Dry paint mist filter

A technology of filter and paint mist, which is applied in the direction of dispersed particle filtration, chemical instruments and methods, and separation of dispersed particles, which can solve the problems of water resources and environmental pollution, large water consumption, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

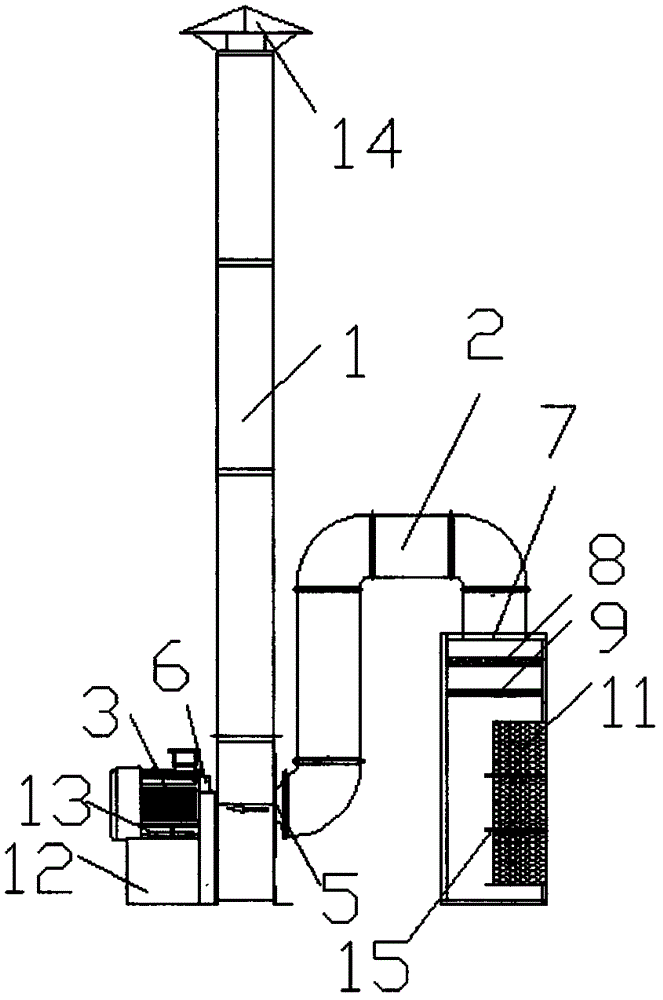

[0018] refer to figure 1 and figure 2 A dry paint mist filter shown includes an exhaust cylinder 1, a suction duct 2, a centrifugal fan 3 and a filter device 4, and the two sides of the bottom of the exhaust cylinder 1 are provided with a round hole 5 and a small hole 6 , the suction duct 2 is connected to the exhaust tube 1 with an angle steel flange through a round hole 1, the centrifugal fan 3 is softly connected to the exhaust tube 1 through a small hole 6, and the top of the filter device 4 is provided with a round hole 2 7. The air suction pipe 2 is connected to the filter device 4 with an angle steel flange through the round hole 2 7, the top of the filter device 4 is provided with an activated carbon adsorption layer 8, and the bottom of the activated carbon adsorption layer 8 is provided with a turbulent ball filter layer 9, One side of the filtering device 4 is provided with a square hole 10, the square hole 10 is inlaid with a multi-layer pleated filter 11, and a ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com