Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

265 results about "Oxidised cellulose" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Oxidized cellulose may contain carboxylic acid, aldehyde, and/or ketone groups, in addition to the original hydroxyl groups of the starting material, cellulose, depending on the nature of the oxidant and reaction conditions. It is an antihemorrhagic.

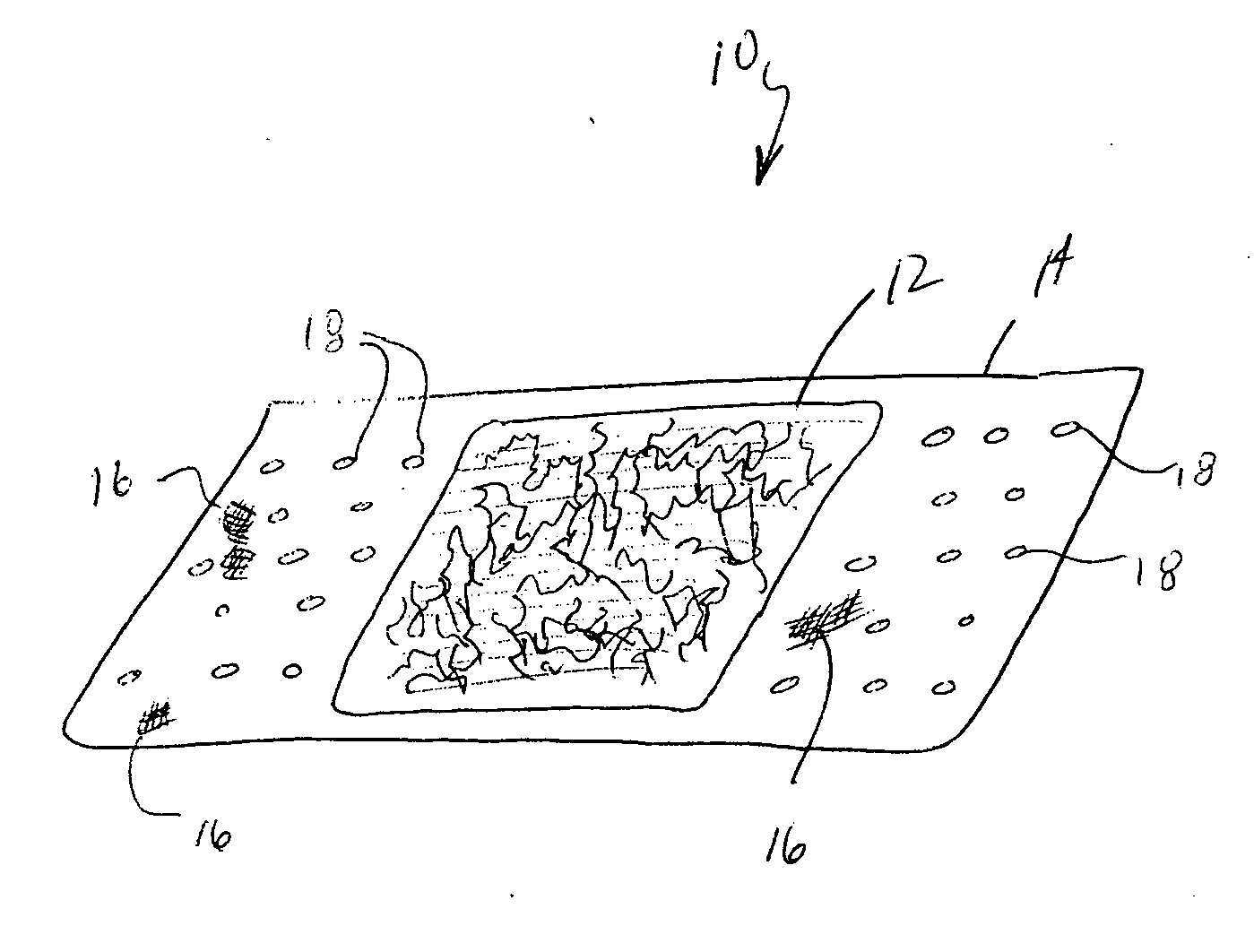

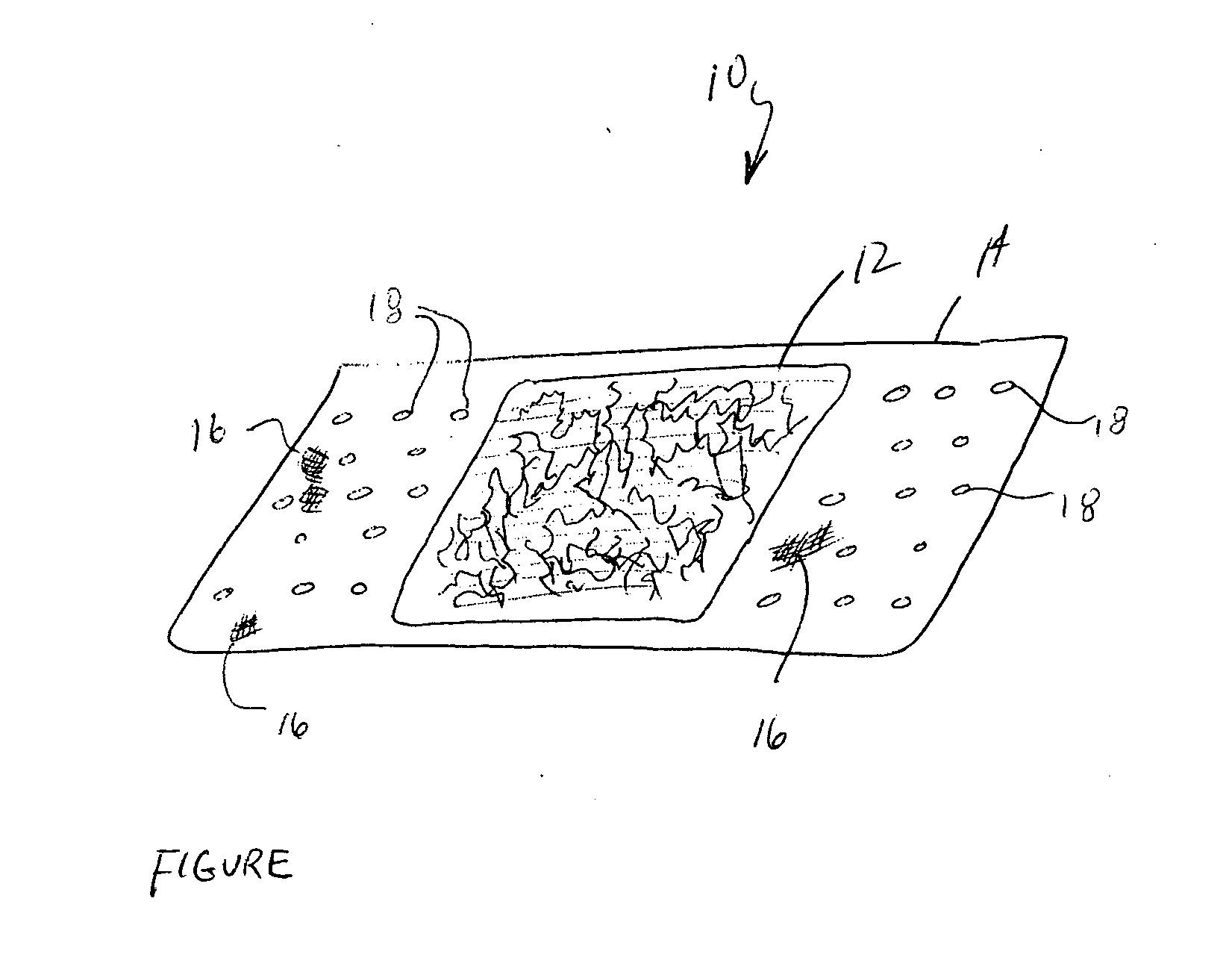

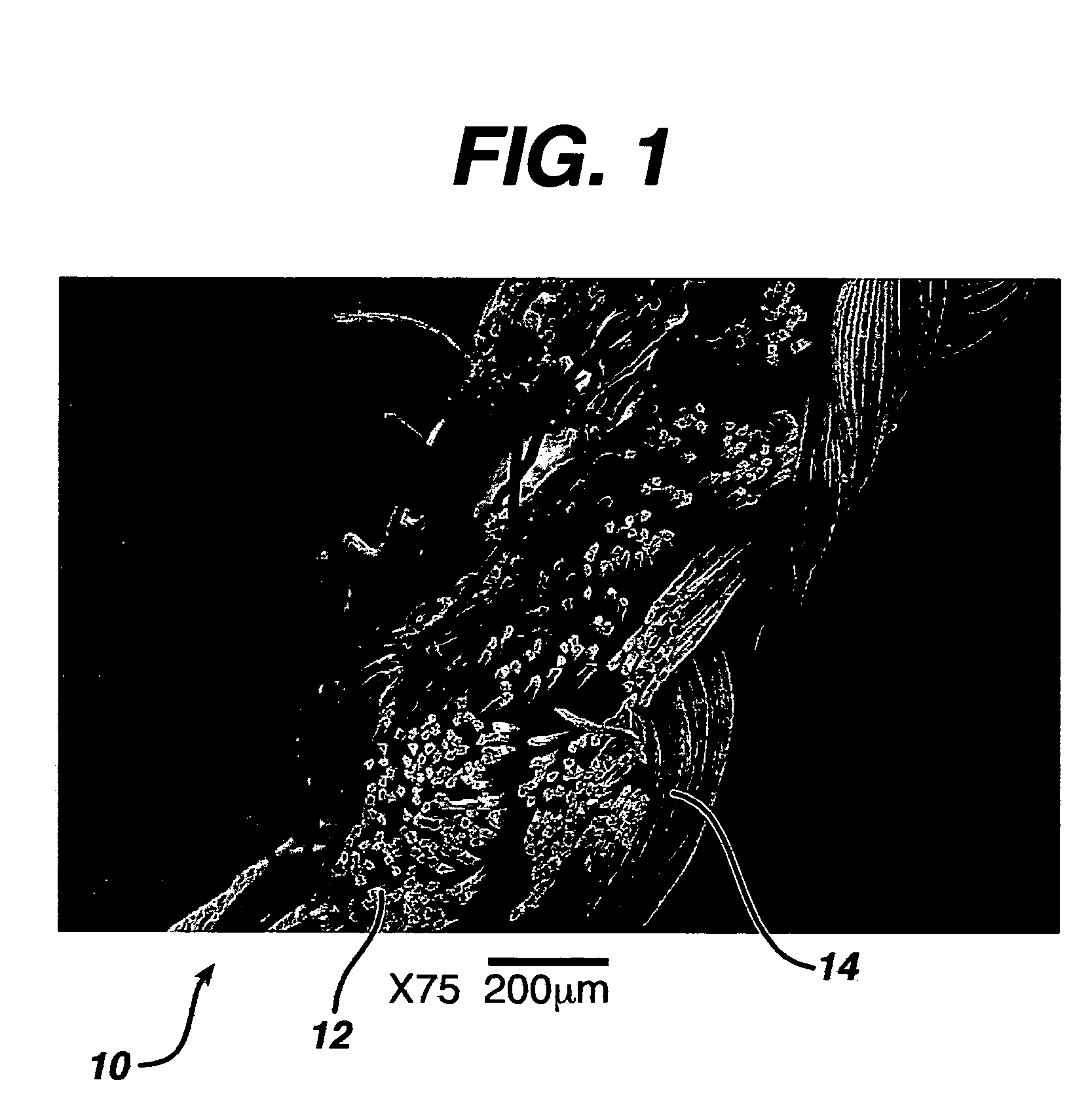

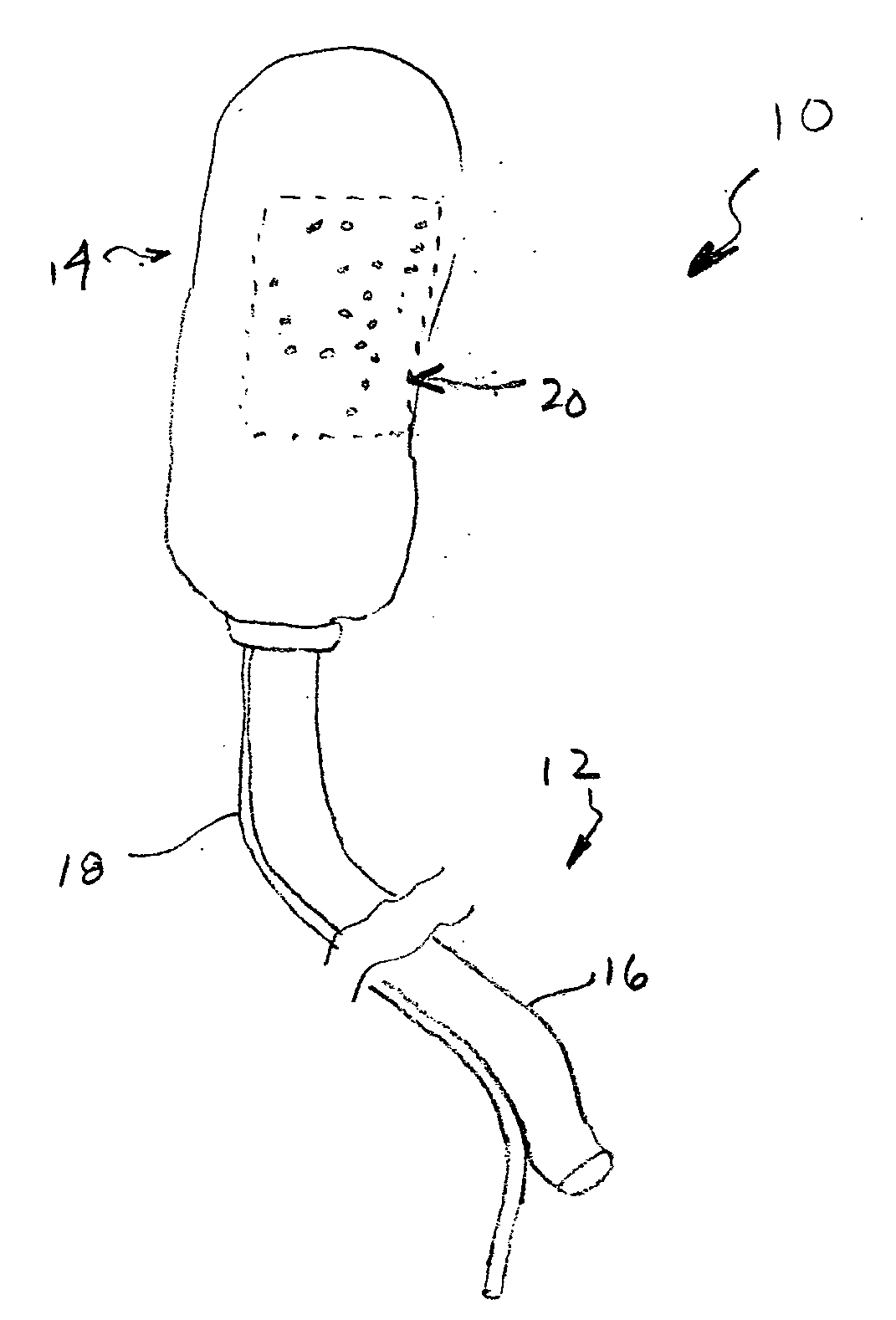

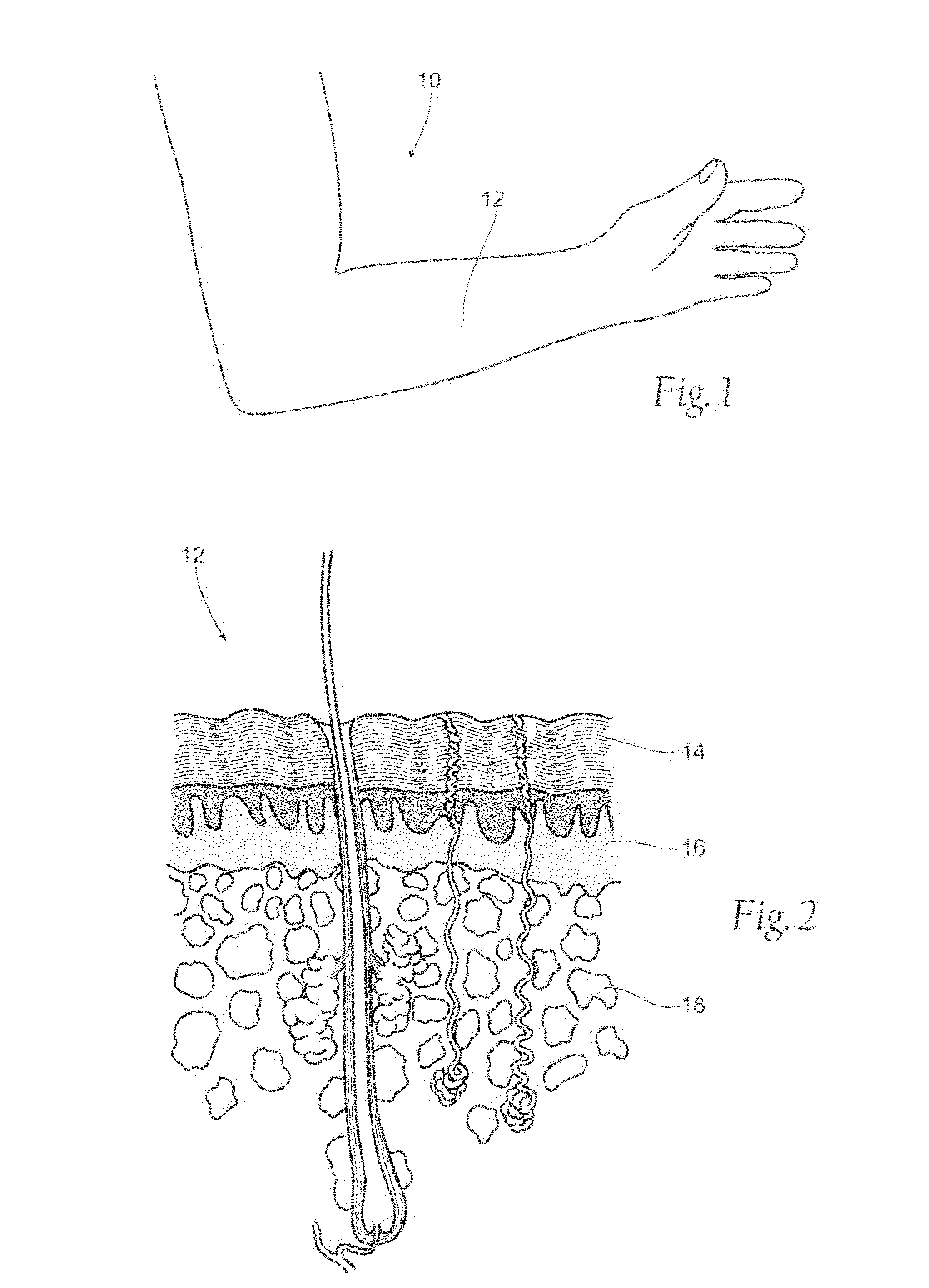

Agents and devices for providing blood clotting functions to wounds

InactiveUS20070190110A1Promote healingShorten the timePhysical treatmentAntithrombogenic treatmentNitrogen dioxideMedicine

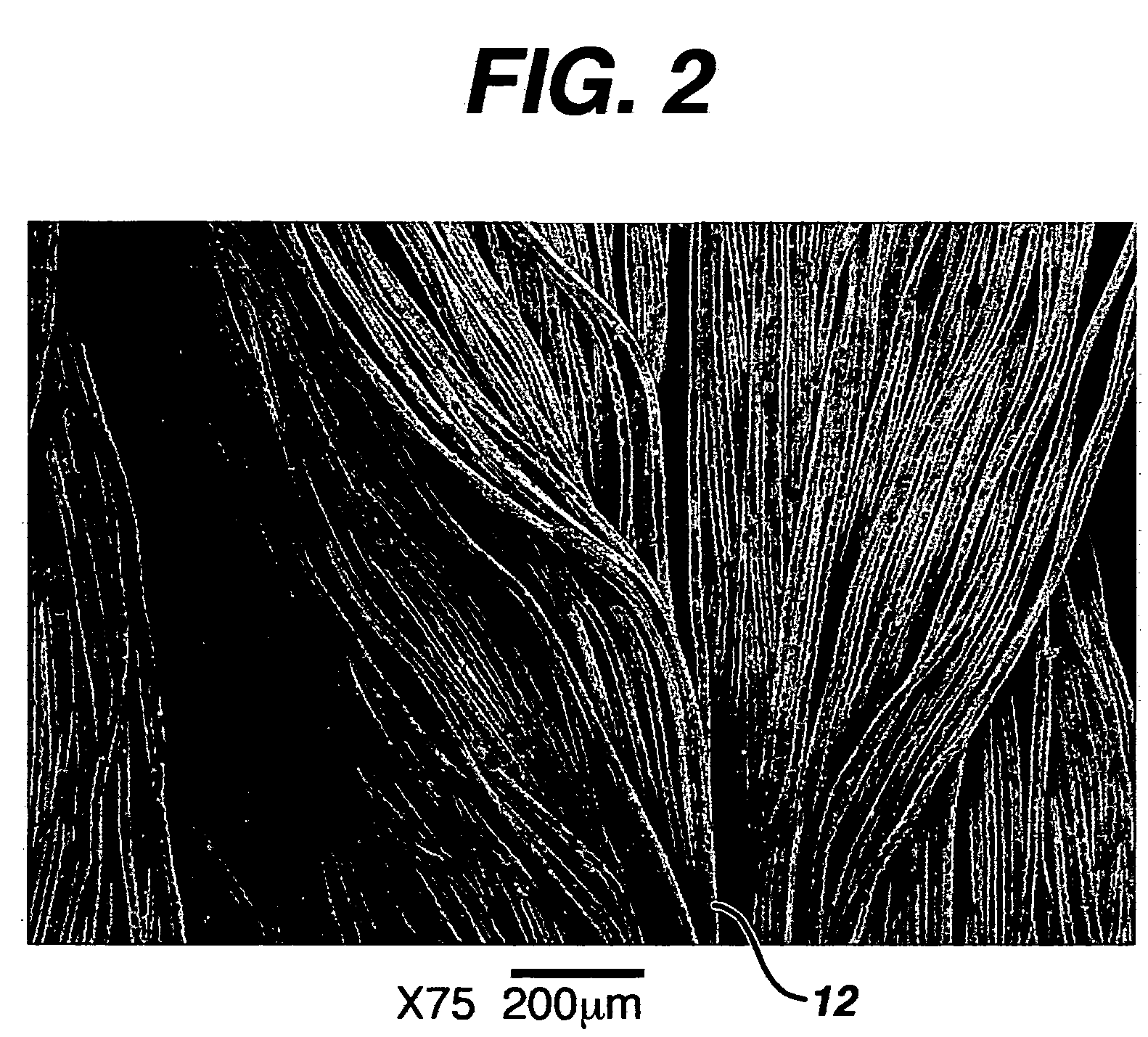

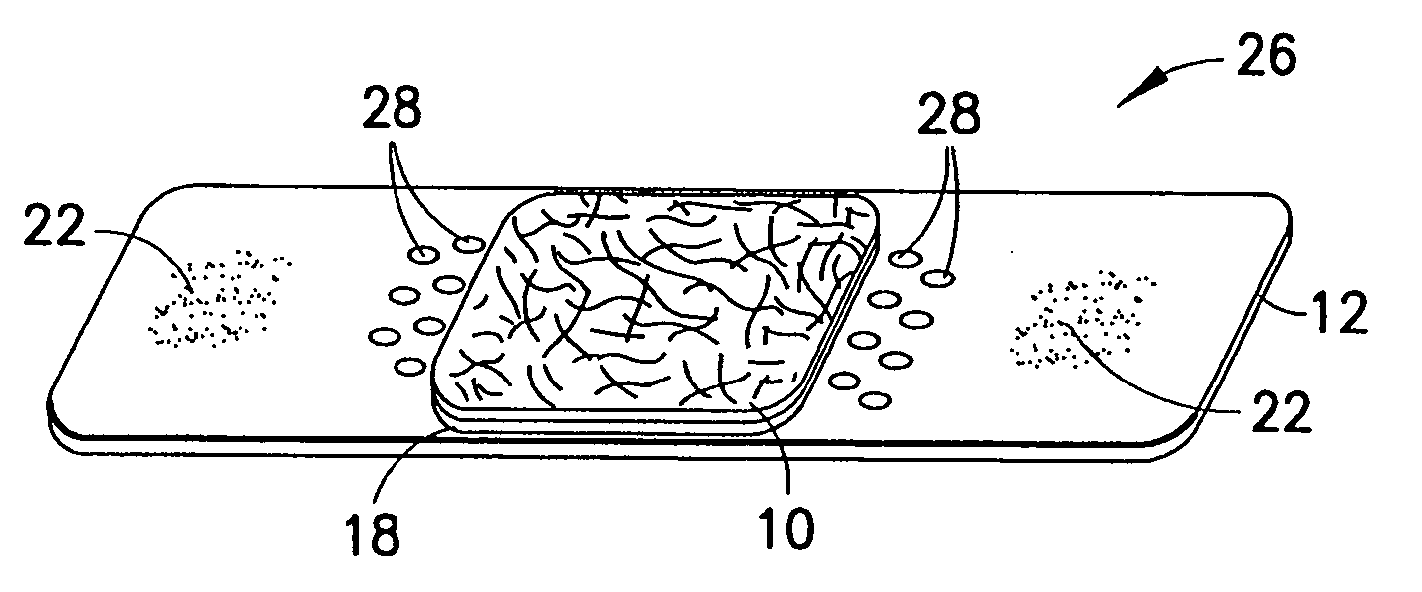

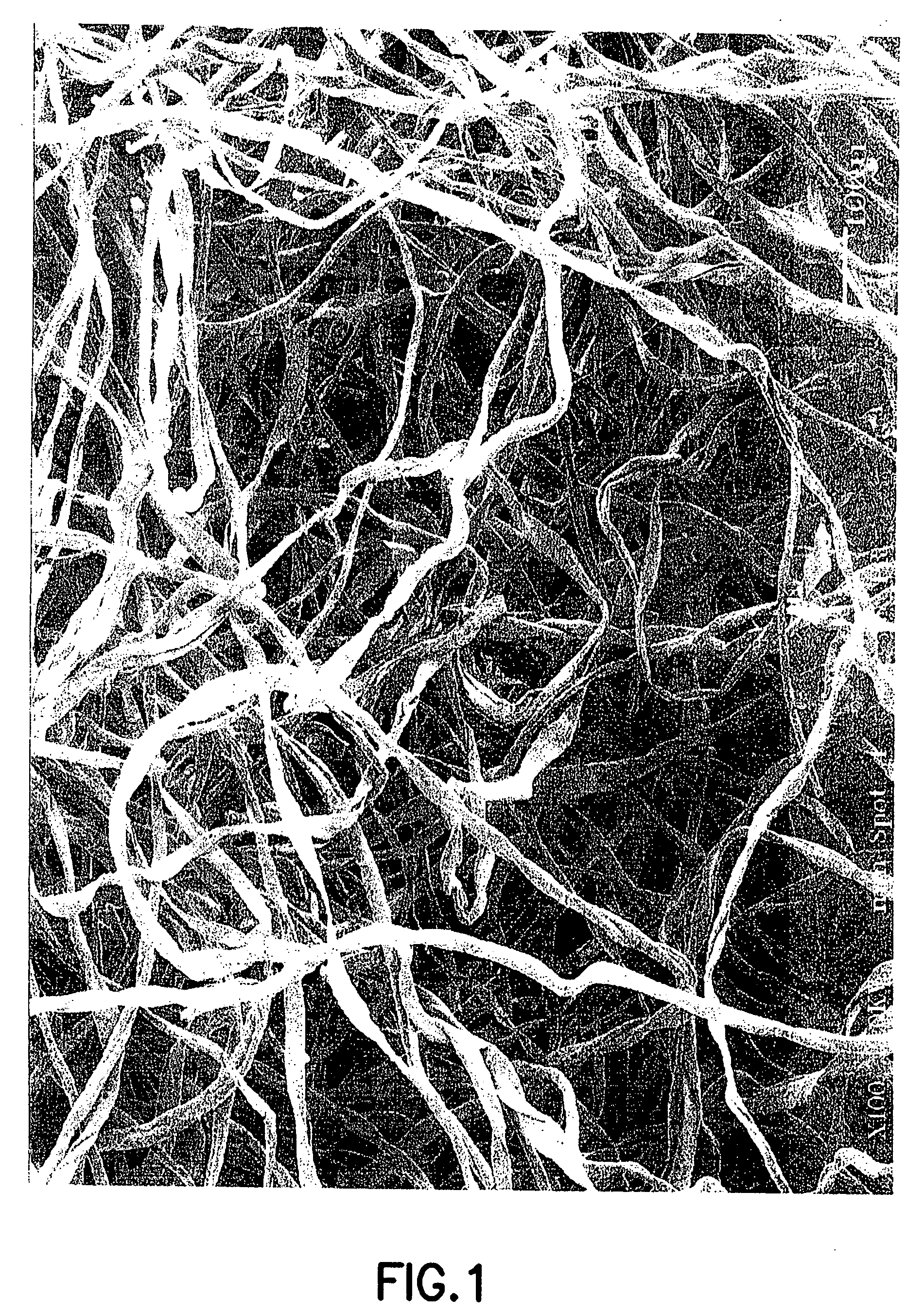

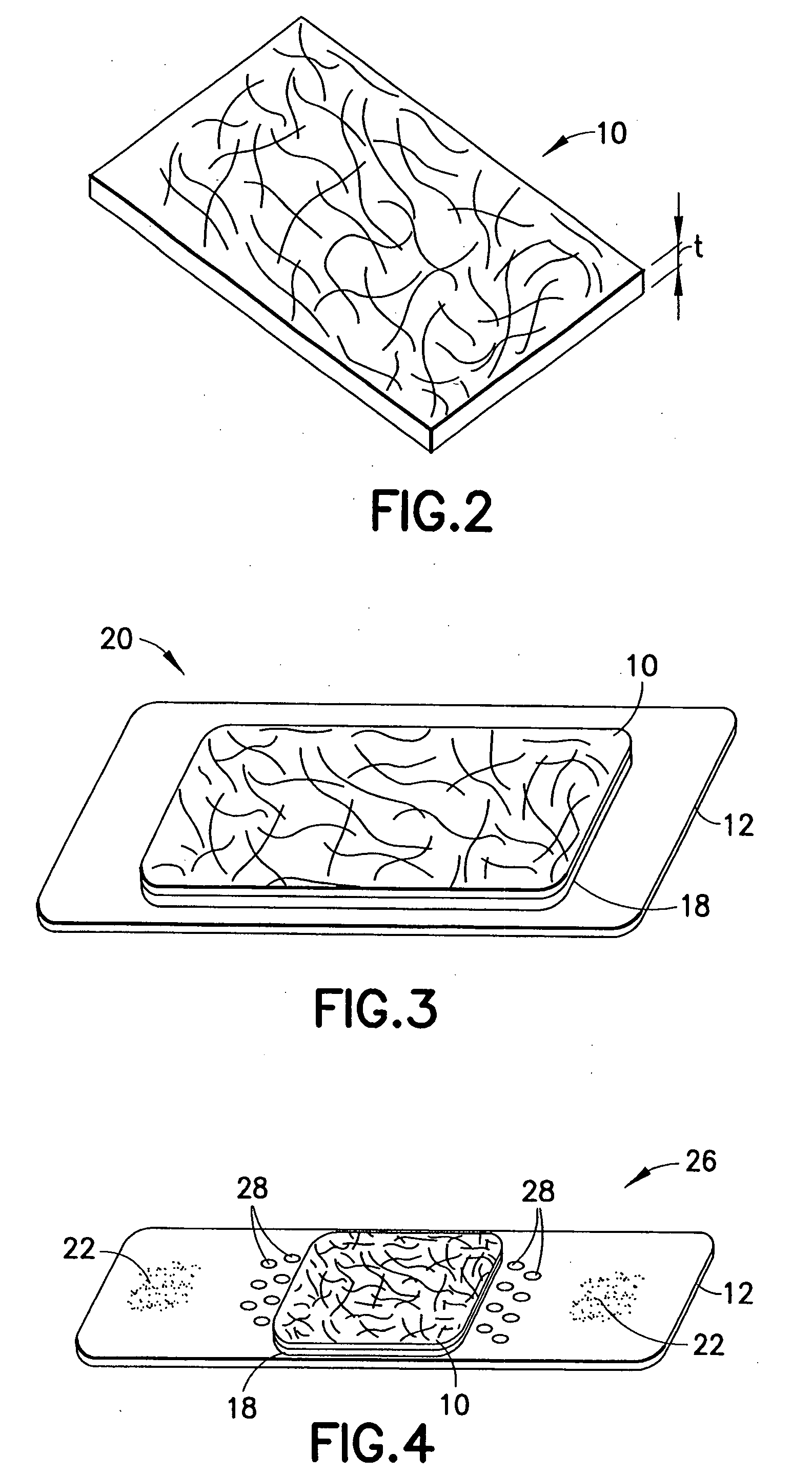

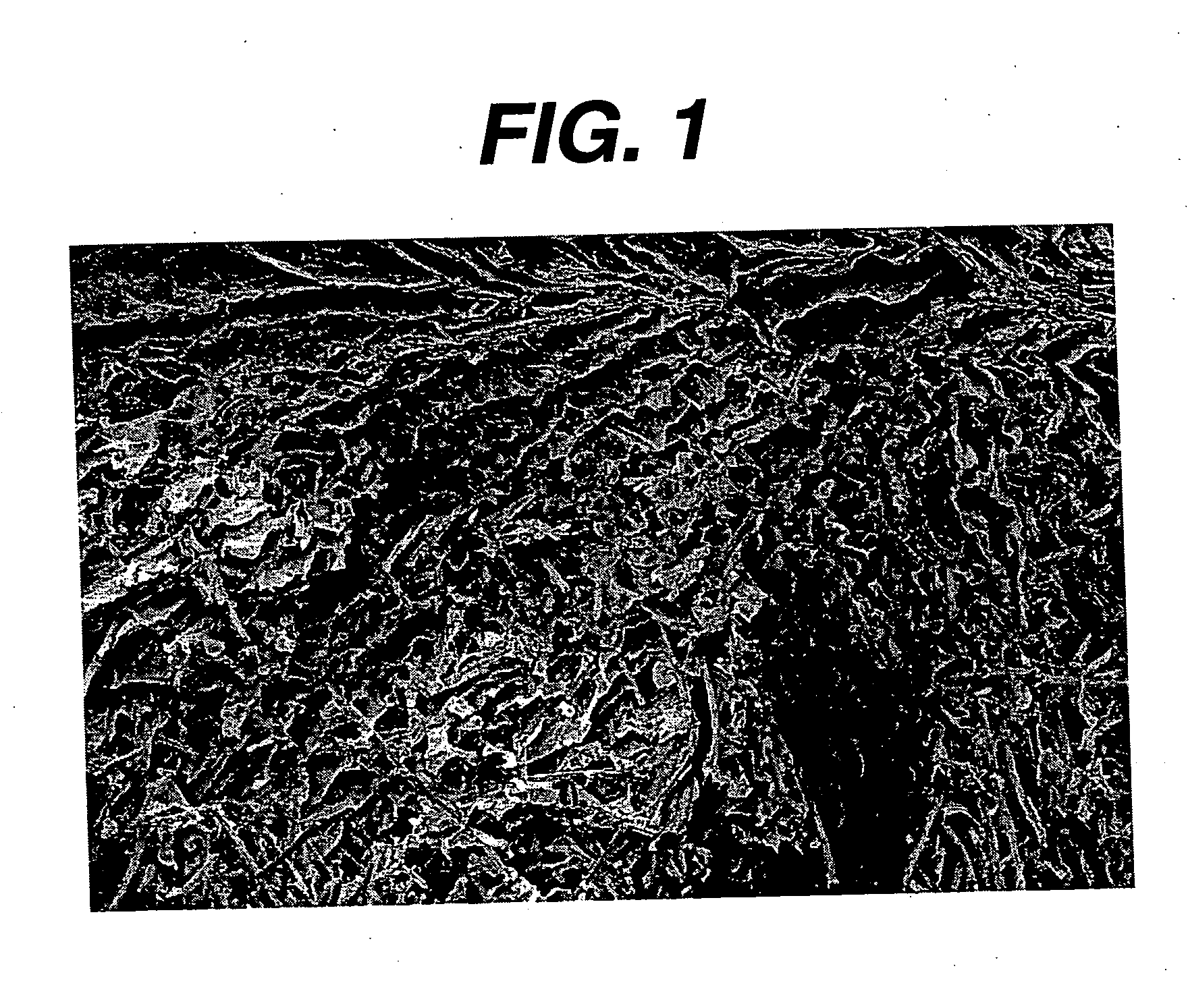

Hemostatic agents and devices are made from oxidized cellulose fiber, the oxidized cellulose having a carboxylation content increased by the action of nitrogen dioxide on virgin cellulose fiber. A composition may be incorporated into the oxidized cellulose fiber to cause a pharmacological effect on a wound to which the hemostatic agents and devices are applied. When applied, the oxidized cellulose fiber causes blood emanating from the wound to clot. The oxidized cellulose fiber can either be resorbed into the wound or removed from the wound after healing. A hemostatic bandage includes a pad of unwoven oxidized cellulose fibers mounted on a substrate. Methods of arresting a flow of blood emanating from a wound using such devices are also disclosed. Methods of fabricating oxidized cellulose are also disclosed.

Owner:PAMEIJER CORNELIS H +1

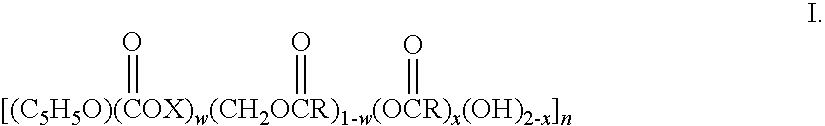

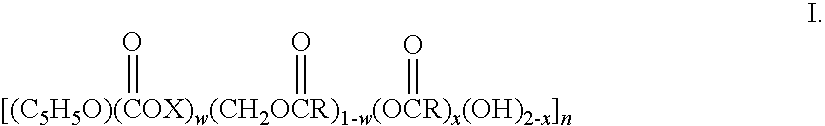

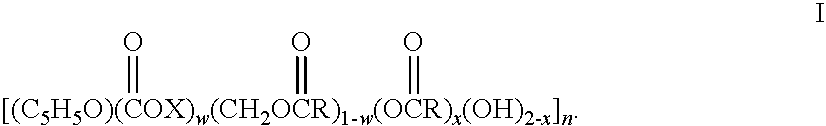

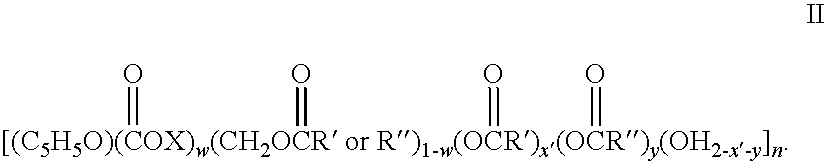

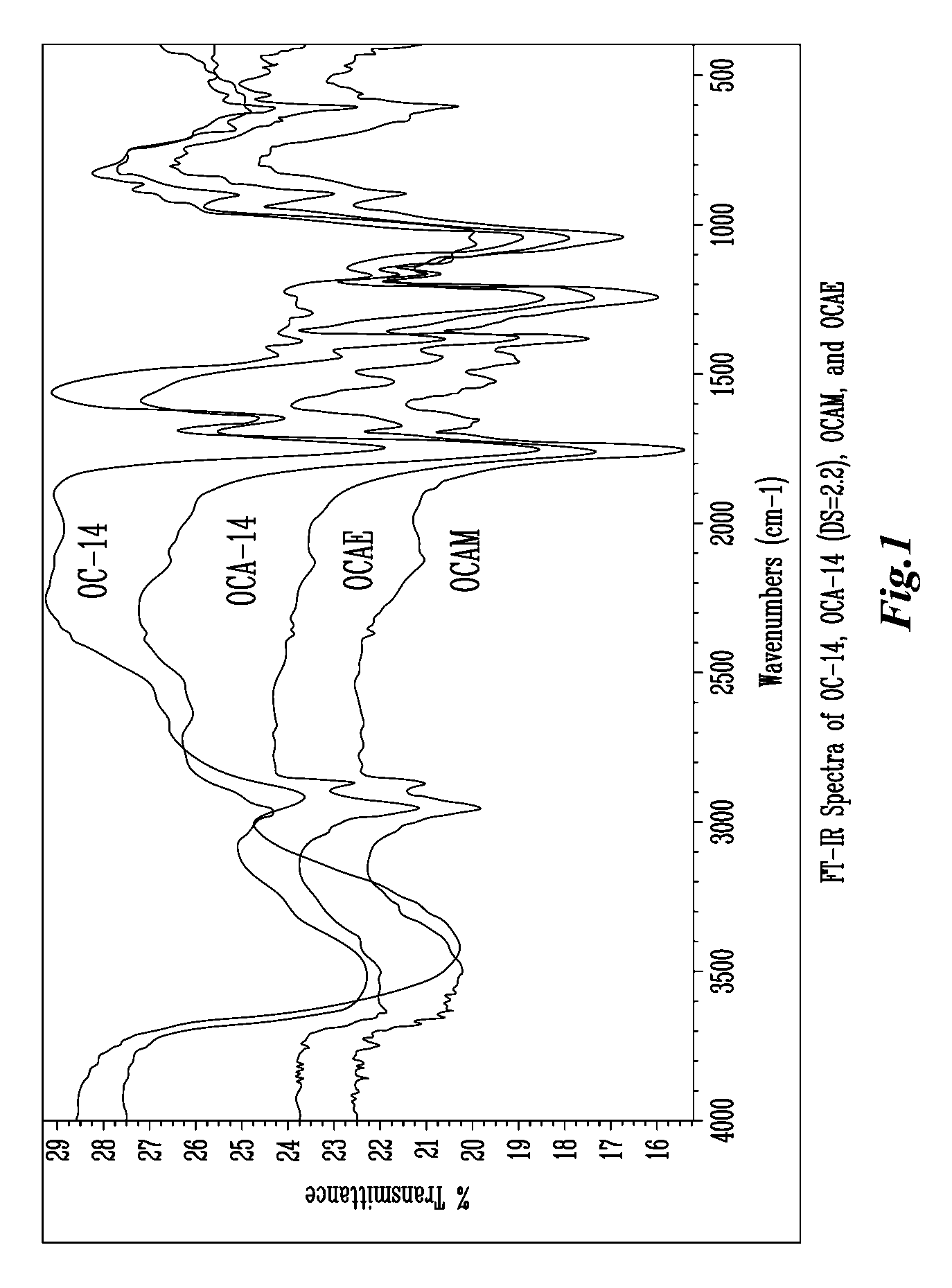

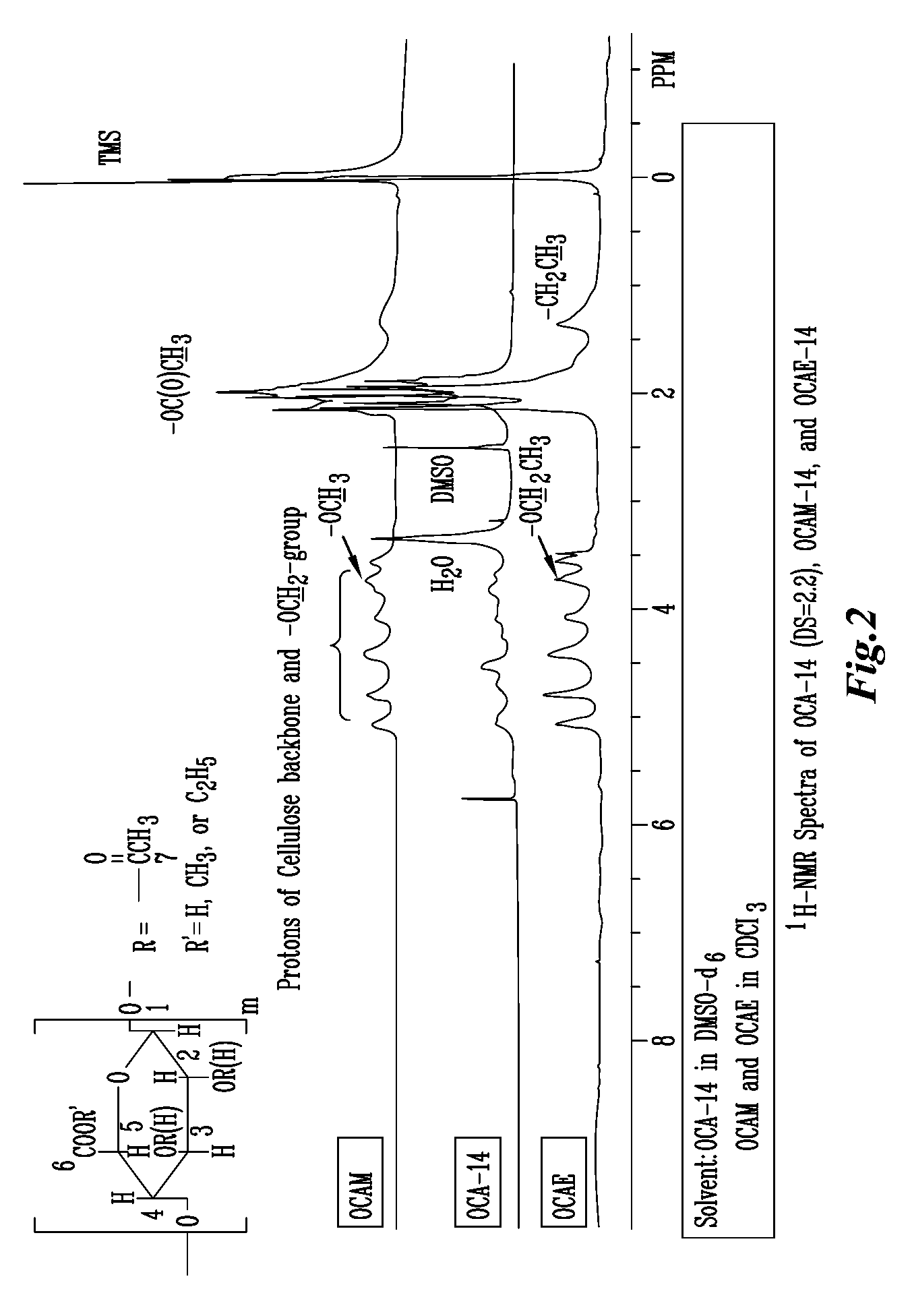

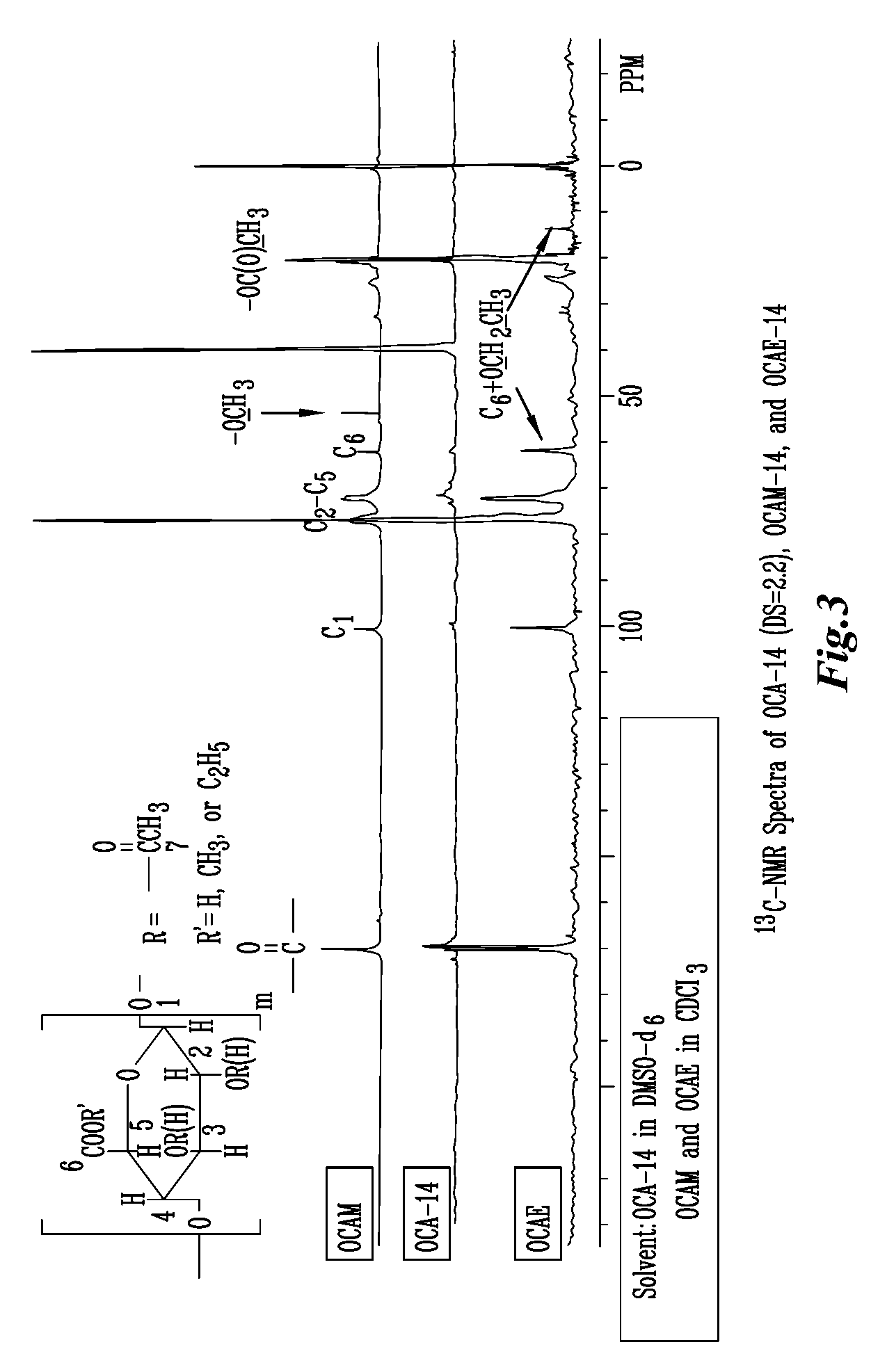

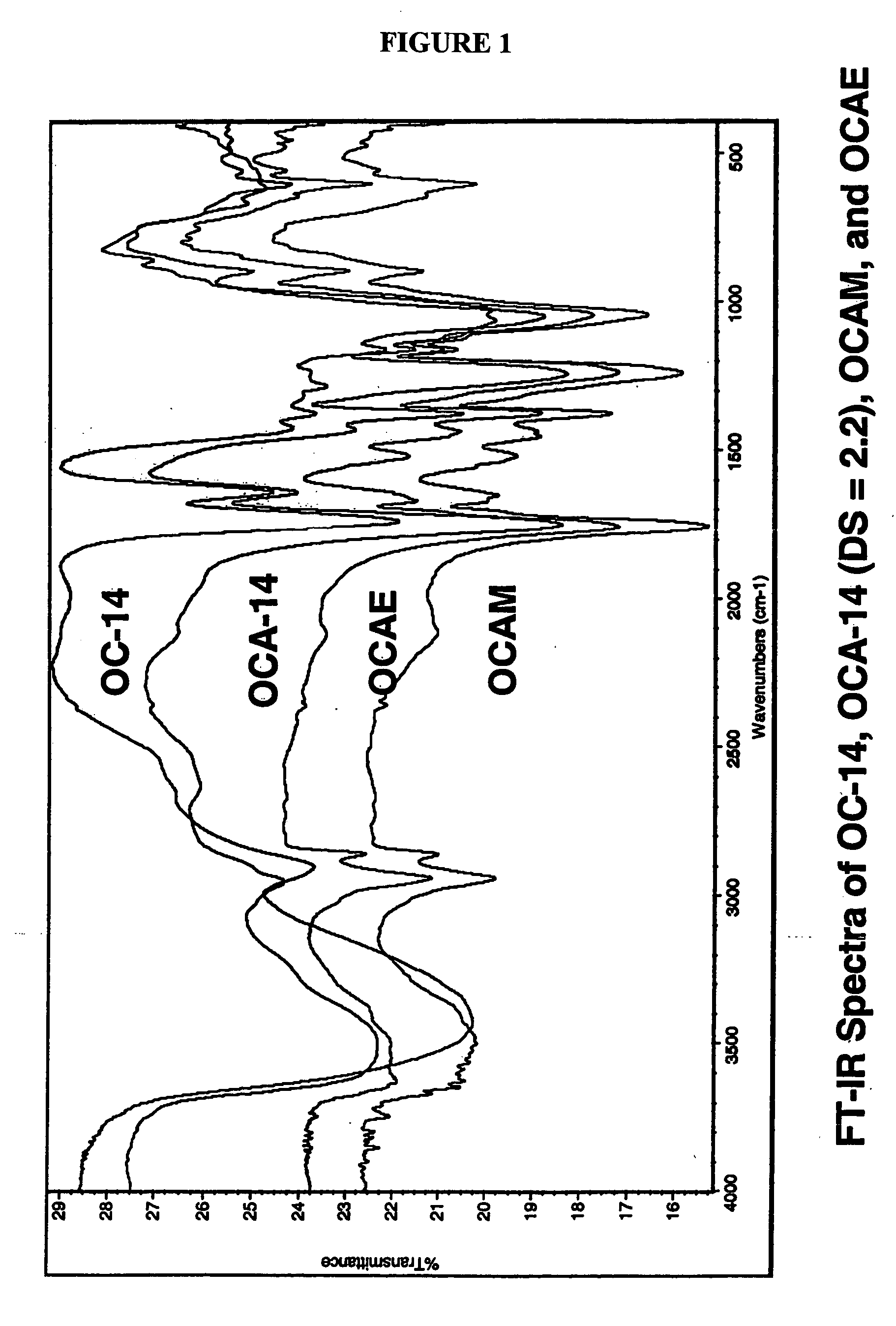

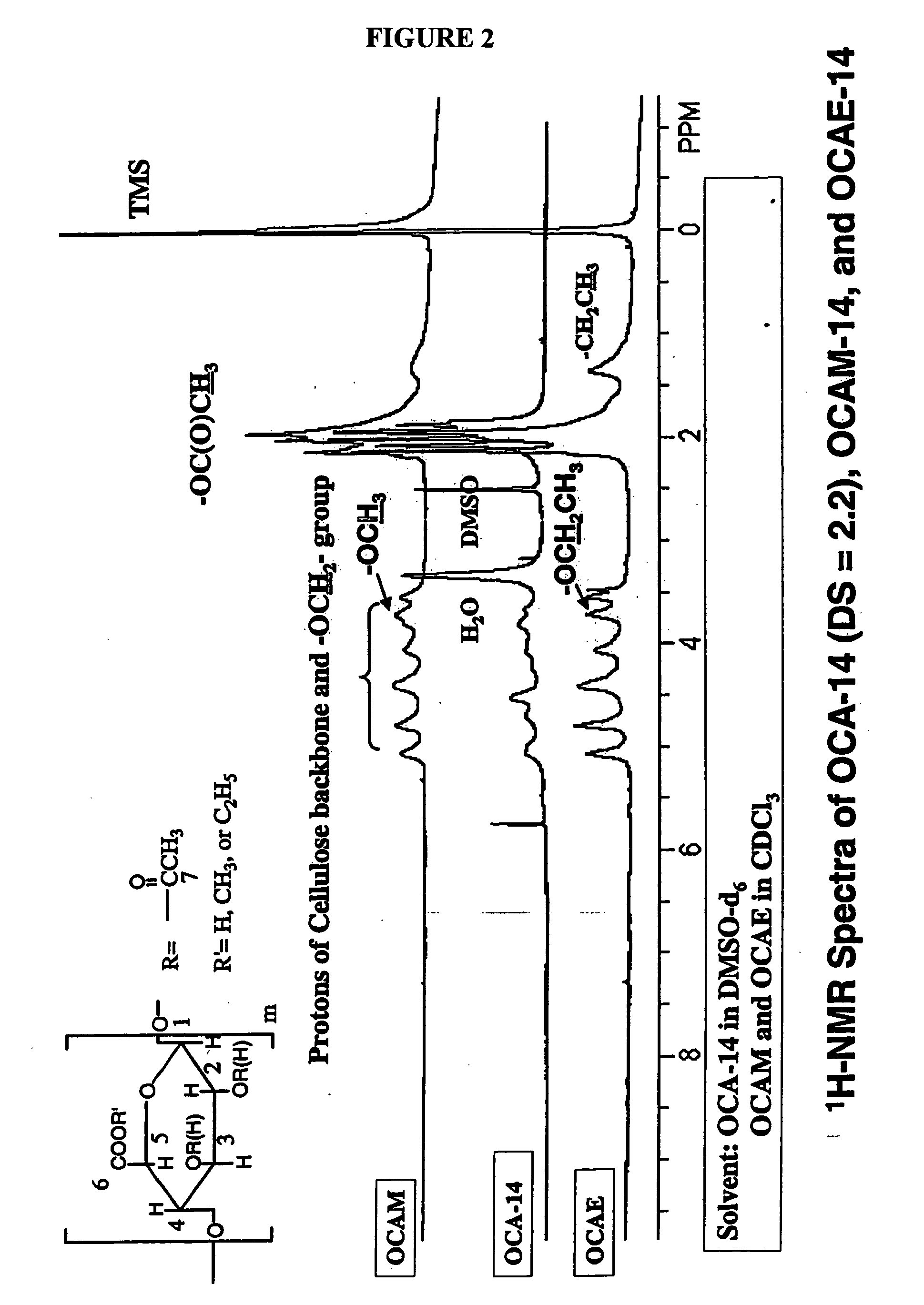

Biodegradable oxidized cellulose esters

Owner:UNIV OF IOWA RES FOUND

Biodegradable oxidized cellulose esters

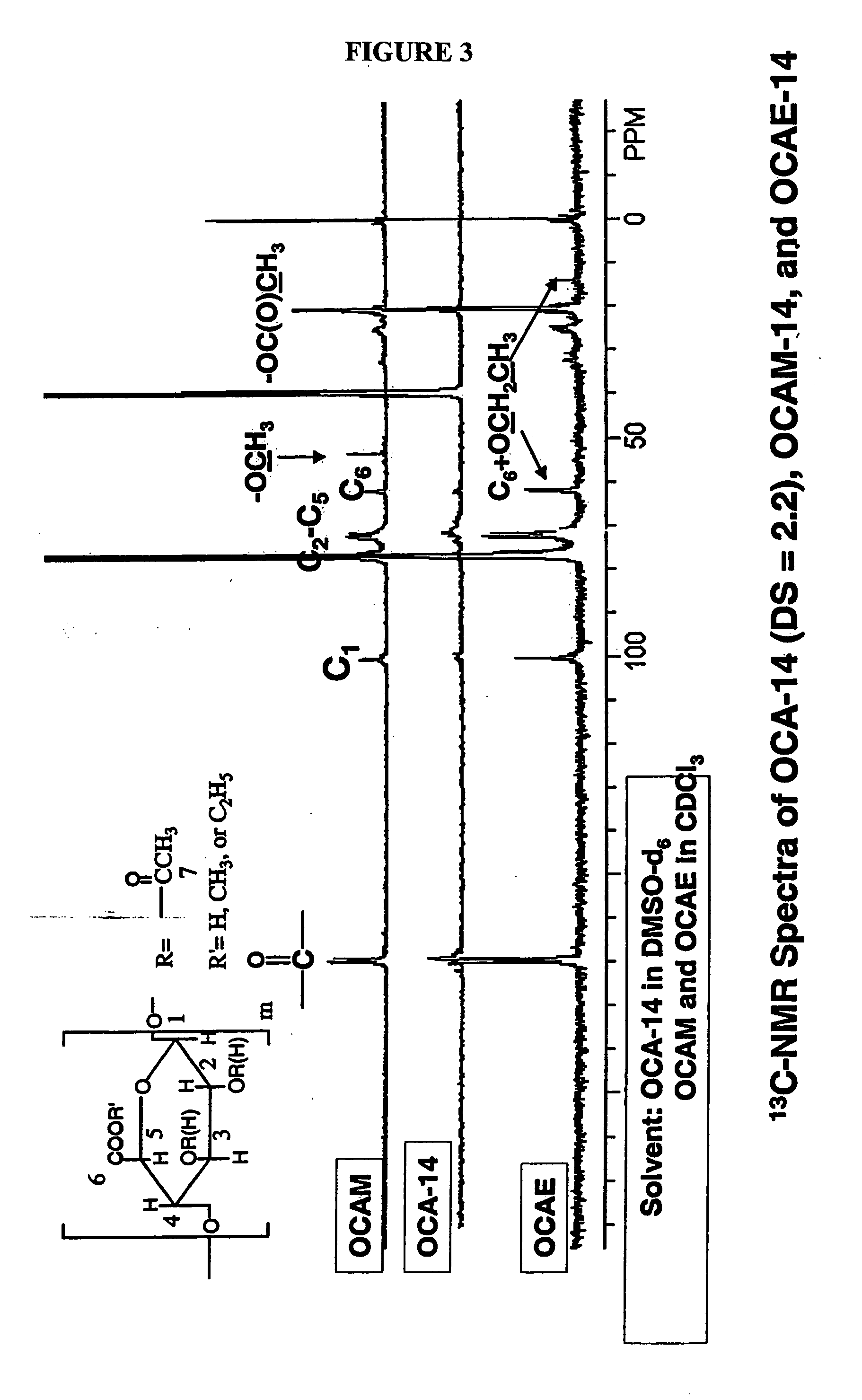

The present invention relates to the preparation of a series of oxidized cellulose esters suitable for use as a drug carrier in the development of biodegradable controlled and / or sustained release pharmaceutical, agricultural, and veterinary compositions, such as films, compacts, microspheres, and pellets. The esters are prepared by acylation of oxidized cellulose having at least 3% carboxyl groups. The resulting oxidized cellulose esters are soluble in aqueous alkaline solutions, water, and a variety of organic solvents.

Owner:UNIV OF IOWA RES FOUND

Oxidized microbial cellulose and use thereof

This application describes a bioresorbable biocellulose suitable for medical and surgical applications. In particular, the invention describes periodate oxidized microbial cellulose that can be produced to have any mechanical and degradation profile, depending on the desired application of the oxidized cellulose.

Owner:DEPUY SYNTHES PROD INC

Biodegradable oxidized cellulose esters and their uses as microspheres

InactiveUS7649089B2Extended durationOrganic active ingredientsGranular deliveryControlled releaseAlcohol

A new cellulose excipient, OCCAE, suitable for use as a binder, filler, and / or disintegrant in the development of solid dosage forms and as a bodying agent or a drug carrier in the preparation of topical formulations is described. The cellulose excipient is formed by reacting an oxidized cellulose ester with an alcohol in the presence of a catalyst. The invention also describes the formation of controlled release microspheres using OCCAE and / or oxidized cellulose esters that may be used to control the release of drug in a patient over a time period of several hours to several days.

Owner:UNIV OF IOWA RES FOUND

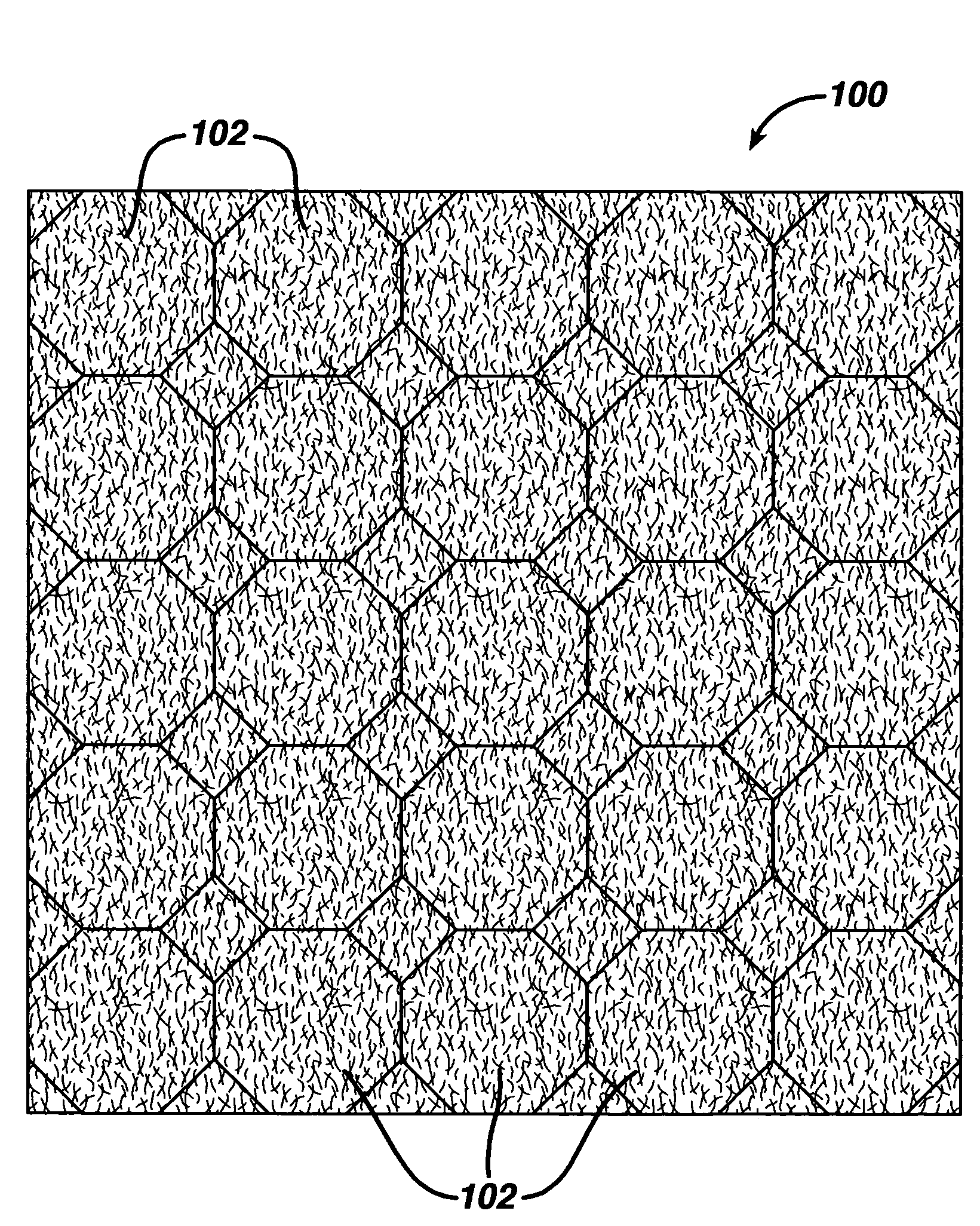

Hemostatic wound dressings and methods of making same

The present invention is directed to a hemostatic wound dressing that utilizes a fibrous, fabric substrate made from carboxylic-oxidized cellulose and containing a first surface and a second surface opposing the first surface, the fabric having flexibility, strength and porosity effective for use as a hemostat; and further having a porous, polymeric matrix substantially homogeneously distributed on the first and second surfaces and through the fabric, the porous, polymeric matrix being made of a biocompatible, water-soluble or water-swellable cellulose polymer, wherein prior to distribution of the polymeric matrix on and through the fabric, the fabric contains about 3 percent by weight or more of water-soluble oligosaccharides.

Owner:ETHICON INC

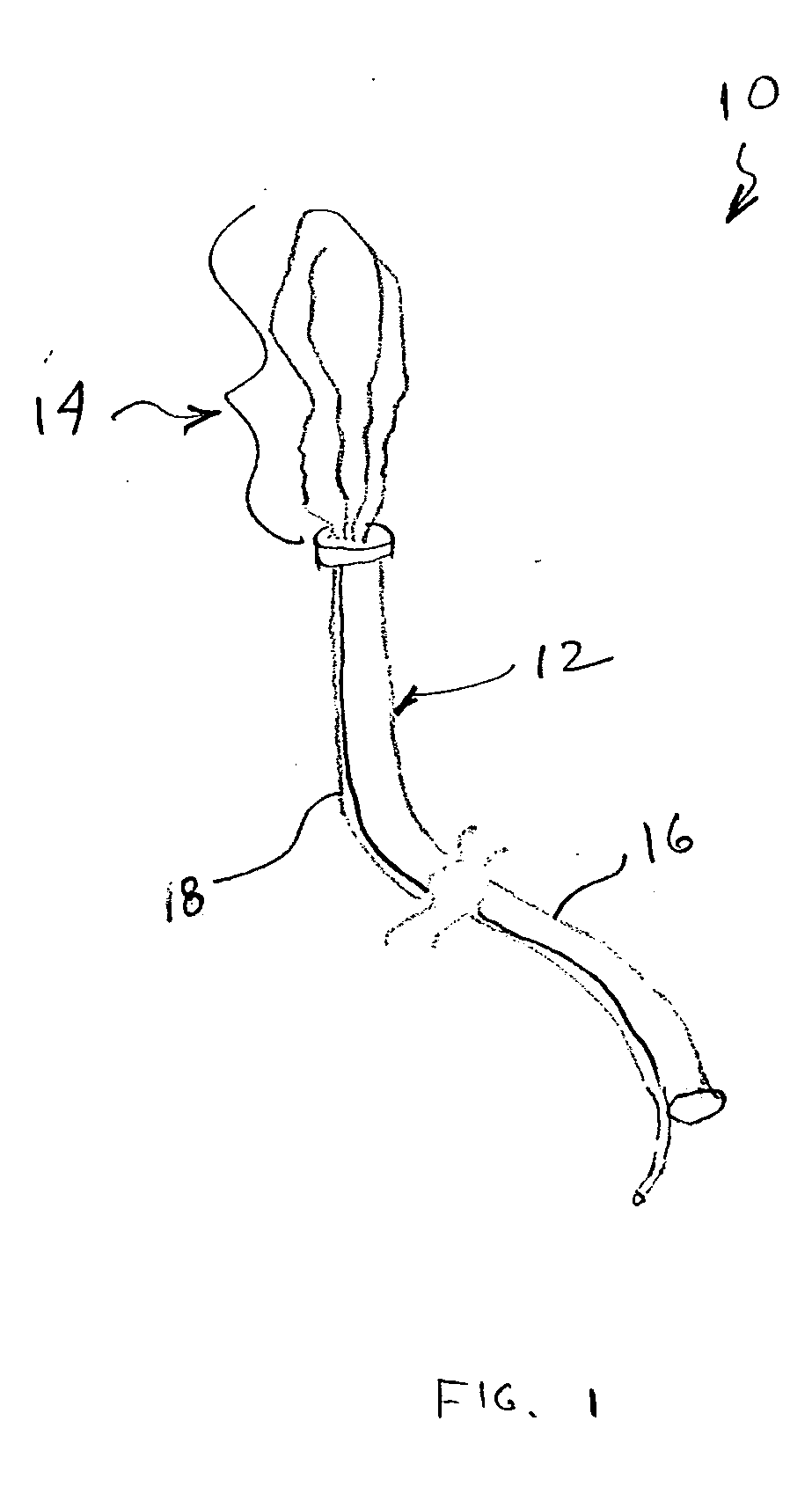

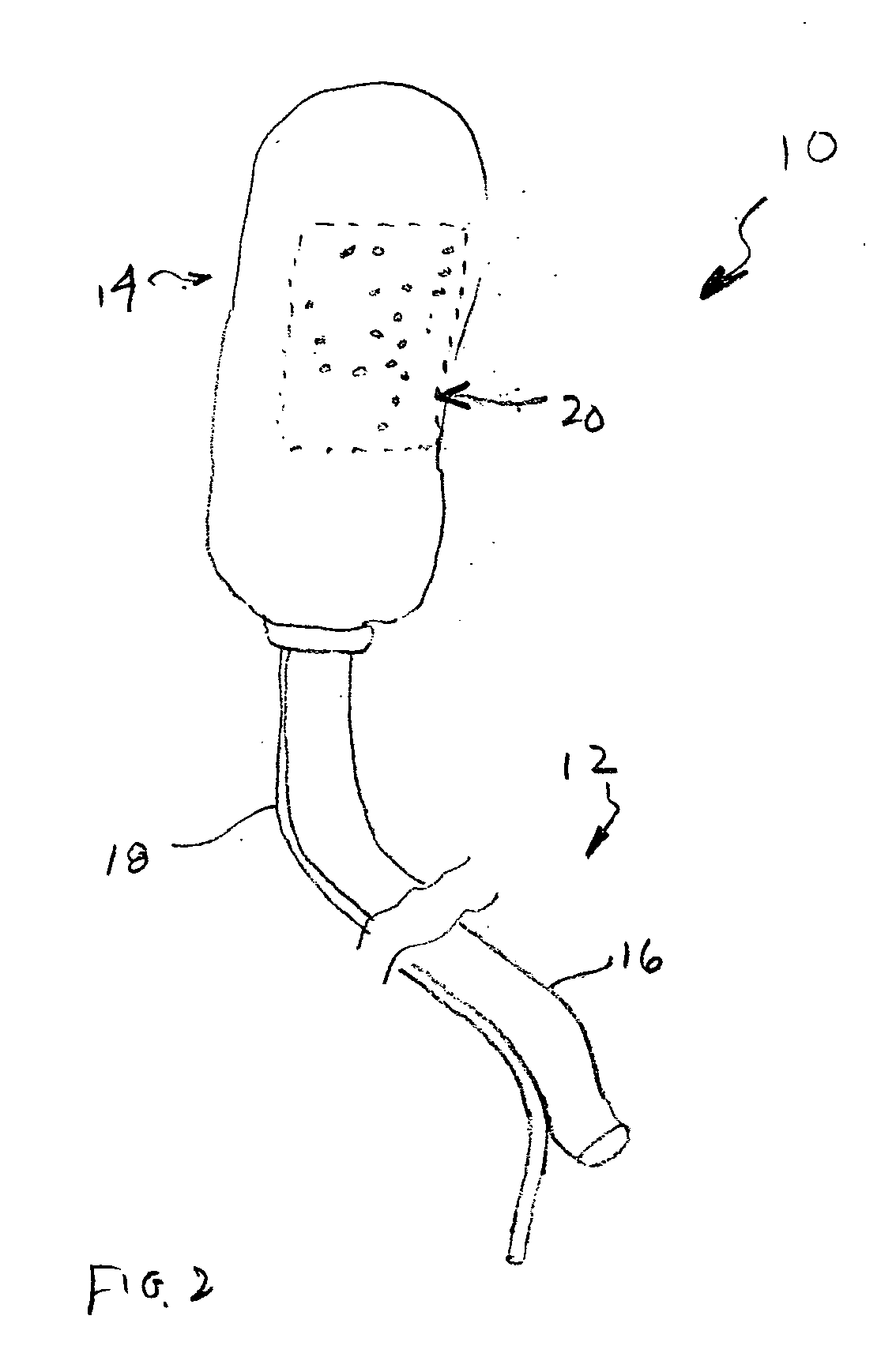

Hemostatic device with oxidized cellulose pad

InactiveUS20080027365A1Easy to disassembleTreatment process is streamlinedPharmaceutical delivery mechanismAdhesive dressingsBandageOxidised cellulose

In one aspect, an apparatus for promoting hemostasis includes oxidized cellulose in the form of a compressible, shapeable mass that is formed into a sheet for placement on a bleed site. In a second aspect, a sleeve for promoting hemostasis includes a tubular shell having at least one open end and oxidized cellulose material attached to an inner surface of the tubular shell. The open end of the tubular shell is dimensioned to receive a limb such that donning the sleeve causes at least a portion of the oxidized cellulose material to be placed in contact with a bleeding wound. In a third aspect, a bandage includes a substrate and oxidized cellulose material attached to a surface of the substrate. The oxidized cellulose material is arranged to contact a bleeding wound when the bandage is applied thereto.

Owner:Z MEDICA CORP

Oxidized microbial cellulose and use thereof

This application describes a bioresorbable biocellulose suitable for medical and surgical applications. In particular, the invention describes periodate oxidized microbial cellulose that can be produced to have any mechanical and degradation profile, depending on the desired application of the oxidized cellulose.

Owner:DEPUY SYNTHES PROD INC

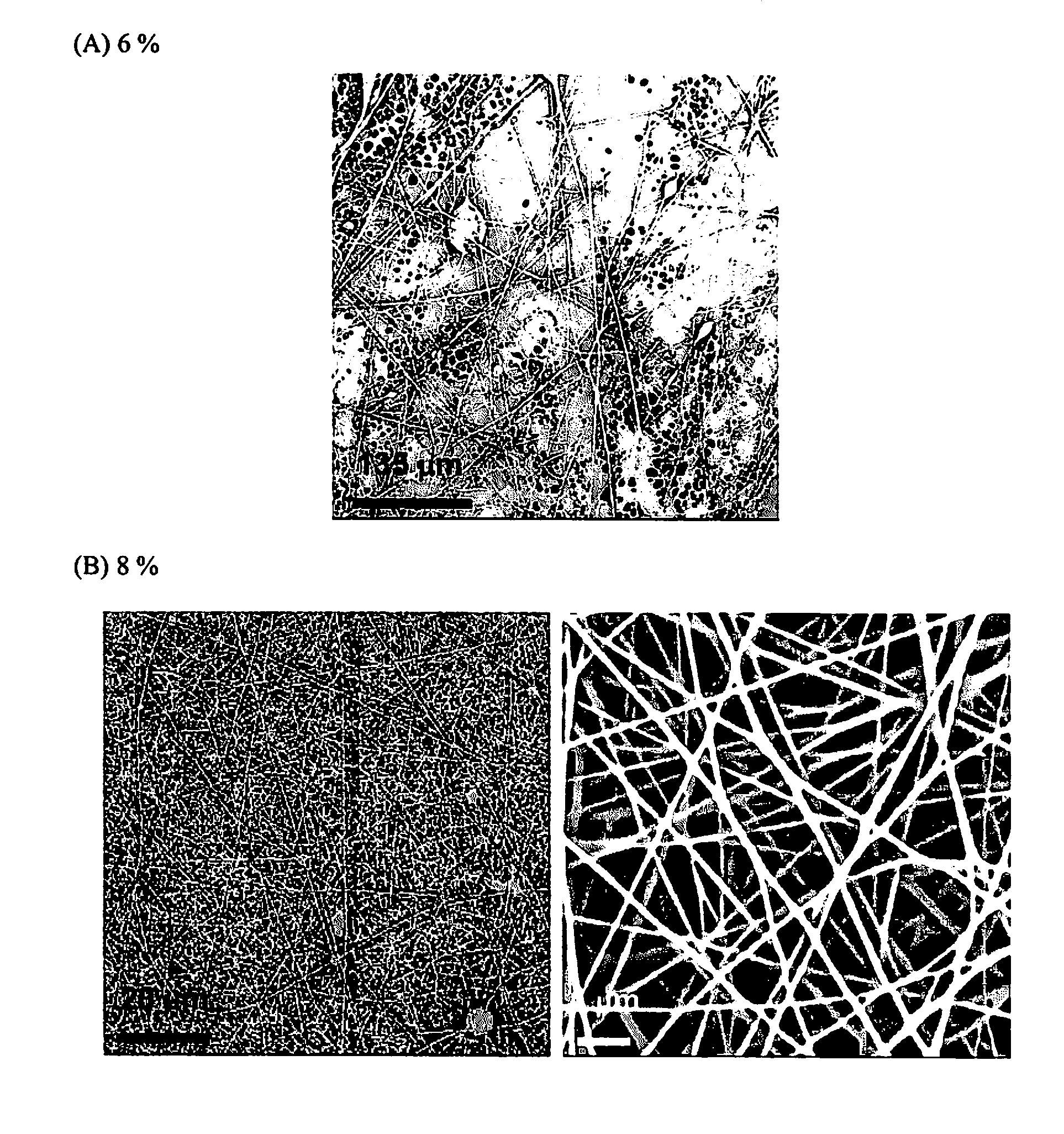

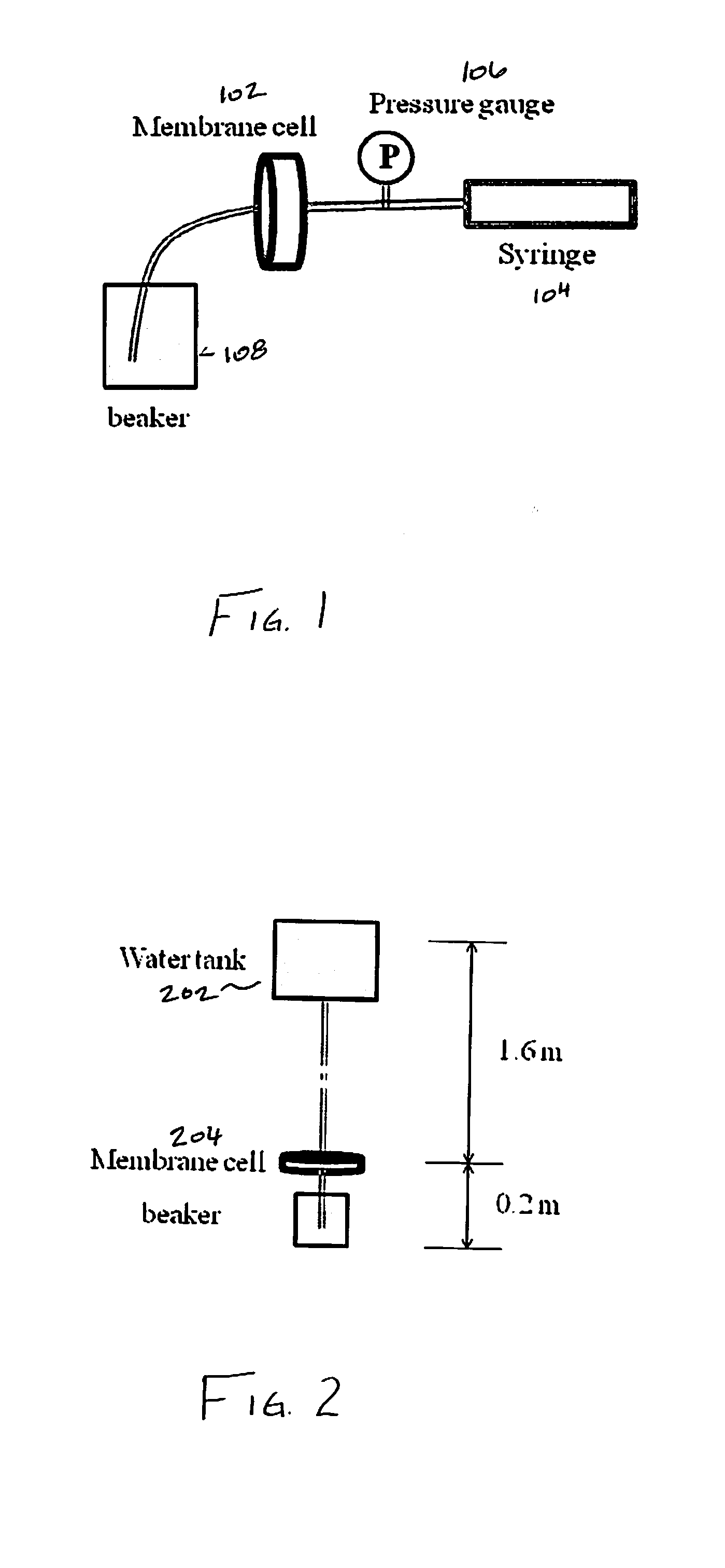

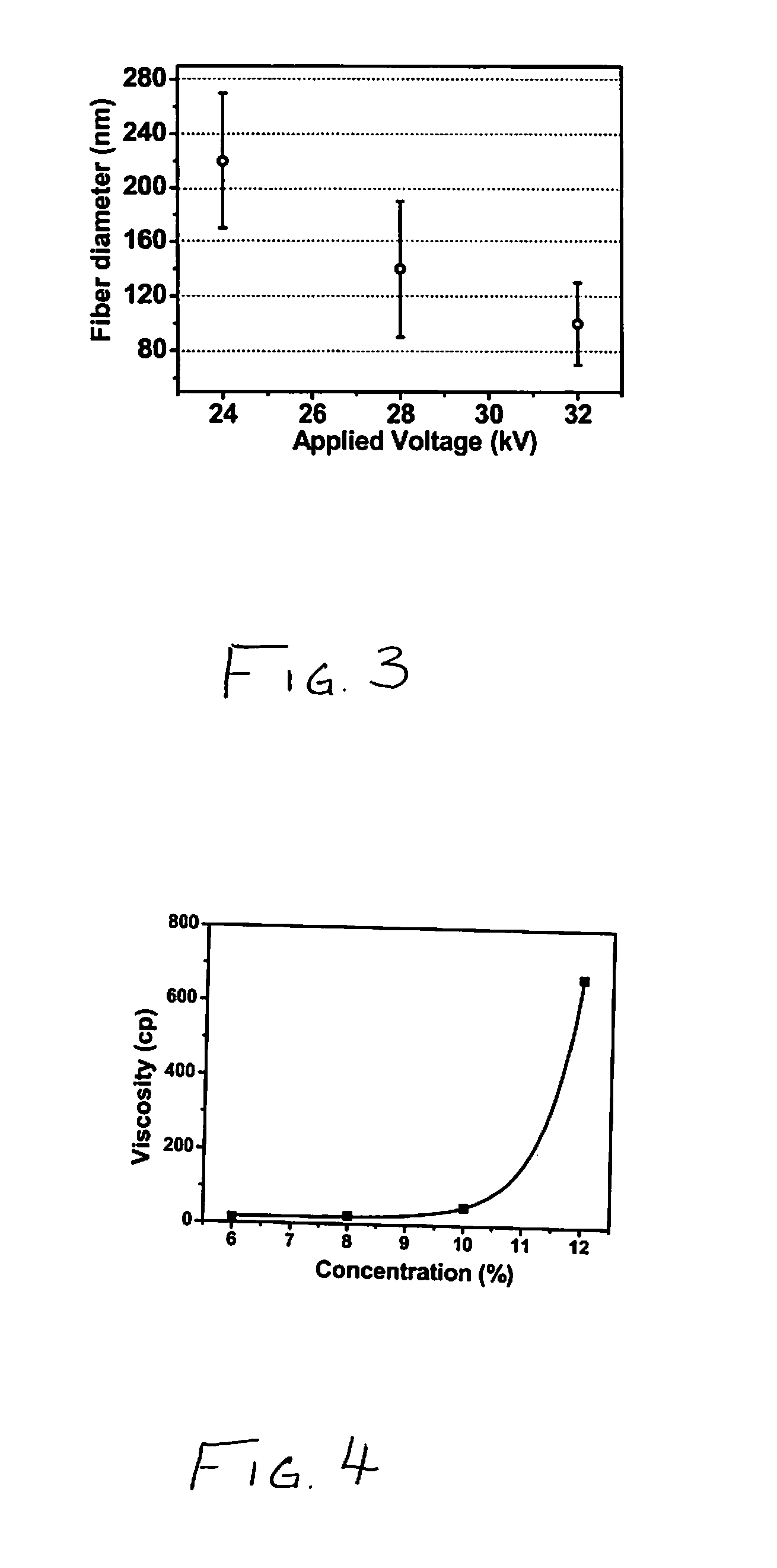

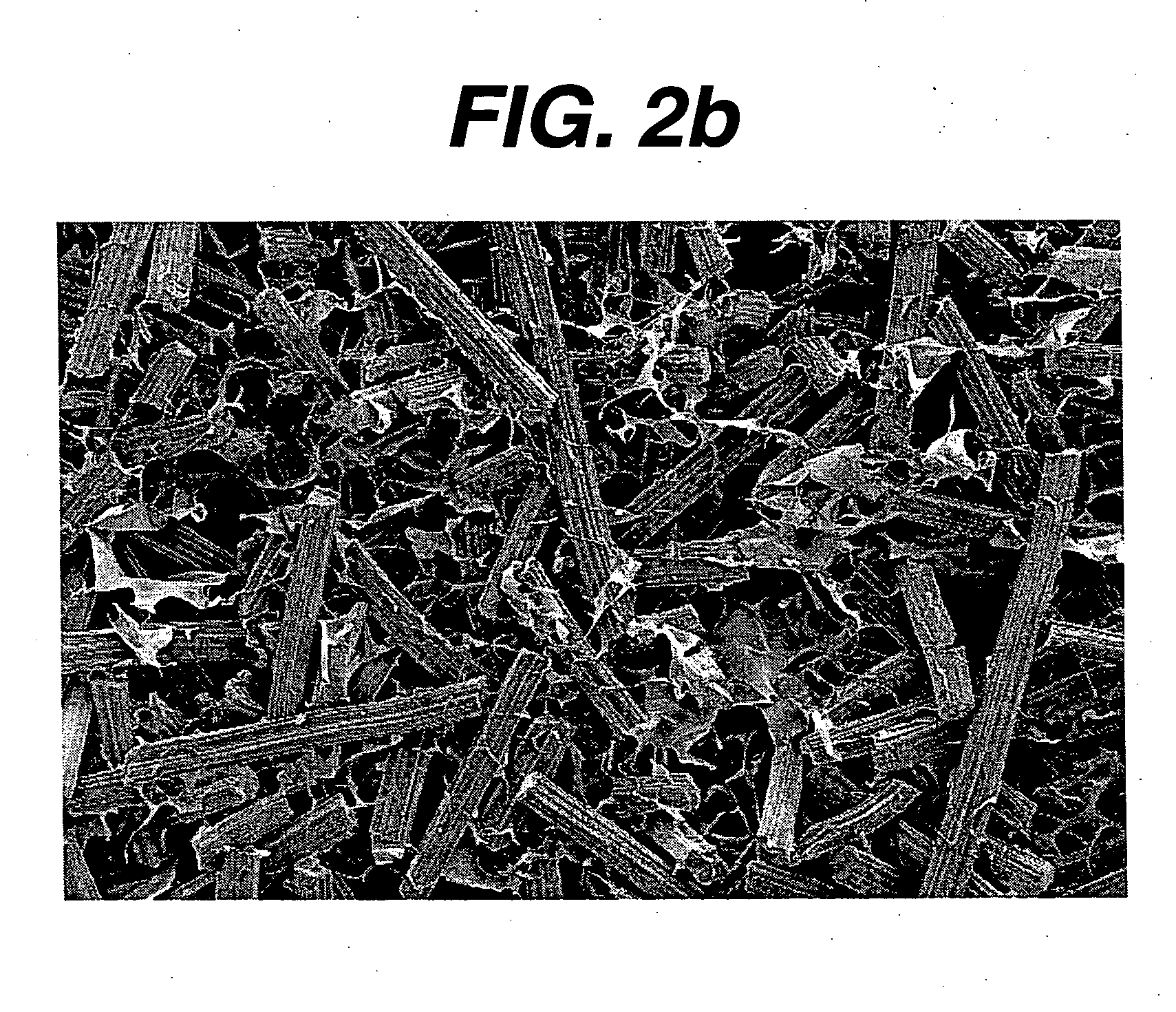

High flux high efficiency nanofiber membranes and methods of production thereof

A membrane is provided including a coating layer having cellulose nanofibers produced from oxidized cellulose microfibers and an electrospun substrate upon which the coating layer is applied. The nanofibers of the electrospun substrate have a diameter greater than that of the cellulose nanofibers. The membrane also has non-woven support upon which the electrospun substrate is disposed. Microfibers of the non-woven support have a diameter greater than that of the nanofibers of the electrospun substrate. Application of electrospun membrane is in microfiltration area, while the cellulose nanofiber membrane serves in ultra-filtration, nanofiltration, and reverse osmosis after chemical modification.

Owner:THE RES FOUND OF STATE UNIV OF NEW YORK

Devices and methods for promoting the formation of blood clots in esophageal varices

InactiveUS20070167971A1Inhibit injectionPromote formationBalloon catheterSurgeryThrombusSilicon dioxide

A device for promoting the clotting of blood in body cavities includes a flexible body portion; an expandable member located on the flexible body portion; and a blood clotting material attached to the expandable member. When used, insertion of at least a portion of the blood clotting material into the body cavity causes at least a portion of the blood clotting material to contact blood emanating from a bleed site. Methods of providing therapies to tube-shaped organs include the steps of providing suitable devices having expansion capabilities, positioning the devices at the appropriate bleed sites, and expanding the devices to cause blood clotting materials to contact the bleed sites. Materials that may be used as the blood clotting material include zeolites, molecular sieve materials, diatomaceous earth, clay, silica-based materials, oxidized cellulose, carboxymethyl cellulose, bioactive glass, biological hemostats, chitosan, and combinations of the foregoing.

Owner:TELEFLEX LIFE SCI LTD

Cellulose oxidation by nitrogen dioxide in a perfluorinated tertiary amine solvent

ActiveUS7645874B2Efficiently oxidizedReduce usageBiocideOrganic active ingredientsAqueous alcoholNitrogen dioxide

This invention relates to a process for preparing bioabsorbable oxidized cellulose comprising combining cellulose material, with nitrogen dioxide and a nonaqueous solvent chosen from the class of perfluorinated tertiary amines. This invention also relates to a method of oxidizing cellulose material comprising introducing a solvent into the vessel, circulating the solvent through the cellulose material, adding nitrogen dioxide to said vessel containing the solvent and cellulose in the required amounts, circulating the solution for 7 to 24 hours while controlling the reaction temperature, and isolating the oxidized material. Preferably, isolation of the oxidized product is followed by first washing the oxidized cellulose material with cold water, then washing the oxidized cellulose material with an aqueous alcohol solution several times, then washing the material with 100% alcohol several times, and finally drying the oxidized material.

Owner:DEPUY SYNTHES PROD INC

Biodegradable oxidized cellulose esters and their uses as microspheres

A new cellulose excipient, OCCAE, suitable for use as a binder, filler, and / or disintegrant in the development of solid dosage forms and as a bodying agent or a drug carrier in the preparation of topical formulations is described. The cellulose excipient is formed by reacting an oxidized cellulose ester with an alcohol in the presence of a catalyst. The invention also describes the formation of controlled release microspheres using OCCAE and / or oxidized cellulose esters that may be used to control the release of drug in a patient over a time period of several hours to several days.

Owner:UNIV OF IOWA RES FOUND

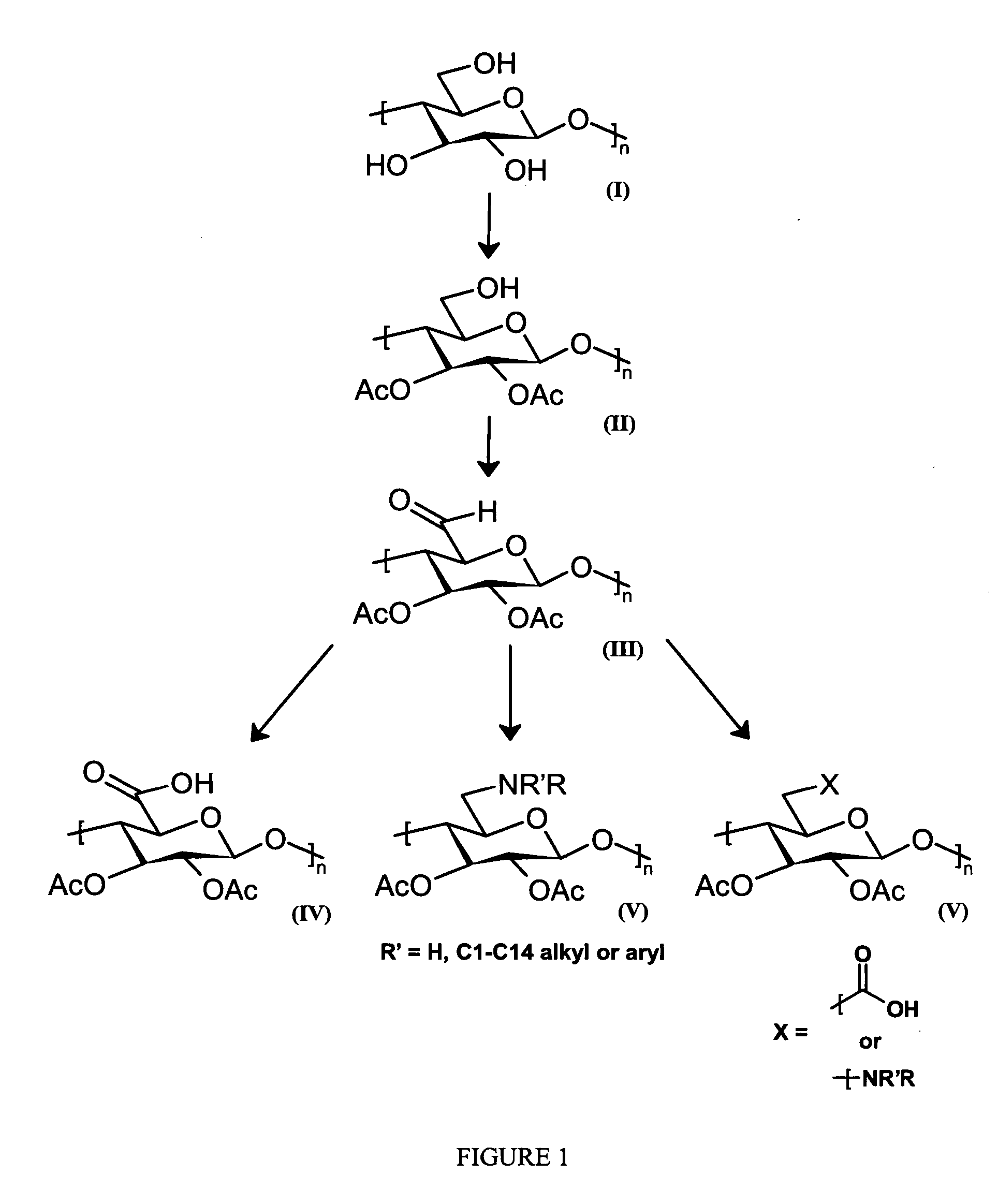

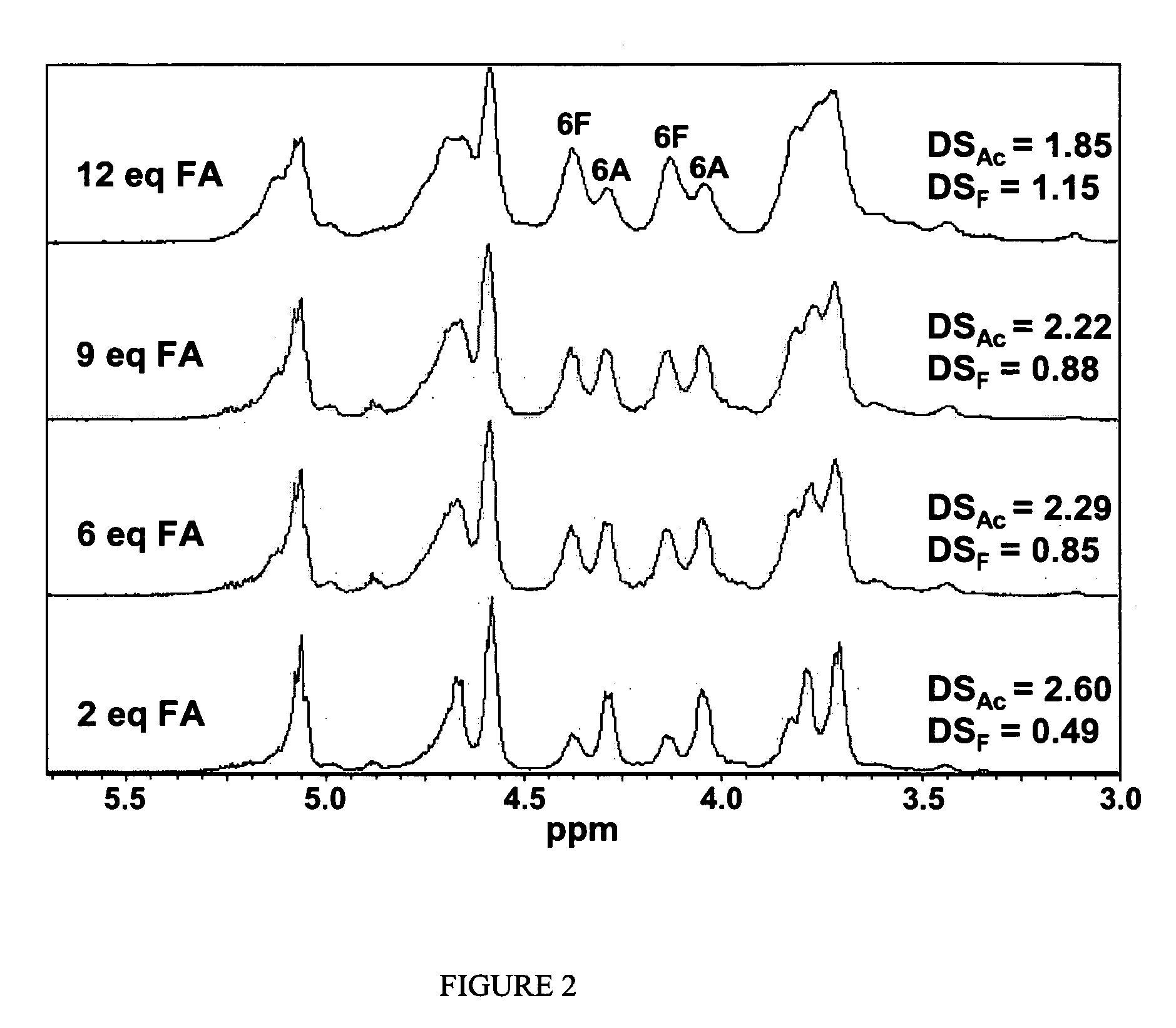

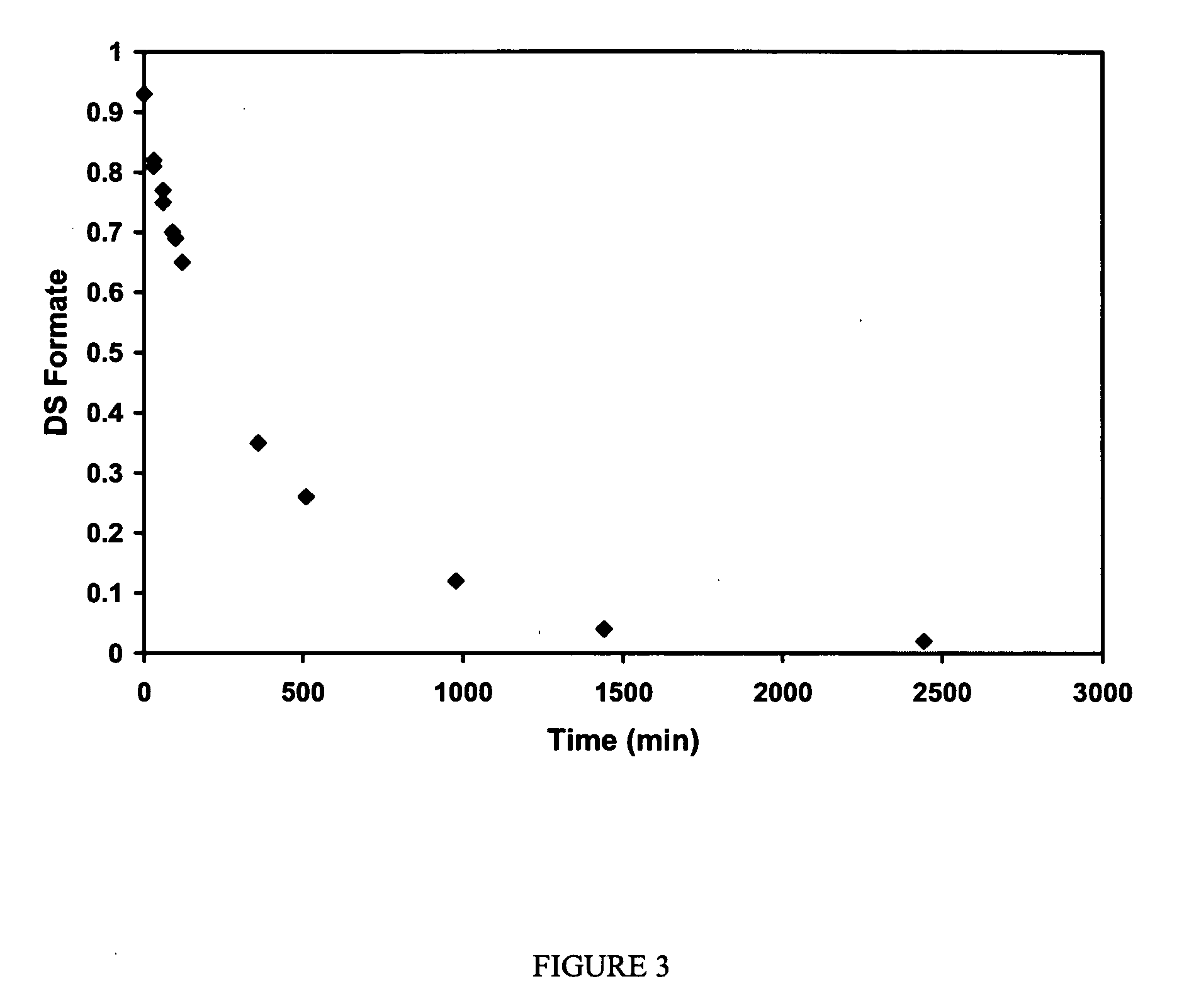

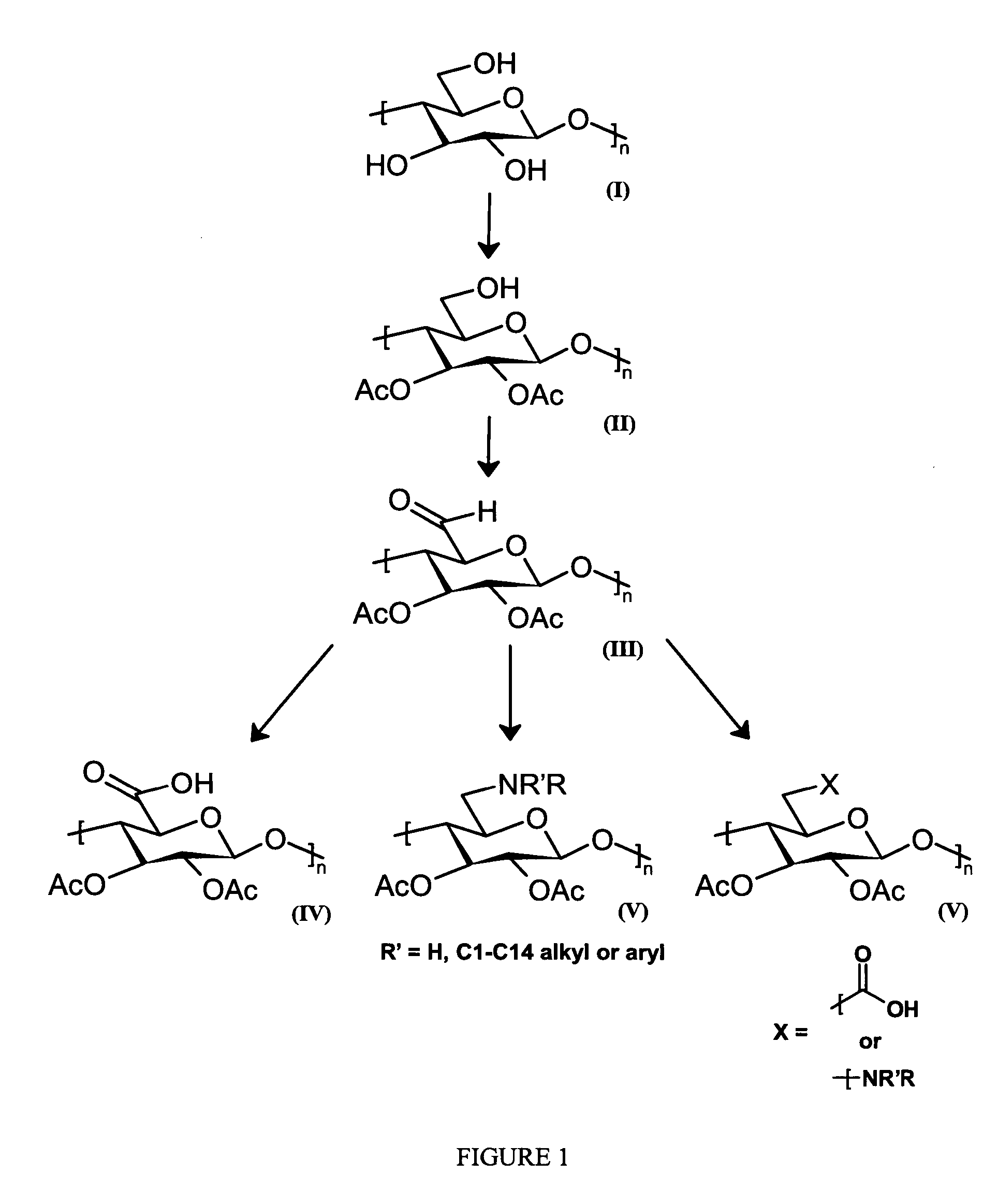

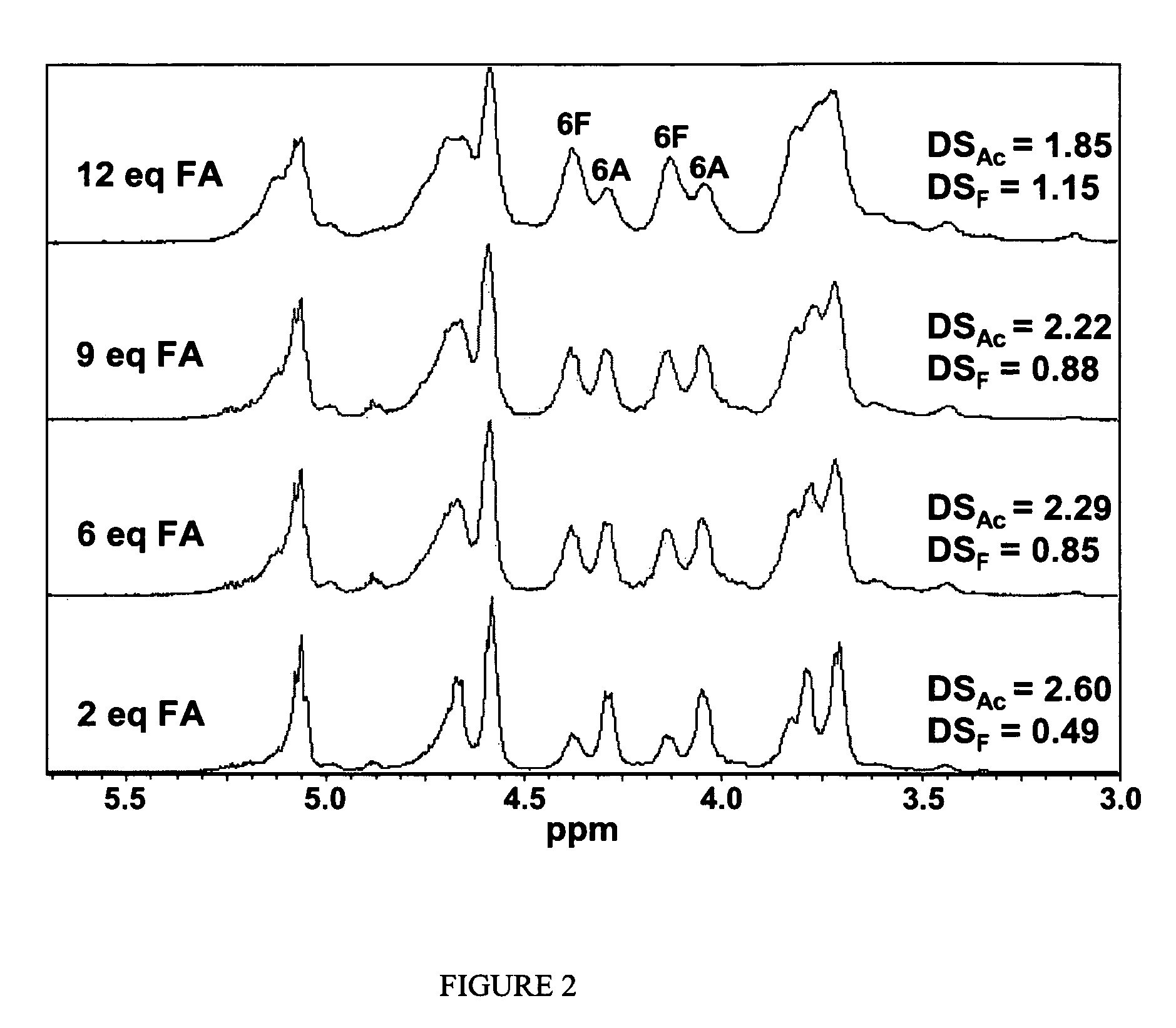

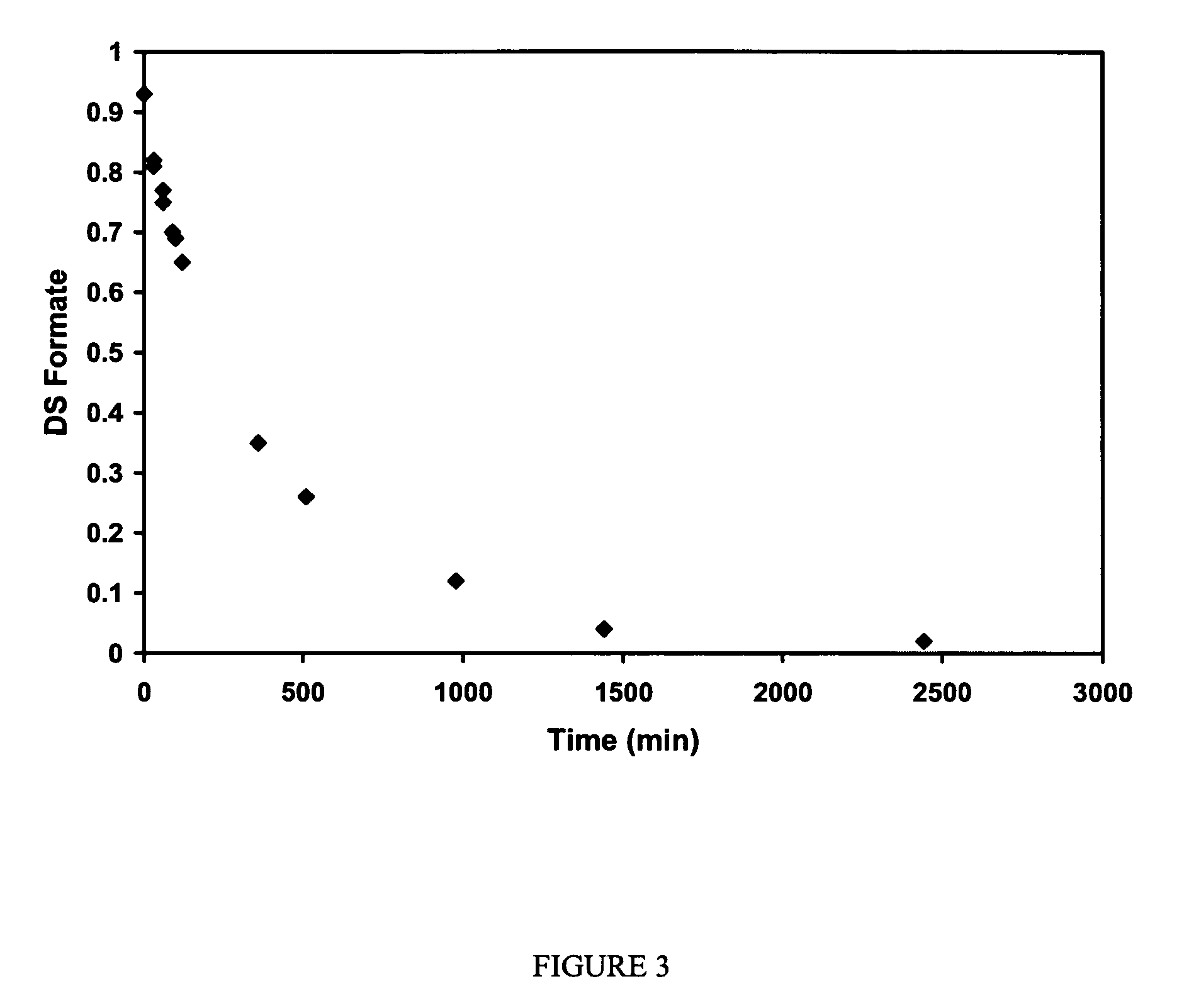

Cellulose interpolymers and method of oxidation

ActiveUS20050192434A1Decreasing and preventing frequencyPowder deliverySugar derivativesPolymer sciencePharmaceutical drug

This invention provides cellulose ester interpolymers, and methods of oxidizing cellulose interpolymers and cellulose ester interpolymers. The invention also provides routes to access carboxylated cellulose ester derivatives with high acid numbers wherein the carboxyl group is attached directly to the cellulose backbone by a carbon-carbon bond. Through functionalization of an intermediate aldehyde, the corresponding cationic or zwitterionic cellulose ester derivatives can also be accessed. The interpolymers of the present invention have a number of end-use applications, for example, as binder resins in various types of coating compositions and as drug delivery agents.

Owner:EASTMAN CHEM CO

Hemostatic devices and methods of making same

InactiveUS20060233869A1Organic active ingredientsPharmaceutical non-active ingredientsMedicineWater soluble

The present invention includes compositions suitable for use in a hemostatic device and hemostatic devices utilizing such compositions, as well as methods of making the compositions and the medical devices utilizing such compositions where the compositions contain biocompatible, oxidized cellulose particles having an average designated nominal particle size of about 0.035-4.35 mm and a biocompatible, water-soluble or water-swellable polysaccharide porous binder component.

Owner:ETHICON INC

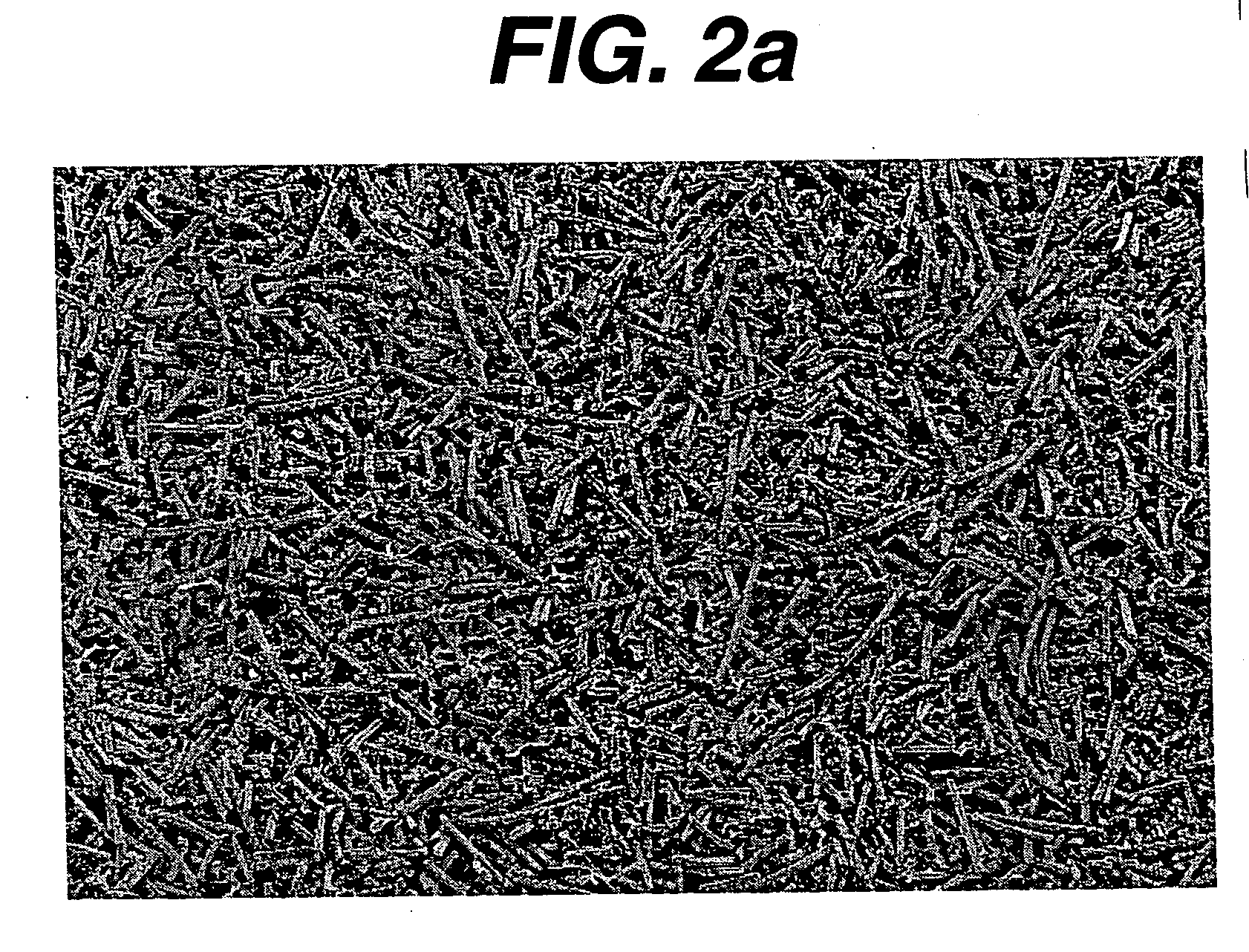

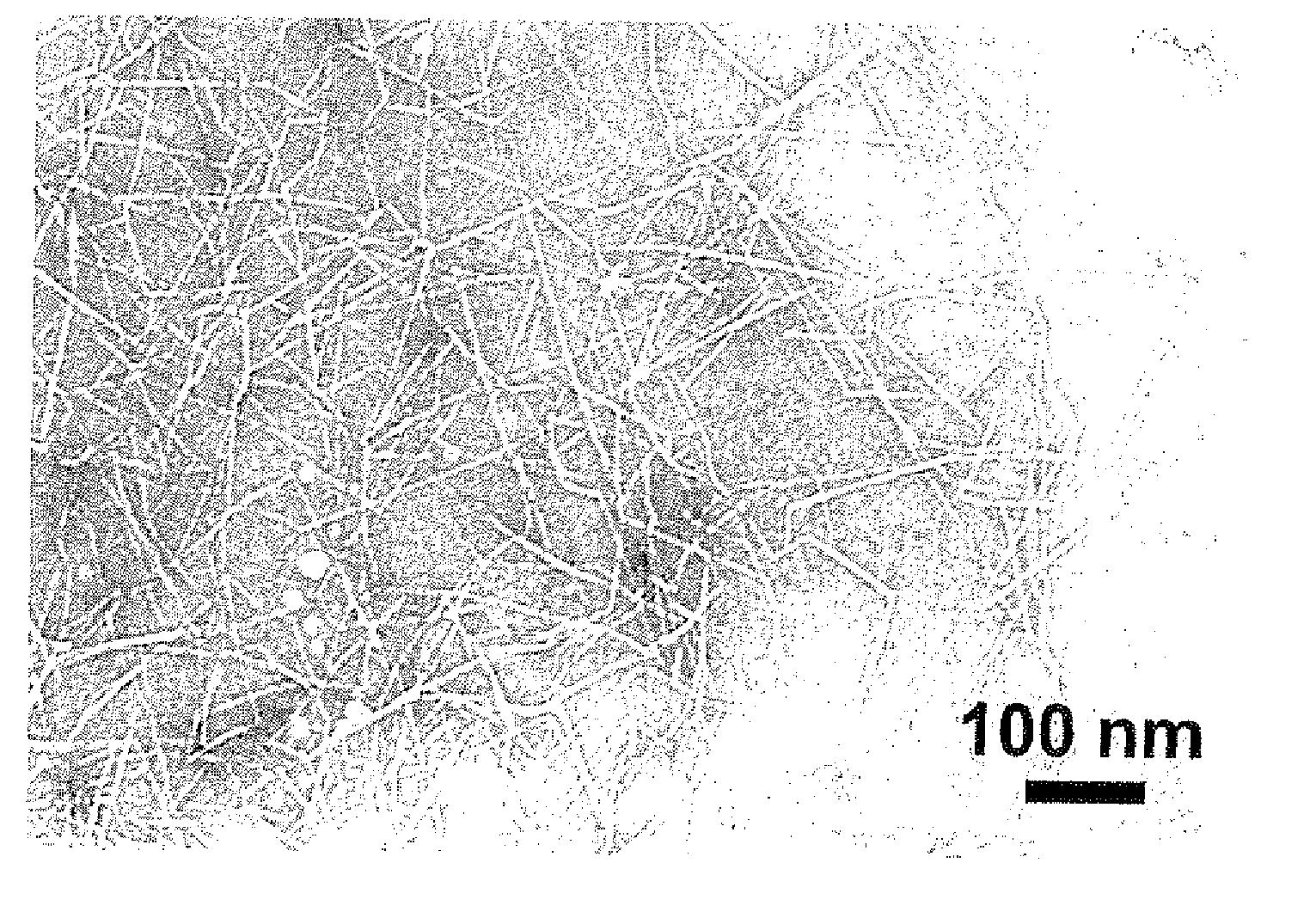

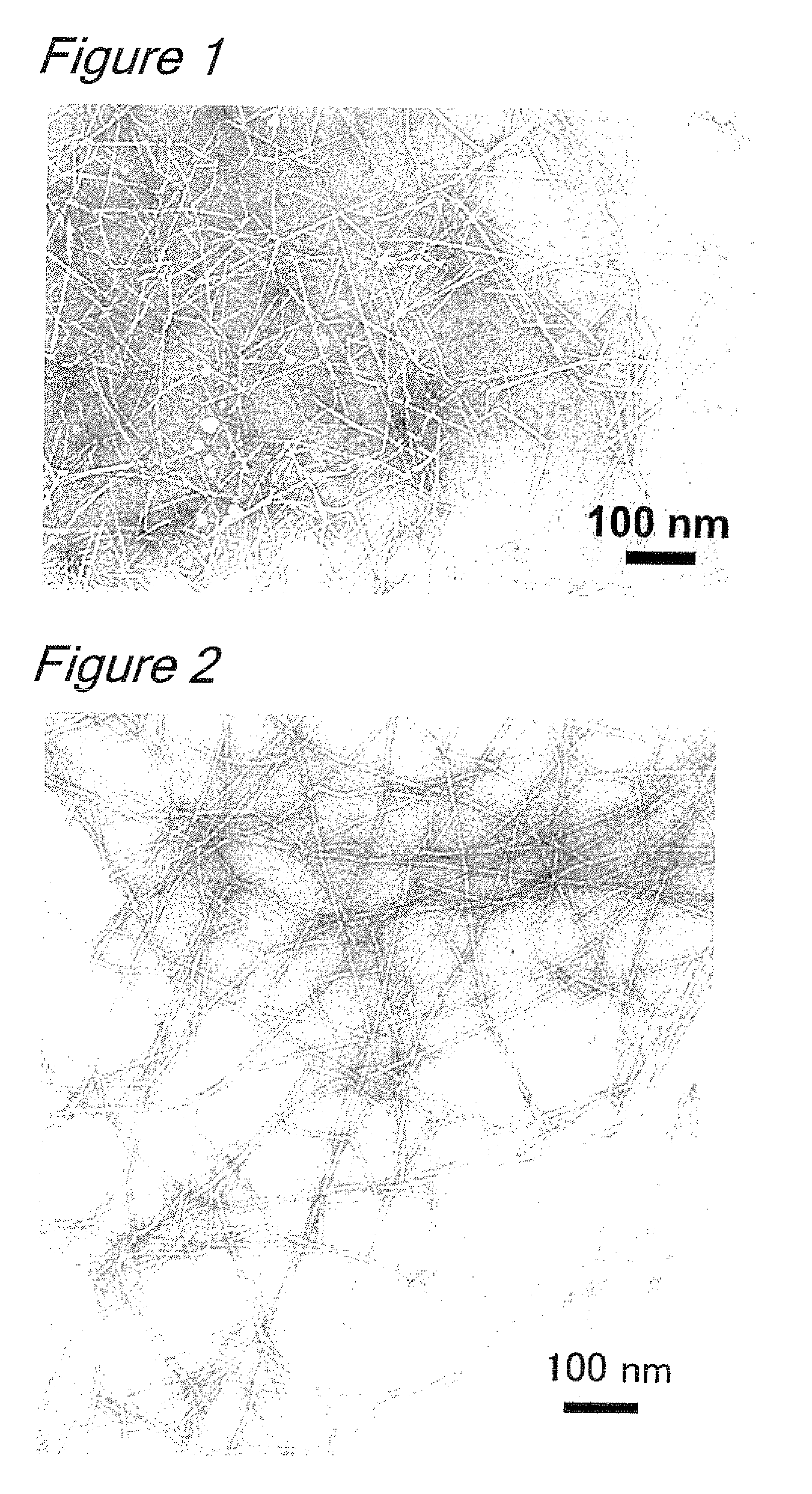

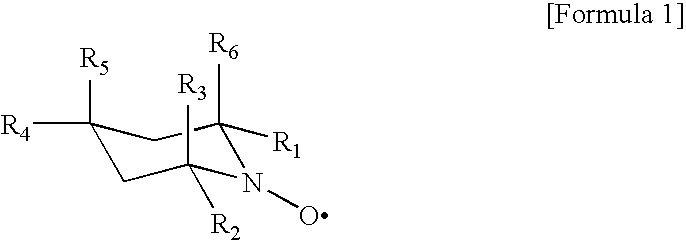

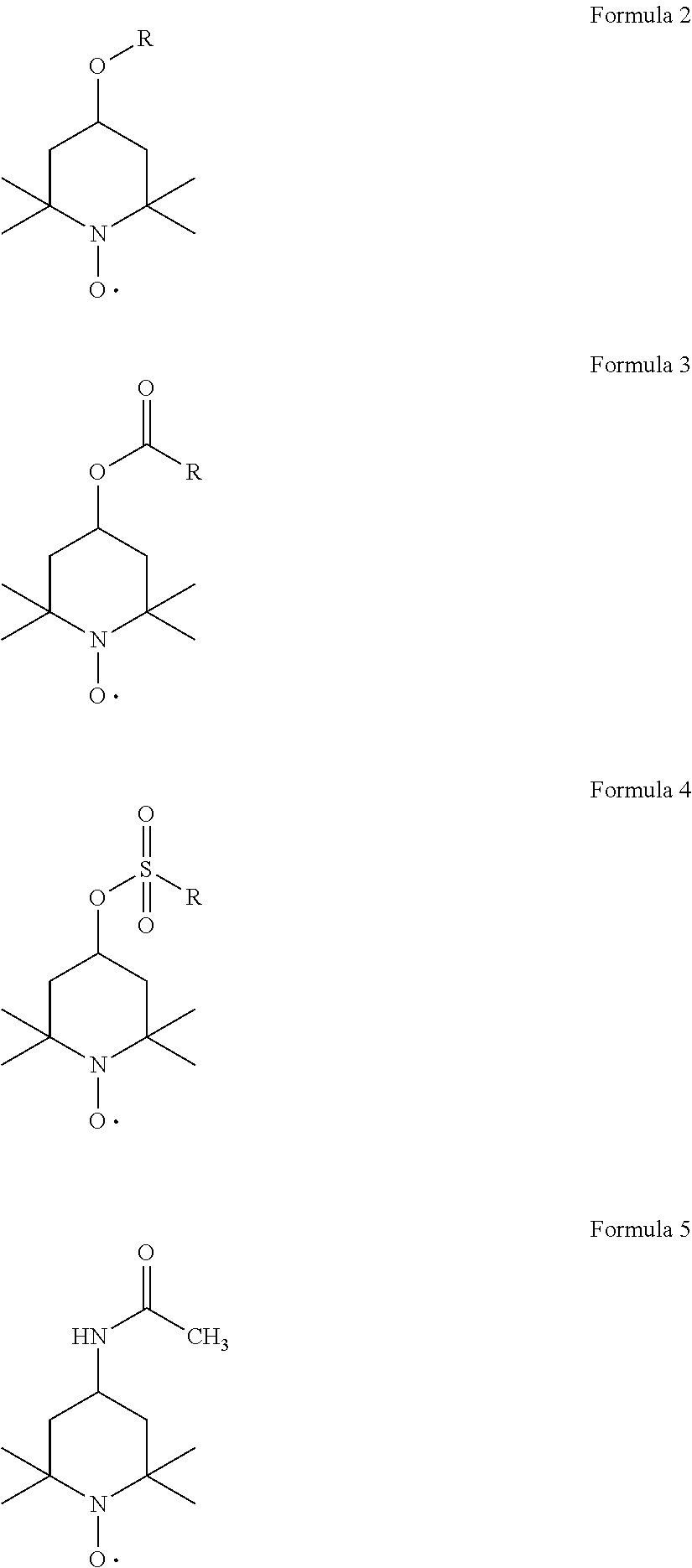

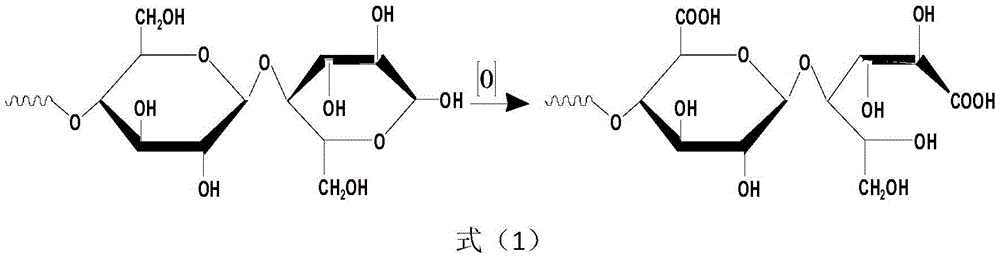

Processes for producing cellulose nanofibers, cellulose oxidation catalysts and methods for oxidizing cellulose

The present invention aims to provide a process for producing cellulose nanofibers using a 4-hydroxy TEMPO derivative less expensive than TEMPO and a process capable of rapidly producing homogeneous cellulose nanofibers. Wood cellulose can be efficiently converted into nanofibers by a process for producing cellulose nanofibers comprising treating a cellulosic material with an oxidizing agent in water in the presence of a cellulose oxidation catalyst comprising an N-oxyl compound represented by formula 1 below:wherein R1 and R2 are each independently hydrogen or a C1-C6 straight or branched alkyl group; and(i) one of R4 or R5 is —OR, —OCOR or —OSO2R wherein R is a straight or branched carbon chain having 4 or less carbon atoms, and the other of R4 or R5 is hydrogen, and R3 and R6 are methyl, or(ii) R4 is hydrogen, and R5, R3 and R6 are taken together with a piperidine ring to form an aza-adamantane compound having formula 2 below:or a mixture thereof, and a compound selected from the group consisting of bromides, iodides and mixtures thereof to prepare oxidized cellulose, and microfibrillating the oxidized cellulose to convert it into nanofibers.

Owner:NIPPON PAPER IND CO LTD

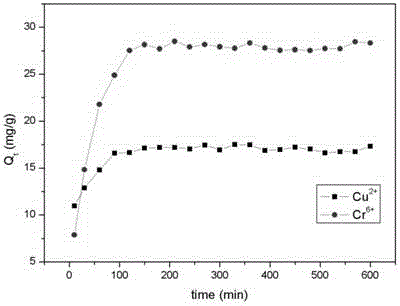

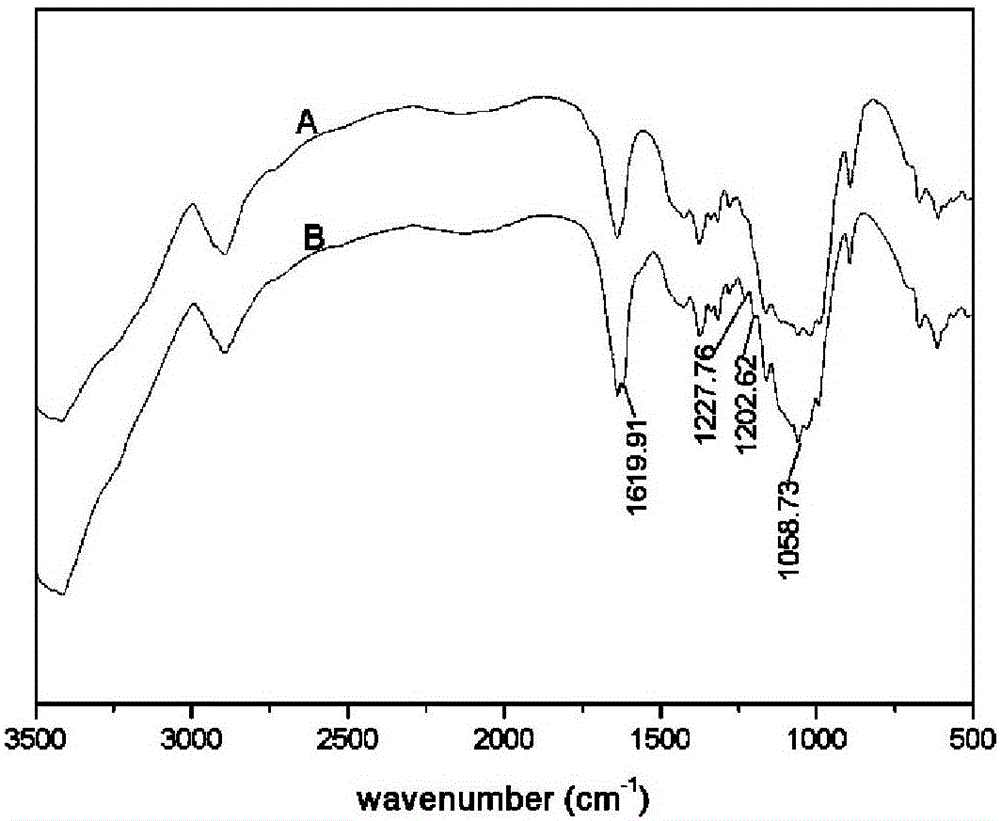

Preparation method of modified cellulose adsorbents

InactiveCN103480348AWide variety of sourcesLow priceOther chemical processesWater/sewage treatment by sorptionEpoxyPolymer science

The invention discloses a preparation method of modified cellulose adsorbents. The preparation method comprises the following steps: (1) activating cellulose in alkaline aqueous solution to obtain activated cellulose; (2) reacting the activated cellulose with epoxy chloropropane to obtain epoxy cellulose; (3) reacting the epoxy cellulose with an oxidizing agent to obtain epoxy dialdehyde oxidized cellulose; (4) reacting cyclodextrin with epoxy dialdehyde oxidized cellulose to obtain cyclodextrin grafted modified cellulose; and (5) reacting the cyclodextrin grafted modified cellulose with amino-terminated hyperbranched polymer to obtain the modified cellulose adsorbents. The raw material source is wide, the price is low, and the environment-friendly effect is achieved; the preparation method is simple, the reaction condition is mild, the equipment requirement is low and scale production is facilitated; and the prepared adsorbent has stable performance and broad-spectrum adsorption capacity for heavy metal ions, dyes and other organic matters and is environment-friendly, the cellulose additional value is remarkably promoted, and good economic and social benefits are achieved.

Owner:SUZHOU UNIV

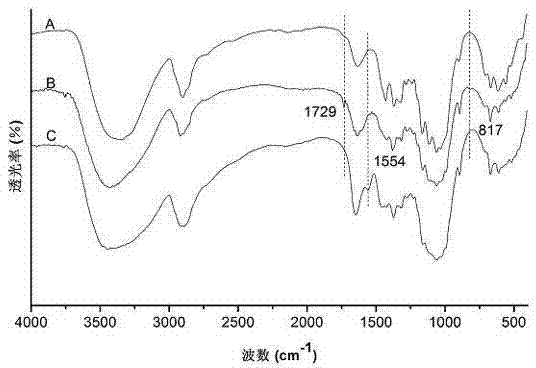

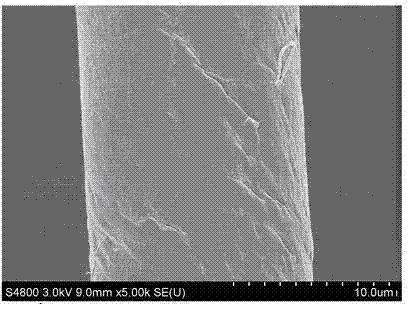

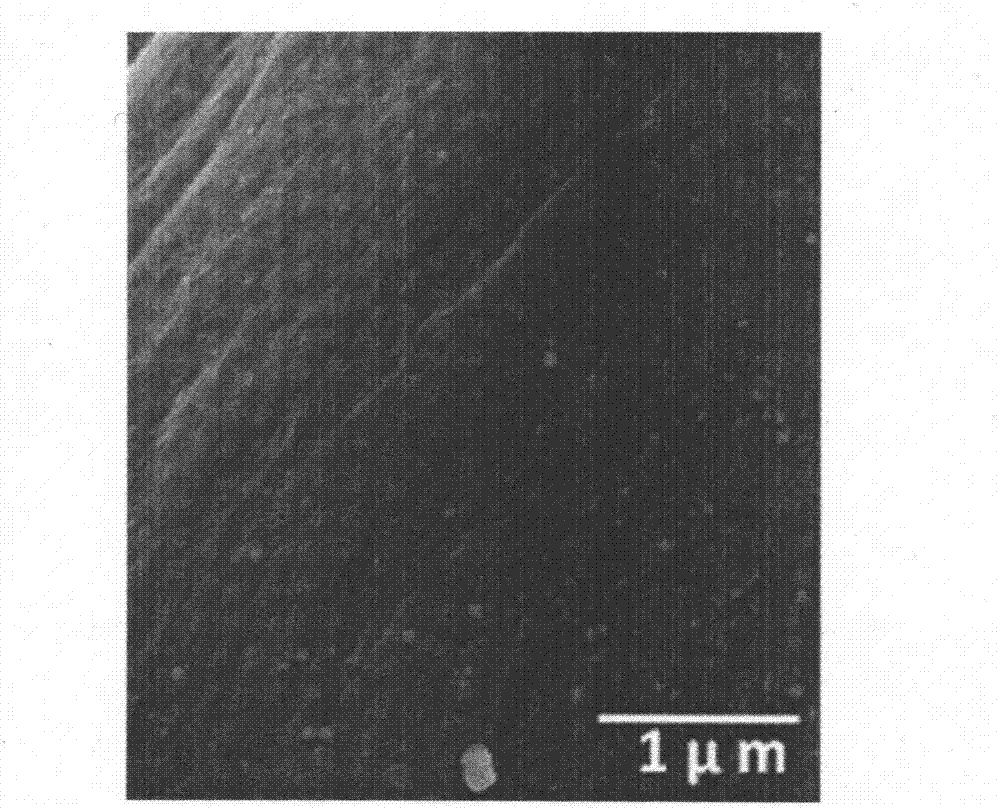

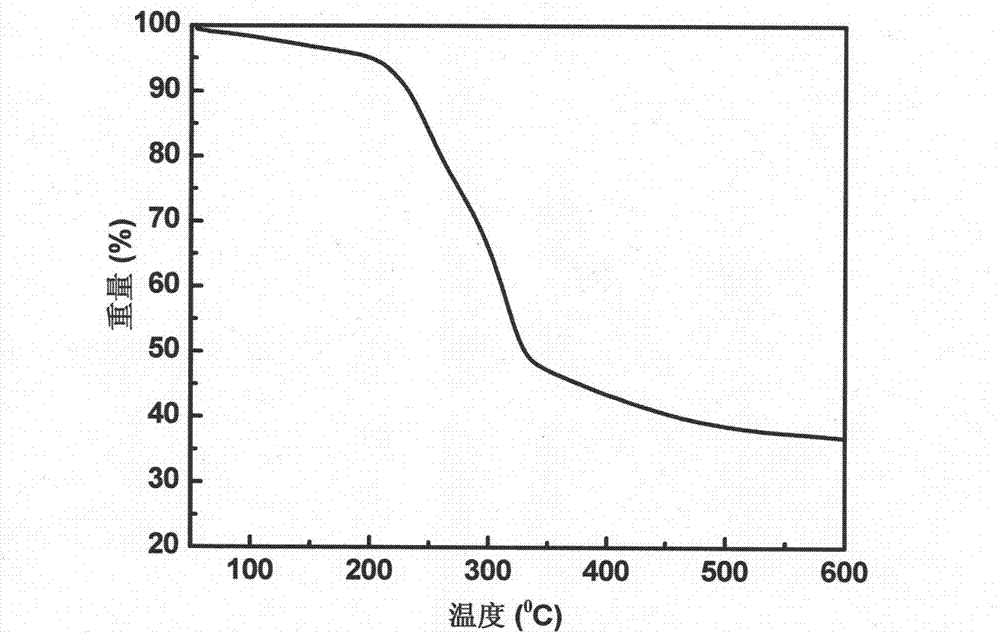

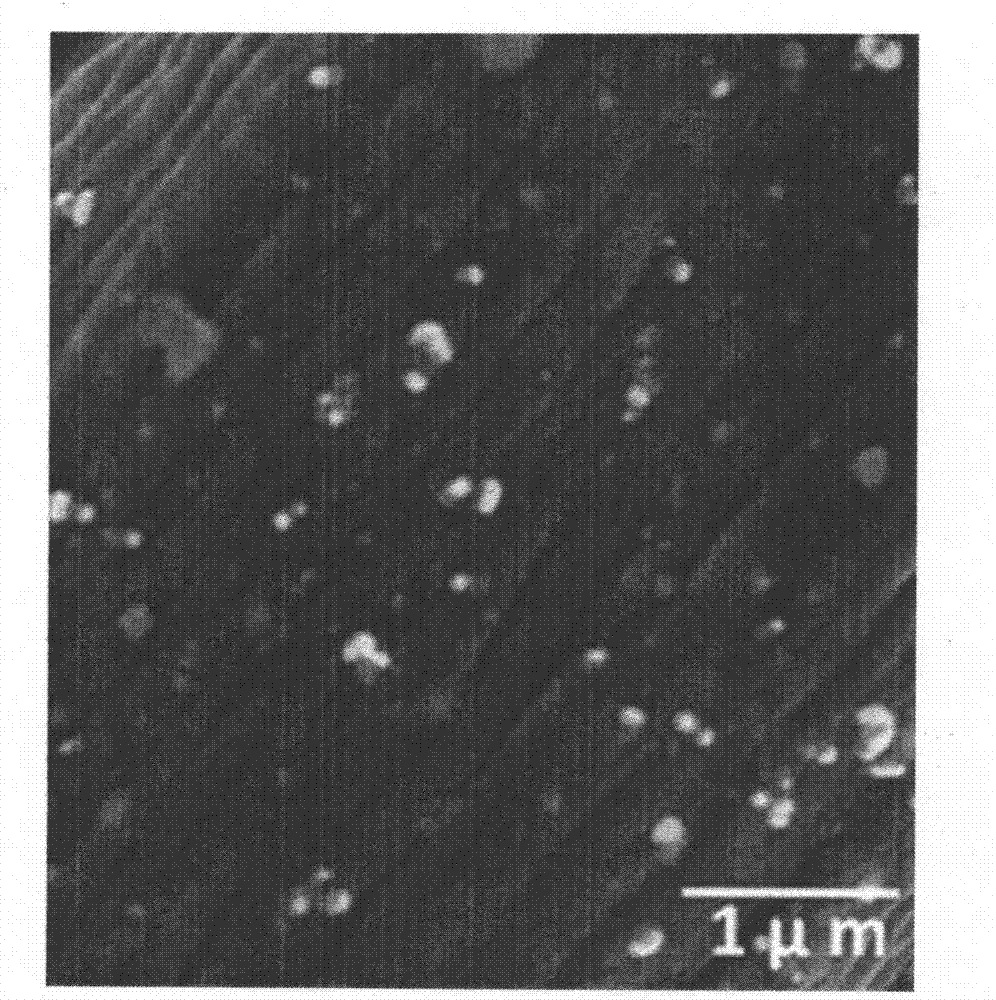

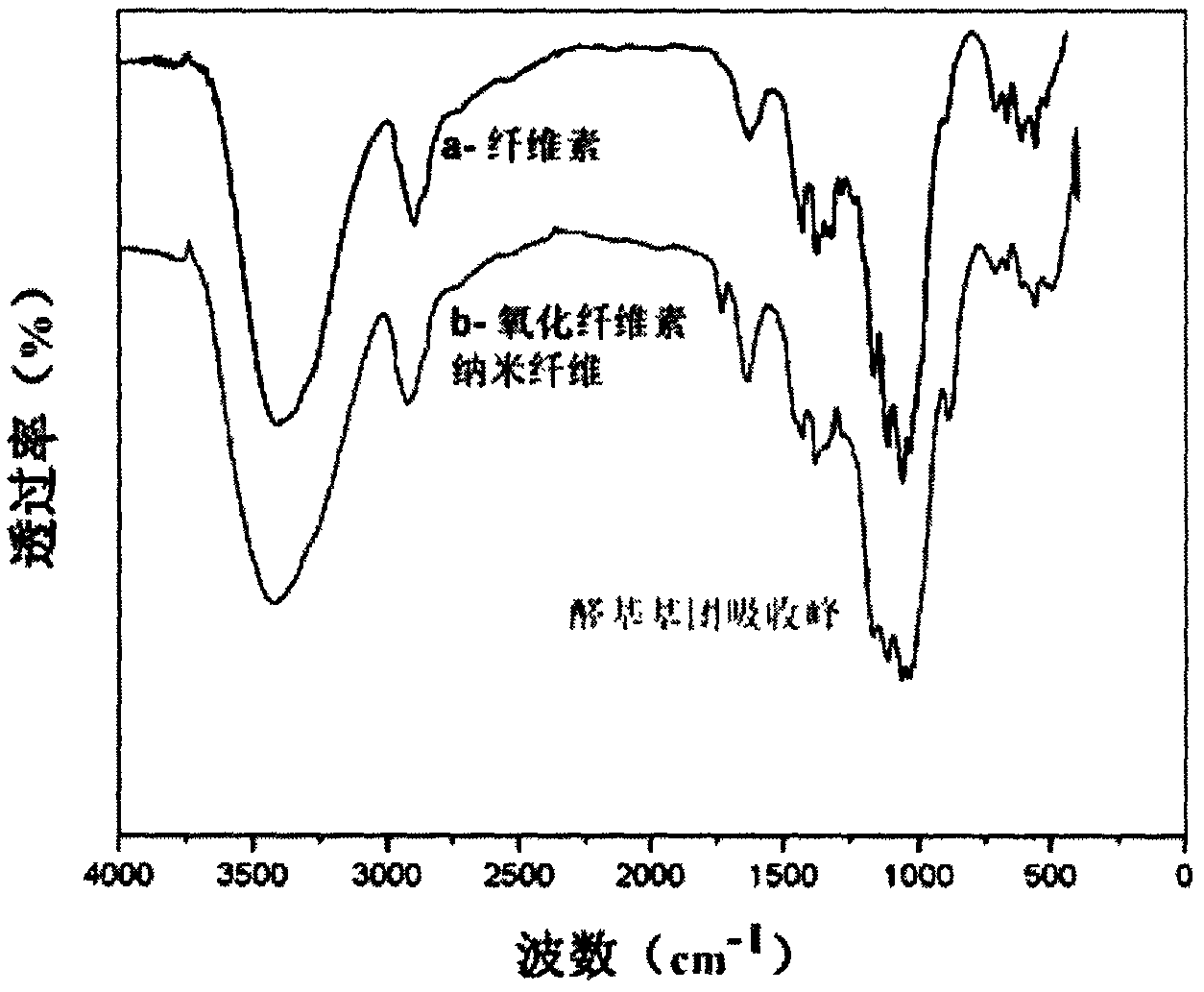

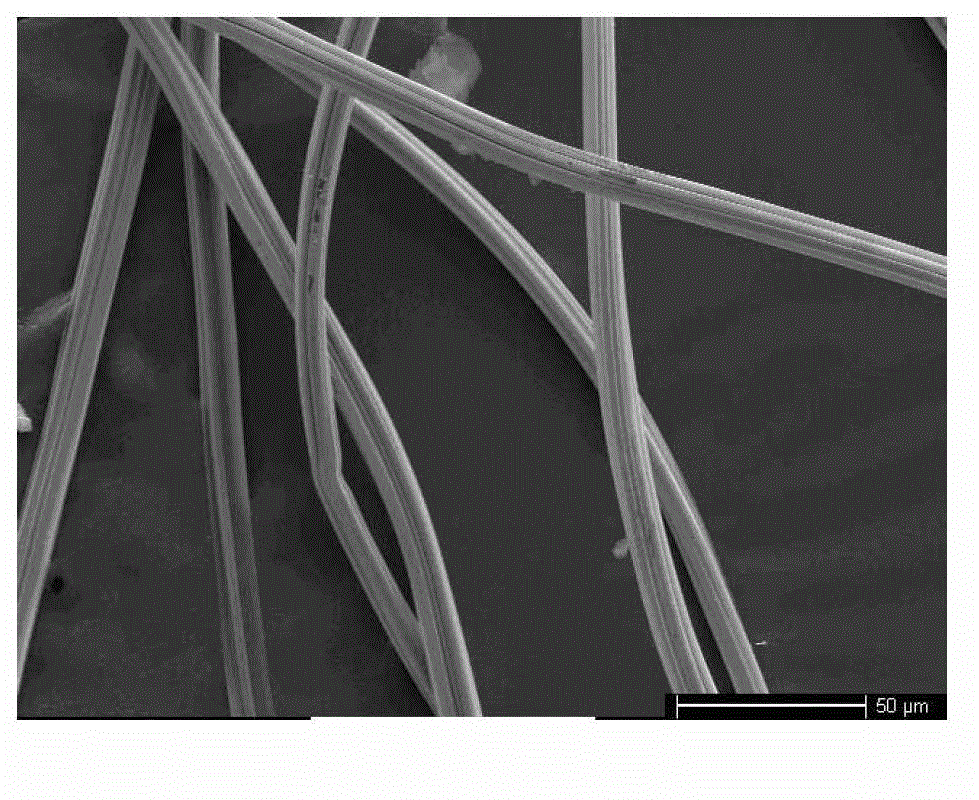

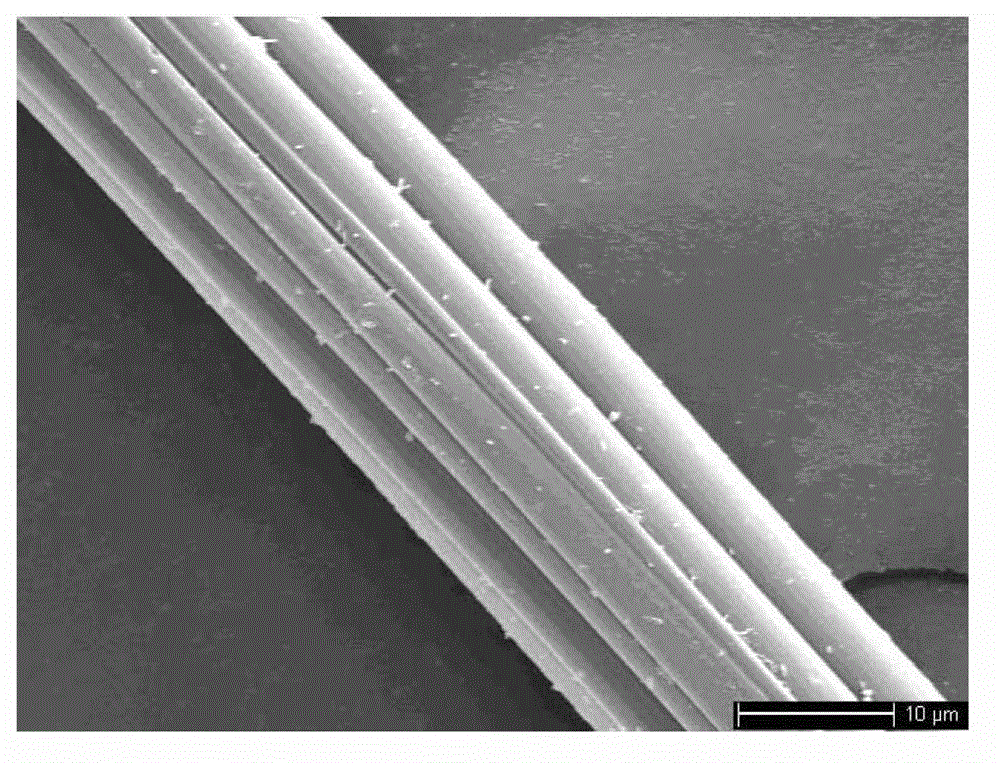

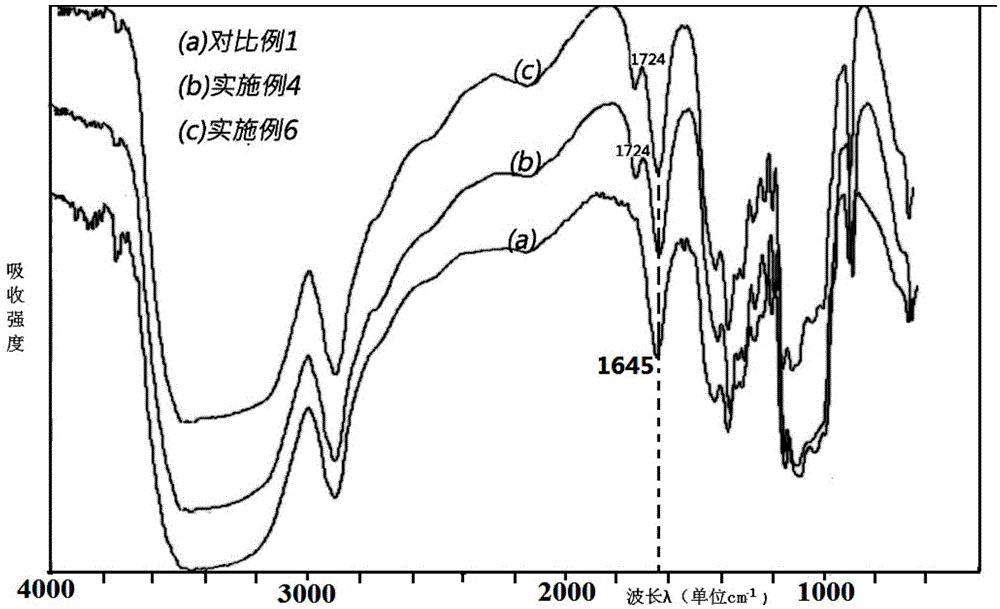

Cellulose fiber-supported nano silver antibacterial material and preparation method thereof

InactiveCN102776594ARich sourcesLow priceArtificial filaments from cellulose solutionsCellulose/protein filament chemical after-treatmentControlled releaseWound dressing

The invention discloses a cellulose fiber-supported nano silver antibacterial material and a preparation method thereof. The preparation method comprises the steps of: conducting chemical pretreatment on cellulose fibers, then conducting TEMPO (2, 2, 6, 6-tetramethylpiperidine-1-oxyl) selective oxidization on the cellulose fibers, and finally on the premise that not any reducing agent is added, enabling the oxidized cellulose fibers to react with silver nitrate in silver nitrate water solution through a short-time microwave heating method to prepare the cellulose fiber-supported nano silver antibacterial material with small-diameter and even-structure nano silver particles. By adopting the preparation method, on the premise that not any reducing agent is added, in-situ reduction and growth of nano silver on carboxylated cellulose fiber supporters are realized. The prepared cellulose fiber-supported nano silver antibacterial material has the advantages of small nano grain size and even size, and can be widely applied to the fields of antibacterial operation clothes, wound dressing, drug controlled release, textile coating and the like.

Owner:DONGHUA UNIV

Cellulose interpolymers and method of oxidation

ActiveUS7879994B2Decreasing and preventing frequencyPowder deliverySugar derivativesCarbon–carbon bondAcid value

This invention provides cellulose ester interpolymers, and methods of oxidizing cellulose interpolymers and cellulose ester interpolymers. The invention also provides routes to access carboxylated cellulose ester derivatives with high acid numbers wherein the carboxyl group is attached directly to the cellulose backbone by a carbon-carbon bond. Through functionalization of an intermediate aldehyde, the corresponding cationic or zwitterionic cellulose ester derivatives can also be accessed. The interpolymers of the present invention have a number of end-use applications, for example, as binder resins in various types of coating compositions and as drug delivery agents.

Owner:EASTMAN CHEM CO

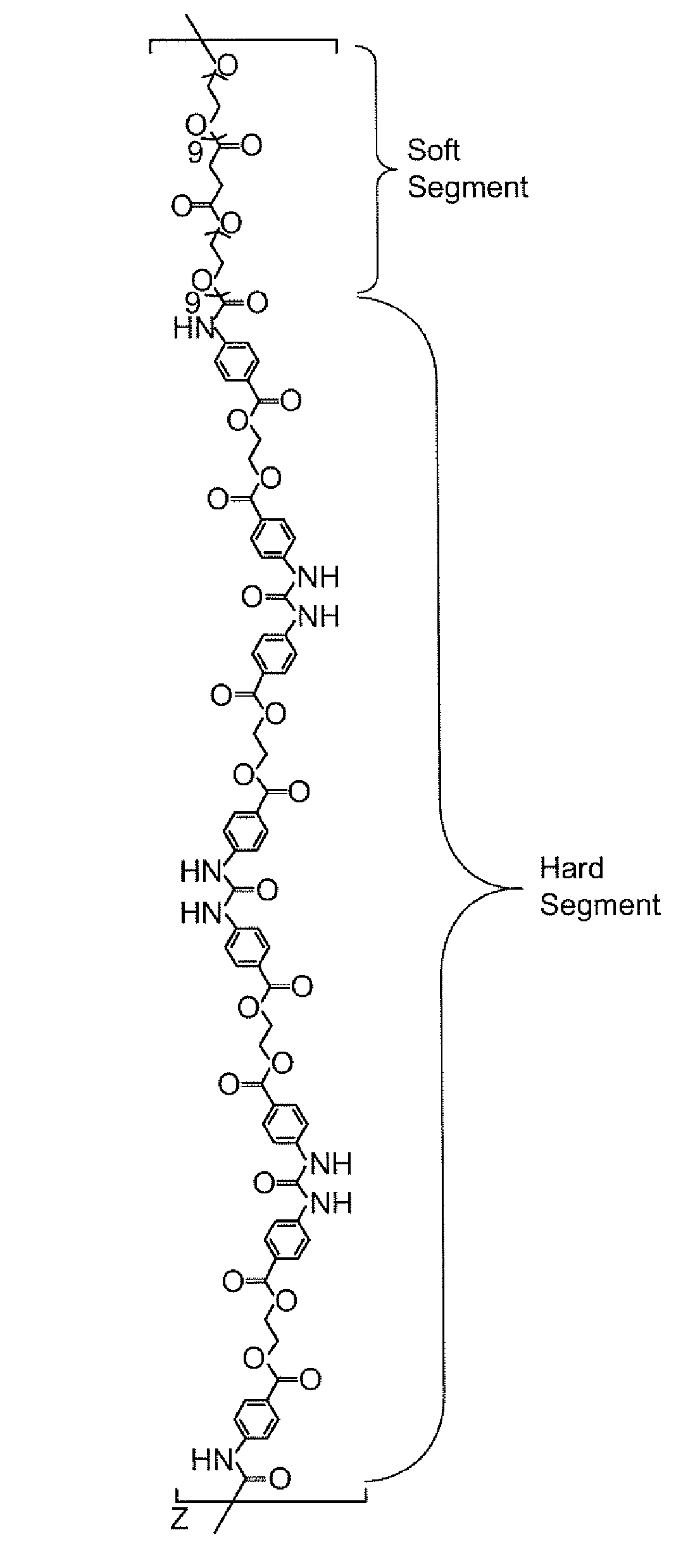

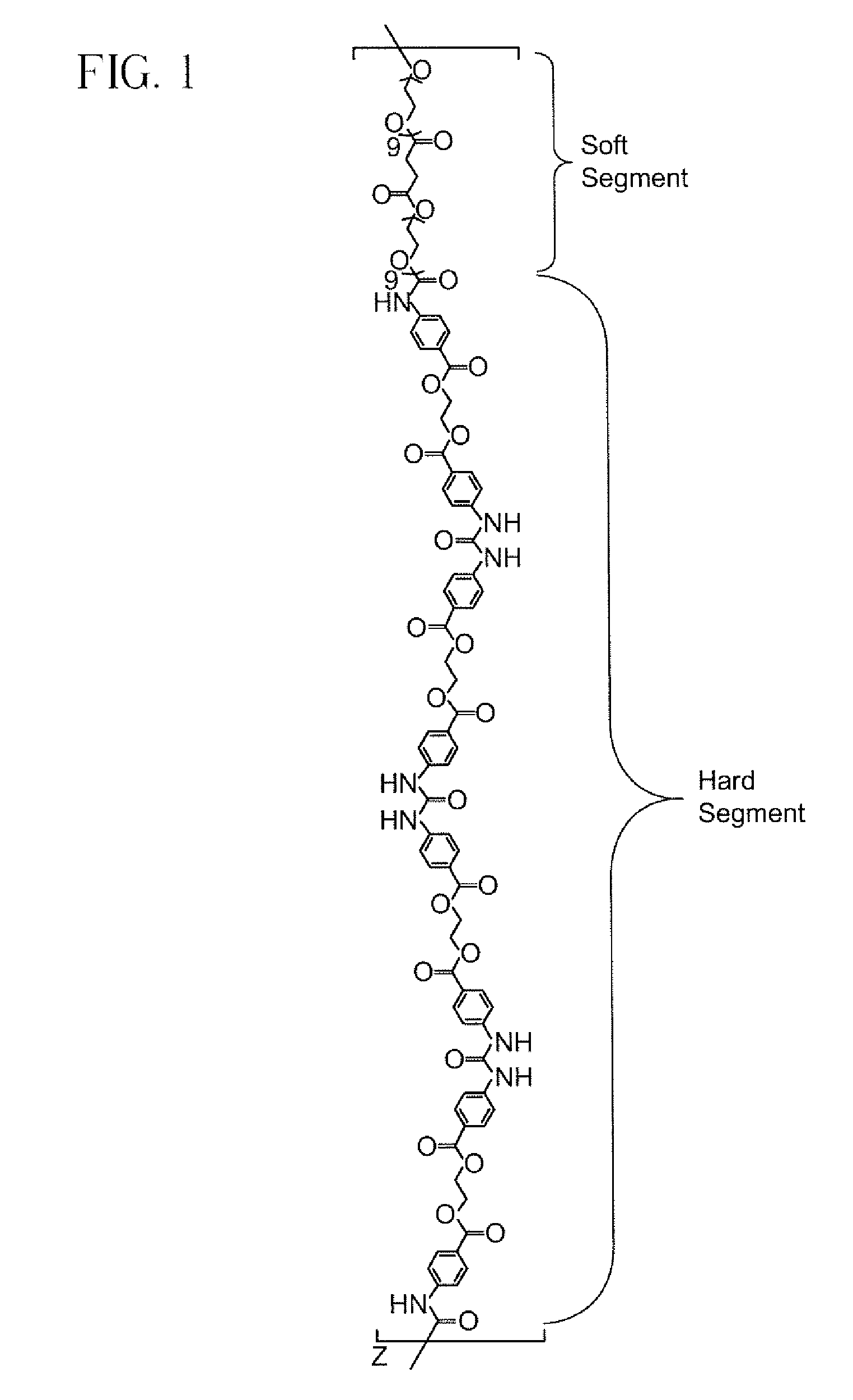

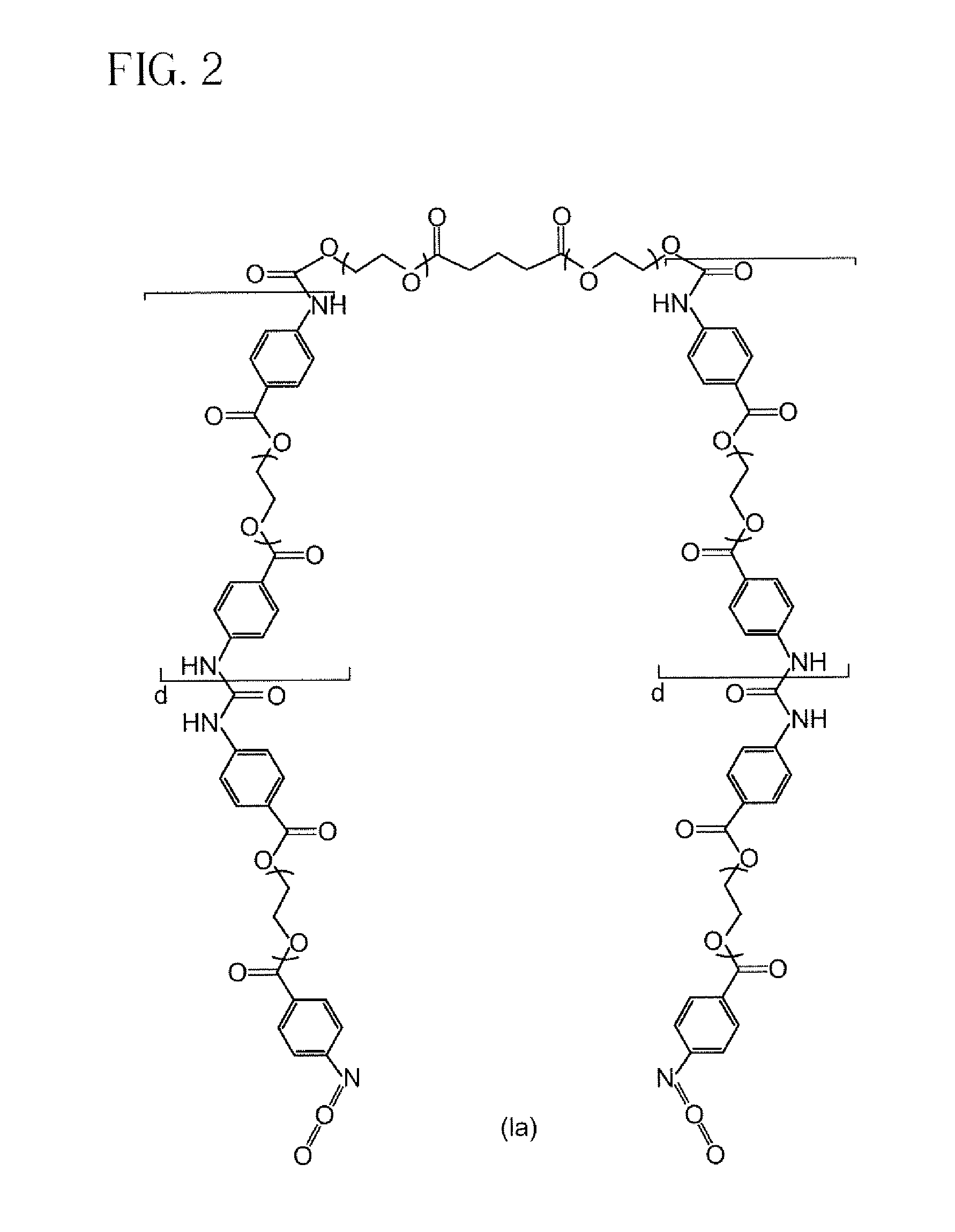

Medically acceptable formulation of a diisocyanate terminated macromer for use as an internal adhesive or sealant

A medically acceptable formulation comprising a diisocyanate terminated macromer or mixture thereof, and an oxidized cellulose.

Owner:ETHICON INC

Preparation method of modified cellulose heavy metal adsorbent

InactiveCN105013447AEfficient use ofRaw materials are cheap and easy to getOther chemical processesWater/sewage treatment by sorptionSorbentWastewater

The invention discloses a preparation method of a modified cellulose heavy metal adsorbent. The method includes the steps of: 1. preparation of alkalized cellulose; 2. preparation of oxidized cellulose; and 3. preparation of polyamino modified cellulose. The method specifically includes: firstly conducting alkali pretreatment on cellulose to obtain alkalized cellulose, then using sodium periodate as the oxidizing agent to carry out selective oxidation on the alkalized cellulose to obtain oxidized cellulose, then using glutaraldehyde as the cross-linking agent, and employing a polyamino compound to conduct amination modification on the oxidized cellulose, thus obtaining the modified cellulose heavy metal adsorbent. The method provided by the invention has the advantages of relatively mild preparation conditions, simple process, convenient operation, easy large scale, and good industrial popularization prospect. The product has strong heavy metal adsorption ability, and can be used for heavy metal ion wastewater, organic wastewater treatment and other fields.

Owner:NANTONG UNIVERSITY

A method of preparing a cellulose-based difunctional adsorbent

InactiveCN106914225AWide variety of sourcesEasy to prepareOther chemical processesWater contaminantsFreeze-dryingSorbent

Owner:GUANGXI UNIVERSITY OF TECHNOLOGY

Method for producing cellulose nanofibers

ActiveUS20140238626A1Low viscosityImprove liquidityPretreatment with water/steamPulp properties modificationHigh concentrationWater use

Provided is a method which is capable of producing a cellulose nanofiber dispersion liquid that has a low viscosity and excellent fluidity even at a high concentration, while exhibiting excellent transparency. In a method for producing cellulose nanofibers, wherein a cellulosic starting material is oxidized in water using an oxidant in the presence of an N-oxyl compound and a compound that is selected from the group consisting of a bromide, an iodide and a mixture thereof and the thus obtained oxidized cellulose is defibrated and dispersed, pulp which is obtained by carrying out kraft cooking after a hydrolysis process is used as the cellulosic starting material.

Owner:NIPPON PAPER IND CO LTD

Starch adhesive with nanometer oxidized cellulose size as matrix and preparation method of starch adhesive

ActiveCN105542676AAvoid replacementPrevent drynessNon-macromolecular adhesive additivesStarch derivtive adhesivesPolymer scienceSlurry

The invention discloses a starch adhesive with nanometer oxidized cellulose size as the matrix. The starch adhesive is prepared from, by weight, 100 parts of nanometer oxidized cellulose size with the oxidation rate of 5-30%, 10-40 parts of starch, 2-5 parts of oxidizing agent, 0.1-2 parts of stabilizer, 0.1-2 parts of preservative and 0.1-2 parts of emulsified paraffin. The preparation method includes the steps of preparing nanometer oxidized cellulose size the with oxidation rate of 5-30%, adding starch and 2-5 parts of oxidizing agent to the prepared nanometer oxidized cellulose size in batches, adding stabilizer, preservative and emulsified paraffin after sufficient stirring, and sufficiently stirring the components at a temperature of 50-70 DEG C till all the components are evenly dispersed to obtain the starch adhesive. The starch adhesive is high in bonding strength and high in water resistance. By means of the preparation method, the solvent replacement and drying process is avoided, energy consumption is greatly lowered, and labor intensity is reduced.

Owner:CENTRAL SOUTH UNIVERSITY OF FORESTRY AND TECHNOLOGY

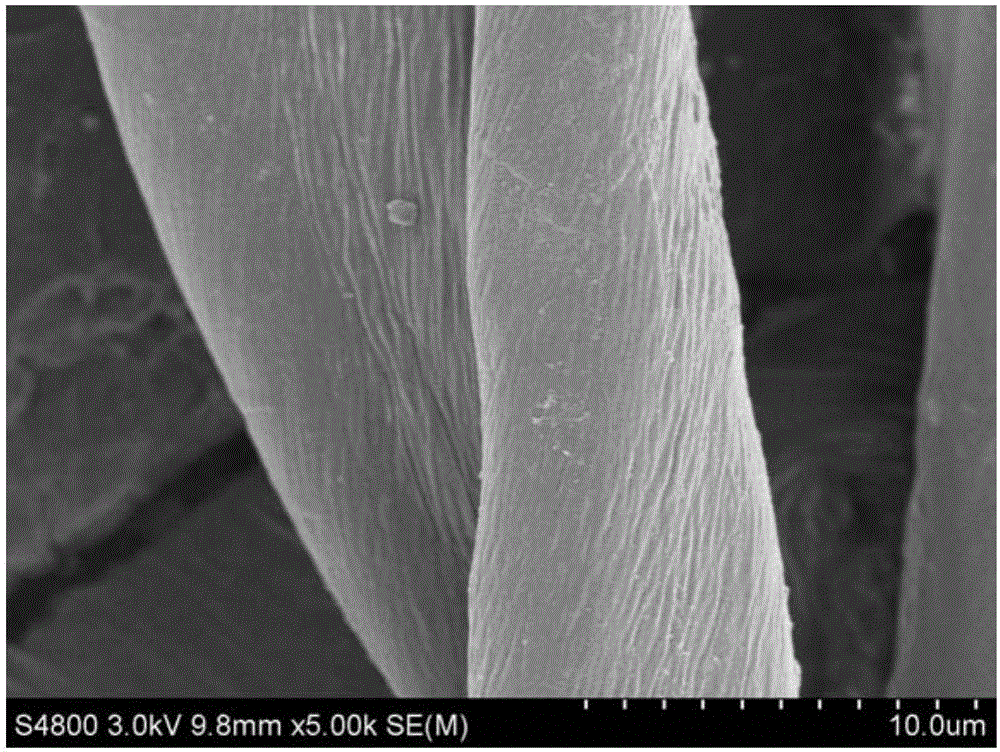

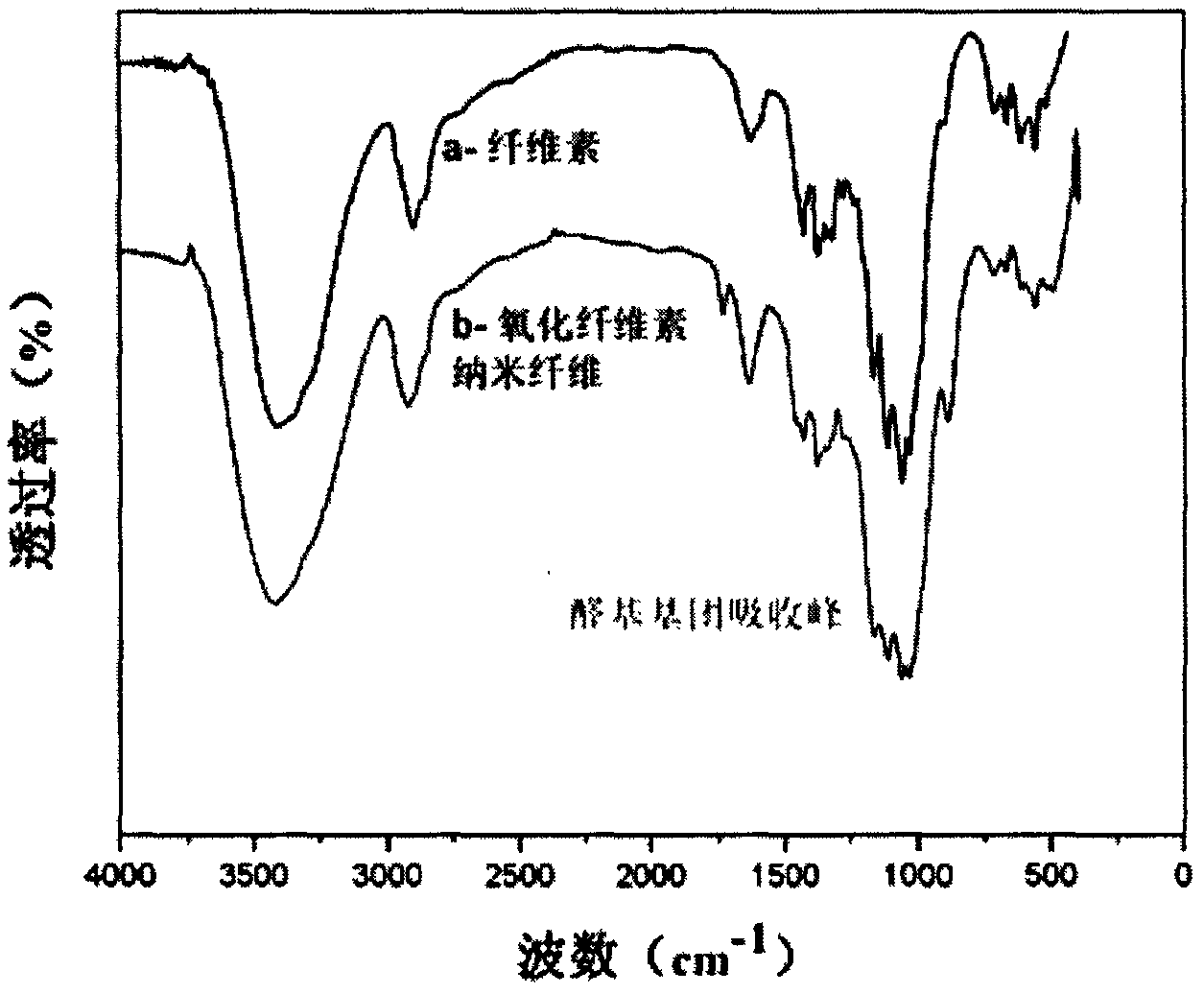

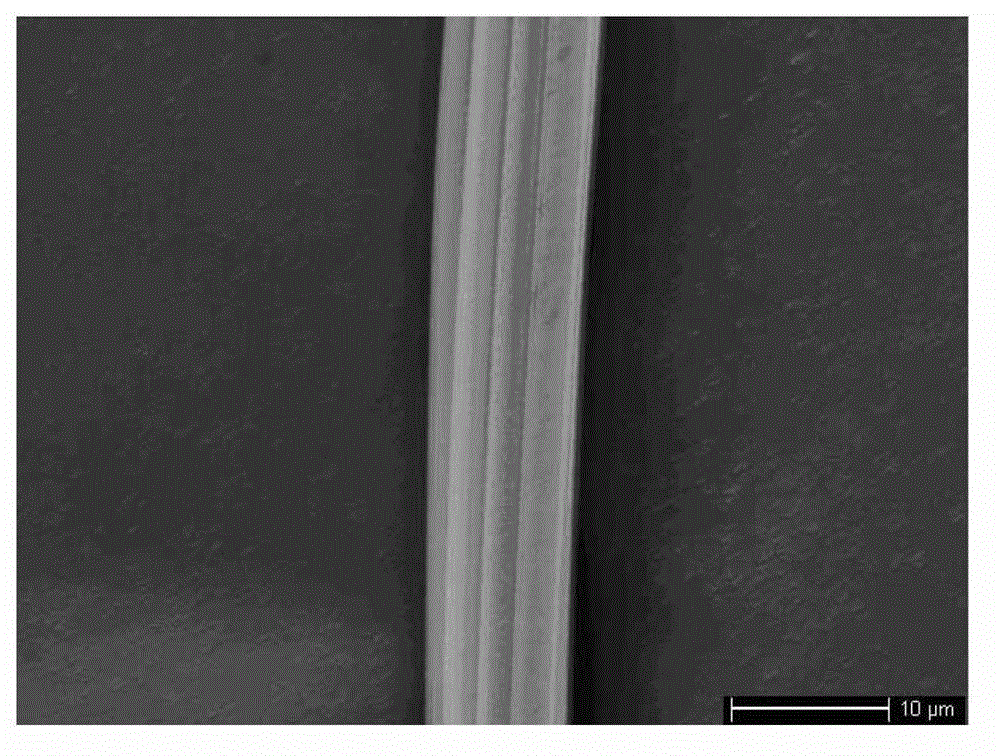

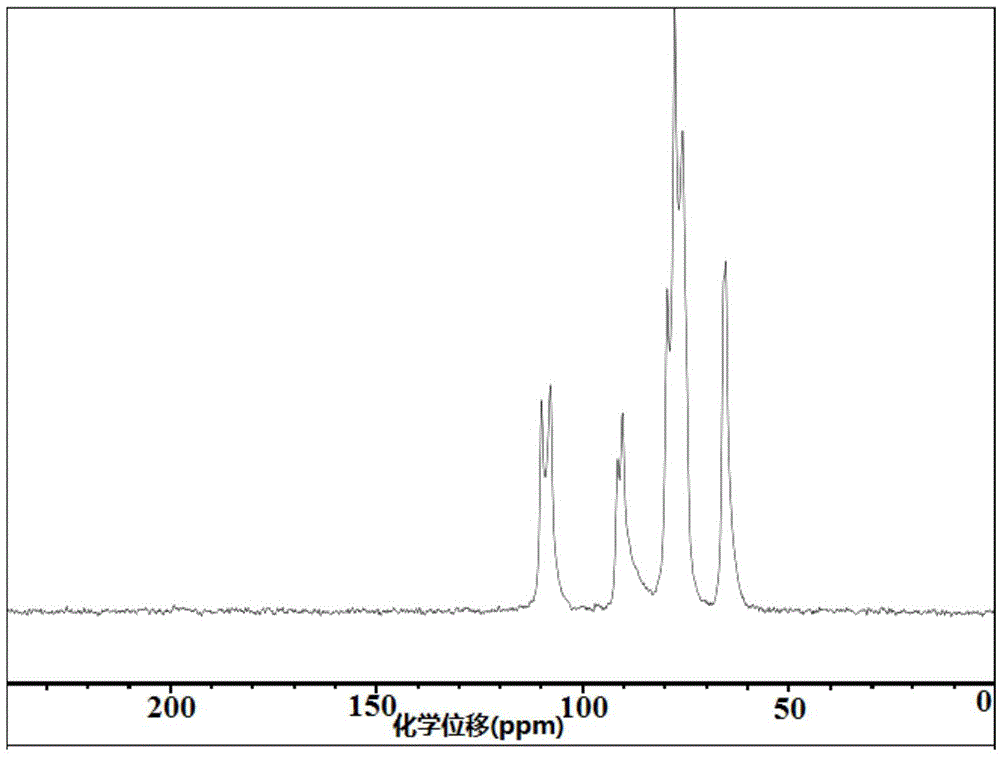

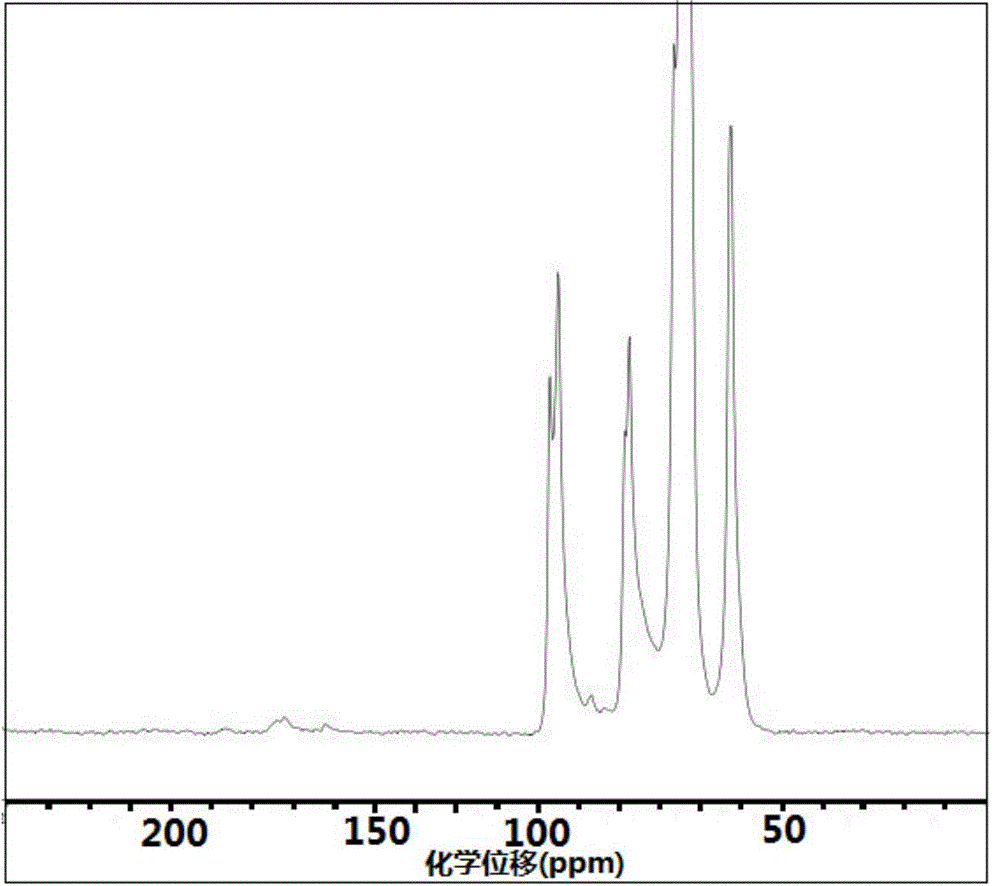

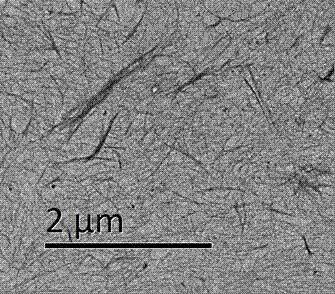

Oxidized cellulose nanofibers and preparation method thereof

InactiveCN102146594AMild degradationImprove conductivityFilament/thread formingArtificial filaments from cellulose derivativesFiberPorosity

The invention relates to a preparation method for aldehyde group or carboxyl group-containing oxidized cellulose nanofibers by adopting an electrostatic spinning method. The preparation method comprises the following steps of: oxidizing cellulose and performing electrostatic spinning on oxidized cellulose solution, wherein aldehyde groups and carboxyl groups are generated in the oxidized cellulose; 0.1 to 30 percent oxidized cellulose solution is obtained by dissolving the oxidized cellulose in a dissolution system; and oxidized cellulose non-woven fabric with the average thickness of 0.01 mu m to 5 mm, the porosity of 60 to 90 percent, the tensile strength of 1 to 20 MPa and the elastic elongation percentage of 1 to 15 percent; and the fibers have the diameters of between 50 nm and 3 mu m.

Owner:ZHANGJIAGANG NELLNANO TECH

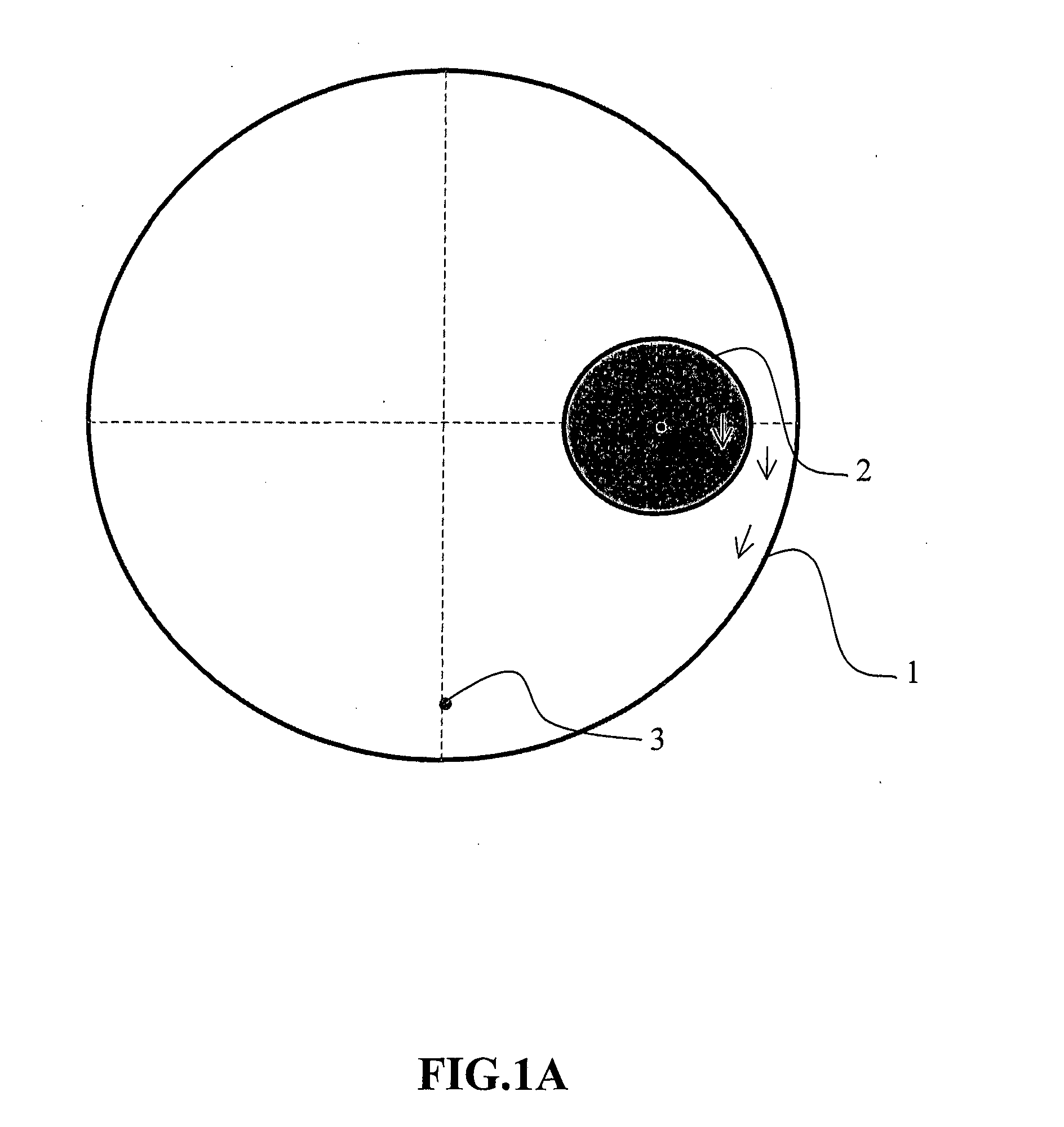

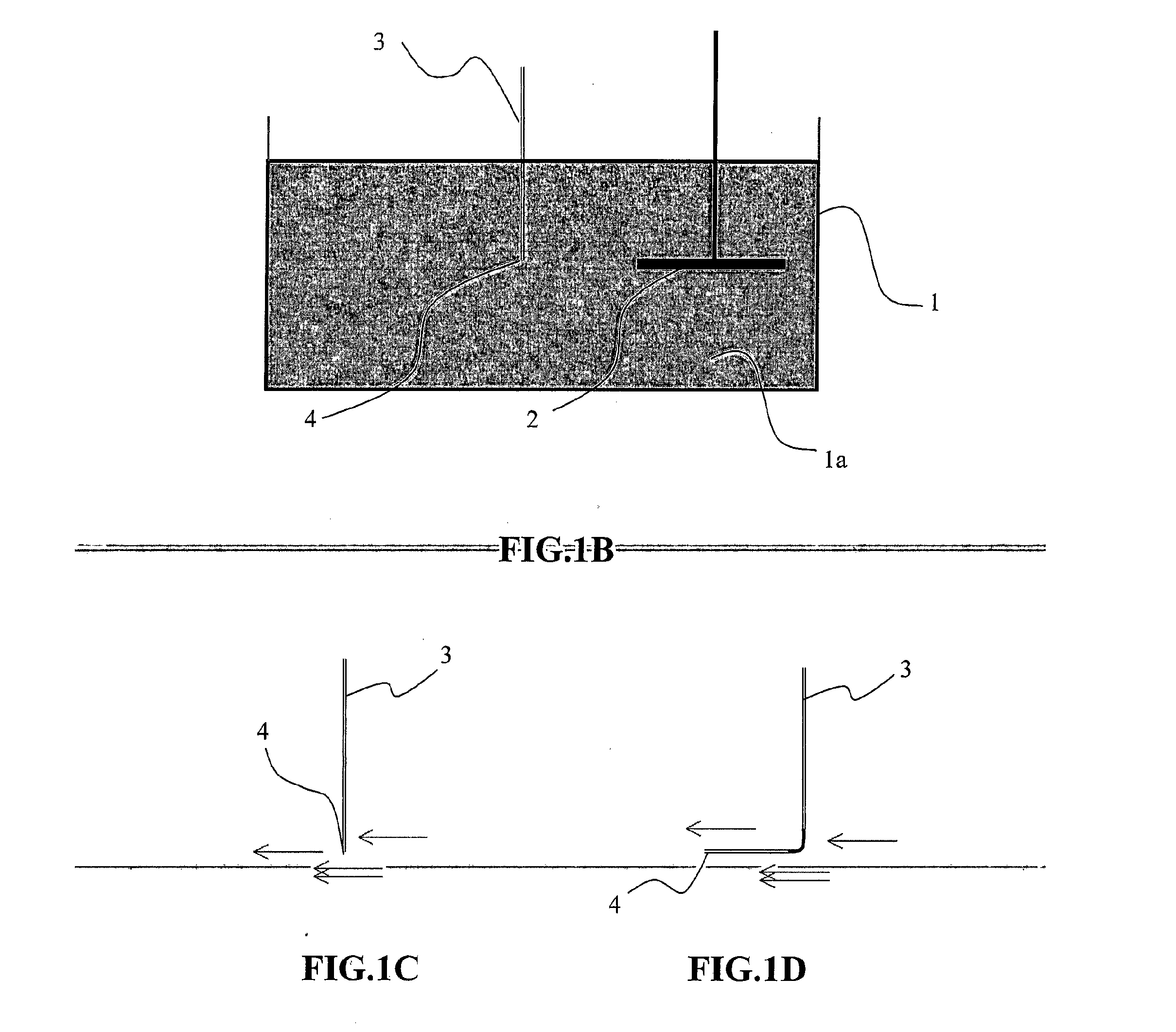

Method of Preparation of Polysaccharide Fibres, Wound Covers that Contain Them, Method of Manufacturing of Wound Covers, and Apparatus for Preparation of Polysaccharide Fibres

InactiveUS20150119783A1Low areal weightEasy to useNon-adhesive dressingsSpinning head liquid feederFiberCarboxymethyl cellulose

The invention relates to the method of the preparation of polysaccharide fibers based on hyaluronic acid, a compound comprising hyaluronic acid and metal ions, schizophylan, chitin / chitosan-glucan complex, a compound comprising chitin / chitosan-glucan complex and metal ions, internal mixture of chitin and chitosan, a compound comprising internal mixture of chitin and metal ions, sodium alginate, potassium alginate, ammonium alginate, xanthane, xanthane sodium salt, xanthane potassium salt, oxycellulose, oxycellulose sodium salt, oxycellulose potassium salt, carboxymethyl cellulose, carboxymethyl cellulose sodium salt, and carboxymethyl cellulose potassium salt, or a mixture of polysaccharides, in a non-stationary coagulation bath. Further the invention relates to covers of internal and external wounds and skin defects based on these fibers, and a method of production thereof, and the apparatus for the preparation of polysaccharide fibers.

Owner:CONTIPRO BIOTECH

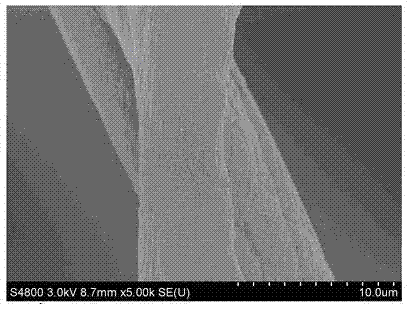

Preparation method for oxidized regenerated cellulose hemostatic material with surface nanostructure

ActiveCN102912622AAchieve hemostasisImprove adhesionFibre treatmentAbsorbent padsPolymer scienceViscose

The invention provides a preparation method for an oxidized regenerated cellulose hemostatic material with a surface nanostructure. In order to solve problems of small specific surface area, water insolubility, single hemostatic effect mechanism and low hemostatic speed of the traditional oxidized cellulose hemostatic material, the invention provides the preparation method for the oxidized regenerated cellulose hemostatic material with the surface nanostructure. The method comprises the following steps of: (1) preparing a collagen aqueous solution; (2) preparing a viscose fiber gauze; (3) preparing oxidized viscose staple fiber and oxidized viscose fiber gauze; (4) preparing an oxidized regenerated cellulose sodium solution or an oxidized regenerated cellulose potassium solution; (5) preparing an oxidized regenerated cellulose gauze; and (6) after collagen particles are sprayed, freezing and drying the oxidized regenerated cellulose gauze, so as to finish the preparation of the oxidized regenerated cellulose hemostatic material with the surface nanostructure. The preparation method for the oxidized regenerated cellulose hemostatic material with the surface nanostructure, provided by the invention, is applied to the preparation field of the oxidized regenerated cellulose hemostatic materials.

Owner:WEIGAO HLDG +1

Method for preparing carboxycellulose by using hydrogen peroxide

ActiveCN104017090AMild reaction conditionsEasy to manufactureOther chemical processesCooking & bakingFiltration

The invention relates to a method for preparing carboxycellulose by using hydrogen peroxide. The method comprises the steps of weighing 20 parts of cellulose in parts by mass, soaking in a pre-treatment solution of which the mass percentage is 5-40%, washing by using distilled water after soaking for 1-48 hours, performing suction filtration to be neutral, adding 10-80 parts of oxidant in parts by mass and a catalyst which accounts for 0.01-5% of the mass of cellulose, stirring for 0.5-96 hours by using a magnetic stirrer, performing solid-liquid separation, washing a solid product by using the distilled water until the pH value is 7.0, and baking an obtained solid sample in a baking oven at 40-80 DEG C for 4-12 hours to obtain oxidized cellulose with different oxidation degrees. The method disclosed by the invention is relatively mild in reaction condition, simple in process and high in yield, does not have special requirements for equipment technologies, is convenient for industrial application, is low in preparation cost, can not generate any harmful by-products, is green and environment-friendly, and can not cause any hazards and pollutions to the environment.

Owner:SOUTH CHINA UNIV OF TECH

Preparation method of cellulose nanofiber biomass gel and aerogel

The invention relates to a preparation method of cellulose nanofiber biomass gel and airgel, comprising the following steps: (1) treating cellulose with a TEMPO / NaBr / NaClO oxidation system to prepare oxidized cellulose; (2) Mechanically treat oxidized cellulose in an aqueous solution or weakly alkaline aqueous solution to obtain a cellulose nanofiber dispersion; (3) process the cellulose nanofiber dispersion through an acidic coagulation bath or an acidic steam bath to obtain a raw cellulose nanofiber. (4) drying and dehydrating the cellulose nanofiber biomass gel to prepare the cellulose nanofiber biomass aerogel. The preparation method of a cellulose nanofiber biomass gel of the present invention is simple and easy to control, low in cost, and environmentally friendly, and can prepare biomass gels and aerogels with good shape, high strength, and low fiber content. Biocompatible, non-toxic and harmless; the prepared biomass gel and aerogel with negative electrical properties have better reactivity and biological activity.

Owner:HEYE HEALTH TECH CO LTD +1

Crease-resistant finishing liquid for cotton fabric and application of crease-resistant finishing liquid

ActiveCN109137499AHigh strengthImprove stabilityWrinkle resistant fibresVegetal fibresFiberCarboxylic acid

The invention discloses crease-resistant finishing liquid for cotton fabric and application of the crease-resistant finishing liquid and belongs to textile finishing. The crease-resistant finishing liquid is characterized in that a laccase / TEMPO system is used to oxidize cellulose nanocrystals into aldehyde groups, the aldehyde groups and Girard's reagent T have Schiff base reaction to prepare positive ion modified cellulose nanocrystals, and the modified cellulose nanocrystals, 1,2,3,4-butanetetracarboxylic acid and chitosan are compounded to apply to the crease-resistant finishing of the cotton fabric. The crease-resistant finishing liquid has the advantages that the chitosan and the cellulose nanocrystals used by the finishing liquid are natural biomass materials and can copolymerize with BTCA on cotton fibers under high temperature to generate a long branched chain structure, and accordingly the cotton fabric after finishing has good crease resistance; in addition, by introducing the cellulose nanocrystals and the chitosan, the break strength retention and dyeing performance of the fabric after the crease-resistant finishing are improved, and the fabric is good in washing resistance stability and meets environment protection standards.

Owner:JIANGNAN UNIV

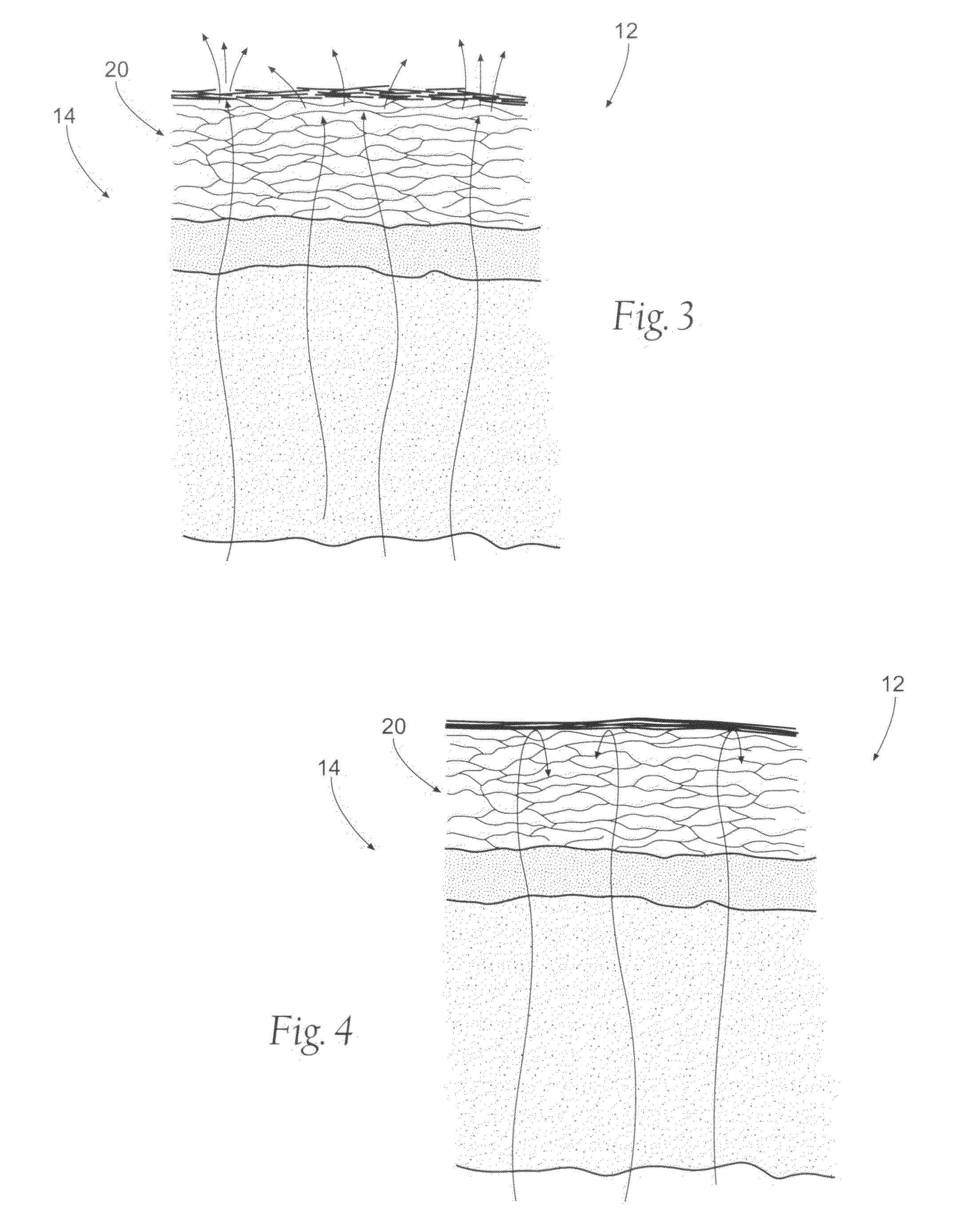

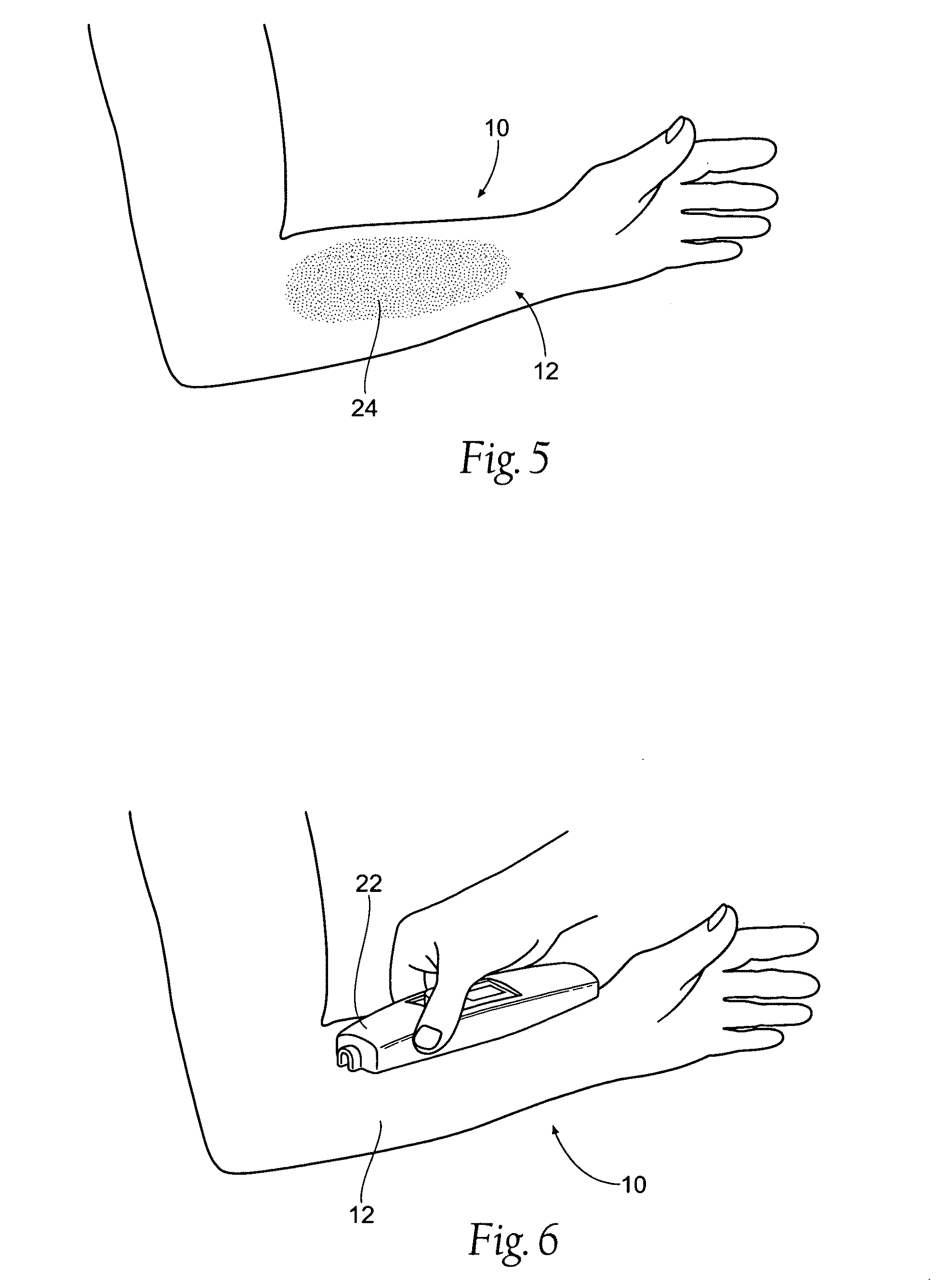

Assemblies, systems, and methods for skin treatment incorporating oxidized cellulose

InactiveUS20100266646A1EfficacyBiocideOrganic active ingredientsSkin treatmentsPolyanhydroglucuronic Acid

A refined oxidised cellulose (OC) material in various salt states having therapeutic treatments for skin. The micronized OC has a uniform particle size of the order of microns (0.001 to 0.050 mm). The OC is treated by further steps of oxidation, hydrolysis and refinement. The final product is chemically known as polyanhydroglucuronic acid, (PAGA). The salt versions of the OC are generally metal salts, such as sodium, calcium, zinc, copper, and silver.

Owner:HEMCON MEDICAL TECH IP

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com