Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

121 results about "Polymer encapsulation" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

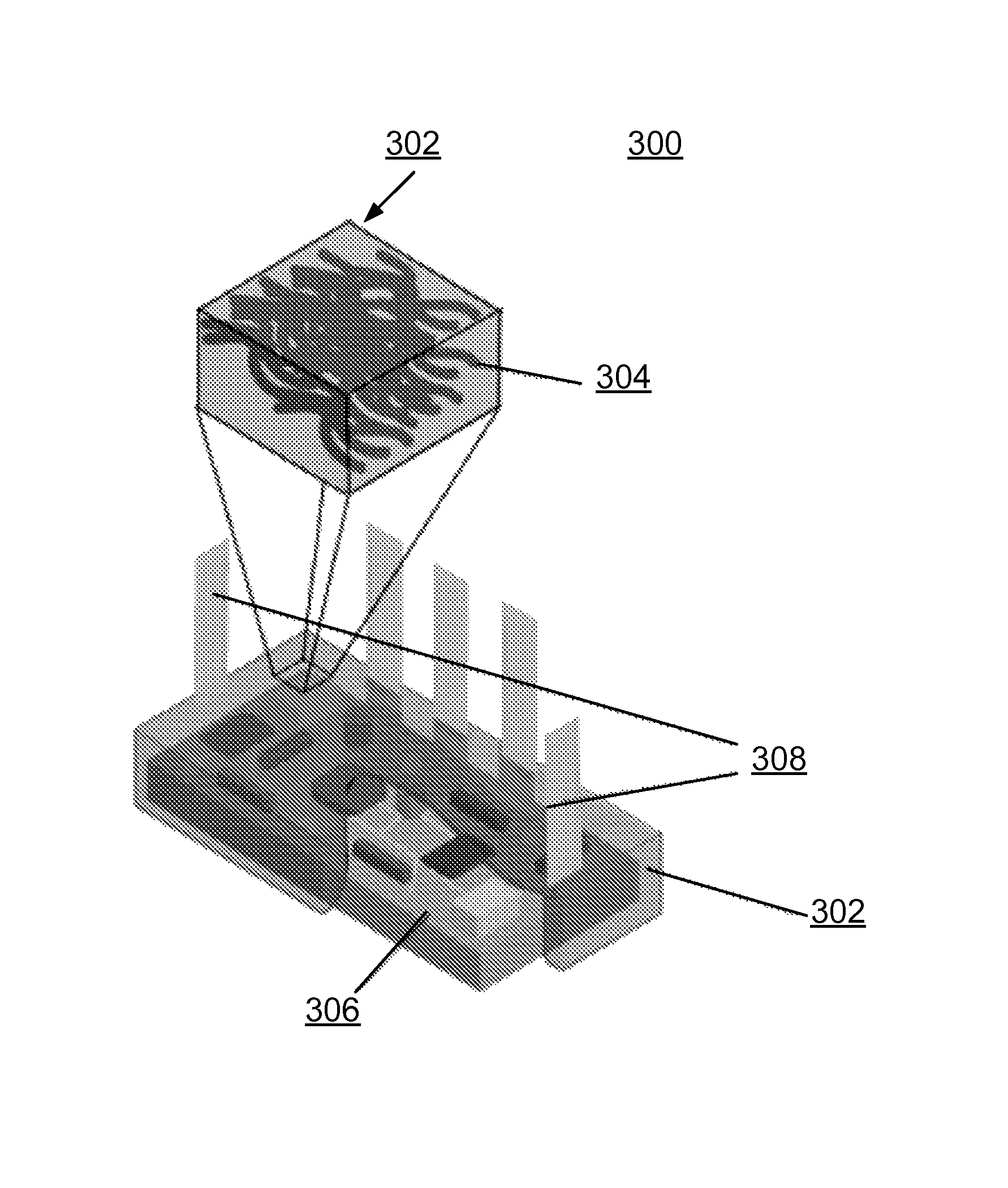

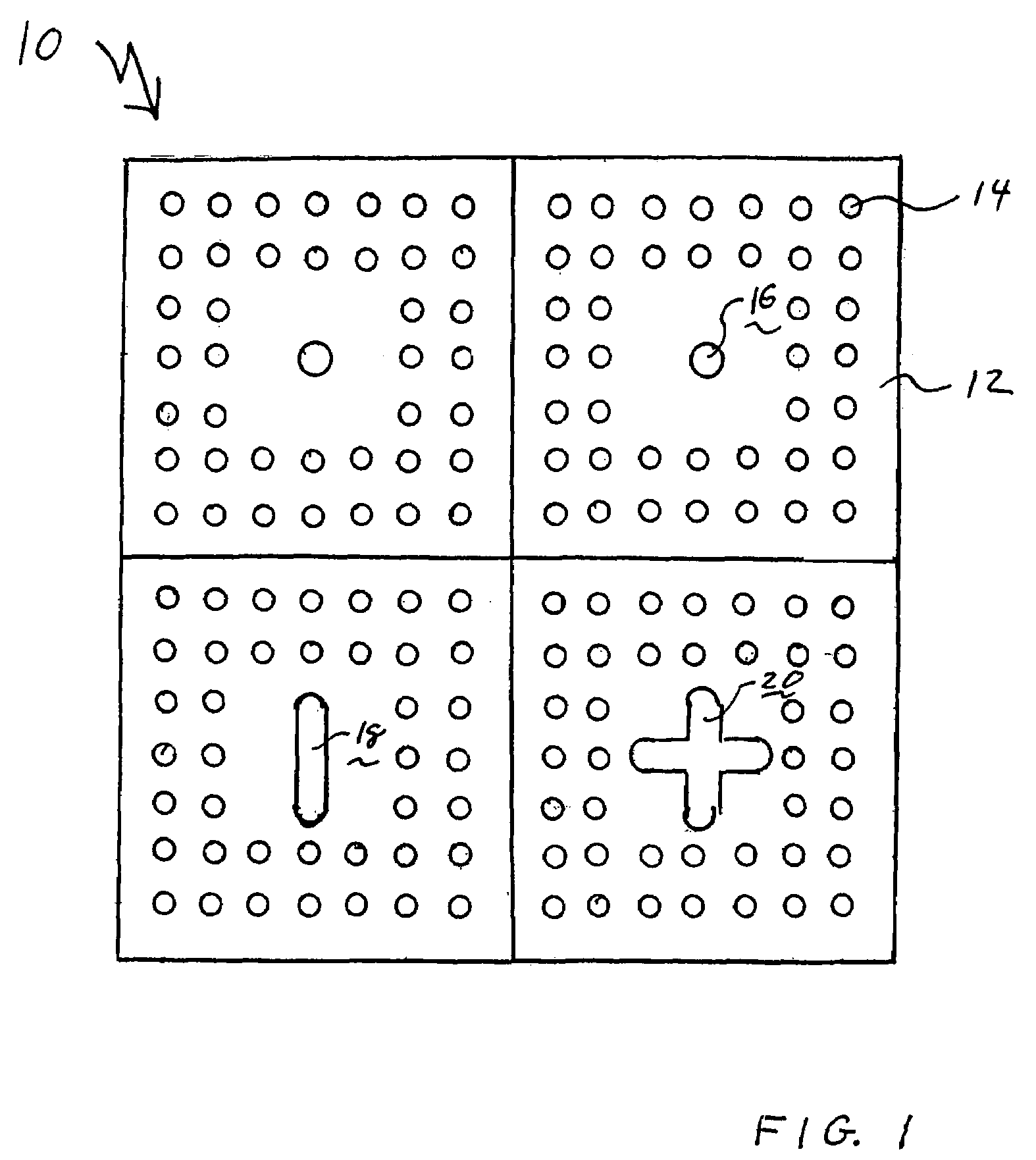

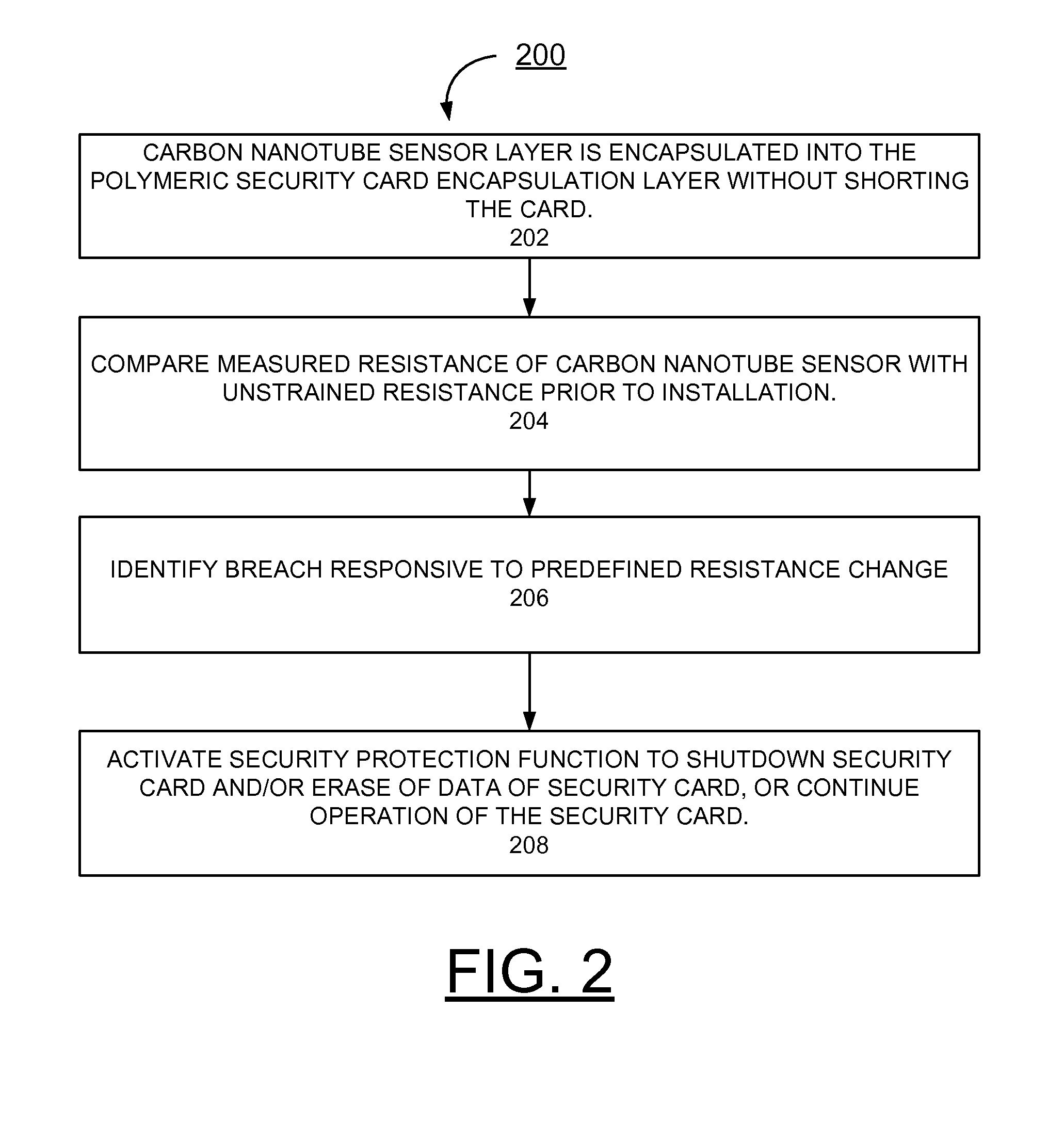

Implementing carbon nanotube based sensors for cryptographic applications

InactiveUS8797059B2Easy to detectMaterial nanotechnologyVolume/mass flow measurementElectricityElectrical resistance and conductance

A method and circuit for implementing security protection with carbon nanotube based sensors for cryptographic applications, and a design structure on which the subject circuit resides are provided. A carbon nanotube layer is incorporated with a polymeric encapsulation layer of a security card. Electrical connections to the carbon nanotube layer are provided for electrical monitoring of electrical resistance of the carbon nanotube layer.

Owner:INT BUSINESS MASCH CORP

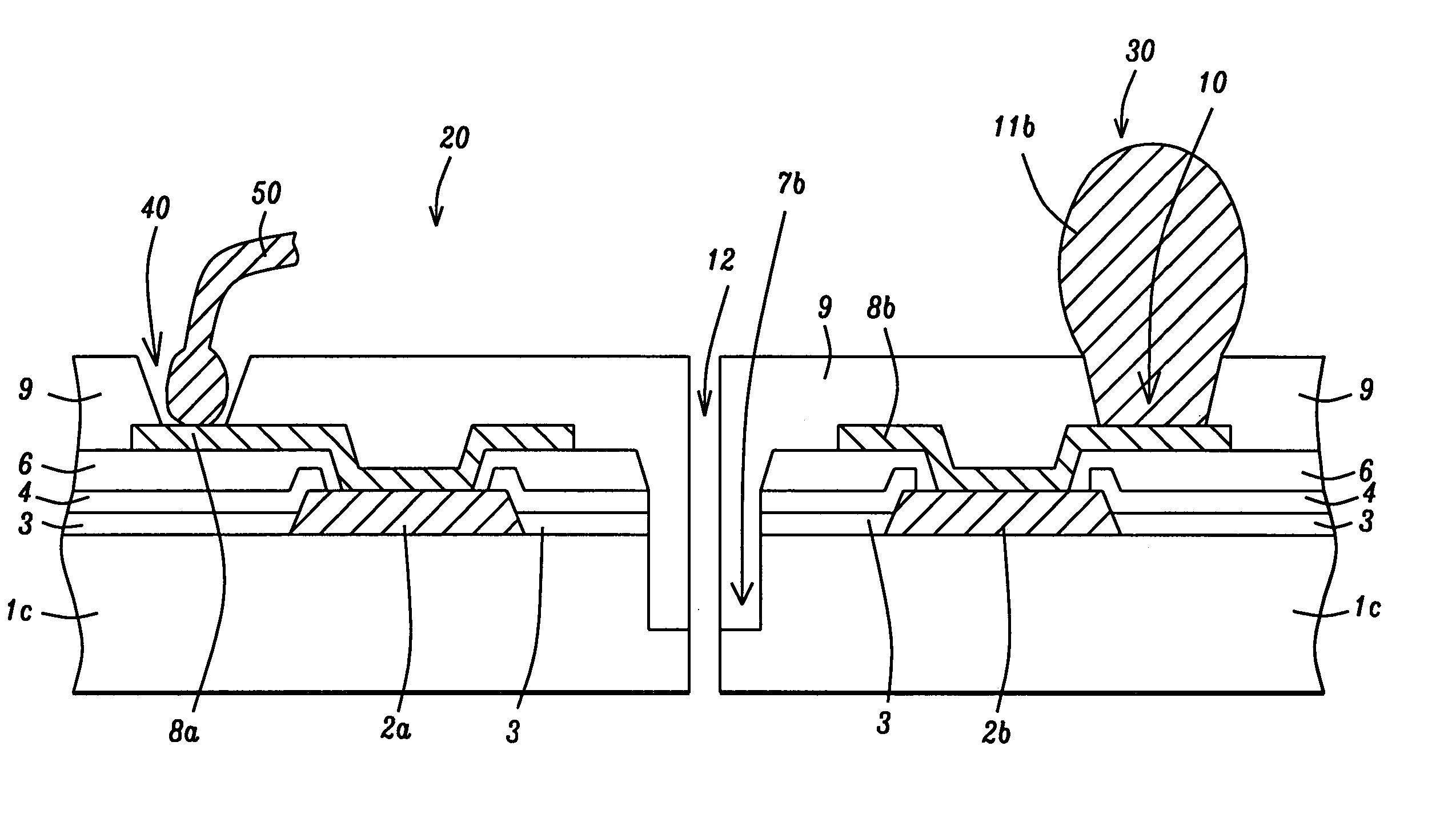

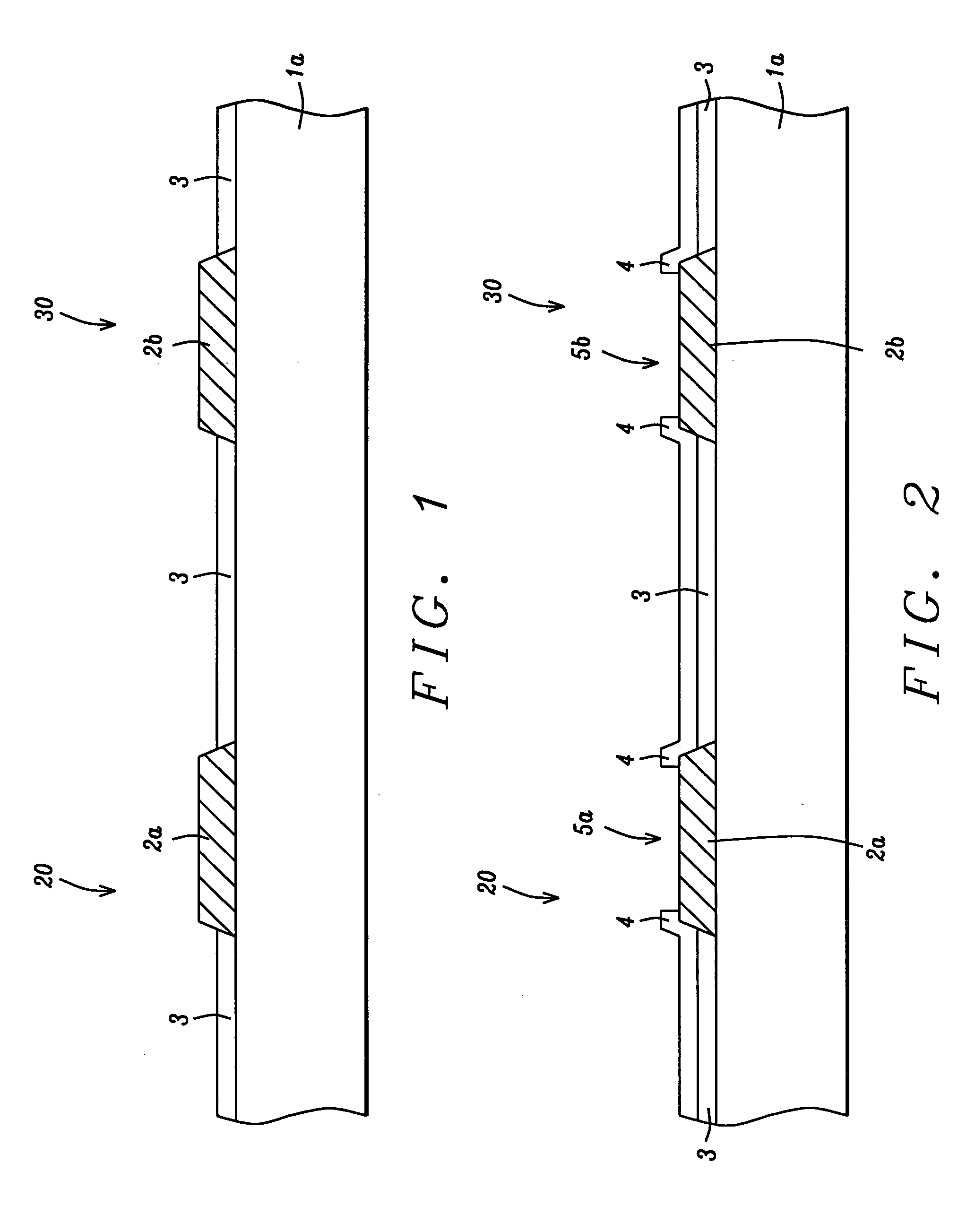

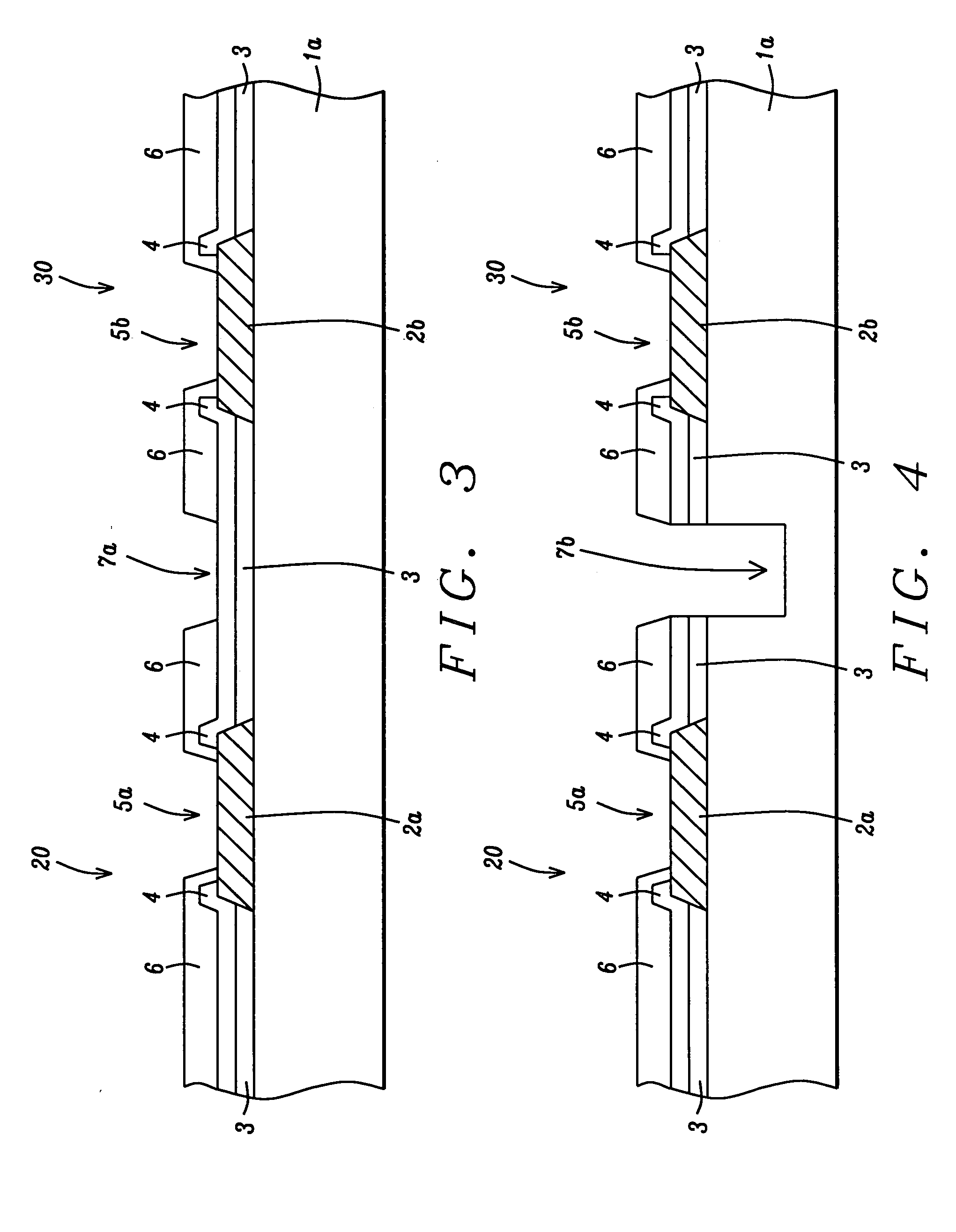

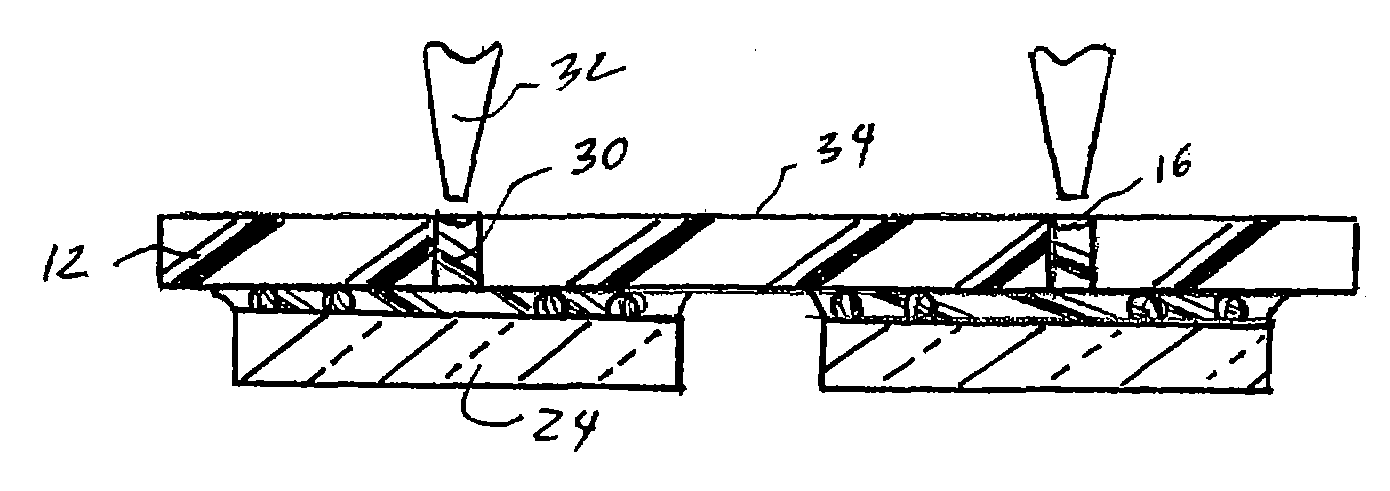

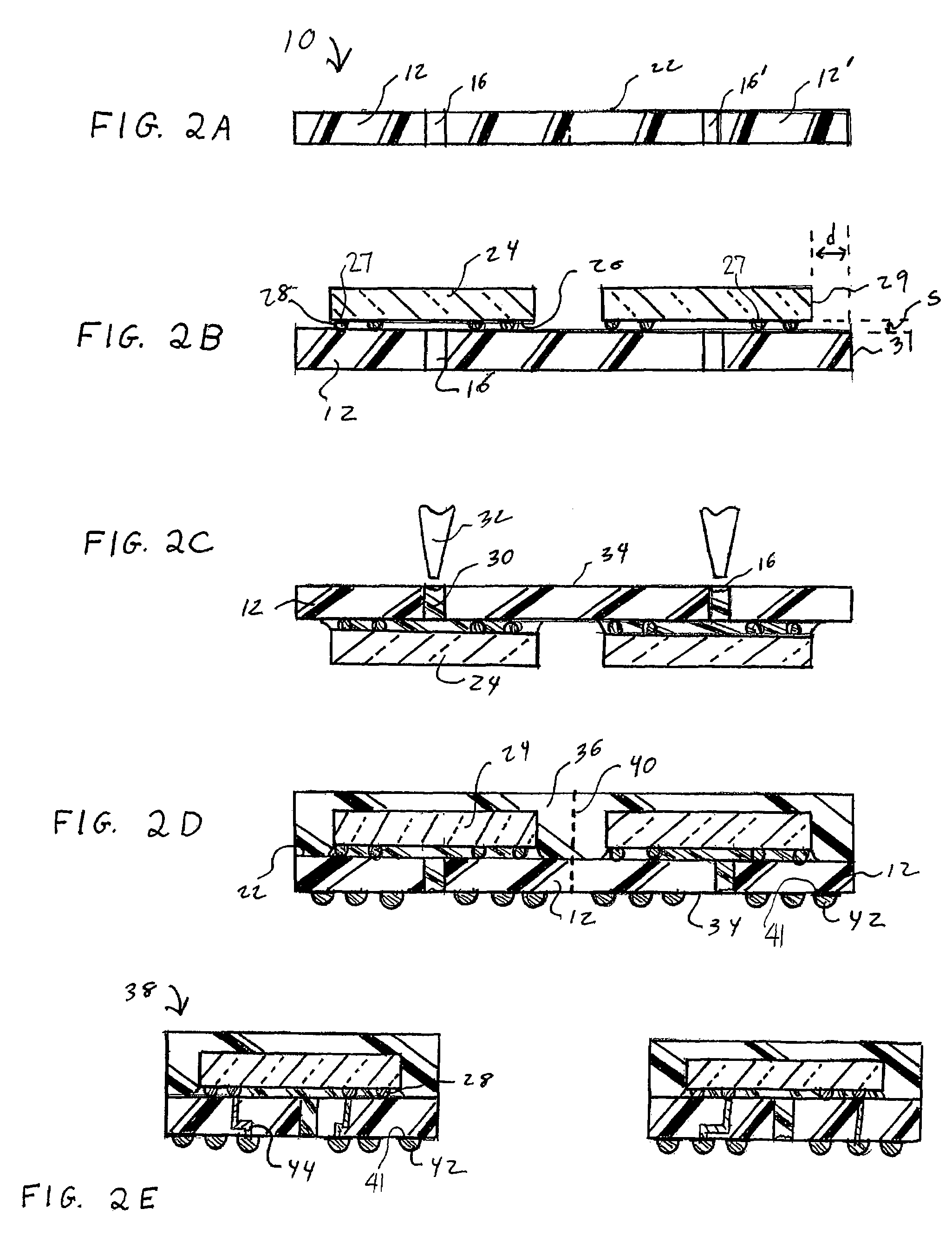

Polymer encapsulated dicing lane (PEDL) technology for Cu/low/ultra-low k devices

InactiveUS20060079025A1Semiconductor/solid-state device detailsSolid-state devicesCopper interconnectLead bonding

A process for packaging semiconductor devices for flip chip and wire bond applications, wherein specific materials of the semiconductor devices are protected during device processing sequences and dicing procedures, has been developed. After definition of copper interconnect structures surrounded by a low k insulator layer, a protective, first photosensitive polymer layer comprised with a low dielectric constant is applied. After definition of openings in the first photosensitive polymer layer exposing portions of the top surface of the copper interconnect structures, a dicing lane opening is defined in materials located between copper interconnect structures. Conductive redistribution shapes are formed on the copper interconnect structures exposed in the openings in the first photosensitive polymer layer, followed by application of a protective, second photosensitive polymer layer. An opening is defined in the second photosensitive polymer layer exposing a portion of the top surface of a redistribution shape followed by placement of a solder ball in this opening. A reflow anneal procedure results in the solder ball wetting and overlying only the portion of the redistribution shape exposed in the opening in the second photosensitive polymer layer. Separation of the solder ball, flip chip regions from the non-solder ball, wire bond regions is accomplished via a dicing procedure performed in the dicing lane.

Owner:AGENCY FOR SCI TECH & RES

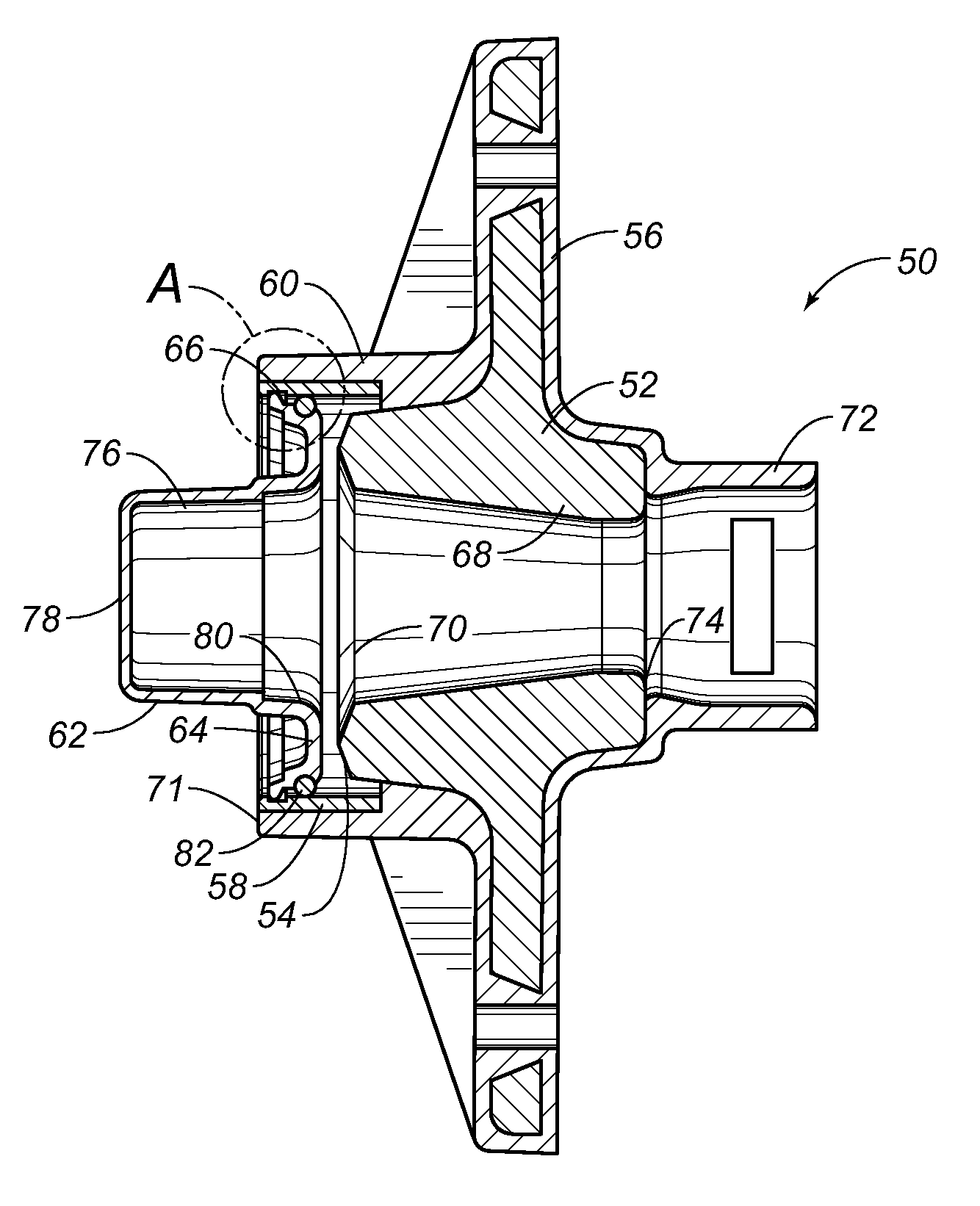

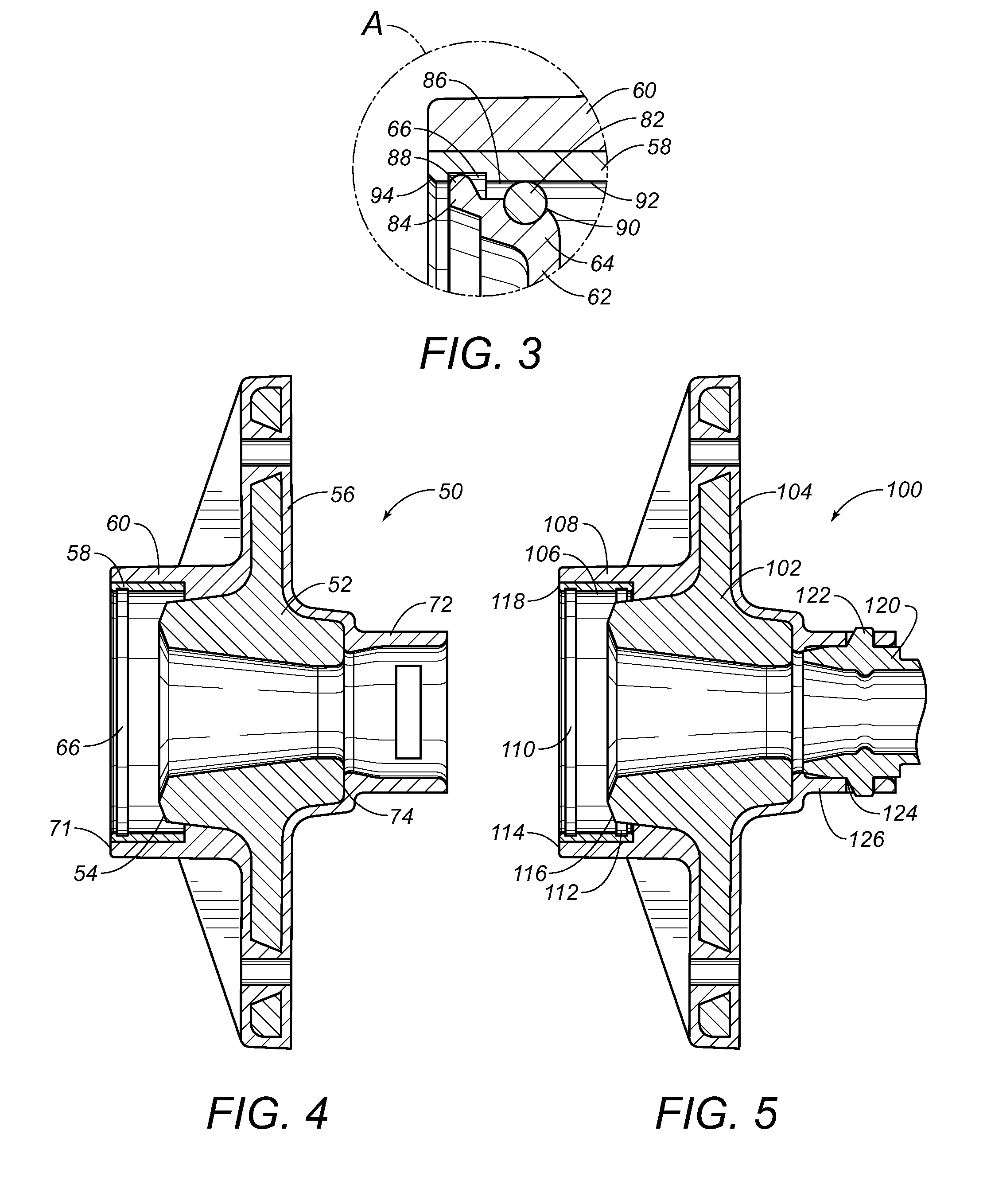

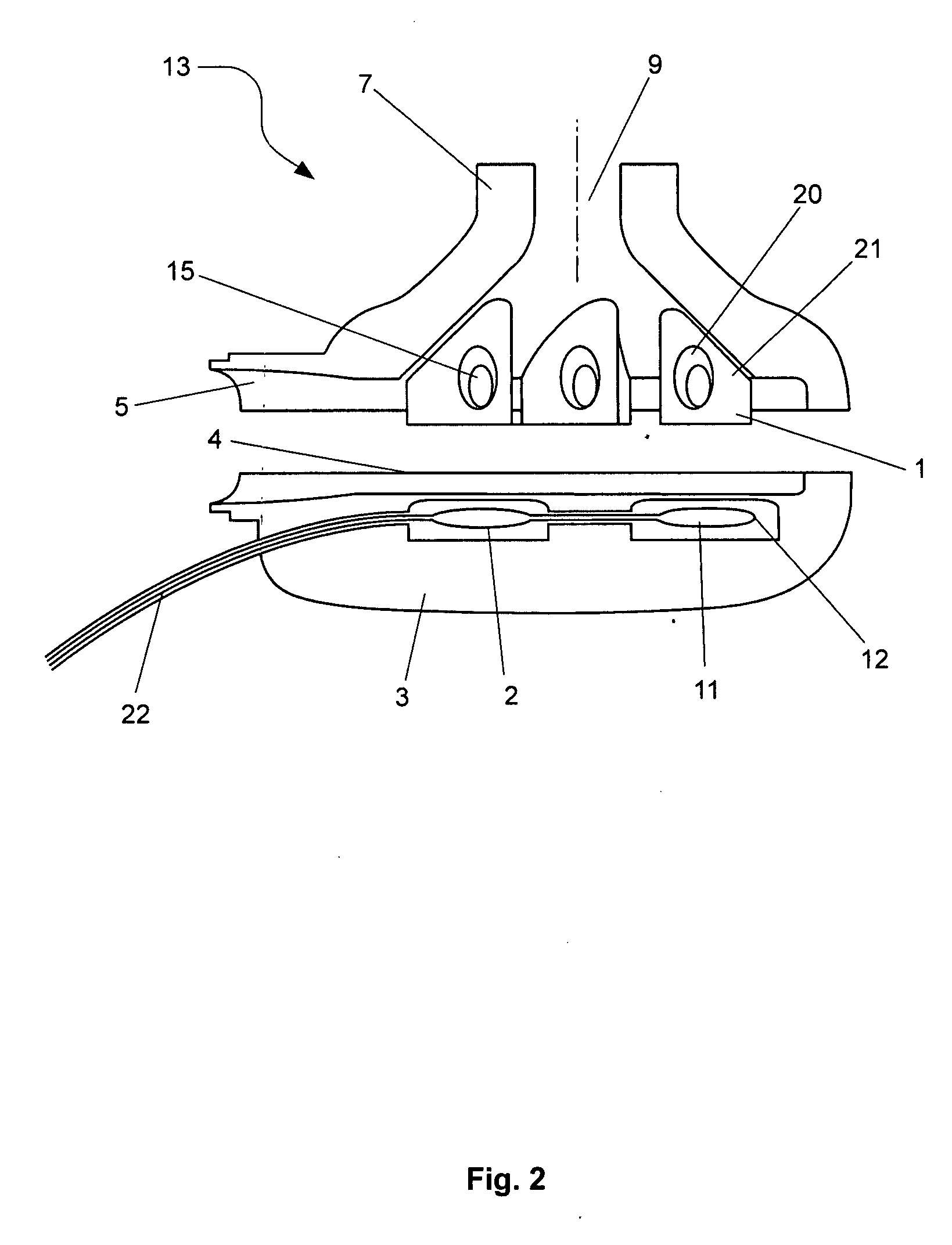

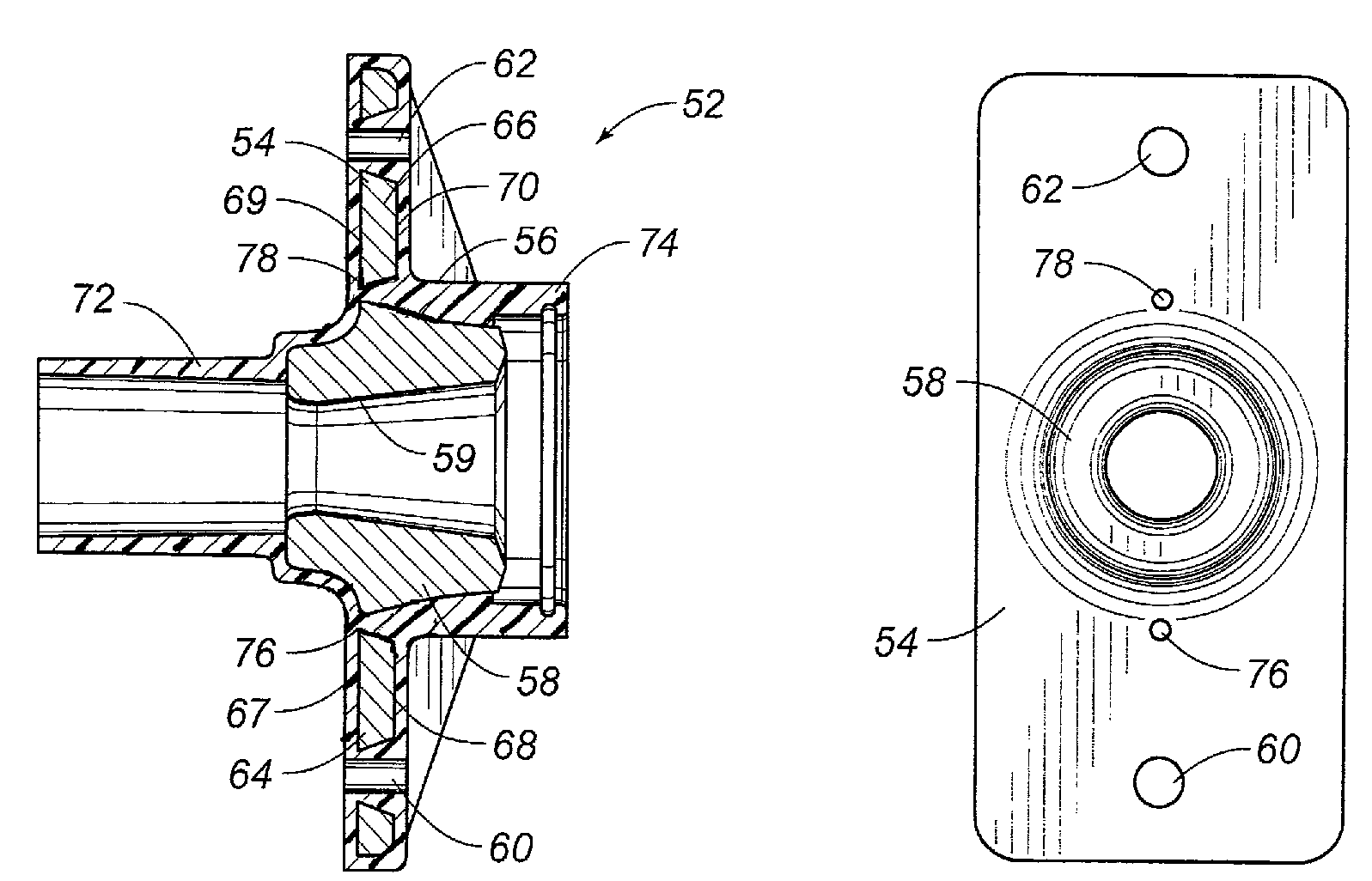

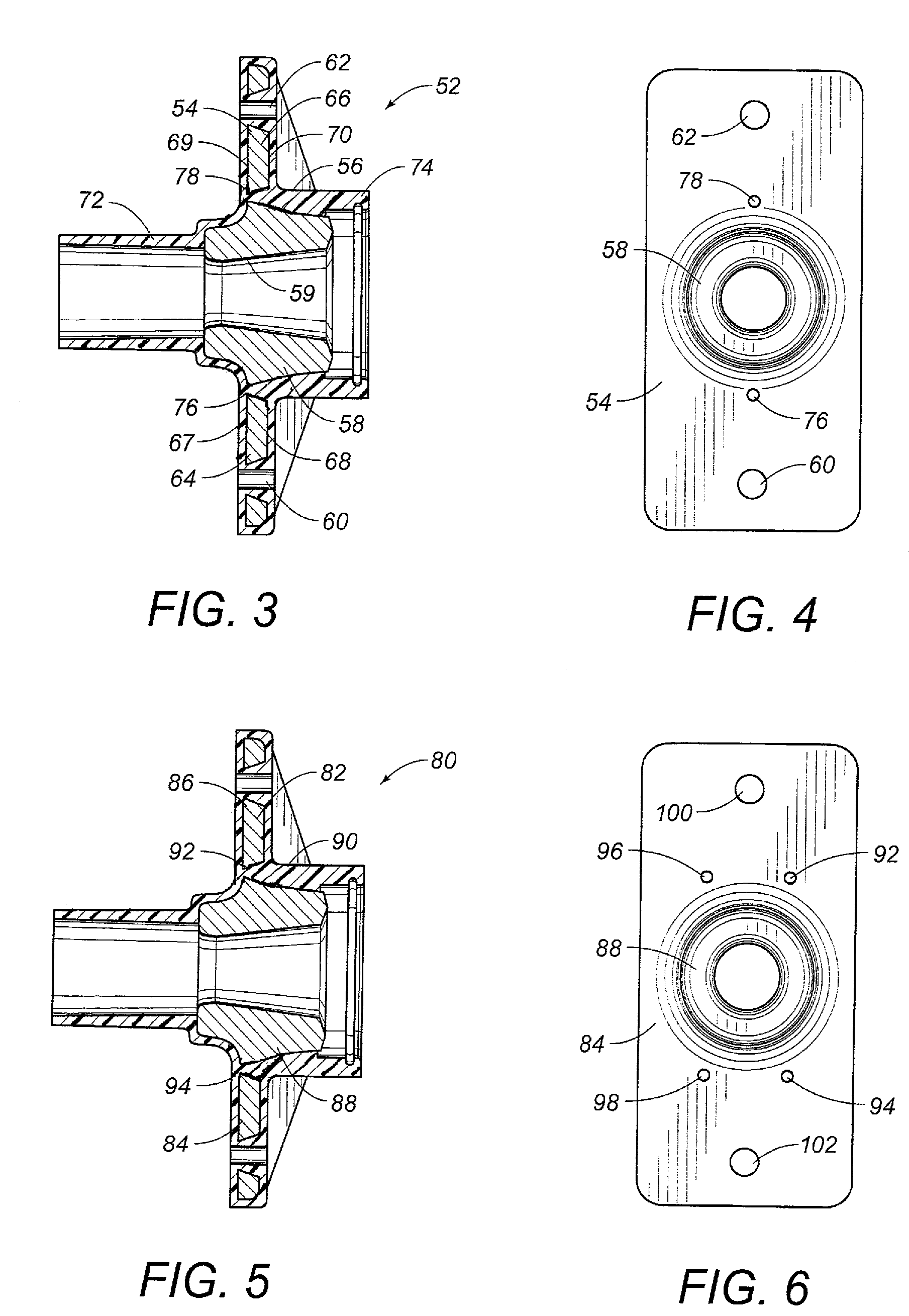

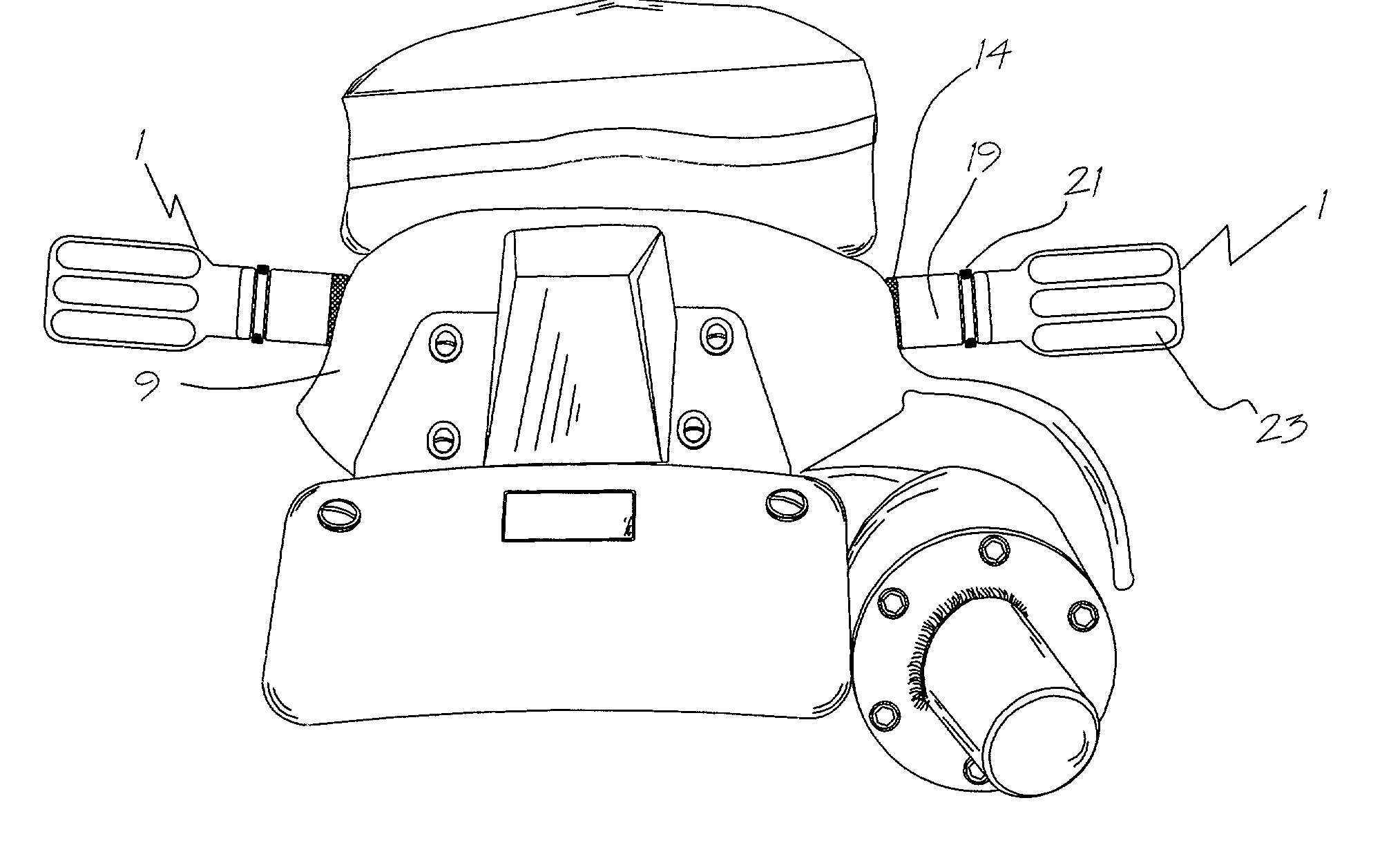

Positively retained cap for use on an encapsulated anchor of a post-tension anchor system

ActiveUS7424792B1Improve abilitiesBuilding repairsBuilding reinforcementsBiomedical engineeringPolymer encapsulation

An anchor assembly for a post-tension system has an anchor member, a polymeric encapsulation covering the anchor member and defining a tubular section extending outwardly of an end surface of the anchor member, a rigid ring affixed within this tubular section and having a notch formed in an inner wall thereof, and a cap having a generally tubular body with an open end and a closed end. The cap has a flanged end adjacent the open end thereof. This flanged end has an outer periphery engageable within the notch of the rigid ring.

Owner:SORKIN FELIX L

Polymer encapsulation for medical device

InactiveUS20080200750A1Prevent component leakagePrevent leakageBlood pumpsPharmaceutical delivery mechanismImpellerBlood pump

A rotary blood pump comprising an impeller suspended hydrodynamically within pump housing by thrust forces generated by said impeller during movement in use of said impeller as it rotates about an impeller axis, and the driving torque of said impeller is derived from the magnetic interaction between permanent magnets within the blades of said impeller and windings within said housing, and wherein said windings are encapsulated by a first fluid resistant polymer material, and said housing is at least partially made of a second polymer material that encapsulates said first polymer material.

Owner:THORATEC CORPORTION

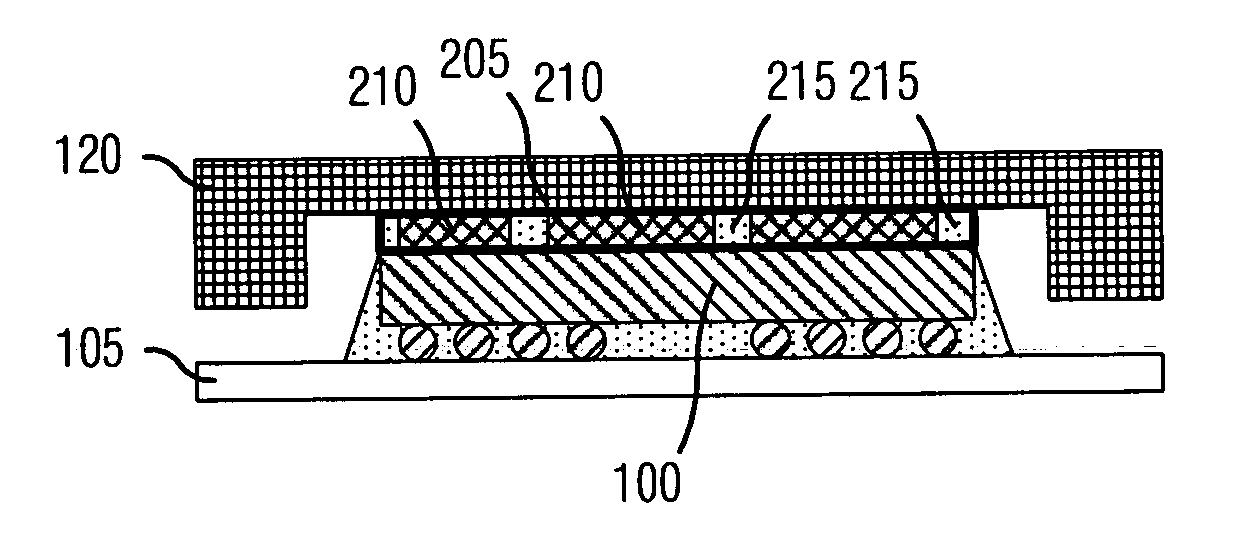

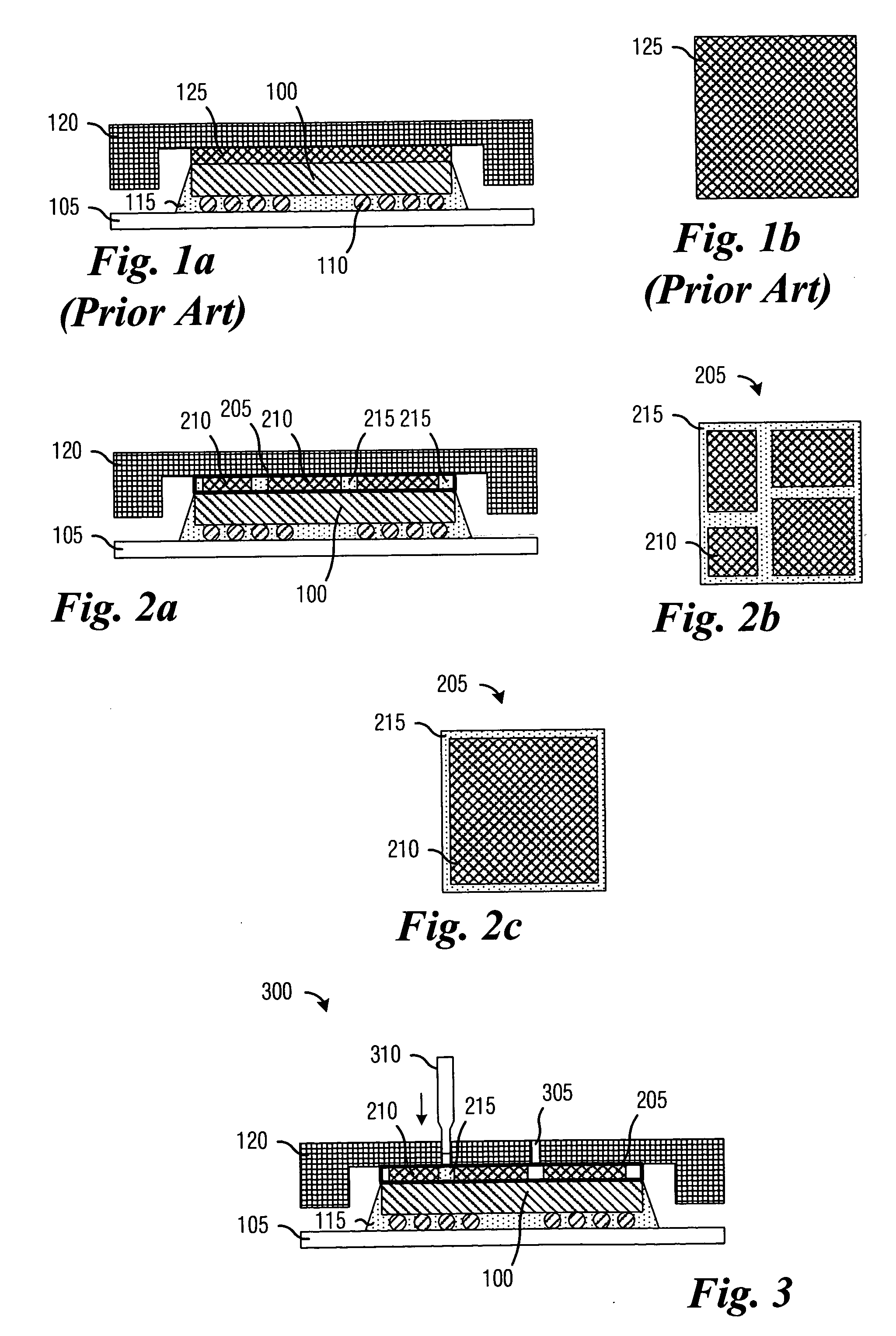

System and method for polymer encapsulated solder lid attach

InactiveUS20060270106A1Avoid delaminationAvoid separationSemiconductor/solid-state device detailsSolid-state devicesPolymer scienceSealant

System and method for a polymer encapsulated solder lid attach. A preferred embodiment comprises one or more metallic islands distributed throughout the combination attach, wherein each metallic island overlays one or more heat producing portions of the integrated circuit die, and a polymer encapsulant to encircle each metallic island and to bind the one or more metallic islands in place. The one or more metallic islands, with their high thermal conductivity, can effectively dissipate large amounts of heat, while the polymer encapsulant binds the one or more metallic islands in place, preventing (or reducing) movement occurring during thermal cycles that can lead to delamination and separation.

Owner:TEXAS INSTR INC

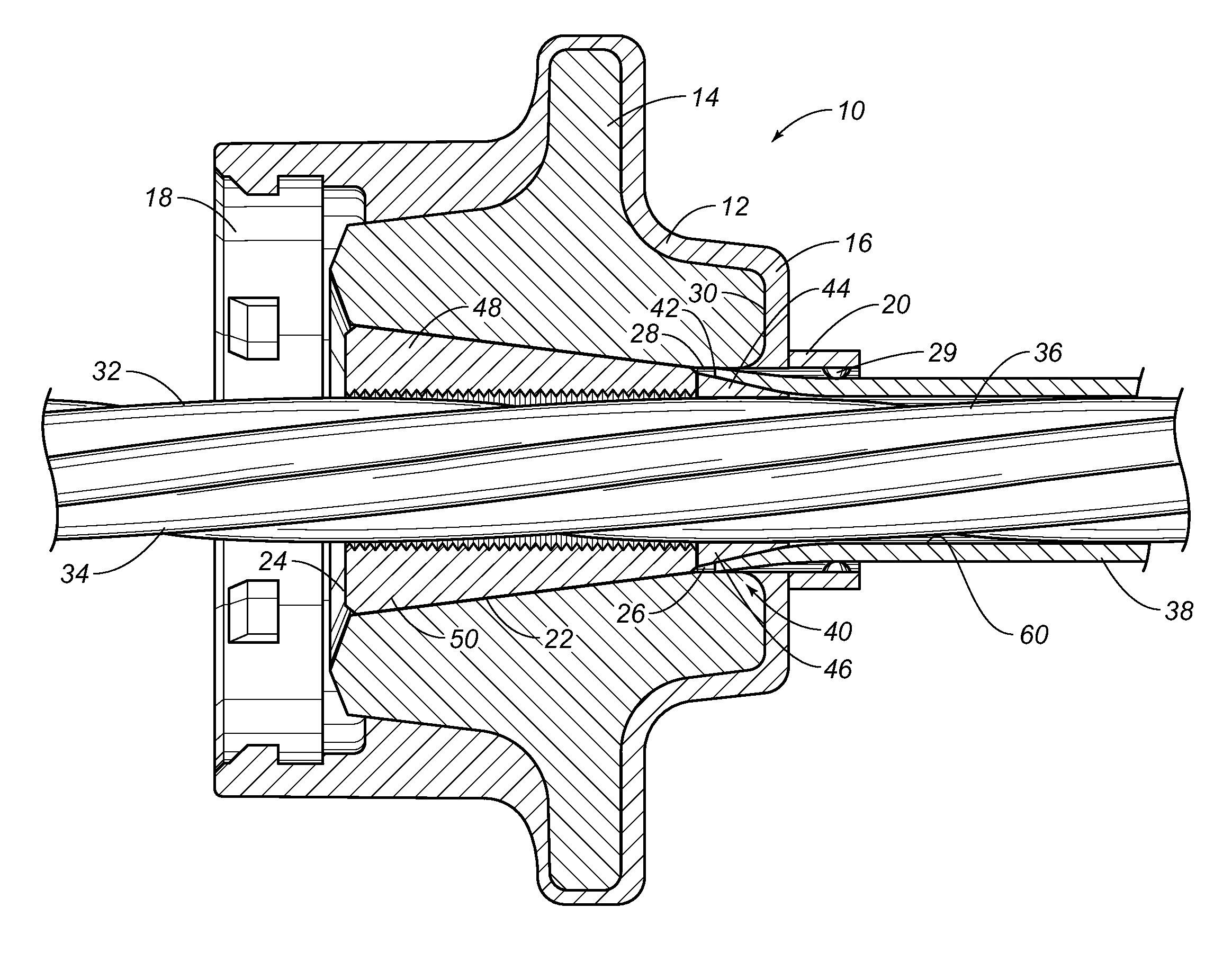

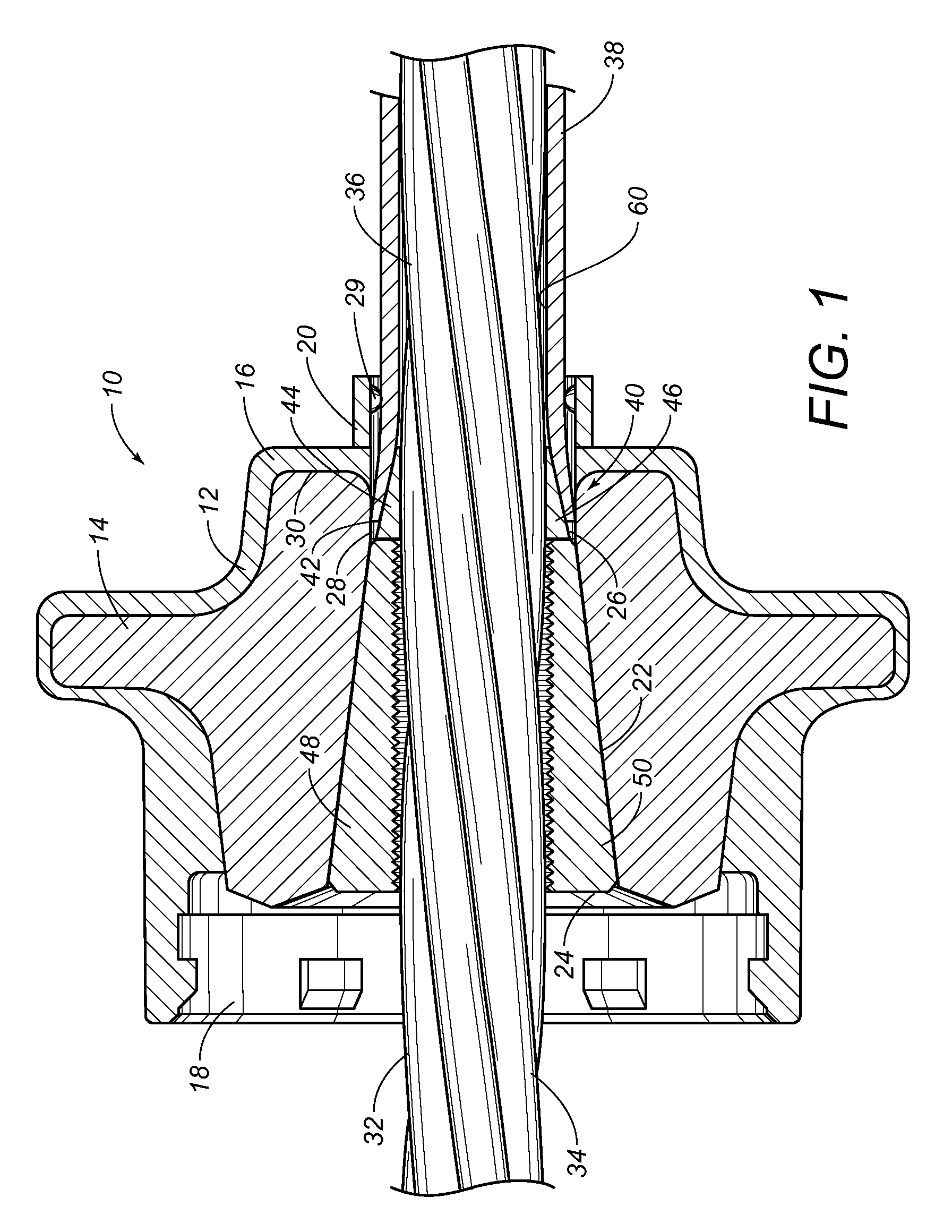

Tendon tensioning anchor system having polymeric encapsulation with reduced shrinkage effects

A tendon tensioning anchor has a base member having a tubular section extending therefrom, and a pair of flanges extending outwardly on opposite sides of the tubular section, and a polymeric encapsulation in generally air-tight juxtaposition with an exterior of the base member. A hole is formed through each of the pair of flanges. The polymeric encapsulation extends entirely through and fills the holes so as to integrally connect the polymeric material overlying one surface of the flange with the polymeric material overlying an opposite surface of the flange. The hole is formed adjacent to the tubular section.

Owner:SORKIN FELIX L

Sealing trumpet for a post-tension anchorage system

An anchorage for post-tension system has an anchor body with an interior passageway, a polymeric encapsulation extending over the anchor body so as to define a trumpet extending outwardly on one side of the anchor body, and an annular seal formed so as to extend inwardly relative to a wall of the trumpet. The annular seal is in liquid-tight sealing relation with an outer surface of a tendon extending through the interior passageway. A fixing element is formed within the interior passageway so as to fix a position of the sheathing on the tendon.

Owner:SORKIN FELIX L

Solar cell modules comprising an encapsulant sheet of a blend of ethylene copolymers

Disclosed is a solar cell module comprising a polymeric encapsulant sheet, wherein the polymeric encapsulant sheet comprises a blend composition of an ethylene copolymer A and an ethylene copolymer B, the blend composition having a melt flow rate of less than 100 g / 10 min, as determined in accordance with ASTM D1238 at 190° C. and 2.16 kg, and wherein the ethylene copolymerA comprises copolymerized units of ethylene and about 3 to about 20 wt % of an ester or anhydride of a C4-C8 unsaturated acid having two carboxylic acid groups and the ethylene copolymer B comprises copolymerized units of ethylene and about 6 to about 40 wt % of a polar monomer selected from the group consisting of vinyl acetate, alkyl (meth)acrylates, and mixtures thereof.

Owner:DOW GLOBAL TECH LLC

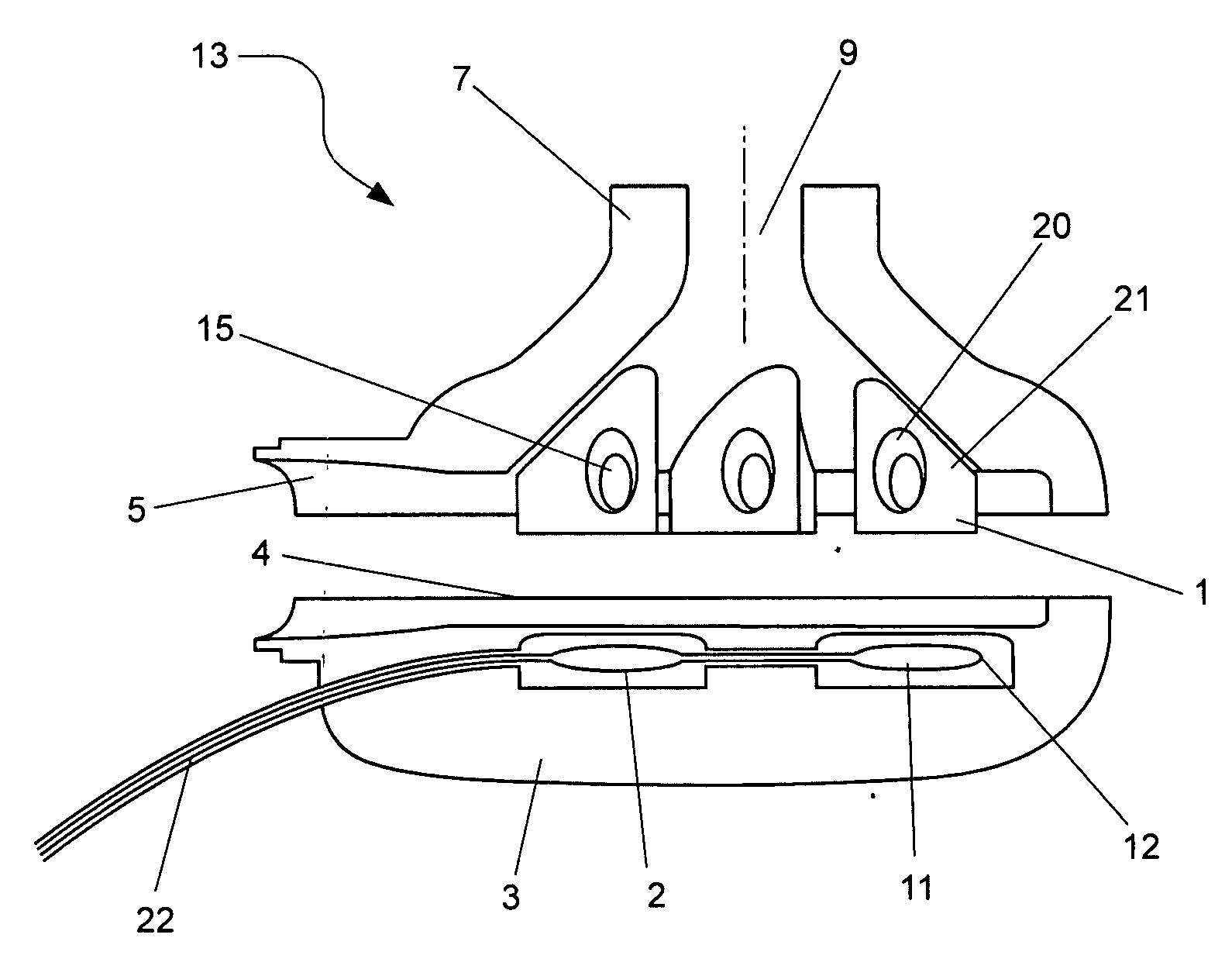

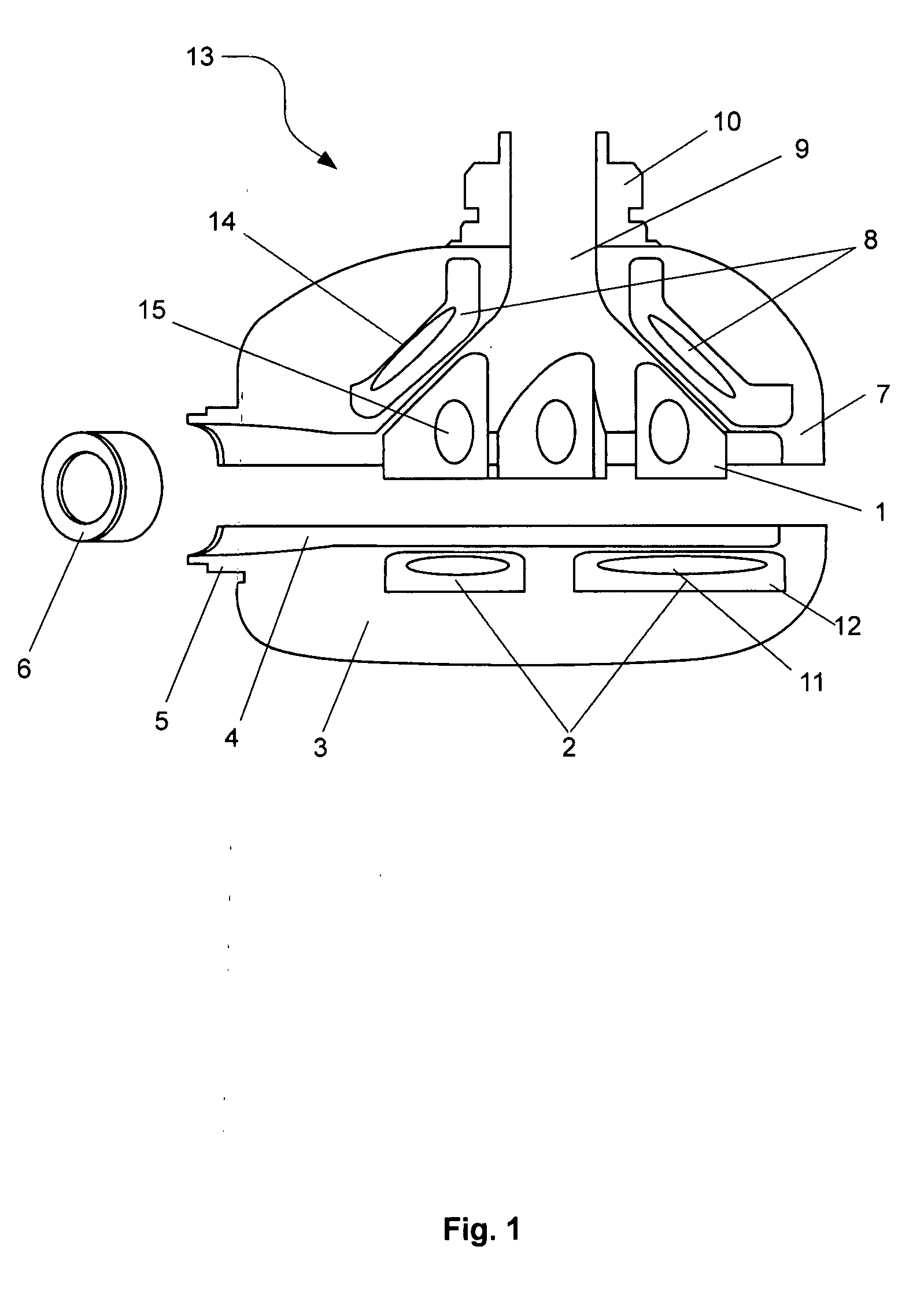

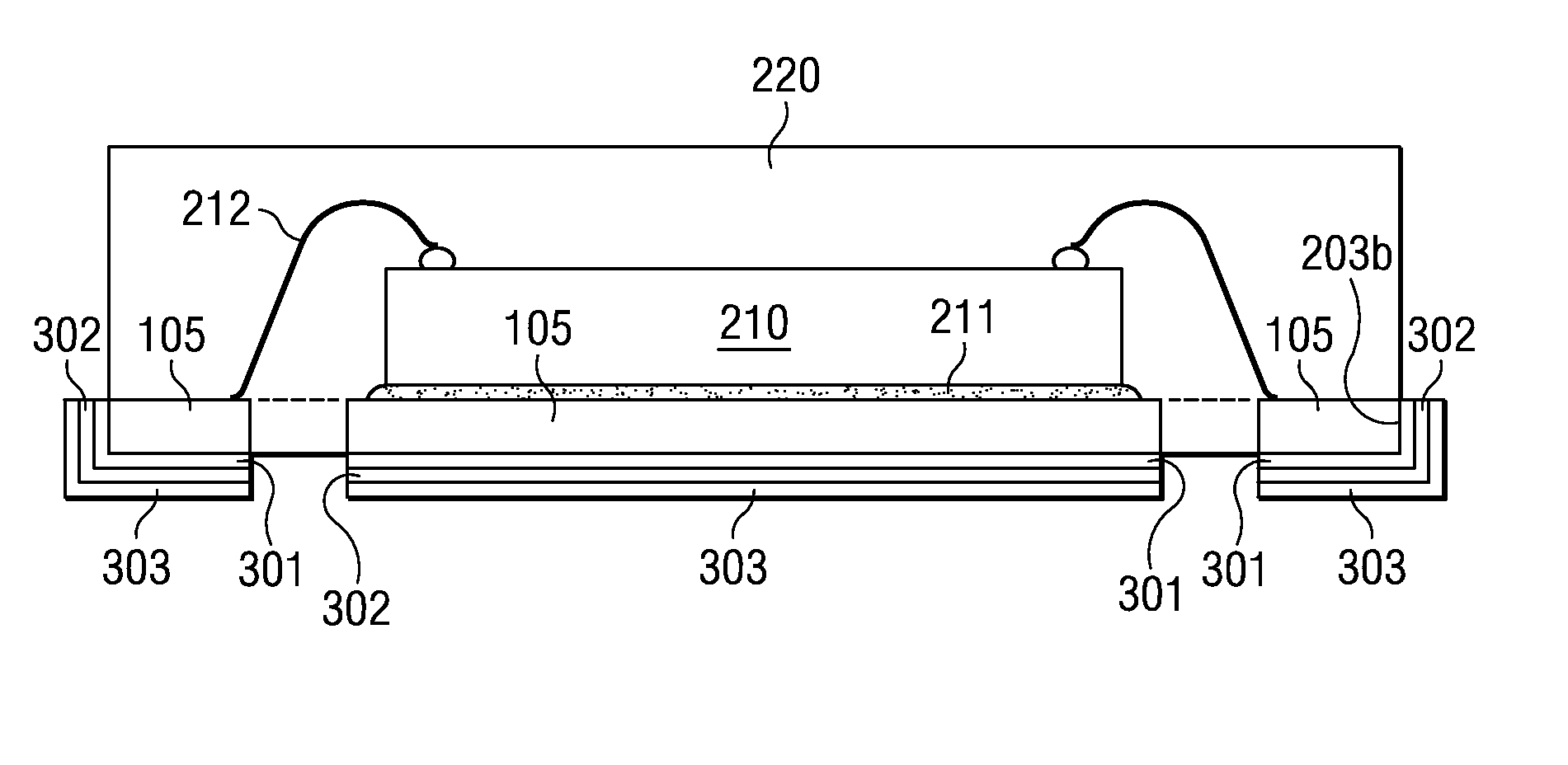

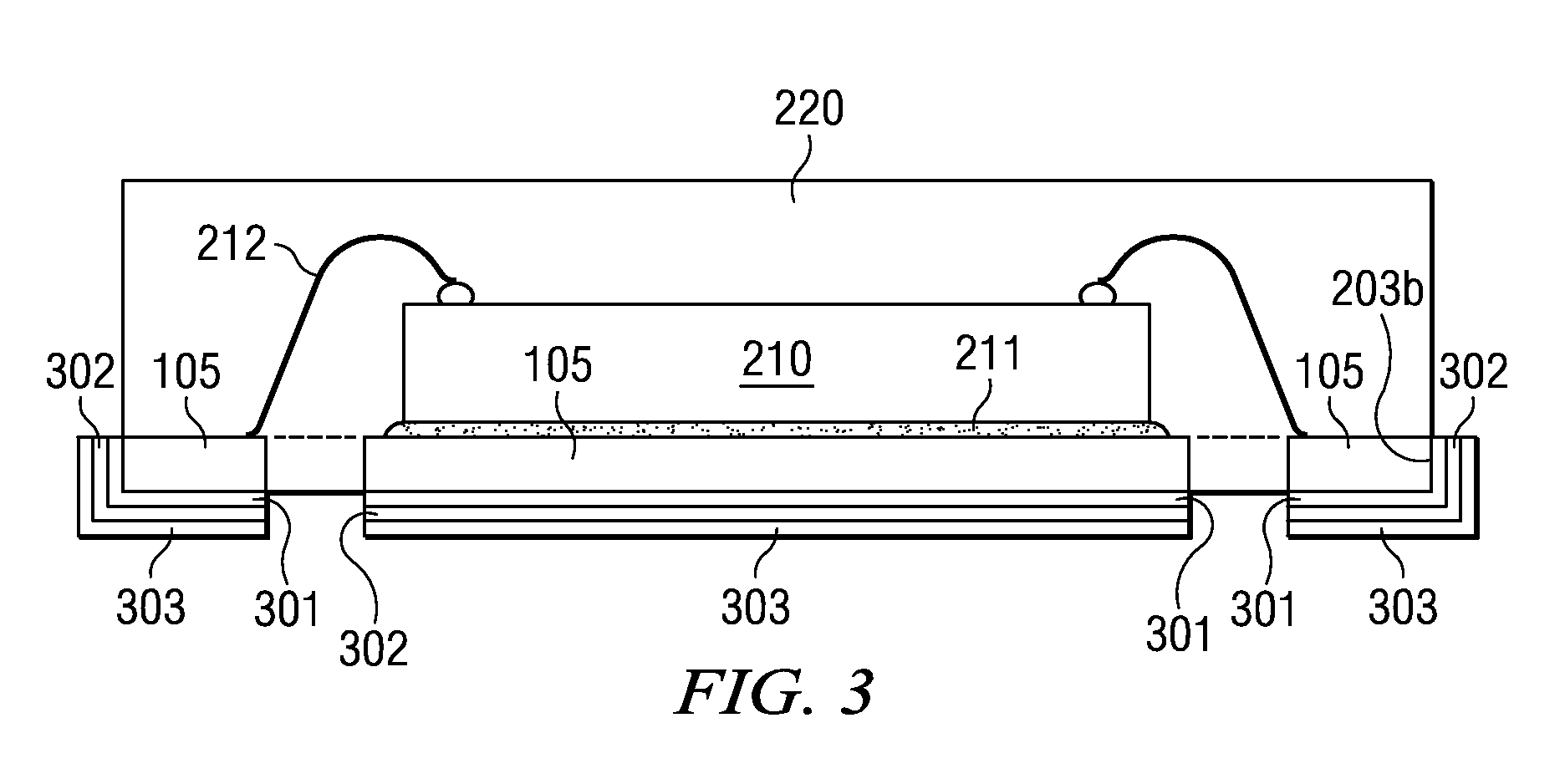

Aluminum leadframes for semiconductor QFN/SON devices

ActiveUS20070176267A1Easy bondabilityImprove protectionSemiconductor/solid-state device detailsSolid-state devicesSemiconductor chipEngineering

A post-mold plated semiconductor device has an aluminum leadframe (105) with a structure including a chip mount pad and a plurality of lead segments without cantilevered lead portions. A semiconductor chip (210) is attached to the chip mount pad, and conductive connections (212) span from the chip to the aluminum of the lead segments. Polymeric encapsulation material (220), such as a molding compound, covers the chip, the connections, and portions of the aluminum lead segments without leaving cantilevered segment portions. Preferably by electroless plating, a zinc layer (301) and a nickel layer (302) are on those portions of the lead segments, which are not covered by the encapsulation material including the aluminum segment surfaces (at 203b) formed by the device singulation step, and a layer (303) of noble metal, preferably palladium, is on the nickel layer.

Owner:TEXAS INSTR INC

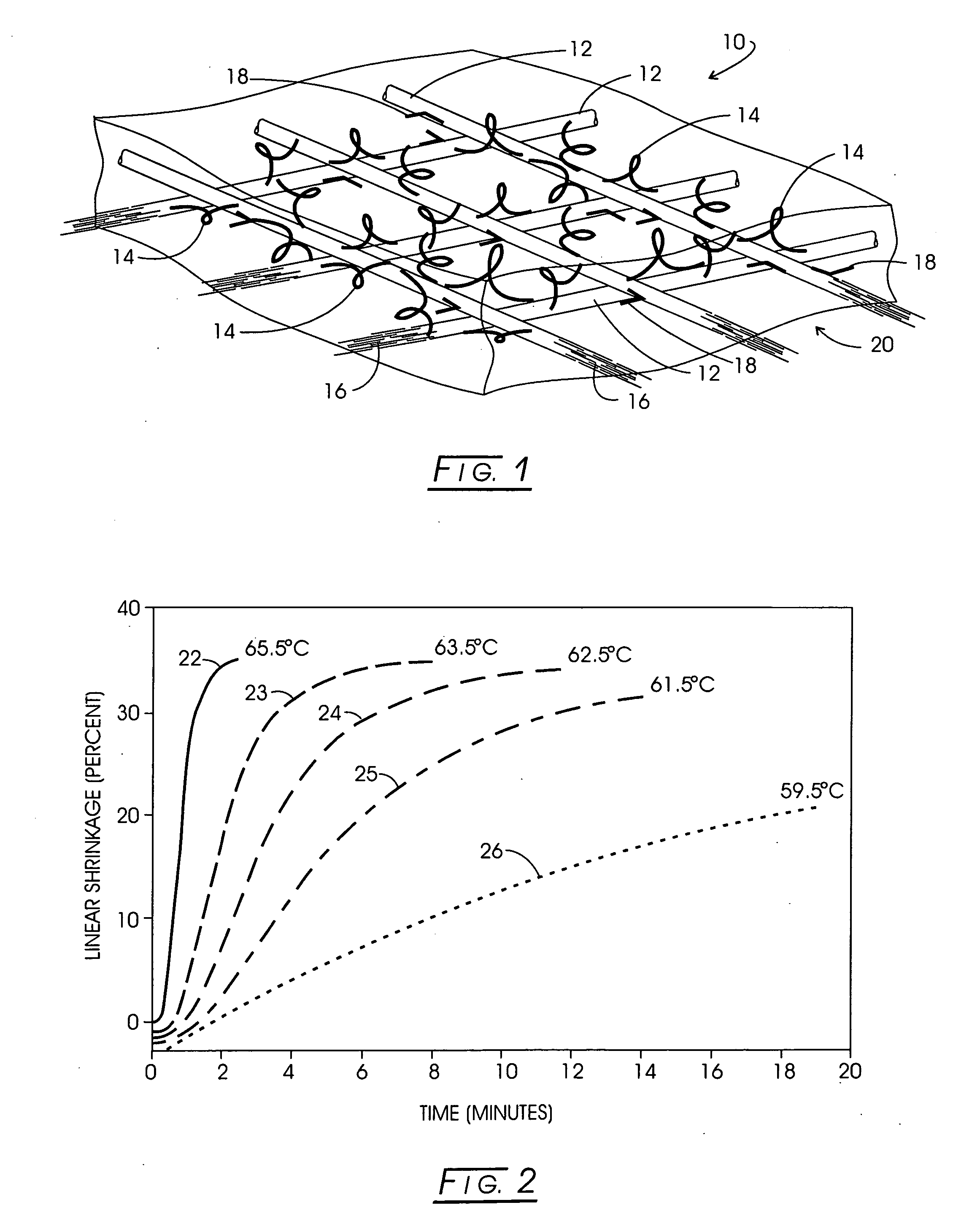

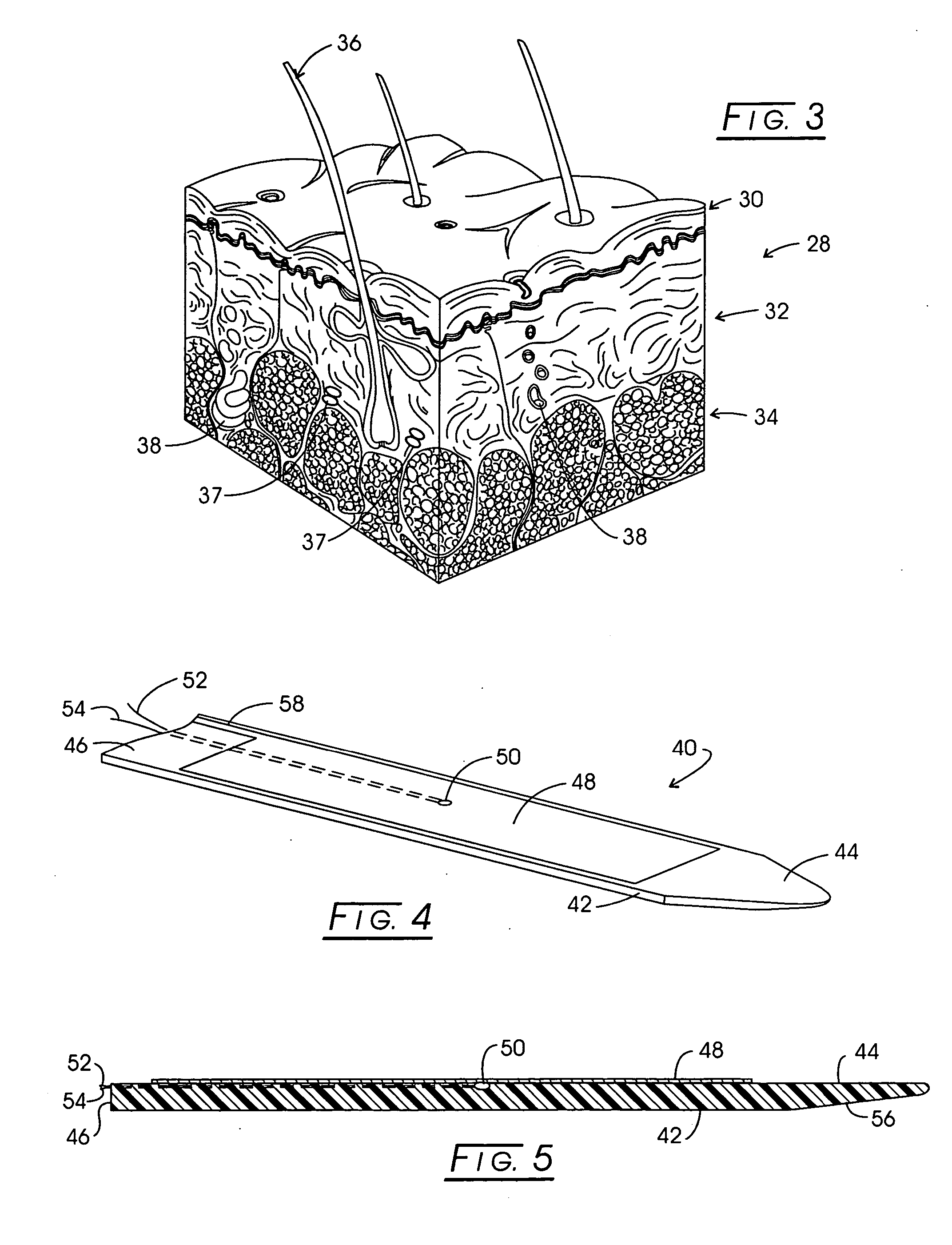

Method and apparatus for carrying out the controlled heating of tissue in the region of dermis

InactiveUS20070135880A1Improve protectionIncrease heatSurgical instrument detailsTherapeutic coolingAdjuvantCapillary malformation

Owner:APSARA MEDICAL

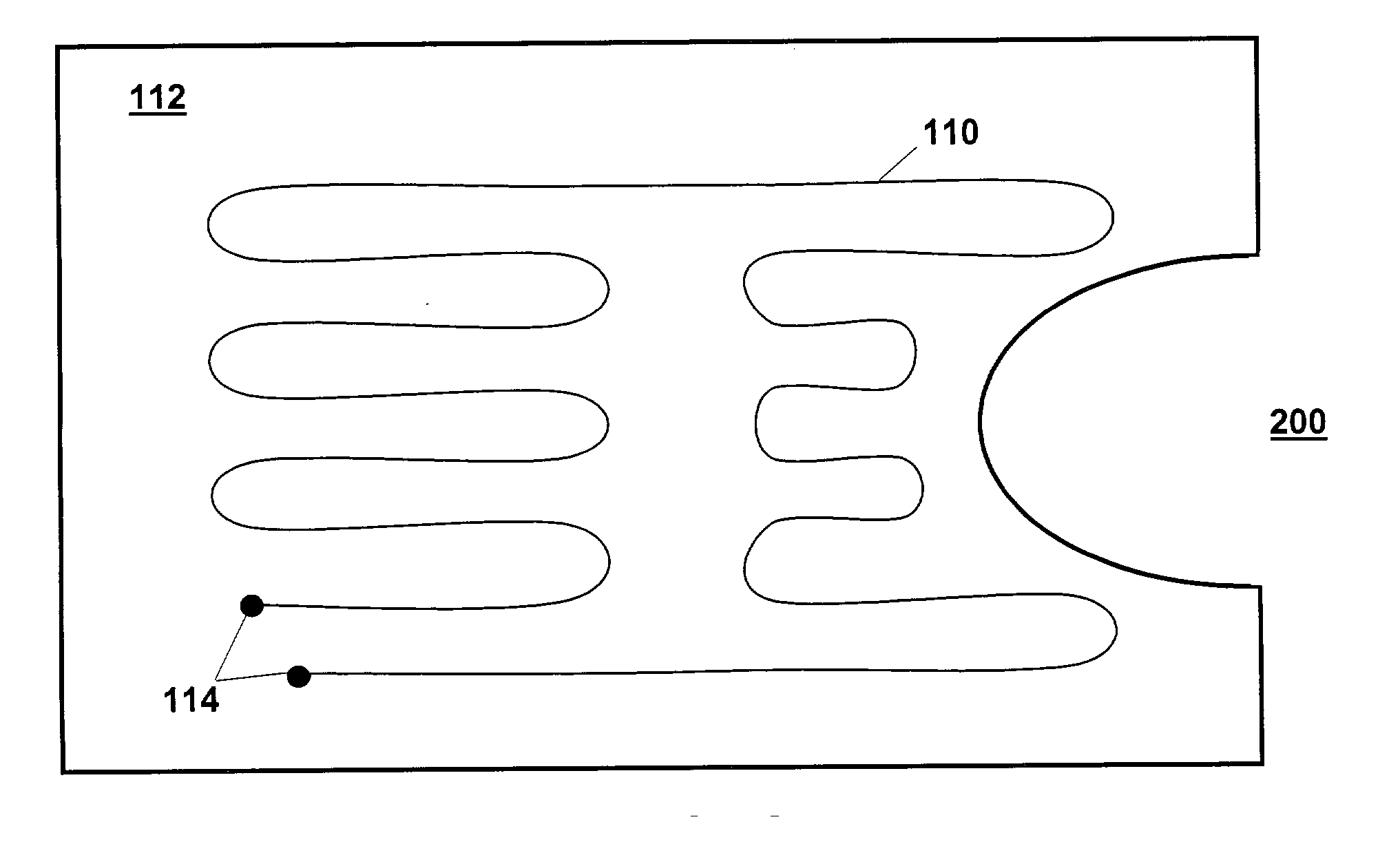

Polymer-encapsulated heating elements for controlling the temperature of an aircraft compartment

InactiveUS20050098684A1Prevents and slows and inhibits loss of heatAir-treatment apparatus arrangementsEnergy efficient board measuresFlight vehicleEngineering

Owner:ADEL WIGGINS GRP TRANSDIGM INC +1

Stretchable multi-mode sensor based on nanofiber core spun yarn and preparation method thereof

ActiveCN109355715AAchieve integrationAvoid separate preparationElectro-spinningUltrasonic/sonic fibre treatmentFiberYarn

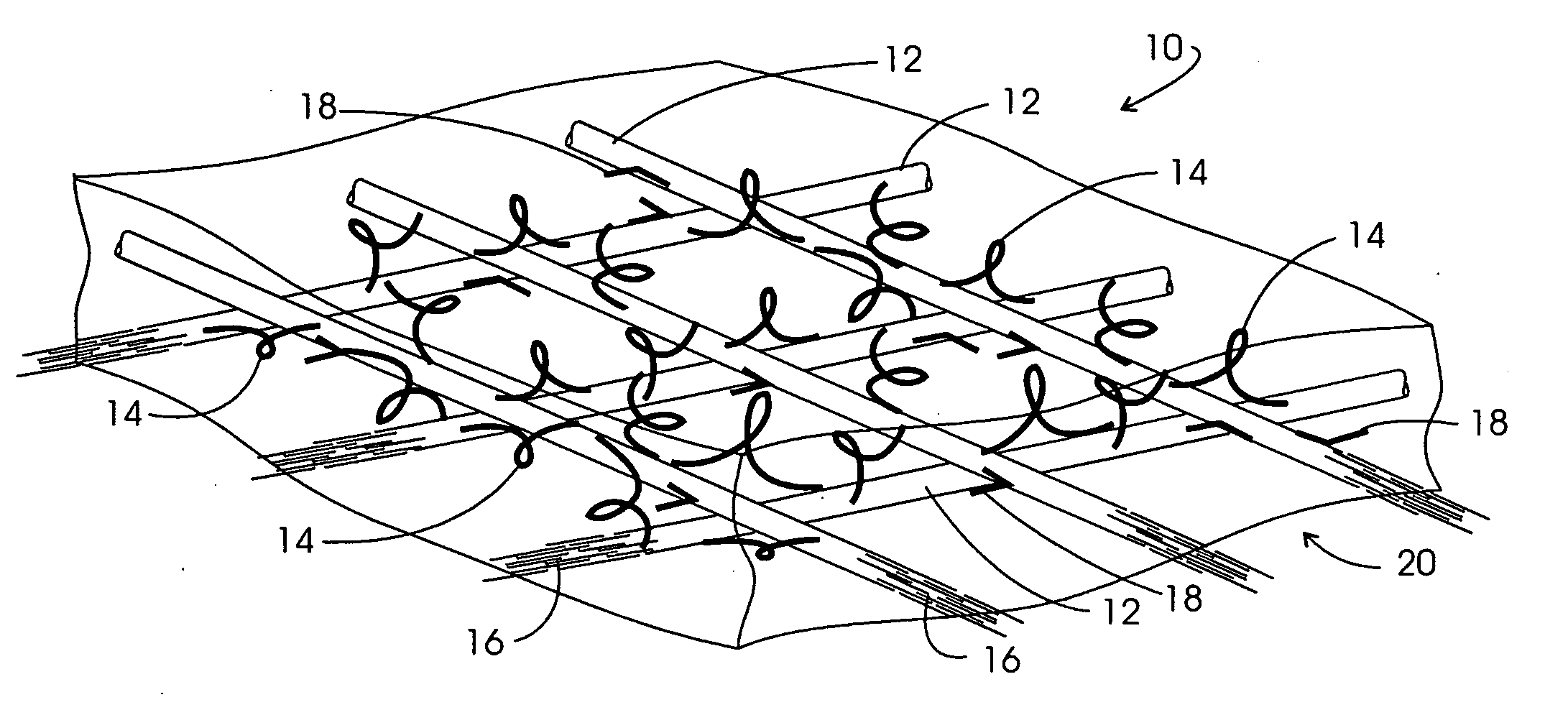

The invention discloses a flexible stretchable multi-mode sensor based on a nanofiber core spun yarn and a preparation method thereof. The flexible stretchable multi-mode sensor comprises an elastic conductive core yarn and a carbon nano tube / polymer compounded nanofiber, wherein the surface of the elastic conductive core yarn is coated with the carbon nano tube / polymer compounded nanofiber through an electrospinning technique to prepare a continuous nanofiber core spun yarn, the nanofiber core spun yarn is woven into a fabric according to a weaving principle, and the flexible stretchable multi-mode sensor based on the nanofiber core spun yarn is obtained by utilizing a flexible polymer packaging mode for the fabric; the elastic conductive core yarn is prepared by coating a carbon nano tube / polymer conductive solution to the surface of the elastic conductive core. By adopting the weaving mode and the like, an intelligent sensing unit weaves the fabric, then a novel intelligent wearableclothing is assembled, and development of a flexible intelligent wearable product is effectively promoted.

Owner:ZHONGYUAN ENGINEERING COLLEGE

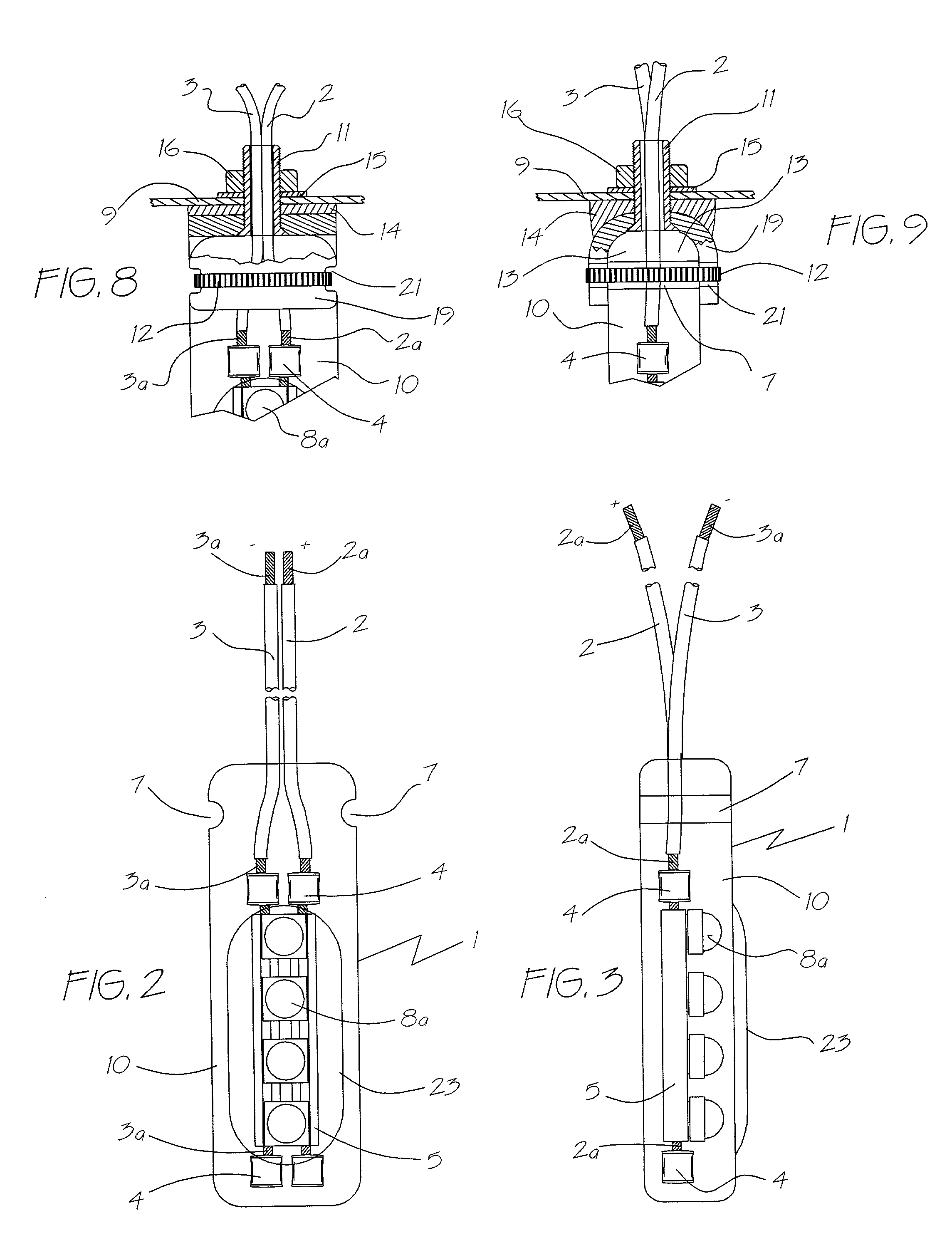

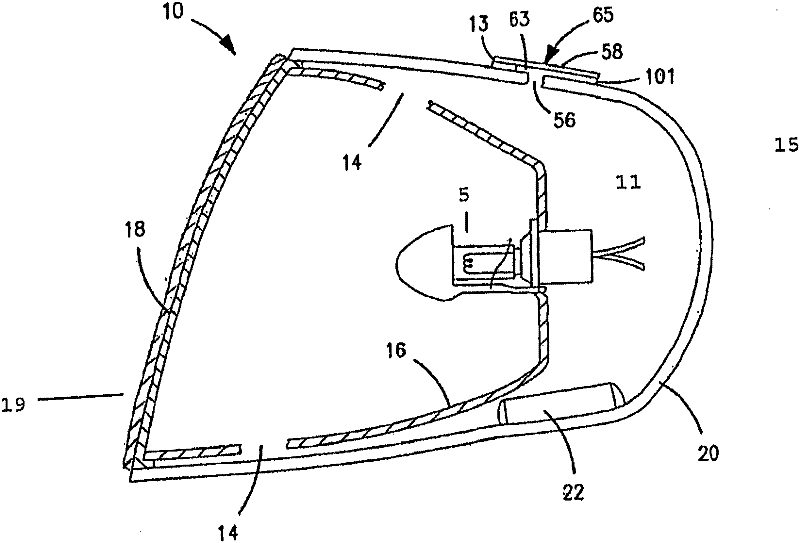

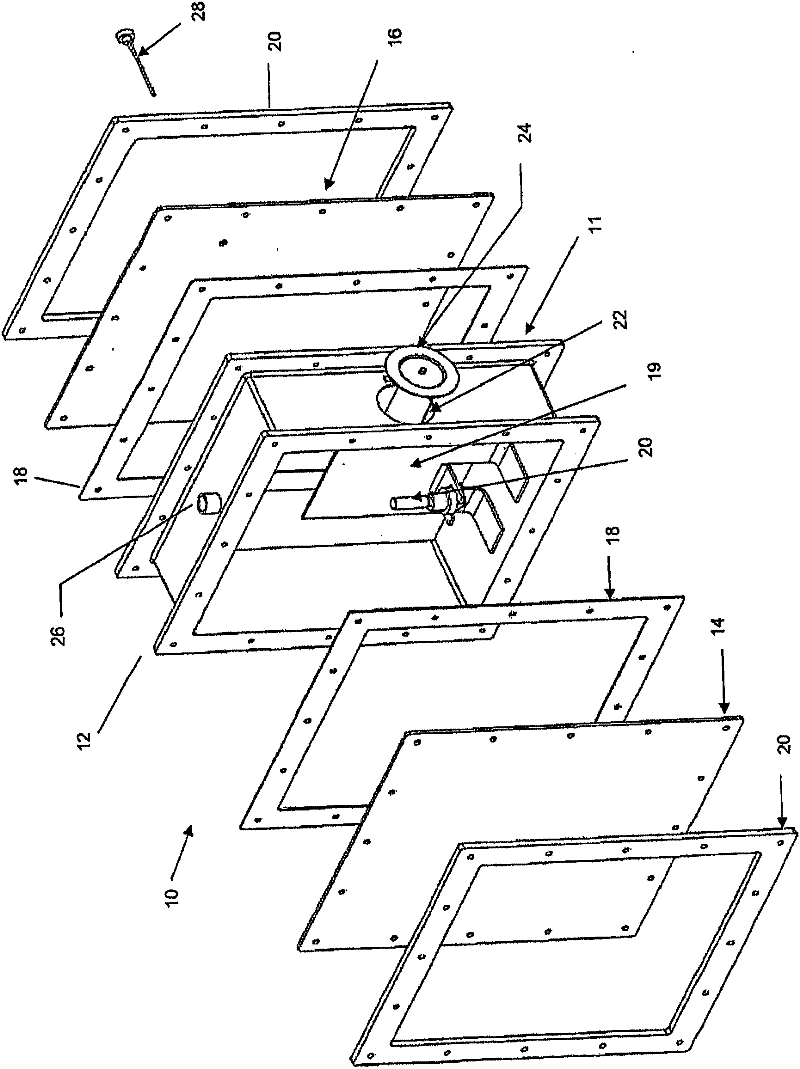

Marker light

InactiveUS20020003700A1Increasing overall marker light operational lifeReduce weightNon-electric lightingLighting support devicesPolyurethane elastomerEngineering

A flexible liquid tight marker light that comprises a light source encapsulated by injection molding a light transmitting elastomeric polymer to form a protective casing which further includes an imbedded wiring harness electrically connected to said light source and imbedded structural members that protect the light source from excessive flexing and impacts. The wiring harness and structural members provide heat sink means for the light source. The casing is comprised of variable durometer tinted polyurethane elastomers with light diffusing pigments added. Diverging optics are molded into the casing outer surface.

Owner:SELKEE TOM V

Polymer-encapsulated pigment with amphiphilic passivation layer

The present invention is drawn to pigment suspensions, methods of forming pigment suspensions, and ink sets. The pigment suspension can comprise an aqueous liquid vehicle and a polymer-encapsulated pigment suspended in the liquid vehicle. The polymer-encapsulated pigment can include a pigment core, a passivation layer formed from a passivation component including an amphiphilic polymer and deposited on a surface of the pigment core, and a polymer-encapsulation layer attached to or deposited on the passivation layer.

Owner:HEWLETT PACKARD DEV CO LP

Method of making flip-chip package with underfill

ActiveUS7700414B1Low viscositySemiconductor/solid-state device detailsSolid-state devicesDielectric substrateViscosity

A method for the manufacture of a package to encapsulate at least one integrated circuit device includes the steps of: (1) providing a dielectric substrate having a first plurality of bond pads formed on a first side thereof and at least one aperture; (2) electrically interconnecting the integrated circuit device to the plurality of bond pads forming a substrate / integrated circuit device assembly; (3) gravitationally aligning the substrate / integrated circuit assembly such that the integrated circuit device is lower than said substrate; (4) introducing a volume of a low viscosity dielectric into the at least one aperture, wherein the volume is effective to coat a surface of the integrated circuit device and substantially fill the at least one aperture; and (5) encapsulating the integrated circuit device and the first side of said substrate with a dielectric polymer.

Owner:UNISEM M BERHAD

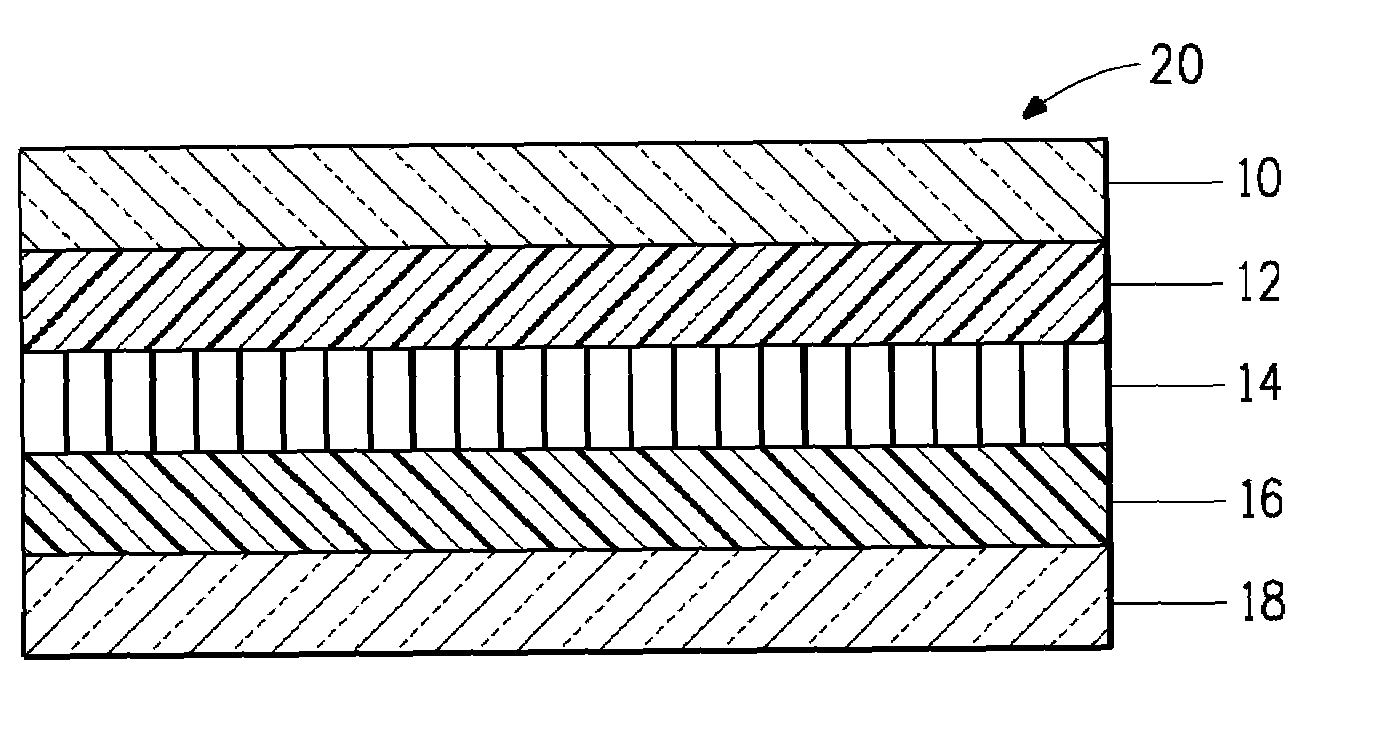

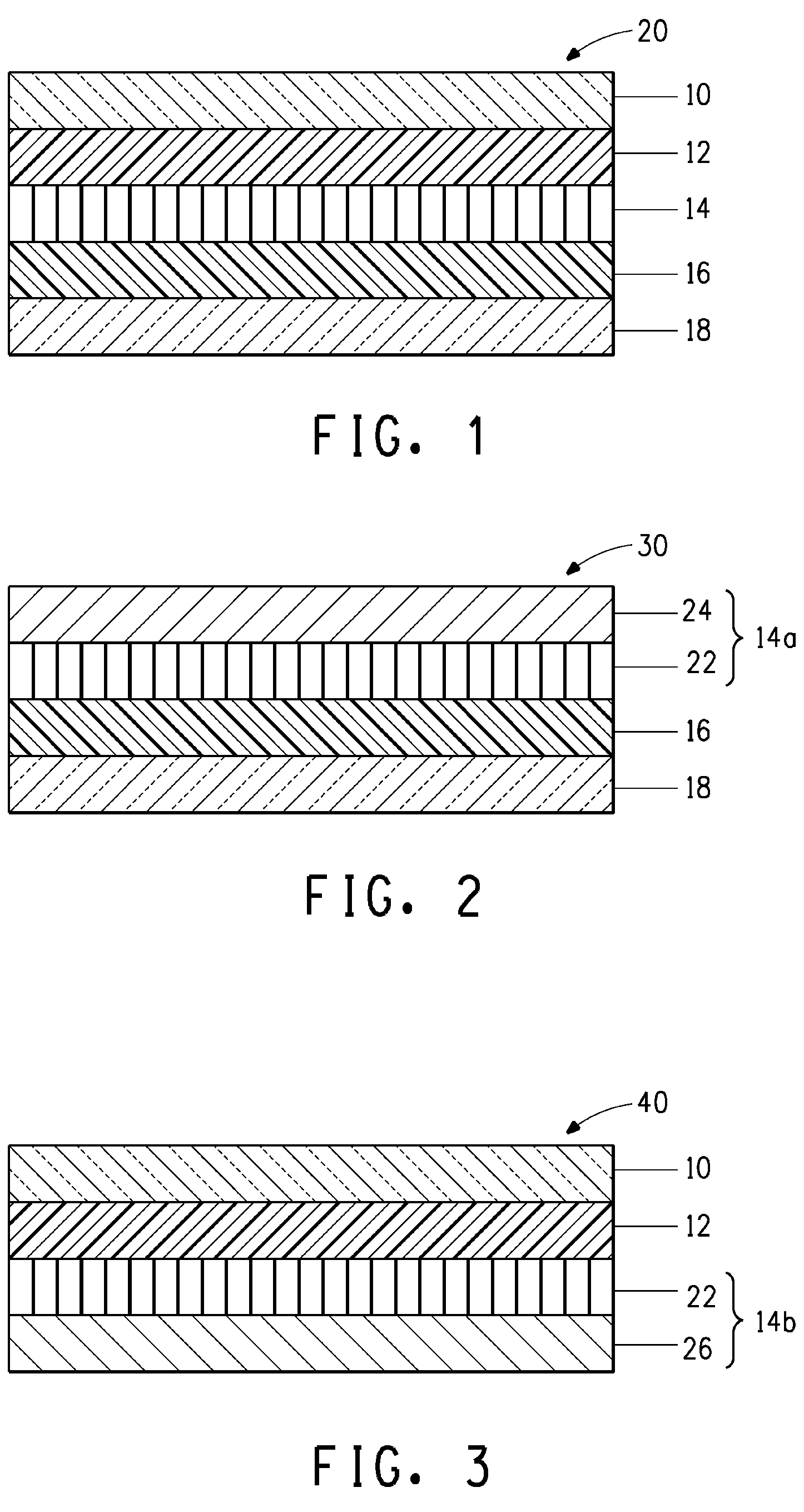

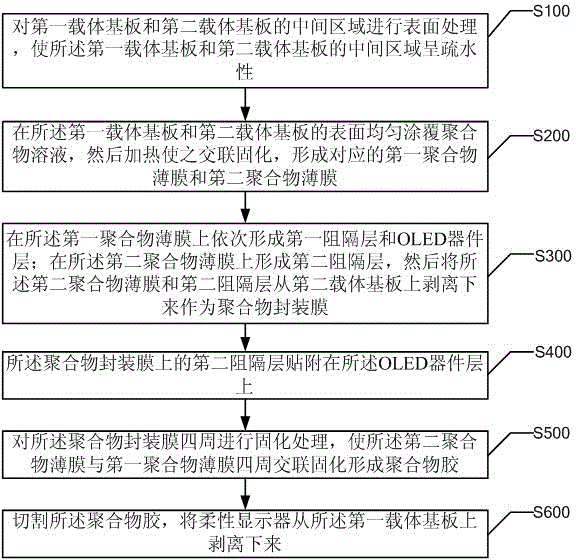

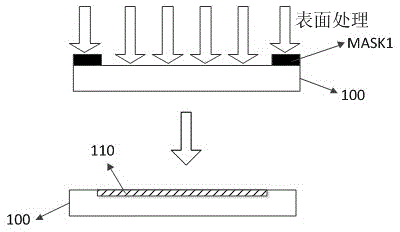

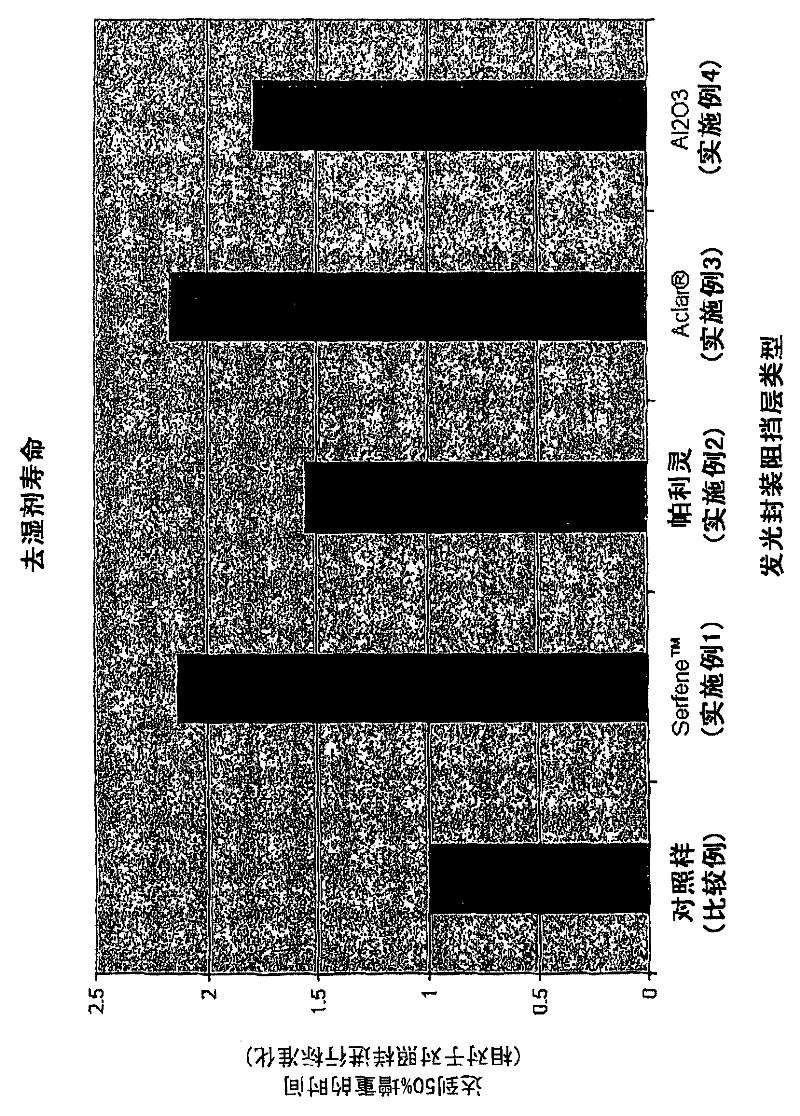

Flexible display and thin film packaging method thereof

ActiveCN105098088ASolve complexitySolve quality problemsSolid-state devicesSemiconductor/solid-state device manufacturingPolymer scienceDisplay device

The invention discloses a flexible display and a thin film packaging method thereof. The thin film packaging method comprises steps: after surface processing is carried out on a middle region between a first carrier substrate and a second carrier substrate, a polymer solution is applied uniformly, and a corresponding first polymer thin film and a second polymer thin film are formed through heating, crosslinking and curing; on the first polymer thin film, a first blocking layer and an OLED device layer are sequentially formed; a second blocking layer is formed on the second polymer thin film, the second polymer thin film and the second blocking layer are separated from the second carrier substrate to serve as a polymer packaging film; curing processing is carried out around the polymer packaging film, and thus the second polymer thin film and the first polymer thin film are crosslinked and cured around to form polymer gel; and the polymer gel is cut, and the flexible display is separated from the first carrier substrate. The thin film packaging technology is simplified, the display device can be separated from the carrier substrate easily, and a bonding agent does not need to be used.

Owner:TCL CORPORATION

Implementing carbon nanotube based sensors for cryptographic applications

InactiveUS20130232587A1Overcome disadvantagesEasy to detectMaterial nanotechnologyError detection/correctionElectrical resistance and conductanceElectricity

A method and circuit for implementing security protection with carbon nanotube based sensors for cryptographic applications, and a design structure on which the subject circuit resides are provided. A carbon nanotube layer is incorporated with a polymeric encapsulation layer of a security card. Electrical connections to the carbon nanotube layer are provided for electrical monitoring of electrical resistance of the carbon nanotube layer.

Owner:IBM CORP

Compositions and methods for producing urethane coated pigment particles

The present invention is drawn to passivated pigment suspensions, methods of forming passivated pigment suspensions, and ink sets based thereupon. The coated pigment suspension can comprise a liquid vehicle and a passivated pigment suspended in the liquid vehicle. The coated pigment can include a pigment core, on which is deposited a passivation layer comprising a polymer precursor synthesized while separate from the pigment. A polymer encapsulation layer may be attached to or deposited on the passivation layer.

Owner:HEWLETT PACKARD DEV CO LP

Polymer encapsulated dicing lane (PEDL) technology for Cu/low/ultra-low k devices

InactiveUS7160756B2Semiconductor/solid-state device detailsSolid-state devicesCopper interconnectPhotosensitive polymer

A process for packaging semiconductor devices for flip chip and wire bond applications, wherein specific materials of the semiconductor devices are protected during device processing sequences and dicing procedures, has been developed. After definition of copper interconnect structures surrounded by a low k insulator layer, a protective, first photosensitive polymer layer comprised with a low dielectric constant is applied. After definition of openings in the first photosensitive polymer layer exposing portions of the top surface of the copper interconnect structures, a dicing lane opening is defined in materials located between copper interconnect structures. Conductive redistribution shapes are formed on the copper interconnect structures exposed in the openings in the first photosensitive polymer layer, followed by application of a protective, second photosensitive polymer layer. An opening is defined in the second photosensitive polymer layer exposing a portion of the top surface of a redistribution shape followed by placement of a solder ball in this opening. A reflow anneal procedure results in the solder ball wetting and overlying only the portion of the redistribution shape exposed in the opening in the second photosensitive polymer layer. Separation of the solder ball, flip chip regions from the non-solder ball, wire bond regions is accomplished via a dicing procedure performed in the dicing lane.

Owner:AGENCY FOR SCI TECH & RES

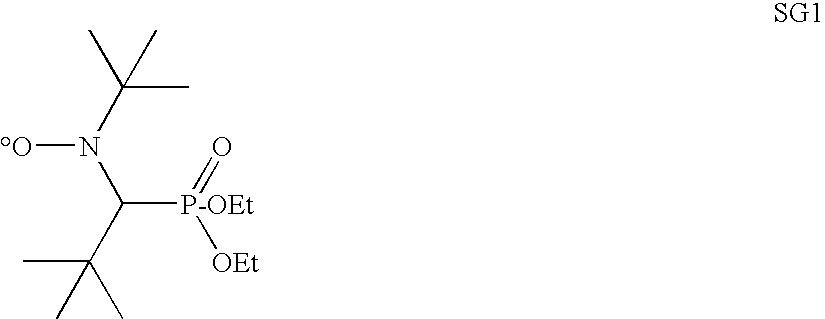

Polymer encapsulation and/or binding

ActiveUS20100010103A1Easy to controlImprove encapsulationCosmetic preparationsToilet preparationsPolymer chemistryBioactive molecules

Encapsulation of and binding to pegylated bioactive molecules via functionalized comb, block, branched type polymers formed by nitroxide mediated controlled radical polymerization is disclosed.

Owner:ARKEMA INC

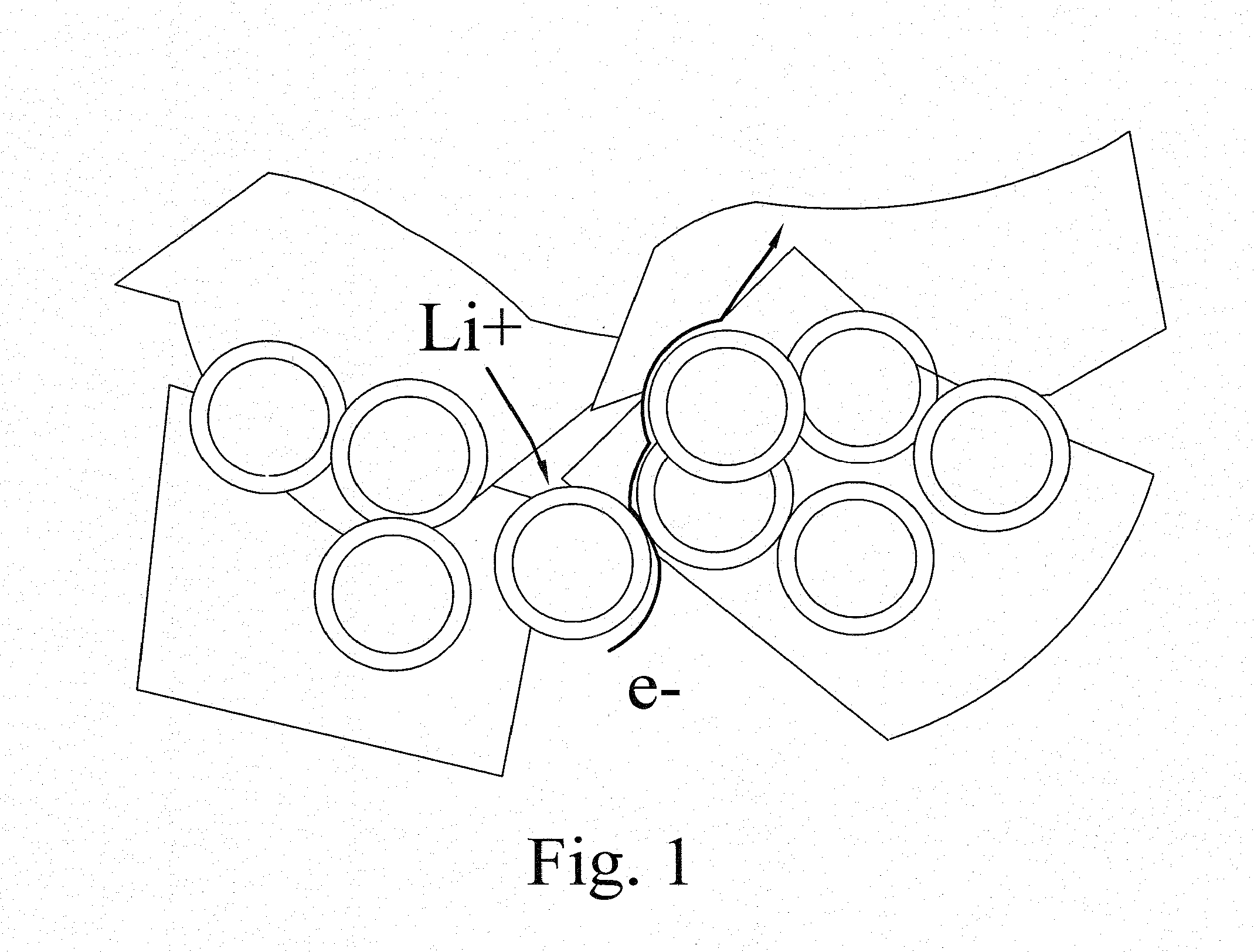

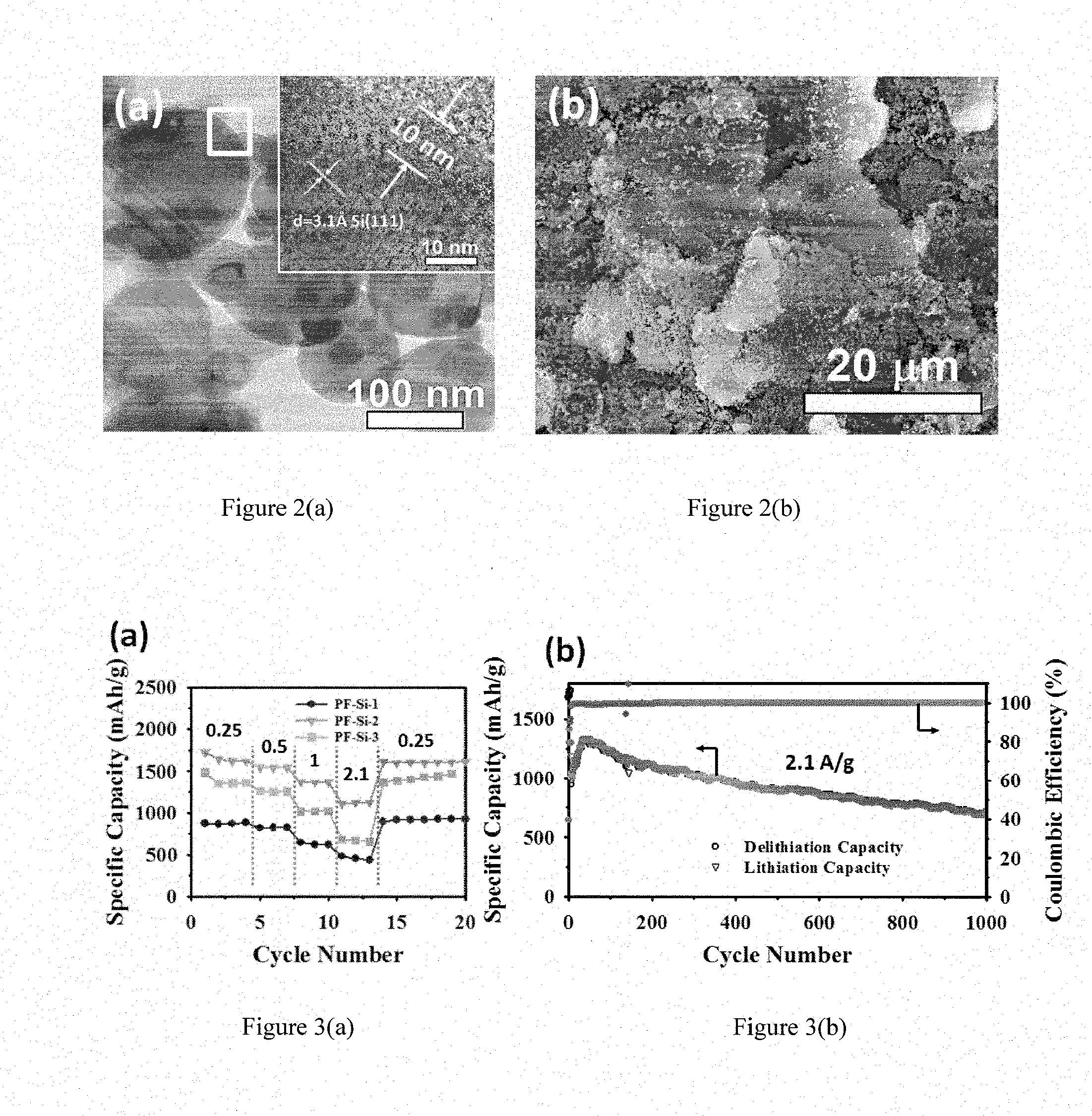

Silicon and graphene-incorporated rechargeable li-ion batteries with enhanced energy delivery and cycling life by using silecon and graphene based anode for energy storage

InactiveUS20150295227A1Prolong lifeSuperior rate capabilityOrganic electrolyte cellsSolid electrolyte cellsCarbonizationLithium-ion battery

A silicon graphene-incorporated rechargeable Li-ion battery with enhanced energy delivery and cycling life comprising a high-performance Si / graphene composite anode, a cathode film and electrolyte is disclosed. The anode and cathode are immersed in or partially immersed in the electrolyte; wherein the anode is formed of a mixture of carbon coated Si and graphene composite with a polymer binder and a conductive additive. A method for fabricating such Si and graphene-based anode comprises the steps synthesis of carbon coated Si particles by polymer encapsulation and carbonization; enveloping the coated Si particles in graphene by mechanical agitation; formulating the carbon coated Si and graphene with a polymer binder and conductive additive; depositing the mixture onto current collectors. The anode structure affords a combination of superior rate capability, cycling life and improved volumetric capacity.

Owner:BLUESTONE GLOBAL TECH

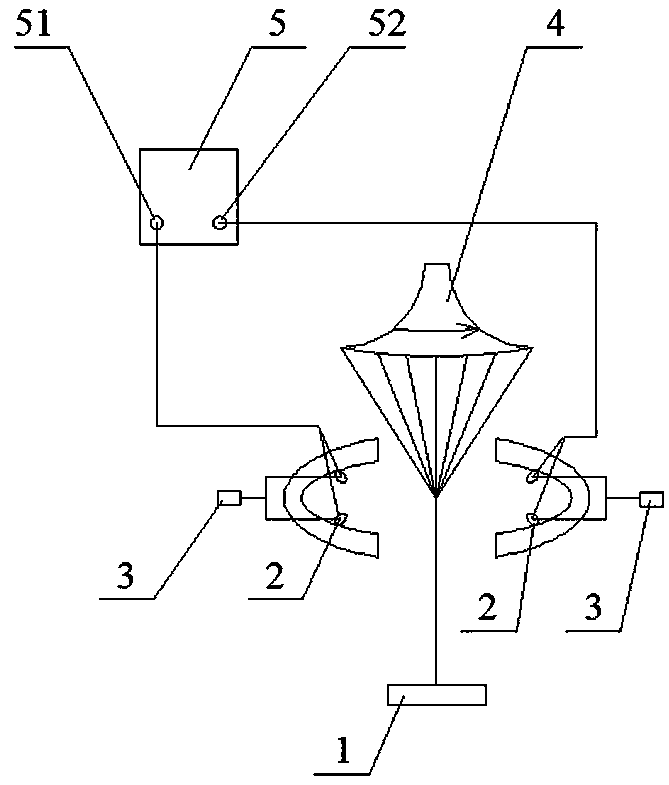

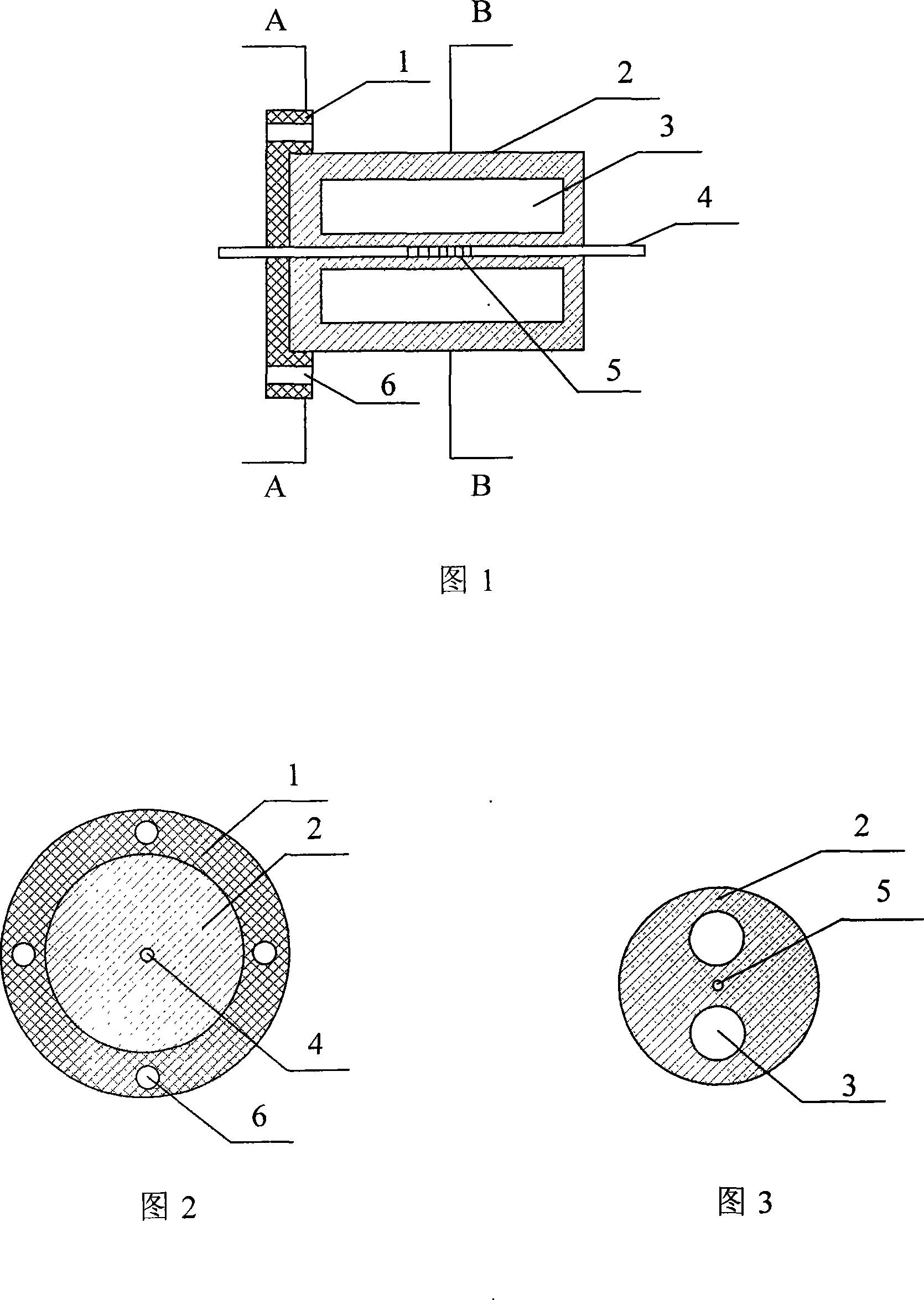

Passive optical fiber grating submarine sound signal sensor and making method thereof

InactiveCN101118176ABroaden the field of applicationExpand the scope ofSubsonic/sonic/ultrasonic wave measurementUsing wave/particle radiation meansMolten stateGrating

The present invention relates to a passive optical fiber grating underwater acoustic signal sensor and a manufacture method. Two cavity bodies being distributed by the central symmetrical way is arranged inside a polymer encapsulation body, the both ends of the cavity body are sealed, and an optical fiber grating is threaded through and fixed at the axle line position of the polymer encapsulation body. The polymer encapsulation body is a columnar body, the cross section of the cavity body can be circular, elliptic, quadrate or D-shaped. The manufacturing method is that firstly, a die is made according to the structure of the polymer encapsulation body, an optical fiber grating is fixed into the die, and then a polymer is heated to be the molten state and slowly poured into the die, finally the optical fiber grating polymer encapsulation body is arranged into a warm box to be solidified and aged. The present invention is characterized in that the sensitivity of the acoustic pressure is high, the passive optical fiber grating underwater acoustic signal sensor is three to four magnitude orders higher than the underwater acoustic sensor directly made of optical fiber grating, the characteristics of light mass, small structure, and high sensitivity are fully realized, thus the present invention has important application prospect in the underwater acoustic detection field.

Owner:李智忠

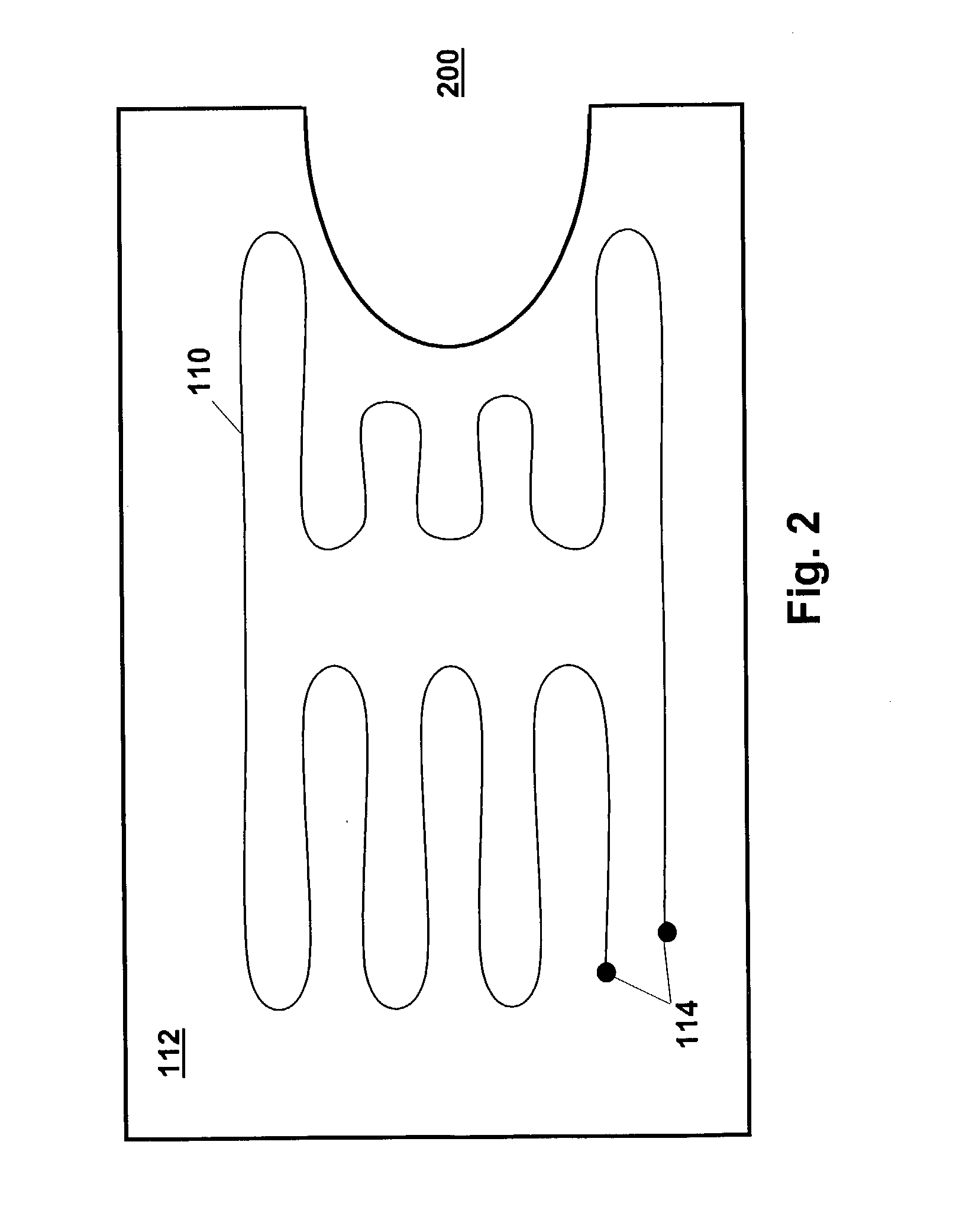

Structure and method for thin single or multichip semiconductor QFN packages

InactiveUS20070132075A1Easy to controlImprove reliabilitySemiconductor/solid-state device detailsSolid-state devicesContact padSemiconductor chip

A semiconductor device (100) has one or more semiconductor chips (110) with active and passive surfaces, wherein the active surfaces include contact pads. The device further has a plurality of metal segments (111) separated from the chip by gaps (120); the segments have first and second surfaces, wherein the second surfaces (111b) are coplanar (130) with the passive chip surface (101b). Conductive connectors span from the chip contact pads to the respective first segment surface. Polymeric encapsulation compound (150) covers the active chip surface, the connectors, and the first segment surfaces, and are filling the gaps so that the compound forms surfaces coplanar (130) with the passive chip surface and the second segment surfaces. In this structure, the device thickness may be only about 250 μm. Reflow metals may be on the passive chip surface and the second segment surfaces.

Owner:TEXAS INSTR INC

Low cost lead-free preplated leadframe having improved adhesion and solderability

ActiveUS20080224290A1Low costNo risk of growthSemiconductor/solid-state device detailsSolid-state devicesSolderabilityWhiskers

A leadframe with a structure made of a base metal (105), wherein the structure has a plurality of surfaces. On each of these surfaces are metal layers in a stack adherent to the base metal. The stack comprises a nickel layer (201) in contact with the base metal, a palladium layer (202) in contact with the nickel layer, and an outermost tin layer (203) in contact with the palladium layer. In terms of preferred layer thicknesses, the nickel layer is between about 0.5 and 2.0 μm thick, the palladium layer between about 5 and 150 nm thick, and the tin layer less than about 5 nm thick, preferably about 3 nm. At this thinness, the tin has no capability of forming whiskers, but offers superb adhesion to polymeric encapsulation materials, improved characteristics for reliable stitch bonding as well as affinity to reflow metals (solders).

Owner:TEXAS INSTR INC

Process for oxidizing organic compounds

InactiveUS20070142651A1Improve productivityLoss of useOrganic chemistryBulk chemical productionSimple Organic CompoundsProduction rate

This invention is a process for oxidizing an organic compound with a hydrogen peroxide solution produced by reacting hydrogen and oxygen in the presence of an oxidation catalyst. The hydrogen peroxide is produced by reacting hydrogen and oxygen in a solvent in the presence of a H2O2-producing catalyst comprising a polymer-encapsulated combination of a noble metal and an ion-exchange resin. Polymer encapsulation of the H2O2-producing catalyst improves its productivity in making hydrogen peroxide and is expected to reduce metal loss.

Owner:LYONDELL CHEM TECH LP

Plane substrate packed polymer composition and its application

InactiveCN1514246AHigh activityMinimize non-specific binding activityMicrobiological testing/measurementMaterial analysisPolymer scienceHigh activity

The present invention relates to an encapsulation composition for encapsulating plane substrate, a polymer encapsulating chip base, a reactor containing polymer encapsulation and a device including the reactor especially chip device. The encapsulation polymer provided by the present invention consists of surface activated agent of high polymer and optimization substituted polymer which have enough high activity of combination genin and minimizing activity of non-specific combination.

Owner:CHENGDU KUACHANG SCI & TECH CO LTD

Angle unbiased color display material based on photonic crystal microspheres

The invention discloses an angle unbiased color display material based on photonic crystal microspheres, which comprises three-dimensional photonic crystal microspheres, a polymer and a flexible transparent material, wherein the three-dimensional photonic crystal microspheres are fixed in the polymer; the polymer is packaged in the flexible transparent material; and the diameter of each photonic crystal microsphere is 22-1001 micrometers. With the adoption of the mode, angle unbiased display is achieved, and the characteristics of high reflectivity, bright color and the like of a photonic crystal are kept simultaneously, so that a photonic crystal display technology has an important application value.

Owner:SOUTHEAST UNIV

Moisture resistant coatings for polymeric enclosures

InactiveCN102395830AVehicle headlampsGas-tight/water-tight arrangementsInterior spaceMoisture permeation

A moisture resistant housing assembly is provided, the housing defining an internal space and an ambient space surrounding said internal space, the housing constructed at least partially of a polymeric material and a moisture barrier layer covering a portion of the polymeric material, the moisture barrier layer having a moisture permeation coefficient that is lower than the moisture permeation coefficient of the polymeric material.

Owner:GORE ENTERPRISE HLDG INC

Polymer-encapsulated pigment with passivation layer

The present invention is drawn to pigment suspensions, methods of forming pigment suspensions, and ink sets. The pigment suspension can comprise a liquid vehicle and a polymer-encapsulated pigment suspended in the liquid vehicle. The polymer-encapsulated pigment can include a pigment core, a passivation layer of an alkoxy metal deposited on a surface of the pigment core, and a polymer encapsulation layer attached to or deposited on the passivation layer.

Owner:HEWLETT PACKARD DEV CO LP

Polymer-encapsulated pigment with bridging layer

ActiveUS7608646B1Synthetic resin layered productsCellulosic plastic layered productsPigmentAnalytical chemistry

The present invention is drawn to pigment suspensions, methods of forming pigment suspensions, and ink sets. The pigment suspension can comprise an aqueous liquid vehicle and a polymer-encapsulated pigment suspended in the liquid vehicle. The polymer-encapsulated pigment can include a pigment core, a bridging layer deposited on a surface of the pigment core, and a polymer encapsulation layer attached to or deposited on the bridging layer.

Owner:HEWLETT PACKARD DEV CO LP

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com