Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

192results about "Disc dough shaping" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

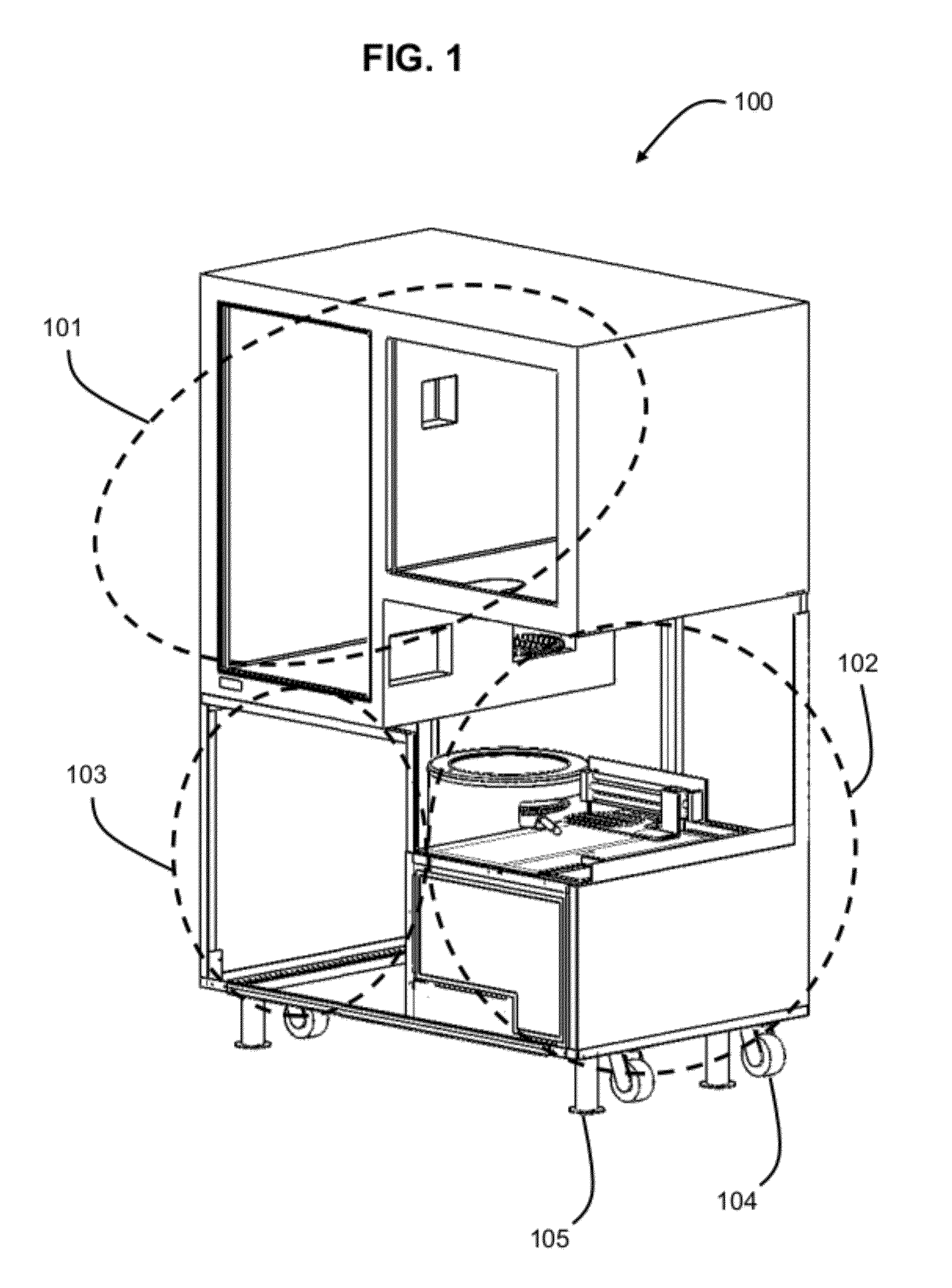

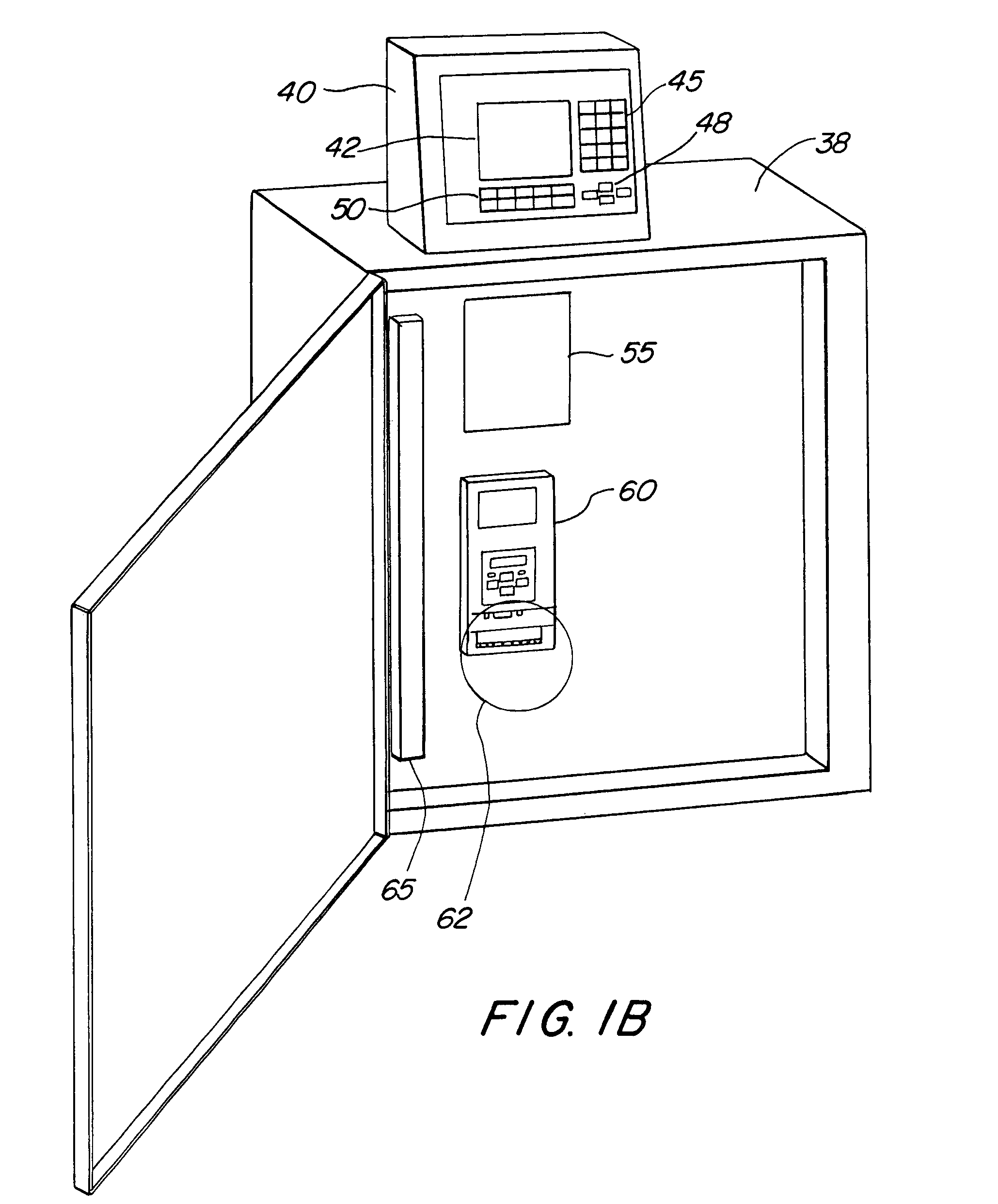

Automated pizza preparation apparatus

InactiveUS20120185086A1Facilitate pizza-making processDough treatmentDough dividingAdditive ingredientEngineering

Automated apparatus for preparing pizza, and method of operating same. A customer selects a type of pizza, such as toppings or crust style. The apparatus slices and defrosts dough, applies cheese, slices and applies toppings, and cooks the pizza to order. The cooked pizza is packaged for delivery to the customer and may include a separate cutting apparatus. Proper temperature of hot and cold sections is maintained while ingredients are stored and as the pizza is cooked. The process is monitored and controlled by one or more processors.

Owner:K & G ENTERPRISES

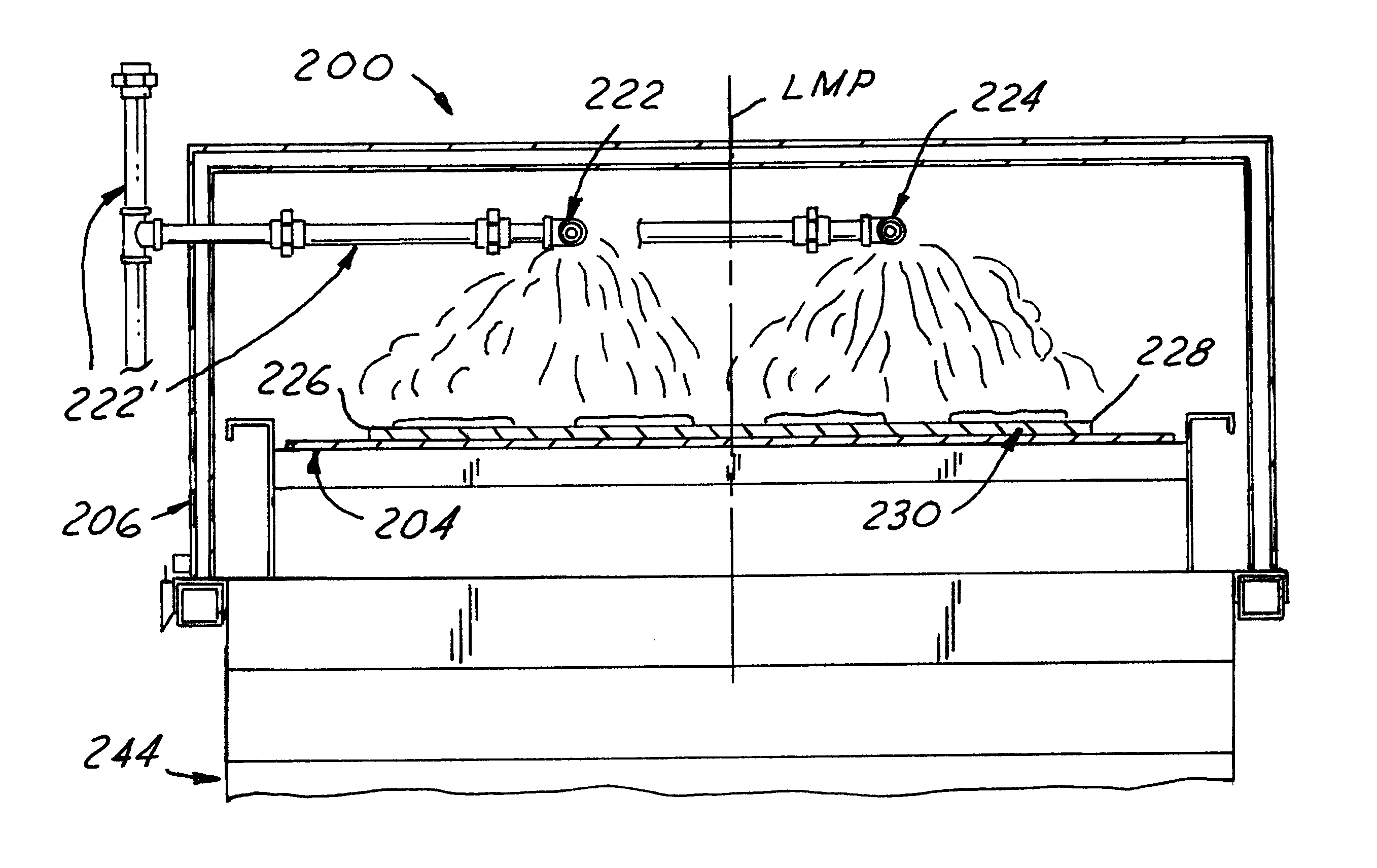

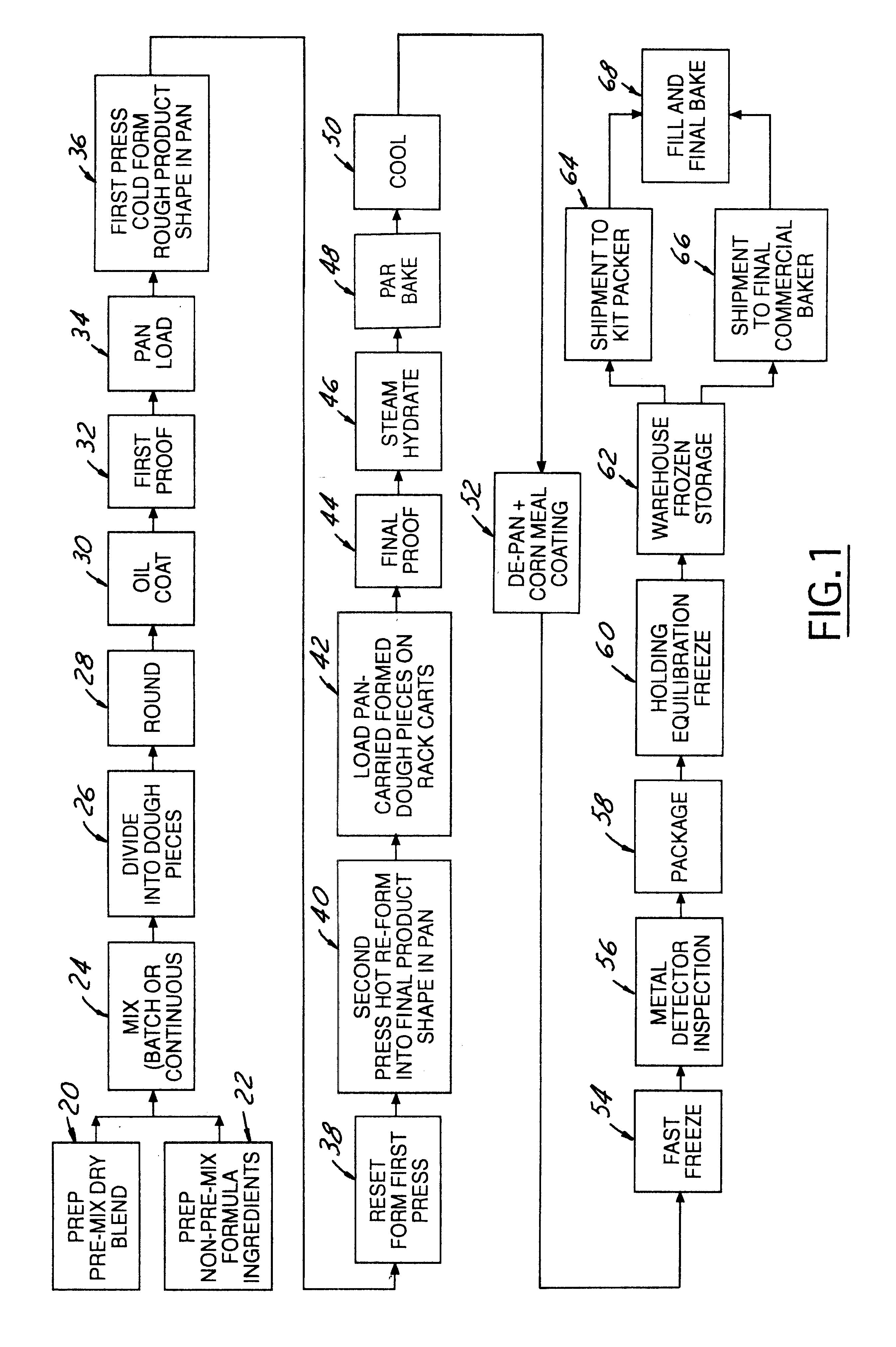

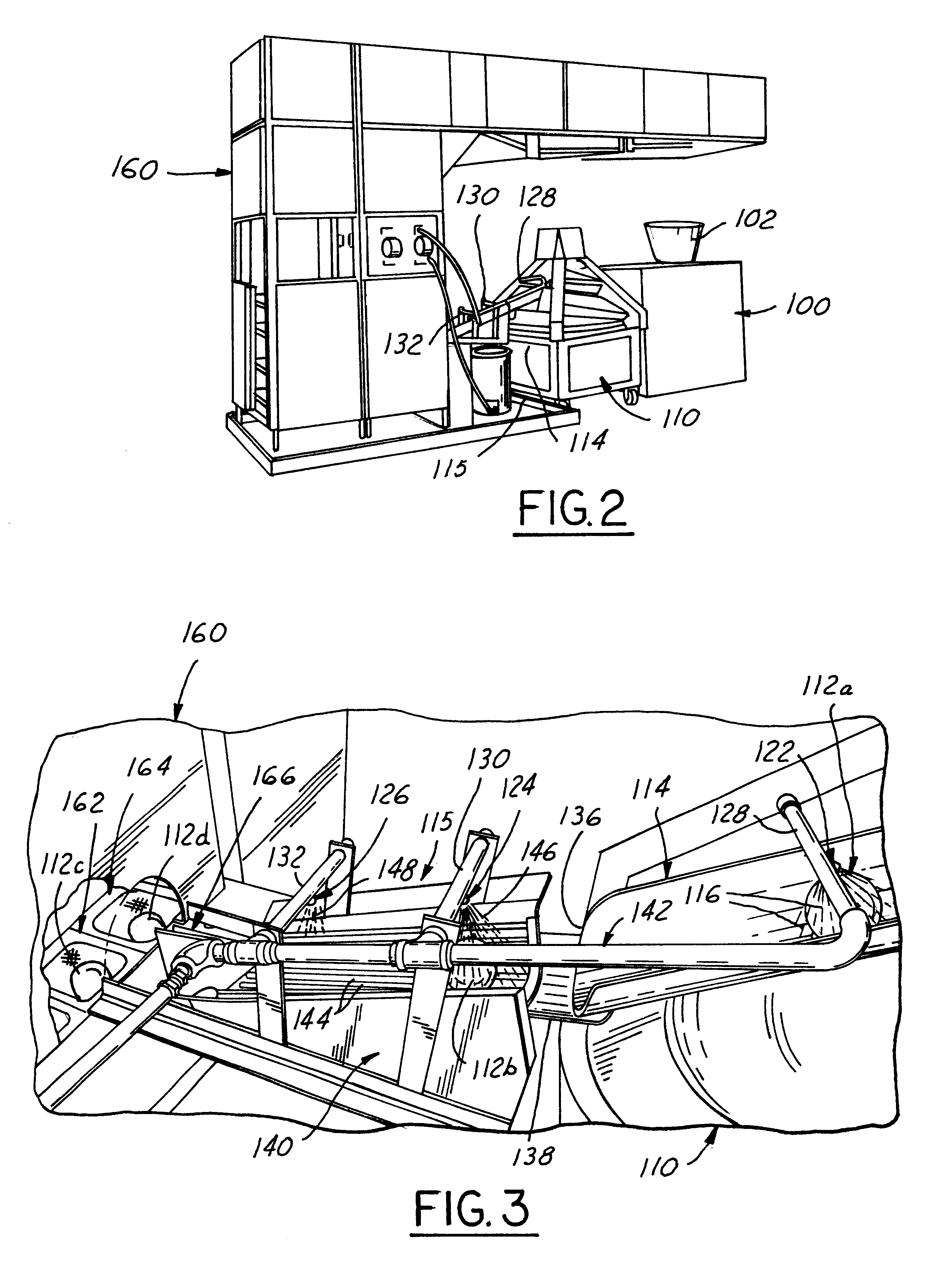

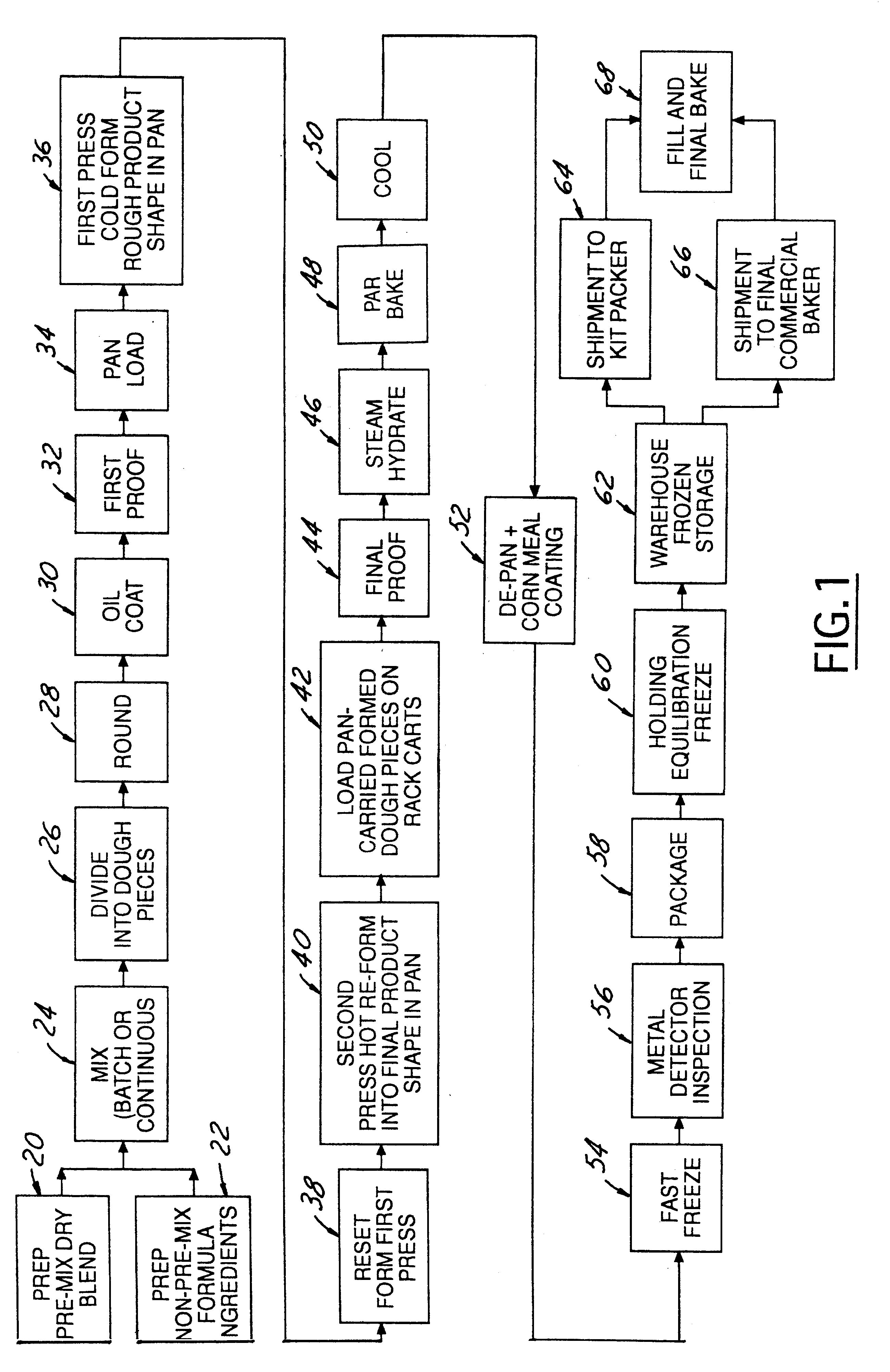

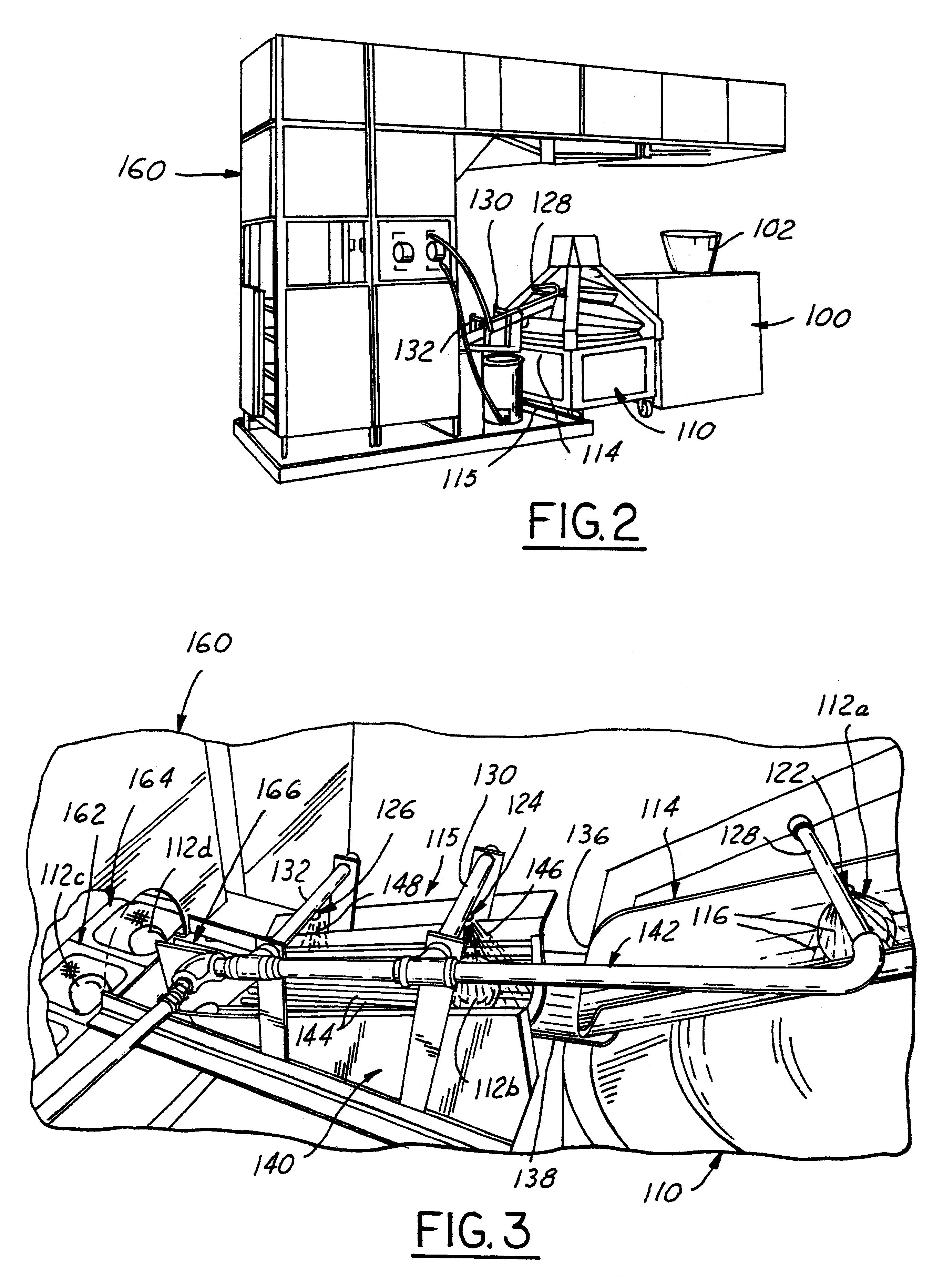

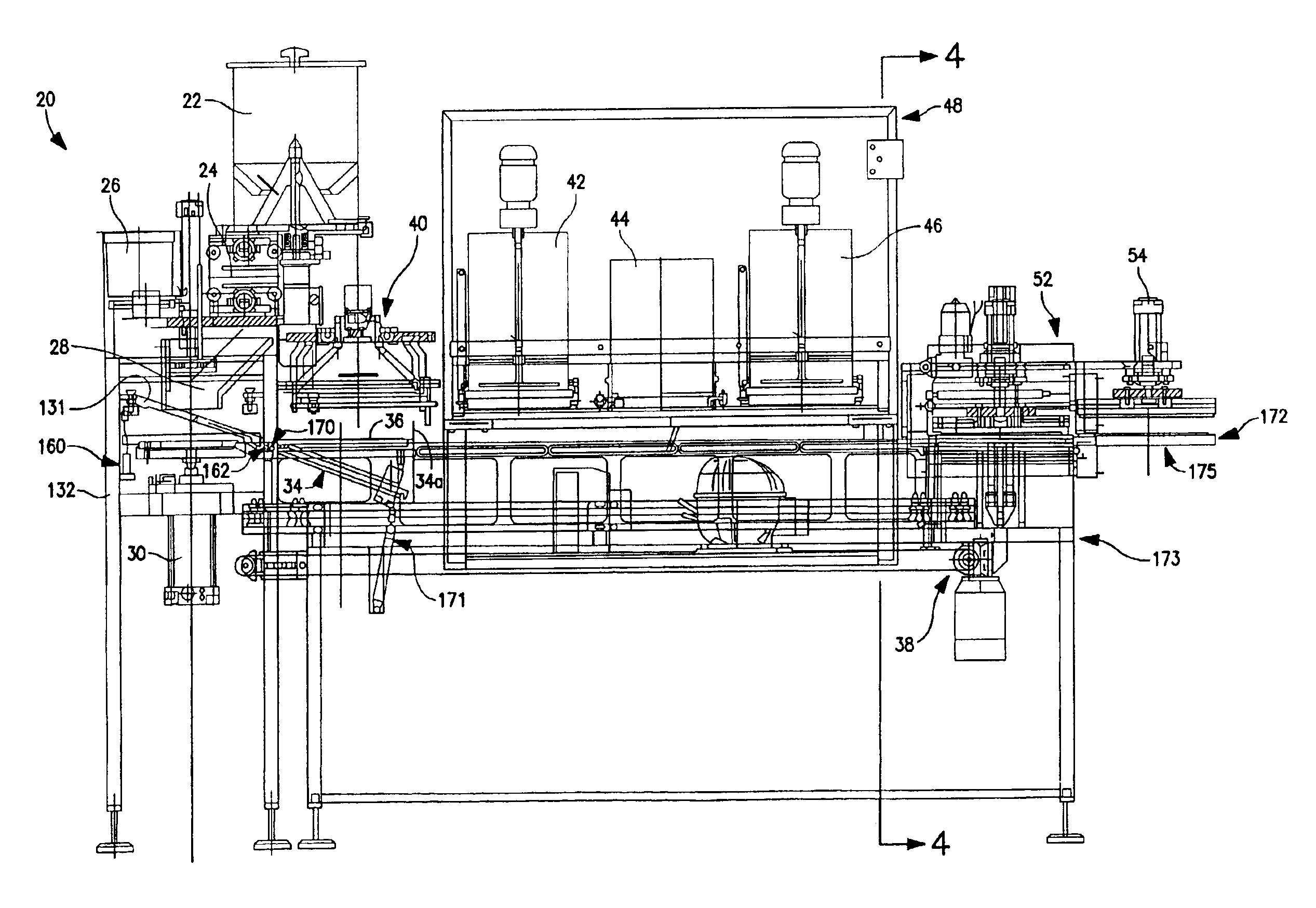

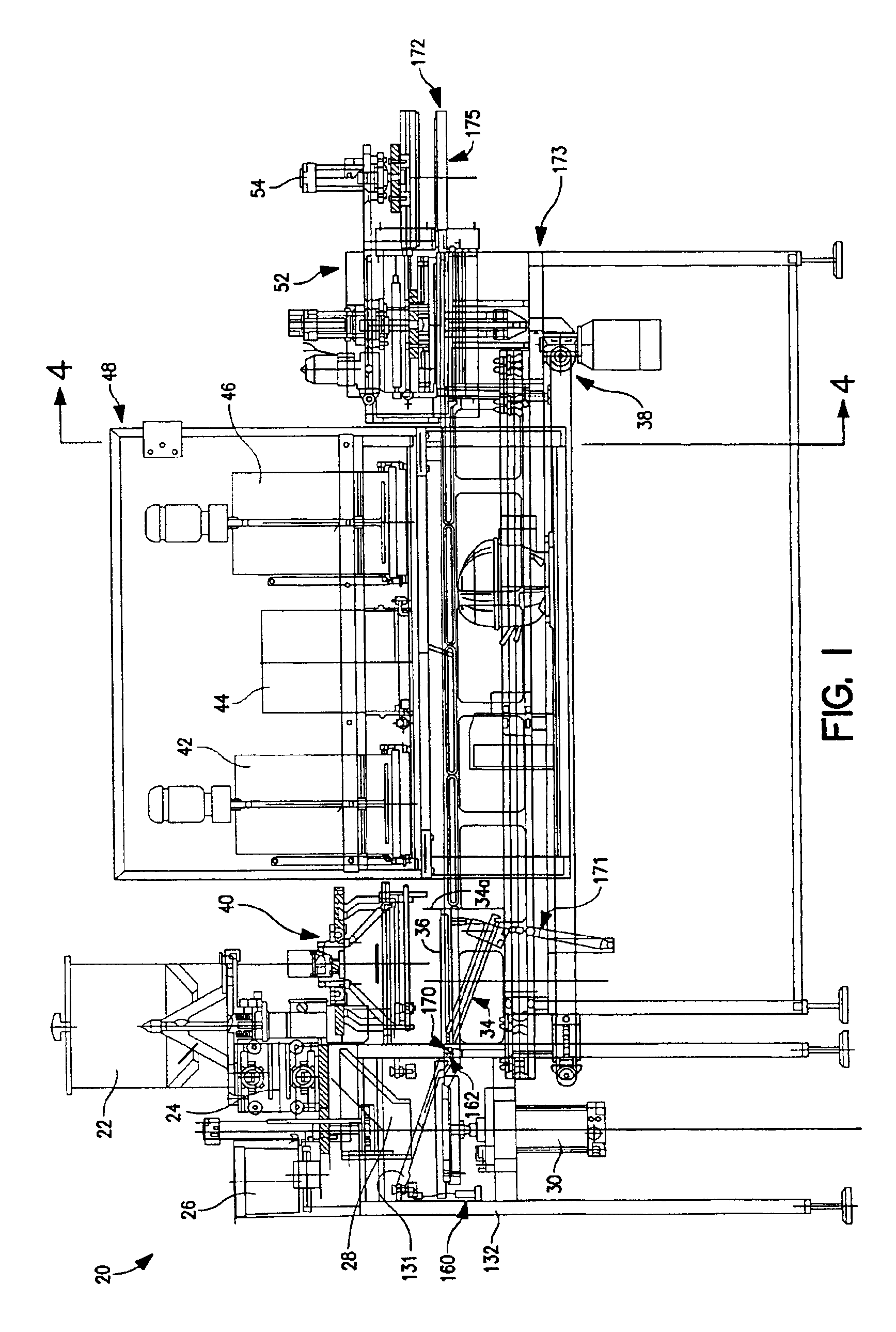

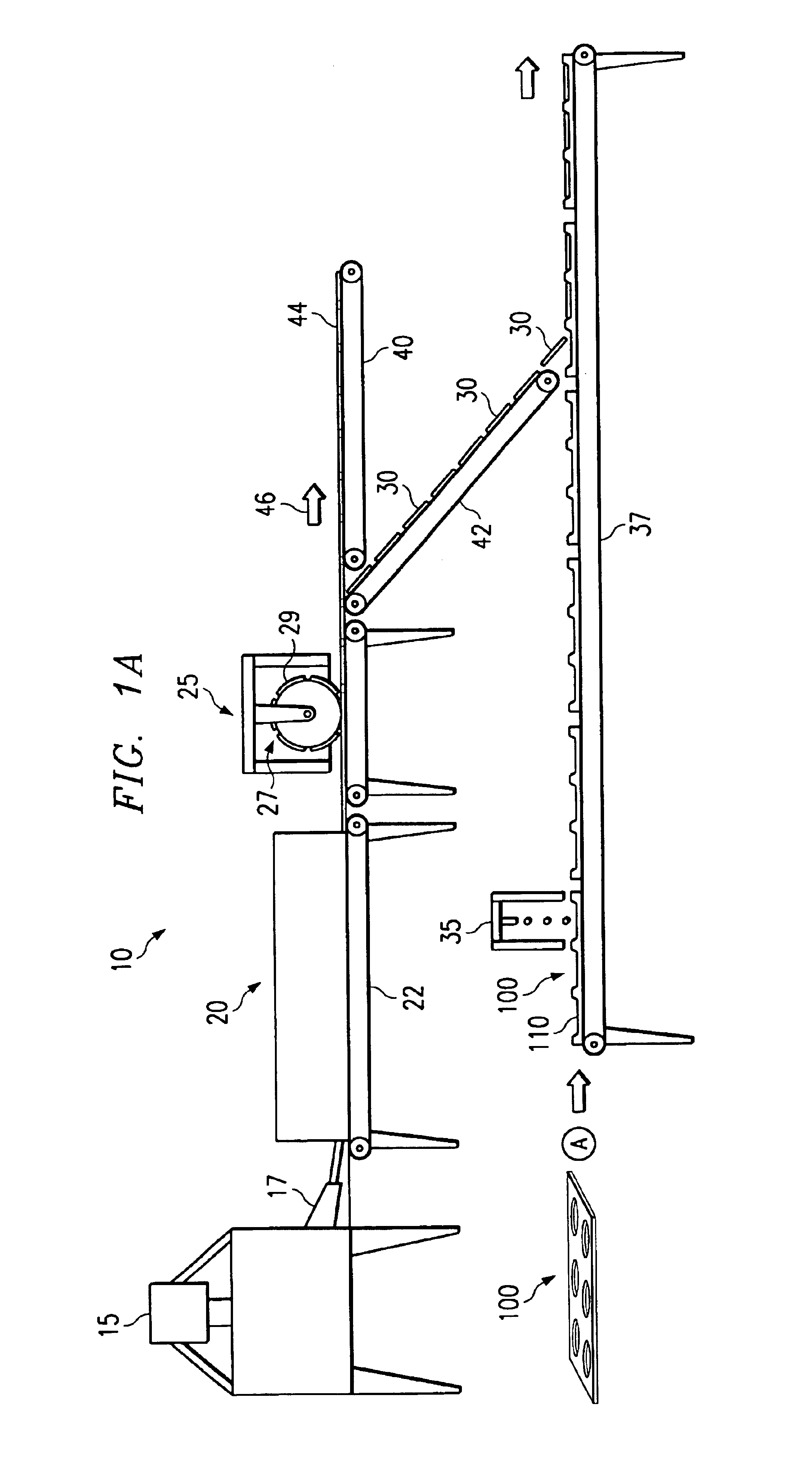

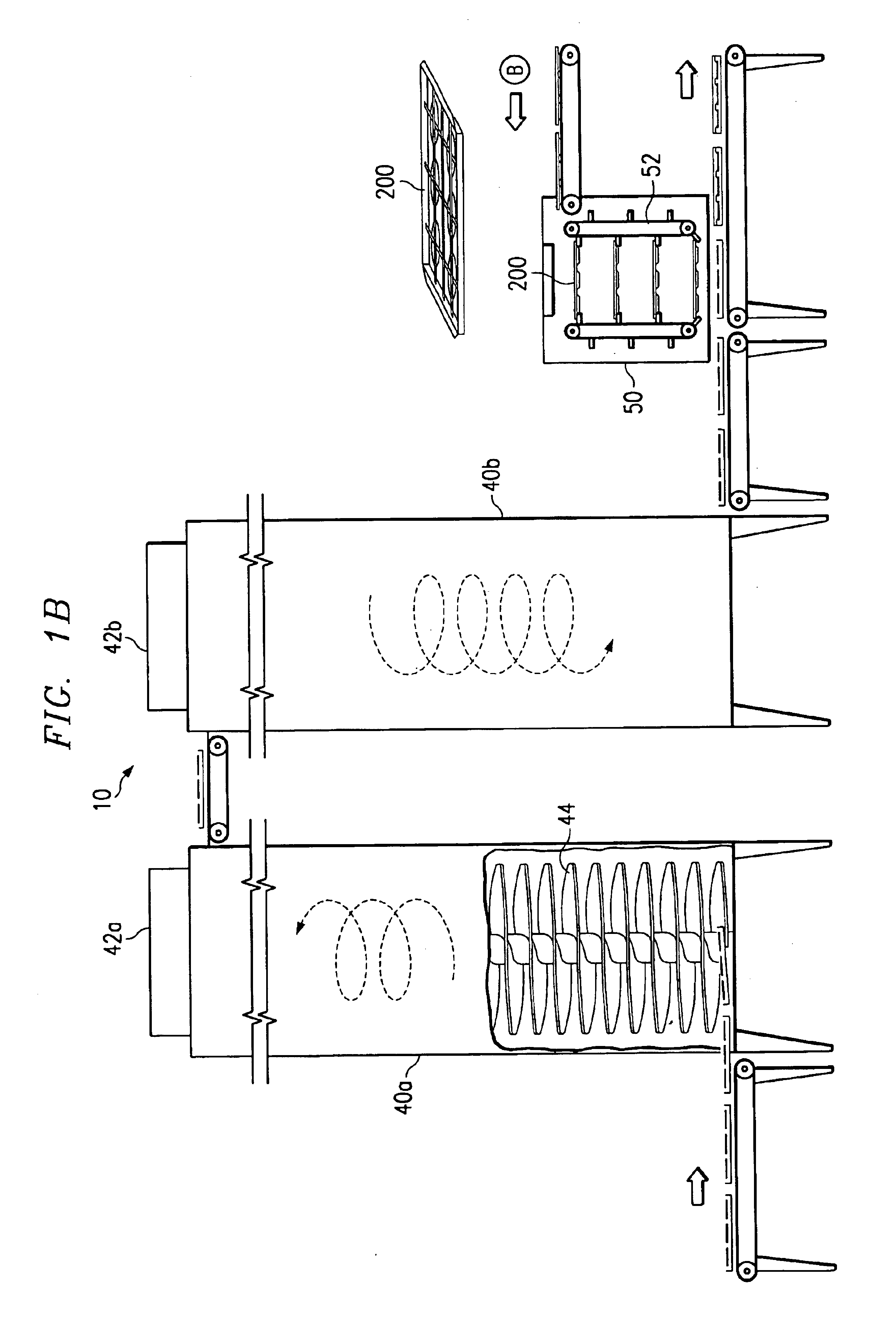

Pizza crust and process and apparatus for making same

InactiveUS6629493B1Speed up the processEasy to adjustAir-treating devicesBakery productsStarch gelatinizationMoisture absorption

Apparatus for preparing parbaked food products, such as pizza crust shells, and dough formulation used therein, and the product produced thereby and / or therefrom. The apparatus operates on a starting material dough including flour, sugar and water, and preferably also a leavening agent such as instant yeast. The dough is rounded, first proofed, panned, pressed and second proofed in the apparatus. The prepared dough piece is then steam hydrated in the apparatus under conditions sufficient to cause moisture absorption and a resultant increase in moisture content throughout the dough. Then the hydrated dough piece is immediately sequentially parbaked until gelatinization of the starch is complete. At least one parbaking condition of the apparatus is adjusted as selected from the group consisting of initial dough temperature, oven temperature, parbaking time, dough absorption and dough thickness and coordinated with the moisture content condition of the dough upon completion of the steam hydration for thereby delaying external browning of the dough until the starch gelatinization is complete, and for thereby discontinuing the parbaking before substantial caramelization of the sugar in the crust takes place.

Owner:M & M HLDG

Pizza crust and process and apparatus for making same

InactiveUS6365210B1Increase moistureImprove the finishMilk preservationDough treatmentMoisture absorptionSugar

A method of preparing parbaked food products, such as pizza crust shells, apparatus and dough formulation used therein, and the product produced by the process. The process comprises the steps of providing a dough including flour, sugar and water, and preferably also a leavening agent such as instant yeast. The dough is rounded, first proofed, panned, pressed and second proofed. The prepared dough piece is then steam hydrated under conditions sufficient to cause moisture absorption and a resultant increase in moisture content throughout the dough. Then the hydrated dough piece is immediately sequentially parbaked until gelatinization of the starch is complete. At least one parbaking condition is adjusted selected from the group consisting of initial dough temperature, oven temperature, parbaking time, dough absorption and dough thickness and coordinated with the moisture content condition of the dough upon completion of the steam hydration for thereby delaying external browning of the dough.

Owner:M & M HLDG

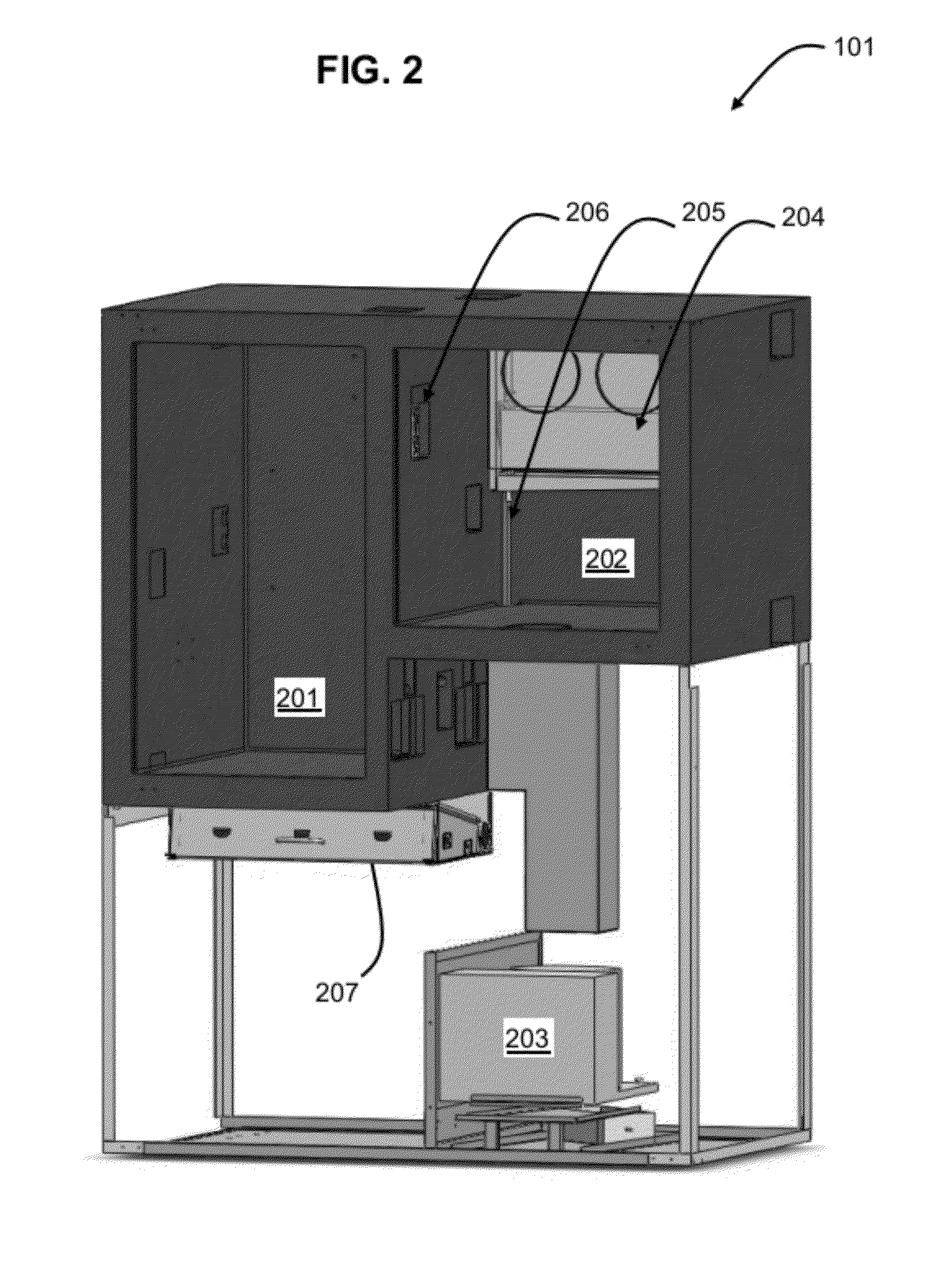

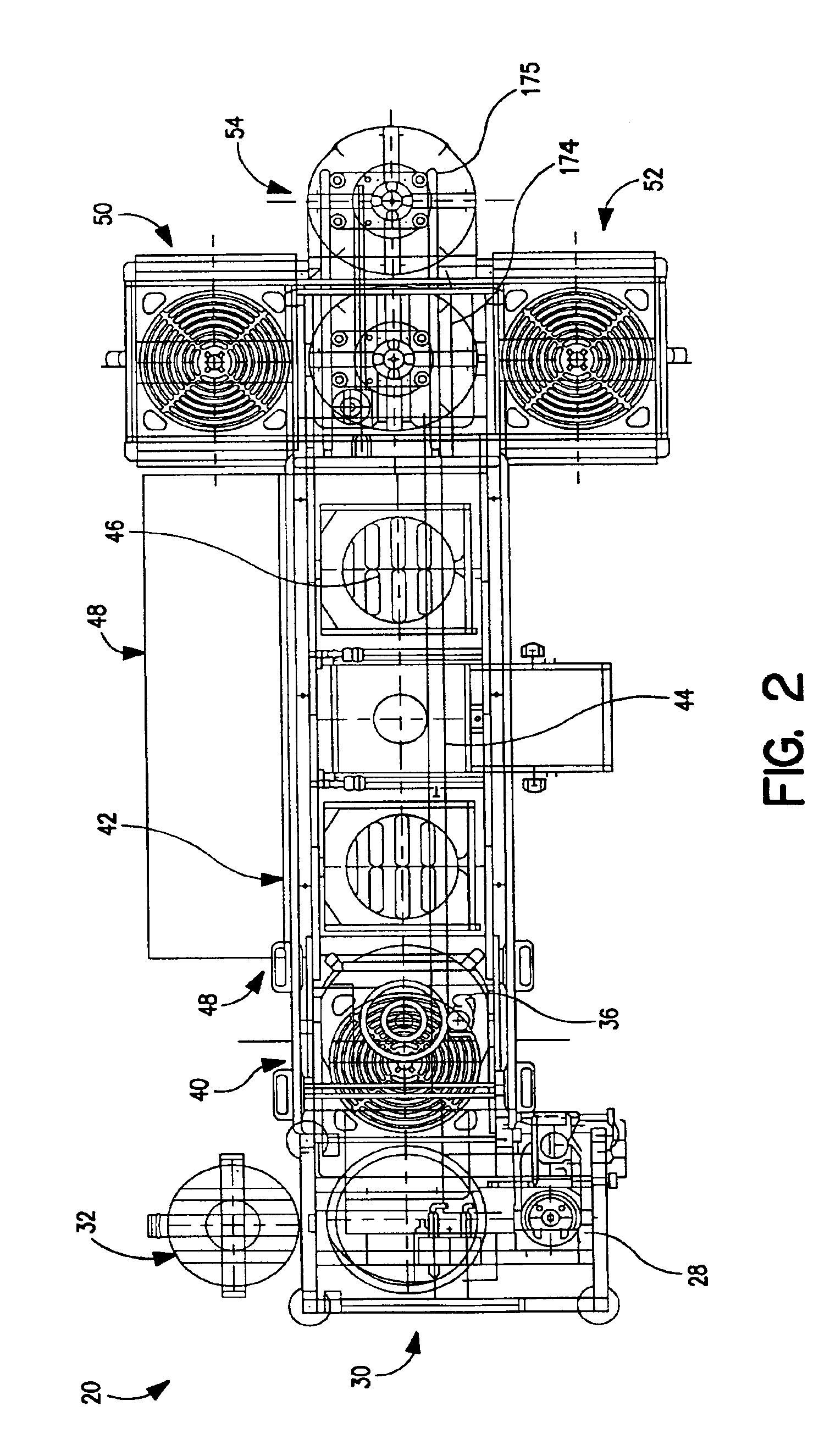

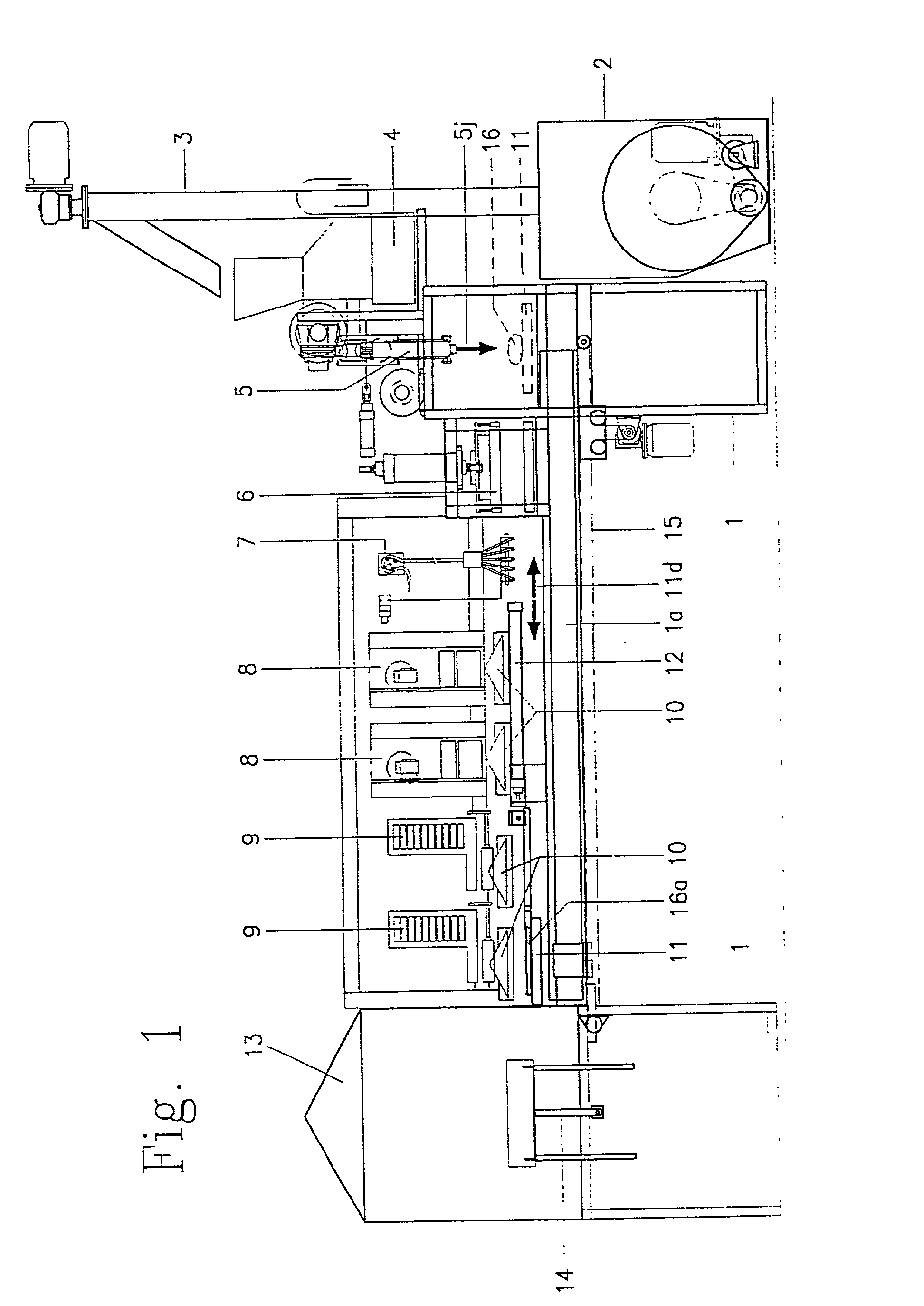

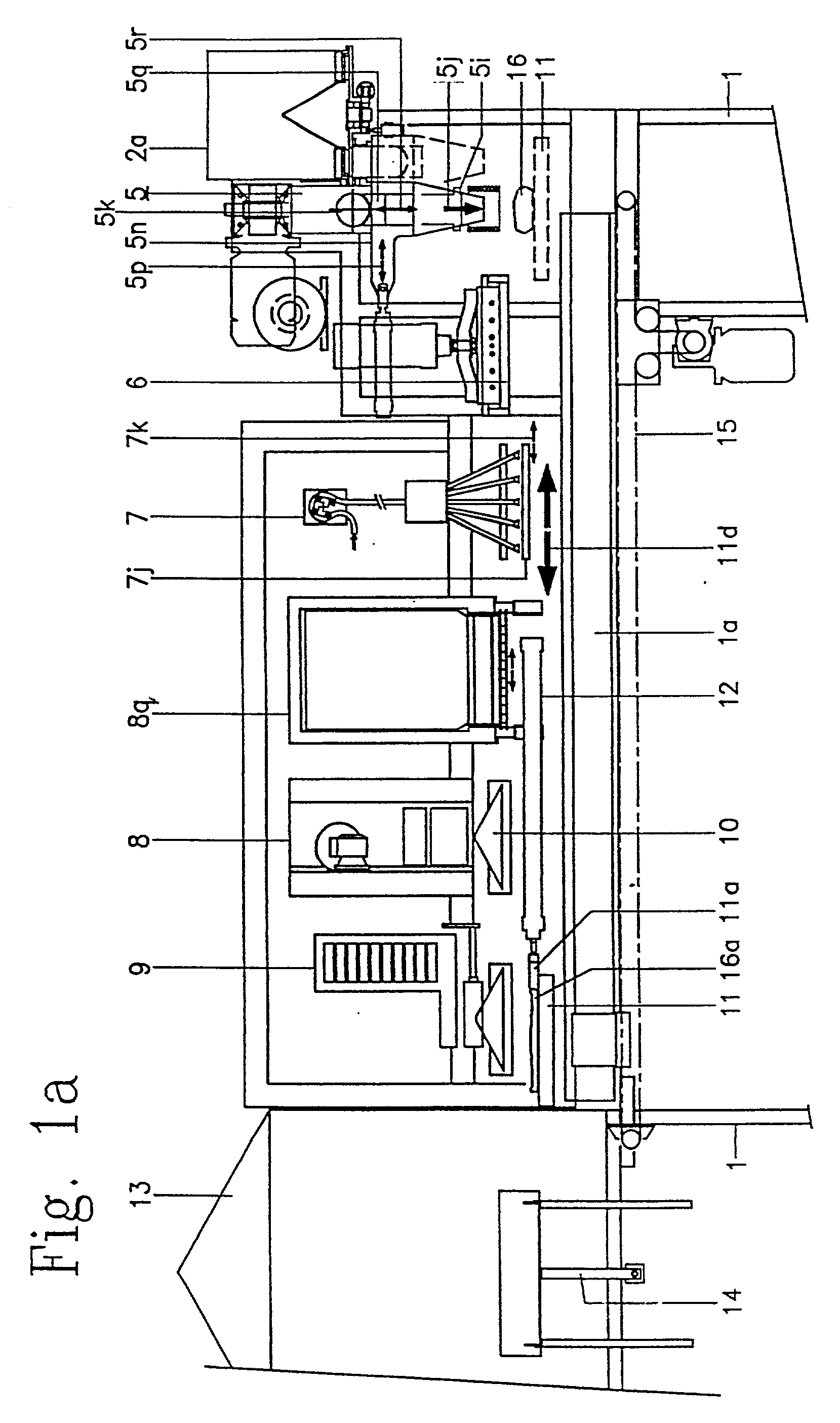

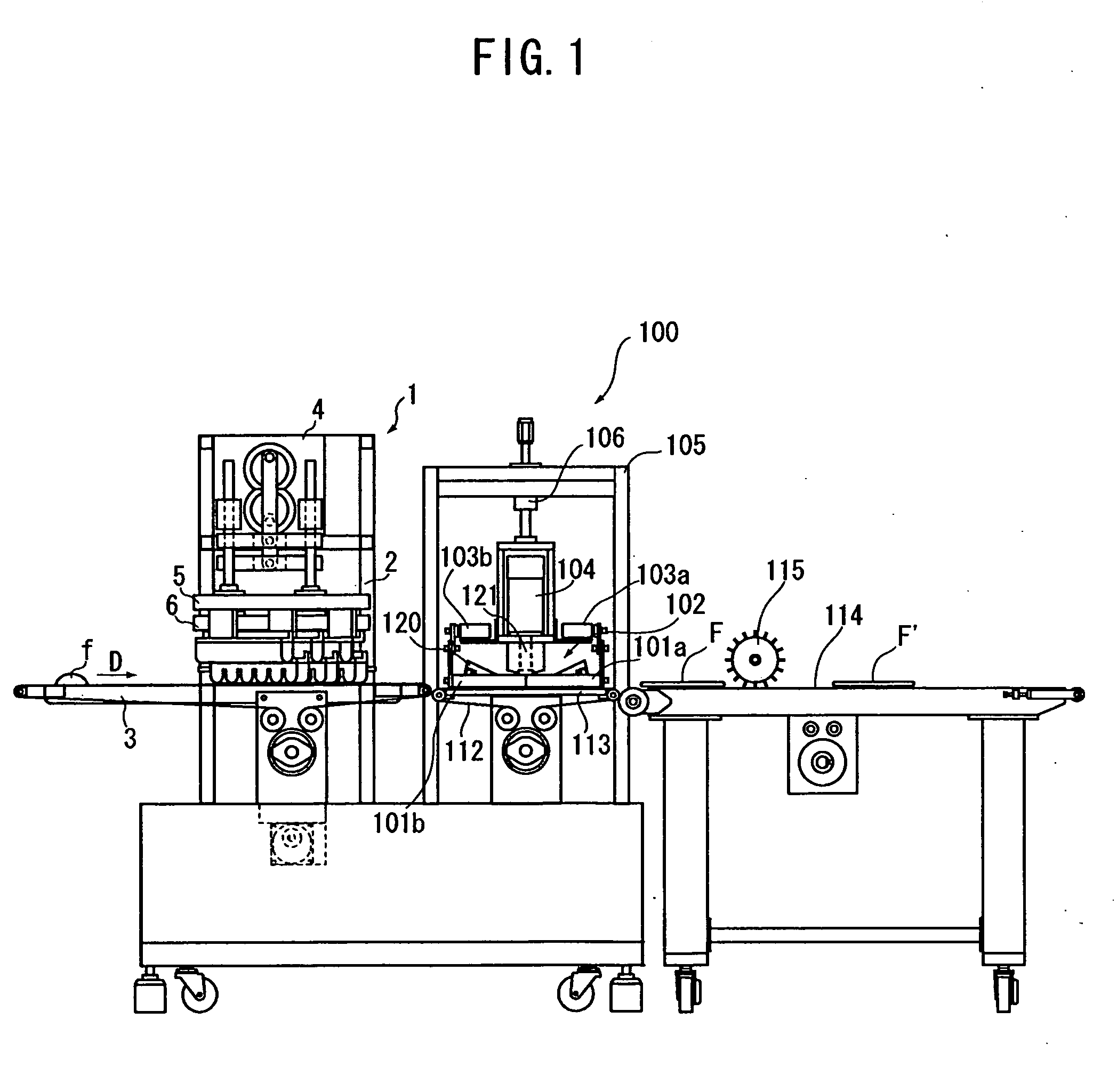

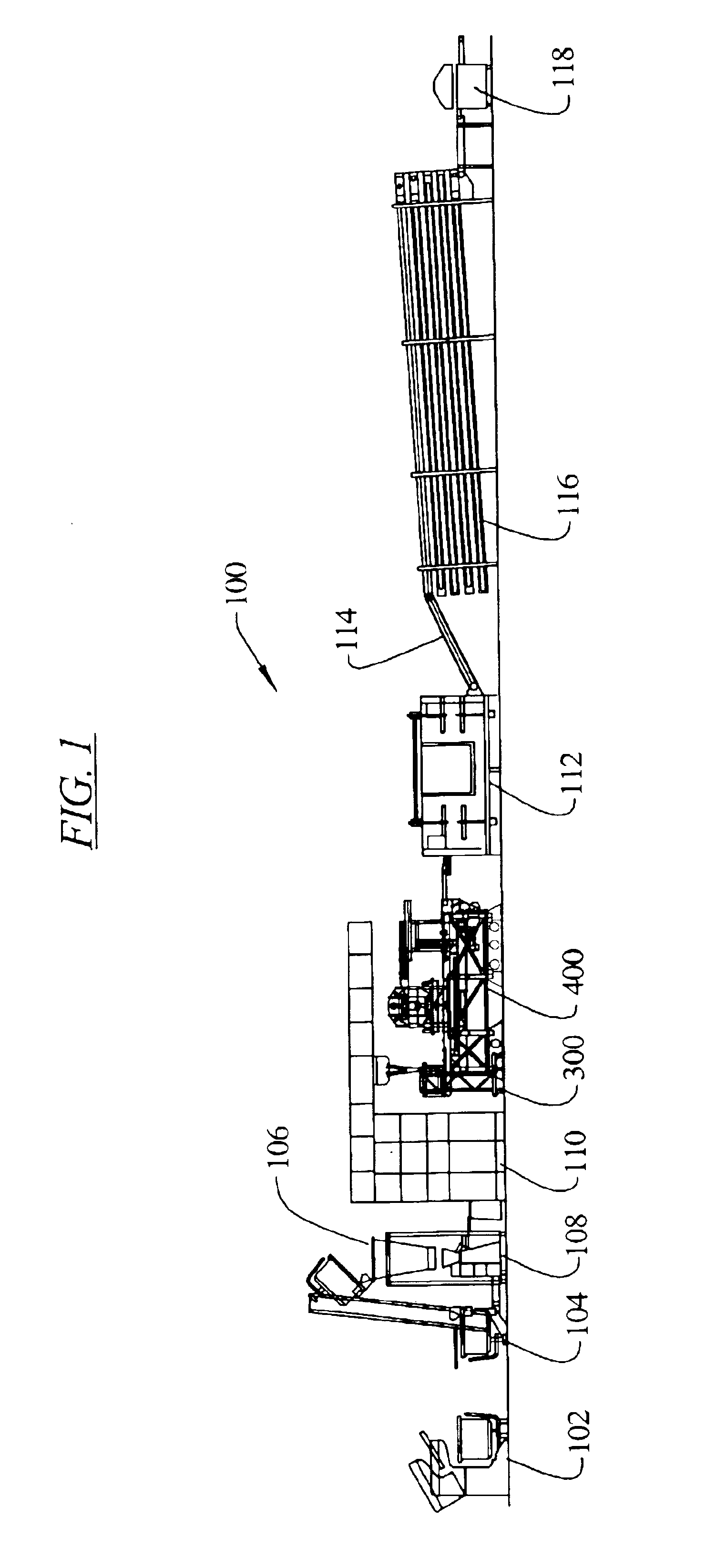

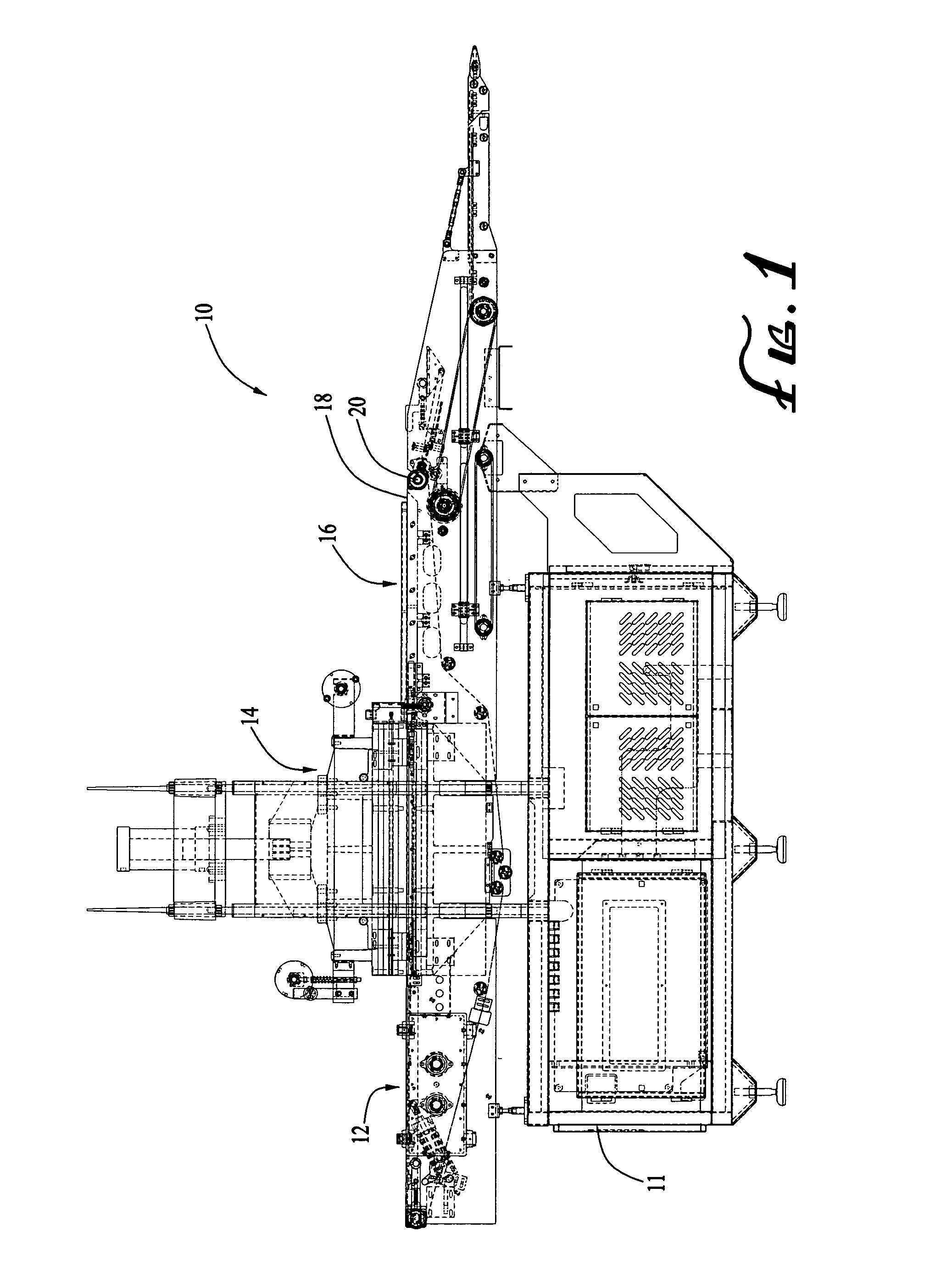

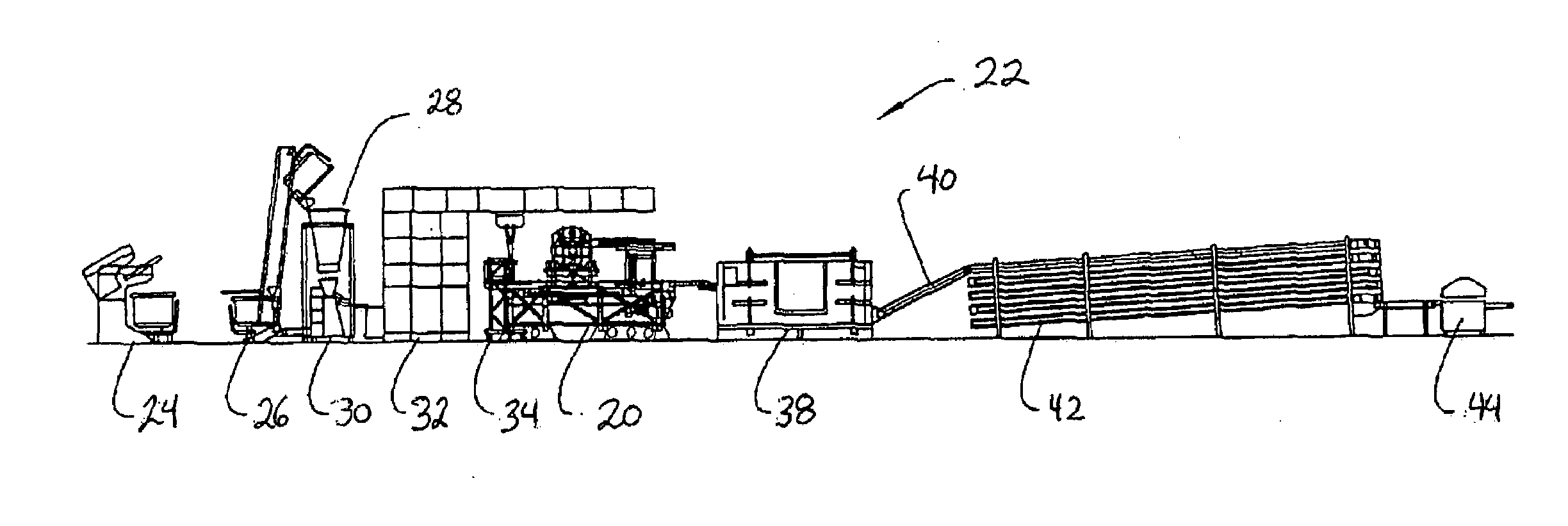

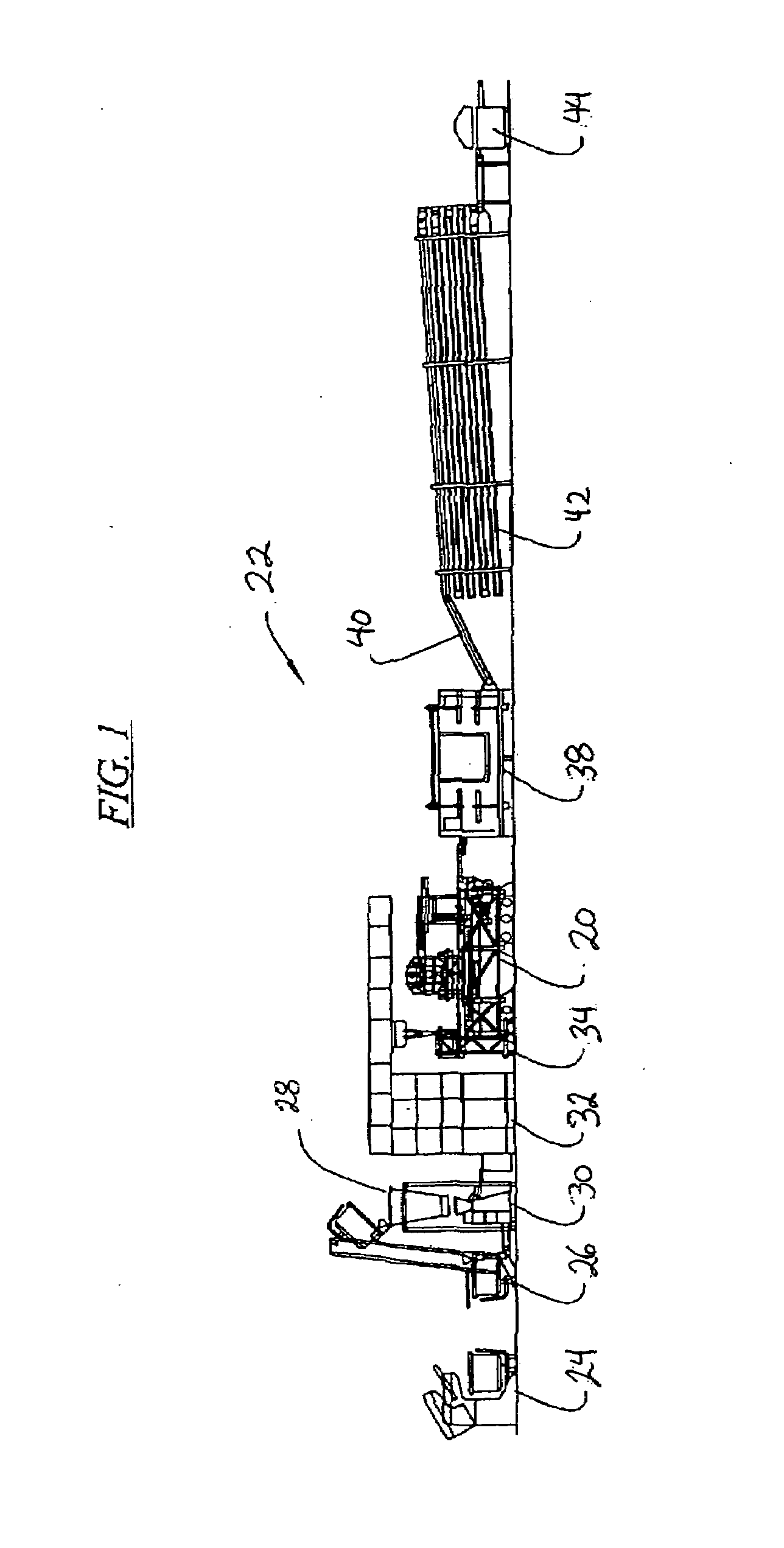

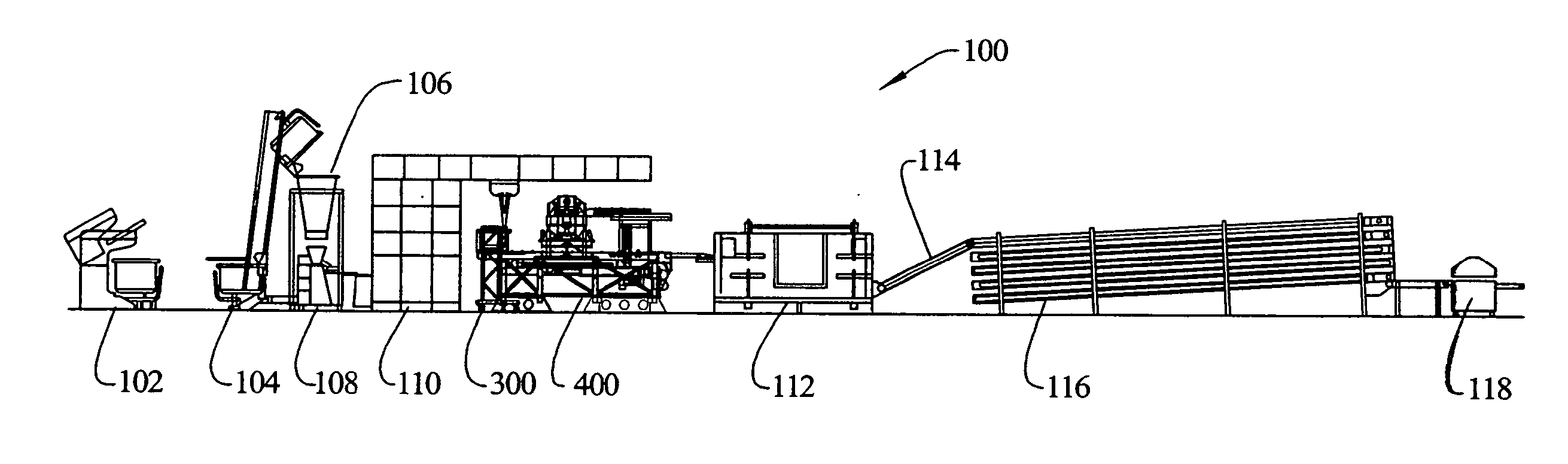

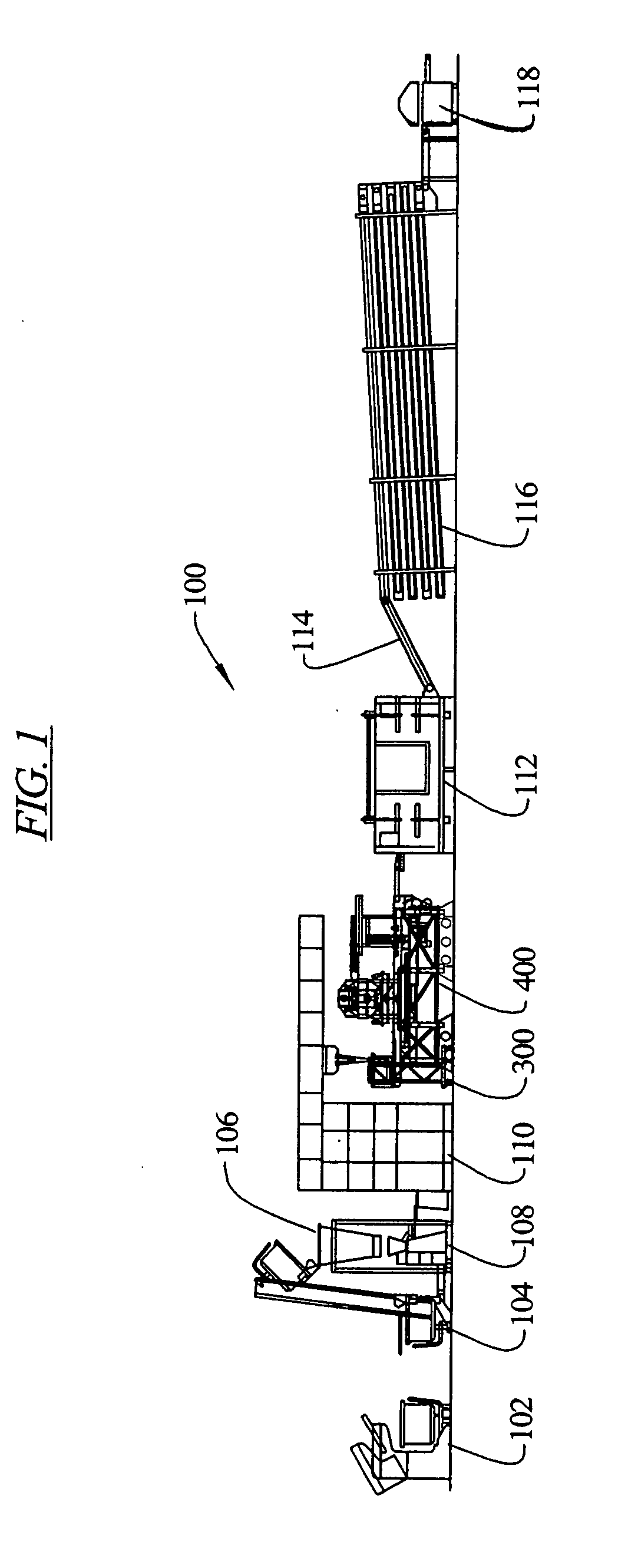

Pizza making method and system

InactiveUS6915734B2Simple and compact designMeet actual needsTransportation and packagingRotary stirring mixersCooking & bakingAdditive ingredient

The invention provides an automated method and apparatus for pizza production which is initiated by individual order placement and uses only fresh ingredients (no ingredients are frozen, pre-prepared or pre-cooked). Each dough portion is individually and mechanically prepared from flour and other fresh, pre-proportioned ingredients. The dough portion passes through a series of shaping and pre-heating processing stations to prepare a flattened and partially baked pizza base. Using a preheated or continuously heated conveying tray, the pizza base passes under a number of metering and distribution devices for selected application of tomato sauce and / or various other toppings according to the order. Baking occurs in one of multiple ovens to complete pizza preparation. Multiple ovens are provided to facilitate the automated preparation of multiple pizzas at any given time. A tray conveying system transports one or more trays through the various processing stations to accommodate multiple orders at the same time.

Owner:SITOS

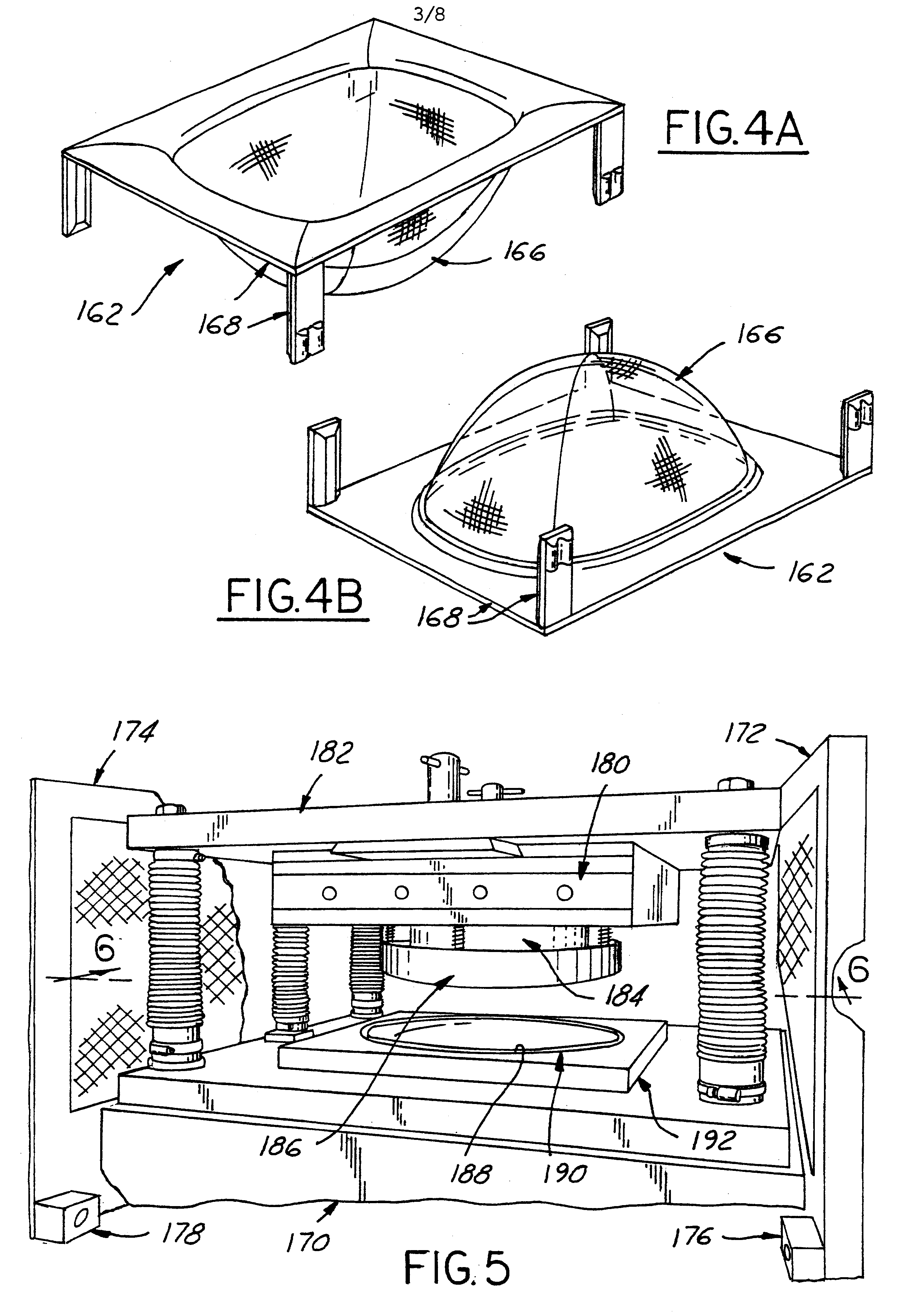

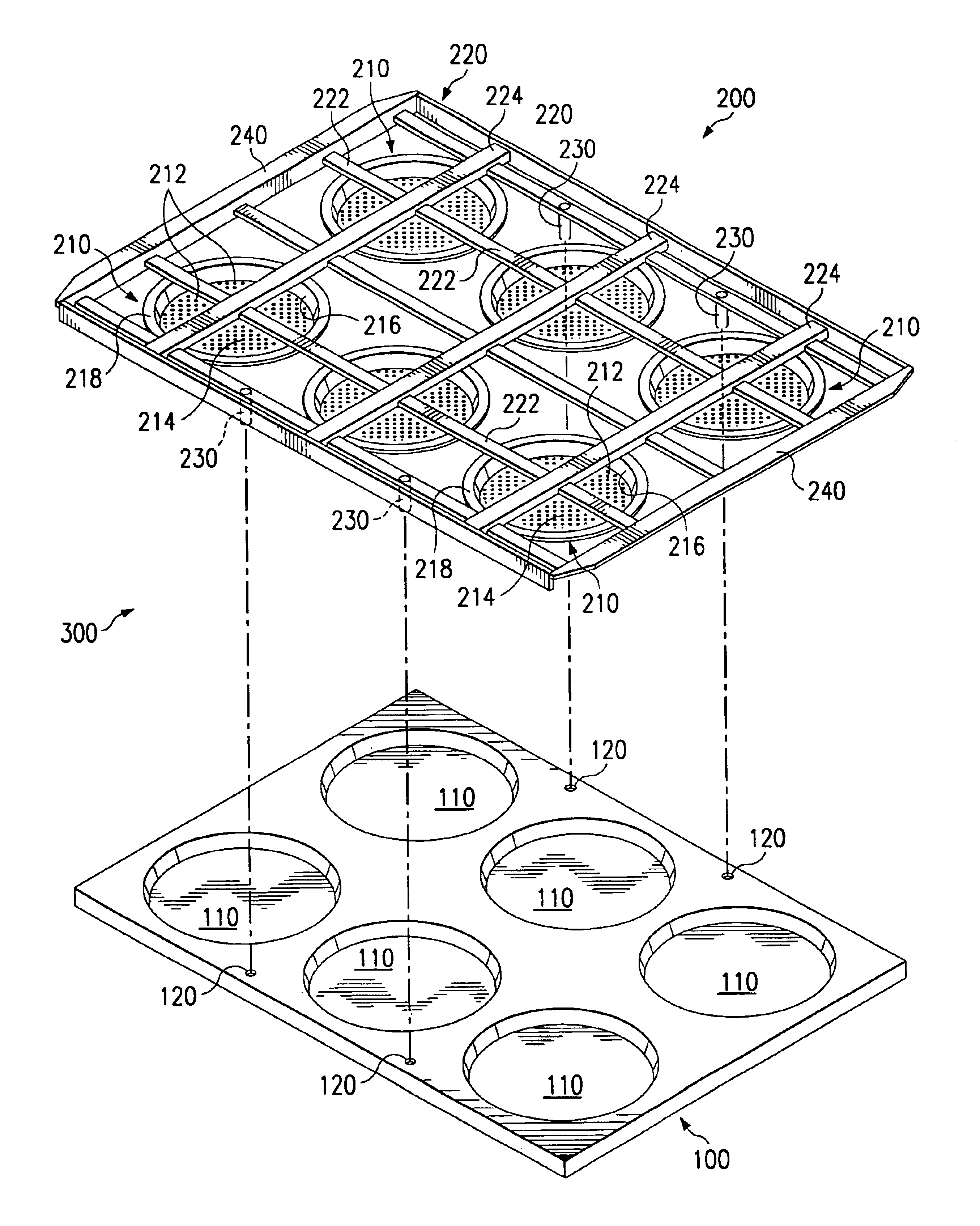

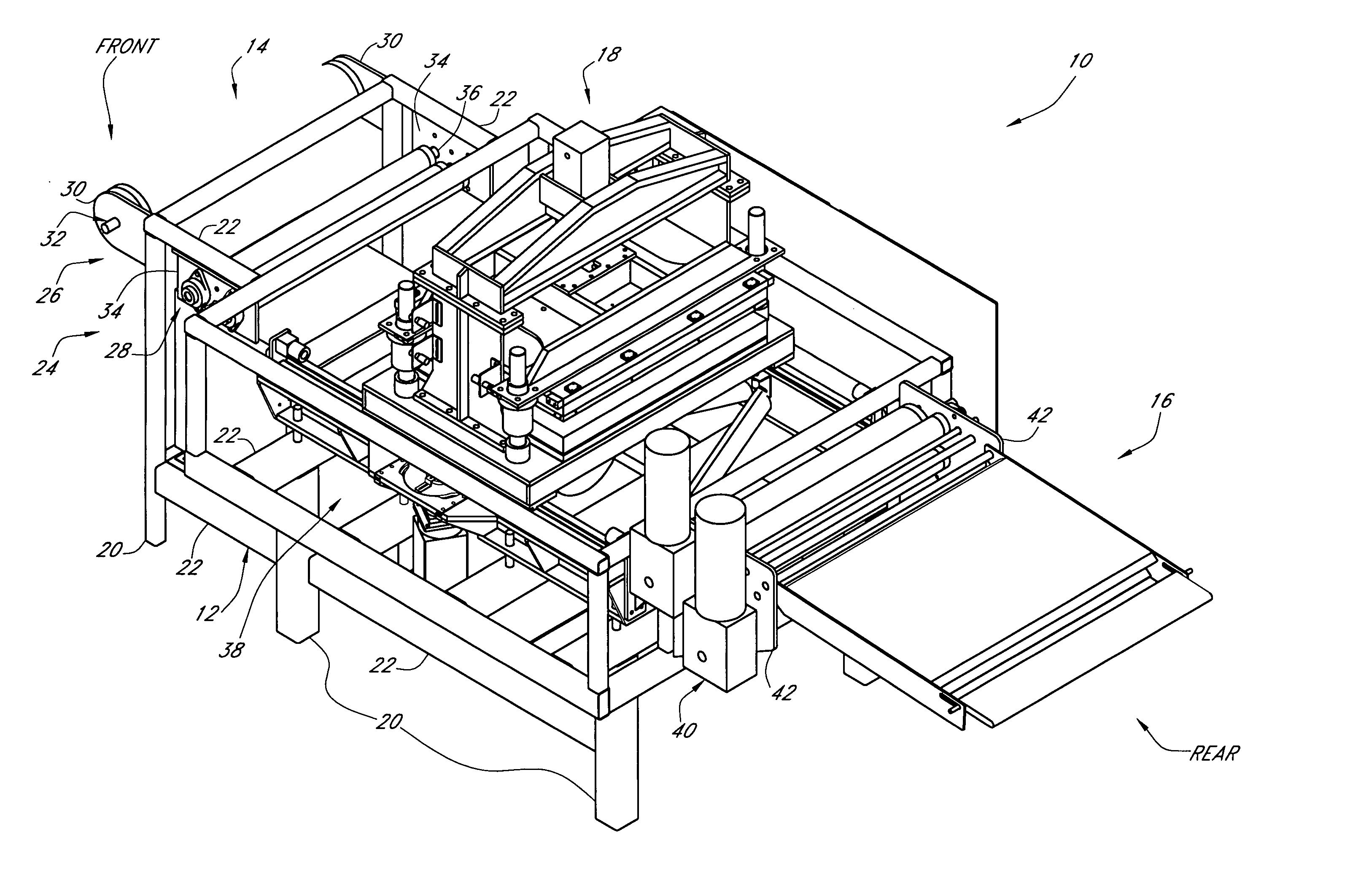

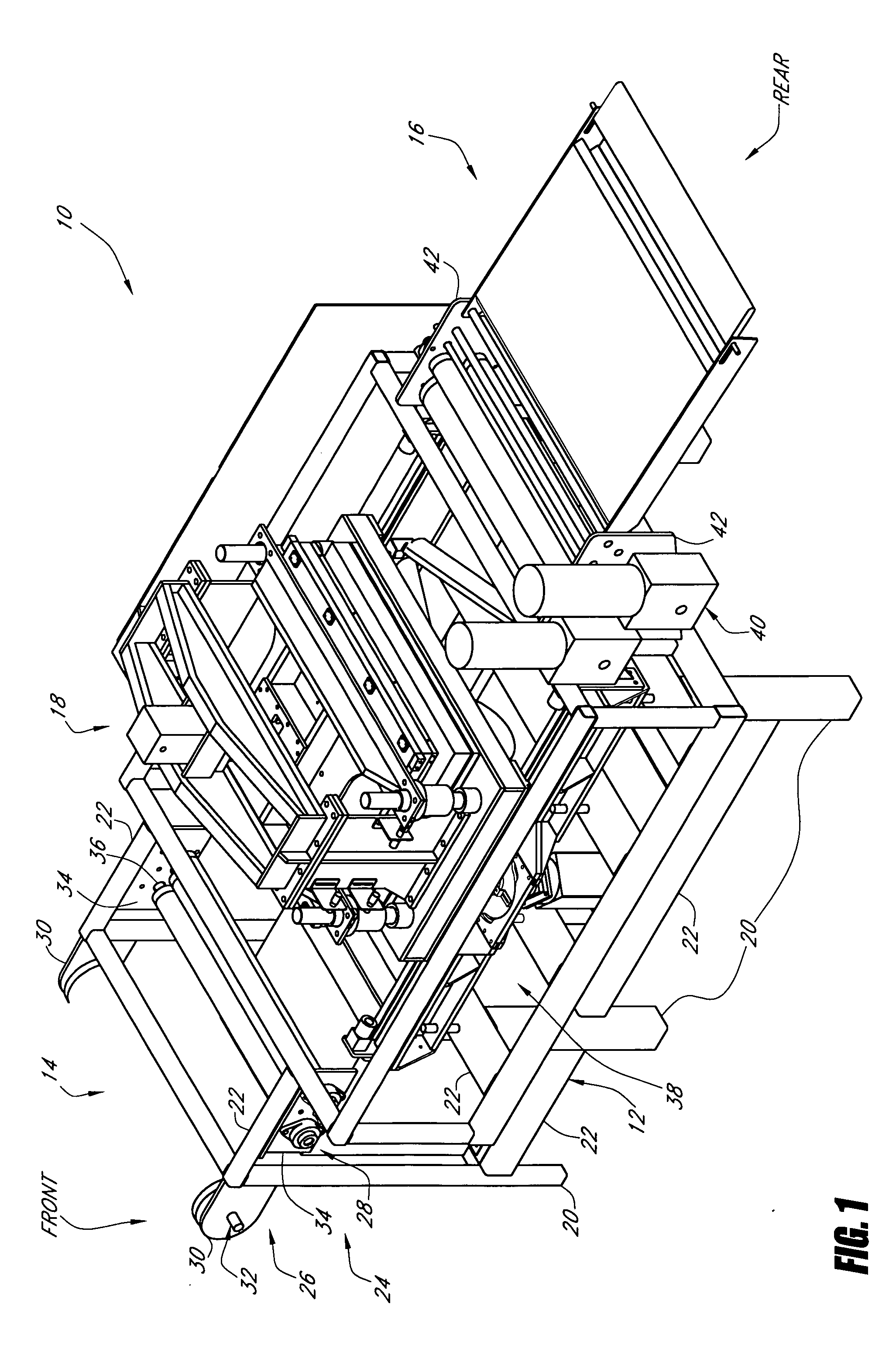

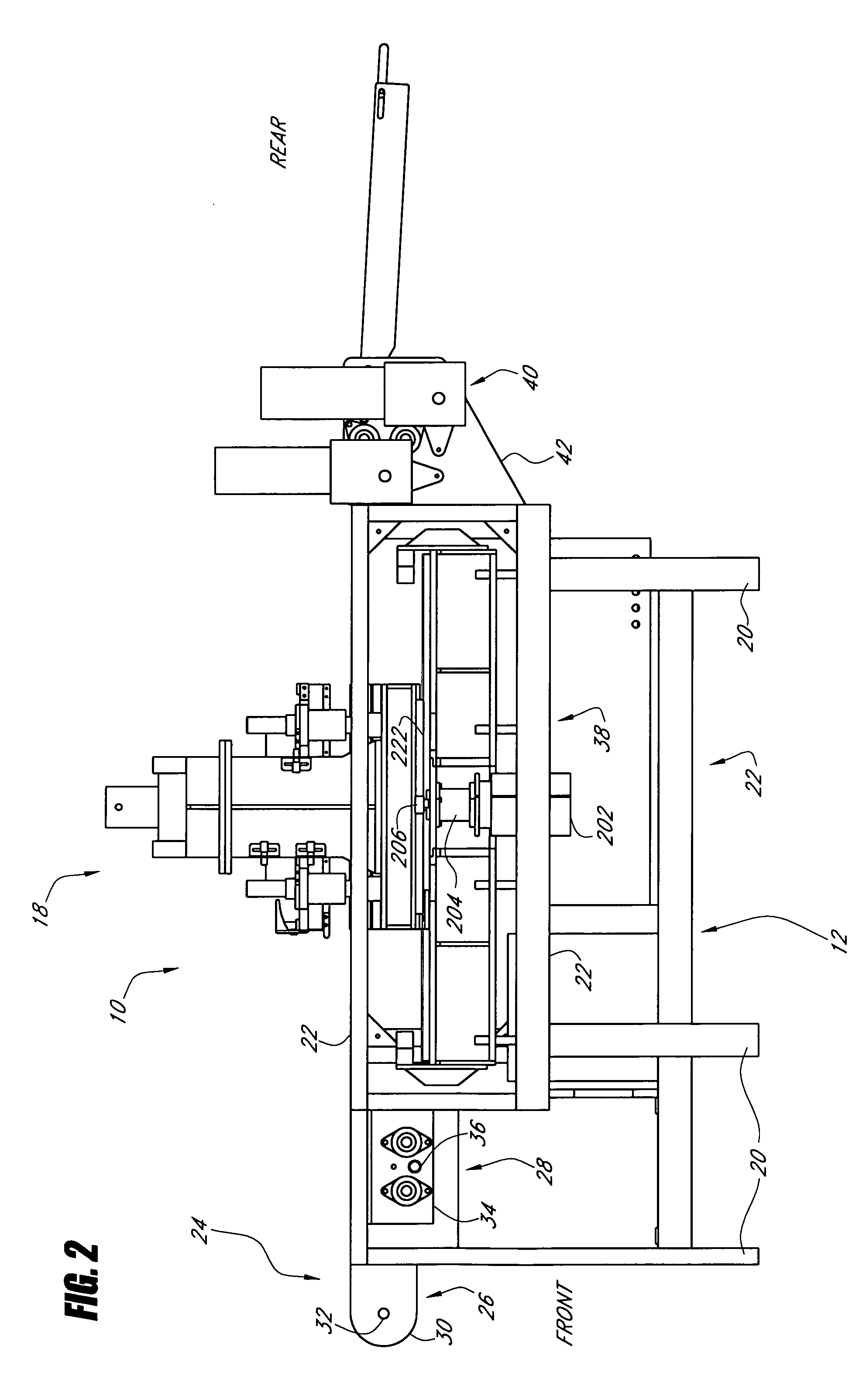

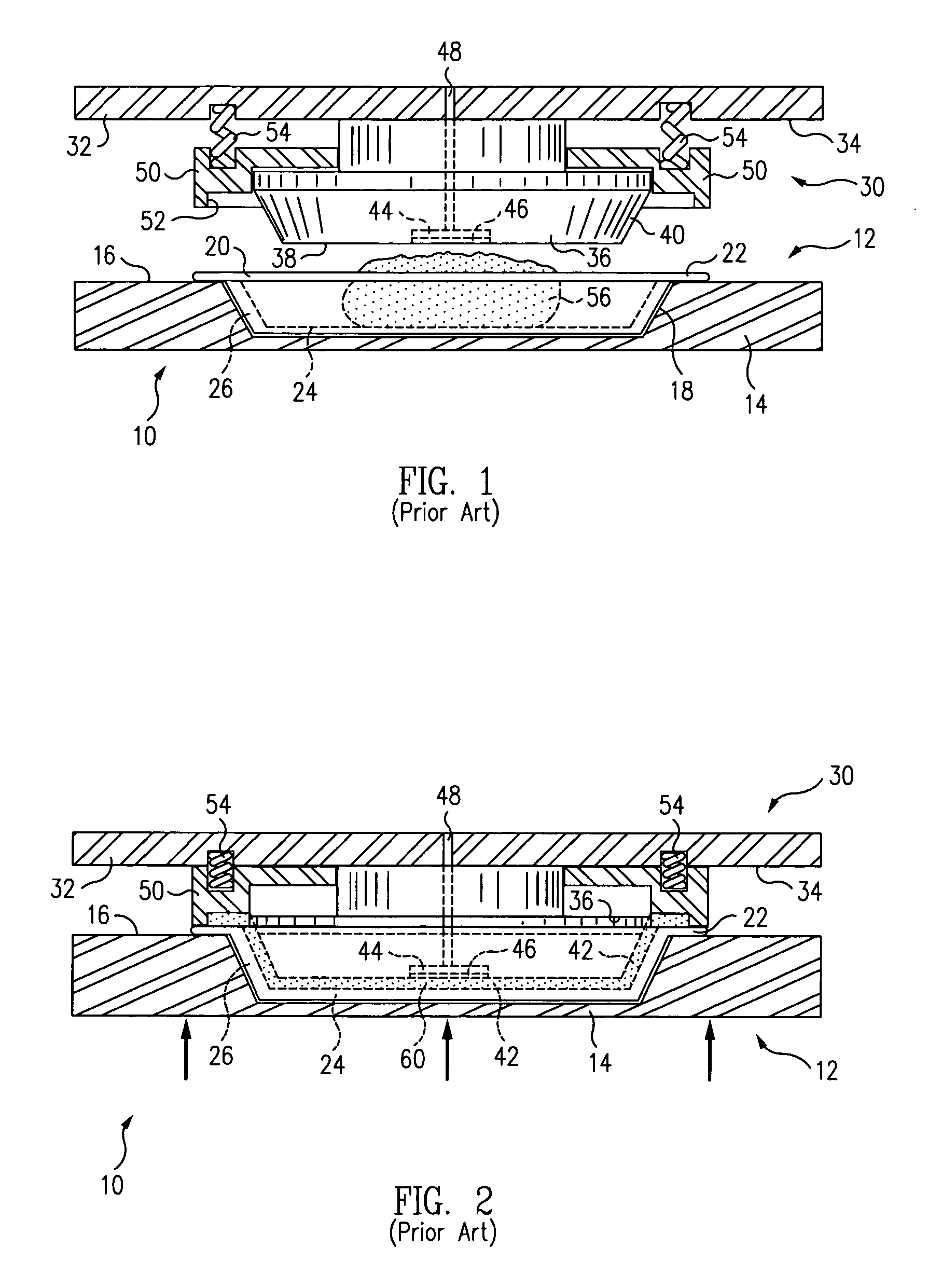

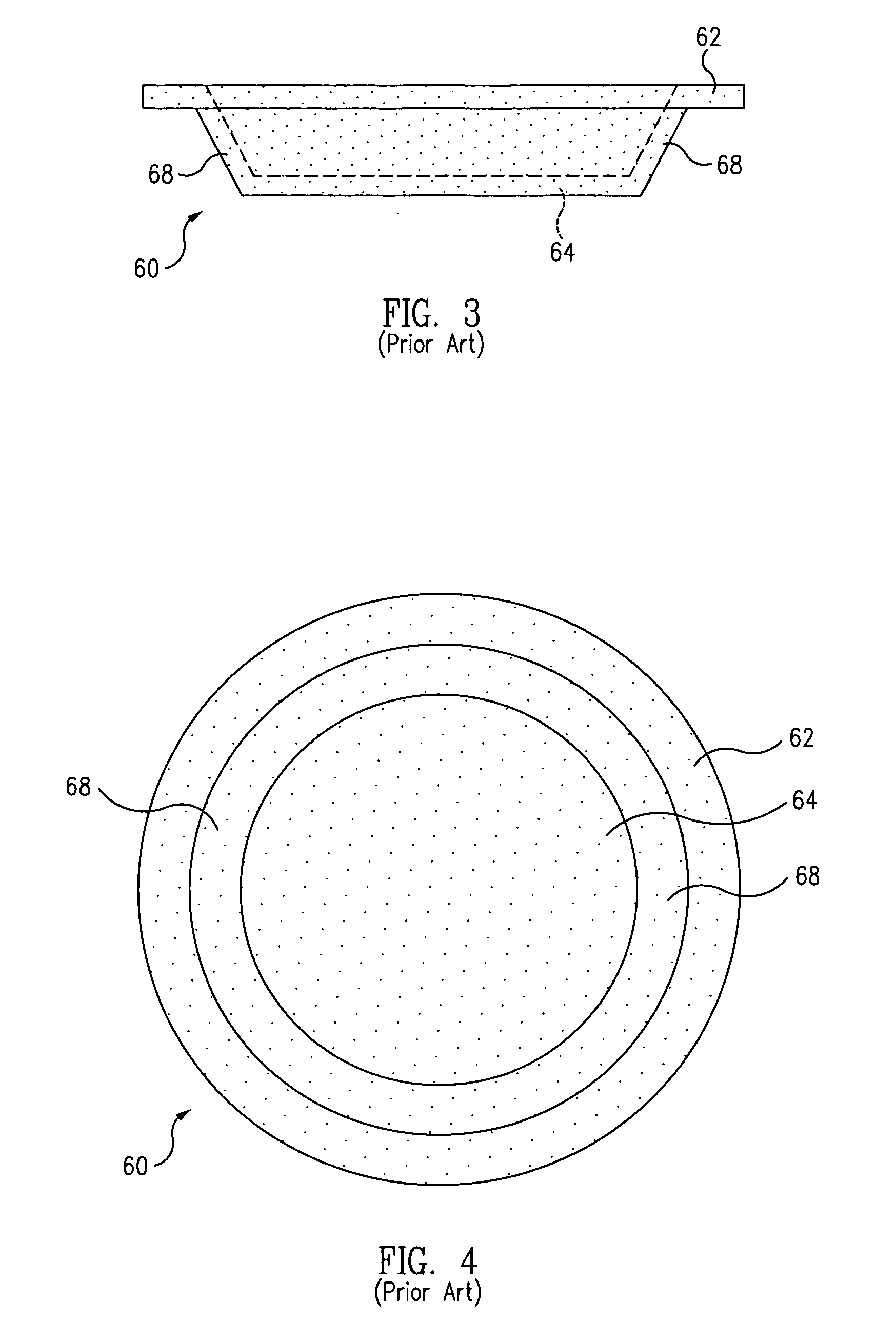

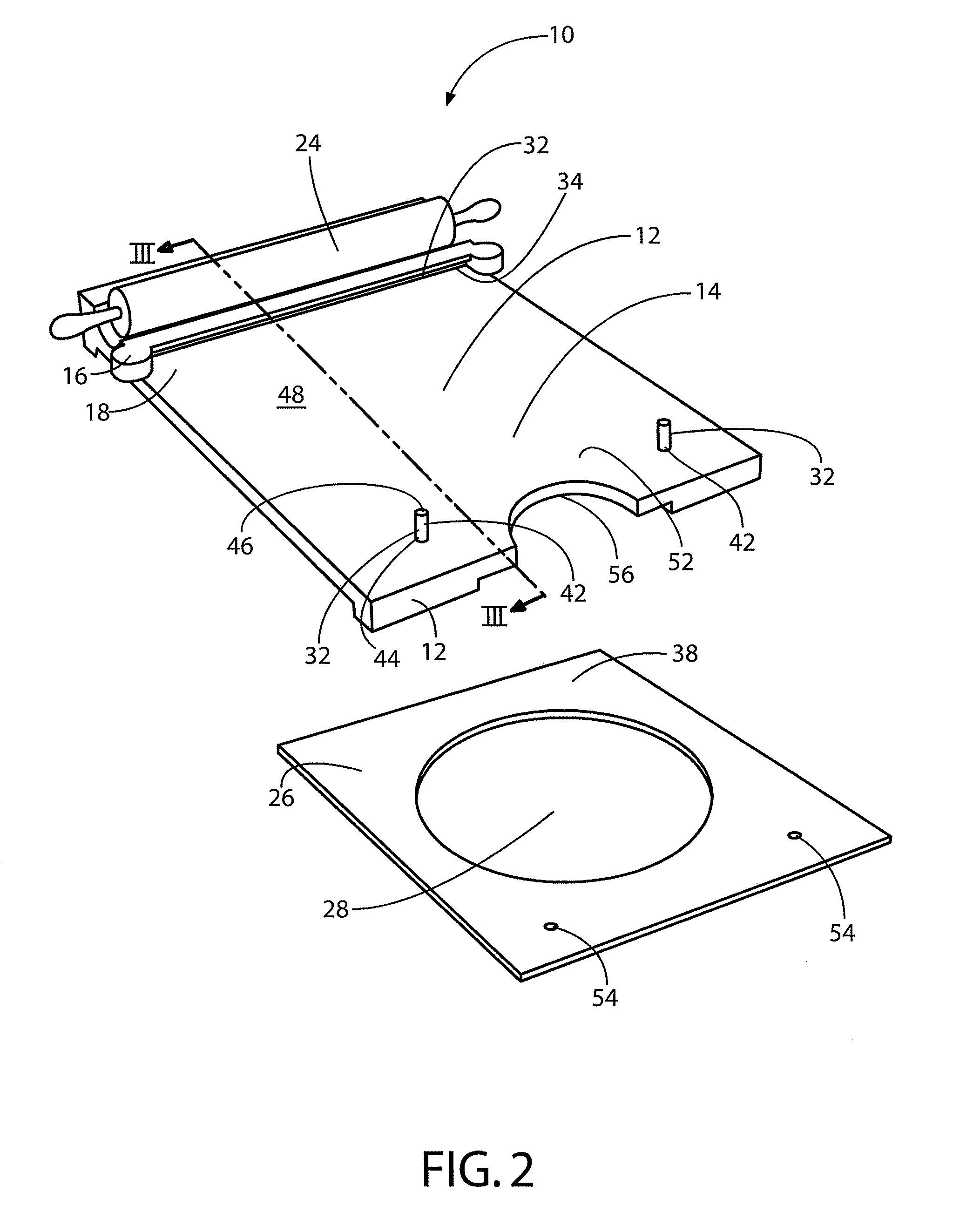

System and method for producing par-baked pizza crusts

InactiveUS6843167B1Reduces final cooking timeFast deliveryFood preservationMeat processingBiomedical engineering

A system for producing par-baked pizza crusts from dough portions includes a pan adapted to support the dough portions. A lid assembly is positioned to contact each dough portion. The dough portions are par-baked in an oven, while the lid assembly contacts the dough portions, in order to produce par-baked pizza crusts.

Owner:PIZZA HUT LLC

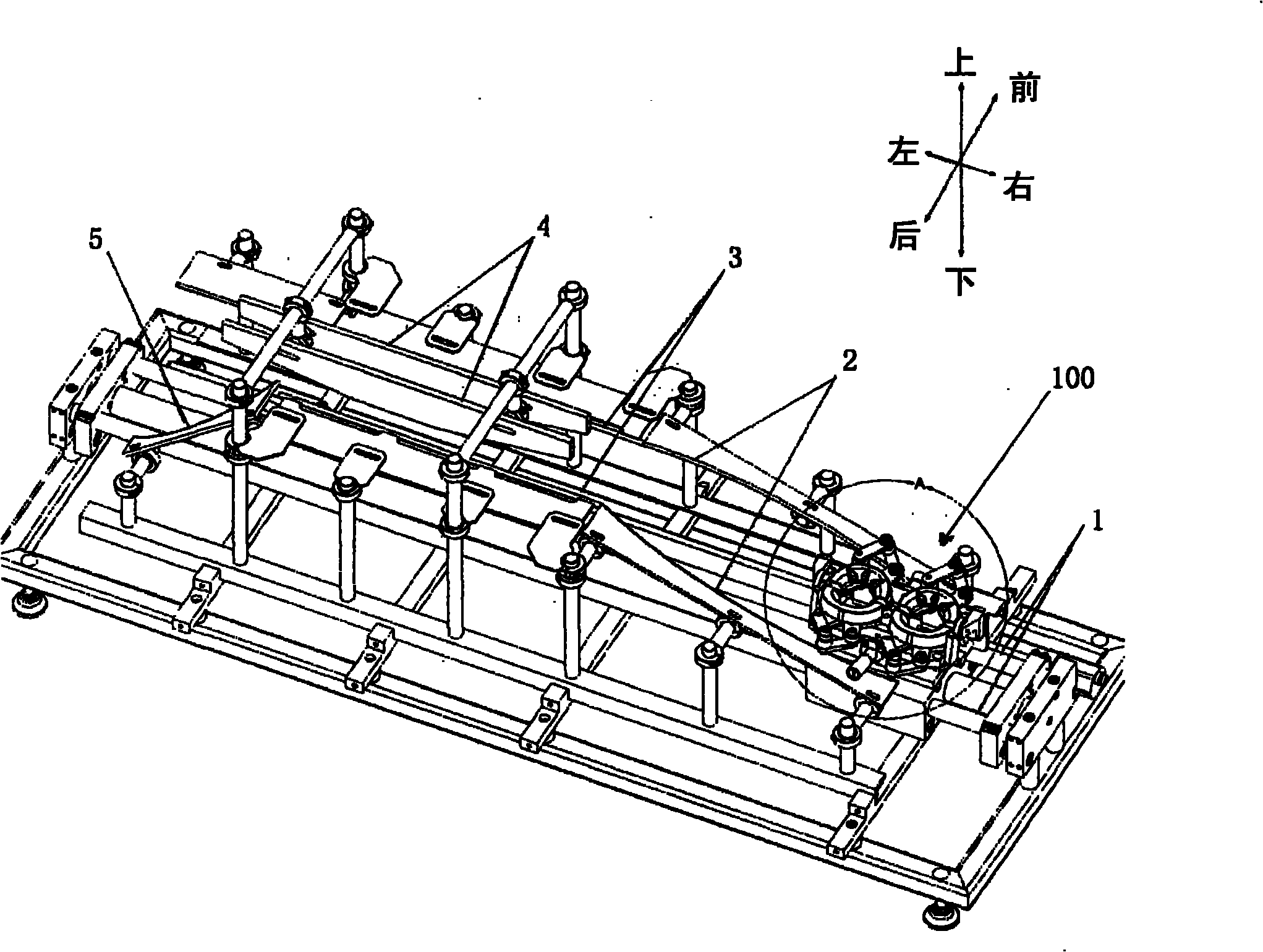

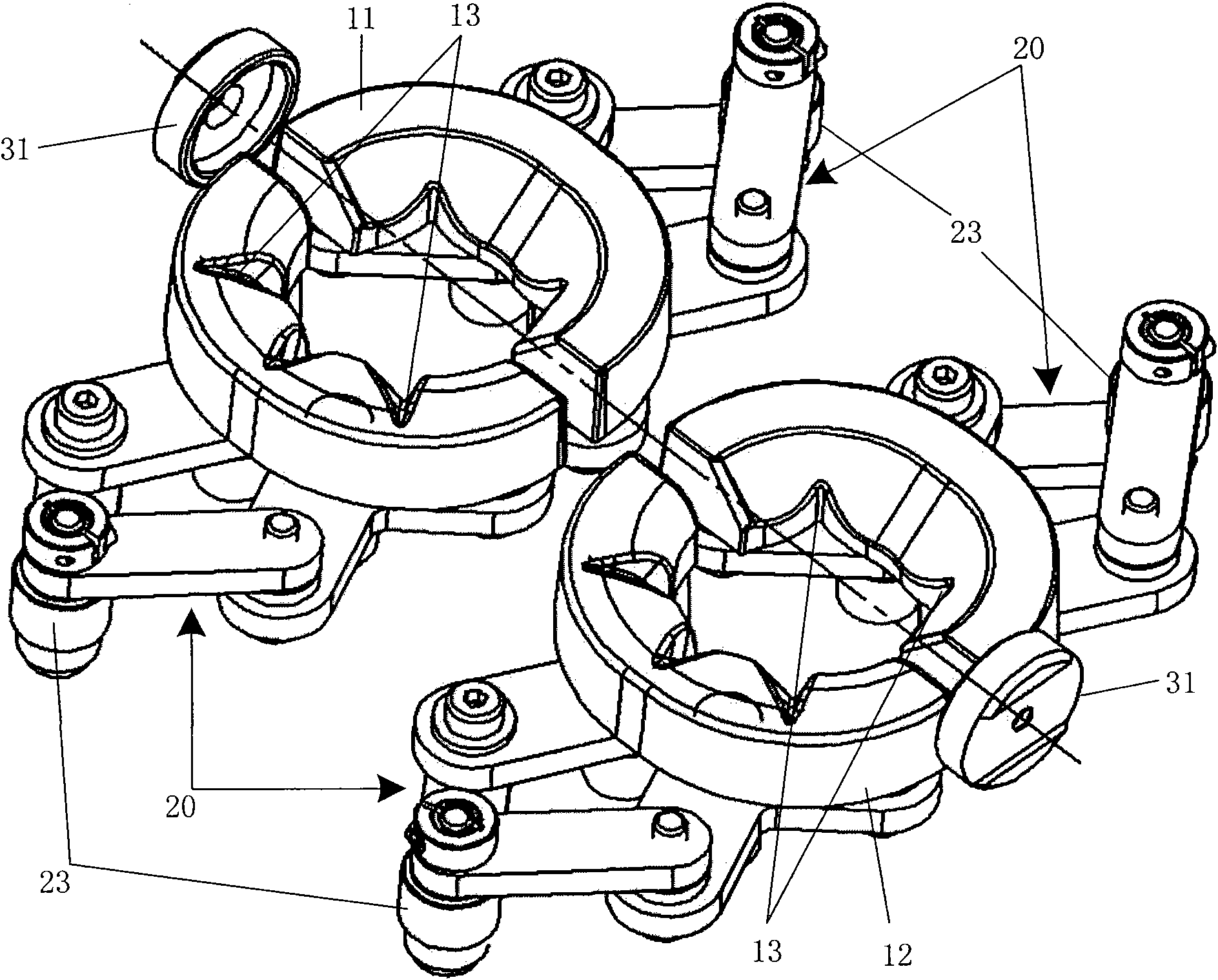

Mold, extruding device and dumpling-making machine

The invention provides a mold which comprises a pair of clamp jaws, and a dumpling wrapper filled with fillings can be extruded to have a shape of a dumpling semi-finished product by closing the pair of clamp jaws. Thereinto, the pair of clamp jaws in a closed state can simulate a human action of manual extrusion of a dumpling filling capsule under the action of external force. . The invention also provides an extruding device for driving the mold action, and the extruding device can apply external force with the pair of clamp jaws being in a closed state so as to drive the pair of clamp jaws to perform the simulated human action of extruding a dumpling filling capsule with both hands.

Owner:GENERAL MILLS MARKETING INC

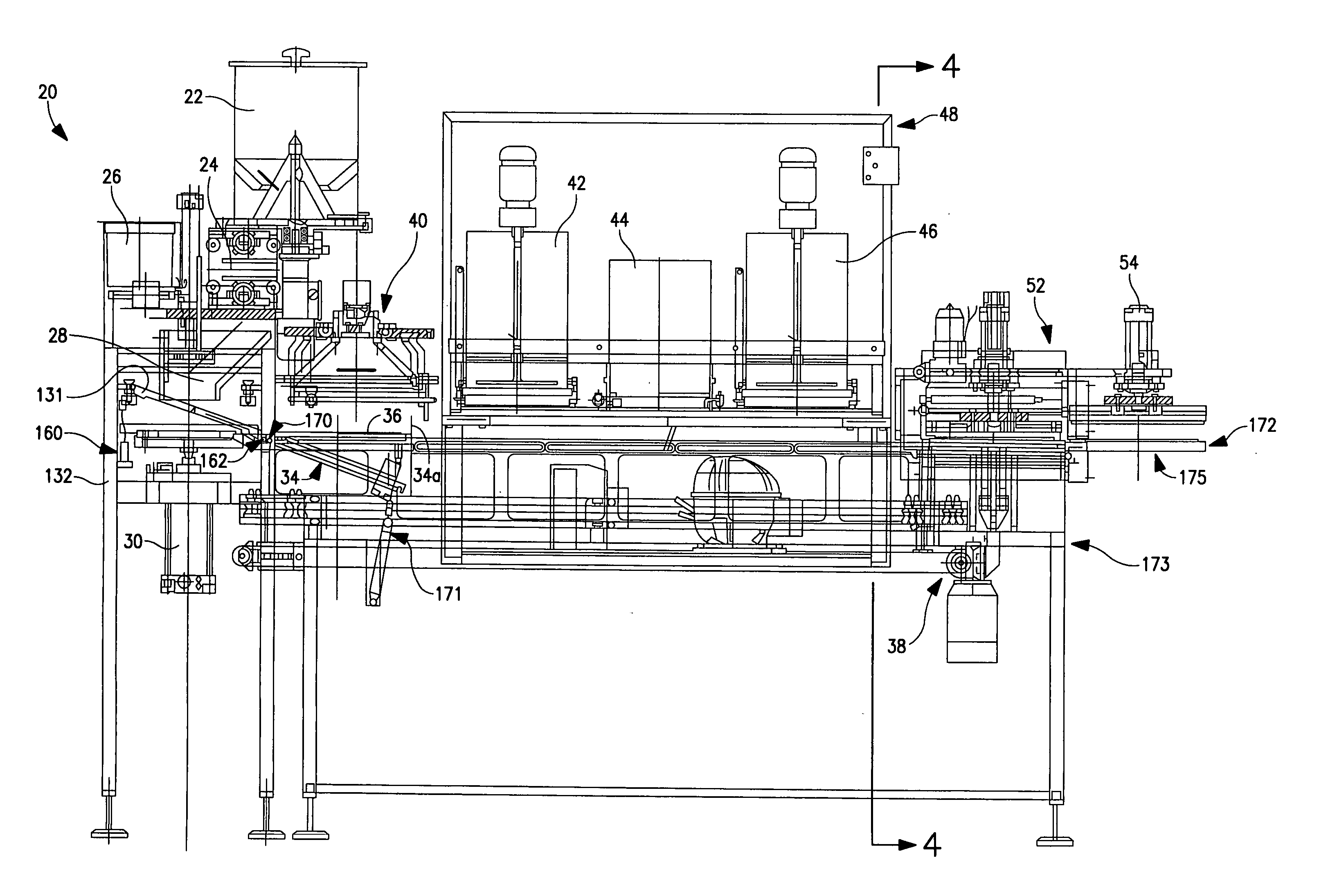

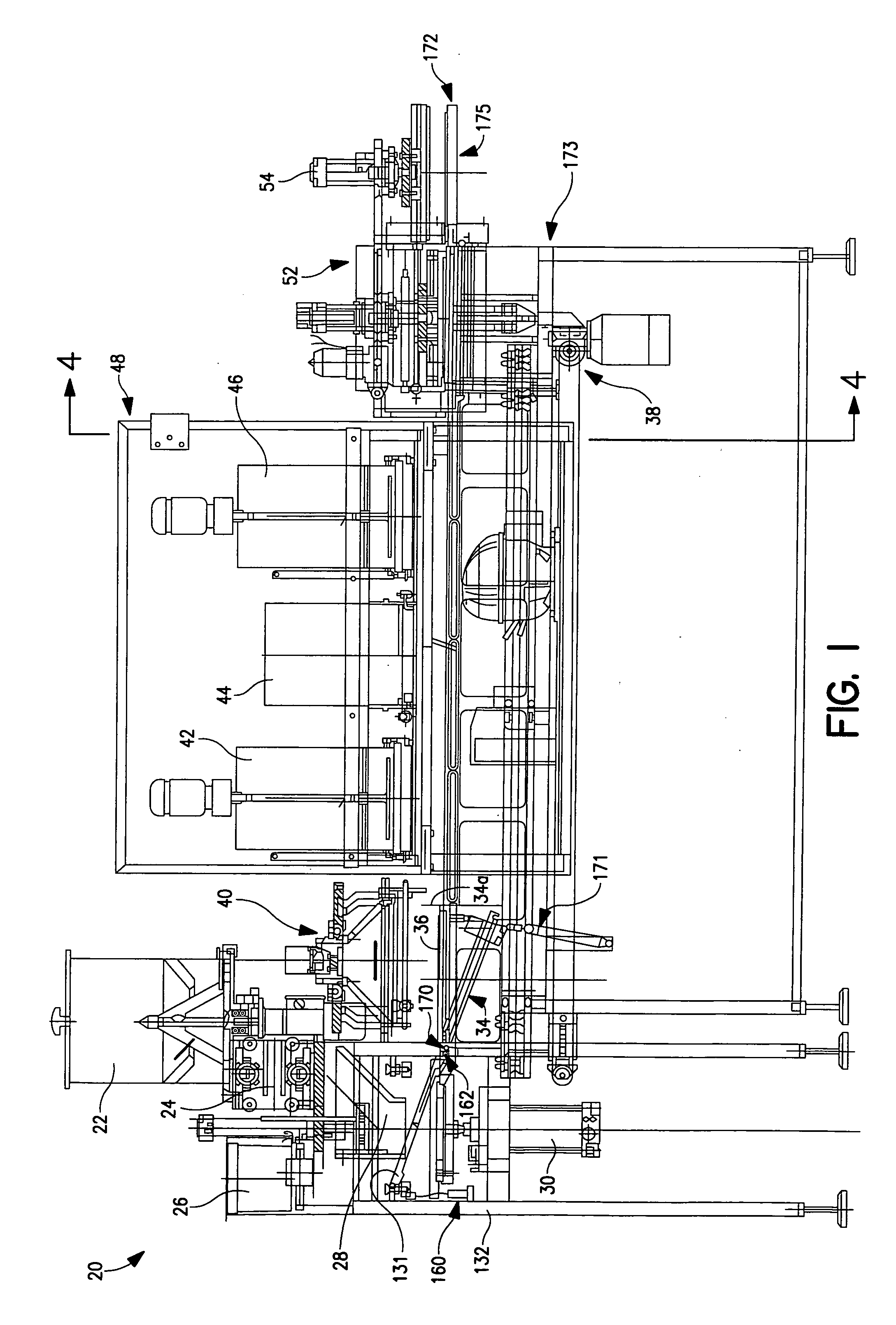

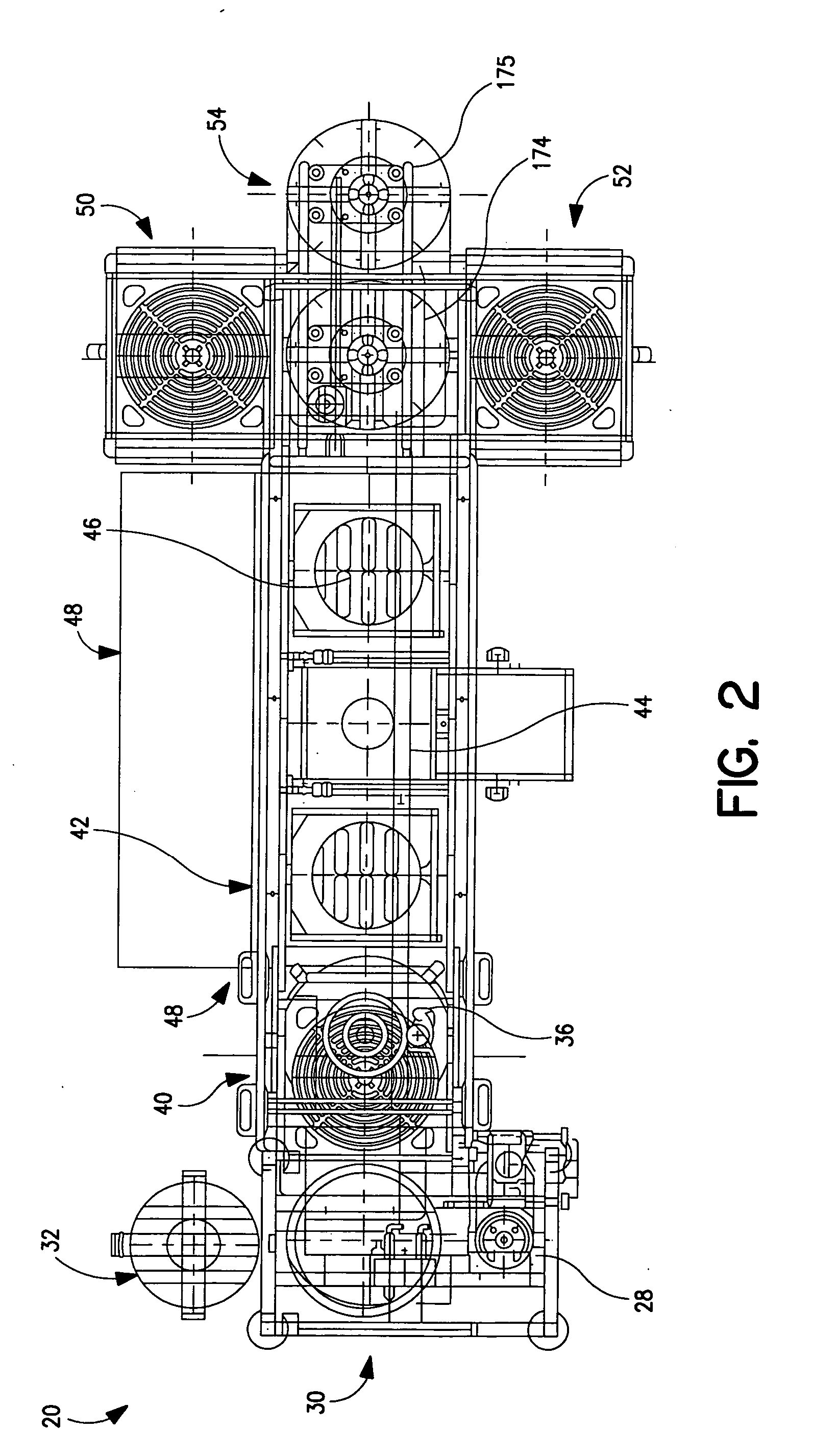

Pizza making method and system

InactiveUS20050123659A1Simple and easy-to-clean cuttingEasy to separateRotary stirring mixersTransportation and packagingCooking & bakingAdditive ingredient

The invention provides an automated method and apparatus for pizza production which is initiated by individual order placement and uses only fresh ingredients (no ingredients are frozen, pre-prepared or pre-cooked). Each dough portion is individually and mechanically prepared from flour and other fresh, pre-proportioned ingredients. The dough portion passes through a series of shaping and pre-heating processing stations to prepare a flattened and partially baked pizza base. Using a preheated or continuously heated conveying tray, the pizza base passes under a number of metering and distribution devices for selected application of tomato sauce and / or various other toppings according to the order. Baking occurs in one of multiple ovens to complete pizza preparation. Multiple ovens are provided to facilitate the automated preparation of multiple pizzas at any given time. A tray conveying system transports one or more trays through the various processing stations to accommodate multiple orders at the same time.

Owner:SITOS

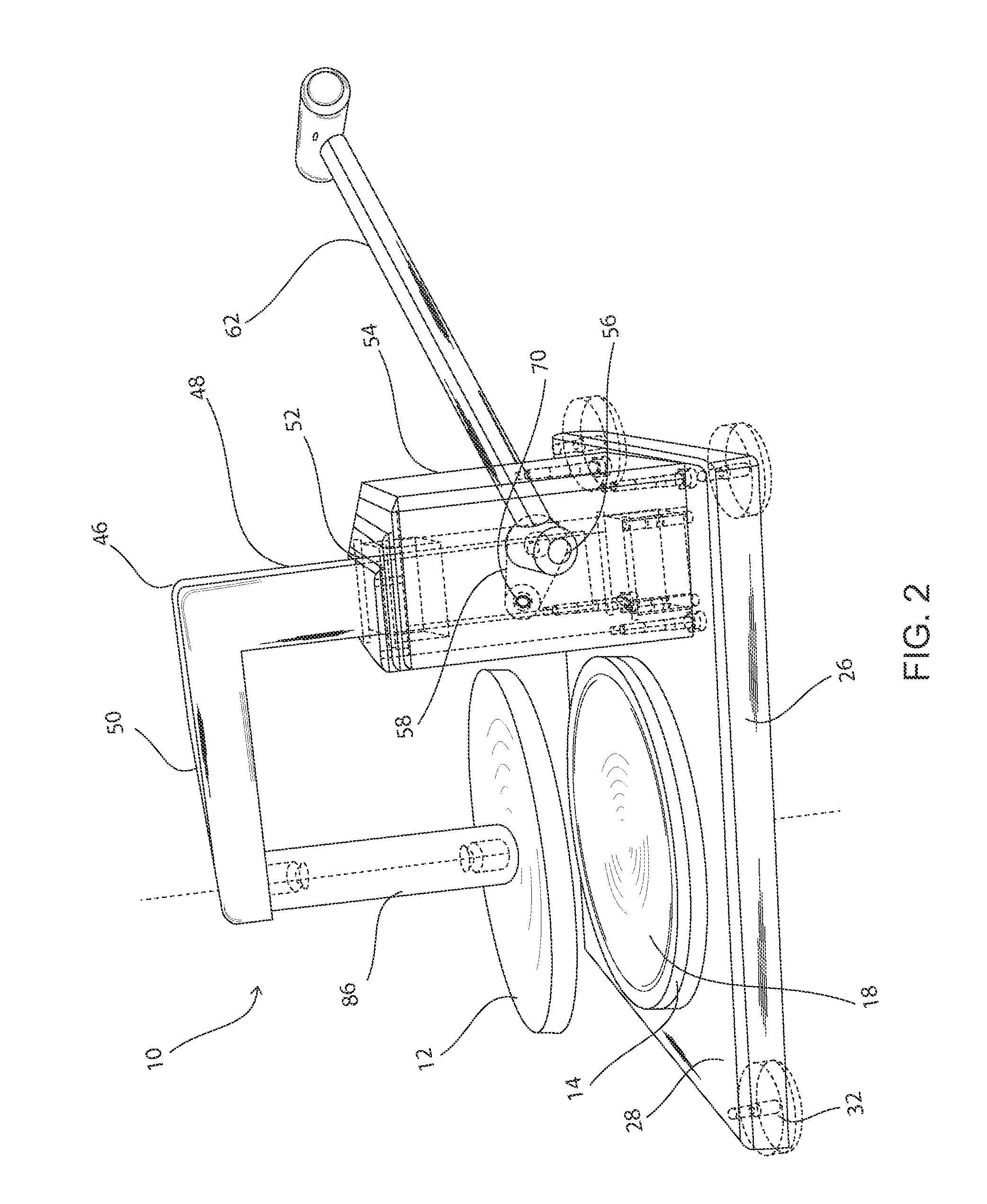

Moving head dough press

A reciprocating press is configured to press articles while moving in synchronicity with a conveyor belt carrying the articles. The press is driven through a rack and pinion system. The press can be used for pressing any type of article, including, but without limitation, pieces of dough for forming tortillas.

Owner:MATTIAS SCOTT +1

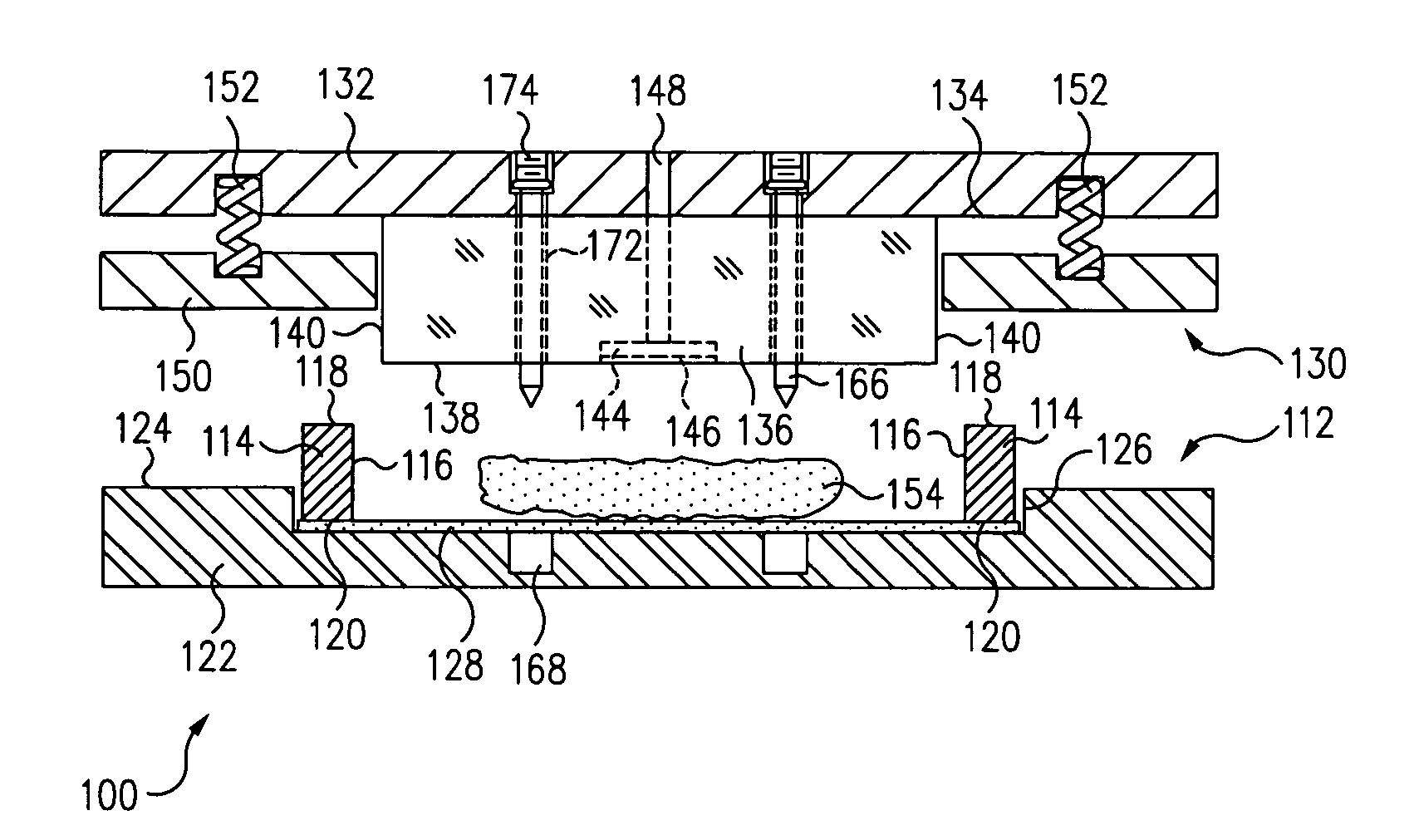

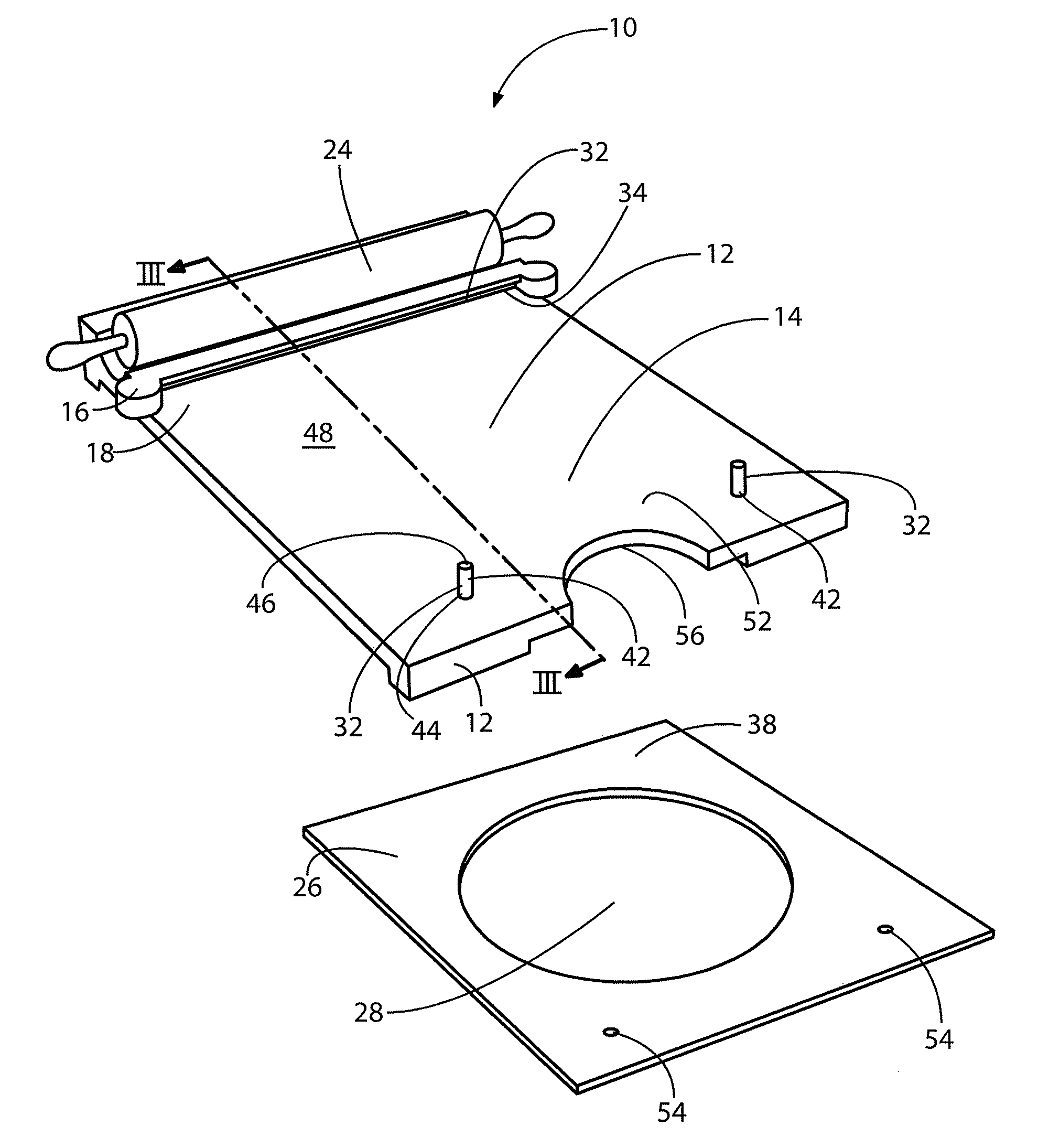

Making pastry shells

Apparatus for making variously shaped pastry shells includes an annular baking ring supported on a horizontal lower plate to define an upward-facing female die. A gasket is disposed between the baking ring and the plate. An upper plate is positioned above and parallel to the lower plate, and includes a downward-facing male die configured to be inserted concentrically into the upper end of the female die and thereby define a die space having a flat floor and annular, vertical side walls between the dies. An annular collar is disposed concentrically about the male die and resiliently supported on the upper support plate such that, when the two plates are urged toward each other, the collar seals the upper and lower ends of the die space, and a volume of pastry dough disposed in the cavity of the female die is formed into a pastry shell conforming to the die space.

Owner:LICHTENSTEIN DAVID M

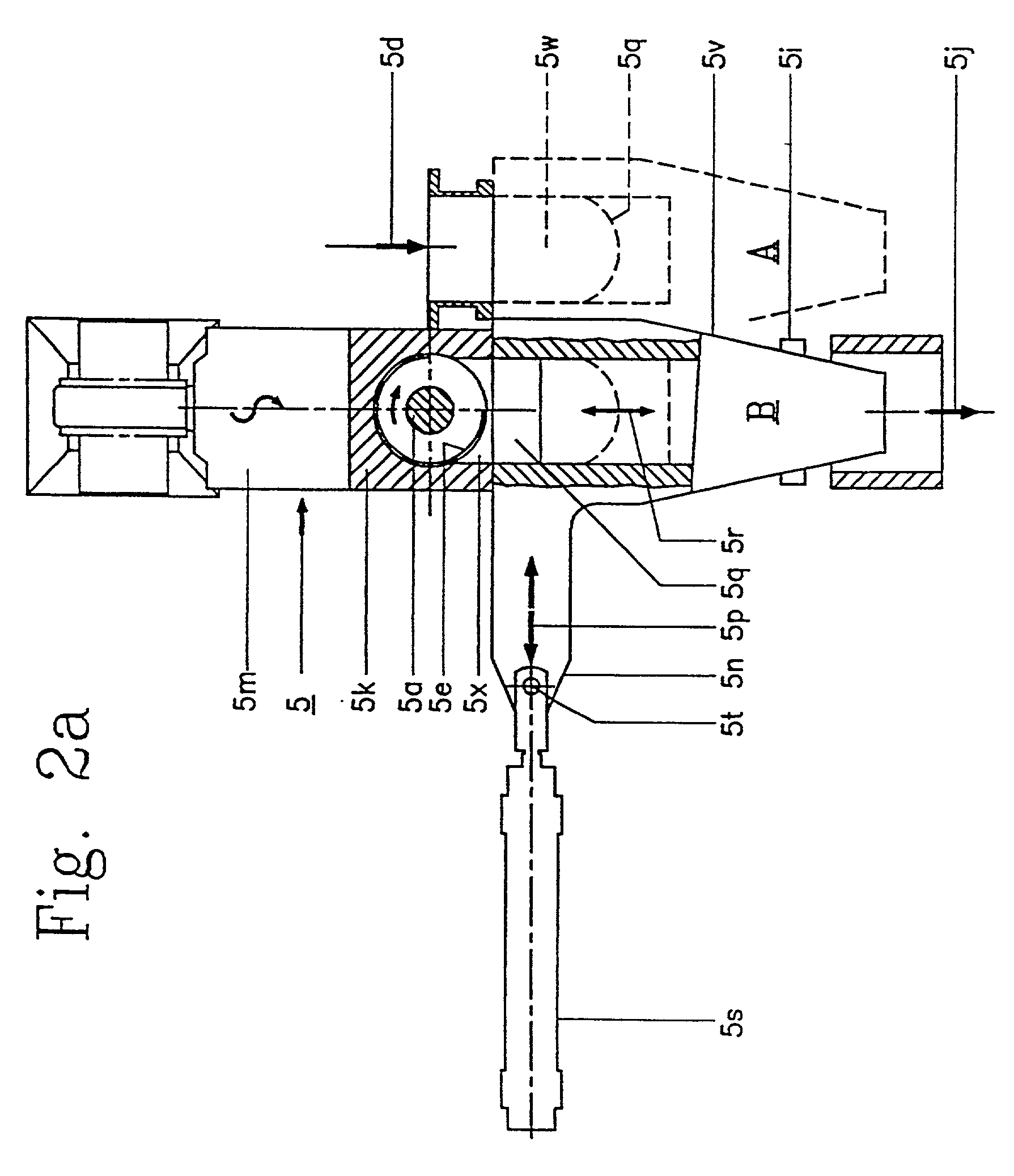

Method and device for producing pizza

InactiveUS20010024671A1Short timeReduce baking timeBaking mixturesConfectioneryAdditive ingredientEngineering

The invention is an apparatus for producing pizza by a mechanical, automated system without using baking tins for the dough bases and without using pre-prepared or pre-shaped bases. Dough bases are individually prepared from fresh pre-proportioned dough ingredients by a kneading and extrusion device. The dough base is then passed through a series of processing stations, such as a shaping press, a metering and distribution device for tomato purees or sauces, at least one metering and distribution station for garnishing (topping) ingredients and a baking station. The dough bases pass through the series of stations on a preheated or continuously heated transportation sheet. No pre-produced or pre-cooked, semi-finished products are used in the method. Each dough base is prepared and provided with toppings according to individual orders selected from a list.

Owner:SITOS

Dough processing apparatus

ActiveUS20060222748A1Apply evenlyAccurate shapeDough treatmentArtificial flowers and garlandsEngineeringThin sheet

It is an object of the present invention to provide a dough processing apparatus capable of not only stably thinning and shaping dough, such as a pizza dough, and so forth, into a thin sheet-like shape, but also coping with dough in a wide variety of shapes with ease. A rounded dough f obtained by portioning out dough to a predetermined quantity is transferred toward under a first beating mechanism, and a second beating mechanism by a belt conveyor. The first beating mechanism, and the second beating mechanism make the vertical movement, alternately, whereupon the dough f is pressed under pressure to be thereby thinned. The dough f after thinned is then transferred by the belt conveyor to be delivered to a dough-shaping apparatus. The dough f is transferred by a belt conveyor to be surrounded by a horizontal die. The dough f as surrounded by the horizontal die is pushed down from above by a rotator provided with a plurality of push-rollers. Upon rotation of the rotator, the dough f is thinned by the plurality of the push-rollers to be thereby shaped into a shaped dough F in the shape of a thin sheet, circular in a plan view.

Owner:KOBIRD CO LTD

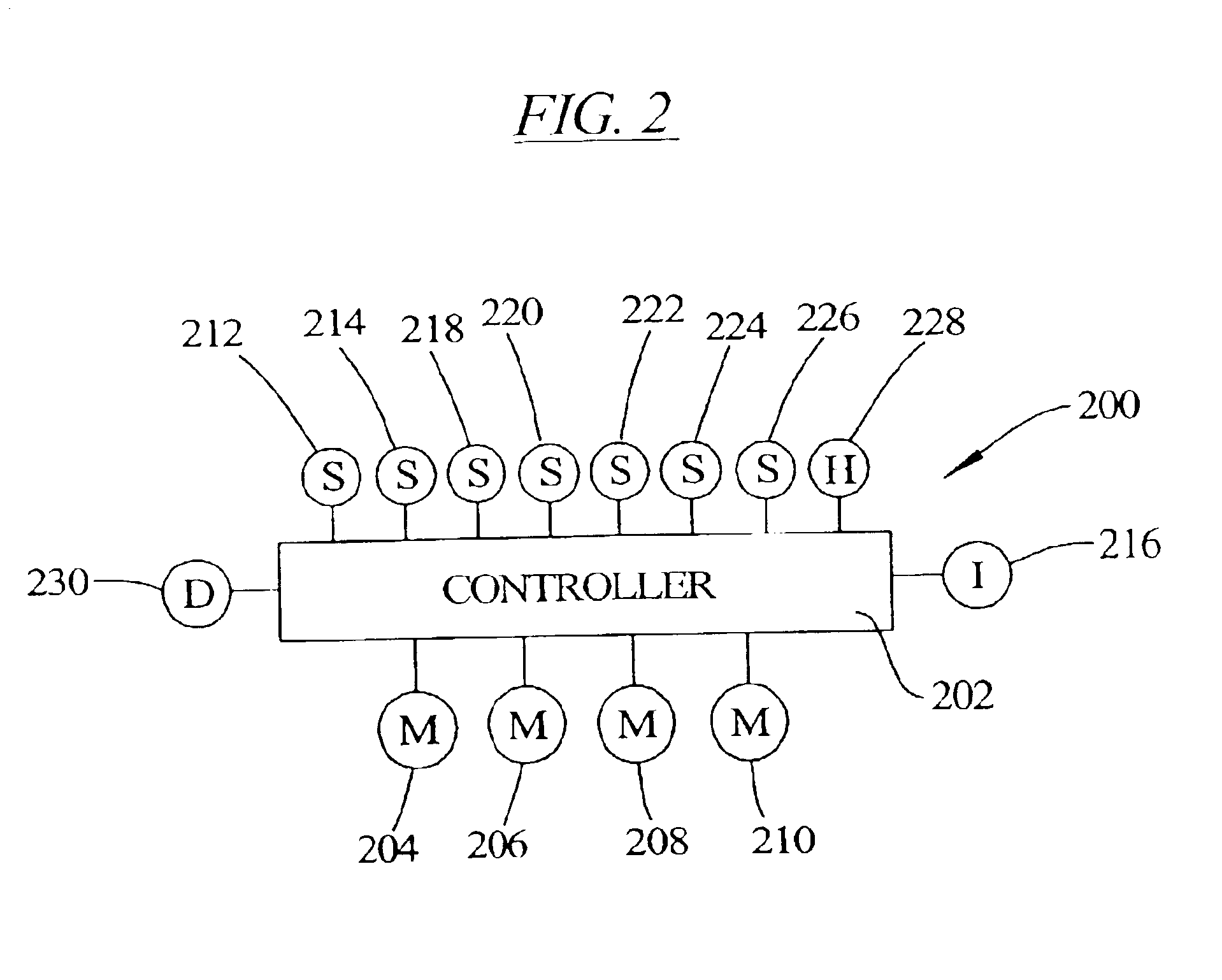

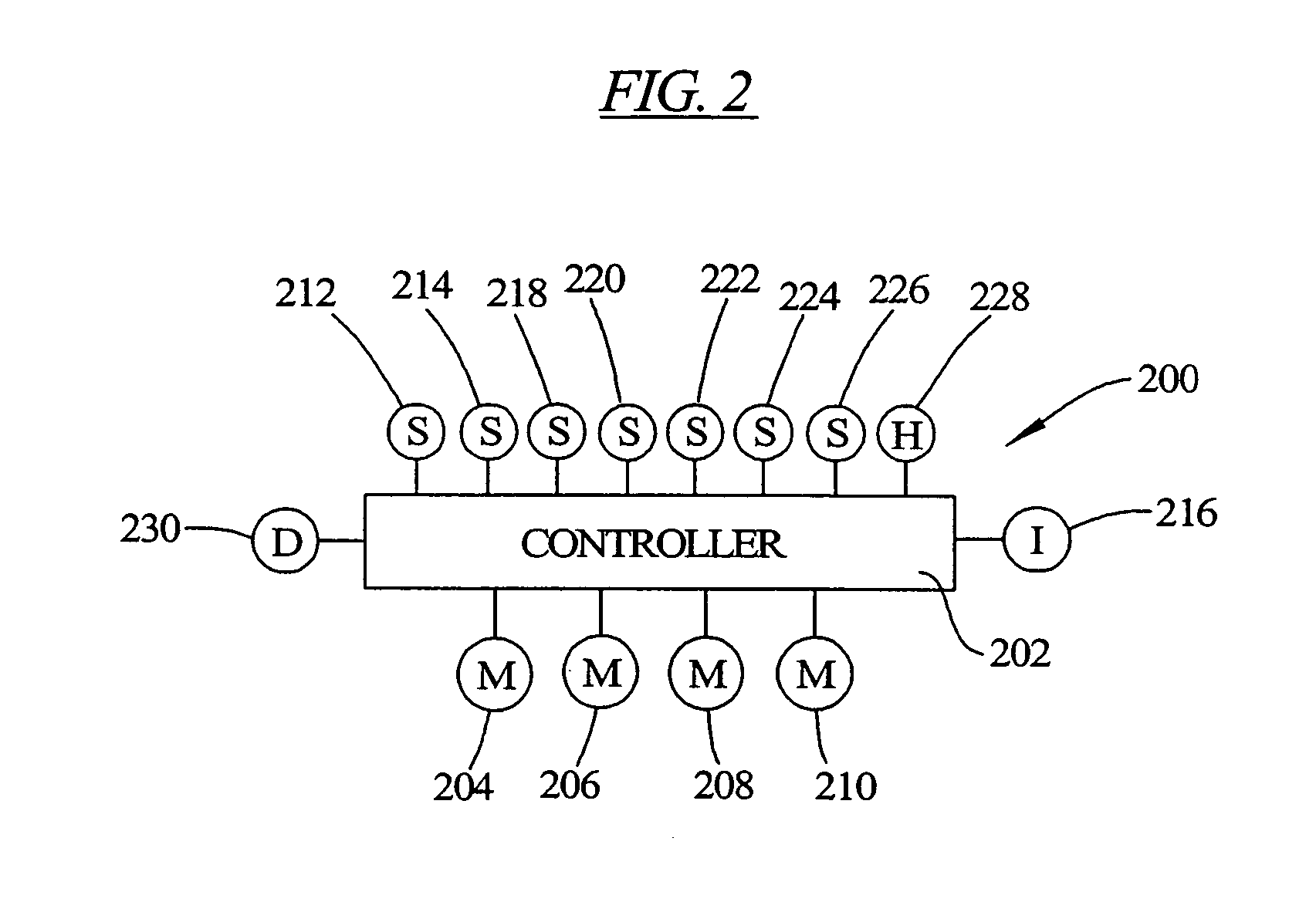

Single sensor press system

ActiveUS7086325B2Great efficiency and accuracy and flexibilityOvercome deficienciesMaterial strength using tensile/compressive forcesRoasters/grillsHydraulic cylinderProgrammable logic controller

A tortilla press utilizing a single sensor provides improved efficiency and accuracy. The press has a belt driven by a motor and a platen driven by a hydraulic cylinder. The motor is controlled by an AC inverter. A programmable logic controller (PLC) controls the AC inverter and hydraulics associated with the hydraulic cylinder of the platen. The PLC coordinates the movement of the belt and the movement of the platen. A sensor detects detectible elements on the belt and sends a signal to the inverter to initiate stopping of the belt. The inverter detects the zero hertz from the motor once the motor and belt have stopped and sends a signal to the PLC indicating that the belt has stopped. The PLC in turn passes a command that sends a signal to bring the platen down.

Owner:CASA HERRARA

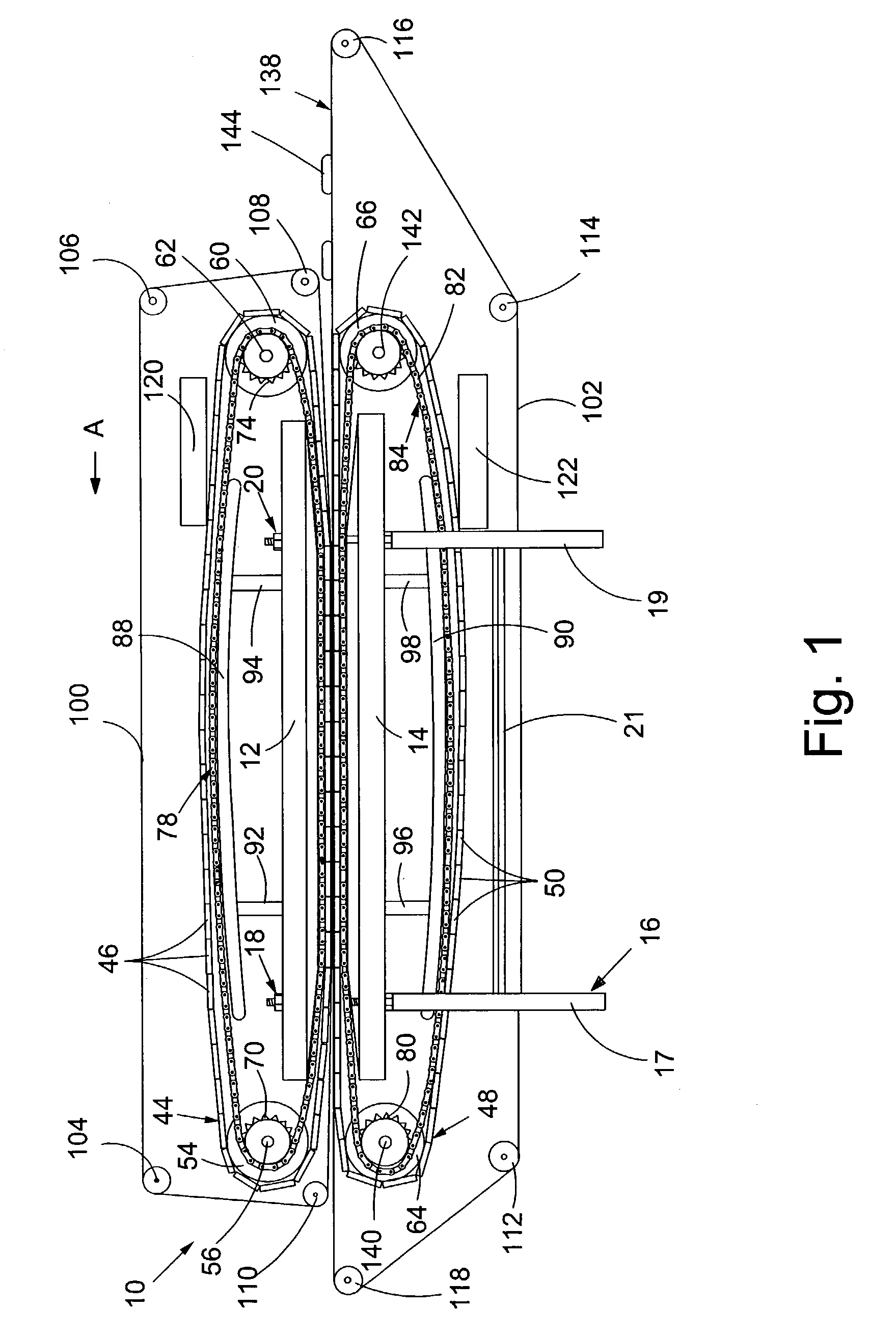

Apparatus and method for forming food products by gradual compression

The present invention is directed to methods and apparatuses for processing food products and utilizes a series of guides for moving platens through several operative zones to press a food product intermediate. In particular, the present invention relates to an apparatus and method for forming generally flat dough products such as tortillas, taco shells, snacks and the like by gradually pressing a dough intermediate between movable platens that are disposed on concentric, endless belts.

Owner:GENERAL MILLS INC

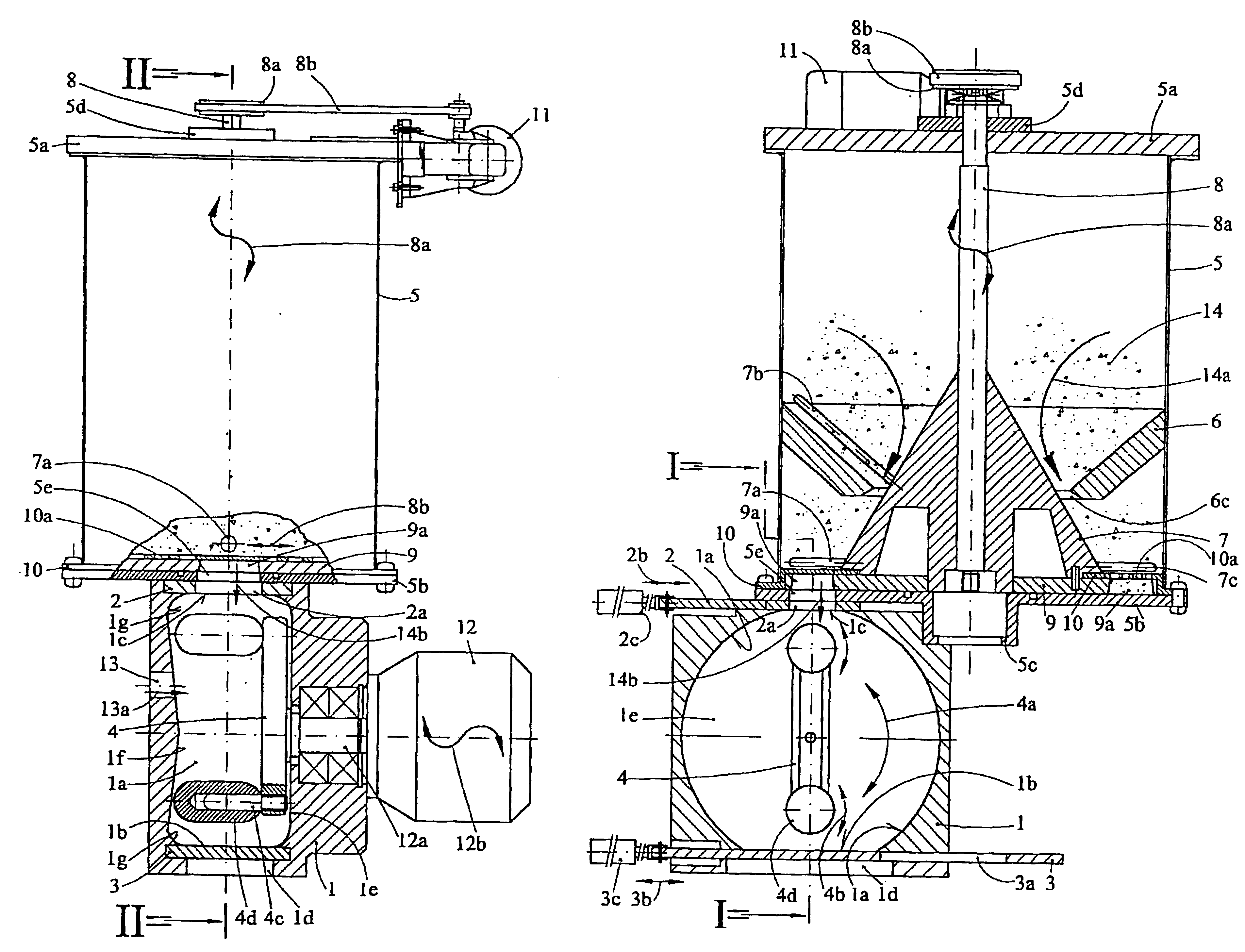

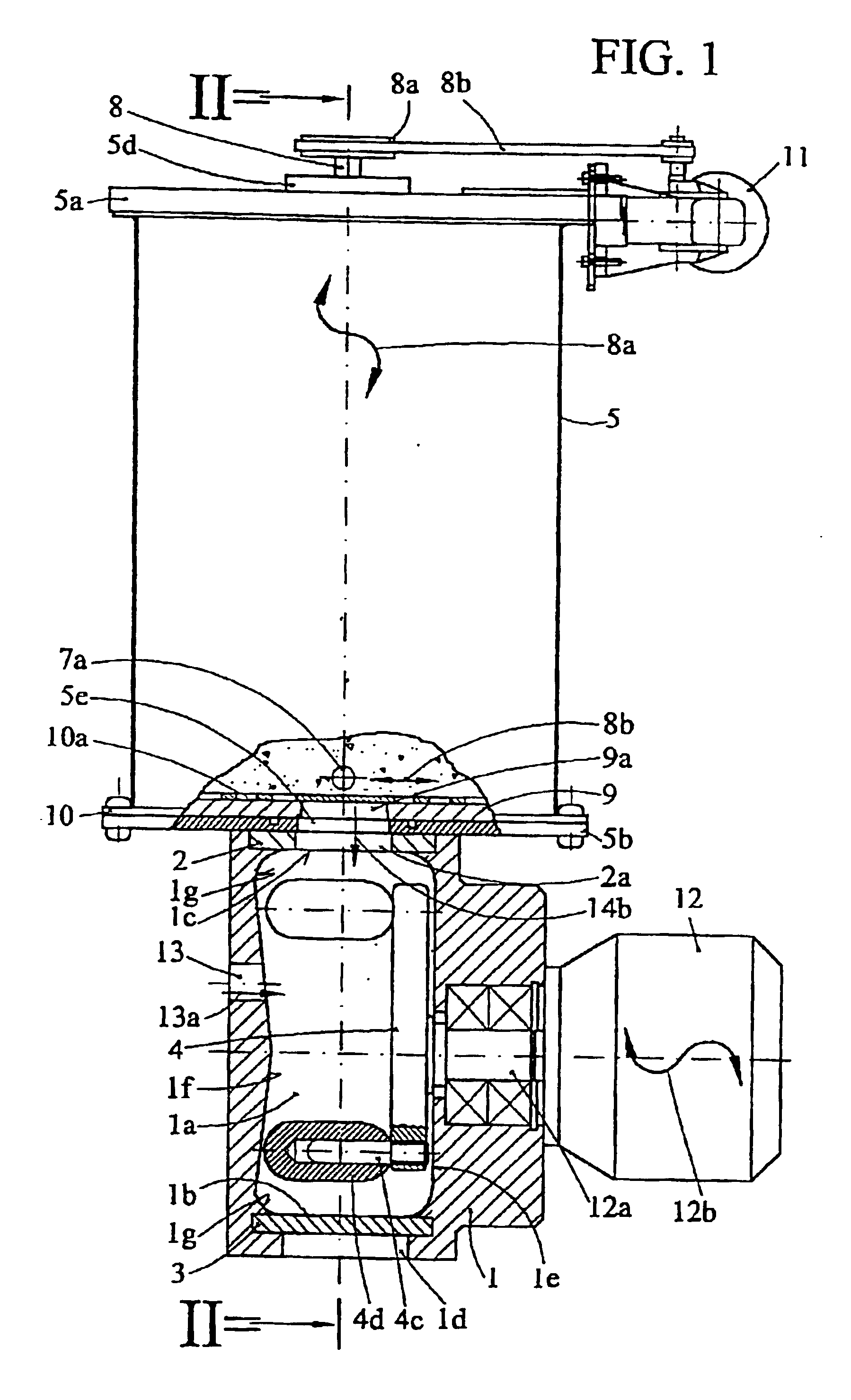

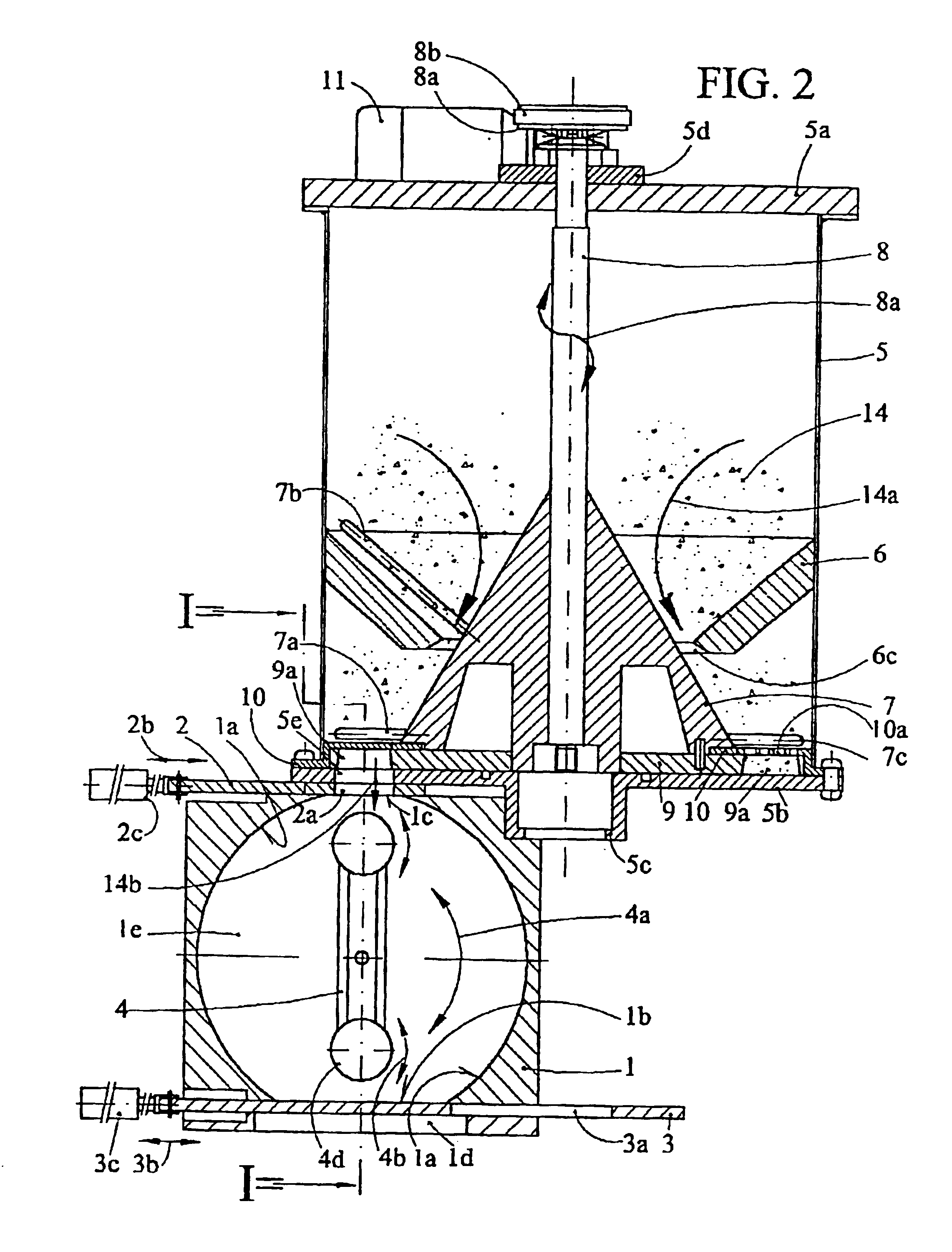

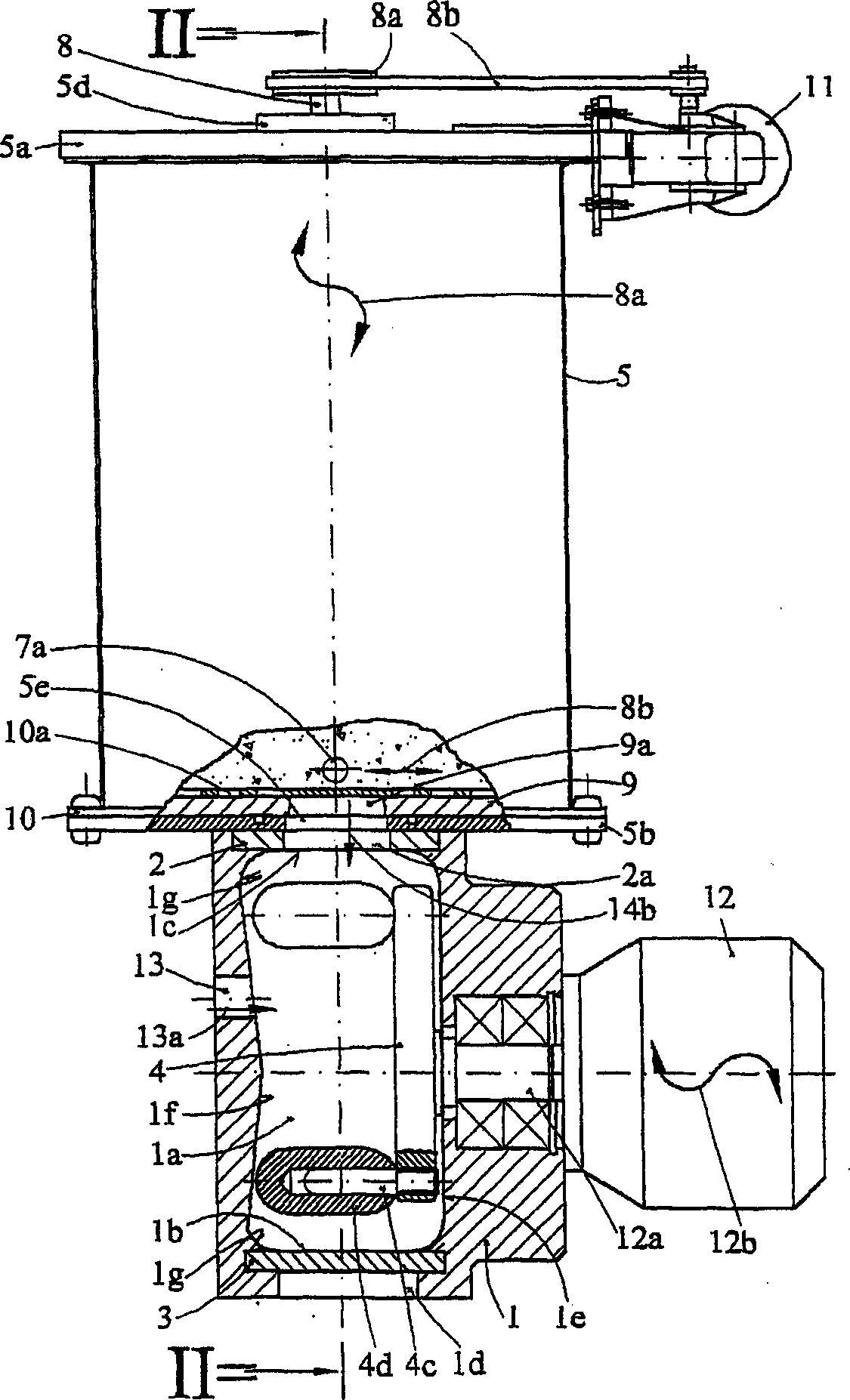

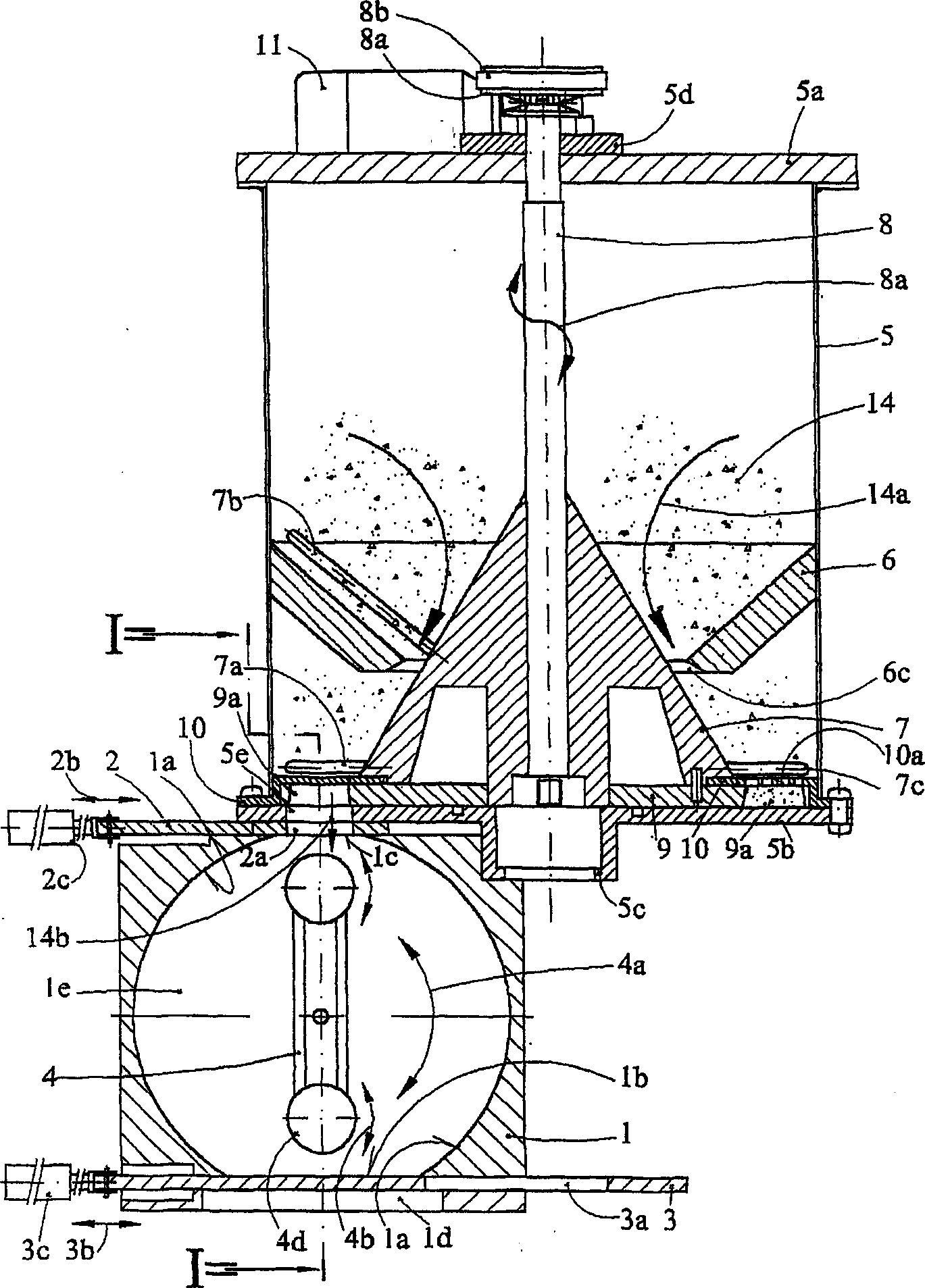

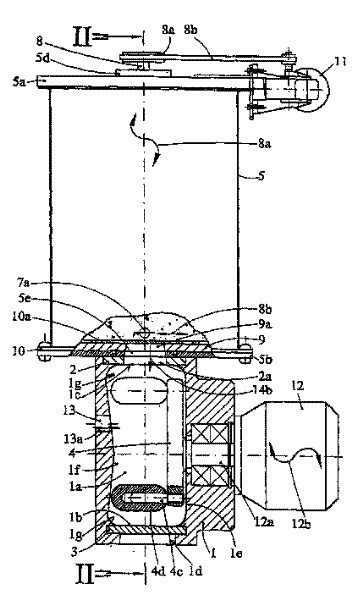

Dough mixer with metering device

InactiveUS6863429B2Simple and compact designMixing/kneading structural elementsTransportation and packagingHorizontal axisCircular surface

In a dough mixer for preparing dough, the essentially cylindrical chamber with horizontal axis within which kneading elements (4, 4c, 4b) rotate coaxially or parallel to this axis, between two casing surface sections (1a) with the same casing line, two level surface sections (1b, 1c) which are essentially formed by the surface of sliding (2b, 3b) blades (2, 3) with upper charging opening (2a) and lower discharging opening (3a) in closed position, and the aforementioned surfaces (1a, 1b, 1c) turn into two front, coaxial, separated circular surfaces (1e, 1f) via rounded areas (1g) with the largest possible radius, such that, together with the rotating (4a) kneading element (4, 4c, 4d), which likewise has very round forms, they enable the preparing and compressing of dough and rolling into balls of an individual dough portion that is discharged without residue of ingredients or dough. The metering device for charging the dough mixer with volumetric calibrated and the most homogeneous portion of flour-like ingredients has a vertical shaft (8) that rotates coaxially (8a) to the cylindrical container (5, 5a, 5b), which drives stirring elements (7a, 7b), a distribution cone (7) and a metering disk (9a) with metering holes (9a) positioned on the rim that are equidistant both from one another and from the axis. The container of the metering device is divided on the inside by an annular, funnel-like partition (6) into an upper container and a lower, smaller region for the metering mechanism.

Owner:SITOS

Kneading machine with dosing device

InactiveCN1372489AAbsorb evenlyMix completelyMixing/kneading structural elementsRotary stirring mixersRotational axisVertical plane

A dough or pastry mixer assembly has a main mixing chamber (5) discharging into a high speed single portion lower kneading chamber (1). In one horizontal plane the kneading chamber has essentially ring-shaped sidewalls with mixer paddles rotating through the vertical plane. At right angles to the first horizontal plane, the chamber has two circular facing sidewalls, one slightly conical and the other flat. The top and bottom of the kneading chamber are slightly flattened. The top has an inlet aperture which is kept free of food particles by a slide closure. The chamber bottom has a slide closure for discharge of the kneaded mixture. The slightly conical chamber sidewall terminates in a rounded tip parallel to the axis of mixer paddle rotation.

Owner:ARTOS SA

Dough shaping device and kit

Owner:ALVIDREZ NORMAN

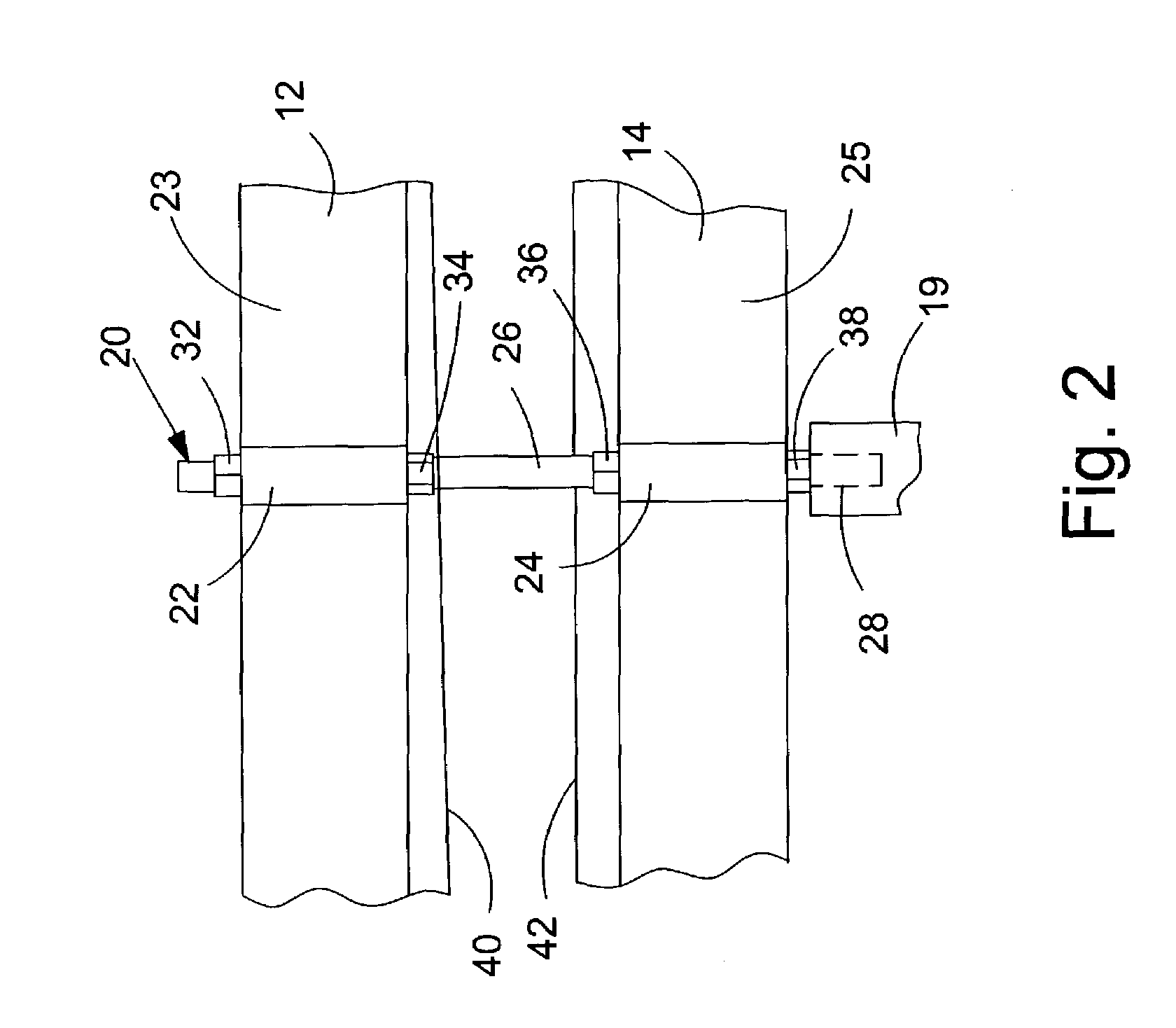

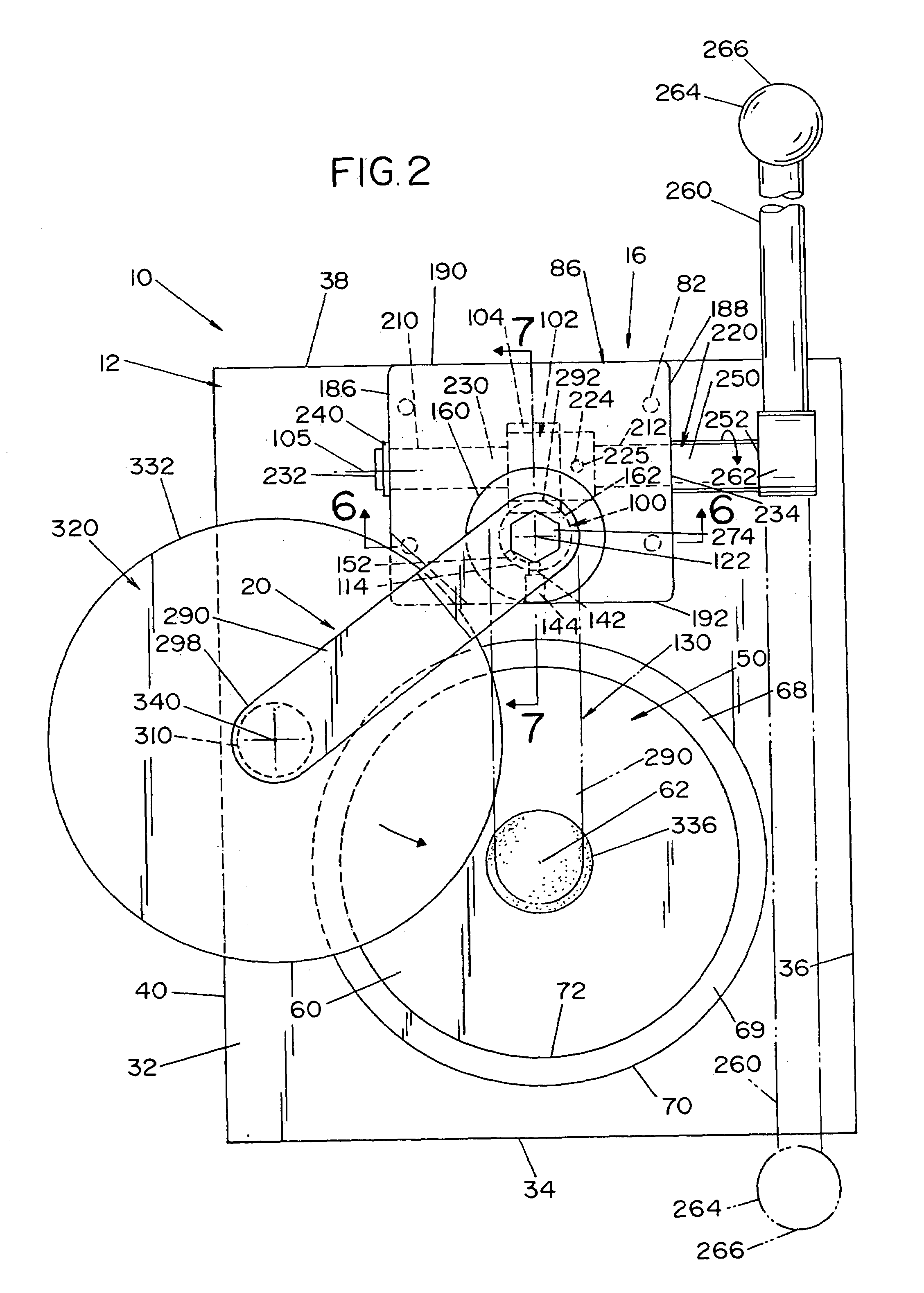

Reciprocating head press

ActiveUS6951451B2Avoid problemsQuickly and precisely alignedDough-sheeters/rolling-machines/rolling-pinsConfectioneryConveyor beltLinear actuator

A press for flattening dough pieces is provided having a floor supported frame, an endless conveyor belt movably carried on the frame and presenting an upper horizontal surface, and at least one movable platen carried on the frame for pressing the dough pieces against the belt. In an embodiment, a sub frame is adjustably supported by the frame to permit leveling and adjustment of said sub frame relative to the frame. Attachment mechanisms are provided for securing the sub frame to the main frame following adjustment between the two. In an embodiment, at least two movable platens are carried on at least one of said frames, both of the platens being movable in a longitudinal horizontal direction and at least one of the platens is movable in a vertical direction. A linear actuator is drivingly connected to the two movable platens. In an embodiment, a loading system for loading dough balls onto the belt is provided. The loading system includes a transport mechanism to receive dough balls in a sequential stream and to deliver the dough balls to the belt at a speed equal to a speed of the belt. In an embodiment, a belt splicing hot press is carried on the frame operatively engageable with the belt to splice together severed ends of the belt to form a continuous endless belt.

Owner:AM MFG

Tortilla forming machine

ActiveUS7140864B1Well formedMechanism is expensiveConfectioneryMeat processingMolding machineEngineering

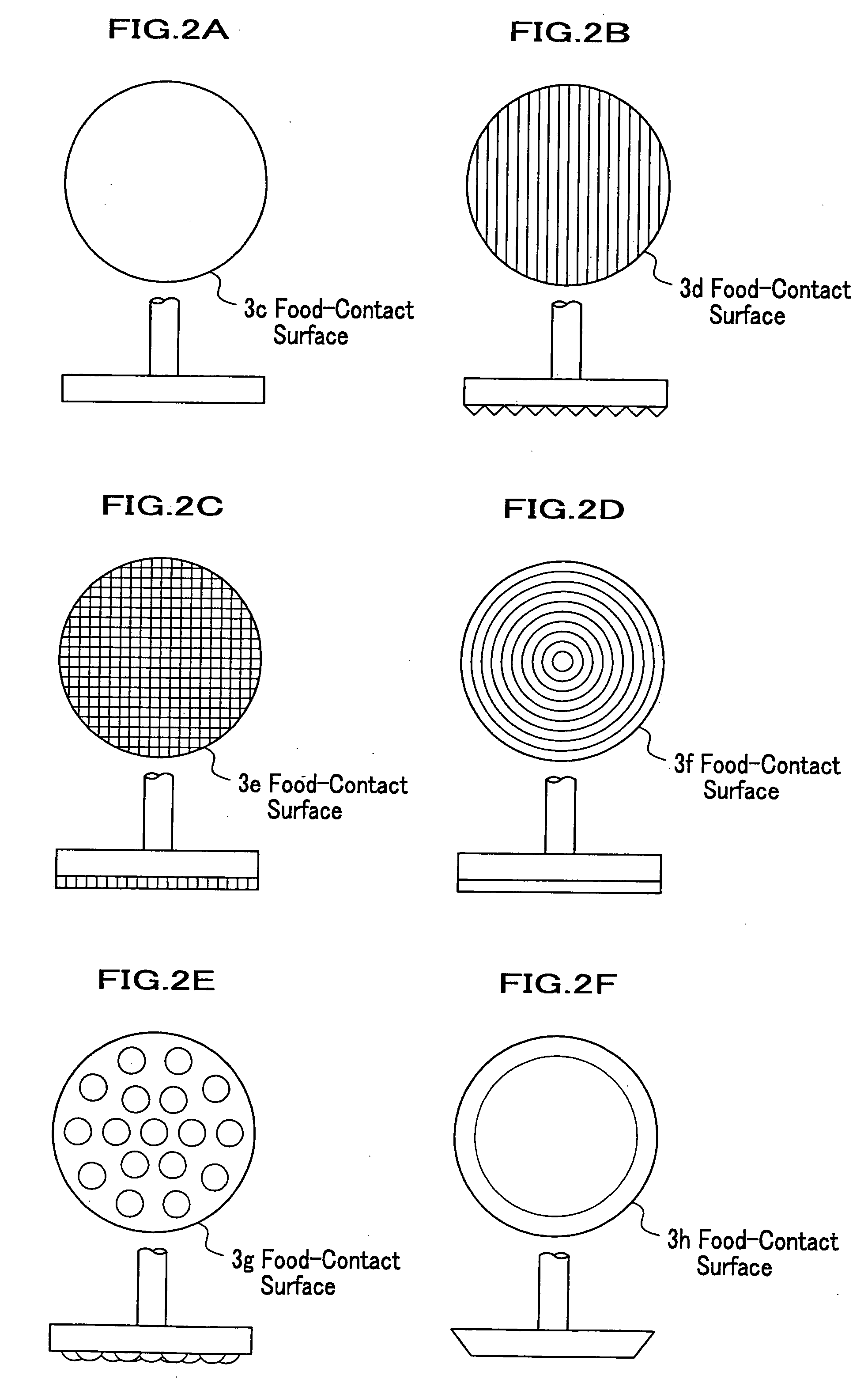

A tortilla-forming machine for molding dough into a tortilla shell. The forming machine having a base with an upwardly facing forming surface and a push plate with a downwardly facing forming surface. The forming machine further including an actuating mechanism with a first member joined to the base and a second member joined to the push plate which moves relative to the base for molding the dough into the tortilla shell. The relative movement including the upper push plate moving relative to the base axially along an actuating axis which is perpendicular to the upwardly facing forming surface and rotating about the actuating axis.

Owner:POQUITO MAS

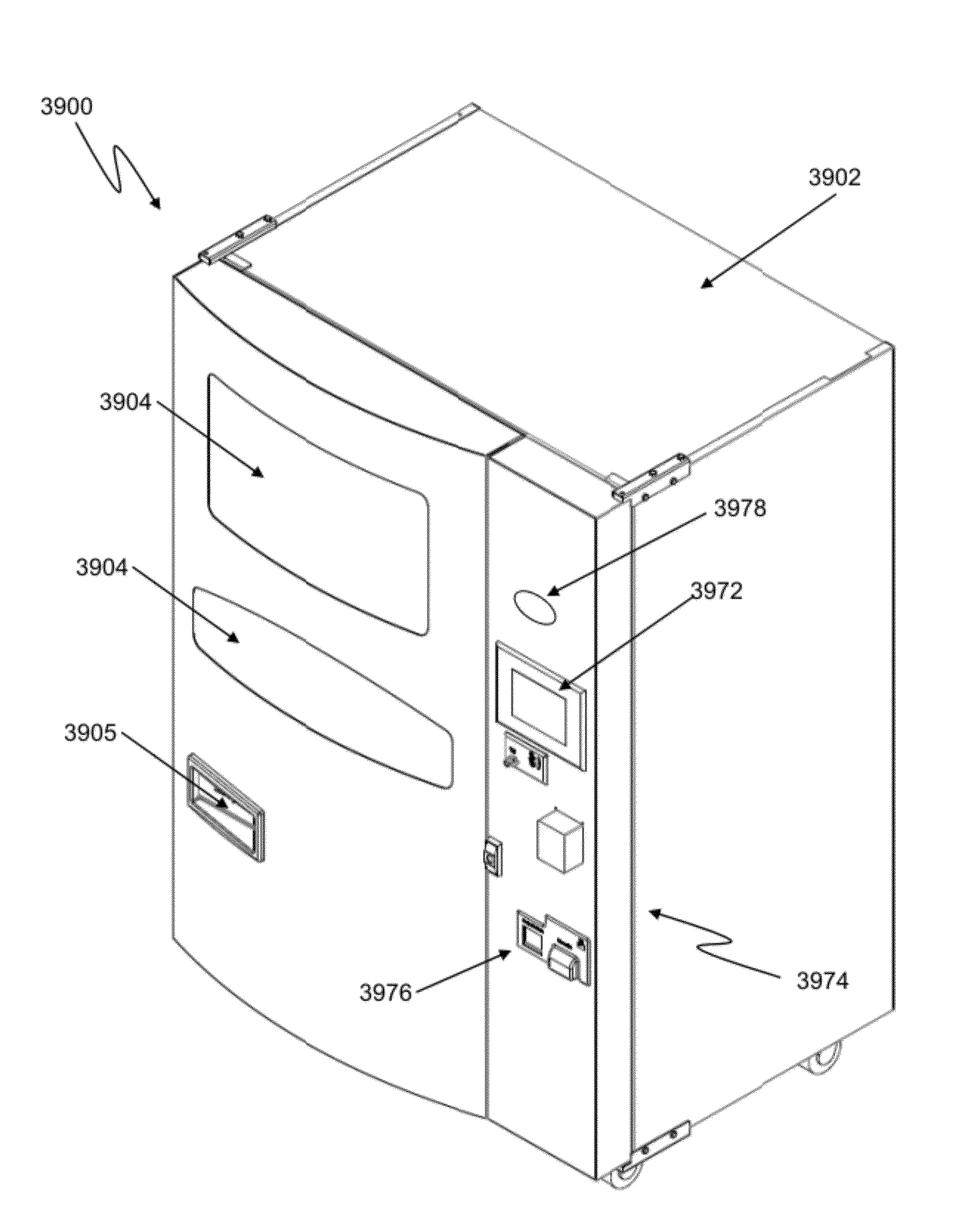

Automated pizza preparation and vending system

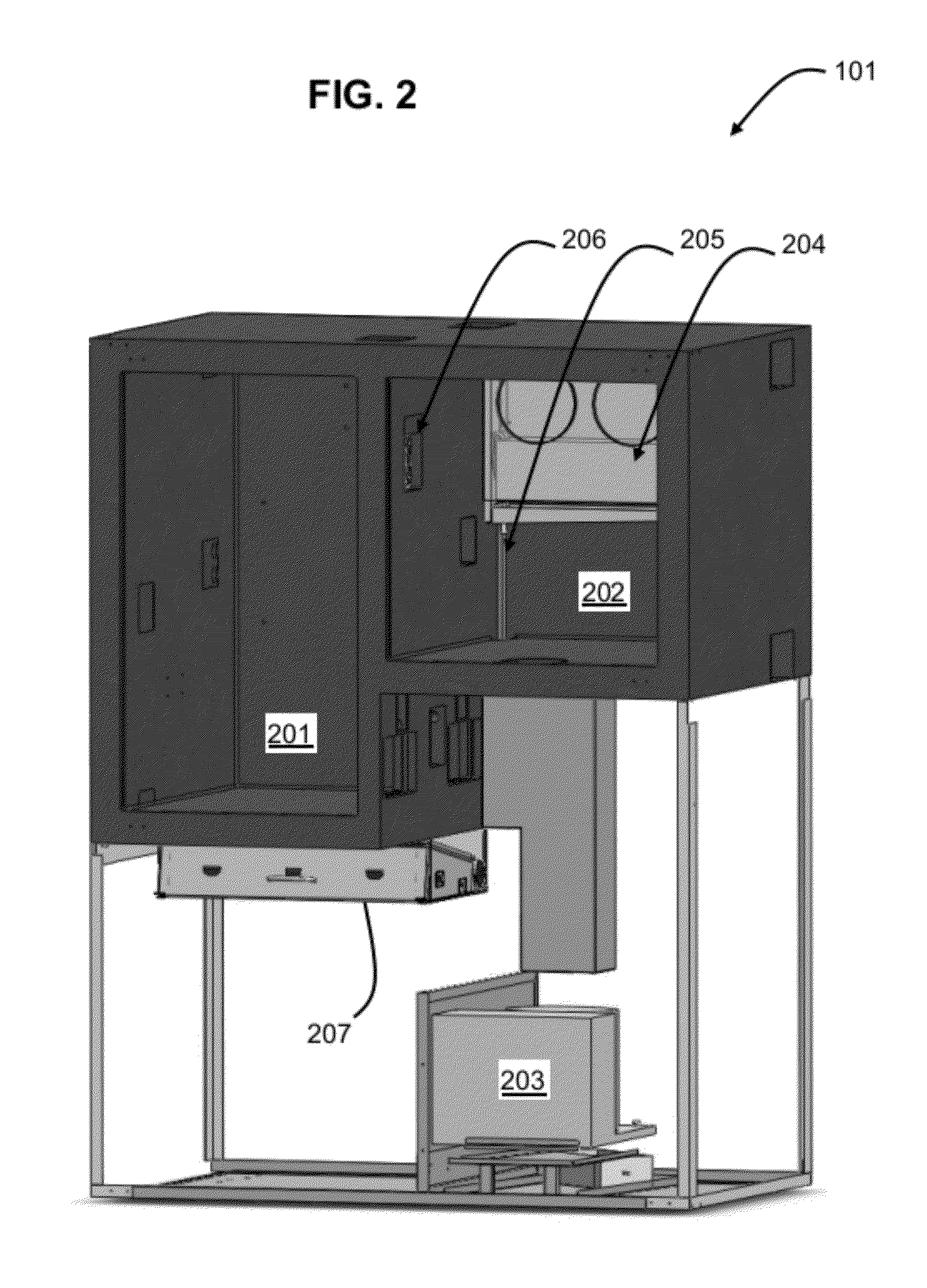

ActiveUS20120308702A1Milk preservationCoin-freed apparatus detailsAdditive ingredientBiomedical engineering

Automated apparatus for preparing pizza, and method of operating same. A customer selects a type of pizza, such as toppings or crust style. The apparatus slices and defrosts dough, applies cheese, slices and applies toppings, and cooks the pizza to order. The cooked pizza is packaged for delivery to the customer and may include a separate cutting apparatus. Proper temperature of hot and cold sections is maintained while ingredients are stored and as the pizza is cooked. The process is monitored and controlled by one or more processors.

Owner:K & G ENTERPRISES

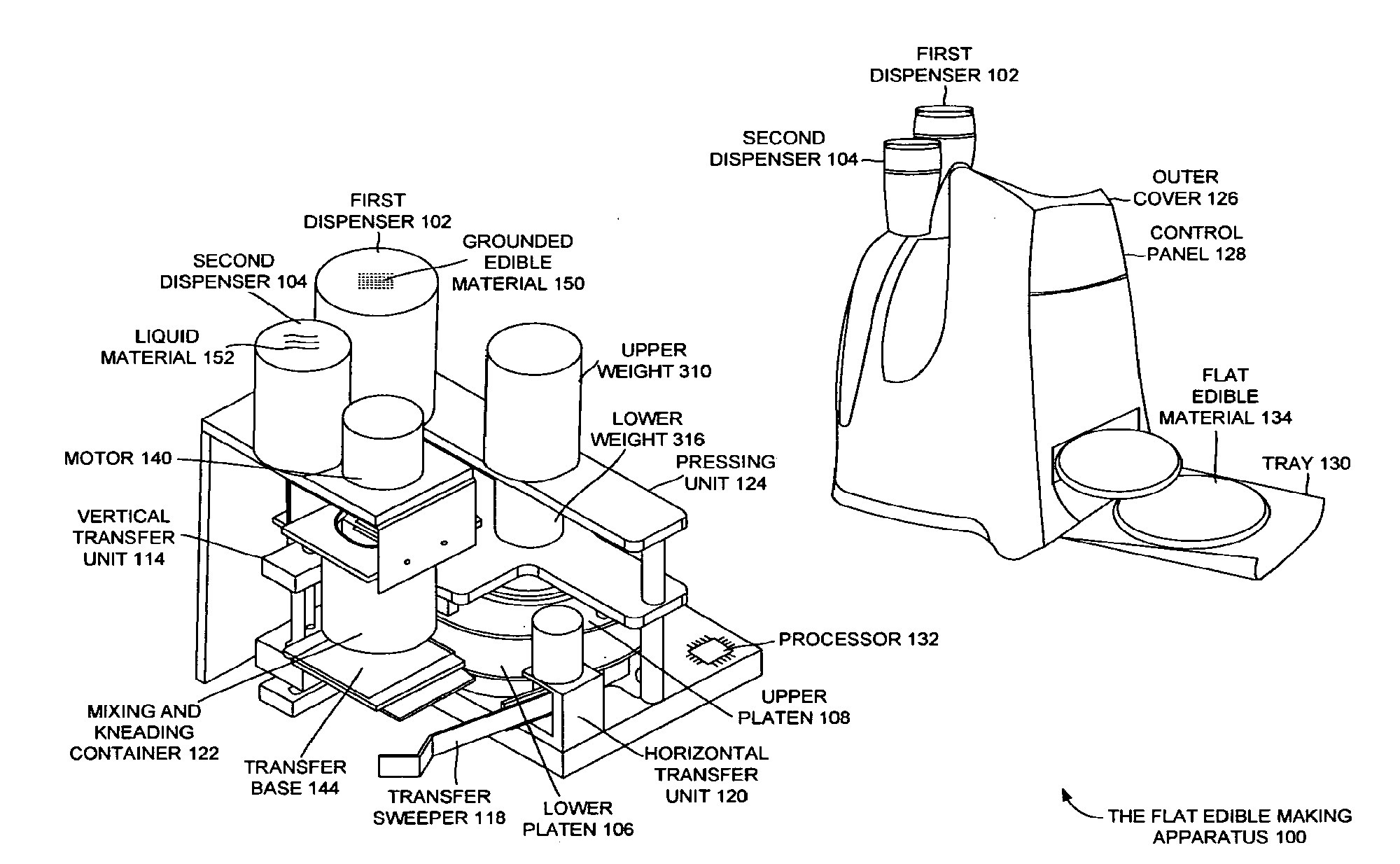

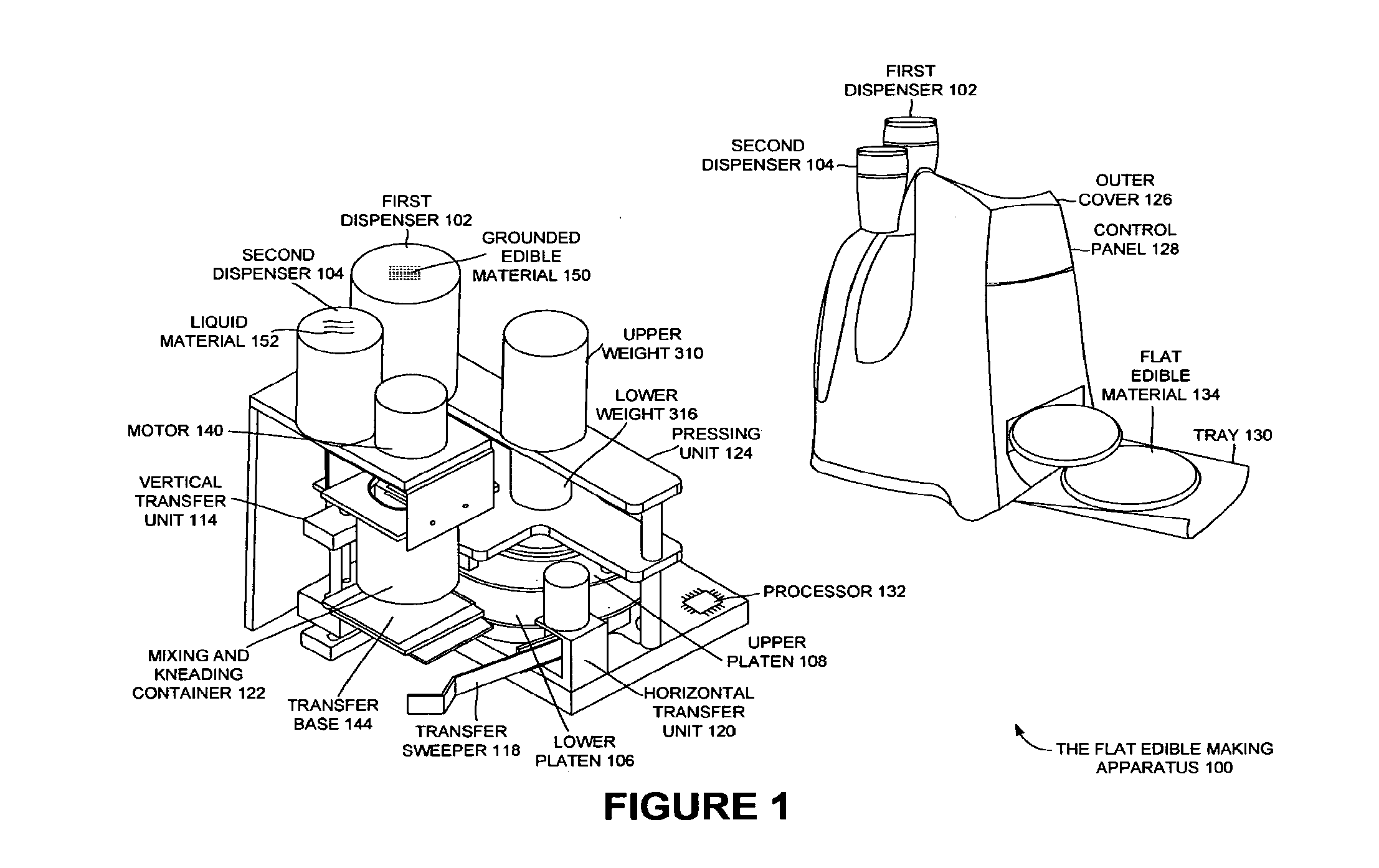

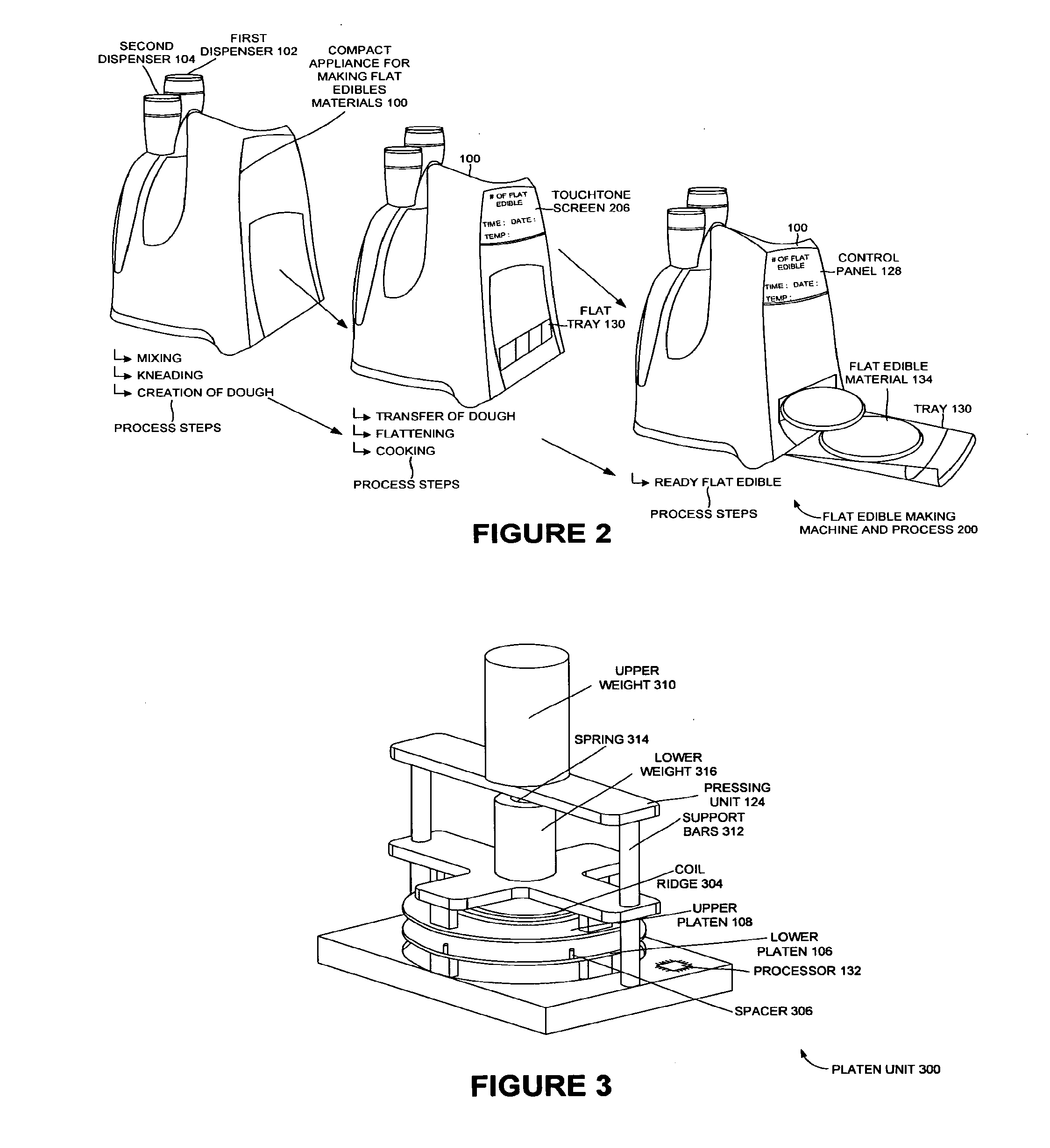

Method of making flat edible using a compact apparatus

ActiveUS20140335243A1Minimize user interventionEliminate needMixing/kneading structural elementsBakery productsAdditive ingredientMechanical engineering

Owner:ZIMPLISTIC

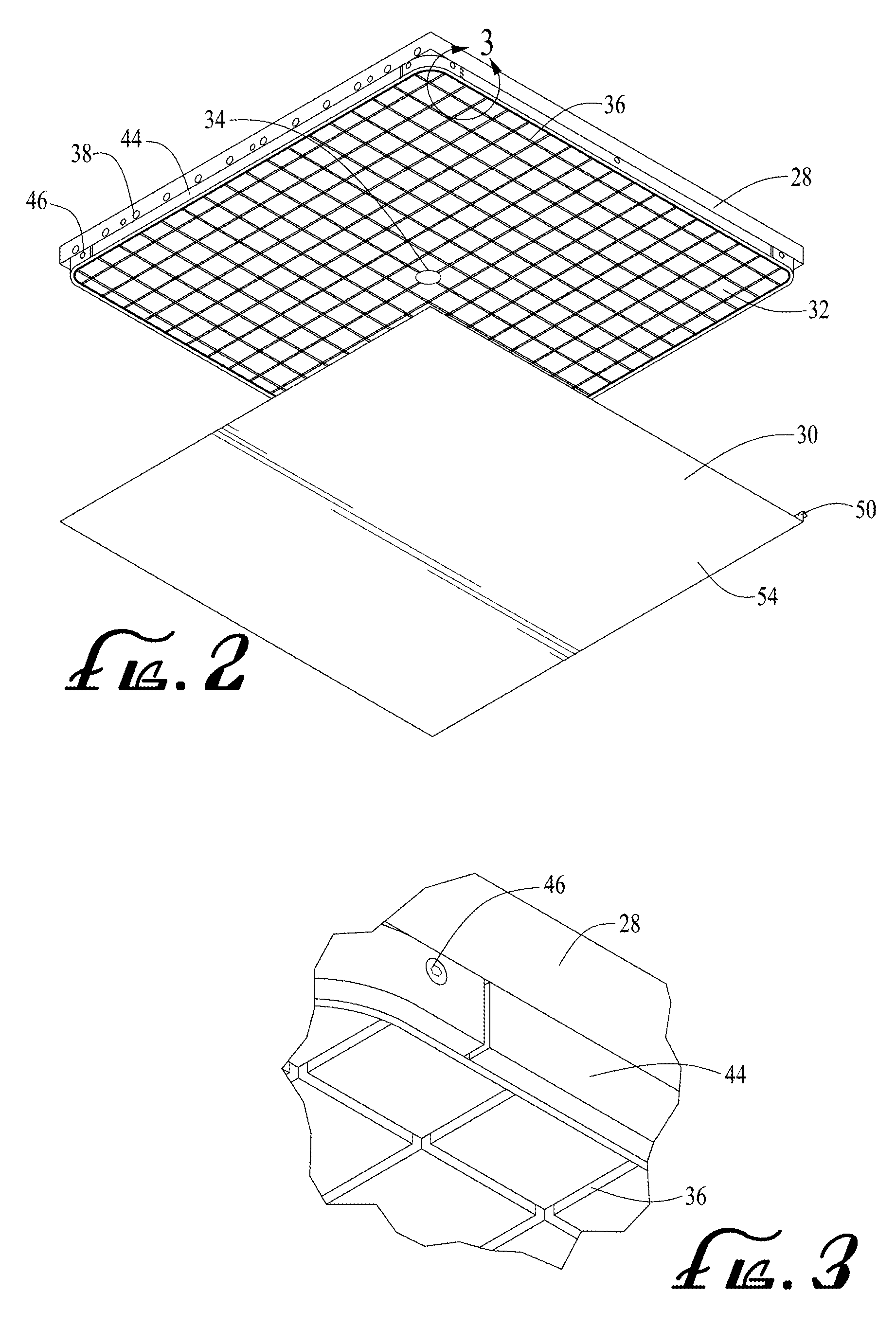

Vacuum Pressing Platen Assembly and Method for Adjustment

A dough forming apparatus comprising a lower support frame, a lower pressing platen coupled to the lower support frame, and an upper pressing platen assembly positioned above the lower pressing platen. The upper pressing platen assembly further comprises a backing structure, an upper backing platen coupled to the backing structure, and a pressing plate removably coupled to the upper backing platen by vacuum or electromagnetic means. Means for heating the pressing plate, and shims for adjusting the flatness of the pressing surface are provided. A conveyor supported by the lower support frame is positioned to pass between the lower pressing platen and the upper pressing platen assembly. A method of adjusting the apparatus is also disclosed.

Owner:LAWRENCE EQUIP INC

Encased Snack

InactiveUS20080166456A1Extended shelf lifeAppealing appearanceBakery product recyclingDough treatmentMaterials sciencePolymer science

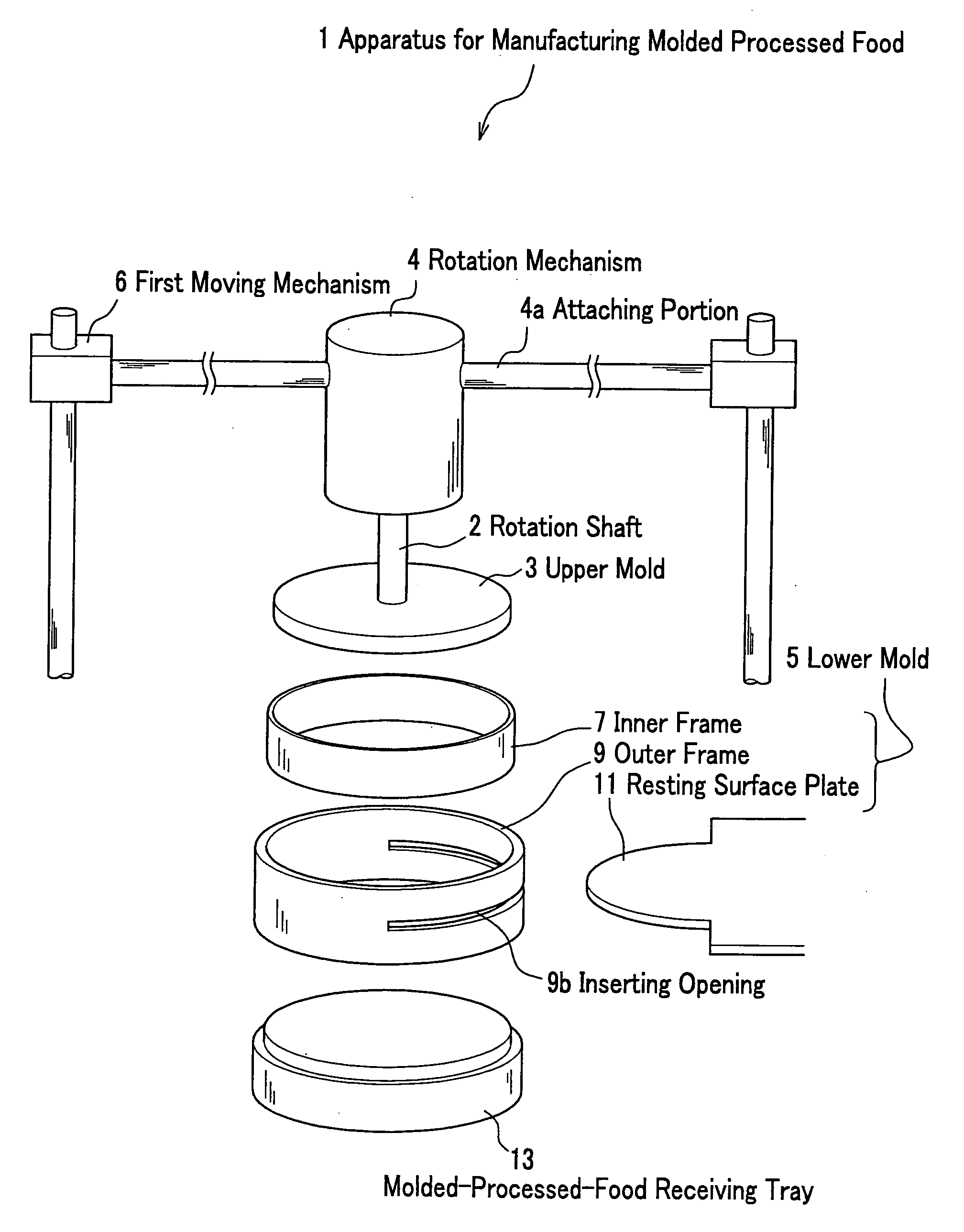

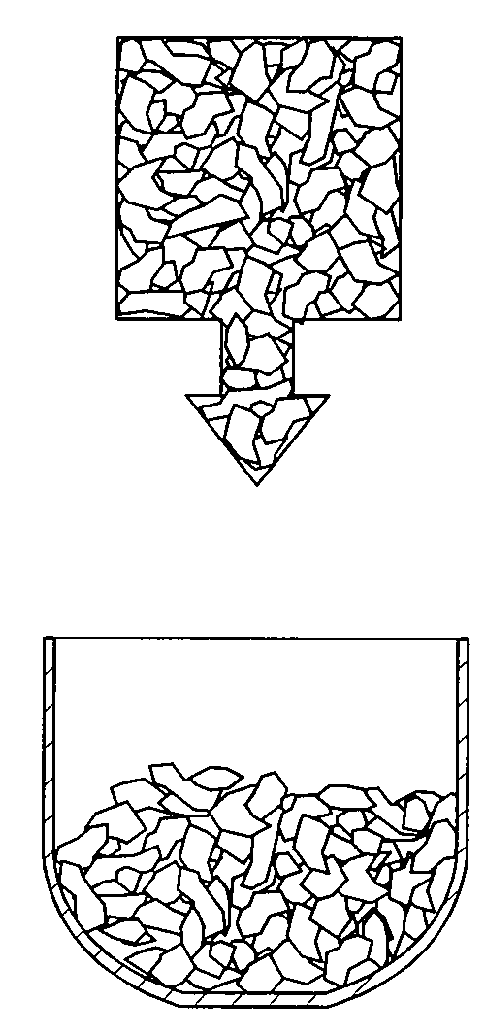

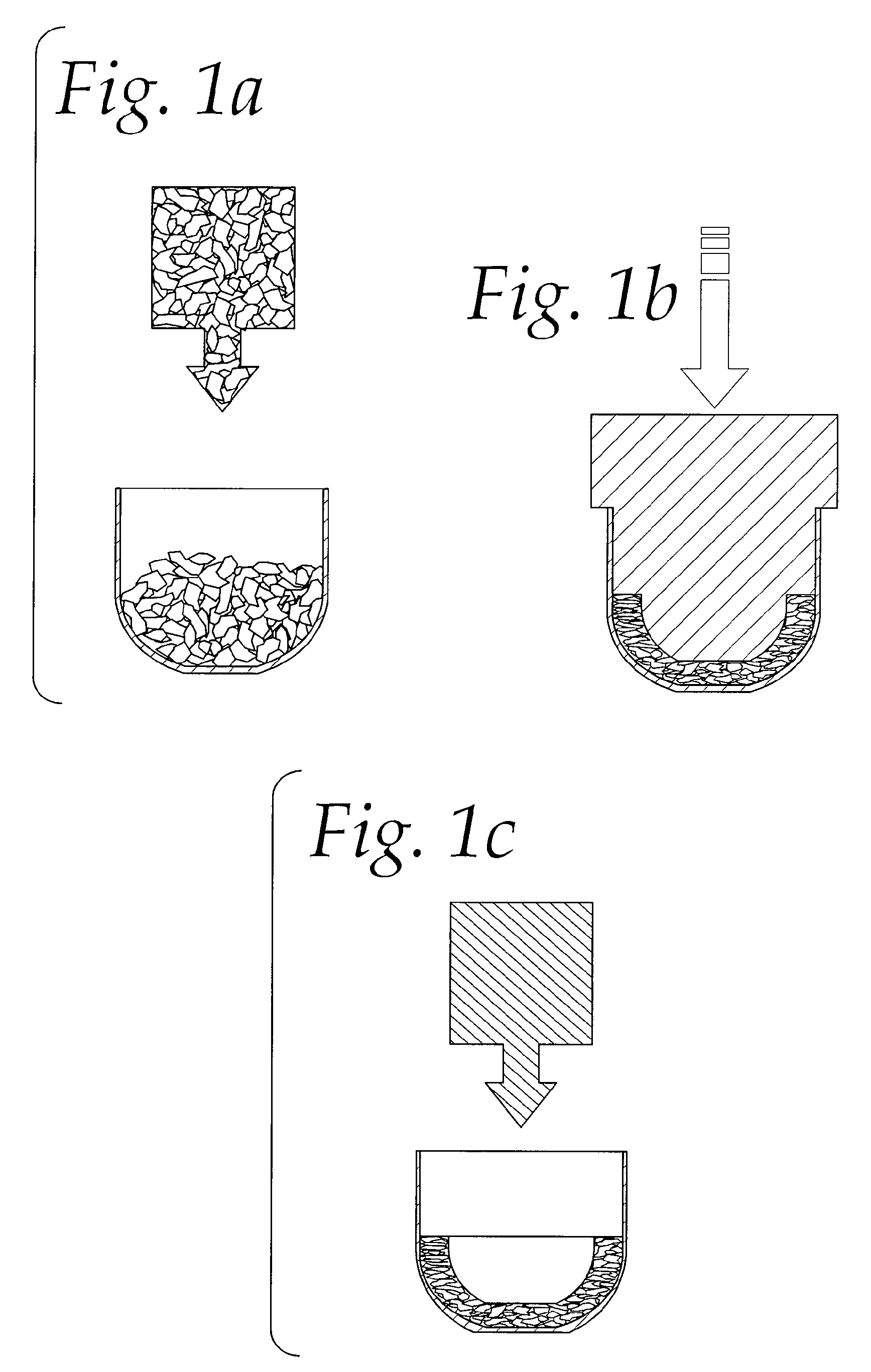

The invention is directed to a process for the preparation of an encased snack comprising in this order the steps of (1) providing crumb material, (2) forming the crumb material under pressure to produce a shell, (3) introducing a filling into the shell, (4) forming a cover of crumb material on the filling in the shell under pressure, and (5) optionally baking the thus formed assembly. The invention is also directed to the encased snack obtainable by the process and to a mould comprising a lower die and first and second upper dies for use in the process.

Owner:KRAFT FOODS R & D INC

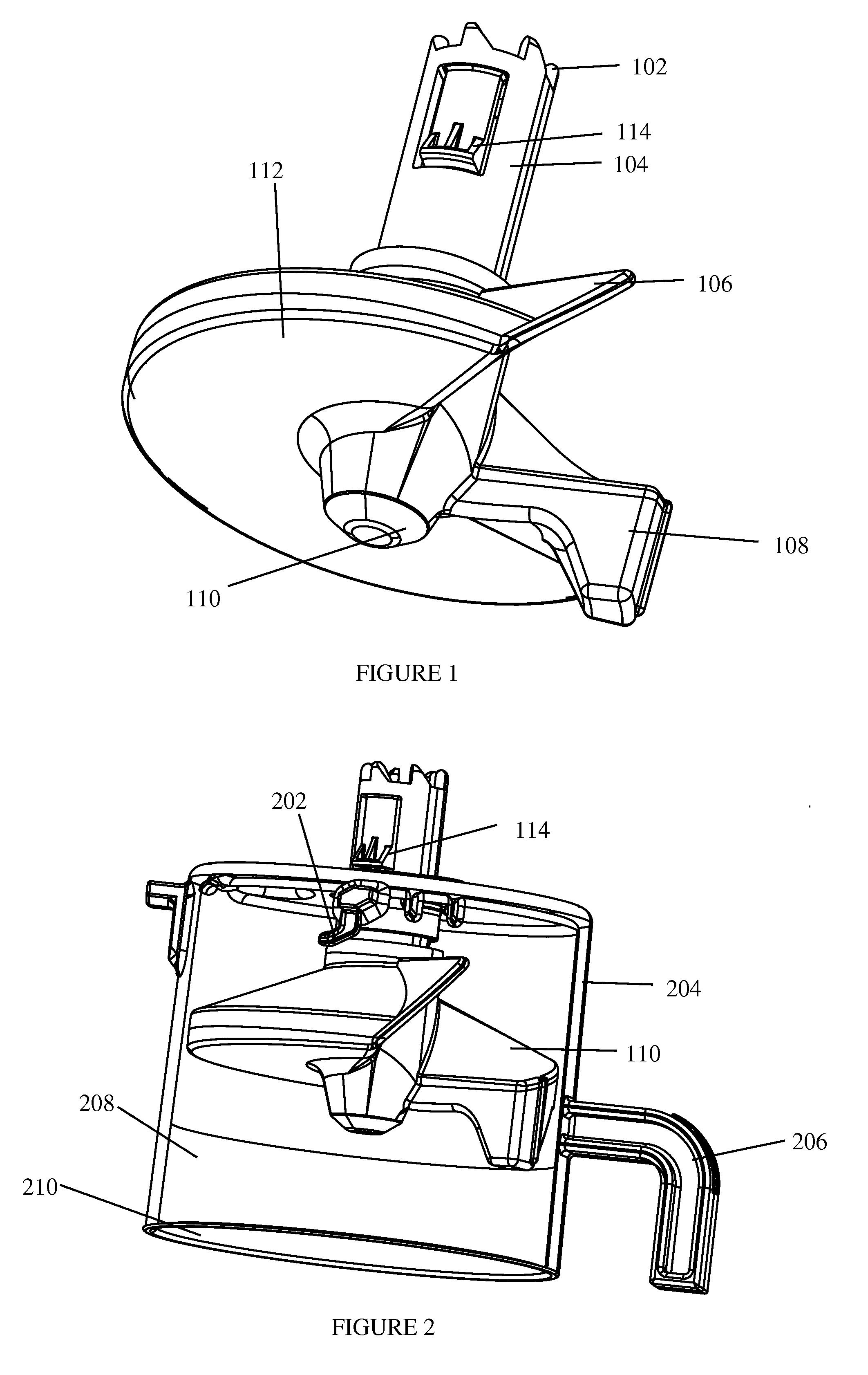

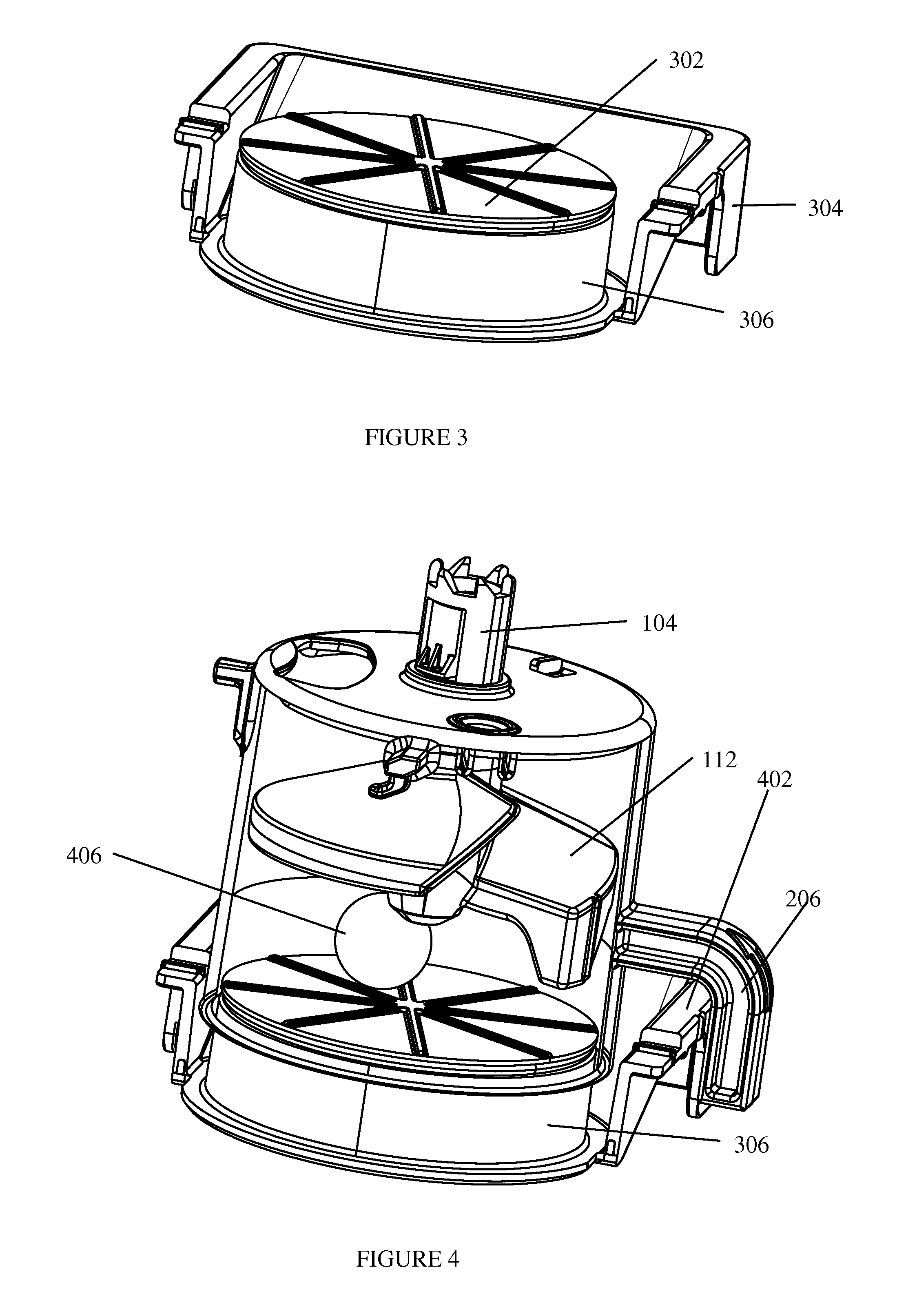

Tortilla press assembly

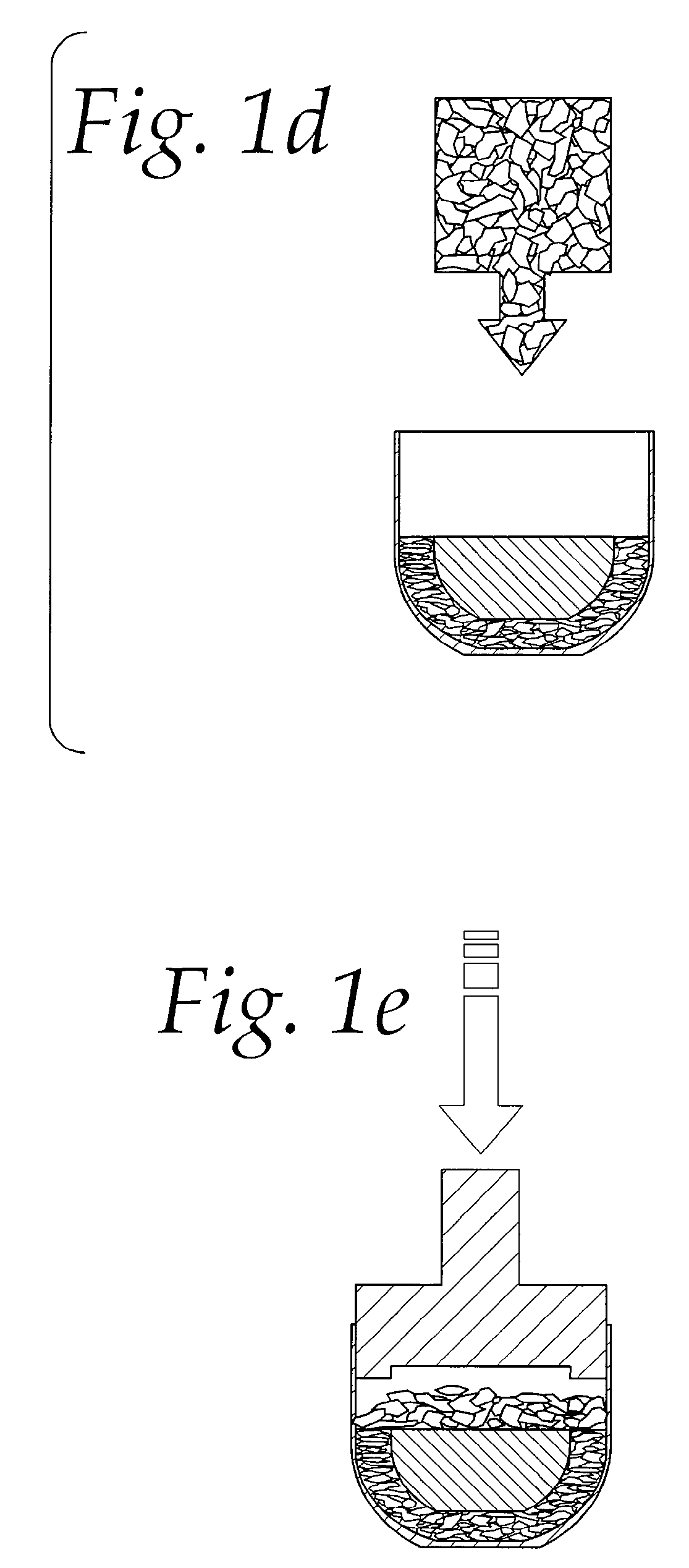

InactiveUS9149046B2Fast formingDough embossing machinesDisc dough shapingEngineeringMechanical engineering

A tortilla press assembly is provided having an actuating mechanism for actuating the push plate along an actuating axis between a loading position and a forming position. The actuating mechanism includes arm having a vertical portion and a horizontal portion that extends over the base plate. A crank extends between the crank shaft and the vertical portion of the arm to enable the push plate to engage and disengage from dough in a smooth manner to ensure proper formation of a tortilla shell, which can include an embossed pattern.

Owner:MCCARNEY KEVIN

Apparatus, system and method for an adaptive kneading technology for a food preparation appliance

The present invention presents a kneading mechanism for a food preparation appliance. The kneading mechanism has a kneading container, a blade assembly and a kneading base. The kneading container has an open bottom face and the kneading base has a textured surface. An adaptive kneading technology which resides in a processor is used to form an optimal viscoelastic dough ball. Since there is variation in the gluten content and the amount of water used makes the dough ball have a viscoelastic nature this technology due to its self-learning mechanism optimizes the kneading of single dough balls using adaptive kneading technology.

Owner:ZIMPLISTIC

Heated discharge platen for dough processing system

A dough forming apparatus for flatbread products, the apparatus having: a loading station; a pressing station; a discharge station; and a conveyor belt passing through the loading station, the pressing station and the discharge station; wherein the discharge station further comprises a heated discharge platen.

Owner:LAWRENCE EQUIP INC

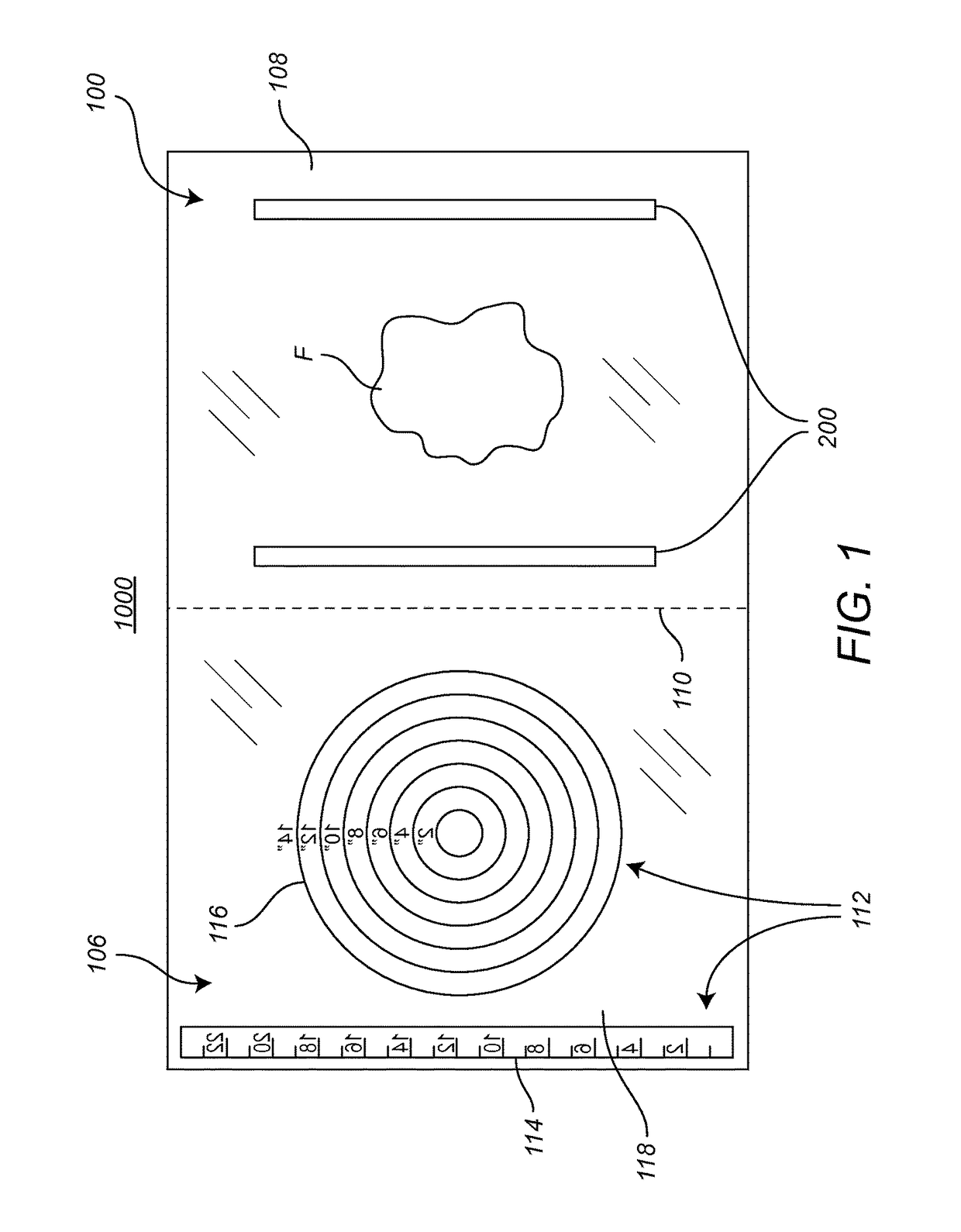

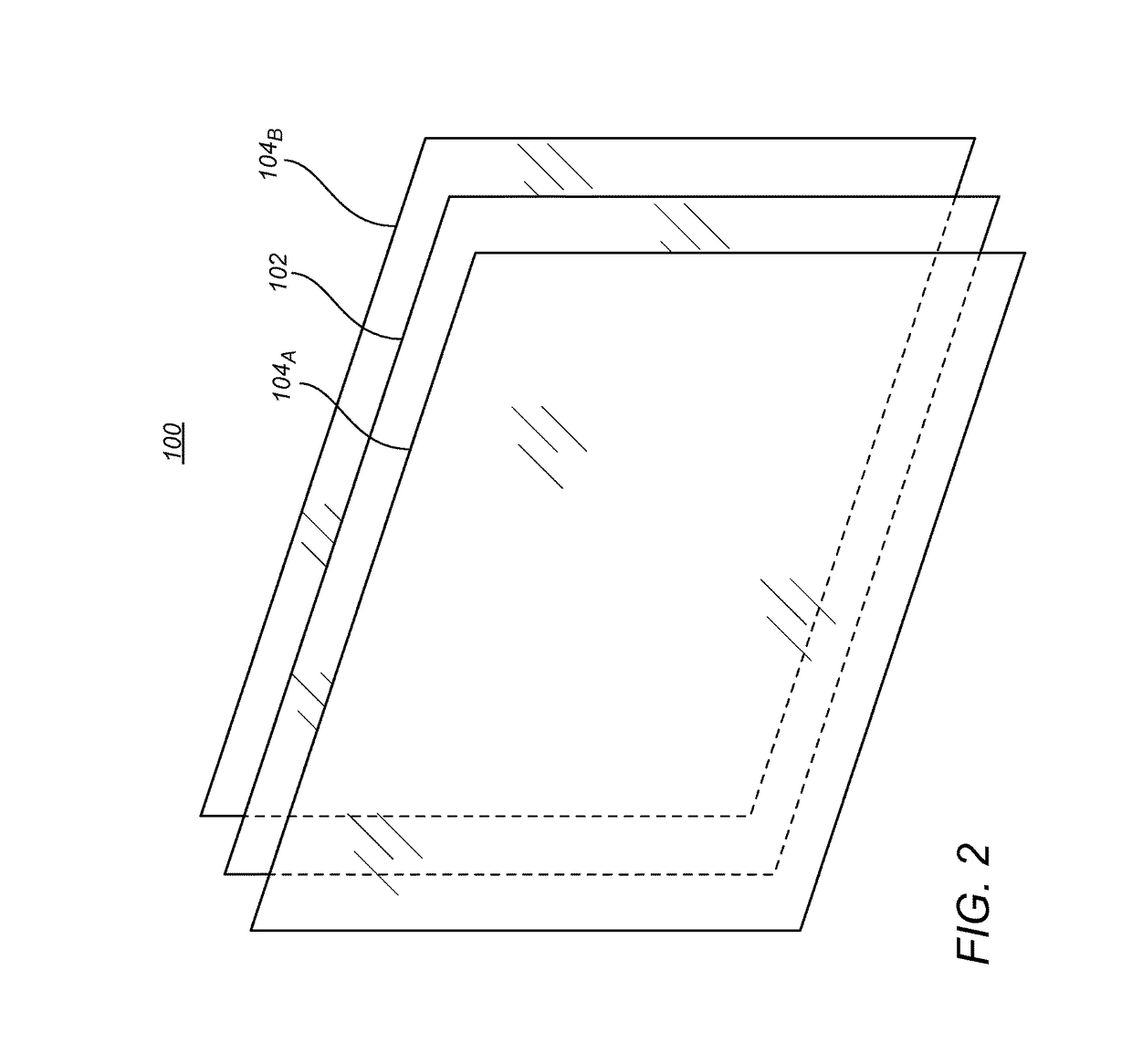

Food preparation system and associated methods

InactiveUS9648986B1Increasing the thicknessAvoid stickingDough-sheeters/rolling-machines/rolling-pinsKitchen equipmentEngineeringMechanical engineering

In accordance with one aspect of the present disclosure, a food preparation system is disclosed comprising a mat including a deformable material permitting a first portion of the mat to be folded onto a second portion of the mat, and at least one utensil defining a height. The at least one utensil is positionable between the first and second portions of the mat such that a food product positioned between the first and second portions of the mat can be flattened to a thickness approximately equivalent to the height of the at least one utensil by applying a force to the mat.

Owner:BYRNE BRENDA

Moving belt dough press with heated platen

ActiveUS20080141874A1Improve reliabilityReduce replacementPlywood pressesVeneer pressesElectrical resistance and conductanceEngineering

A moving belt conveyor dough press is provided with a pair of vertically opposing platens, at least one of which is movable toward and away from the other. A continuous belt is arranged to pass between the pair of platens, and to carry on an upper surface thereof, a supply of dough masses to be pressed by the platens. At least one of the platens is formed of a cast metal material, and an electrical resistance heating element is cast in place within the at least one platen.

Owner:AM MFG

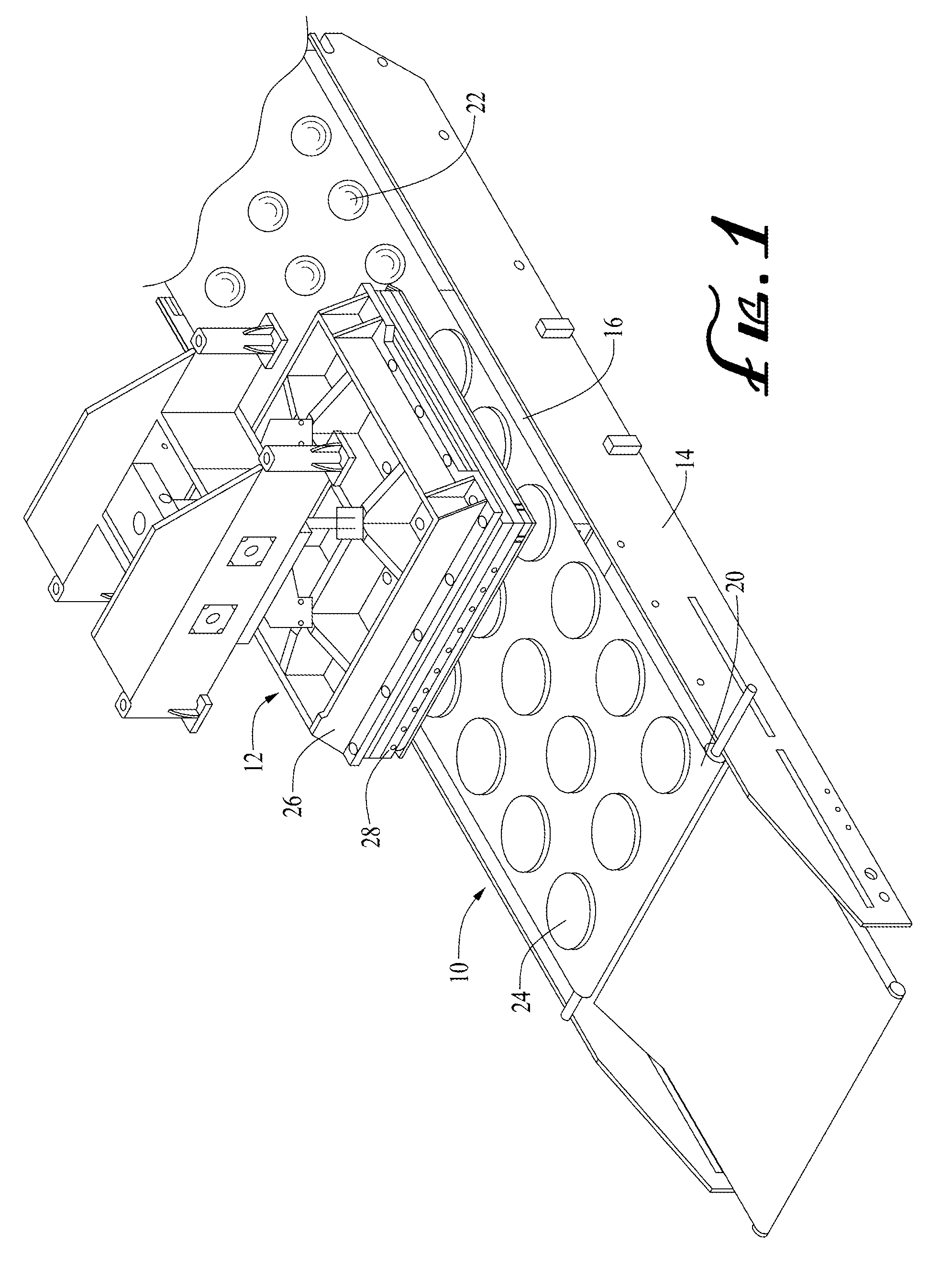

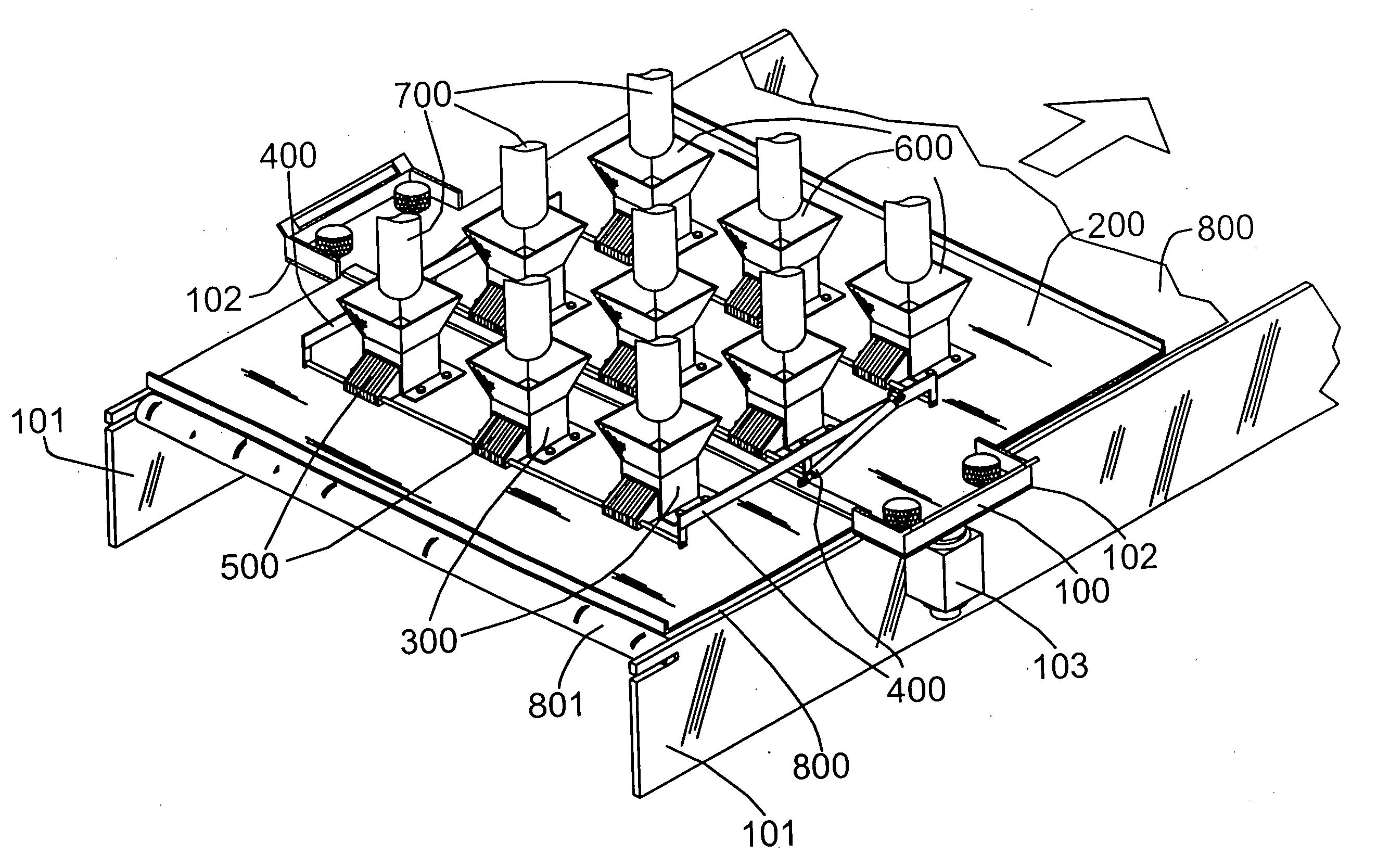

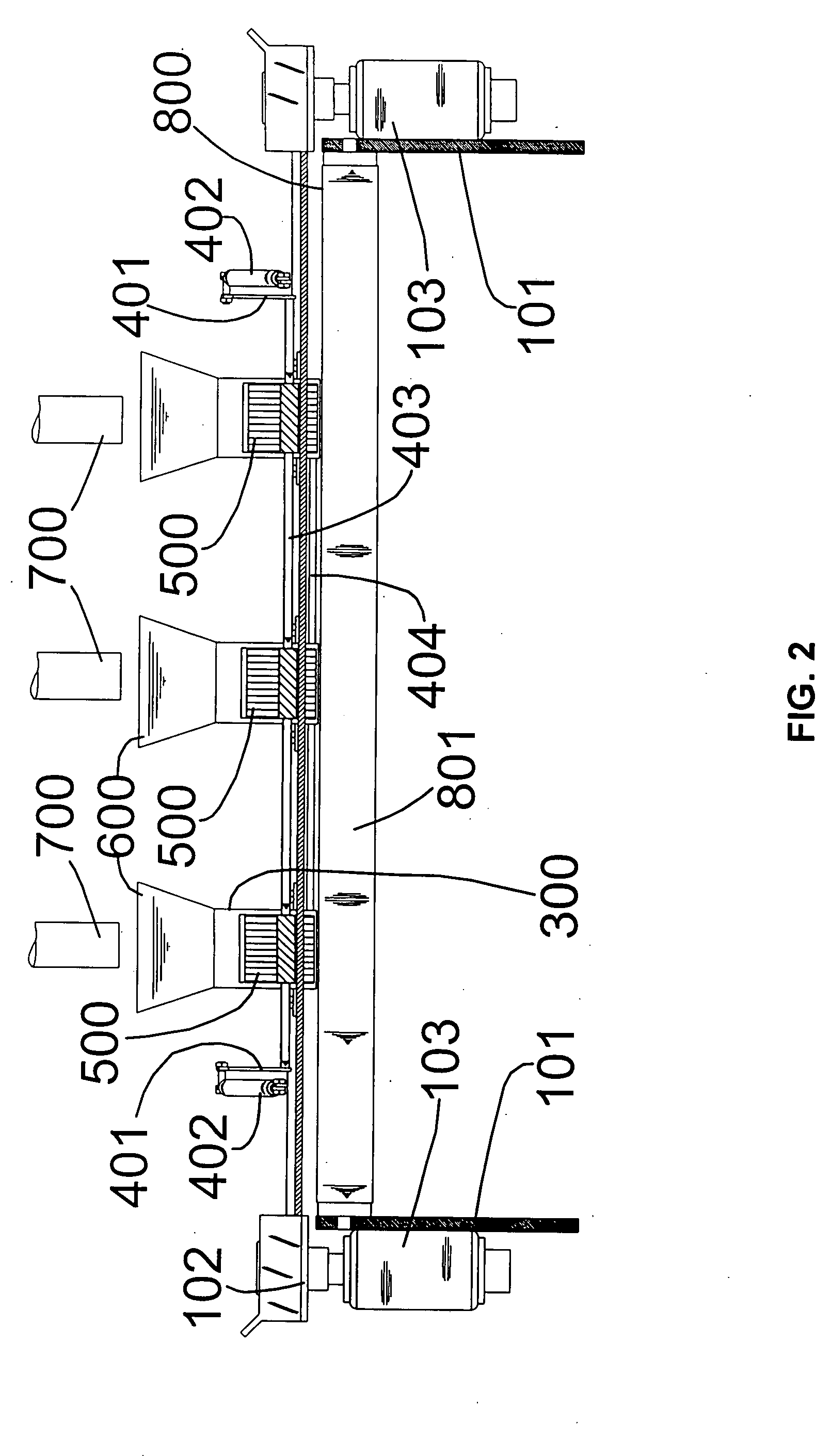

Apparatus for pre-shaping dough balls

InactiveUS20080276810A1Speeding up tortilla productionWiden meansCocoaDisc dough shapingEngineeringMechanical engineering

An automated machine for pre-shaping dough balls in a high speed tortilla machine. A main frame contains a holding press plate with a set of regularly distributed openings, and where a press box is located over the regular openings. Each press box contains a catching ball tube, and a press gate. Each dough ball is sequentially deposited onto a pre-shaper catching ball tube to permit balls to pass through open press gates and onto the surface of a transport band, where they are kept in a predetermined position. Once all of the dough balls reach a predetermined location, they are pre-pressed in place by means of a set of press gates. The flattener press gates close the ball entrance in the catching ball tubes to prevent dough balls entering any further into the press boxes. The press gate devices are actuated to open the catching ball tube and separate the pressing gate device from the pre-pressed balls. The transport band advances the pre-pressed balls towards the main press area. The main frame lowers its position towards the transport band.

Owner:CEJA ALBERT M +1

Dough ball loading system

InactiveUS20070039480A1Quickly and precisely alignedDough treatmentMeat/fish preservationEngineeringConveyor belt

A loading system for loading dough balls onto a moving upper surface of a conveyor belt includes a transport mechanism arranged to receive dough balls in a sequential stream and to deliver the dough balls to the moving conveyor belt at a speed equal to a speed of the upper surface of the conveyor belt.

Owner:AM MFG

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com