Pressing type egg tart manufacturing equipment

A kind of manufacturing equipment and pressing technology, which is applied in the direction of dough forming and cutting equipment, dough forming machinery or equipment, baking, etc., can solve the problems of inconsistent size of egg tarts and low working efficiency of egg tarts, so as to facilitate collection and improve work efficiency Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0066] A pressing type egg tart manufacturing equipment, such as figure 1 As shown, it includes a bottom plate 1, a gear motor 2, a feeding mechanism 3, a support column 4, a top plate 5, a first unloading mechanism 6, and an extrusion mechanism 7. A feeding mechanism 3 is provided between the output shaft of the geared motor 2, a support column 4 is provided on three sides of the top of the bottom plate 1, a top plate 5 is provided between the top of the support column 4, and a top plate 5 is provided between the front side of the top of the top plate 5 and the feeding mechanism 3. The first unloading mechanism 6 is provided with an extruding mechanism 7 between the top right side of the top plate 5 and the feeding mechanism 3 .

[0067]When people need to make egg tarts, first put the dough made by people into a certain part of the first feeding mechanism 6, then turn on the reduction motor 2, put the tin foil tray on a certain part of the feeding mechanism 3 in turn, and sl...

Embodiment 2

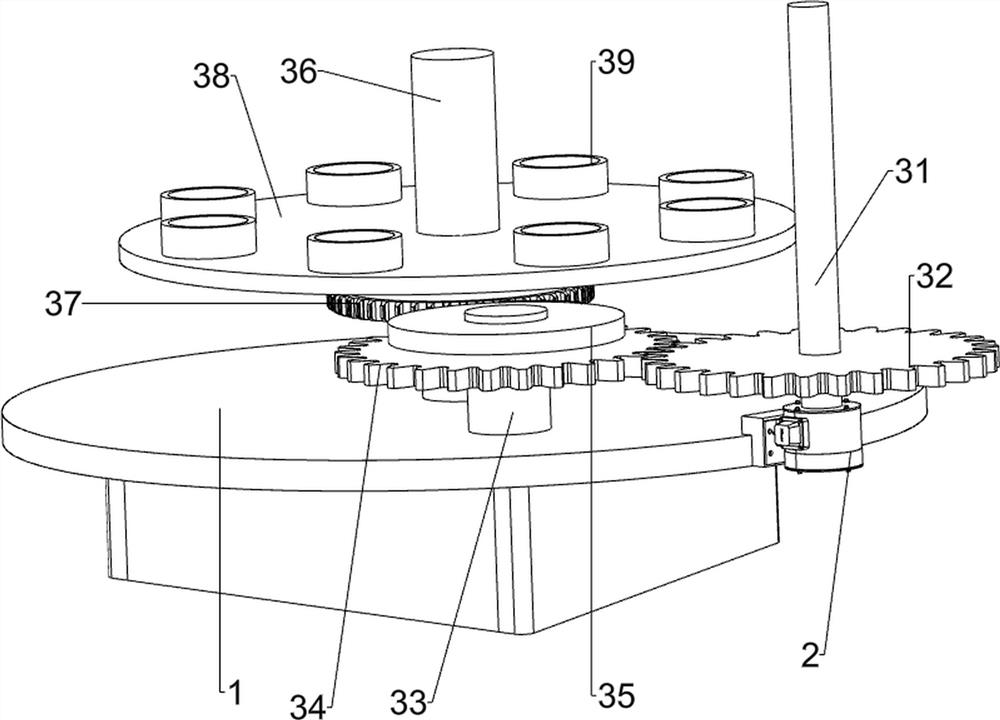

[0069] On the basis of Example 1, such as figure 2 , image 3 , Figure 4 and Figure 5 As shown, the feeding mechanism 3 includes a first rotating shaft 31, a first gear 32, a second rotating shaft 33, a second gear 34, a first missing gear 35, a third rotating shaft 36, a third gear 37, a turntable 38 and a lower extrusion Die 39, geared motor 2 output shafts are provided with the first rotating shaft 31, the first rotating shaft 31 bottoms are provided with the first gear 32, the bottom plate 1 top front side right part rotation type is provided with the second rotating shaft 33, and the second rotating shaft 33 middle parts are provided with There is a second gear 34, the second gear 34 is meshed with the first gear 32, the second rotating shaft 33 top is provided with the first missing gear 35, the bottom plate 1 top middle rotation type is provided with the third rotating shaft 36, and the third rotating shaft 36 bottom is provided with There is a third gear 37, the ...

Embodiment 3

[0076] On the basis of Example 2, such as Figure 6 and Figure 7 As shown, a second unloading mechanism 8 is also included, and the second unloading mechanism 8 includes a second hopper 81, a first support rod 82, a second guide rod 83, a third spring 84, a second stopper 85 and a second A baffle plate 86, a second hopper 81 is provided in the middle of the rear portion of the top plate 5, a first support rod 82 is provided in the middle of the top rear side of the bottom plate 1, and a second stopper 85 is provided on the rear side of the top of the first support rod 82. Sliding type is provided with second guide rod 83 on block 85, and the middle part of second guide rod 83 is provided with first baffle plate 86, and first baffle plate 86 top front side contacts with second hopper 81 bottoms, and first baffle plate 86 rear side A third spring 84 is provided between the lower part and the front side of the second stopper 85 , and the third spring 84 is sleeved on the outsid...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com