Engine simulation test device capable of achieving ultrahigh compression temperature and pressure

A technology of compression temperature and simulation test, applied in the direction of engine test, measurement device, internal combustion engine test, etc., can solve the problem that can not meet the requirements of high temperature, temperature, pressure and gas composition can not be flexibly adjusted, temperature and pressure can not meet the test requirements And other issues

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

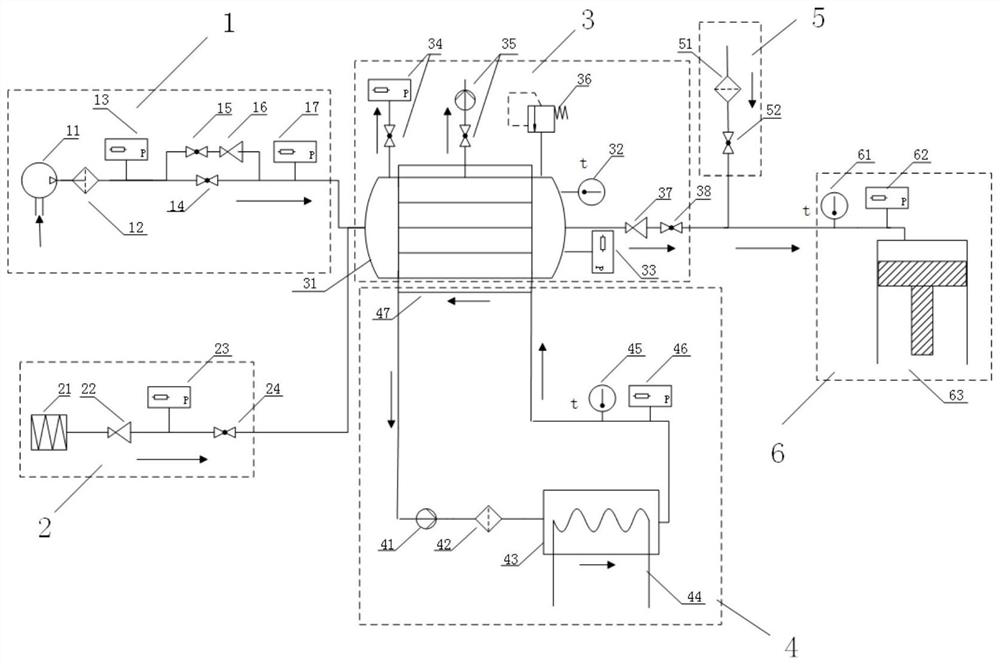

[0018] The technical solutions in the embodiments of the present invention will be clearly and completely described below in conjunction with the drawings in the embodiments of the present invention.

[0019] see figure 1 Describe this embodiment, an engine simulation test device that can realize ultra-high compression temperature and pressure, it includes a compressed air intake mechanism 1, a nitrogen gas intake mechanism 2, a pressure stabilizing mechanism 3, a circulation heating mechanism 4, an air intake mechanism 5 and a fast compressor mechanism 6, the compressed air intake mechanism 1 and the nitrogen gas intake mechanism 2 are all connected to the intake end of the surge tank 31 in the pressure stabilizing mechanism 3, the compressed air intake mechanism 1 and the nitrogen gas intake mechanism The air intake mechanism 2 feeds air and nitrogen into the surge tank 31 respectively, and the surge tank 31 is connected to the circulation heating mechanism 4, and the circul...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com