Experimental device for simulating evaporation and combustion of liquid drops of engine under high-temperature and high-pressure conditions

A high-temperature, high-pressure, droplet evaporation technology, applied in chemical analysis by combustion, internal combustion engine test, investigation stage/state change, etc., can solve the problem of large size difference, less research on spontaneous combustion characteristics, changing droplet heat transfer conditions, etc. question

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0025] The present invention will be further described below in conjunction with the accompanying drawings.

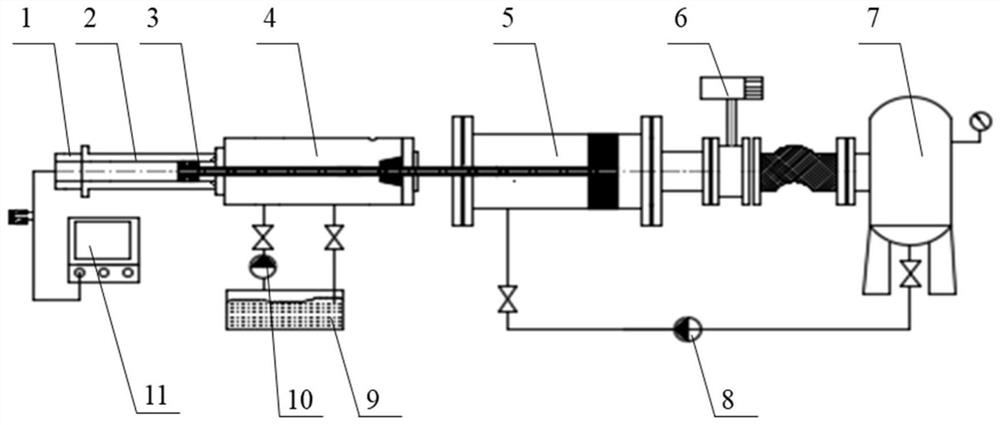

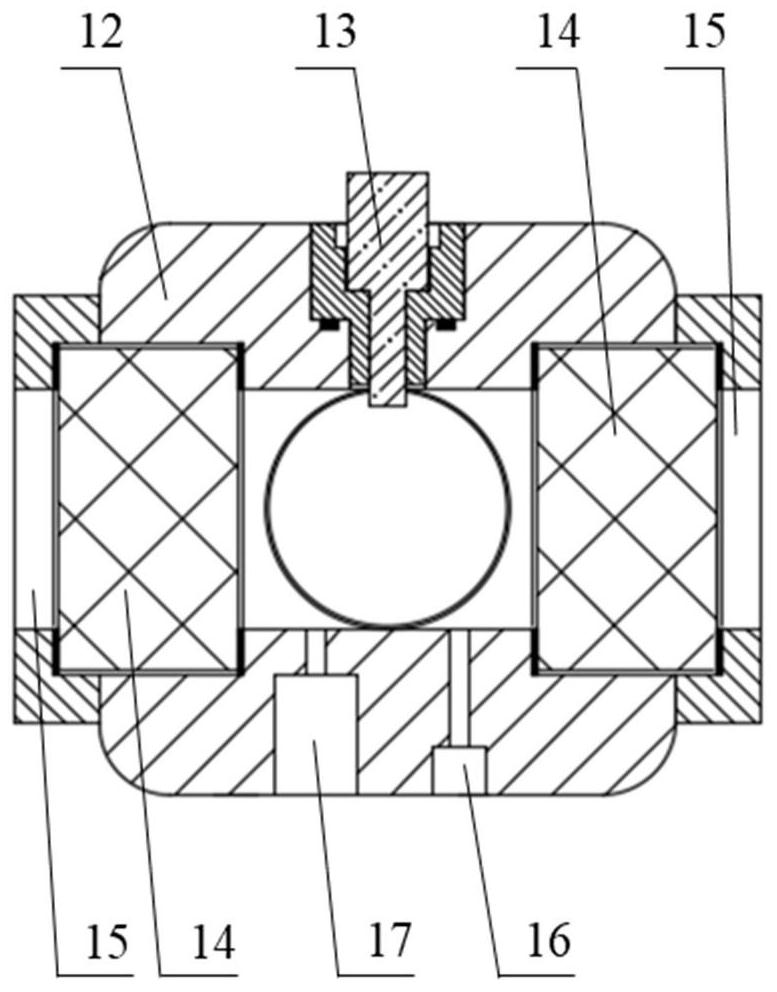

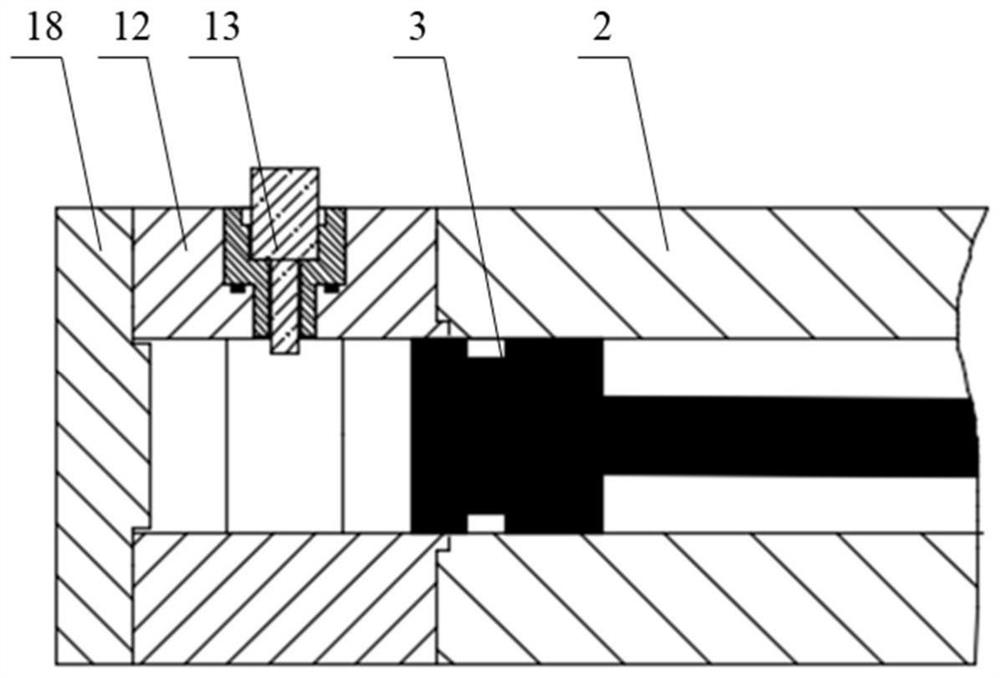

[0026] see Figure 1 to Figure 4 , the present invention provides an experimental device for simulating the evaporation and combustion of droplets under high temperature and high pressure conditions of an engine, including a visual combustion chamber 1, a compression section 2, a piston linkage mechanism 3, a hydraulic section 4, a driving section 5, an electric butterfly valve 6, a storage The air tank 7, the high-pressure air pump 8, the hydraulic oil tank 9 with the hydraulic oil pump 10, and the signal generating and collecting system 11 are composed. The visible combustion chamber 1 is composed of a combustion chamber main body 12, a quartz window 14, a quartz window cover 15, an intake and exhaust port 16, a pressure sensor hole 17 and an injector installation hole. The microscopic imaging system is composed of a backlight 21 , a quartz window 14 , a telephoto m...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com