Method for preparing carboxycellulose by using hydrogen peroxide

A carboxycellulose, hydrogen peroxide technology, applied in chemical instruments and methods, other chemical processes, etc., can solve the problems of limiting the wide application of oxidized cellulose, harsh conditions, and by-products leftover, etc., and achieves convenient industrial application and reaction conditions. Mild, lower production cost effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

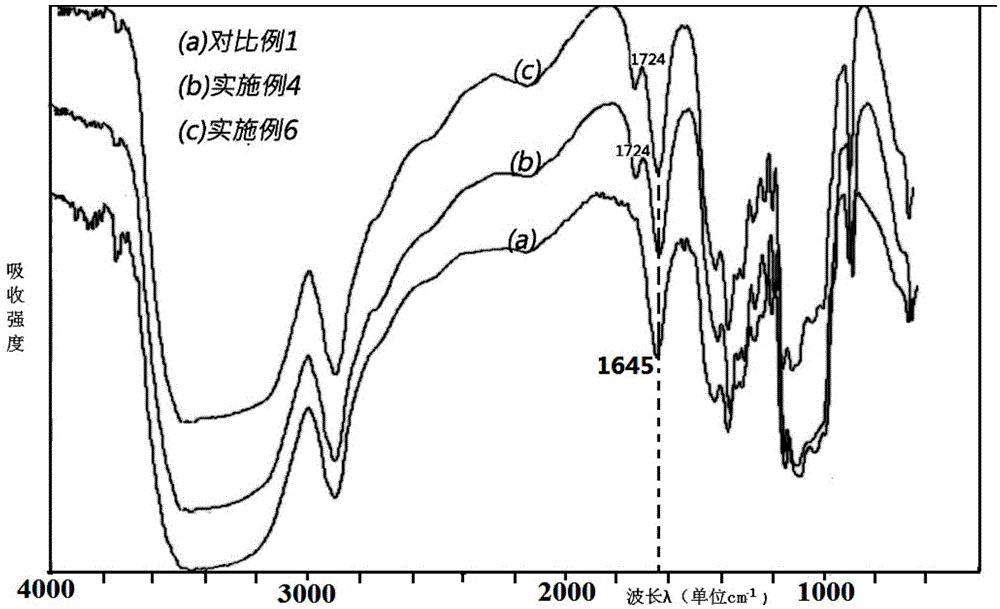

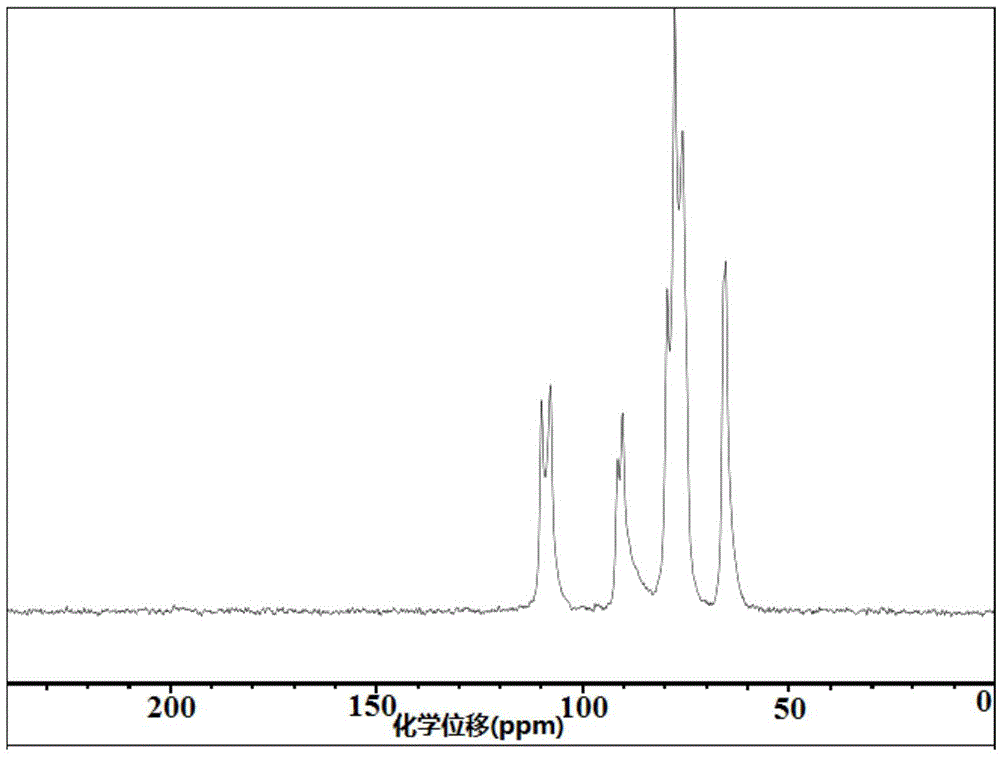

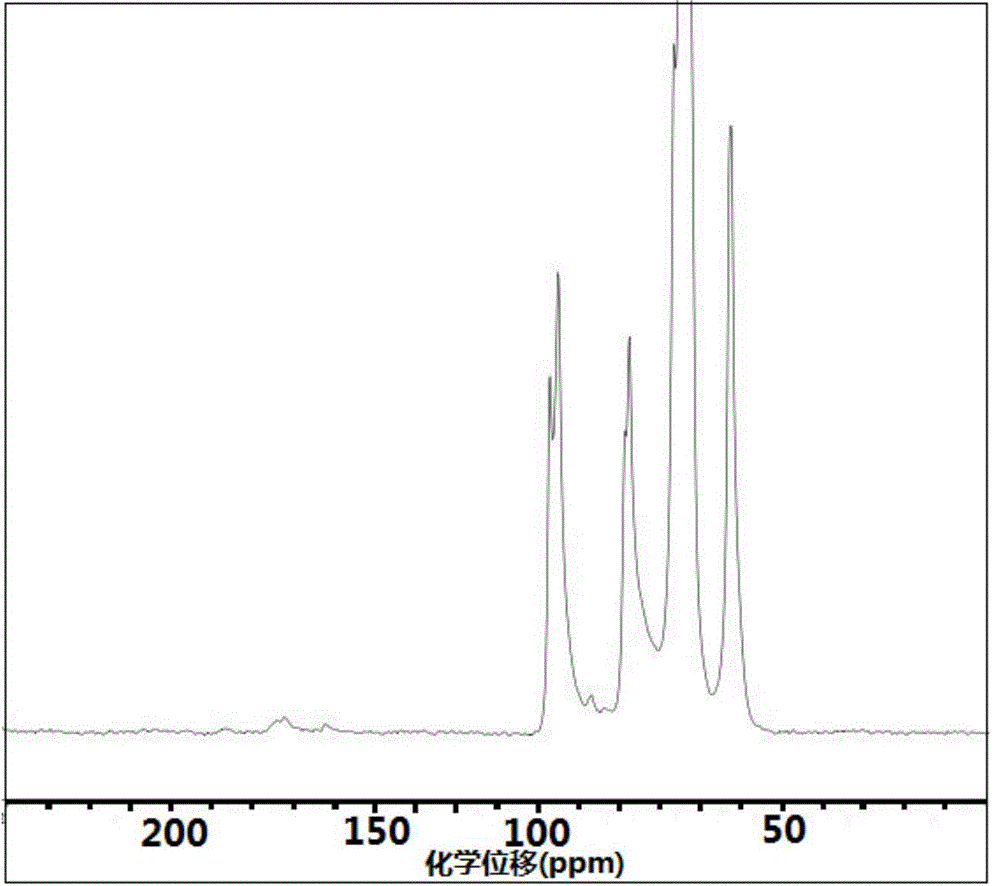

Method used

Image

Examples

Embodiment 1

[0040] Take 20 parts by mass of cellulose and soak it in a potassium carbonate solution with a mass fraction of 24%, wash it with distilled water after soaking for 2 hours, and filter it to neutrality, then add 14 parts of hydrogen peroxide and 100 parts of water , and cobalt sulfate accounting for 0.025% of the cellulose mass, stirred with a magnetic stirrer for 24 hours at a temperature of 20°C. After oxidation, it was washed with distilled water until the pH was 7, and the obtained sample was dried in an oven at 55°C for 8 hours to obtain oxidized cellulose with high carboxyl content, which was ground into powder and then dissolved and titrated, and the carboxyl content was measured as 6.3%.

Embodiment 2

[0042] Weigh 20 parts by mass of cellulose and soak it in 18% sodium hydroxide solution, wash with distilled water after soaking for 12 hours, and filter it to neutrality, then add 30 parts of hydrogen peroxide and 100 parts of cellulose Water, and iron sulfate accounting for 0.075% of the mass of cellulose were stirred with a magnetic stirrer for 48 hours at a temperature of 15°C. After oxidation, it was washed with distilled water until the pH was 7, and the obtained sample was dried in an oven at 60°C for 6 hours. After drying, it was ground into powder and then dissolved and titrated. The carboxyl content was found to be 6.7%.

Embodiment 3

[0044] Take 20 parts by mass parts of cellulose and soak it in a potassium hydroxide solution with a mass fraction of 30%, wash it with distilled water after soaking for 8 hours, and filter it to neutrality, then add 28 parts of hydrogen peroxide and 100 parts of Water and cobalt sulfate accounting for 1% of the cellulose mass were stirred with a magnetic stirrer for 75 hours at a temperature of 25°C. After oxidation, the sample was washed with distilled water until the pH was 7, and the obtained sample was dried in an oven at 60°C for 7 hours. After drying, it was ground into powder and then dissolved and titrated. The carboxyl content was found to be 6.6%.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com