Kneading machine with dosing device

A technology of metering equipment and mixers, which is applied to dough mixers, mixers, dough processing, etc., and can solve problems such as difficulty in filling the metering cavity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

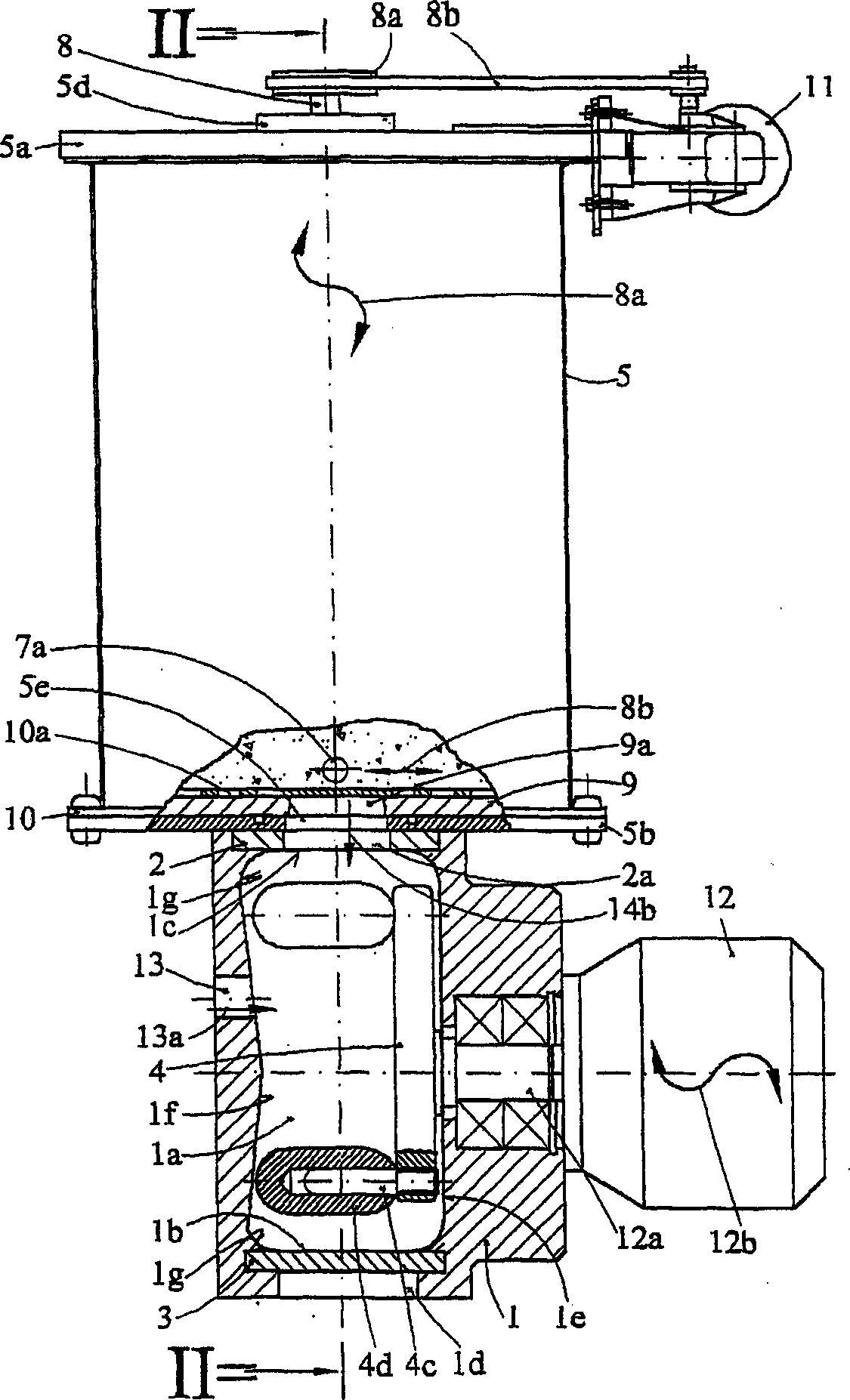

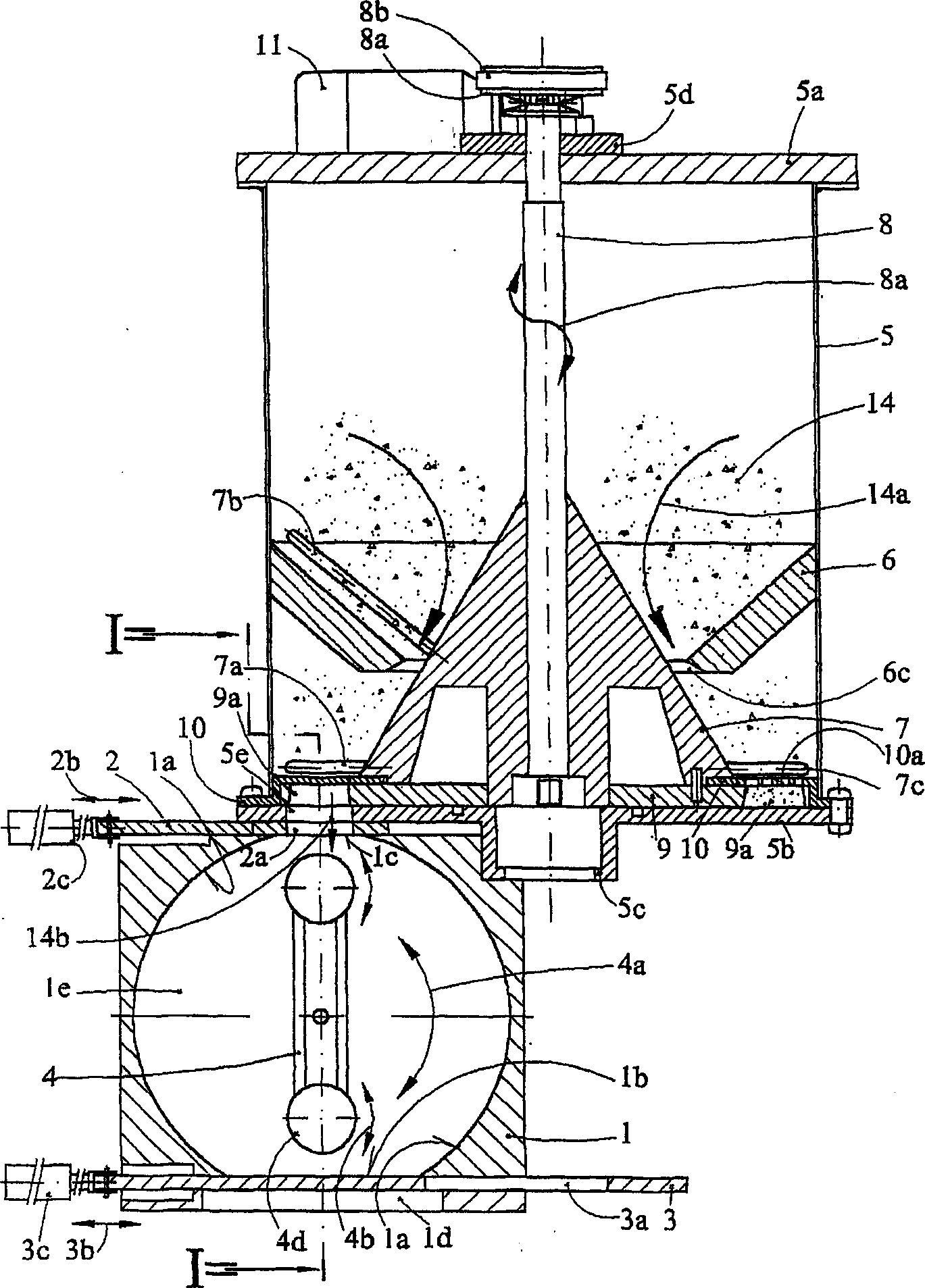

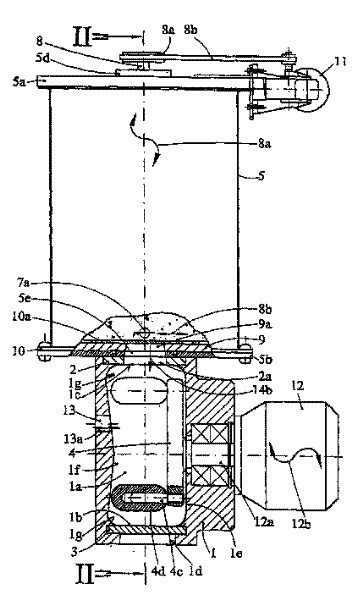

[0021] According to the invention, the dough mixer for preparing a batch of separately separated spherical doughs contains a housing 1 with an inner chamber and stirring elements 4, 4c, 4d, which housing includes a feed opening 2a and a row Discharge openings 3a, 1d, which are provided with corresponding vanes 2 and 3, respectively. A substantially cylindrical chamber with a horizontal axis consisting of: a flat circular surface 1e from which the axis 12a protrudes and is coaxial; The surface corresponds to the circular surface 1f, but the circular surface is conical and slightly convex into the chamber; two curved surfaces 1a, which have the contour of the wall equidistant from the chamber axis; An upper planar portion 1c corresponding to the area of the opening 2a; and a lower planar portion 1b which is larger than the upper planar portion and corresponds to the area of the discharge openings 1d, 3a.

[0022] Stirring element comprises an arm 4, and its front side is fi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com