Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

34results about How to "Consistent shape and size" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Small-size gold nanorod and preparation method and applications thereof

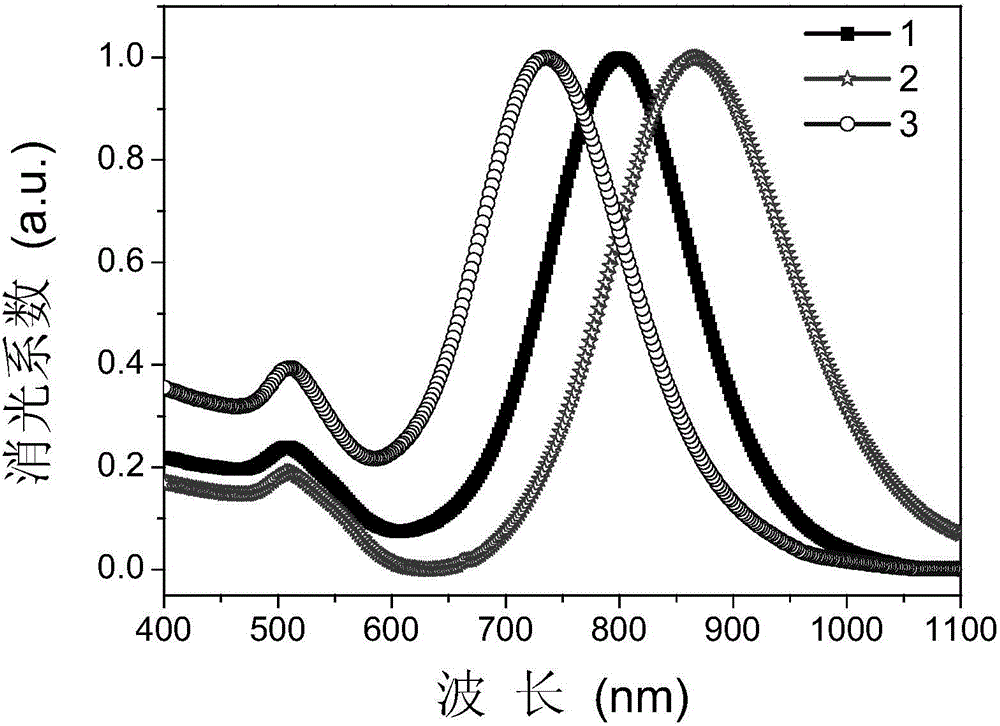

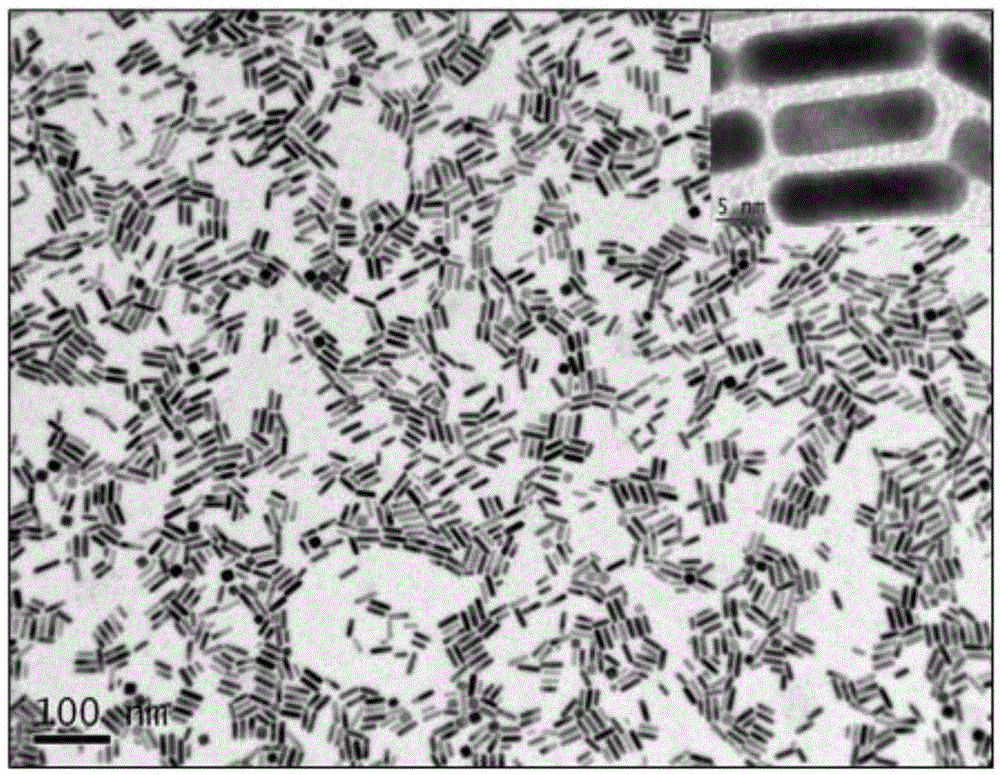

ActiveCN105618730AConsistent shape and sizeGood monodispersityNanotechnologySurface plasmonic resonanceUltrasound

The invention discloses a small-size gold nanorod and a preparation method and applications thereof. The growth reaction is adjusted by utilization of cationic-anionic surfactants as a mixed growth template, and synthesis of the small-size gold nanorod with the diameter of 5-9 nm is achieved through the non-gold-seed one-step method. The diameter and the length-diameter ratio of the small-size gold nanorod are adjusted through changes of the mole ratio of the chloroauric acid to the cationic-anionic surfactants to the silver nitrate. Operation is simple, consumed time is short, repeatability is good, and the small-size gold nanorod good in monodispersity and uniform in size can be obtained with no ultrasound in the preparation process. The diameter of the small-size gold nanorod is 5-9 nm, the size is small, and the ratio of the absorption value of a longitudinal surface plasma resonance absorption peak to the absorption value of a transverse surface plasma resonance absorption peak of the small-size gold nanorod is 2.5-5.5. The prepared small-size gold nanorod can be applied to the fields of preparation of photo-thermal treatment drugs, optical mark drugs, sensors and the like.

Owner:武汉中科先进材料科技有限公司

Method for producing humic-acid coal balls

This invention relates to one kind of humic acid coal briquette the production method, after raw coal froth screening, smashing, is ready to be used; Joins the right amount clear water in the system fluid pot, pours into including the humic acid 45-55% lignite and the density is 96% fever alkali, passes over the steam to carry on the elevation of temperature, the vapor temperature for 100-105degree C, elevates temperature for 1-1.5 hours, the full agitation, causes the acid, the alkali to carry on and the response, forms the humic acid sodium solution; After will crush qualified the original dust coal after the leather belt input mixer, simultaneously even puts in the humic acid sodium solution the mixer and the original dust coal agitation is even, its area south of Yellow River dust coal and the humic acid sodium solution load ratio for 100:4, then the pile of bubbles 16-20 hours, causes the coal and the fluid infiltrates Run to adsorb fully; After piles the bubbles the Chalmette coal sends in the geosyncline, after the leather belt input powder lot machine, the elevator, the re-entry presses the ball machine, presses out fresh ball after class screen-out froth, by leather belt input helix, further after the froth lives the ball to distribute evenly in the coal spherical tank, carries on 15-18 hour elevation of temperature air seasoning to the wet bulb, after the coal briquette air seasoning, or gives the gas-producing fever after the coal briquette tank bottom department by the leather belt input coal briquette warehouse storage to use directly.

Owner:HENAN JUNHUA DEV

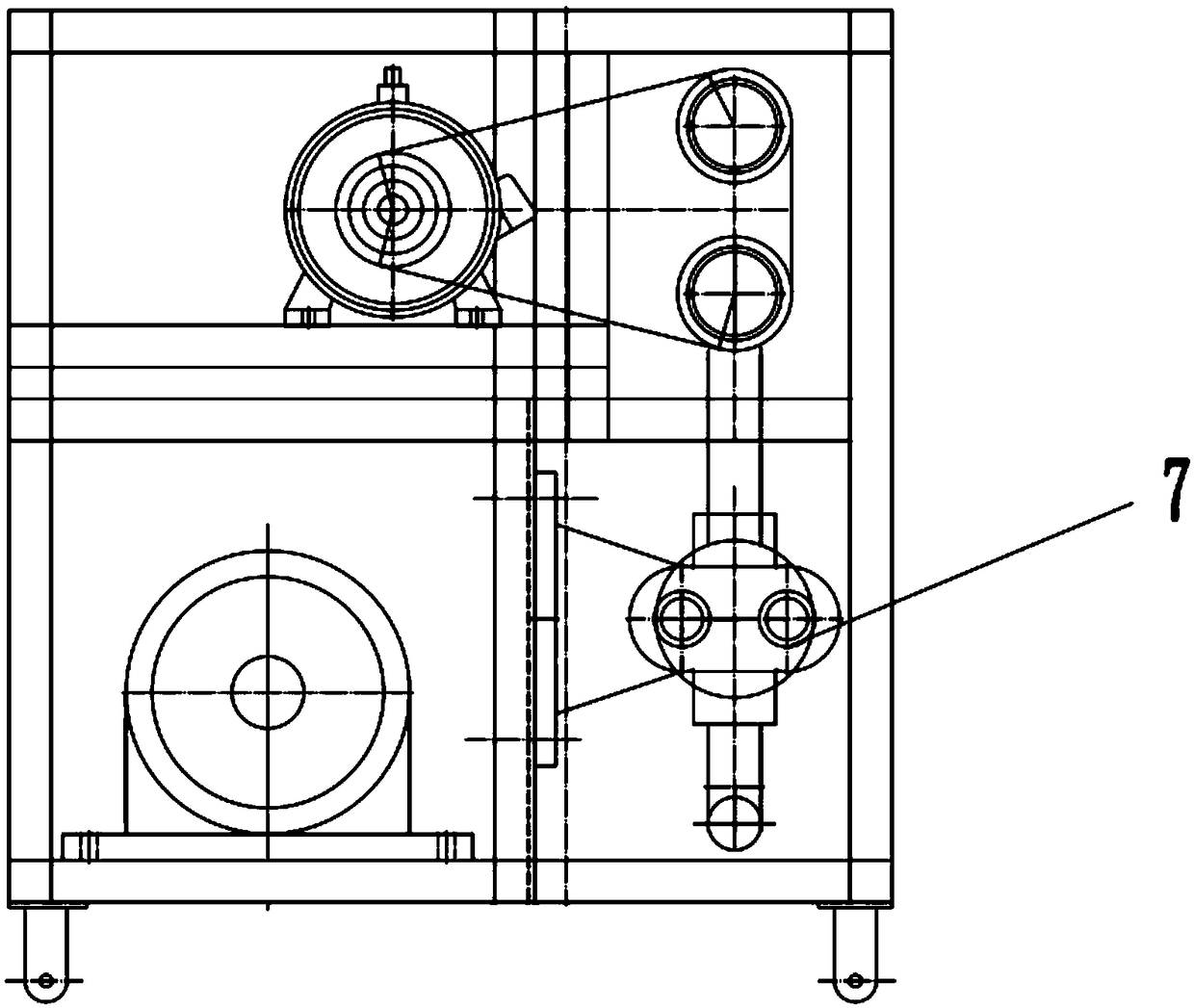

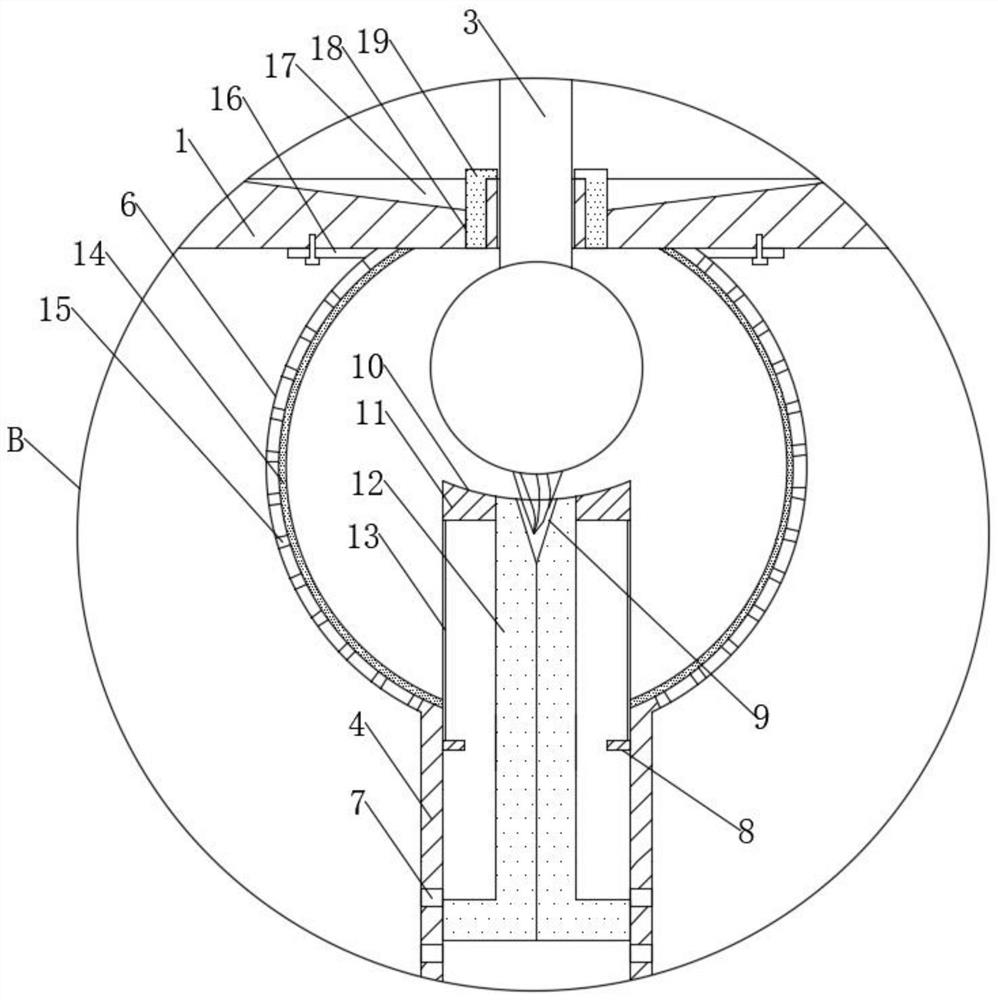

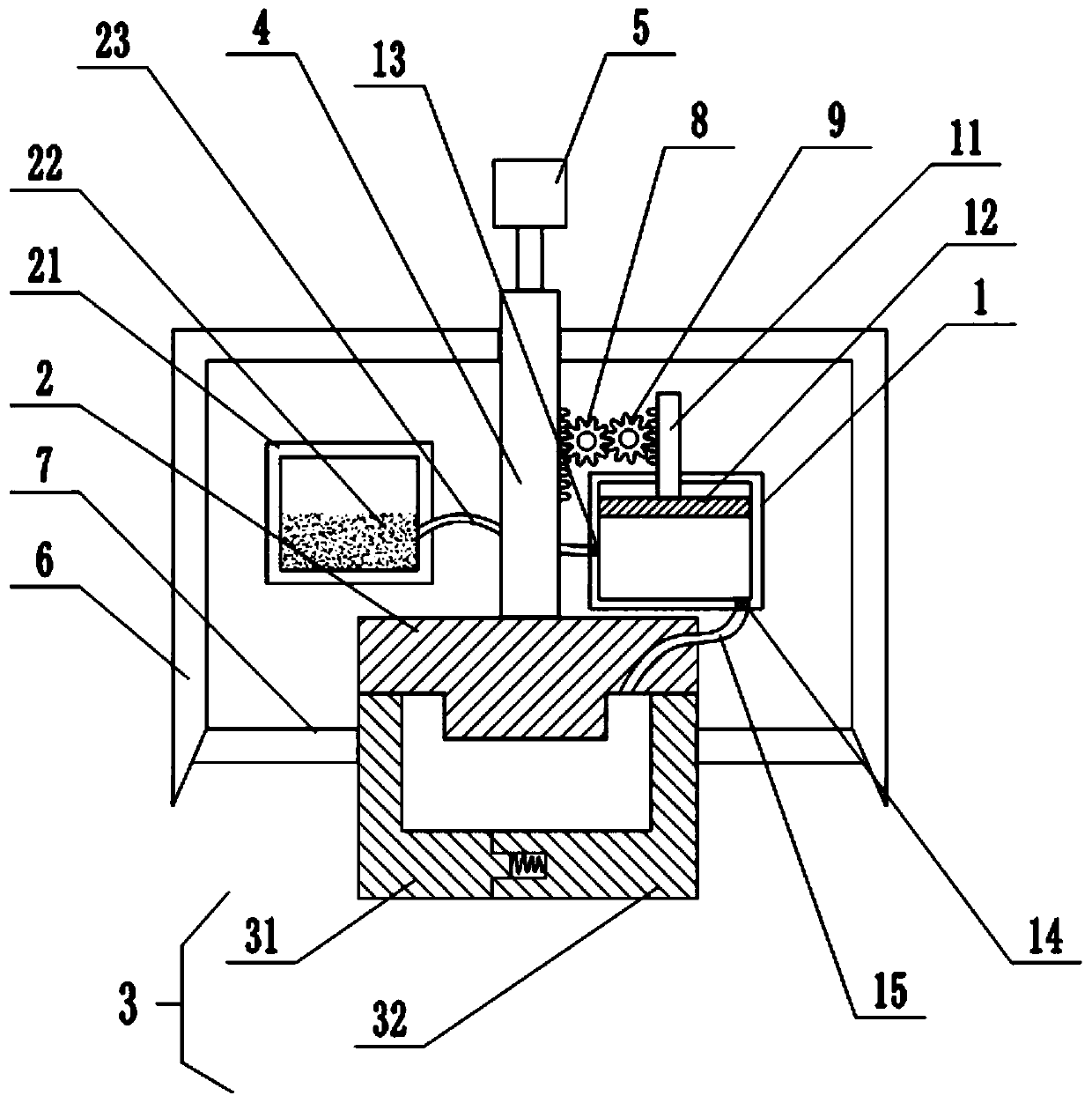

Waste sand disposal equipment

InactiveCN108672651AConsistent shape and sizeSimple designMould handling/dressing devicesProgrammable logic controllerWaste management

The invention discloses waste sand disposal equipment. The waste sand disposal equipment comprises a base, a first tank body, a second tank body, a first fixing rod, a second fixing rod, an O-shaped rack, a programmable logic controller (PLC) and a plurality of motors. The waste sand disposal equipment is simple in design structure and convenient to use, the PLC controls the motors to rotate forwards or reversely so that a fixing plate and a collision plate in the second tank body can collide continuously, blocky substances in waste sand are crushed, and it can be ensured that the recycled waste sand is basically coincident in shape and size; besides, upper toothed plates are additionally installed on the fixing plate and the collision plate in the second tank body, so that the waste sanddisposal effect is further ensured; and by using a half gear and a vibrator, dust in the waste sand is continuously screened out through an arc screen, accordingly, high-quality recycling is ensured,and the recycling efficiency is improved.

Owner:柳晶(溧阳)环保科技有限公司

Automatic forming mold for automatic parts

The invention relates to the technical field of mold equipment and discloses an automatic forming mold for automatic parts. The automatic forming mold comprises a rack, a guide box, a storage box, anupper mold base and a lower mold base, wherein the lower mold base comprises a first lower mold base and a second lower mold base spliced with each other; the upper mold base is connected with a pushrod; one end of the push rod is connected with a cylinder; two sides of the push rod are connected with an L-shaped rod; the first lower mold base and the second lower mold base are respectively connected with supporting rods; the guide box penetrates through a piston rod; a first rack is arranged on the piston rod and meshed with a first gear; the first gear is meshed with a second gear; a secondrack is arranged on the push rod and meshed with the second gear; the guide box and the upper mold base are communicated with a feed pipe. During injection molding, the upper mold base and the lowermold base are closed, and the molten pattern material is injected into an injection molding cavity from the guide box. During demolding, the upper mold base is separated from the lower mold base, thefirst lower mold base and the second lower mold base are mutually separated, and the injection molding product drops from the interior of the lower mold base so as to realize demolding.

Owner:宁波高盛模具制造有限公司

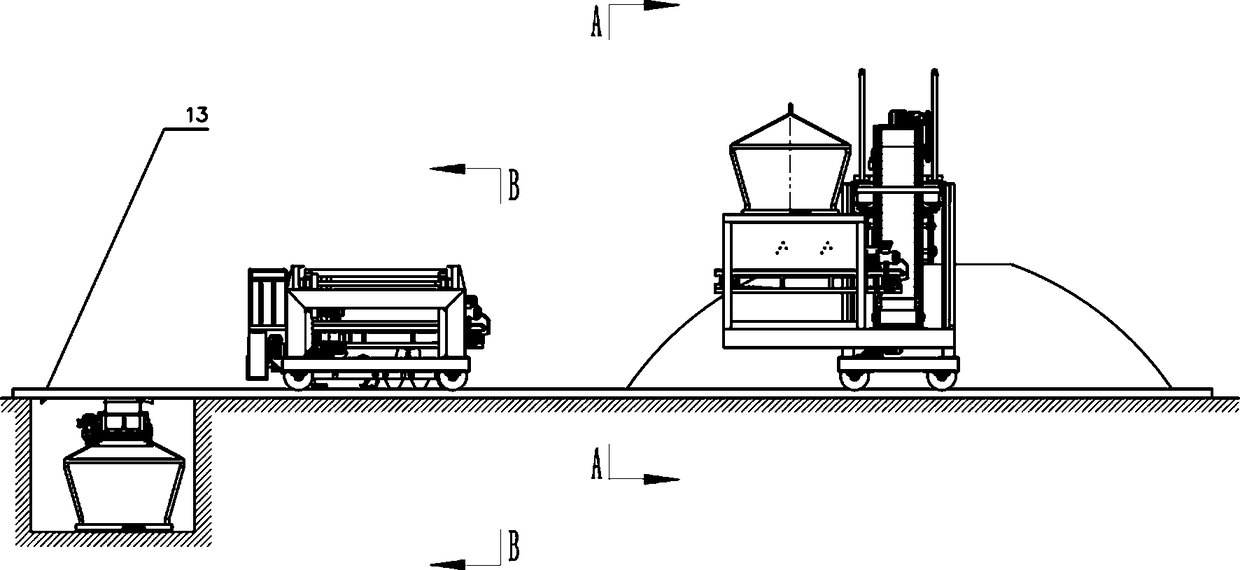

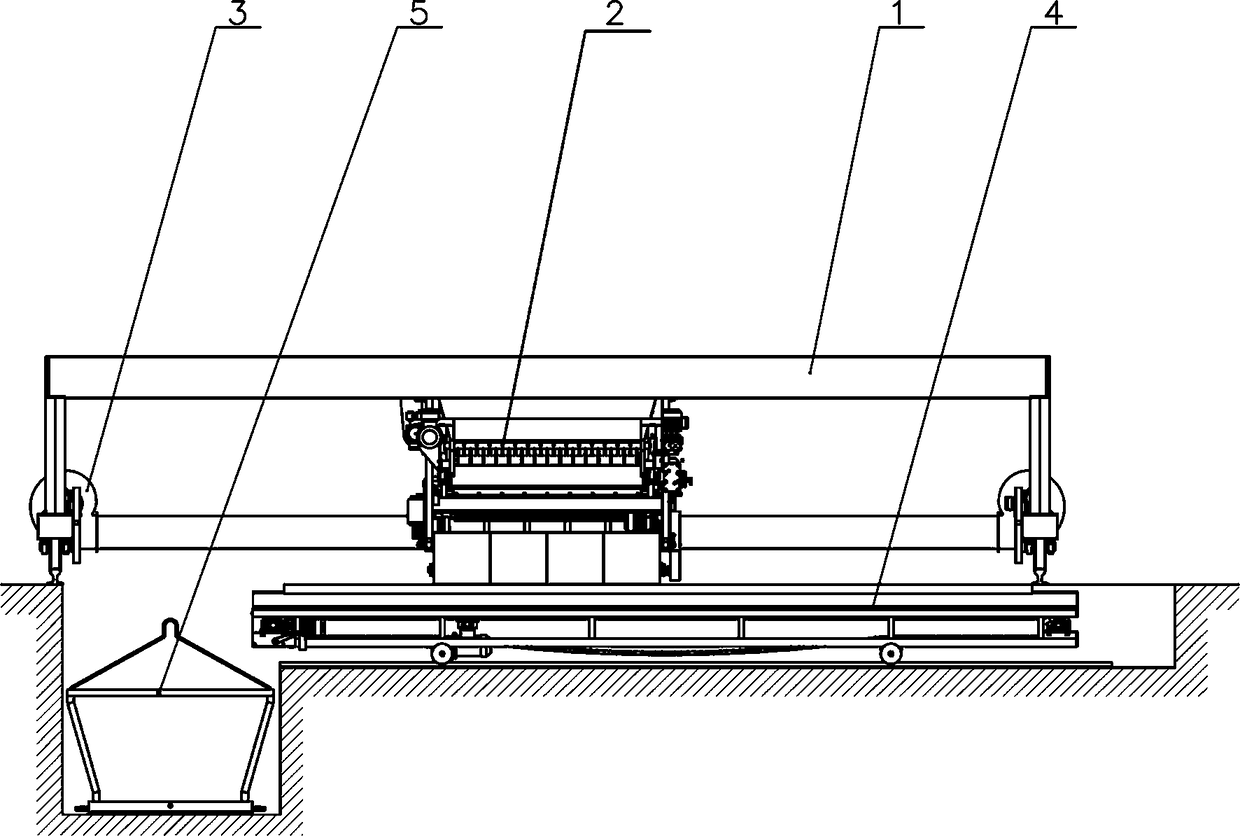

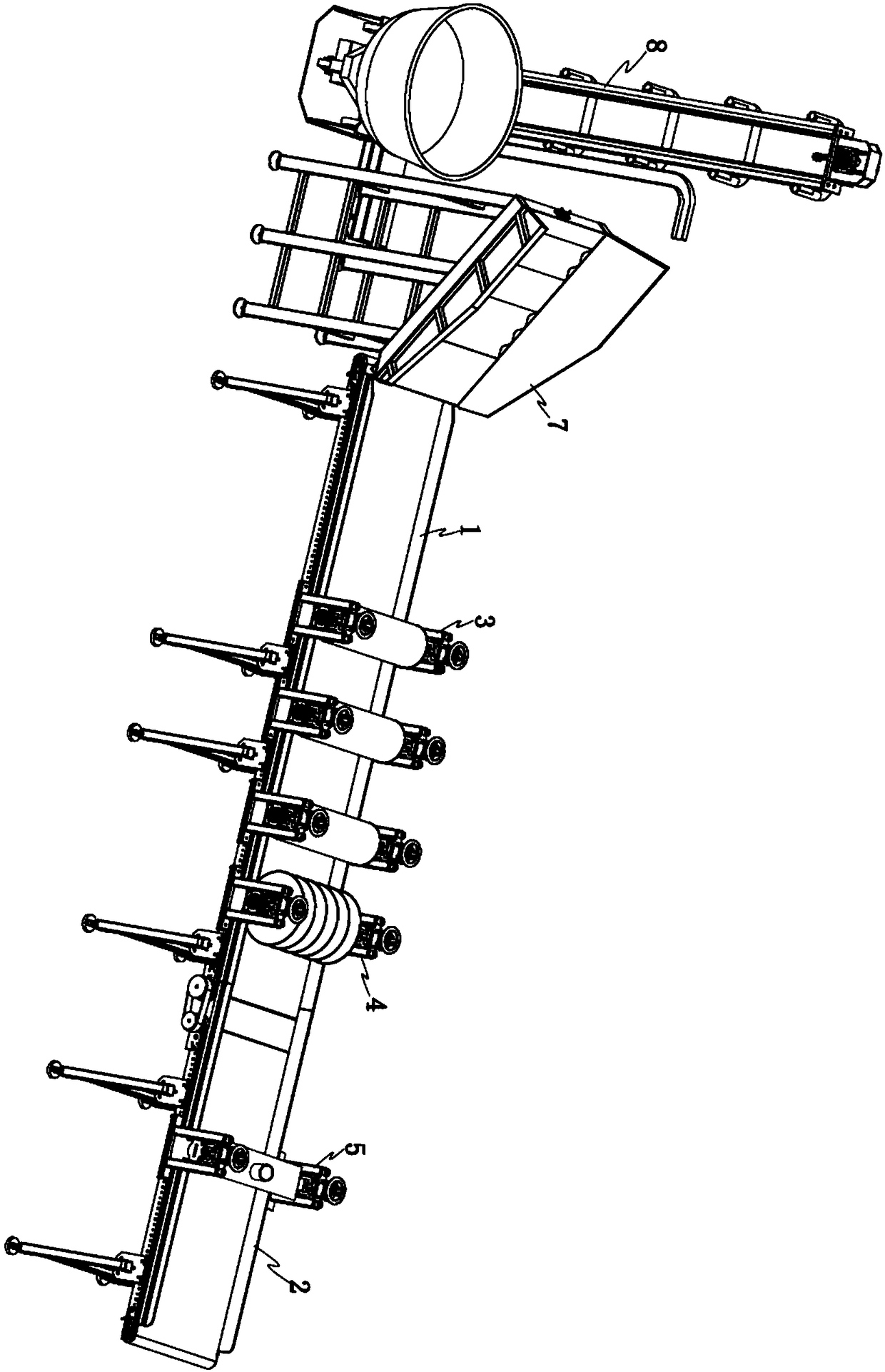

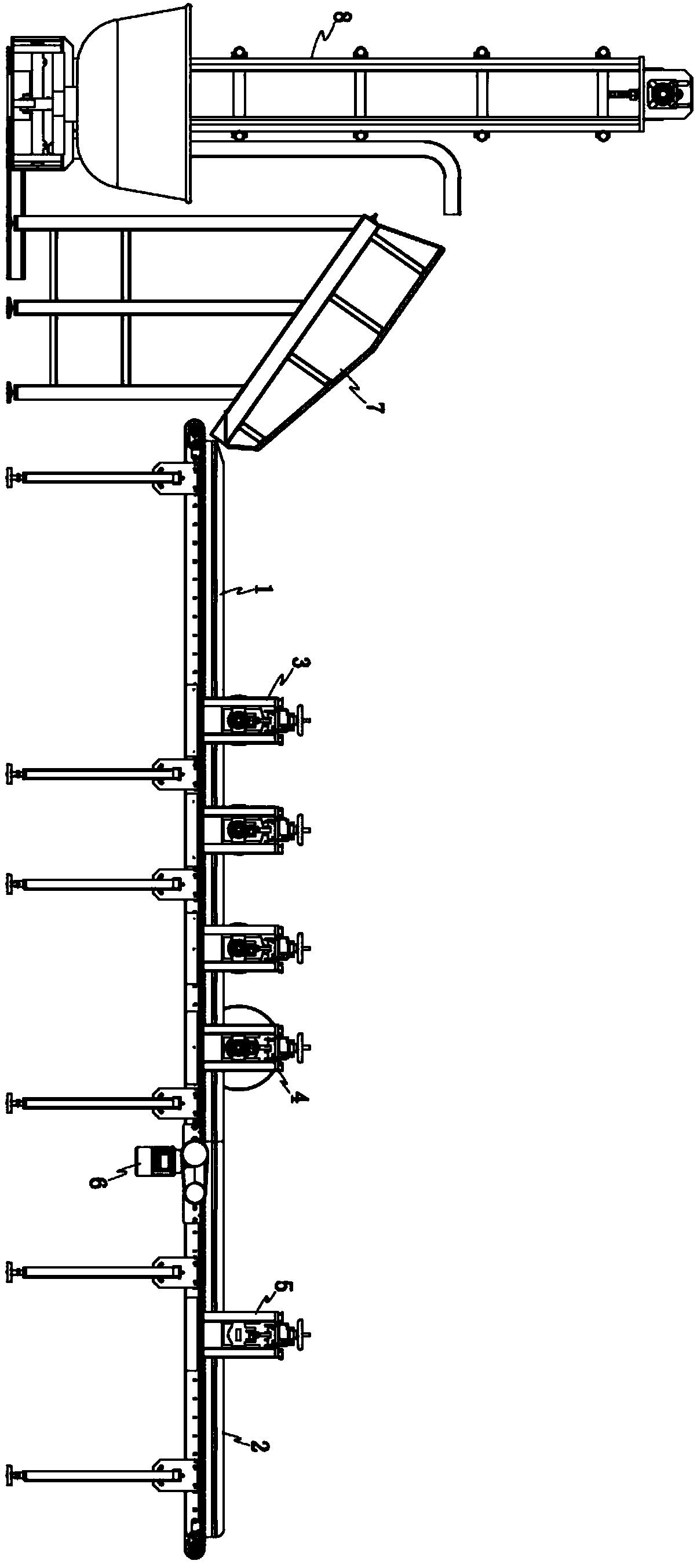

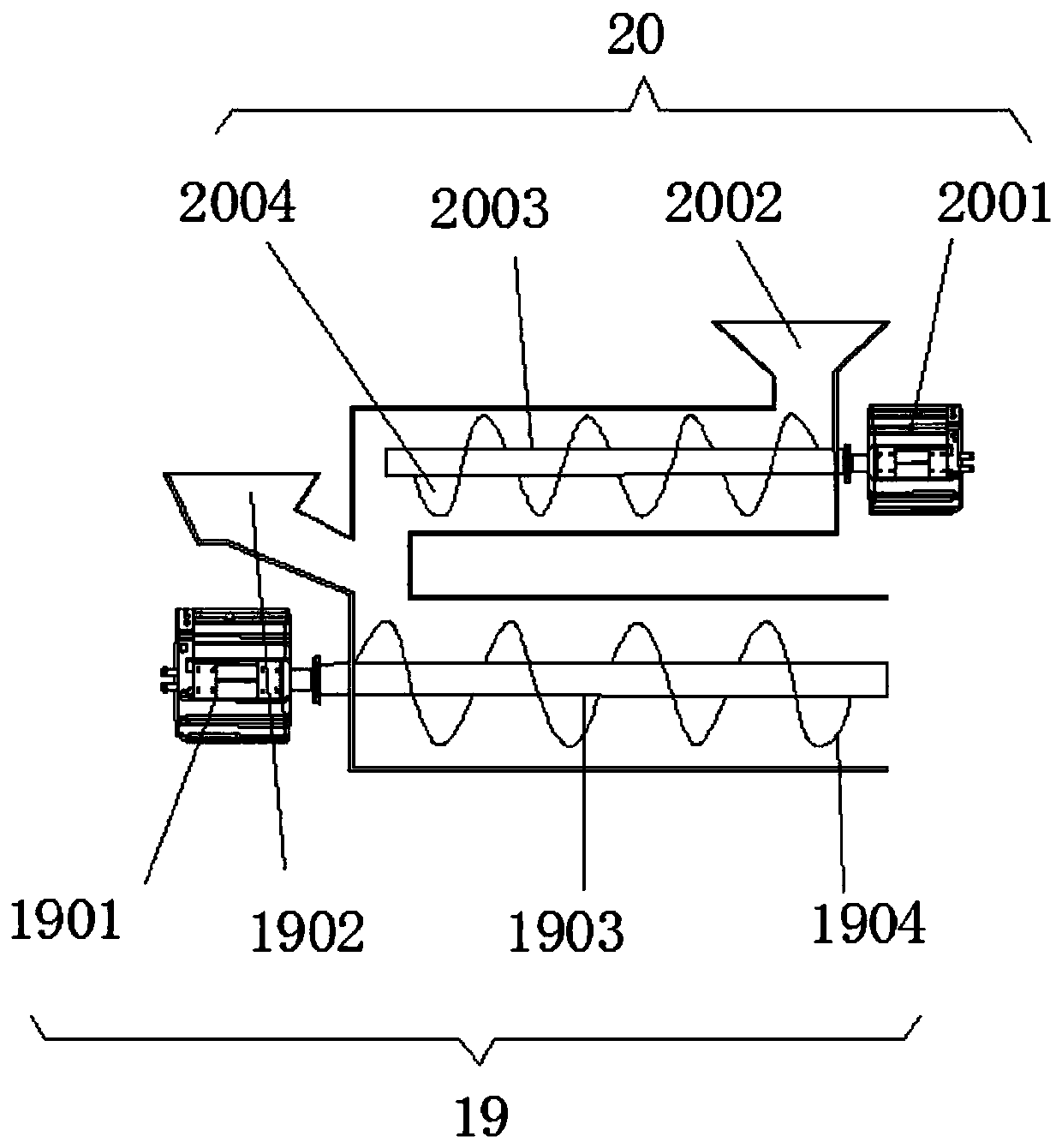

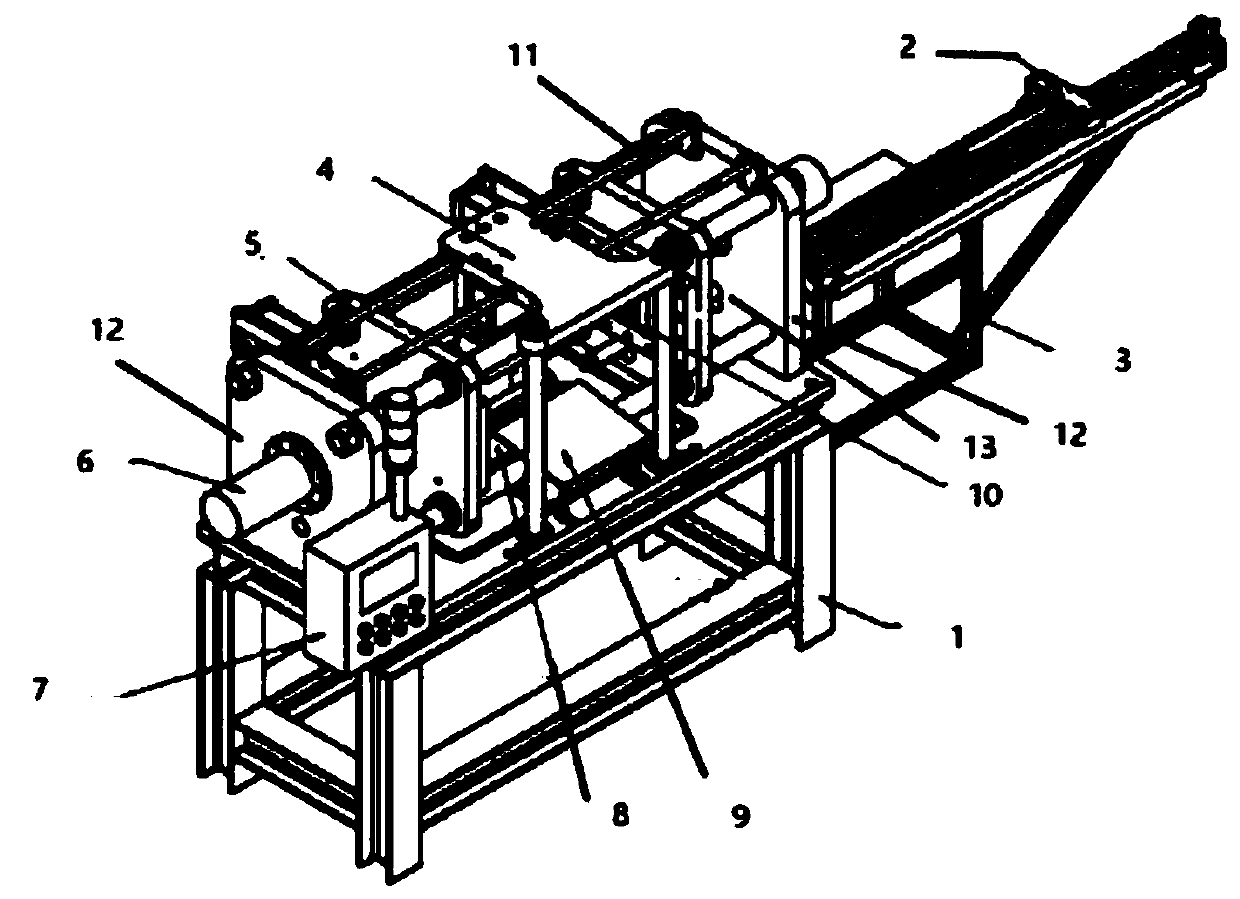

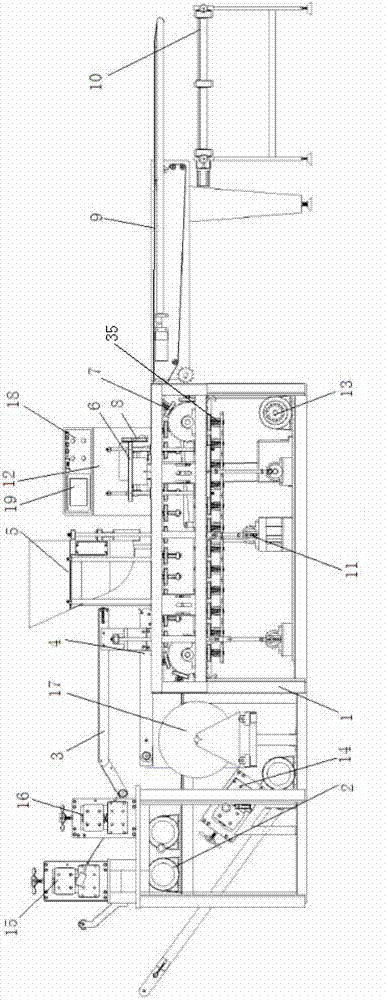

Method and system for spread cooling and stacking during brewing

InactiveCN108624438AConsistent shape and sizeAlcoholic beverage preparationEngineeringUltimate tensile strength

The invention relates to a method and a system for spread cooling and stacking during brewing. The method comprises: spreading, spread cooling, koji adding, and stacking. The system comprises a fermented mash spread-cooling component arranged on a spread-cooling truss and a stacking component arranged on a stacking truss, wherein the spread-cooling truss and the stacking truss slide along a trackunder the action of external force, and one end of the track is provided with a lees transfer box. According to the present invention, with the method and the system, the mechanical flipping spreadingand koji adding can be achieved so as to substantially reduce the labor intensity and improve the quality stability of the brewed liquor.

Owner:HUBEI ZONGHENG TECH

Rice cake production device

InactiveCN108272010ARealize mechanized mass productionIncrease productivityMetal working apparatusRotary pressEngineeringProduction quality

The invention relates to a rice cake production device. The device comprises a first conveyer belt, a second conveyer belt which is arranged at one end part of the first conveyer belt and an introduction plate frame which is arranged at the other end part of the first conveyer belt; a rolling pressing mechanism and a rolling cutting mechanism are arranged in parallel on the first conveyer belt, and a vertical cutting mechanism is arranged on the second conveyer belt; and the feeding end of the introduction plate frame is provided with a rice mixing and lifting mechanism. The device realizes mechanized batch production of rice cakes, not only reduces manpower investment, but also improves the production efficiency of the rice cakes. Meanwhile, the produced rice cakes are consistent in size,and the device improves the production quality of the rice cakes, and meets commercial production requirements.

Owner:杭州巧狮信息科技有限公司

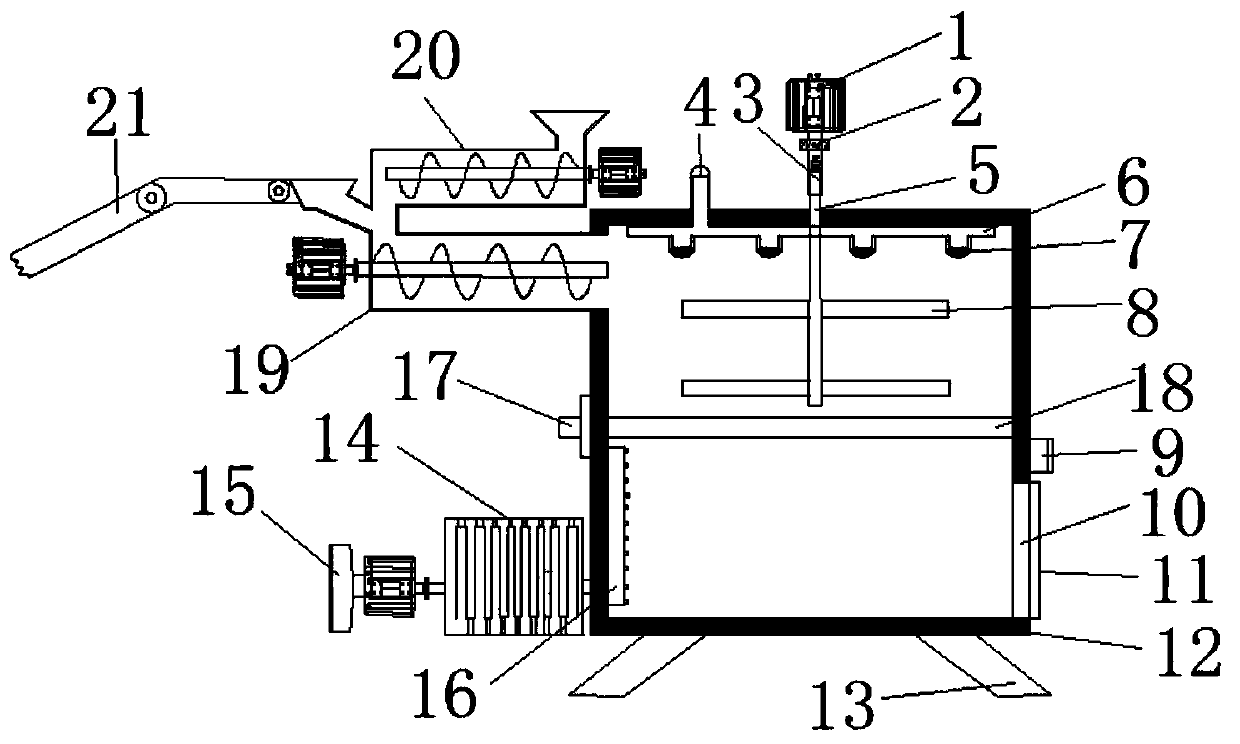

Organic fertilizer blending and fermentation device

InactiveCN110436976AUniform temperatureGuaranteed to be heatedOrganic fertiliser preparationSpray nozzleAgricultural engineering

The invention relates to the technical field of fertilizer fermentation, and discloses an organic fertilizer blending and fermentation device, which comprises a first driving machine. A driving shaftbelow the first driving machine is movably connected with a rotating shaft through a spline, and the rotating shaft passes though a blending kettle and is fixed to stirring blades. A valve is fixedlymounted on the blending kettle. A spraying pipe is movably connected below the valve and the lower part of the spraying pipe is movably connected to spraying nozzles. Stirrers are fixedly mounted at the left upper part of the blending kettle, a temperature controller is fixedly mounted at the right lower part of the blending kettle, and a heat dissipater is fixedly mounted at the left side in theblending kettle. The left side of the heat dissipater is movably connected to the right side of the heater through a pipe, and the left side of the heater is movably connected to a blower. Through thefine stirrer and the coarse stirrer, the device achieves spraying while stirring, blowing by the blower and heating by the heater, and achieves material shape and size uniformity, uniform mixing of astarter and materials, and uniform heating.

Owner:湖南天爱农业科技有限公司

Pneumatic type multi-glue-barrel dispensing mechanism and dispensing method thereof

ActiveCN110947583AHigh movement precisionFeature ConcentrationLiquid surface applicatorsCoatingsRobot handDrive by wire

The invention discloses a pneumatic type multi-glue-barrel dispensing mechanism and a dispensing method thereof. The mechanism comprises a stand column platform, a linear drive assembly, multiple dispensing units, multiple dispensing mechanical hands and a dispensing control box. The linear drive assembly which is transversely arranged is laid flat on the stand column platform. The multiple dispensing units which independently move leftwards and rightwards are arranged on the linear drive assembly. Each dispensing mechanical hand capable of being regulated up and down is arranged at the frontend of the corresponding dispensing unit. Glue barrels on the dispensing mechanical hands are connected with the dispensing control box through gas pipes. The multiple dispensing mechanical hands in the pneumatic type multi-glue-barrel dispensing mechanism can conduct dispensing on a support while doing multidimensional independent movement in the X direction, the Y direction and the Z direction,contact assemblies of the dispensing mechanical hands transmit electrical signals through closing and opening of upper contacts and lower contacts, the relative height of dispensing heads is confirmedthrough the electrical signals, the pressure in the glue barrels can be regulated through the dispensing control box, glue discharged from the dispensing heads can keep consistent micro glue sizes and shapes, and the dispensing speed and precision are remarkably increased.

Owner:SHENZHEN XINYICHANG TECH CO LTD

Planting method capable of shaping organic carrot ginseng

InactiveCN102960170AGuaranteed absorptionGuaranteed stabilityCultivating equipmentsHorticultureOrganic fertilizerQuercetin

A planting method capable of shaping organic carrot ginseng is characterized in that four matched schemes including design of a shaping mould, preparation of nutrient organic fertilizer, preparation of nutrient fluid, and organic planting method, are adopted to perform the whole planting process of shaping carrot ginseng. Therefore, the produced organic carrot ginseng products have a sweet taste, are shaped like ginseng, are uniform in size, and contain high carroty; and the functional substances like quercetin and nucleogelase in the organic carrot ginseng are more than 4 times of those in ordinary carrots, and the overall nutrient value is remarkably improved.

Owner:王盾

Medical dressing cutting device

ActiveCN104027204AConsistent shape and sizeSmooth cutBandagesMechanical engineeringHigh Frequency Waves

The invention discloses a medical dressing cutting device which comprises a working platform. A supporting block is arranged on each of two sides of the front end of the working platform, two ends of a rodless air cylinder communicated with an air source are arranged in grooves of the supporting blocks in a clamped manner respectively to arrange the rodless air cylinder on the working platform in a suspended manner, a high-frequency vibrating knife communicated with the air source is connected with a guide block on the rodless air cylinder through a clamp to vertically arrange the high-frequency vibrating knife on the rodless air cylinder, the guide block can be driven by the rodless air cylinder to drive the high-frequency vibrating knife to slide along a cylinder body of the rodless air cylinder, a groove allowing the high-frequency vibrating knife to pass is formed in the working platform, and the air source is connected with a control device. The medical dressing cutting device has the advantages of simple structure, convenience in operation, orderliness in cut and freeness of generating burrs.

Owner:SUZHOU & SCI & TECH DEV

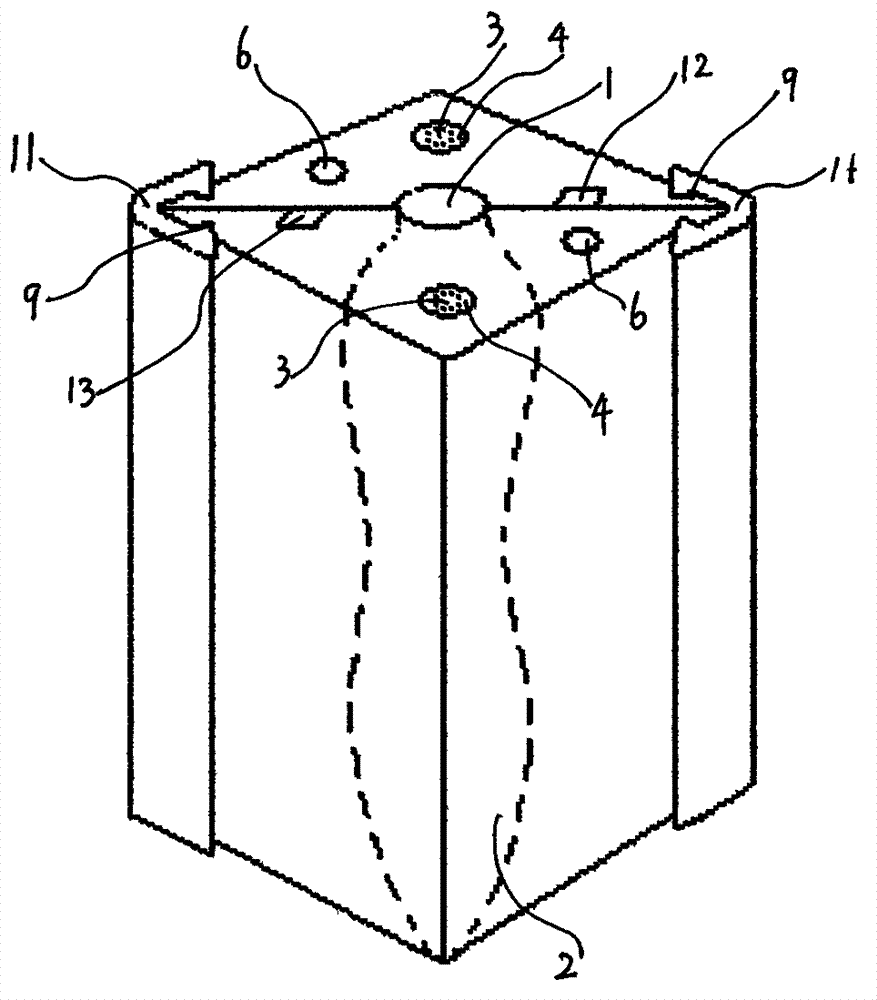

Arc zipper and manufacturing method thereof

ActiveCN104082915AGuaranteed aestheticsEven by forceSlide fastenersAgricultural engineeringInjection moulding

Owner:ZHEJIANG WEIXING IND DEV

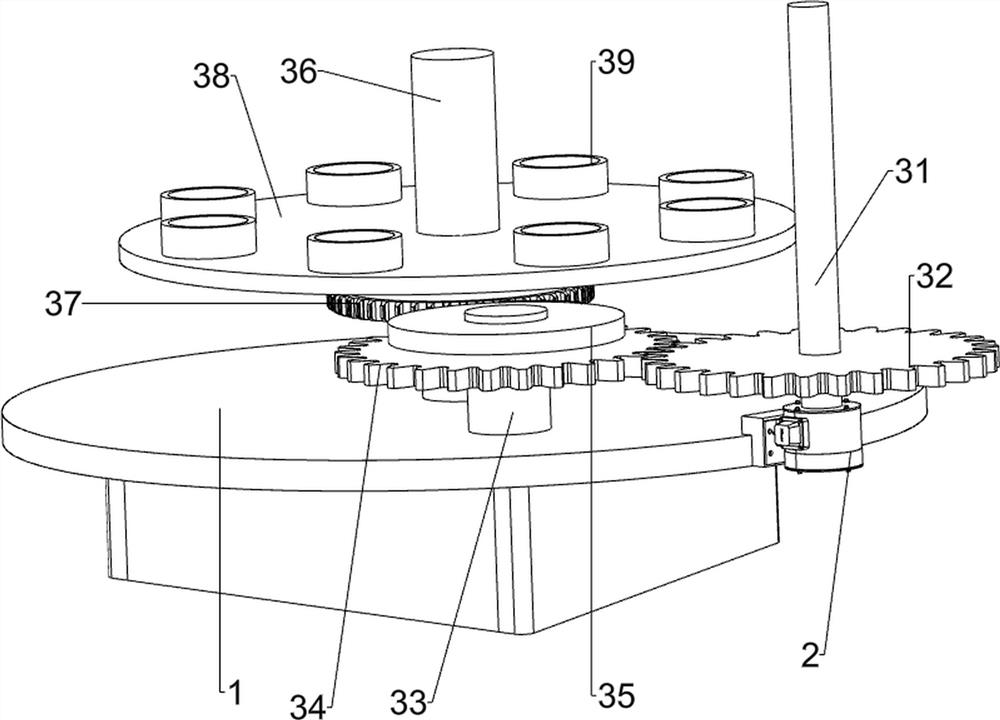

Pressing type egg tart manufacturing equipment

ActiveCN112425620AImprove work efficiencyEasy to collectDough shaping and cutting apparatusDough processingElectric machineryAnimal science

The invention relates to manufacturing equipment, in particular to pressing type egg tart manufacturing equipment. According to the pressing type egg tart manufacturing equipment, dough can be automatically cut, extruded and formed, and manufactured egg tarts are consistent in size. The pressing type egg tart manufacturing equipment provided by the invention comprises: a bottom plate and a gear motor, wherein the gear motor is arranged on the upper portion of one side of the bottom plate; a feeding mechanism which is arranged between the middle of the top of the bottom plate and an output shaft of the gear motor; supporting columns which are arranged on the three sides of the top of the bottom plate; a top plate which is arranged among the tops of the supporting columns; a first discharging mechanism which is arranged between one side of the top of the top plate and the feeding mechanism; and an extrusion mechanism which is arranged between one side of the top of the top plate and thefeeding mechanism. Through cooperation of the feeding mechanism, the first discharging mechanism and the extrusion mechanism, dough can be automatically discharged and cut, the dough is automaticallyextruded to form egg tarts, and the working efficiency of people is improved.

Owner:三明市尚谷食品生产有限公司

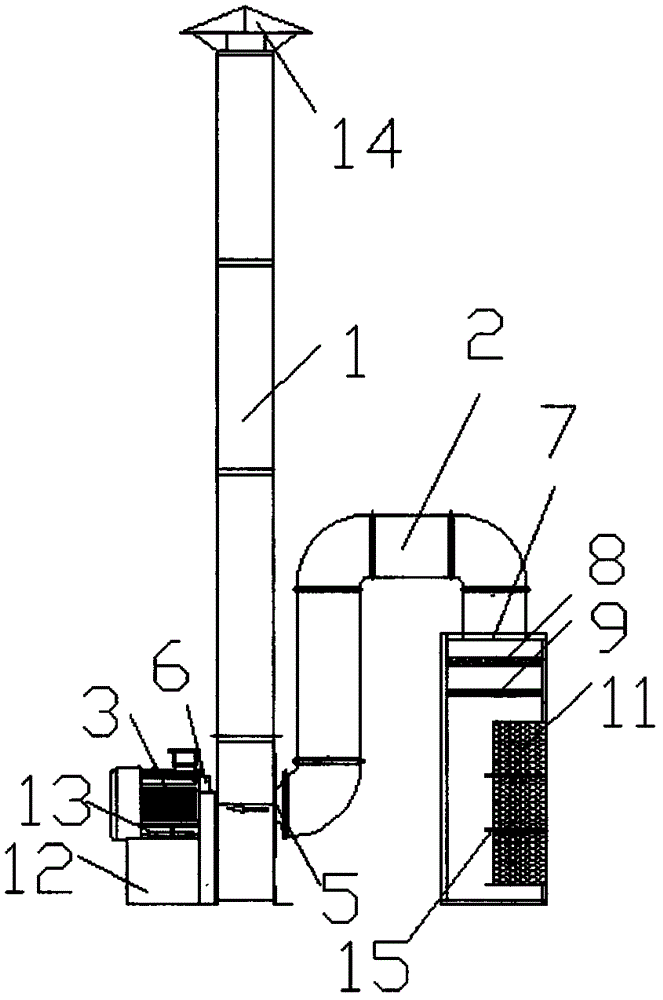

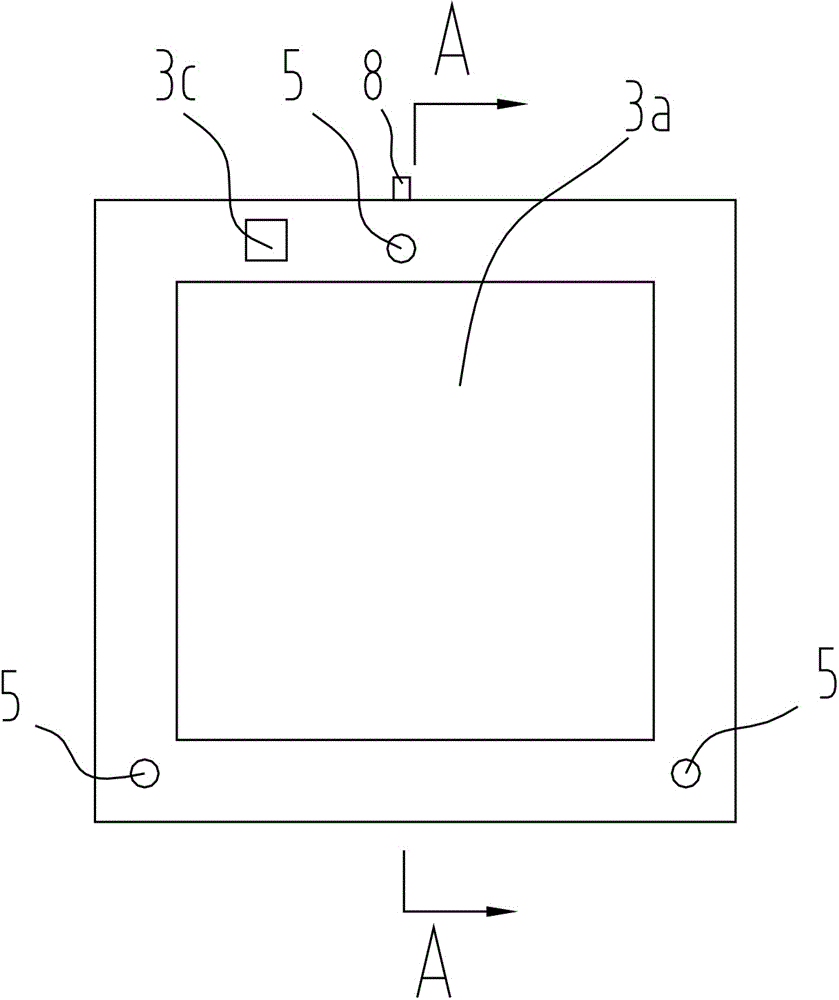

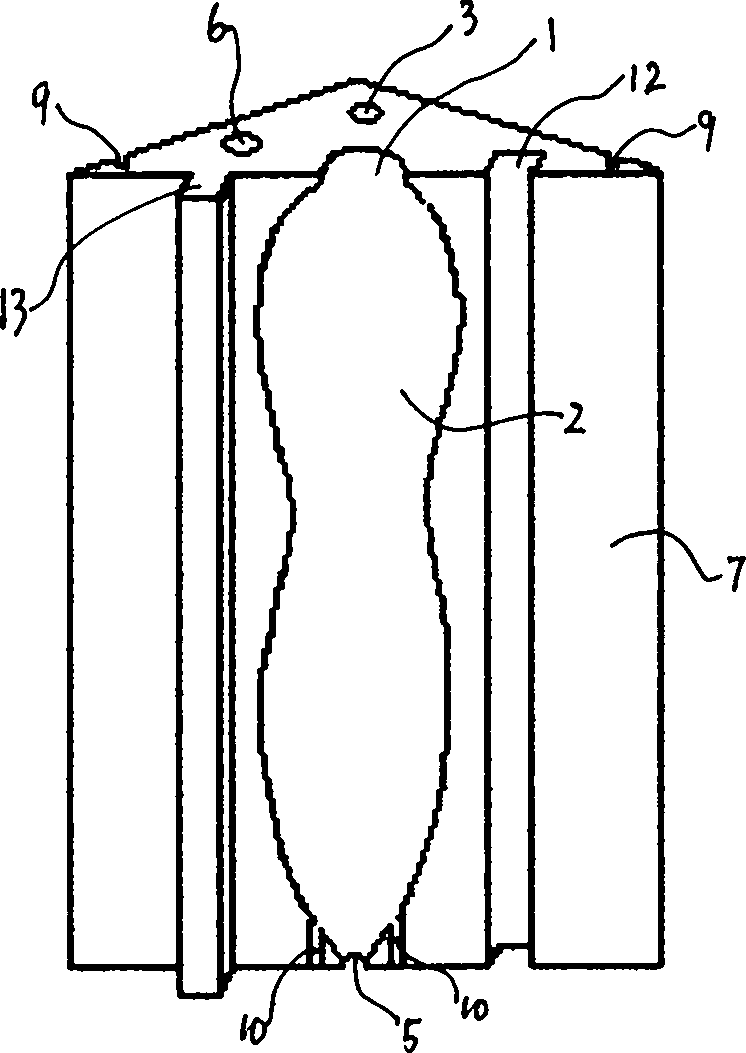

Dry paint mist filter

InactiveCN106178716ADecrease productivityPrevent air leakageDispersed particle filtrationActivated carbonLacquer

The invention discloses a dry paint mist filter, which comprises an exhaust tube, a suction duct, a centrifugal fan and a filtering device. Round holes and small holes are arranged on both sides of the bottom of the exhaust tube. The suction duct Connect with the angle steel flange of the exhaust tube through the round hole one, the centrifugal fan is softly connected with the exhaust tube through the small hole, the top of the filter device is provided with the round hole two, and the suction pipe is connected with the filter device through the round hole two Angle steel flange connection, an activated carbon adsorption layer is provided on the top of the filter device, a turbulent ball filter layer is provided below the activated carbon adsorption layer, a square hole is provided on one side of the filter device, and multi-layer folded holes are inlaid on the square hole. type filter, and the bottom of the centrifugal fan is provided with a shock-absorbing pedestal and a shock absorber. The invention has a simple structure and can effectively filter the environmental protection paint mist.

Owner:宁波市嘉隆节能环保科技有限公司

Picture frame

InactiveCN103584583BPrevent displacement and deformationEasy to replacePicture framesDomestic mirrorsEngineeringDiamond

The invention provides a picture frame which comprises a back plate and a transparent face plate. The picture frame is characterized in that a clamping plate is arranged between the back plate and the transparent face plate, a hollowed picture cavity where a picture is arranged is formed in the middle of the clamping plate, a frame portion of the clamping plate is arranged at the periphery of the picture cavity, and the transparent face plate, the back plate and the clamping plate are detachably and fixed connected through at least three groups of connecting fixing parts. All components of the picture frame can be manufactured in batch. A cross-stitch picture or diamond picture DIY fan can directly buy the picture frame to mount a picture, a complex process for mounting the picture through a picture mounting factory and the higher picture mounting cost are eliminated, and furthermore, the DIY fan can replace the picture in the picture frame at any time to improve DIY enjoyment.

Owner:周巧

Method for manufacturing and cultivating large plant modeling trees

PendingCN112243789AFast formingConsistent shape and sizeCultivating equipmentsForestryAgricultural engineeringBiology

The invention belongs to the technical field of large plant modeling tree cultivation, and particularly relates to a method for manufacturing and cultivating large plant modeling trees. The method comprises the following steps of (1) seedling raising, (2) modelling manufacturing, (3) field transplanting, (4) modelling maintenance and (5) forming. The various large plant modeling trees can be manufactured, forming is fast, the modeling sizes are consistent, large-scale copying production can be achieved, assembly line work is carried out, binding is carried out according to a mold shape duringprocessing production, operation can be carried out by general workers, for example, the plurality of modeling trees which are manufactured by binding through models and have the modellings with the diameter at breast height of 70 cm are fast and attractive in forming in four to five years, and the working efficiency and the ornamental value are greatly improved.

Owner:朱德记

Preparation method of gas atomization Fe-Si-Al magnetic powder core with ultralow magnetic conductivity

ActiveCN114724833AImprove passivation effectHigh hardnessInductances/transformers/magnets manufactureMagnetic materialsAl powderO-Phosphoric Acid

The invention discloses a preparation method of an ultra-low magnetic conductivity atomized Fe-Si-Al magnetic powder core, and relates to the technical field of metal soft magnetic materials. The problem that an oxide layer on the surface of the Fe-Si-Al powder is prone to falling off from the surface of the Fe-Si-Al powder in the subsequent processing link is solved. The method specifically comprises three steps of gas atomization powder preparation, passivation treatment and magnetic powder core preparation, and the gas atomization powder preparation comprises the following steps that pure iron blocks, silicon iron blocks and aluminum particles are poured into a vacuum high-frequency induction furnace to be smelted, and the silicon iron blocks account for 10-11.5%; a proper amount of chromic acid is added into the mixed acid liquor formed by mixing phosphoric acid, boric acid, hydrochloric acid and water, the passivation effect of the mixed acid liquor on the surface of the Fe-Si-Al powder can be effectively improved, meanwhile, lead or chromium contained in the Fe-Si-Al powder is matched, the covering uniformity of an oxidation film on the surface of the Fe-Si-Al powder can be improved, and the service life of the Fe-Si-Al powder is prolonged. And an oxidation film on the surface of the Fe-Si-Al powder is prevented from easily falling off in subsequent processing.

Owner:天通(六安)新材料有限公司

Konjac refining machine

PendingCN108783319AHarmonize and delicateTough enoughTransportation and packagingRotary stirring mixersImpellerPropeller

The present invention provides a konjac refining machine and relates to the technical field of food processing. The konjac refining machine at least comprises a first screw propeller and a second screw propeller arranged on a machine frame and communicating with each other; a first material inlet is arranged on the first screw propeller; a second material outlet is arranged on the second screw propeller; and a first stirring shaft of the first screw propeller and a second stirring shaft of the second screw propeller are both provided with spiral impellers. The konjac refining machine can achieve secondary impelling, thus enables a konjac raw material to be blended more delicately and also have sufficient toughness and elasticity, refines spirally impelled viscous paste konjac and relies onfriction between the stirring shafts and the refining machine to realize the non-heat-source self-cooking of the konjac and high in production efficiency; and the processed cooked instant food reaches quality requirements of consistent shapes and sizes, uniform tube shape and delicious seasoning.

Owner:LUOHE HENGFENG MACHINERY MOLD

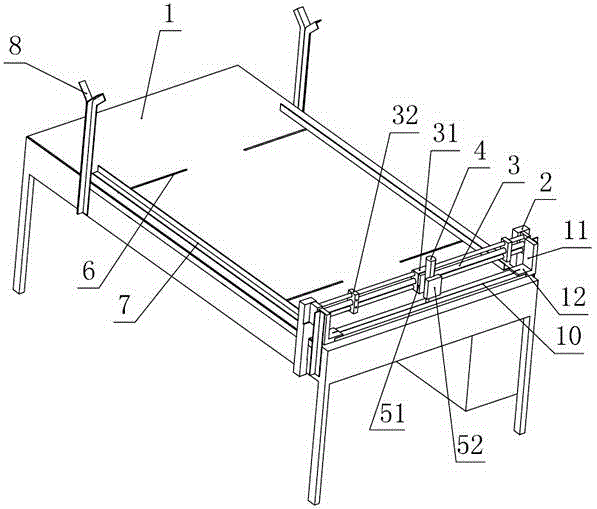

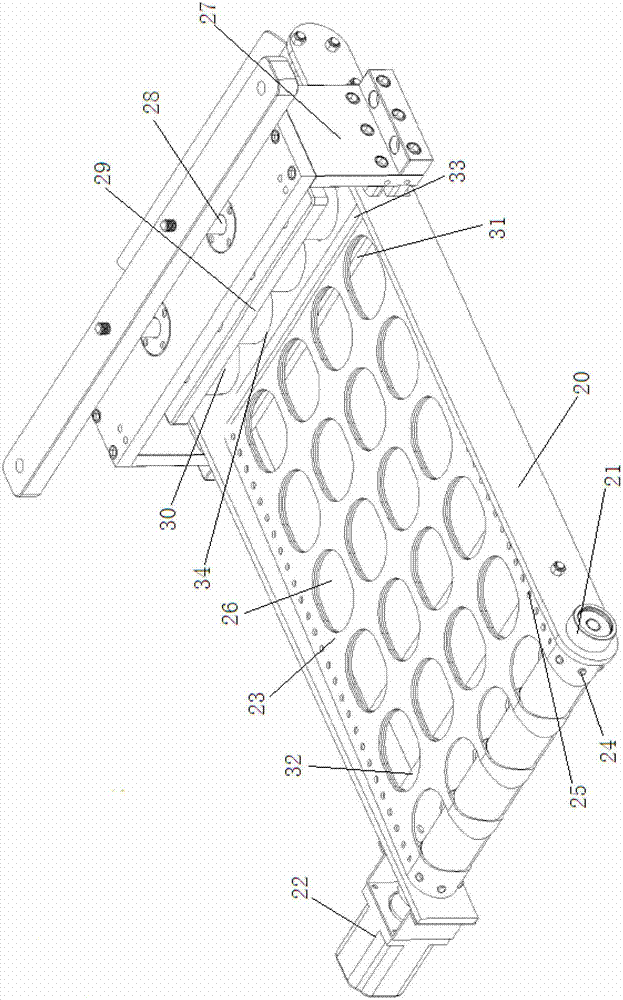

Manual steaming pad punching and forming device

InactiveCN112246964AConsistent shapeConsistent shape and sizeMetal-working feeding devicesStripping-off devicesMoulding deviceStructural engineering

The invention relates to a punching and forming device, in particular to a manual steaming pad punching and forming device. The manual steaming pad punching and forming device has functions of automatically blanking, pushing, punching, forming and discharging circular aluminum plates. The manual steaming pad punching and forming device comprises a worktable, a blanking table, first rotating shafts, rotating cylinders, conveying belts and pushing blocks, wherein the blanking table used for placing circular aluminum plates is arranged on one side of the top of the worktable;the first rotating shafts are symmetrically and rotationally arranged at the upper parts of the two sides of the interior of the worktable;the rotating cylinders are arranged on the first rotating shafts;the conveying belts are arranged on two sides of a part between the rotating cylinders; and the pushing blocks are uniformly arranged on each conveying belt. Through cooperation of a transmission device and a stampingdevice, the circular aluminum plates can be automatically blanked, punched, formed and discharged; the manufactured steaming pads are consistent in shape and size; and the working efficiency of people is improved.

Owner:张彪

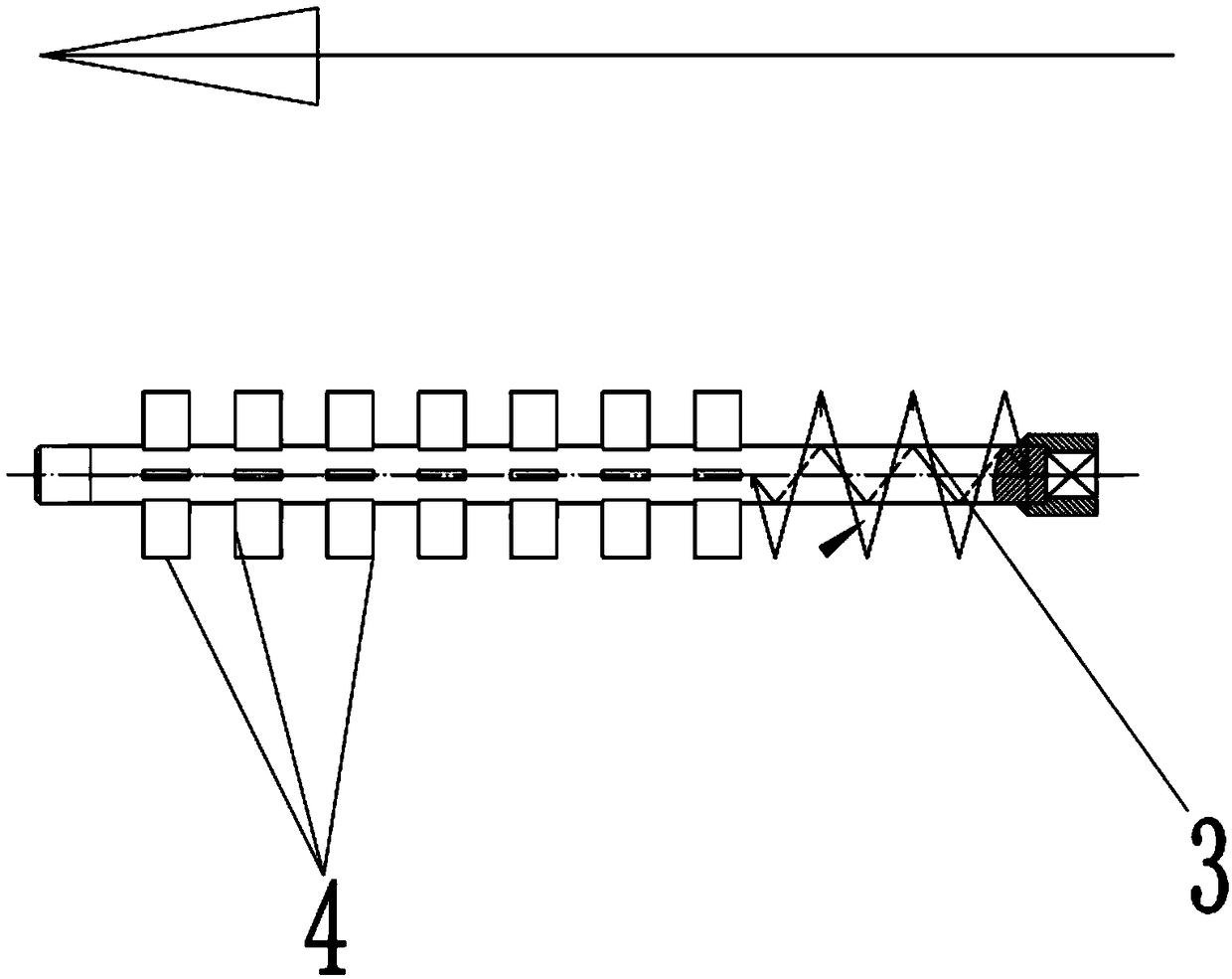

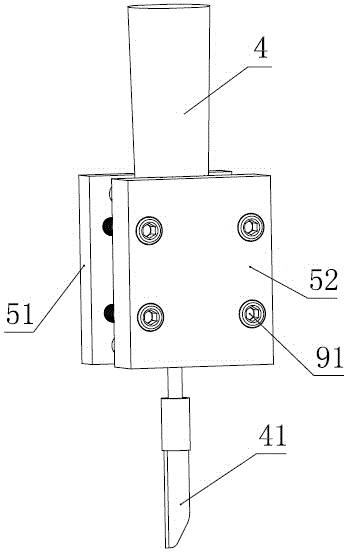

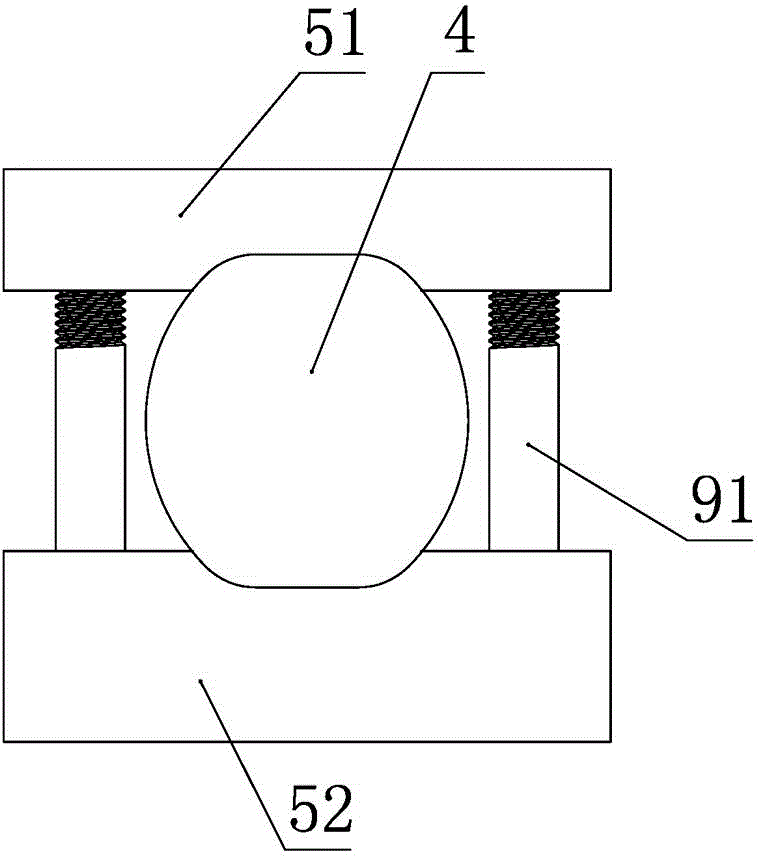

Ball-heading blank-making machine of shackle and using method thereof

The invention provides a shackle ball-heading blank-making technology with repeated forming and realizing production automation. According to the technical scheme, the ball-heading blank-making machine of a shackle comprises a machine frame main body, an automatic feeding mechanism, a die fixing mechanism, a forming die set, a lifting mechanism, an automatic discharging mechanism and a control panel, the forming die set comprises a primary forming die and a secondary forming die, and the forming die set is arranged on the die fixing mechanism. The process steps are designed in a unique manner,so that automatic production is realized, meanwhile, the occupied area and the reference of equipment are optimized, the production cost is reduced, the die forming speed is increased, and the loss of raw materials is reduced; and in addition, secondary forming can make up a part of defects of the primary forming, so that the rate of finished products is improved.

Owner:QINGDAO QINDE RIGGING HARDWARE

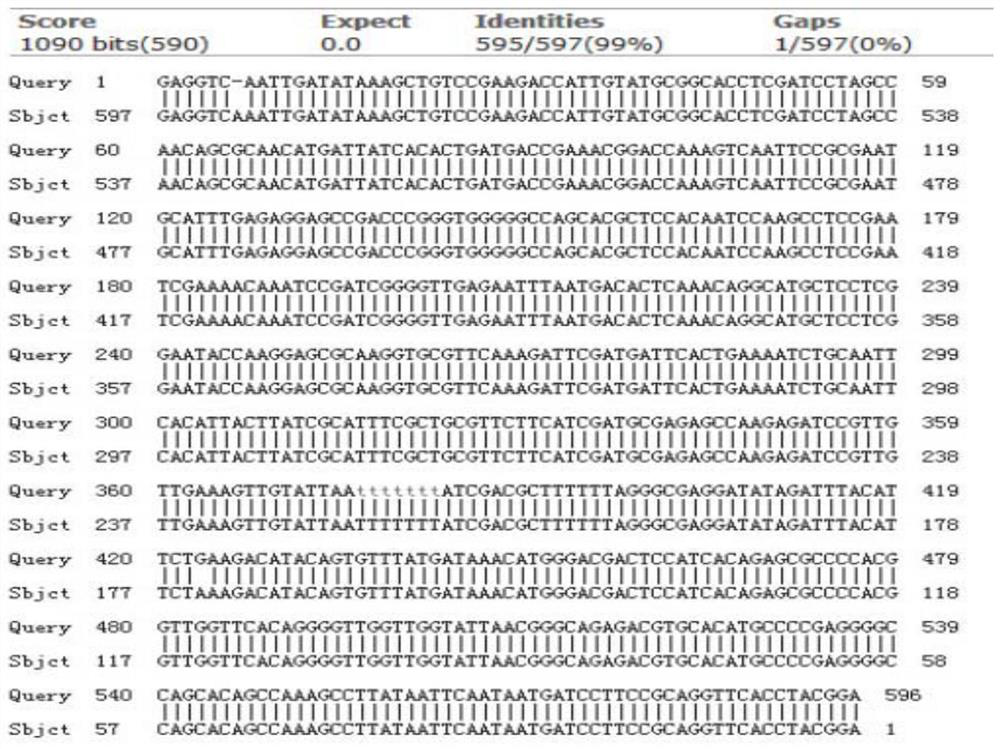

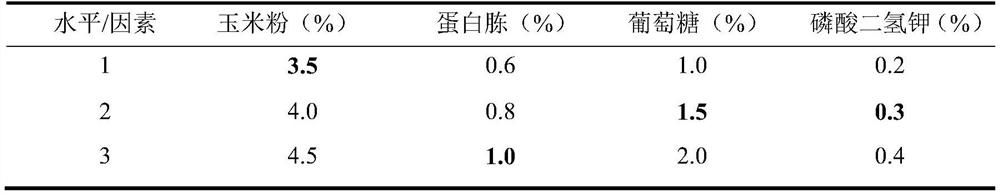

Liquid culture method of a kind of fungal strain and mycelia

ActiveCN110016438BImprove immunityRelieve physical fatigueFungiMetabolism disorderBiotechnologyMycelium

The invention provides a liquid culture method for a novel fungal strain and its mycelium. The fungi are Fibularhizoctonia sp. fungi of Basidiomycota, Agaricomycetes, Atheliales, and Atheliaceae, and the preservation number is CCTCC M 2018446. The mycelium of the strain is rich in polysaccharides and triterpenoids, and can be developed and applied as a new type of edible fungus. The mycelium obtained by the liquid culture method of the invention has good growth and high mycelium yield, and the artificial liquid culture of the strain is successfully realized.

Owner:NORTHWEST UNIV

Planting method capable of shaping organic carrot ginseng

InactiveCN102960170BGuaranteed absorptionGuaranteed stabilityCultivating equipmentsHorticultureOrganic fertilizerQuercetin

A planting method capable of shaping organic carrot ginseng is characterized in that four matched schemes including design of a shaping mould, preparation of nutrient organic fertilizer, preparation of nutrient fluid, and organic planting method, are adopted to perform the whole planting process of shaping carrot ginseng. Therefore, the produced organic carrot ginseng products have a sweet taste, are shaped like ginseng, are uniform in size, and contain high carroty; and the functional substances like quercetin and nucleogelase in the organic carrot ginseng are more than 4 times of those in ordinary carrots, and the overall nutrient value is remarkably improved.

Owner:王盾

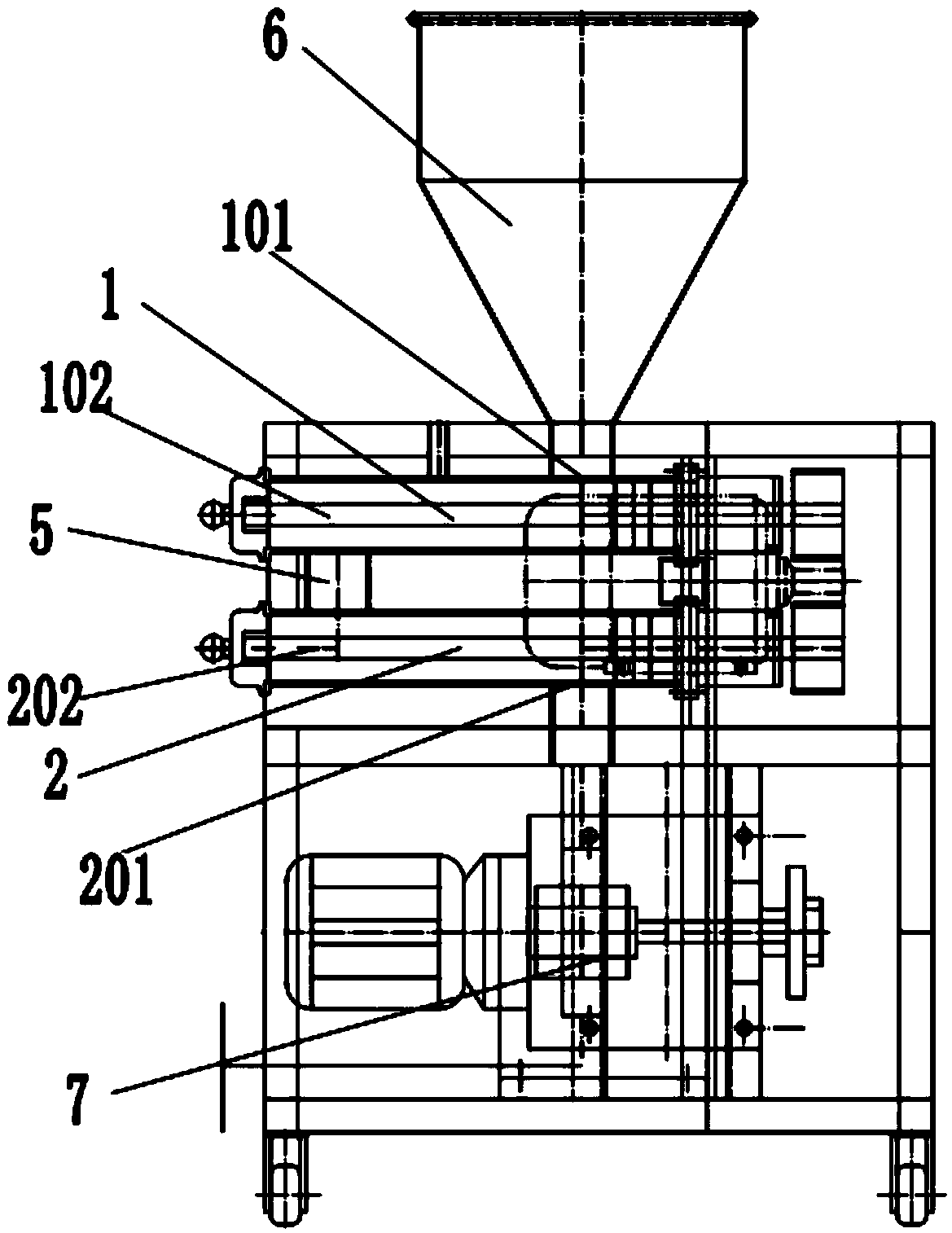

Shaping extrusion type dough discharging equipment

ActiveCN113068727AConsistent shape and sizeImprove work efficiencyPlastic recyclingDough dividingElectric machinePhysics

The invention relates to extrusion discharging equipment, in particular to shaping extrusion type dough discharging equipment. According to the shaping extrusion type dough discharging equipment, dough can be automatically cut, and the cut dough is consistent in shape and size. The shaping extrusion type dough discharging equipment comprises a bottom plate and a motor bottom frame, and the motor bottom frame is arranged on one side of the top of the bottom plate; a servo motor which is arranged at the top of the motor underframe; a discharging mechanism which is arranged on one side of the top of the bottom plate; a pushing mechanism which is arranged on one side of the top of the bottom plate; and a cutting mechanism which is arranged on one side of the top of the bottom plate. Through cooperation of the discharging mechanism, the pushing mechanism and the cutting mechanism, feeding, extrusion shaping and cutting operation of dough can be automatically completed, the working efficiency of people is improved, and the cut dough is consistent in shape and size.

Owner:江苏满嘴香食品科技有限公司

Cutting device for medical dressing

The invention discloses a medical dressing cutting device which comprises a working platform. A supporting block is arranged on each of two sides of the front end of the working platform, two ends of a rodless air cylinder communicated with an air source are arranged in grooves of the supporting blocks in a clamped manner respectively to arrange the rodless air cylinder on the working platform in a suspended manner, a high-frequency vibrating knife communicated with the air source is connected with a guide block on the rodless air cylinder through a clamp to vertically arrange the high-frequency vibrating knife on the rodless air cylinder, the guide block can be driven by the rodless air cylinder to drive the high-frequency vibrating knife to slide along a cylinder body of the rodless air cylinder, a groove allowing the high-frequency vibrating knife to pass is formed in the working platform, and the air source is connected with a control device. The medical dressing cutting device has the advantages of simple structure, convenience in operation, orderliness in cut and freeness of generating burrs.

Owner:SUZHOU & SCI & TECH DEV

Isolation type onion intelligent planting equipment

InactiveCN112825707AConsistent shape and sizeEasy to classifySelf-acting watering devicesHarvestersEnvironmental geologySeedling

The invention discloses an isolated type onion intelligent planting equipment. The equipment comprises a ground-contact plate laid on the ground and a movable collection box; air holes outside a shell are used for ventilation, water vapor in soil at the bottom of the ground-contact plate can also enter the shell through the air holes, and an absorbent cotton layer prevents external soil from entering the shell; and when onion seedlings are planted in holes in the surface of the ground-contact plate, the roots of the onion seedlings grow in the shell and are taken out when growing to the maximum size; when a collecting box slides, the roots of the onion seedlings can be separated from stems above the onion seedlings through cutters on the surface of the collecting box, the stems of the onion seedlings are collected in the collecting box, and the roots of the onion seedlings are collected in the shell. According to the isolated type onion intelligent planting equipment, the roots of the onion seedlings are contained, so that the onion seedlings grow directionally, the shapes and the sizes are consistent, classification is convenient, the roots of the onion seedlings are isolated from soil in the growth process, the cleanliness is high, and the stems of the onion seedlings are harvested and collected at a time.

Owner:安徽维嵩生产力促进有限公司

A kind of preparation method of fungal mycelia fine powder

Owner:NORTHWEST UNIV

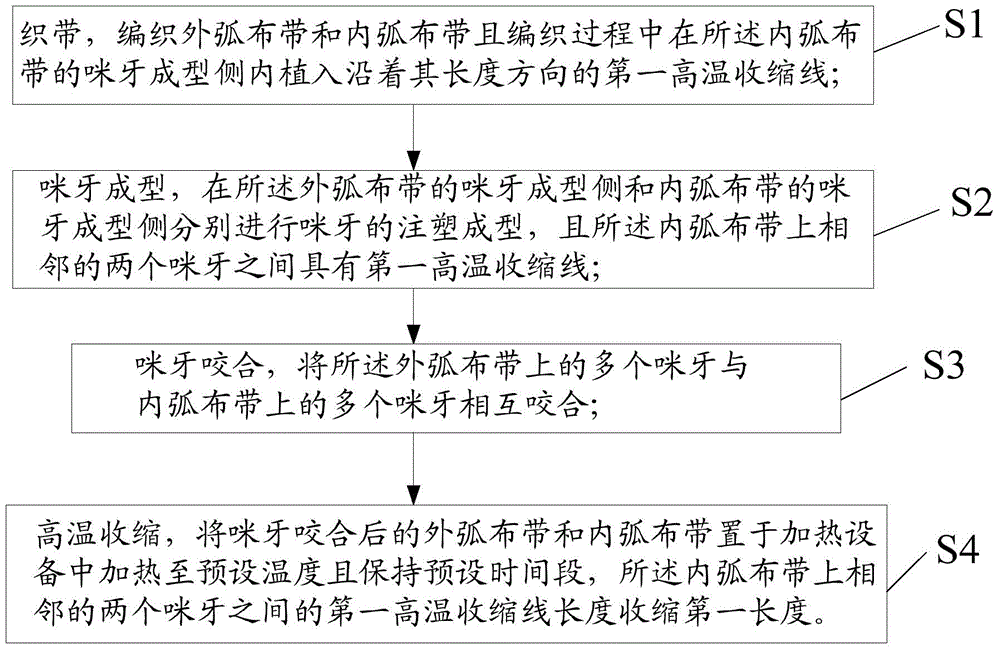

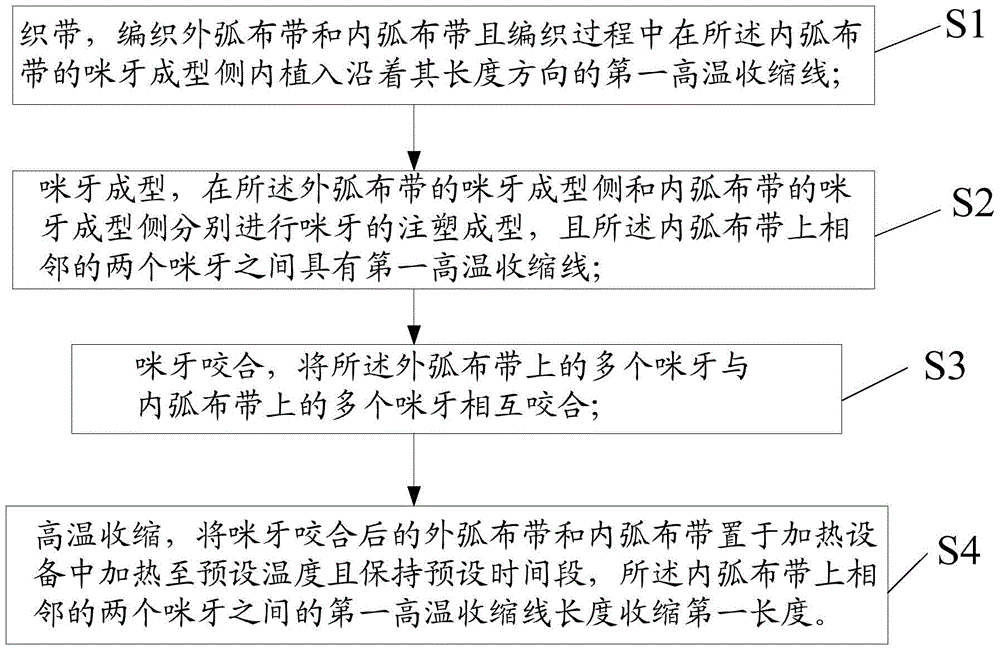

Curved zipper and manufacturing method thereof

ActiveCN104082915BGuaranteed aestheticsEven by forceSlide fastenersInjection mouldingMechanical engineering

The invention discloses an arc-shaped zipper and a manufacturing method thereof. The manufacturing method of the arc-shaped zipper includes the steps of weaving an outer arc cloth tape and an inner arc cloth tape, and implanting the teeth forming side of the inner arc cloth tape during the weaving process. Enter the first high-temperature shrinkage line; the teeth molding, the injection molding of the teeth on the teeth forming side of the outer arc cloth belt and the teeth molding side of the inner arc cloth belt, and the two adjacent teeth on the inner arc cloth belt There is a first high-temperature shrinkage line between the teeth; teeth occlusion, the multiple teeth on the outer arc cloth belt and multiple teeth on the inner arc cloth belt are mutually occluded; high temperature shrinkage, the outer arc after the teeth are occluded The cloth tape and the inner arc cloth tape are placed in a heating device to be heated to a preset temperature and kept for a preset period of time, and the length of the first high-temperature shrinkage line between two adjacent teeth on the inner arc cloth tape shrinks by a first length. The manufacturing method of the arc-shaped zipper can effectively solve the problem of uneven stress on the teeth on the outer-curve cloth tape and the teeth on the inner-curve cloth tape of the arc-shaped zipper.

Owner:ZHEJIANG WEIXING IND DEV

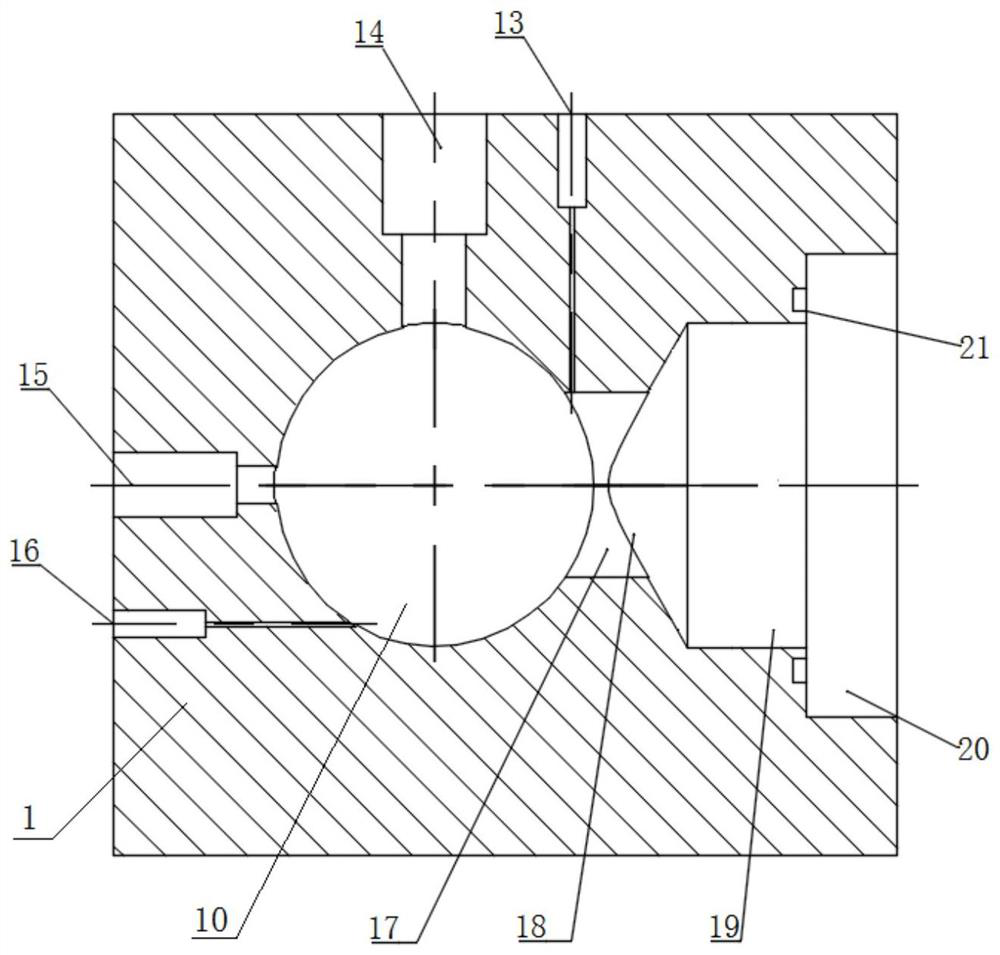

An Optical Fast Compressor Combustion Cylinder Capable of Shooting by Schlieren Method

ActiveCN108060972BMeet the layout requirementsRealize full visual shootingInternal-combustion engine testingInternal combustion piston enginesCombustion chamberPiston

Owner:TIANJIN UNIV

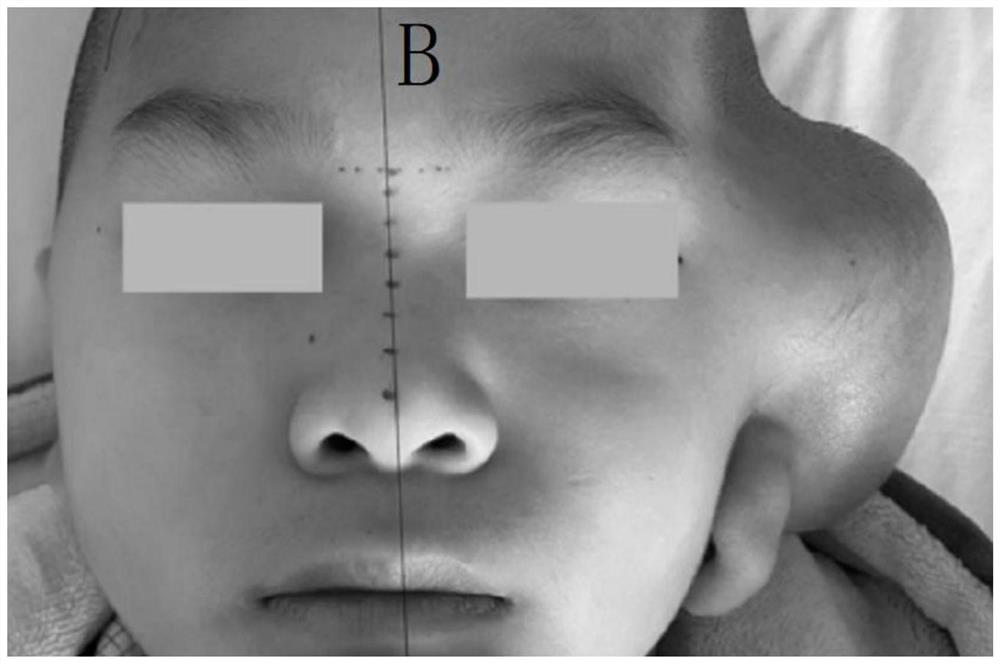

Positioning method for unilateral auricle reconstruction

PendingCN113057625AConsistent shape and sizeLess prone to errorsEar treatmentDiagnostic recording/measuringGonial angleAuricle reconstruction

The invention discloses a positioning method for unilateral auricle reconstruction, the positioning method comprises the following steps: taking the axis of a human face as a calibration axis, transversely straightening by using silk threads respectively by taking the upper edge of an uninjured auricle of a patient as a starting point, and enabling the silk threads to be vertical to the calibration axis; pulling the other end of the silk thread to the reconstructed auricle side of the patient, and drawing lines at the positions, equal in length, of the silk thread on the two sides of the calibration axis to serve as a reconstructed auricle upper edge line, a reconstructed auricle earlobe lower edge line, a reconstructed tragus middle point and a reconstructed auricle earlobe lowest point; connecting the middle point of the reconstructed tragus with the lowest point of the reconstructed auricle earlobe by using the silk thread, drawing the line along the silk thread to connect the middle point of the reconstructed tragus with the lowest point of the reconstructed auricle earlobe to obtain a connecting line, and determining the range of the reconstructed auricle according to the connecting line, the lower edge line of the reconstructed auricle earlobe and the upper edge line of the reconstructed auricle, meanwhile, determining the inclination angle of the reconstructed auricle according to the principle that the long axis of the reconstructed auricle is parallel to the central axis of the nose back part. Positioning is convenient, and precision is high.

Owner:PLASTIC SURGERY HOSPITAL CHINESE ACAD OF MEDICAL SCI

An automatic forming mold for auto parts

The invention relates to the technical field of mold equipment and discloses an automatic forming mold for automatic parts. The automatic forming mold comprises a rack, a guide box, a storage box, anupper mold base and a lower mold base, wherein the lower mold base comprises a first lower mold base and a second lower mold base spliced with each other; the upper mold base is connected with a pushrod; one end of the push rod is connected with a cylinder; two sides of the push rod are connected with an L-shaped rod; the first lower mold base and the second lower mold base are respectively connected with supporting rods; the guide box penetrates through a piston rod; a first rack is arranged on the piston rod and meshed with a first gear; the first gear is meshed with a second gear; a secondrack is arranged on the push rod and meshed with the second gear; the guide box and the upper mold base are communicated with a feed pipe. During injection molding, the upper mold base and the lowermold base are closed, and the molten pattern material is injected into an injection molding cavity from the guide box. During demolding, the upper mold base is separated from the lower mold base, thefirst lower mold base and the second lower mold base are mutually separated, and the injection molding product drops from the interior of the lower mold base so as to realize demolding.

Owner:宁波高盛模具制造有限公司

Multifunctional automatic dumpling machine

InactiveCN102726671BRealize the leather workEasy to reuseFood shapingFood preparationPunchingSkin rolling

The invention discloses a multifunctional automatic dumpling machine, comprising a rack, a skin rolling mechanism, a skin conveyer belt, a punching skin conveying mechanism, a stuffing filling unit, a die closing unit, an encircling intermittent movement dumpling forming template, a disk conveying mechanism, a placement mechanism, an intermittent driving unit and a stepping motor, wherein the punching skin conveying mechanism structurally has a structure that blanking holes on upper and lower side synchronous belts are vertically alignment, the stuffing filling unit realizes multi-hole quantification and synchronization stuffing filling; the contact surface between the skin and the template is reduced by 90% by using the structure of a movable template on the encircling intermittent movement dumpling forming template; protrusion ribs have certain gradients, thus the skins do not adhere to the template and can smoothly enter the forming die; and die assembly can be complete by the projection and concave cavity, thus the produced dumpling has beautiful appearance, and the advantages of firm bonding and low cost are achieved.

Owner:朱景超

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com