Optical experiment platform based on spray combustion visualization of rapid compressor

A technology of spray combustion and experimental platform, which is applied in the direction of engine testing, machine/structural component testing, internal combustion engine testing, etc., and can solve problems such as complex engine structure, poor effect, and great difficulty

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0022] The present invention will be further described below in conjunction with the accompanying drawings.

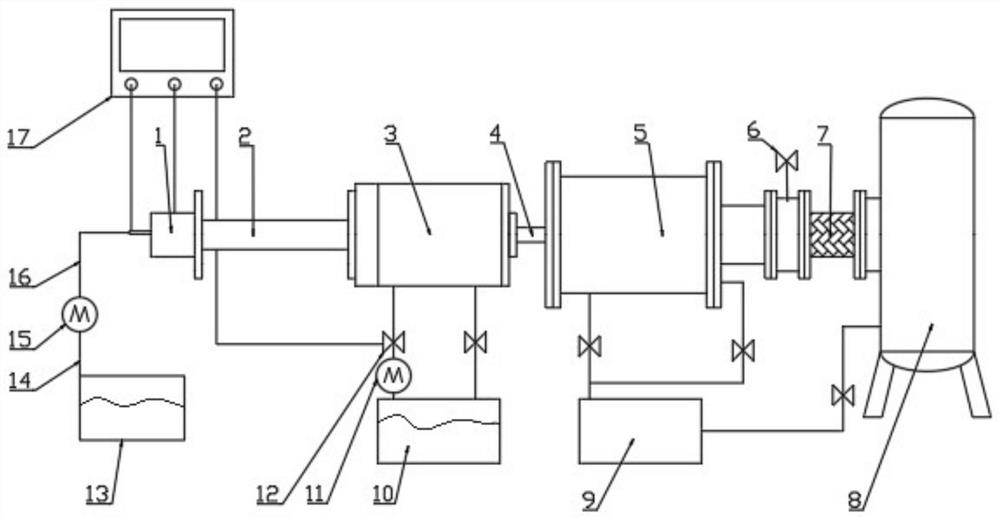

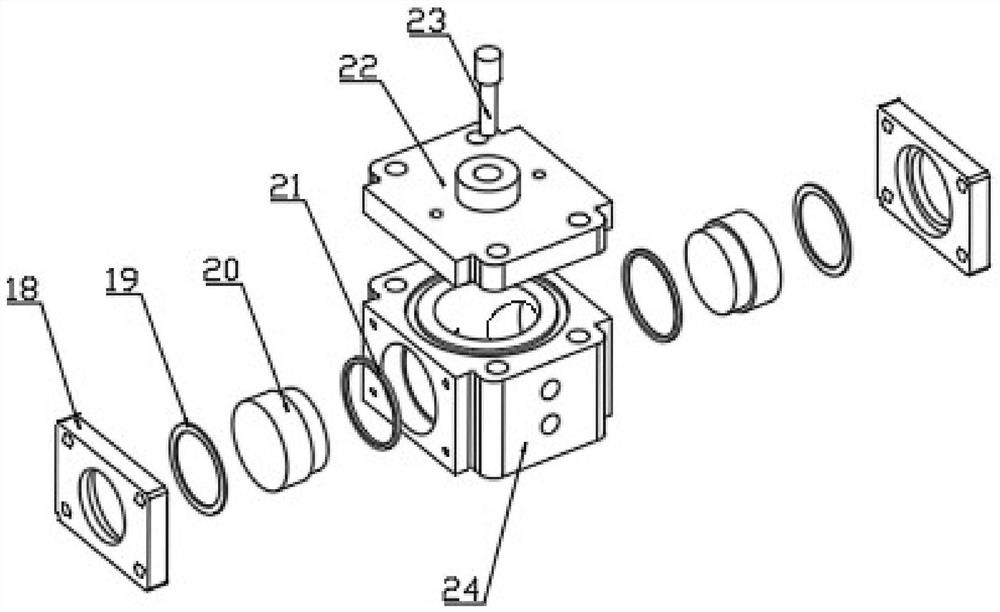

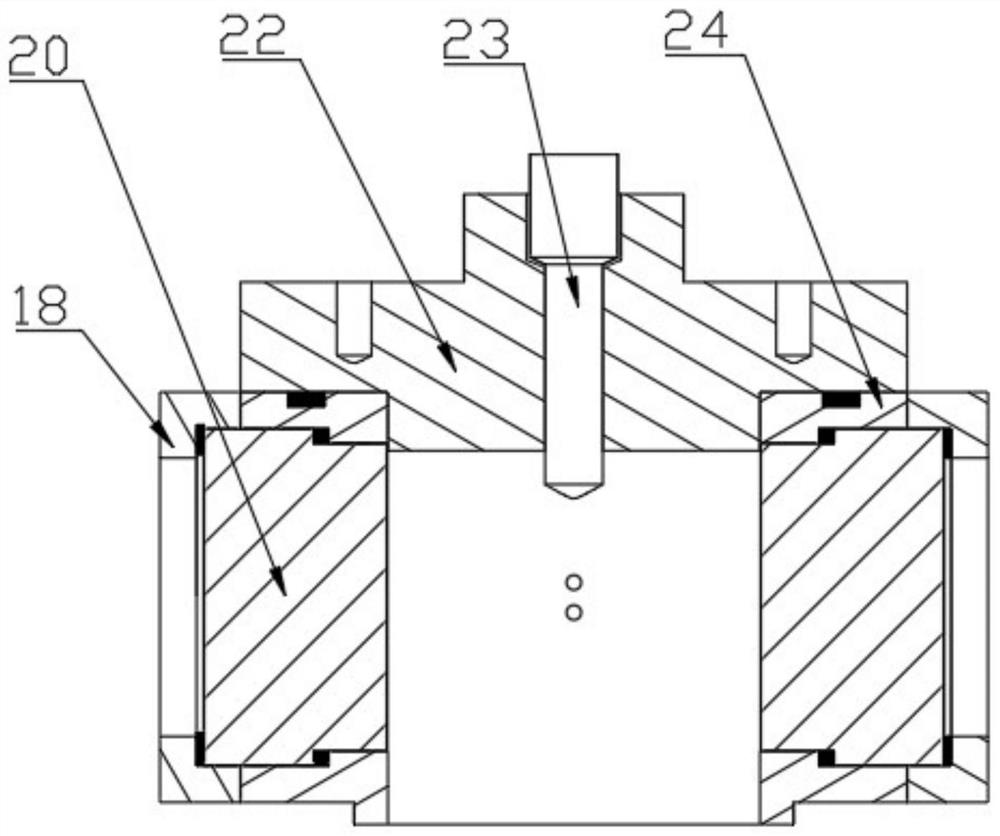

[0023] see Figure 1 to Figure 5 , an optical experiment platform based on the visualization of rapid compressor spray combustion provided by the present invention, including a visual combustion chamber 1, a compression cylinder 2, a hydraulic section 3, a connecting rod 4, a driving section 5, an electric butterfly valve 6, a metal hose 7, The high-pressure air storage tank 8, the air compressor 9, the hydraulic oil tank 10 with the hydraulic oil pump 11 and the piston 28 are composed. The combustion chamber 1 is composed of a window end cover 18 , a rubber gasket 19 , a quartz glass window 20 , a high temperature sealing ring 21 , an injector end cover 22 , and a combustion chamber main body 24 . The Schlieren optical system is composed of LED light source 33 , optical slit 32 , convex lens 31 , knife edge 30 , and high-speed camera 29 . The fuel supply system cons...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com