Optical rapid compression machine combustion cylinder capable of realizing shooting by schlieren method

A technology of combustion cylinder and schlieren method, applied in combustion engine, mechanical equipment, internal combustion engine testing and other directions, can solve the problem of difficult to adapt to the schlieren method optical path layout, and achieve the effect of reducing material consumption, optimizing structural design, and improving accuracy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0026] The technical solution of the present invention will be further described in detail below in conjunction with the accompanying drawings and specific embodiments, and the described specific embodiments are only for explaining the present invention, and are not intended to limit the present invention.

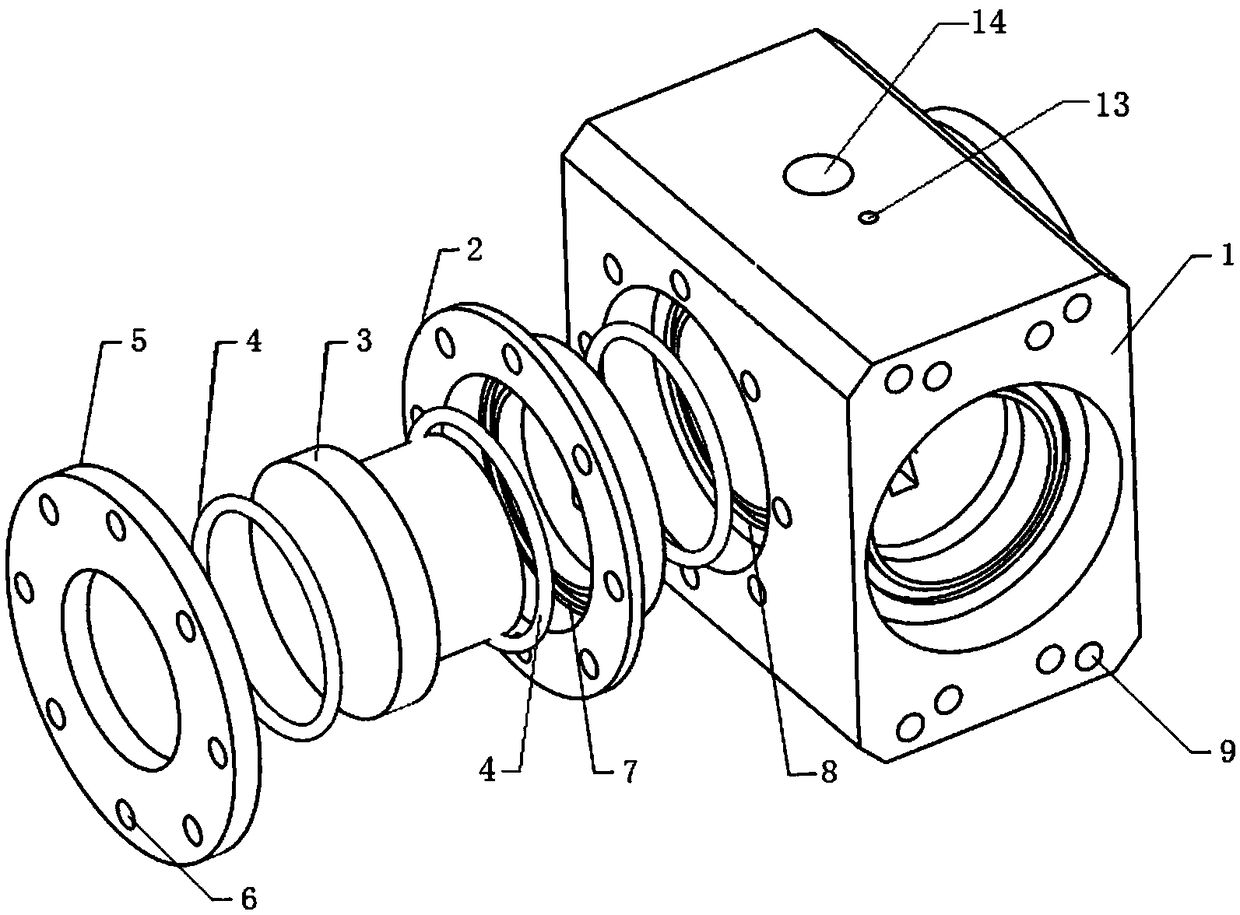

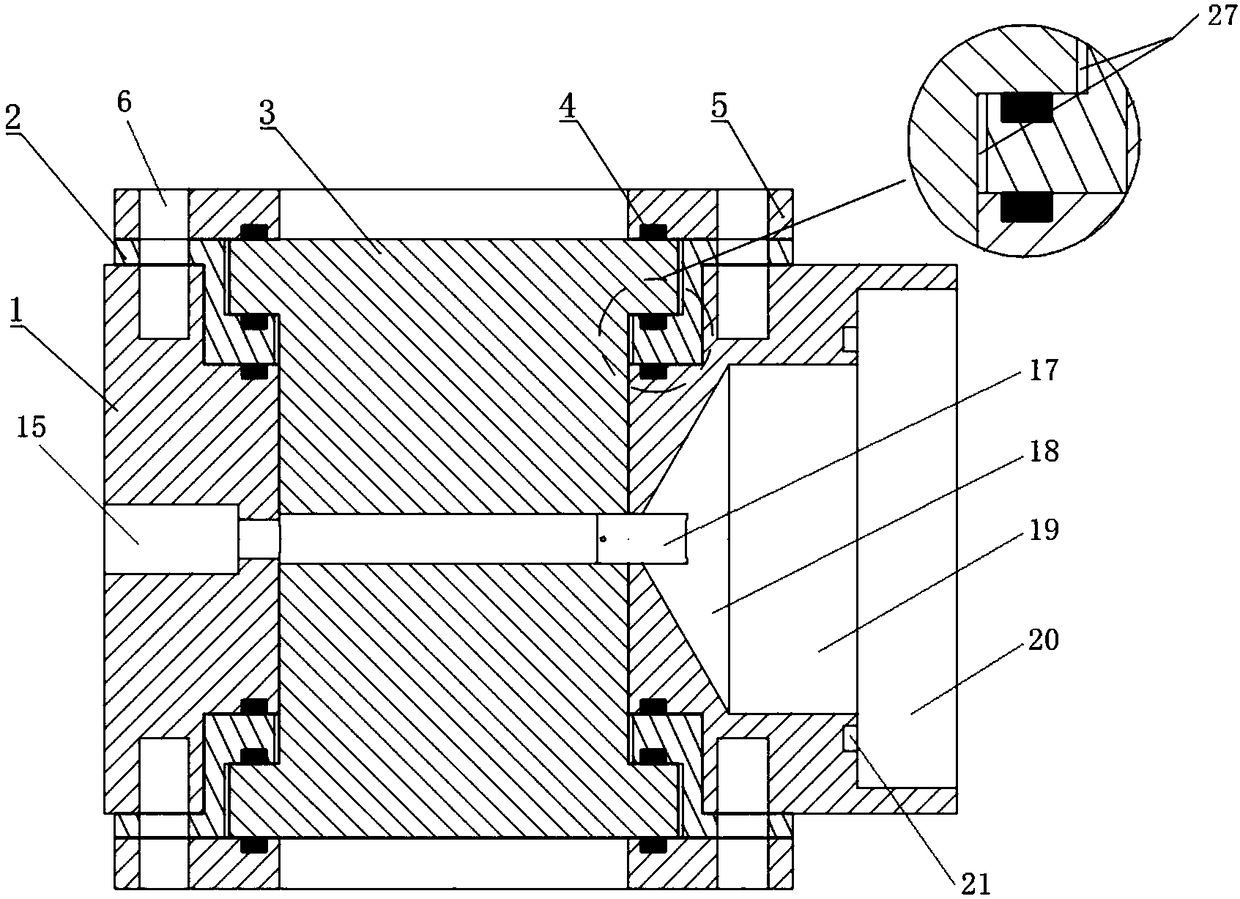

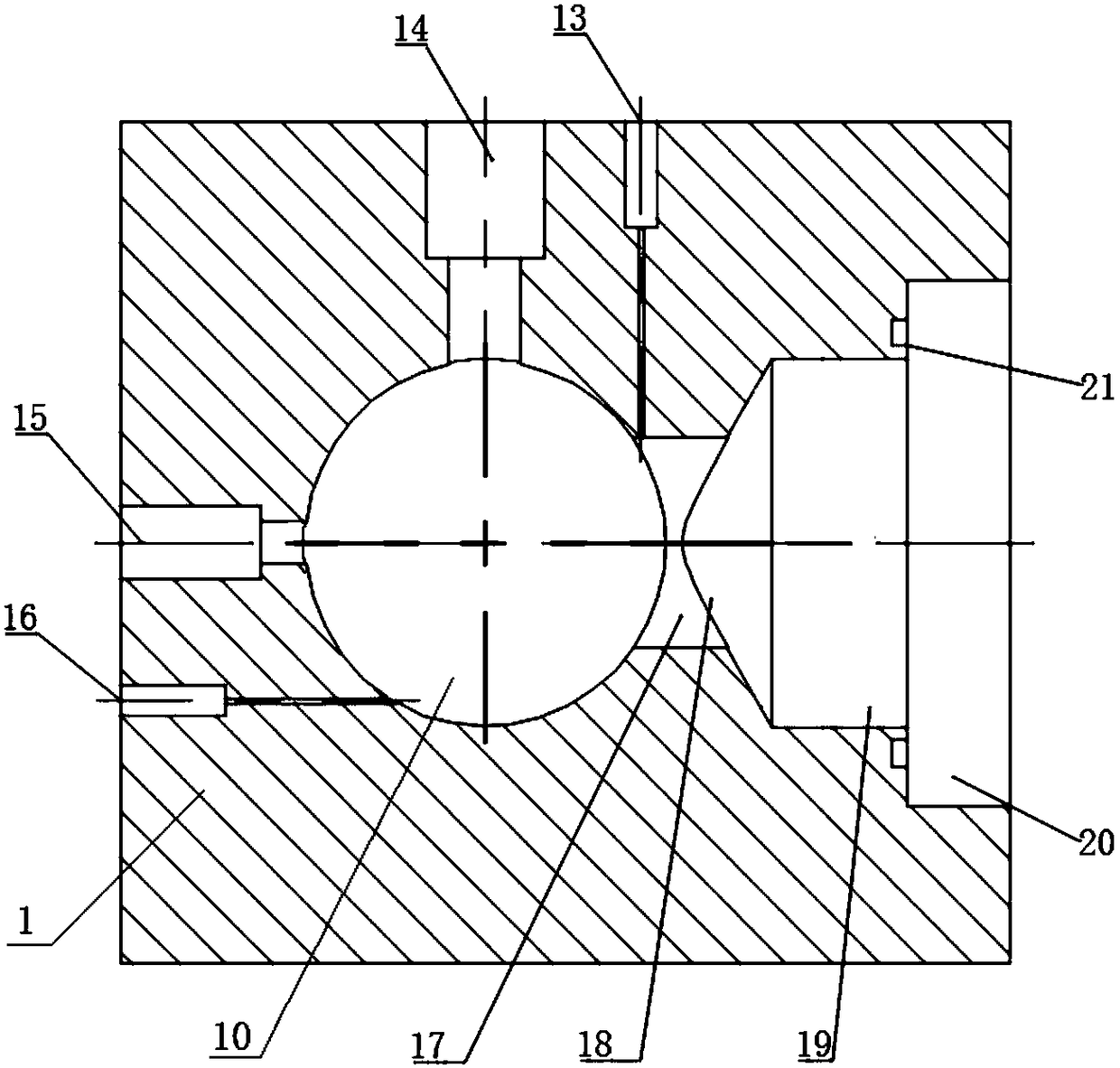

[0027] like Figure 1 to Figure 6 As shown, the present invention can realize the optical fast compressor combustion cylinder of schlieren method photographing, comprise combustion cylinder main body 1, the profile of described combustion cylinder main body 1 can be cuboid, and material is No. 45 steel, and the four corners of cuboid all cut off certain In order to reduce the sharpness of its corners, improve the safety of the experiment, and reduce the weight of the combustion cylinder at the same time. A combustion chamber cavity 10 is arranged between the front and rear ends of the combustion cylinder main body 1, and a window positioning cavity 11 is provided at the fr...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com