Rapid compressor test platform for laboratory and adjustment method of compression ratio

A compression ratio adjustment and experimental platform technology, applied in mechanical equipment, machines/engines, liquid variable capacity machinery, etc., can solve problems such as gasoline engine thermal efficiency decline, engine mechanical damage, engine knocking, etc., to avoid physical strength and time consumption Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0020] The technical solution of the present invention will be further described in detail below in conjunction with the accompanying drawings and specific embodiments, and the described specific embodiments are only for explaining the present invention, and are not intended to limit the present invention.

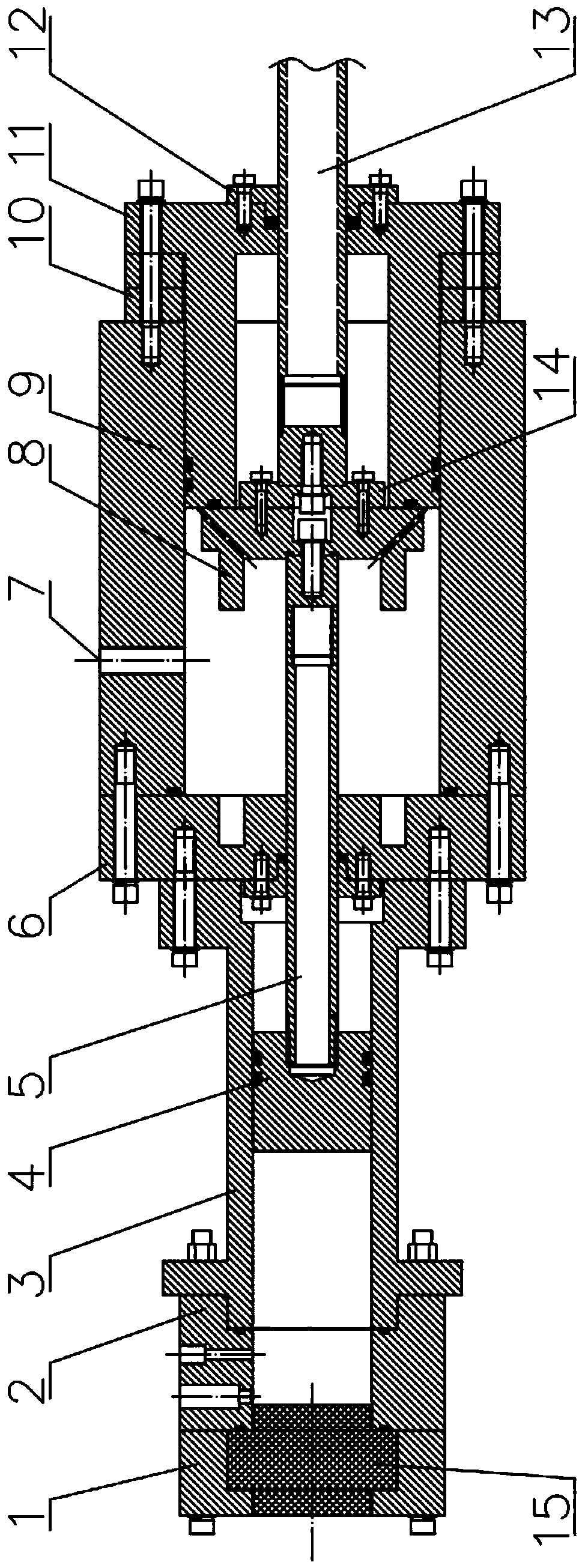

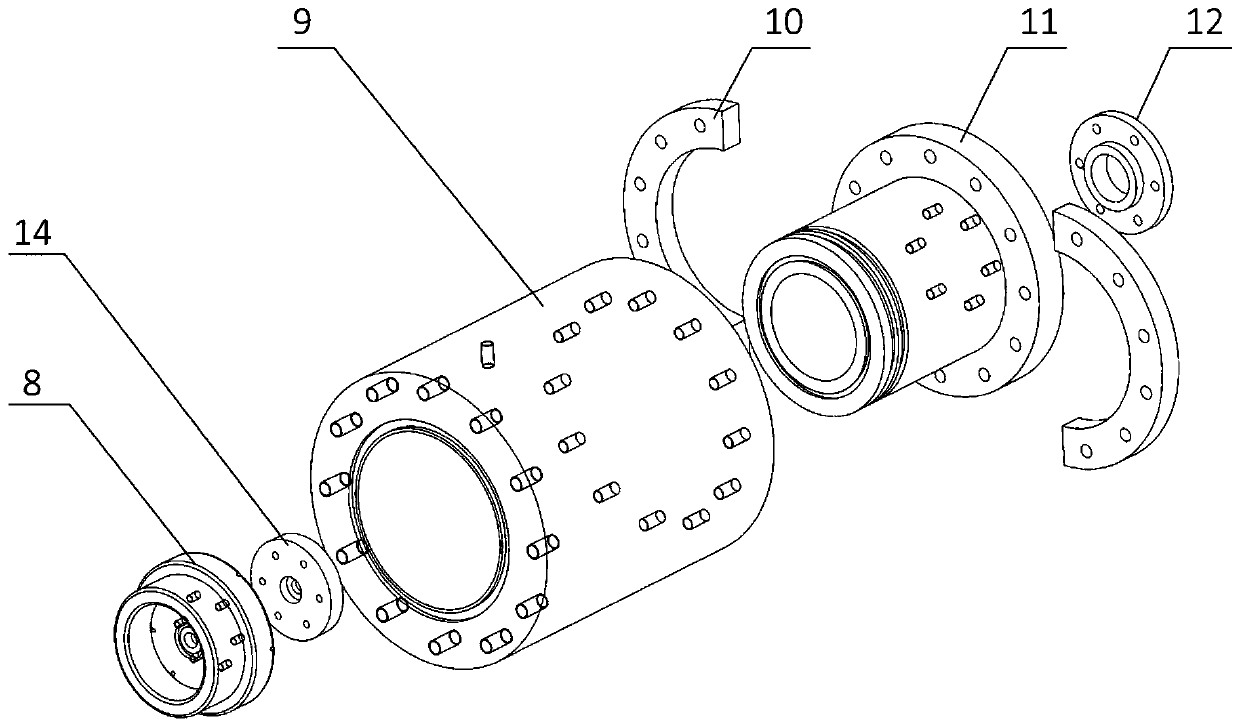

[0021] like figure 1 As shown, the present invention proposes a fast compressor test platform for the laboratory, which is used to adjust the compression ratio to achieve different gas temperatures and pressures after compression. The fast compressor test platform includes sequentially arranged from front to back The combustion chamber unit, the brake cylinder unit and the drive cylinder unit, the combustion chamber unit includes a combustion chamber roof 1, a combustion chamber cavity 2, a combustion chamber cylinder 3 and a combustion chamber piston 4, the combustion chamber cavity 2 The front part is provided with a quartz glass observation window 15; the brake cylinder...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com