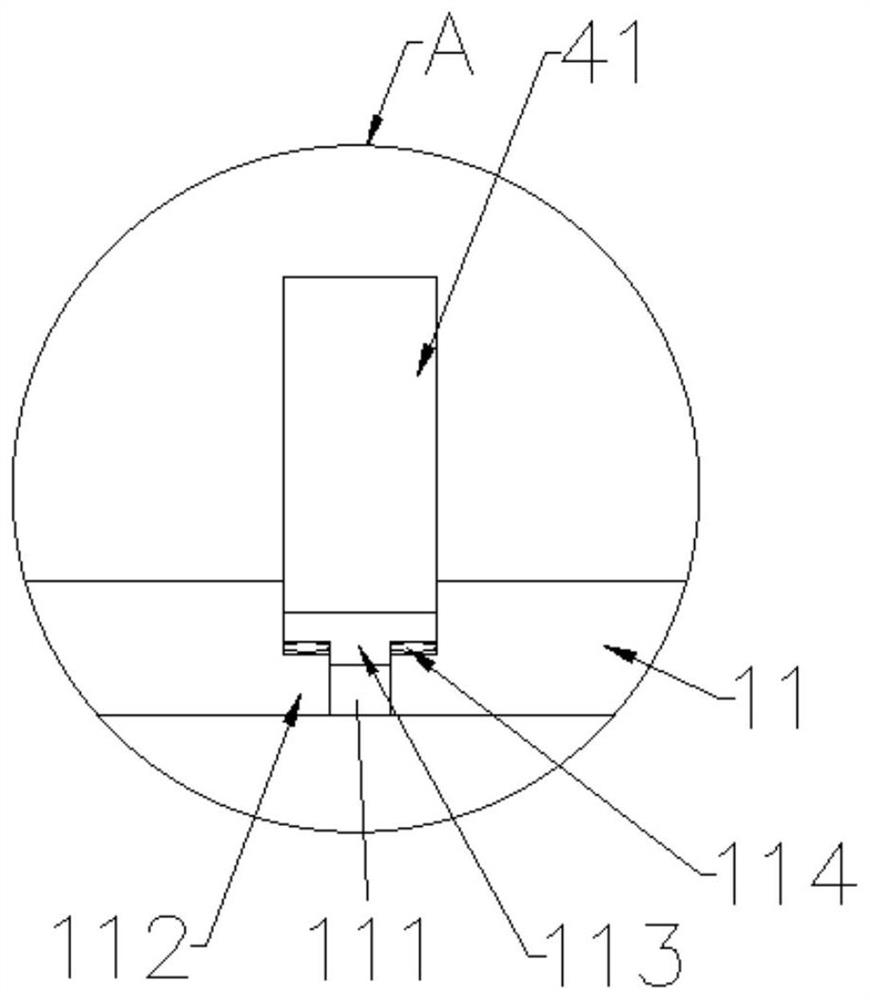

Experimental device and method based on fast compressor

ActiveCN113203572BImprove thermodynamic statusPrecisely control the trigger momentInternal-combustion engine testingCombustion chamberEngineering

The invention provides an experimental device and method based on a fast compressor, comprising: a compression cylinder, including a cylinder barrel provided with a through hole and a piston movably inserted in the through hole; a combustion component, sealed and connected to the cylinder The first end of the barrel and the side of the combustion component close to the cylinder barrel construct a combustion chamber connected to the through hole; the trigger device is installed on the side wall of the combustion chamber; the position sensor is installed on the The cylinder is suitable for sensing the position of the piston; the signal generator is communicatively connected to the position sensor and the trigger device. Precisely controlling the triggering time of the triggering device can establish a data model between the triggering time and engine knocking, which is conducive to in-depth research and utilization of the engine knocking phenomenon, thereby improving the thermal efficiency of the engine. At the same time, the experimental device can also be applied to other combustion studies that rely on precise triggering.

Owner:TSINGHUA UNIV

Combustion Performance Test Bench of Internal Combustion Engine Based on Rapid Compression/Compressor Expansion Machine

ActiveCN110726559BSimple structureReduce complexityInternal-combustion engine testingControl systemElectric machinery

The invention relates to a combustion performance test bench of an internal combustion engine based on a rapid compression / compression expander, belonging to the field of internal combustion engine testing. The invention includes a fast press and an air supply system. The present invention uses a linear motor as a power source to push the piston to move, which greatly simplifies the structure of the fast compressor; by changing the control strategy of the linear motor, the fast compressor can work in a fast compressor (constant volume combustion) and a fast compression expander (free expansion) ) Under the two modes, the device has strong adaptability; it has the characteristics of adjustable compression ratio, multi-fuel adaptability and speed variability. The internal combustion engine combustion performance test bench based on the rapid compression / compression expander of the present invention simplifies the bench structure, reduces the overall volume, reduces the complexity of the control system, and improves the adaptability and reliability of the internal combustion engine test bench sex.

Owner:BEIJING INSTITUTE OF TECHNOLOGYGY

A Schlieren System Based on Fast Compressor

ActiveCN110763479BSimple structureEasy to installInternal-combustion engine testingShock waveCombustion chamber

Owner:TSINGHUA UNIV

A Compression End Temperature Adjustment Method for Laboratory Fast Compressor

ActiveCN109281826BAvoid disassemblyExtended service lifePump testingPositive-displacement liquid enginesCombustion chamberEngineering

The invention discloses a compression end point temperature adjusting method for a fast compressor in a lab. The method comprises the following steps that 1 ) determining the components of combustiblemixed gas in an experiment of the fast compressor; 2 ) determining the total pressure of the combustible mixed gas in a combustion chamber to be P, and calculating the corresponding partial pressurePi = P * Xi according to volume fraction of each gas; 3 ) after evacuating a gas mixing tank, filling the gas sequentially according to the corresponding gas partial pressure to complete the configuration of the combustible gas mixture; 4 ) compressing the combustible mixed gas for one step, and recording the pressure change in the combustion chamber ; 5 ) calculating is carried out according to an ideal gas heat insulation formula to obtain the compression end point temperature Tc of the experiment; and 6 ) replacing a part of argon in diluent gas with nitrogen, repeating the steps 3 )-5 ), and obtaining a compression end point temperature which is lower than the first time. According to the method, under the condition that the structure of an existing experimental device is not changed,the compression end point temperature is changed by changing the diluent gas component in the mixed gas, so that the experimental working condition range is effectively widened.

Owner:永春县产品质量检验所福建省香产品质量检验中心国家燃香类产品质量监督检验中心福建

An Optical Fast Compressor Combustion Cylinder Capable of Shooting by Schlieren Method

ActiveCN108060972BMeet the layout requirementsRealize full visual shootingInternal-combustion engine testingInternal combustion piston enginesCombustion chamberPiston

Owner:TIANJIN UNIV

Electromagnetic braking system and control method for rapid compression machine

ActiveUS11274714B2Small speedPrevent reboundEngine testingBrake typesTop dead centerClassical mechanics

An electromagnetic braking system and control method, with the system having a CCU, a braking cylinder, a push rod, an electromagnetic braking ring, an electromagnetic braking piston fixed to the push rod, a first shading plate and a second shading plate, a photoelectric sensor fixed near the push rod, and an electromagnetic braking control circuit, and the control method including following the steps: initial estimating of the braking distance (l) according to the current magnitude, electromagnetic force between the two electromagnetic coils and initial velocity (v) of the push rod, arranging a restoration distance (Δl) between the top dead center and the piston after braking, installing two shading plates and the photoelectric sensor; and setting the distance between the two electromagnetic coils to when the starts braking.

Owner:TIANJIN UNIV

Dynamic heat engine load impact test device based on rapid compressor

PendingCN114441346ARealize load shock test measurementLow costStrength propertiesExhaust valveInlet valve

The invention provides a dynamic heat engine load impact test device based on a rapid compressor, which comprises a diesel engine, a spark plug, an oil injector and a motor, the spark plug and the oil injector are installed on one side of the diesel engine, the spark plug is located below the oil injector, and the opposite side of the oil injector on the diesel engine is used for installing a test piece which is used for installing a test system. The test system is used for measuring temperature, stress and strain of the test piece, the top of the diesel engine is provided with an air inlet valve and an exhaust valve which are both connected to the test system, and a crankshaft of the diesel engine is connected with the motor. According to the dynamic heat engine load impact test device based on the rapid compressor, the characteristics of an engine are combined, and through flexible control over an oil injection and ignition system, measurement of multiple modes such as jet flow flame heat engine load impact, premixed flame heat engine load impact and premixed flame heat impact can be achieved; and the defect of singleness of the traditional thermal shock / mechanical shock test is overcome.

Owner:CHINA NORTH ENGINE INST TIANJIN

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com