Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

32 results about "Liquid crystal polymer substrate" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

A liquid crystal polymer (LCP) is an inert, highly water-resistant polymer that is suitable for the encapsulation of electronic components and as a substrate material for fabricating neural interfaces.

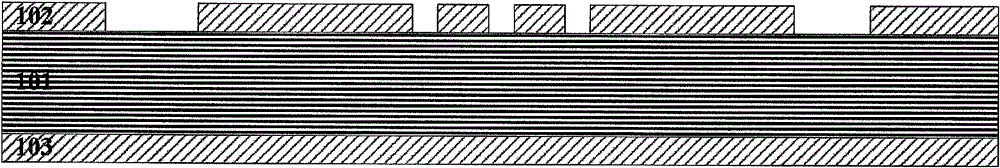

Compact tapered slot antenna

InactiveUS20120313832A1Wide frequency bandwidthImprove rigidityCoupling devicesSlot antennasPermittivityEngineering

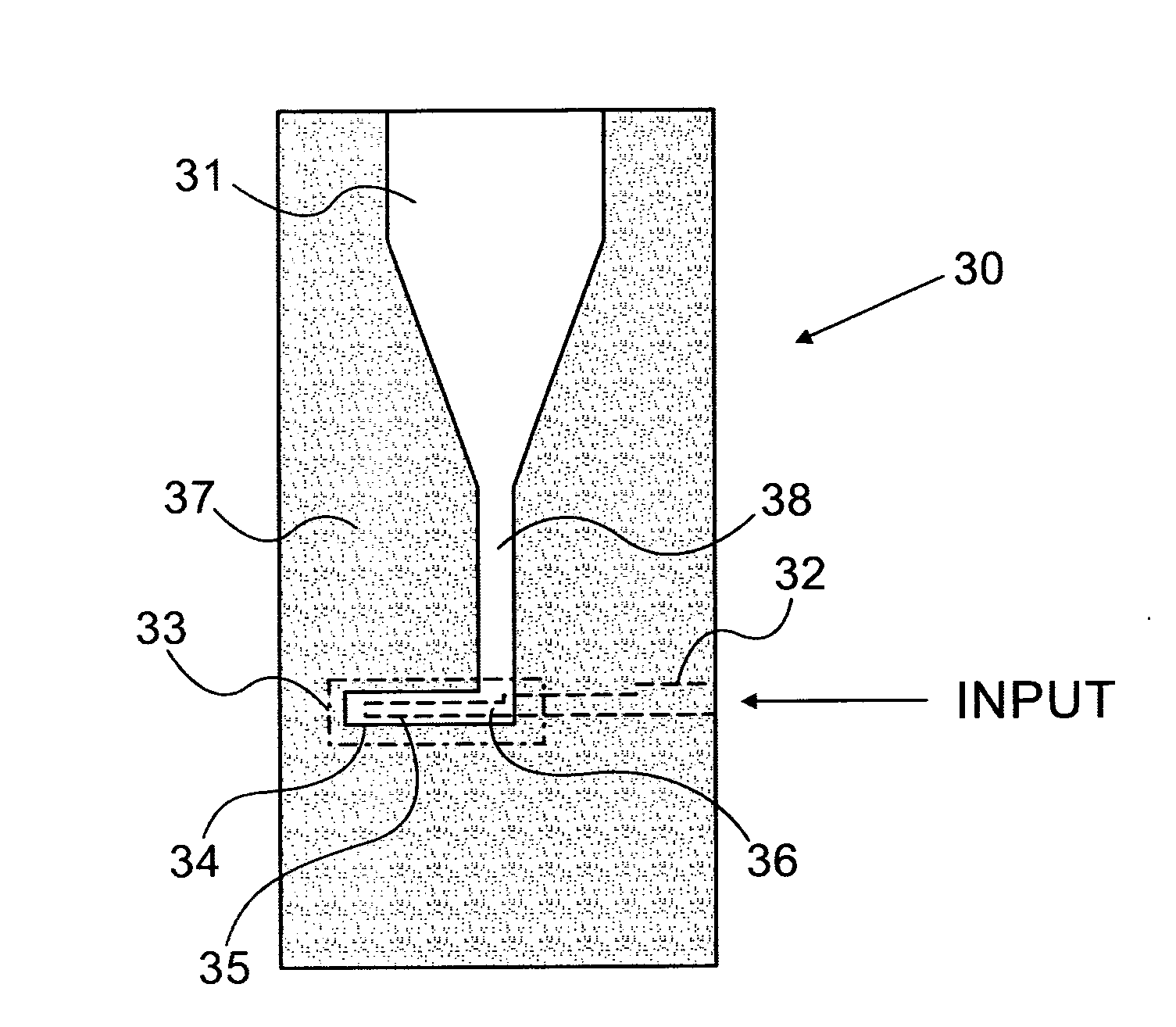

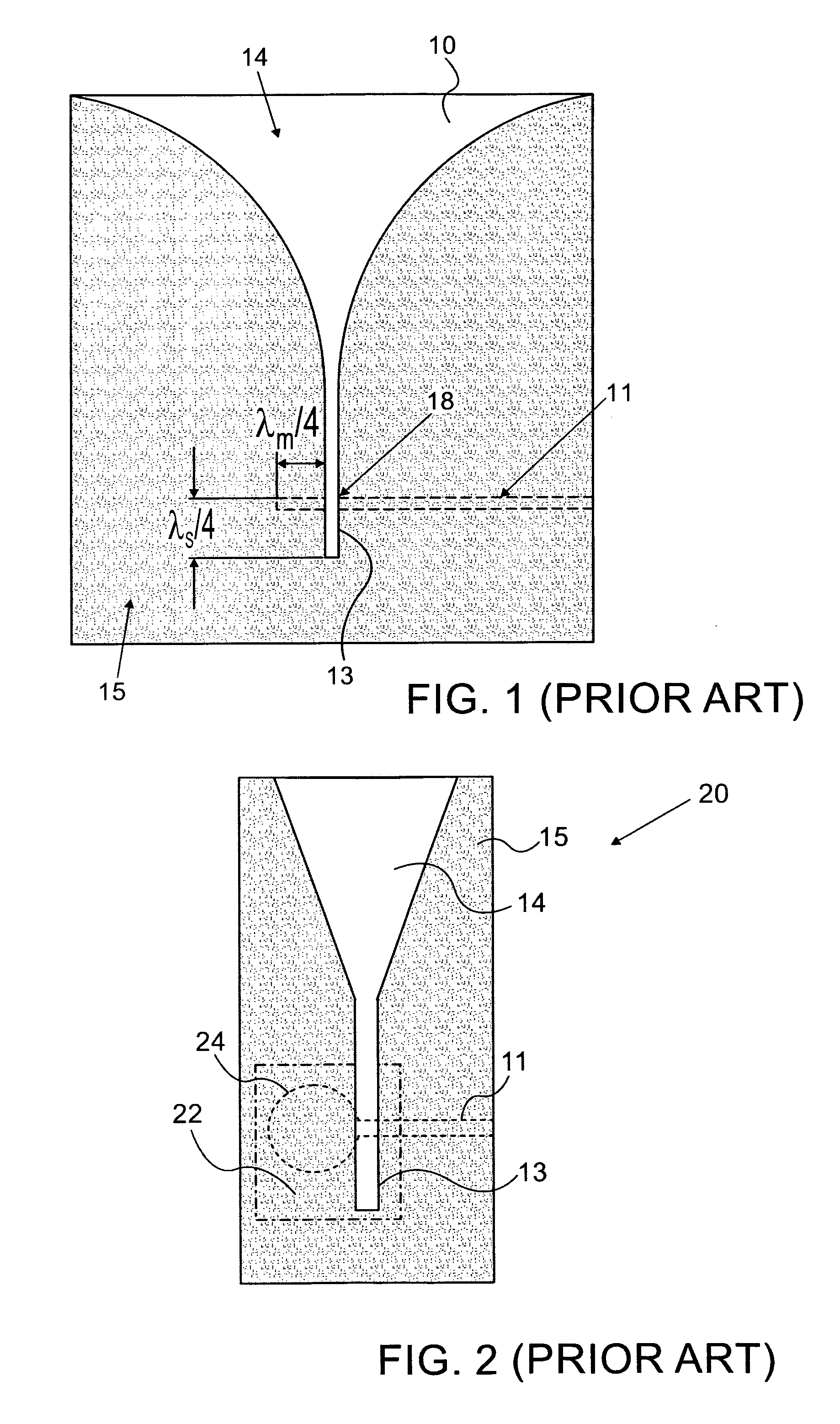

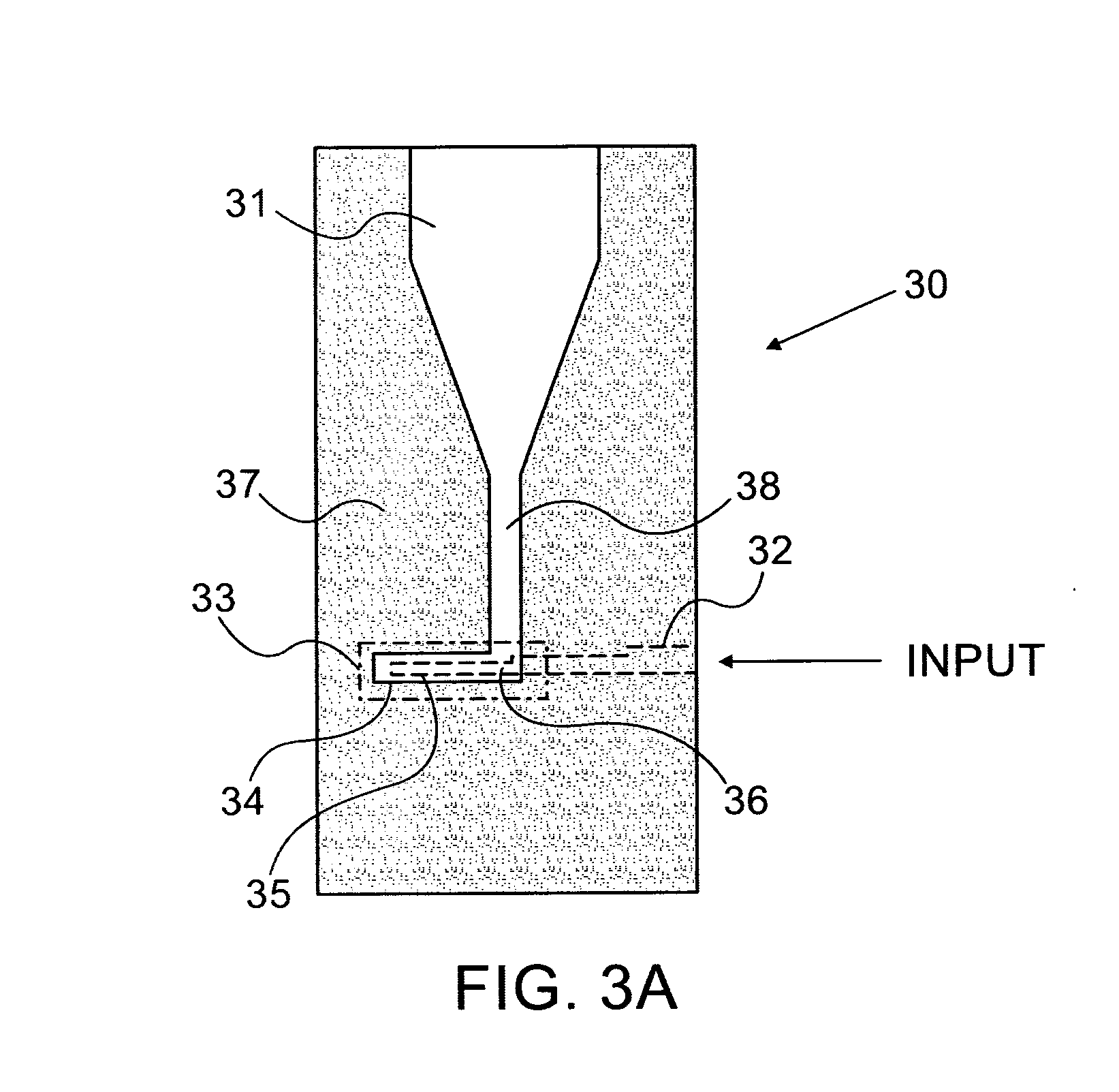

A compact endfire tapered slot antenna, which may be advantageously printed on a low permittivity Liquid Crystal Polymer substrate. The antenna features a microstrip-to-slot transition, in which the matching stubs of the slotline antenna feed and the microstrip input line are collinear. This is achieved using a 90° bend in the slotline. The antenna is consequently of smaller size, and has improved bandwidth over prior art geometries. The antenna may be carried on a fork-shaped metallic carrier, which gives it good rigidity, and may incorporate a metallic reflector, which increases its directive gain. The antenna is simpler to manufacture and a less costly alternative to conventional 60-GHz tapered slot antennas printed on multilayer LTCC substrates. It can be used both as an individual radiator as well as an element of an antenna array and is readily integrated INPUT with an RF module for use in future WPAN applications.

Owner:TECHNION RES & DEV FOUND LTD

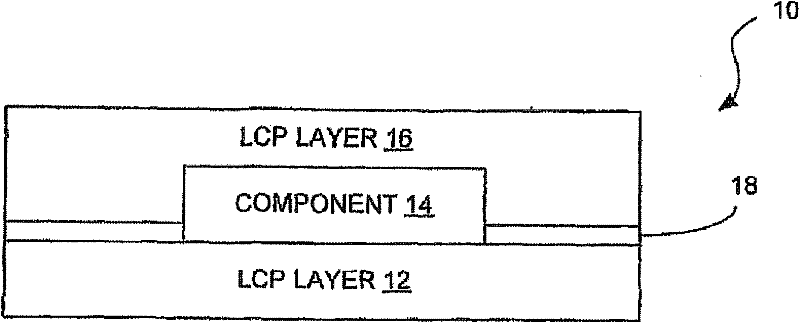

A method of fabricating a multilayer organic liquid crystal polymer substrate structure

ActiveCN102683220BGet Rid of CTE Matching IssuesImprove performancePrinted circuit assemblingSemiconductor/solid-state device manufacturingMicrowaveHigh density

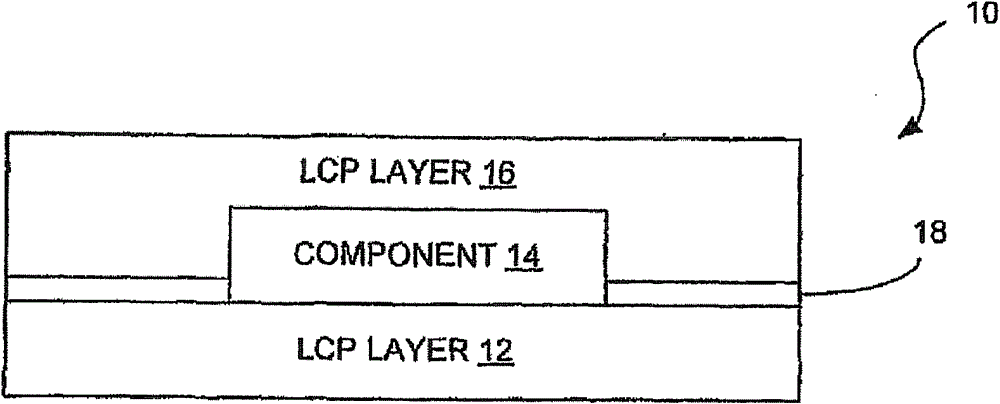

The invention discloses a method for making a multi-layer organic liquid crystal polymer (LCP) substrate structure. The method comprises the following steps: providing a first LCP core substrate and a second LCP core substrate; connecting an active device to the first LCP core substrate in an inverted manner; arranging a passive device on the second LCP core substrate by means of surface mounting, sequentially overlapping and stacking the second LCP core substrate mounted with the passive device, an LCP dielectric layer and the first LCP core substrate connected with the active device in an inverted manner, and thermoforming to obtain the multi-layer LCP substrate structure embedded with both the active device and the passive device. The multi-layer LCP substrate structure can be used for making a microwave / millimeter wave system level module and has the characteristic of achieving a system with high density, small size, high performance, high frequency, low value and low consumption.

Owner:NAT CENT FOR ADVANCED PACKAGING CO LTD

Liquid crystal polymers for flexible circuits

InactiveUS6696163B2Improve bindingElectrical connection between head and armRecord carriersFlexible circuitsSolvent

A process for providing a metal-seeded liquid crystal polymer comprising the steps of providing a liquid crystal polymer substrate to be treated by applying an aqueous solution comprising an alkali metal hydroxide and a solubilizer as an etchant composition for the liquid crystal polymer substrate. Further treatment of the etched liquid crystal polymer substrate involves depositing an adherent metal layer on the etched liquid crystal polymer substrate. An adherent metal layer may be deposited using either electroless metal plating or vacuum deposition of metal such as by sputtering. When using electroless metal plating, a tin(II) solution applied to the liquid crystal polymer provides a treated liquid crystal polymer substrate to which the application of a palladium(II) solution provides the metal-seeded liquid crystal polymer. The etchant composition comprises a solution in water of from 35 wt. % to 55 wt. % of an alkali metal salt, and from 10 wt. % to 35 wt. % of a solubilizer dissolved in the solution to provide the etchant composition suitable for etching the liquid crystal polymer at a temperature from 50° C. to 120° C. A flexible circuit comprising a liquid crystal polymer film having through-holes and related shaped voids may be formed using etchant compositions as previously described. Etchant solutions may be used to prepare the surfaces of materials for formation of composite structures useful in applications including flexures for hard disk drives.

Owner:3M INNOVATIVE PROPERTIES CO

Liquid crystal polymers for flexible circuits

InactiveUS20020028293A1High operating requirementsReduce absorptionInsulating substrate metal adhesion improvementAfter-treatment detailsFlexible circuitsSolvent

A process for providing a metal-seeded liquid crystal polymer comprising the steps of providing a liquid crystal polymer substrate to be treated by applying an aqueous solution comprising an alkali metal hydroxide and a solubilizer as an etchant composition for the liquid crystal polymer substrate. Further treatment of the etched liquid crystal polymer substrate involves depositing an adherent metal layer on the etched liquid crystal polymer substrate. An adherent metal layer may be deposited using either electroless metal plating or vacuum deposition of metal such as by sputtering. When using electroless metal plating, a tin(IT) solution applied to the liquid crystal polymer provides a treated liquid crystal polymer substrate to which the application of a palladium(II) solution provides the metal-seeded liquid crystal polymer. The etchant composition comprises a solution in water of from 35 wt. % to 55 wt. % of an alkali metal salt, and from 10 wt. % to 35 wt. % of a solubilizer dissolved in the solution to provide the etchant composition suitable for etching the liquid crystal polymer at a temperature from 50° C. to 120° C. A flexible circuit comprising a liquid crystal polymer film having through-holes and related shaped voids may be formed using etchant compositions as previously described.

Owner:3M INNOVATIVE PROPERTIES CO

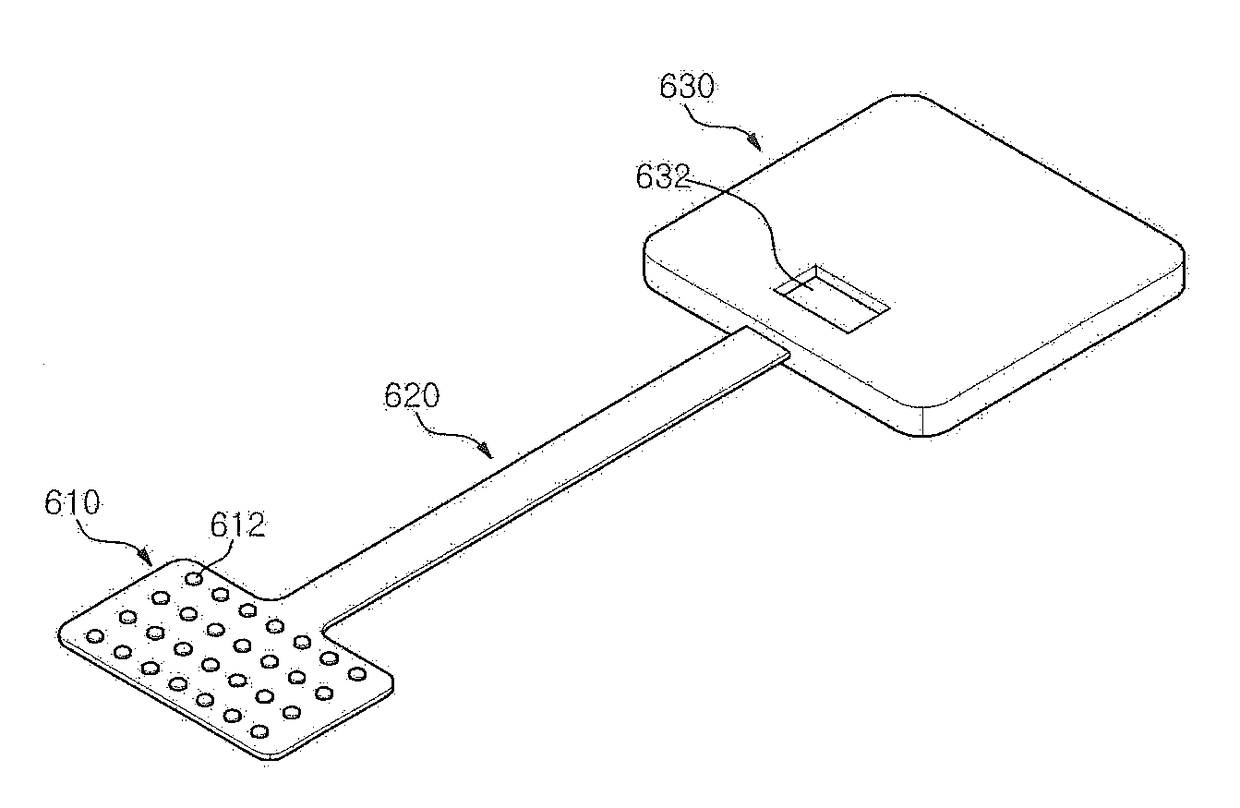

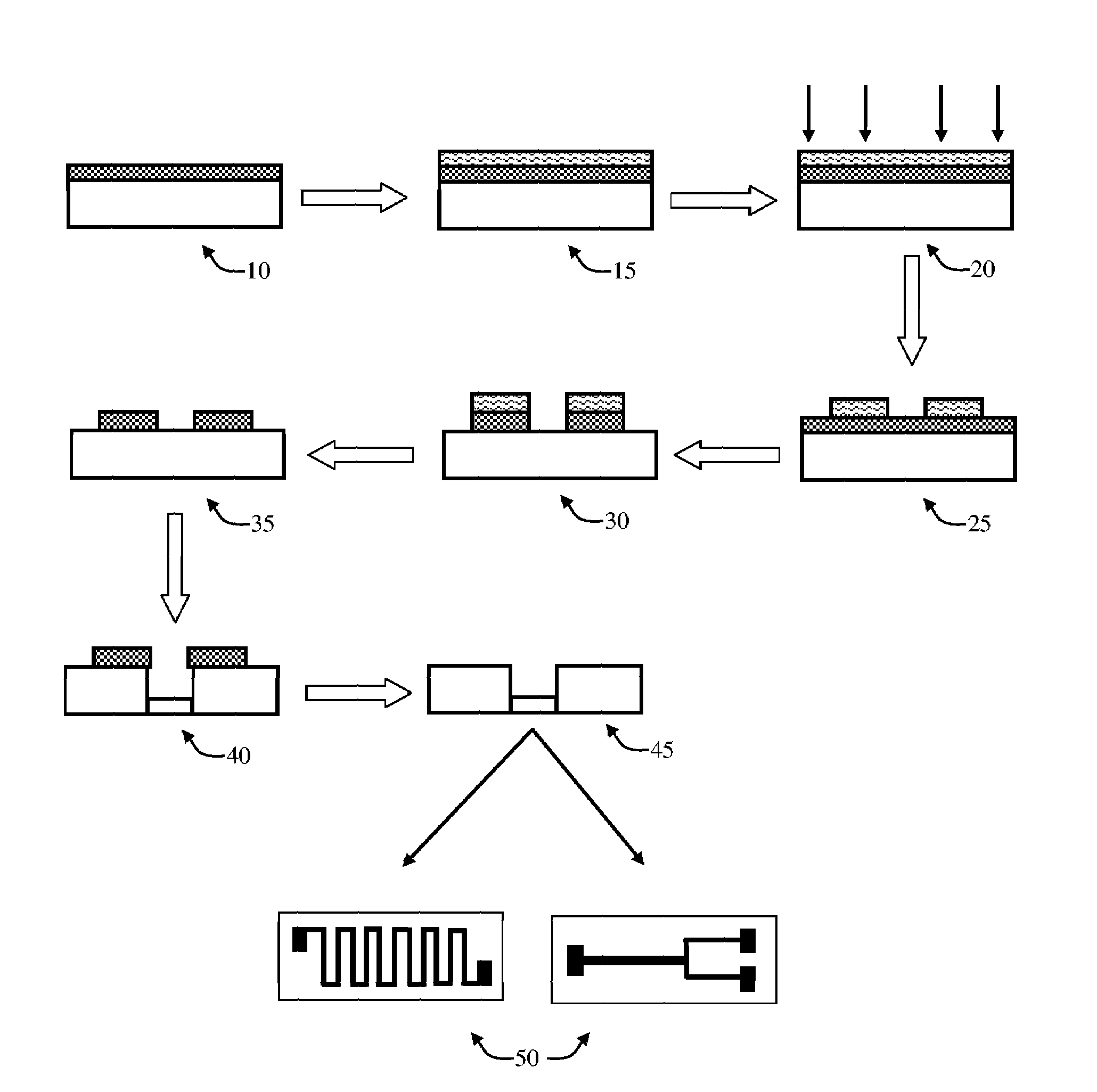

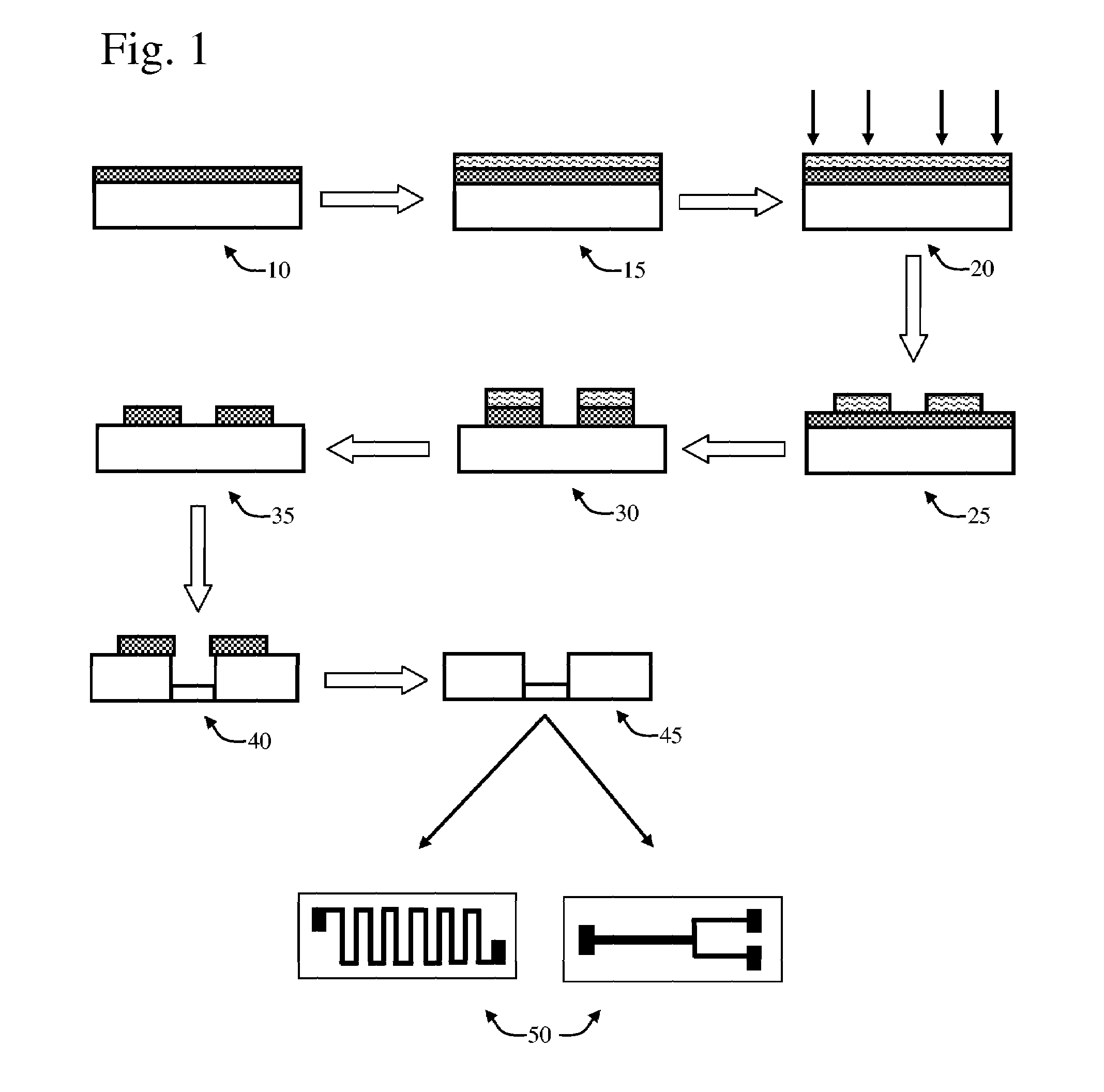

Liquid crystal polymer-based electrode array and package for neural implant, and manufacturing method therefor

ActiveUS20170232250A1Increase productionReduce manufacturing costSpinal electrodesEye implantsLiquid-crystal displayNeurological implant

A method for manufacturing a liquid crystal polymer-based electrode array for a neural implant, according to the present invention, can comprise the steps of: forming a seed layer on a liquid crystal polymer substrate; forming a plating mold having a pattern selectively exposing a part of the upper part of the seed layer; plating an electrode material on the exposed seed layer by using the plating mold as a plating barrier layer; forming an electrode by removing the plating mold and the seed layer therebelow; embedding the electrode by compressing a liquid crystal polymer cover layer on the electrode; and forming an electrode site exposing the upper part of the electrode by selectively removing a part of the liquid crystal polymer cover layer.

Owner:SEOUL NAT UNIV R&DB FOUND

Compact tapered slot antenna

InactiveUS9142889B2Improve rigidityNot possible to improveCoupling devicesSlot antennasEngineeringPermittivity

Owner:TECHNION RES & DEV FOUND LTD

Liquid crystal polymers for flexible circuits

InactiveUS20020155280A1Improve bindingElectrical connection between head and armRecord carriersFlexible circuitsSolvent

A process for providing a metal-seeded liquid crystal polymer comprising the steps of providing a liquid crystal polymer substrate to be treated by applying an aqueous solution comprising an alkali metal hydroxide and a solubilizer as an etchant composition for the liquid crystal polymer substrate. Further treatment of the etched liquid crystal polymer substrate involves depositing an adherent metal layer on the etched liquid crystal polymer substrate. An adherent metal layer may be deposited using either electroless metal plating or vacuum deposition of metal such as by sputtering. When using electroless metal plating, a tin(II) solution applied to the liquid crystal polymer provides a treated liquid crystal polymer substrate to which the application of a palladium(II) solution provides the metal-seeded liquid crystal polymer. The etchant composition comprises a solution in water of from 35 wt. % to 55 wt. % of an alkali metal salt, and from 10 wt. % to 35 wt. % of a solubilizer dissolved in the solution to provide the etchant composition suitable for etching the liquid crystal polymer at a temperature from 50° C. to 120° C. A flexible circuit comprising a liquid crystal polymer film having through-holes and related shaped voids may be formed using etchant compositions as previously described. Etchant solutions may be used to prepare the surfaces of materials for formation of composite structures useful in applications including flexures for hard disk drives.

Owner:3M INNOVATIVE PROPERTIES CO

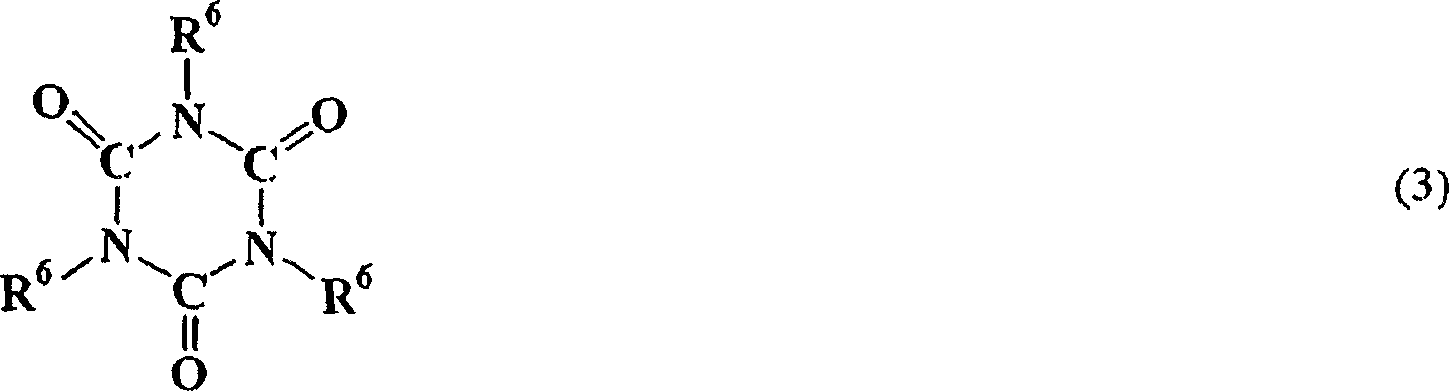

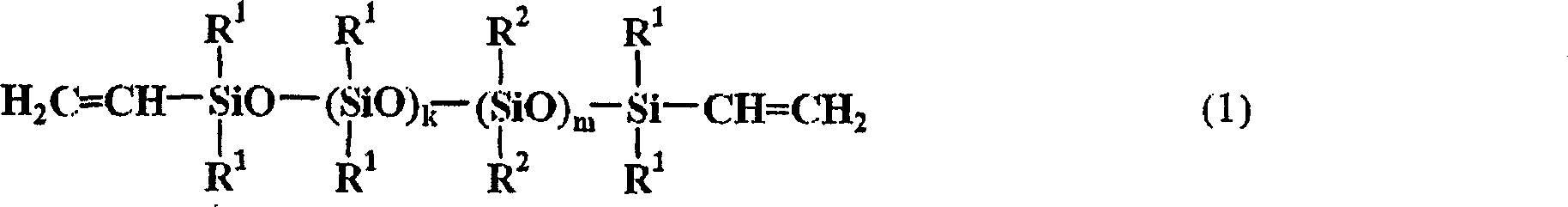

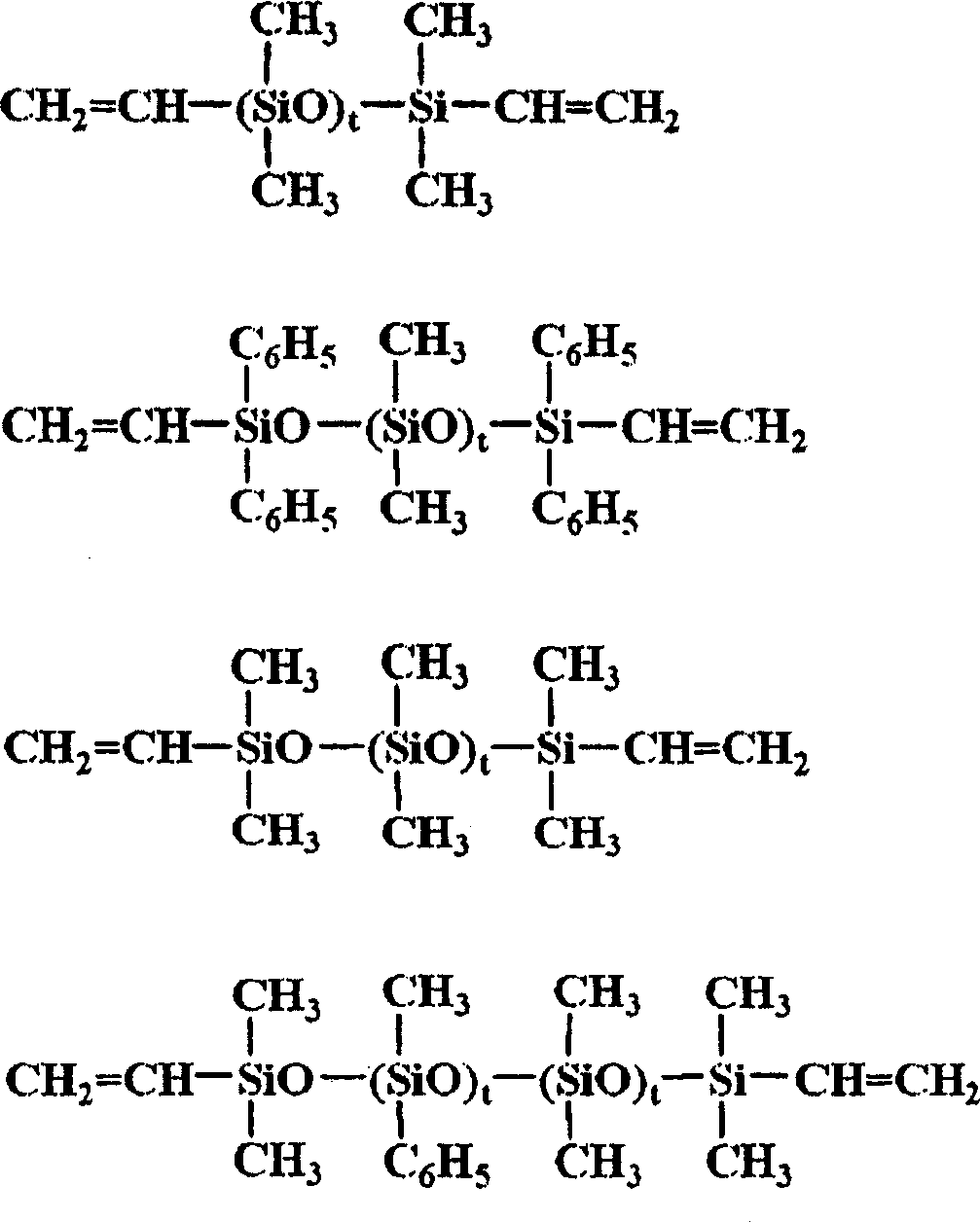

Solidified silicon rubber combination and producing method for compound molding object of liquid crystal polymer and silicon rubber

ActiveCN1834187ALiquid crystal compositionsOther printing matterPolymer scienceLiquid-crystal display

The invention discloses to a solid silicon rubber compound used in liquid crystal polymer, which comprises the organic polysiloxane (A) with aliphatic unsaturated bond, (B) organic hydrogen polysiloxane, at least one (C) acryl, methacryloyl, or the (methyl) acrylate compound that soluble with (A), and (D) platinum group metallic catalyst. With inventive silicon rubber compound, the solid that canadhere the LCP basic plate can be prepared, especially the inventive silicon rubber compound can provides the solid with better transparence, to effectively adhere he liquid crystal polymer basic plate used in the package of light displays, while it can be effectively used in the application of basic plate of optical correlator.

Owner:SHIN ETSU CHEM IND CO LTD

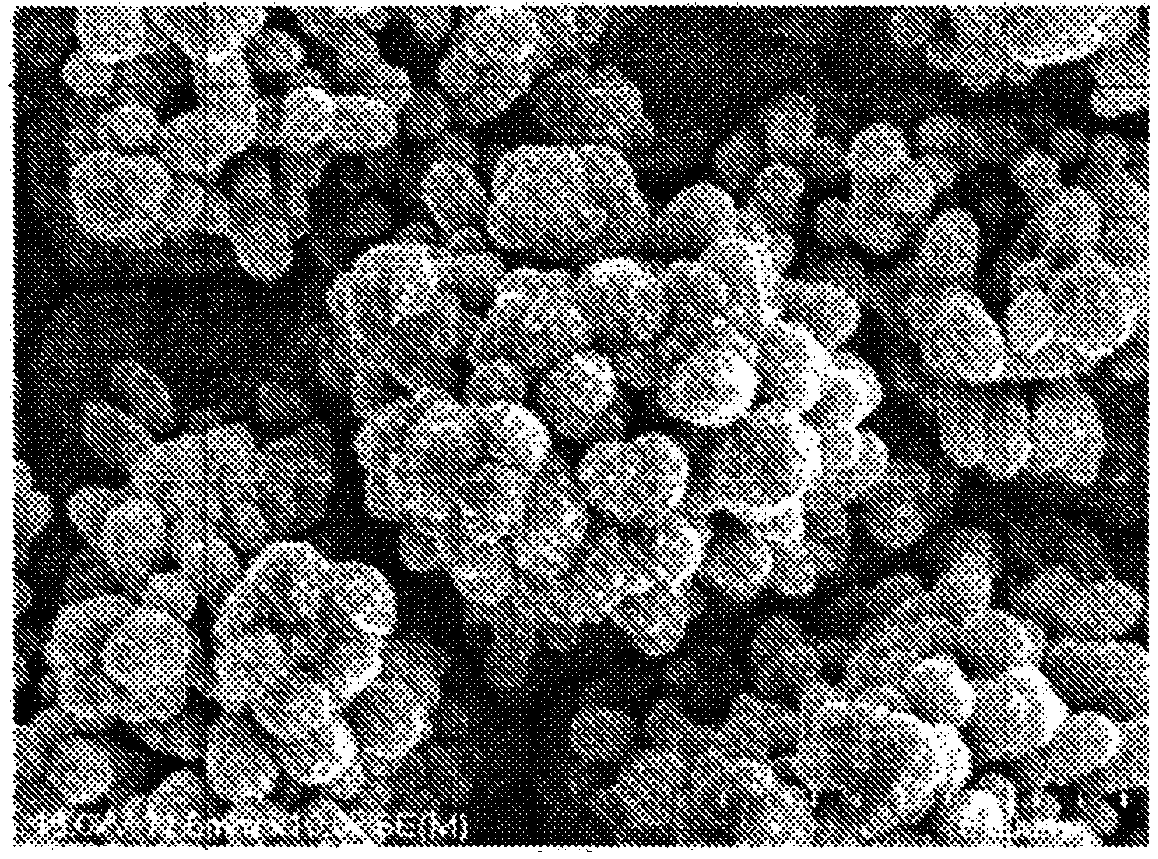

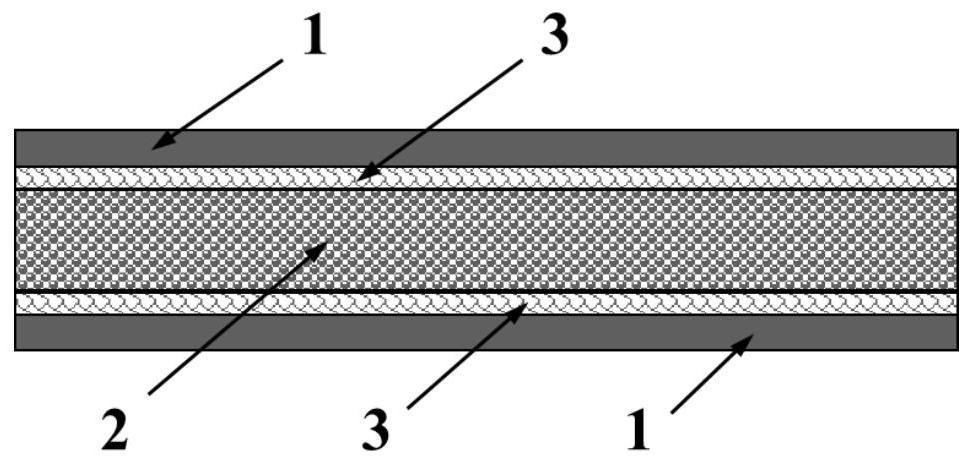

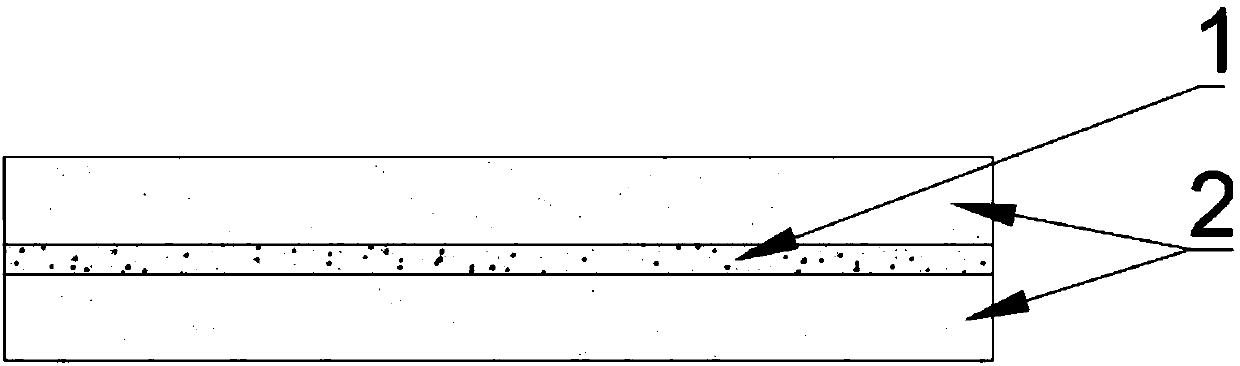

Copper foil excellent in adhesion with resin, method for manufacturing same, and printed wiring board or battery negative electrode material using electrolytic copper foil

ActiveCN103857833AHigh peel strengthHigh bonding strengthInsulating substrate metal adhesion improvementElectrode carriers/collectorsEpoxyElectrolysis

An electrolytic copper foil is characterized by having a roughened surface (M surface) on which roughening particles are formed, wherein the roughening particles have an average size of 0.1 to 1.0 mum. Provided is the electrolytic copper foil capable of, without deteriorating various characteristics of the electrolytic copper foil, improving a roughening treatment layer on the copper foil and enhancing the adhesion strength between the copper foil and a resin substrate, especially, capable of obtaining a stronger peeling strength in comparison with a general-purpose epoxy resin substrate (FR-4 and the like) when used in combination with a semiconductor package substrate having a generally low adhesion with a copper foil and a liquid crystal polymer substrate, and also provided is a method for manufacturing the electrolytic copper foil. The present invention addresses the problem of providing the electrolytic copper foil useful as an electrolytic copper foil to be used for a printed wiring board or a battery (LiB and the like) negative electrode material.

Owner:JX NIPPON MINING & METALS CO LTD

Method for making multi-layer organic liquid crystal polymer (LCP) substrate structure

ActiveCN102683220AGet Rid of CTE Matching IssuesImprove performancePrinted circuit assemblingSemiconductor/solid-state device manufacturingHigh densityMicrowave

The invention discloses a method for making a multi-layer organic liquid crystal polymer (LCP) substrate structure. The method comprises the following steps: providing a first LCP core substrate and a second LCP core substrate; connecting an active device to the first LCP core substrate in an inverted manner; arranging a passive device on the second LCP core substrate by means of surface mounting, sequentially overlapping and stacking the second LCP core substrate mounted with the passive device, an LCP dielectric layer and the first LCP core substrate connected with the active device in an inverted manner, and thermoforming to obtain the multi-layer LCP substrate structure embedded with both the active device and the passive device. The multi-layer LCP substrate structure can be used for making a microwave / millimeter wave system level module and has the characteristic of achieving a system with high density, small size, high performance, high frequency, low value and low consumption.

Owner:NAT CENT FOR ADVANCED PACKAGING

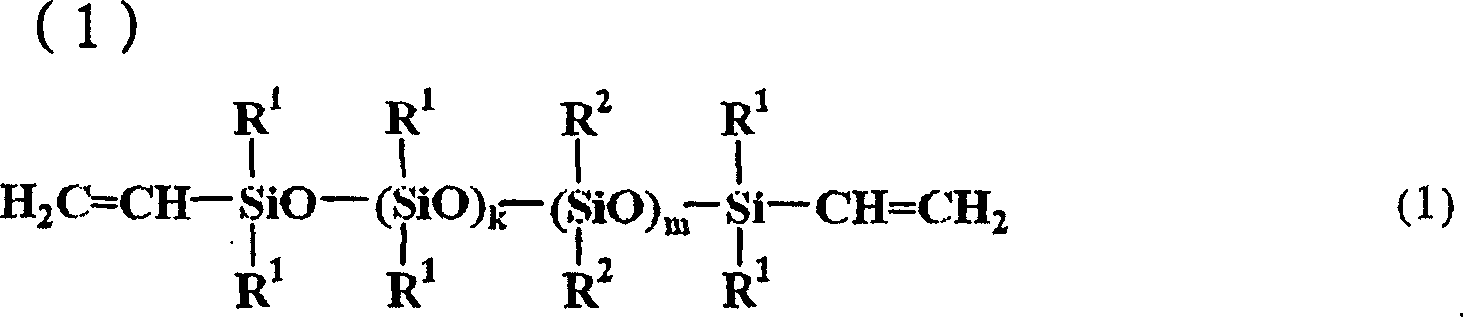

Method and apparatus for sealing flex circuits having heat sensitive circuit elements

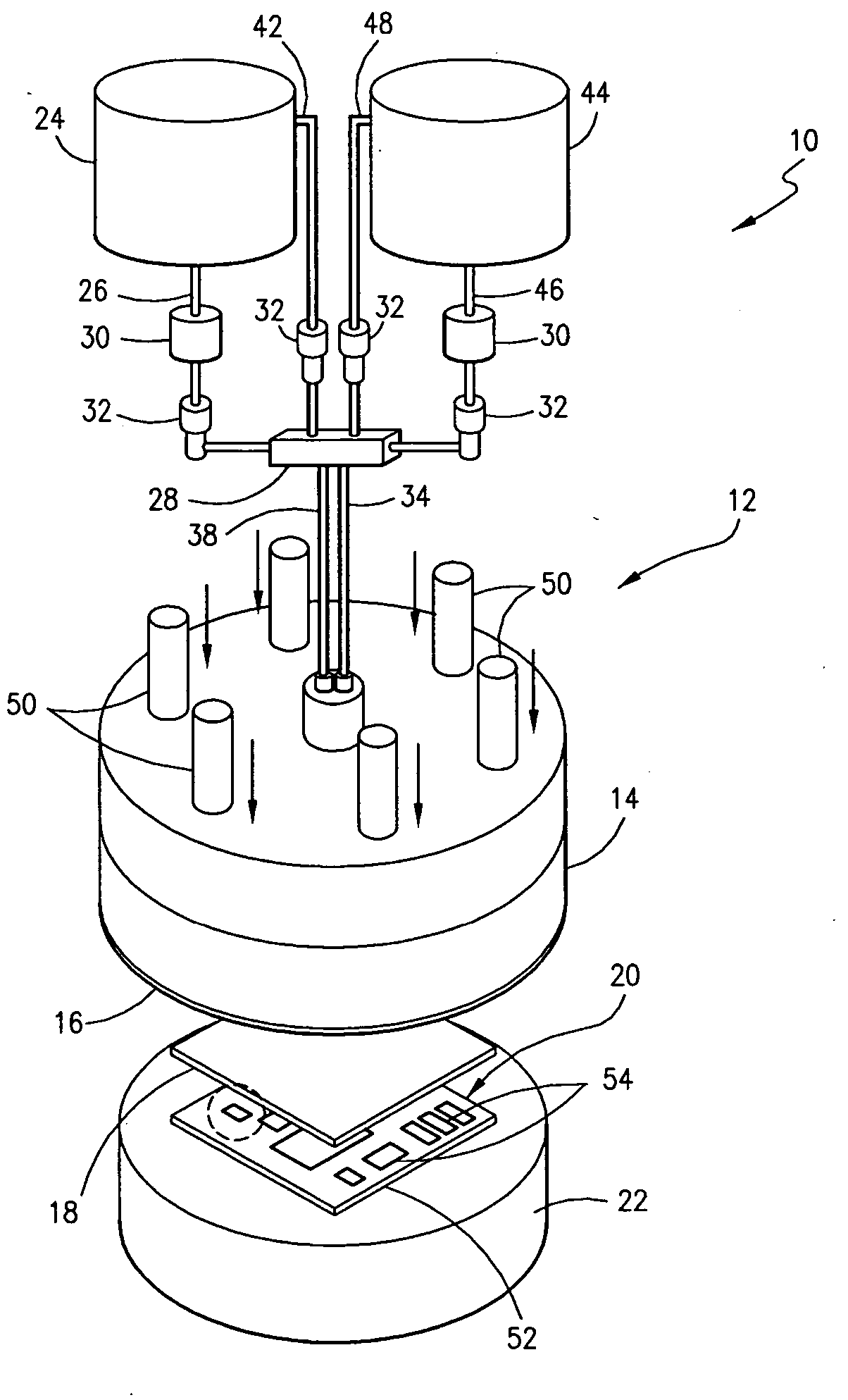

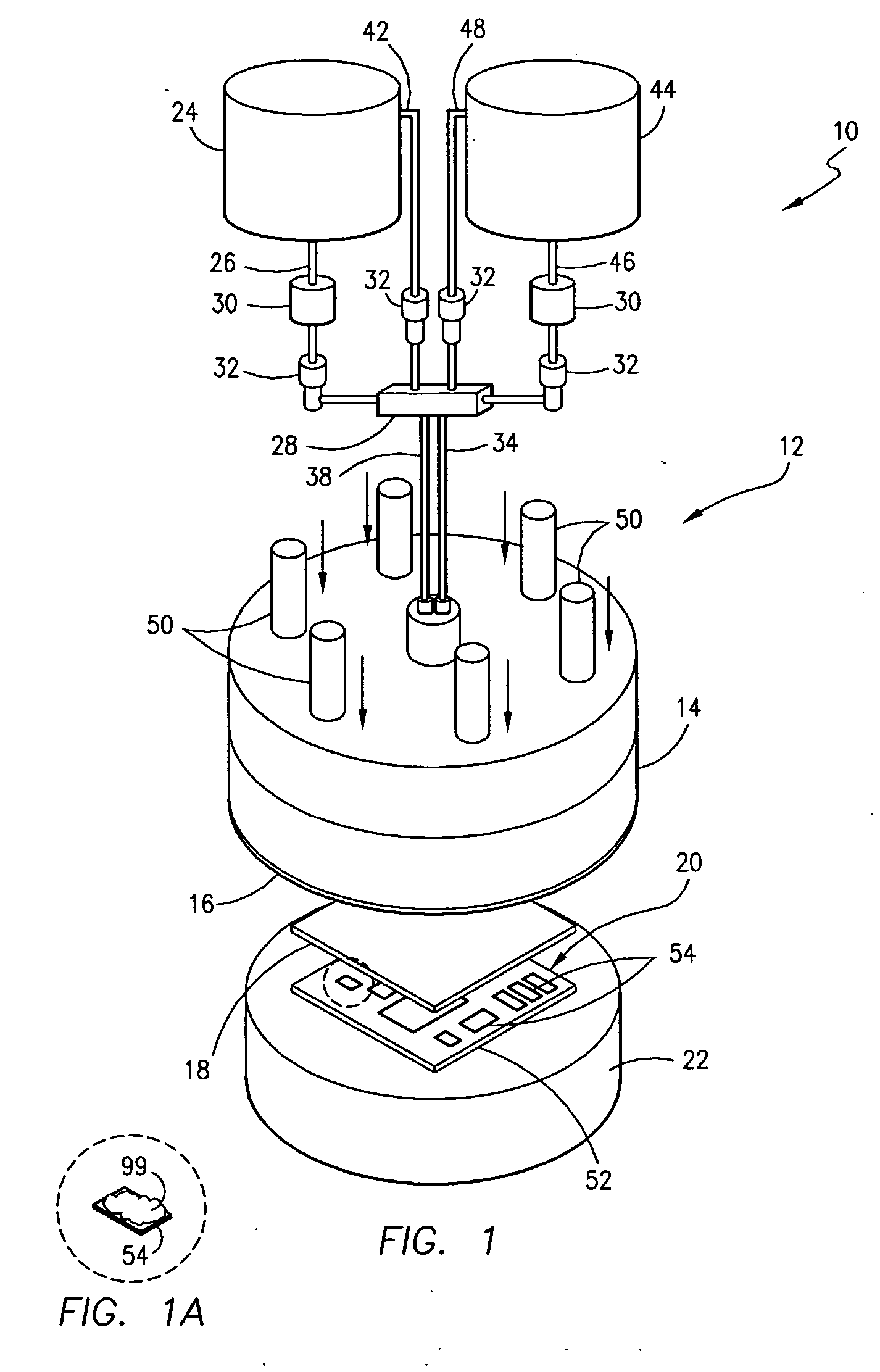

ActiveUS20060169405A1Easy to operateConvenient thermal protectionPrinted circuit assemblingLamination ancillary operationsHeat sensitiveMoisture

A method and apparatus is disclosed for affixing a cover layer formed of liquid crystal polymer to a flex circuit consisting of circuit elements mounted to a liquid crystal polymer substrate in order to encapsulate the circuit elements between the cover layer and substrate to protect them from exposure to moisture and contaminants and to provide thermal protection of temperature sensitive circuit elements within the flex circuit during the encapsulation process.

Owner:HARRIS CORP

Liquid crystal polymers for flexible circuits

InactiveUS6923919B2Insulating substrate metal adhesion improvementAfter-treatment detailsFlexible circuitsSolvent

A process for providing a metal-seeded liquid crystal polymer comprising the steps of providing a liquid crystal polymer substrate to be treated by applying an aqueous solution comprising an alkali metal hydroxide and a solubilizer as an etchant composition for the liquid crystal polymer substrate. Further treatment of the etched liquid crystal polymer substrate involves depositing an adherent metal layer on the etched liquid crystal polymer substrate. An adherent metal layer may be deposited using either electroless metal plating or vacuum deposition of metal such as by sputtering.When using electroless metal plating, a tin(II) solution applied to the liquid crystal polymer provides a treated liquid crystal polymer substrate to which the application of a palladium(II) solution provides the metal-seeded liquid crystal polymer. The etchant composition comprises a solution in water of from 35 wt. % to 55 wt. % of an alkali metal salt, and from 10 wt. % to 35 wt. % of a solubilizer dissolved in the solution to provide the etchant composition suitable for etching the liquid crystal polymer at a temperature from 50° C. to 120° C. A flexible circuit comprising a liquid crystal polymer film having through-holes and related shaped voids may be formed using etchant compositions as previously described.

Owner:3M INNOVATIVE PROPERTIES CO

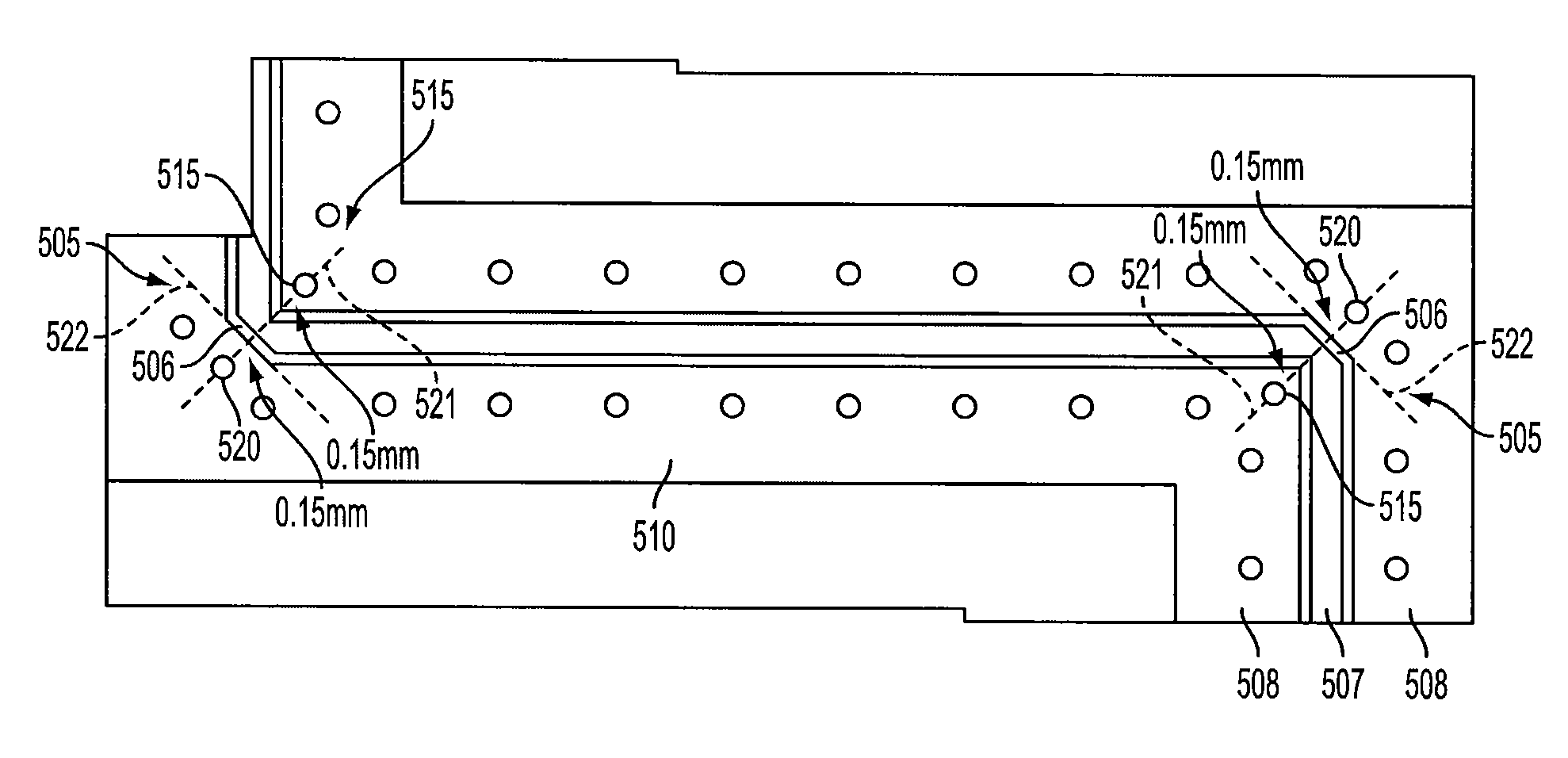

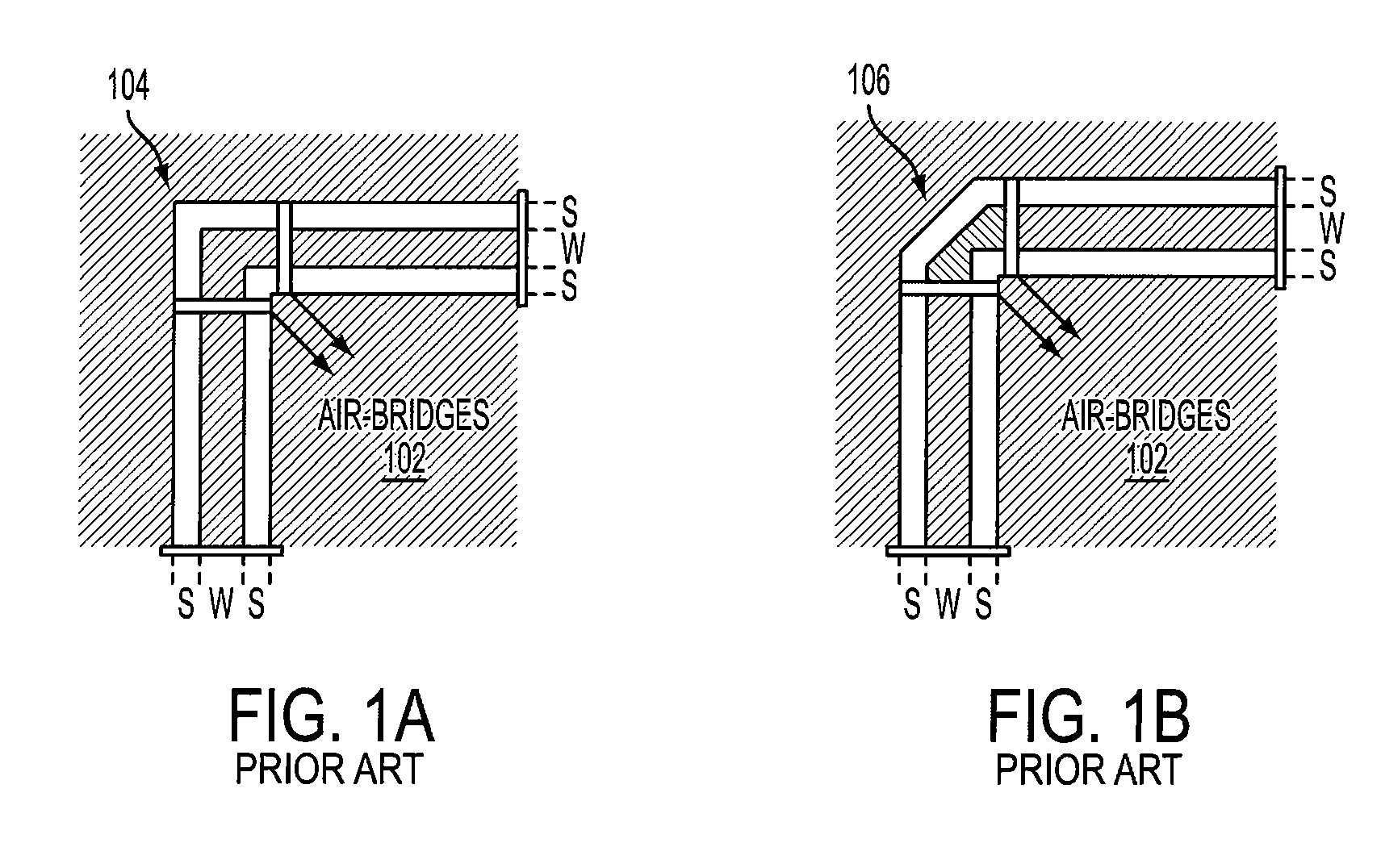

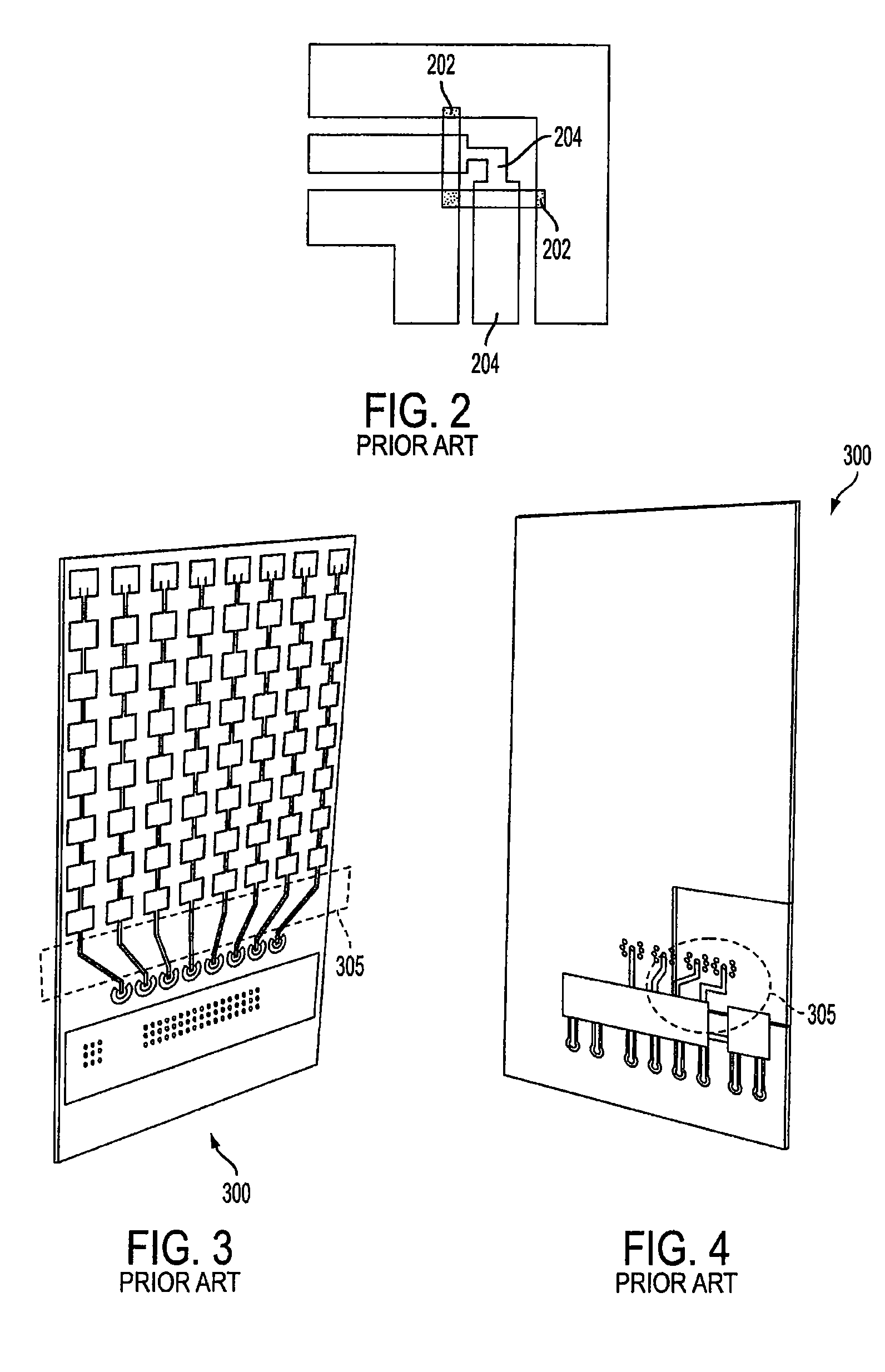

System and method for improving performance of coplanar waveguide bends at mm-wave frequencies

InactiveUS7990237B2Improve performanceMultiple-port networksCross-talk/noise/interference reductionCoplanar waveguideMillimetre wave

An apparatus including a liquid crystal polymer substrate having a top surface and a bottom surface, a coplanar waveguide formed on the top surface of the liquid crystal polymer substrate, the coplanar waveguide having a 90 degree bend with a mitered edge, an inner via positioned adjacent to an inner corner of the 90 degree bend, and an outer via positioned adjacent to the mitered edge of the 90 degree bend, the inner and outer vias positioned along a first plane that is perpendicular to a second plane defined by the mitered edge.

Owner:TOYOTA MOTOR CO LTD

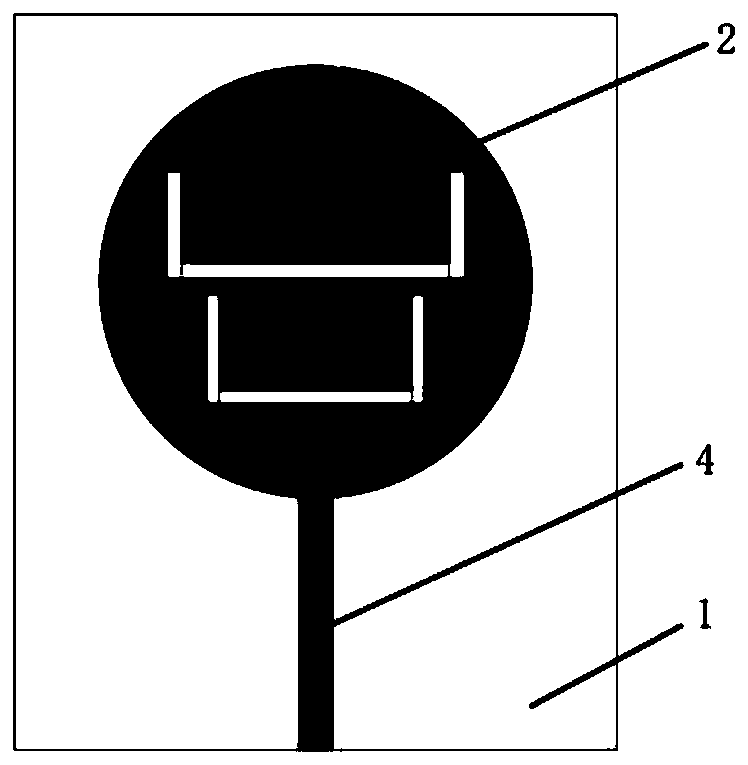

Flexible multi-frequency antenna based on liquid crystal polymer substrate

PendingCN109742534AGood flexibilityBend at willSimultaneous aerial operationsRadiating elements structural formsState of artDielectric loss

The invention relates to a flexible multi-frequency antenna based on a liquid crystal polymer substrate. The antenna comprises the substrate, an antenna body and a grounding plate; the substrate is made of a flexible material; the antenna body is a circular radiation patch located on the front surface of the substrate; two U-shaped grooves are formed in the antenna body; a feeder line is arrangedon one side of the antenna body; and the grounding plate is positioned on the back surface of the substrate. Compared with the prior art, the antenna adopts an LCP material, and has the advantages oflow dielectric loss, low hygroscopicity, high temperature resistance, chemical corrosion resistance, small thermal expansion coefficient, small thickness and the like; and the antenna is the circularradiation patch, the improved circular grounding plate is adopted, and the two U-shaped grooves are added in the round patch, so that a three-frequency working characteristic can be realized.

Owner:SHANGHAI UNIVERSITY OF ELECTRIC POWER

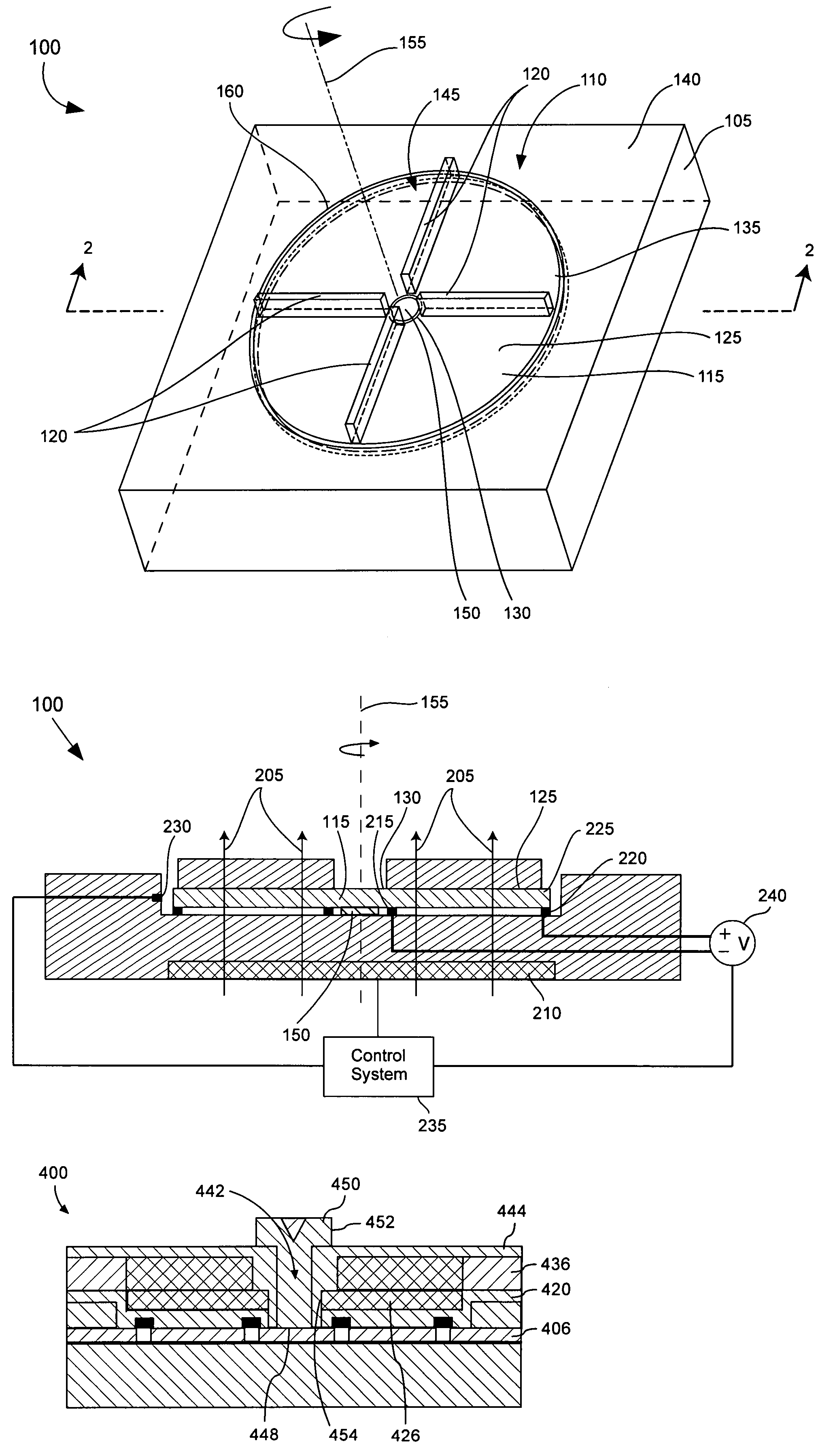

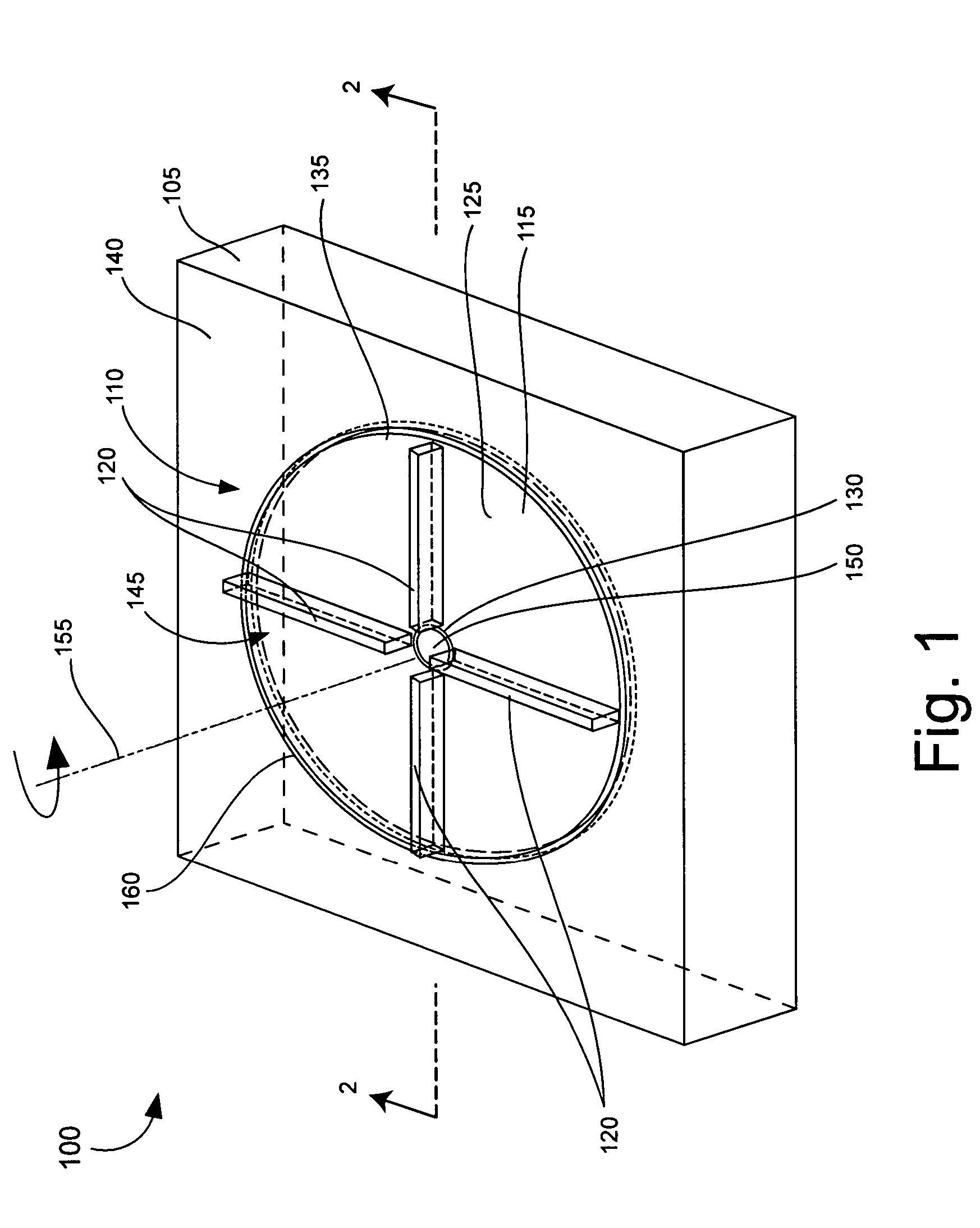

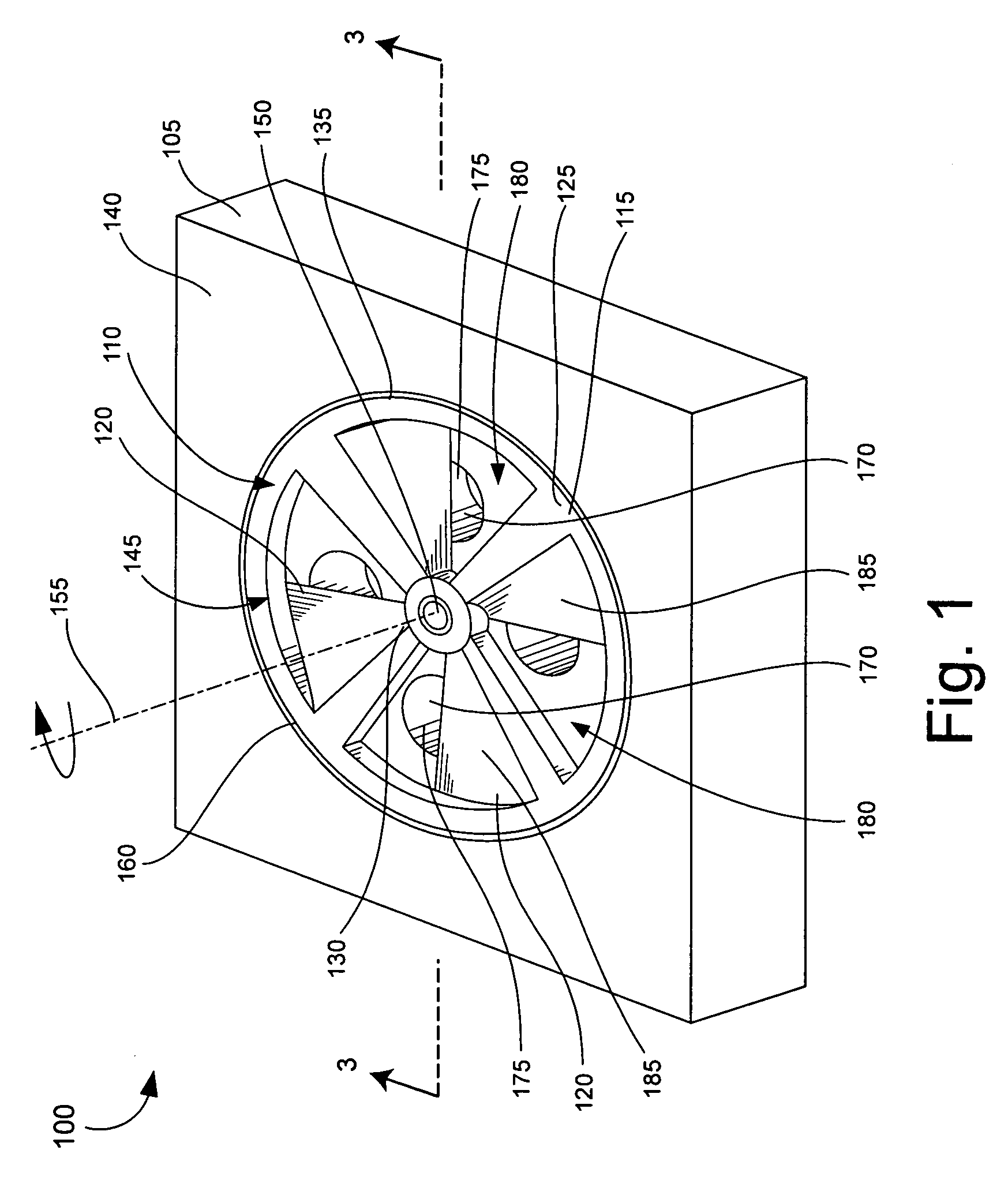

Embedded fluid mixing device using a homopolar motor

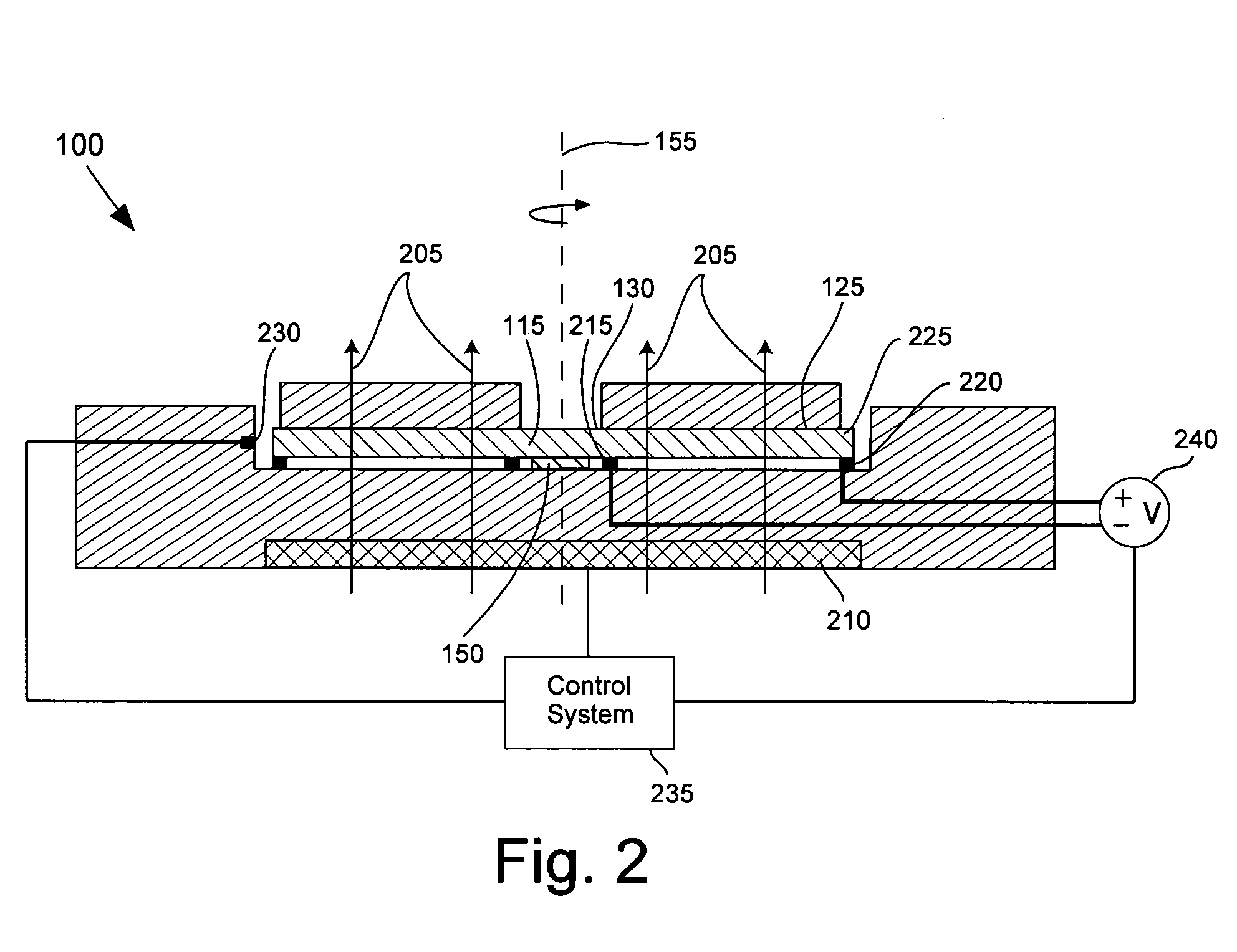

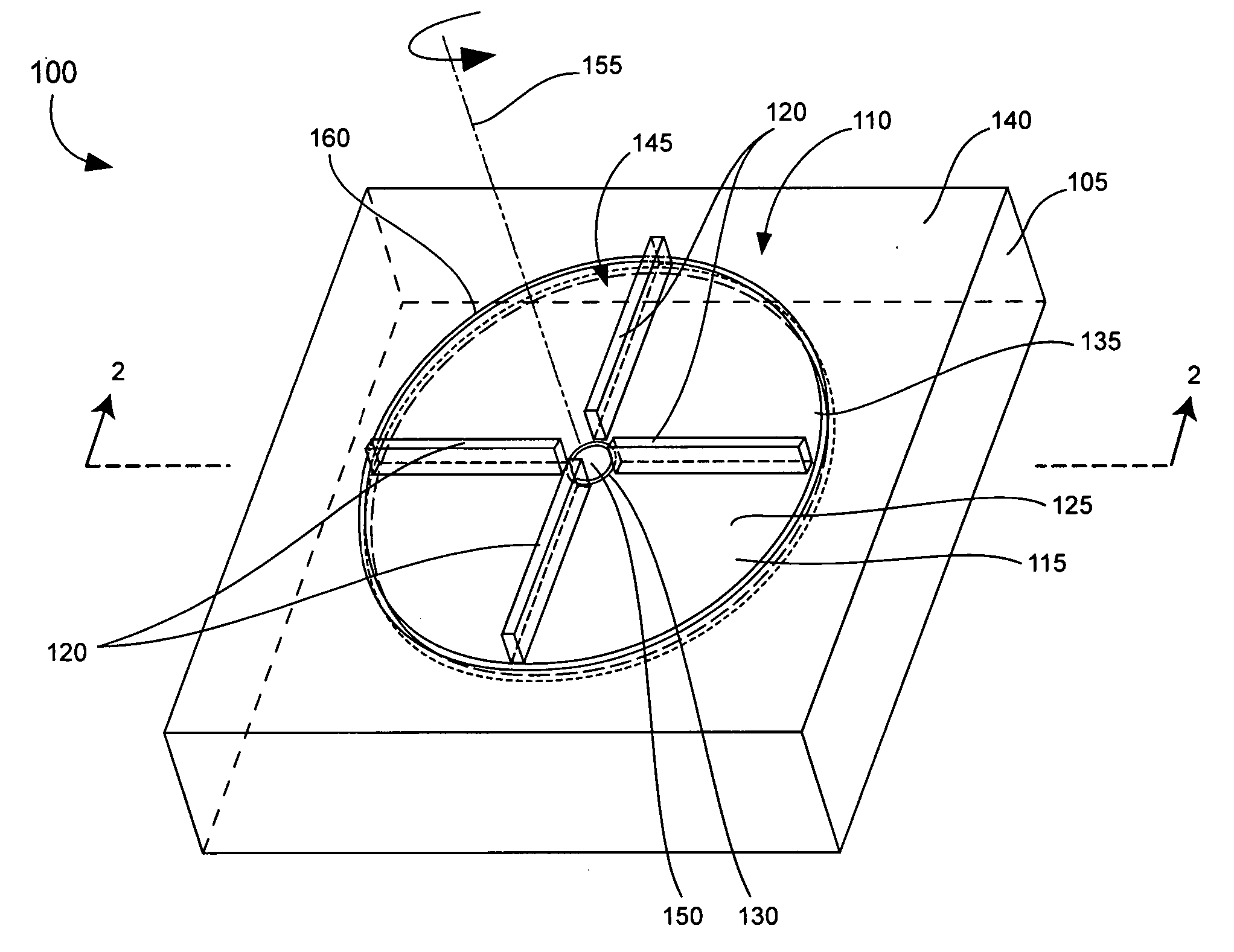

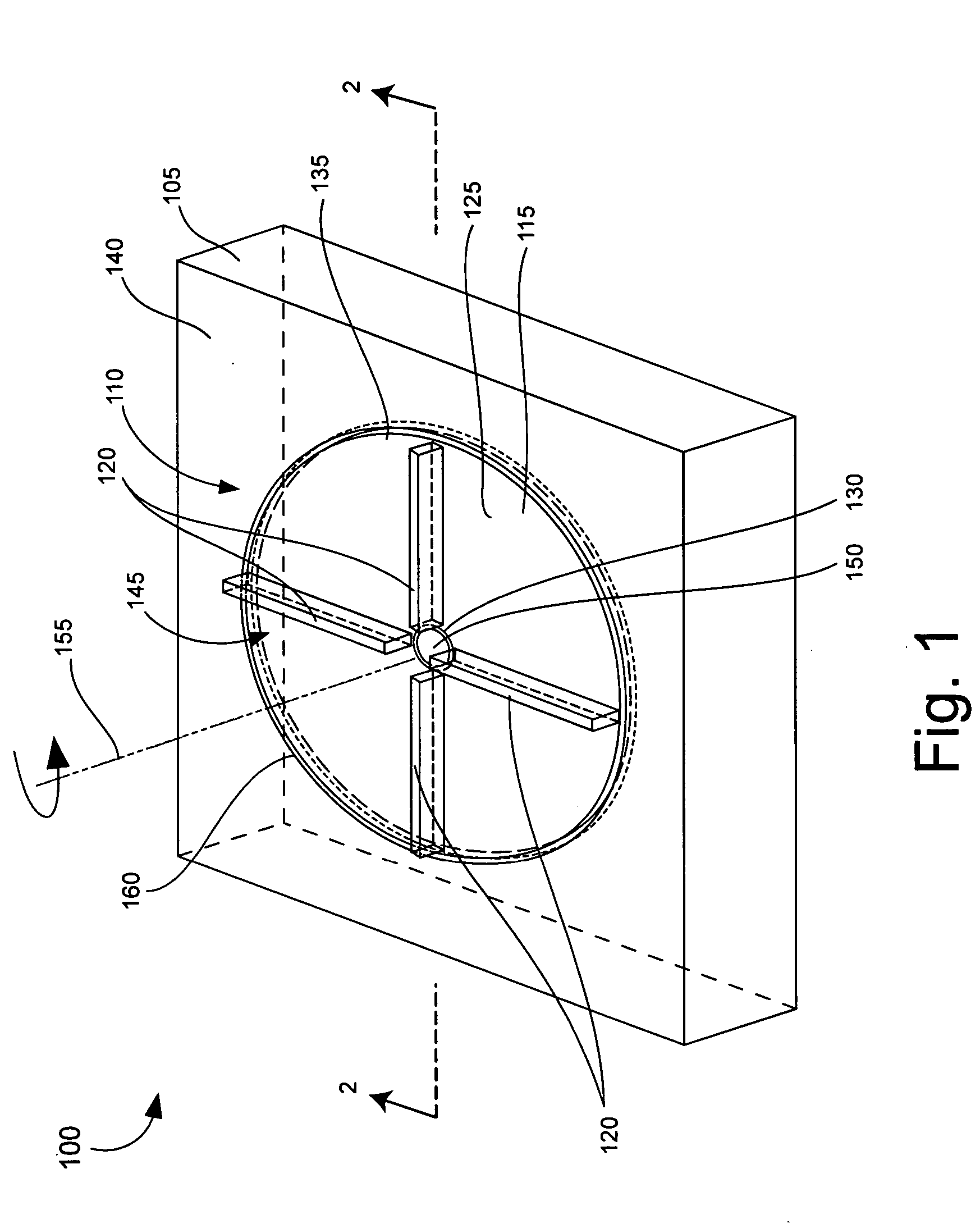

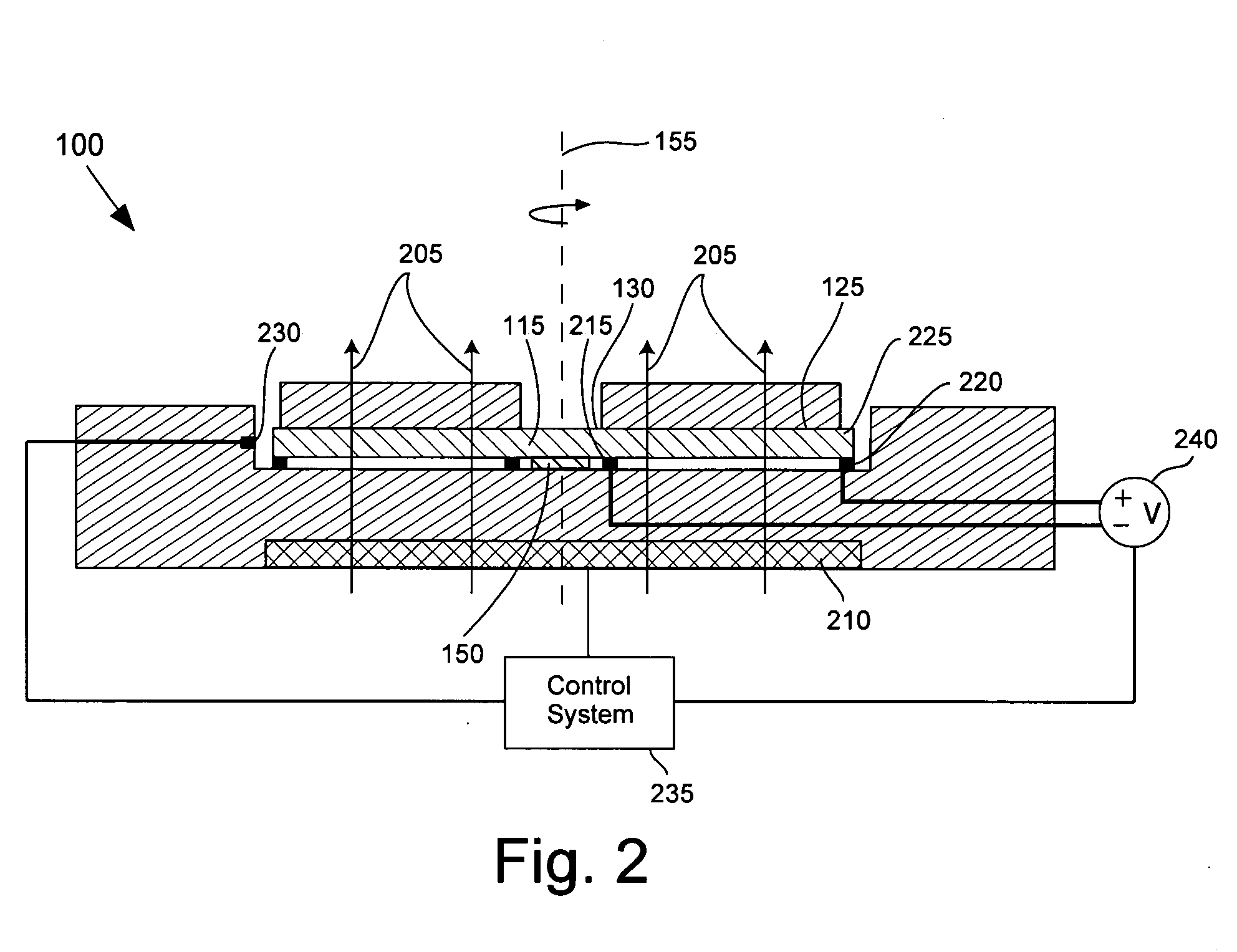

A fluid displacement device (100) having a homopolar motor (110). The homopolar motor includes a rotatable disk (115) with at least one fluid displacement structure (120) disposed thereon. The fluid displacement structure can be a blade. The rotatable disk can be disposed within a cavity (145) defined in a substrate (105), such as a ceramic substrate, a liquid crystal polymer substrate, or a semiconductor substrate. A closed loop control circuit (235) can be included to control the rotational speed of the rotatable disk. For example, the control circuit can control a voltage source or a current source that applies voltage across the rotatable disk. The control circuit also can control a strength of a magnet (210) that applies a magnetic field (205) substantially aligned with an axis or rotation (155) of the rotatable disk.

Owner:HARRIS CORP

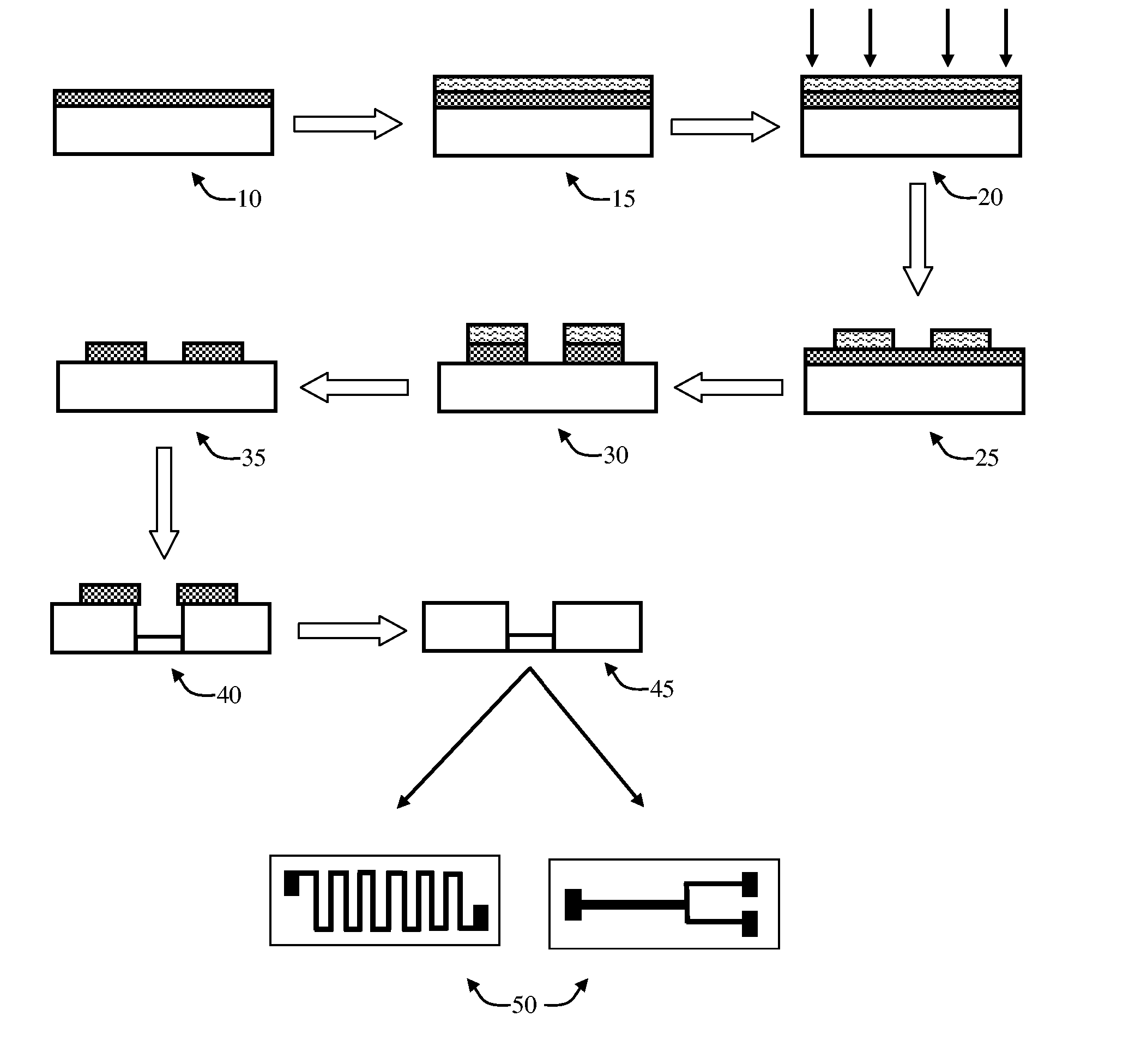

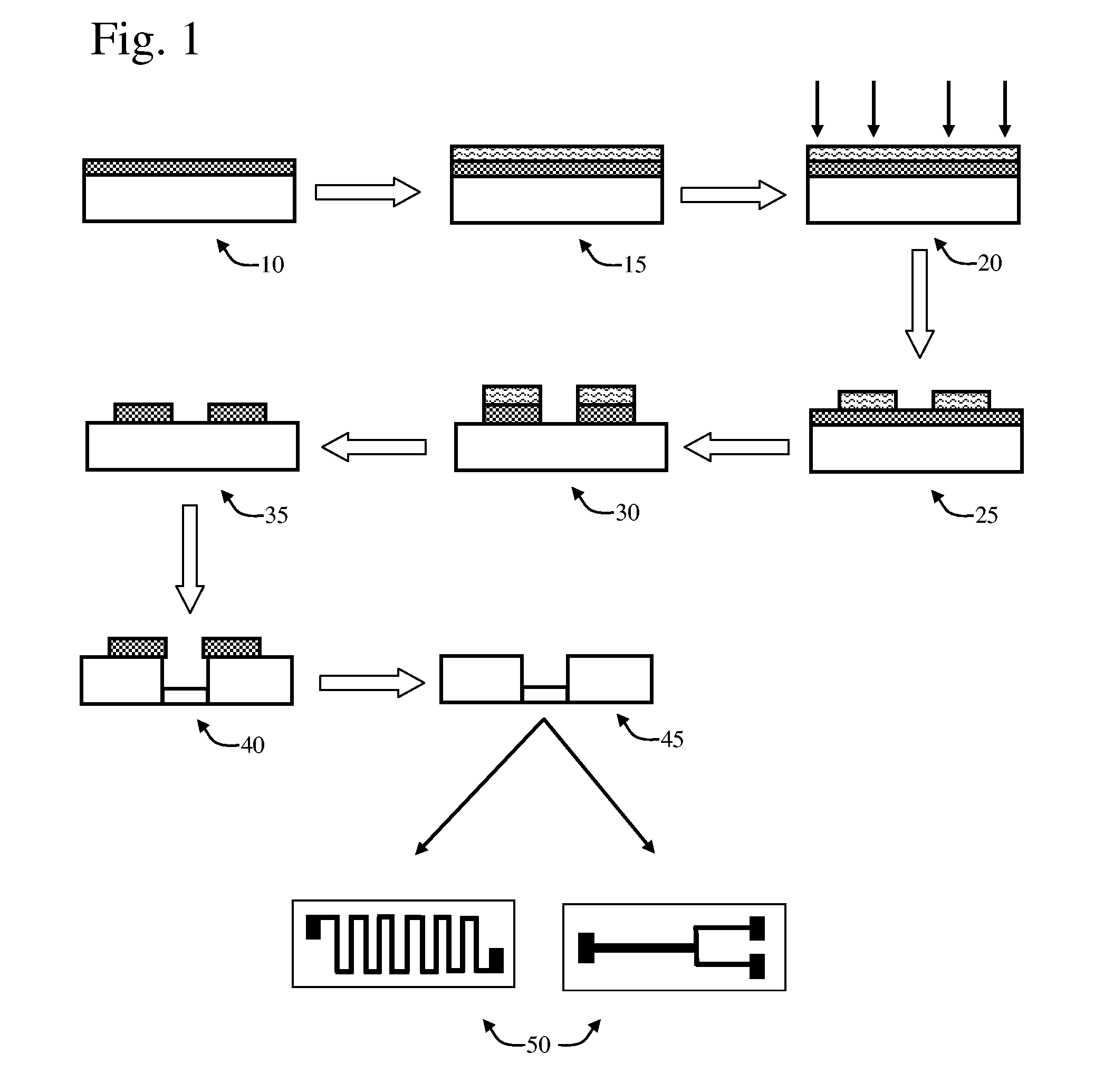

Method for Etching Microchannel Networks within Liquid Crystal Polymer Substrates

InactiveUS20060216654A1Fixed microstructural devicesDecorative surface effectsEtchingPolymer substrate

The present invention provides for a method for the fabrication of microchannels, and more particularly to the fabrication of microchannels for use in Microelectromechanical (MEMS) devices and MEMS related devices. In accordance with an embodiment of the present invention, microchannels are formed by a microfabrication method utilizing electronic imaging techniques in combination with chemical etching and subsequent metallization. The method of the present invention is effective in producing networks of channels in liquid crystal polymer (LCP) polymeric substrates which are highly defined in terms of their patterns, and thus are able to encompass a wide variety of end uses.

Owner:UNIV OF SOUTH FLORIDA

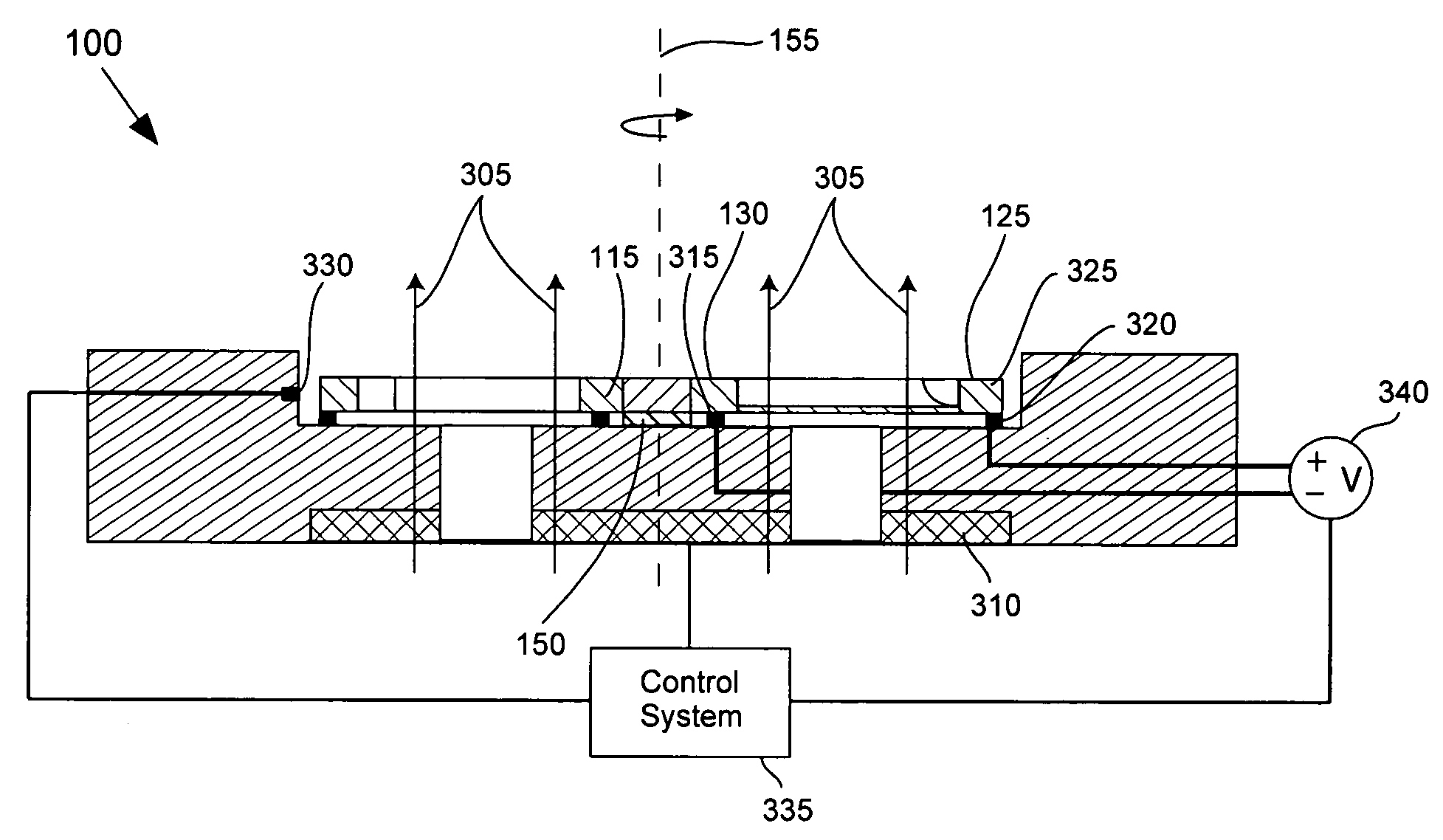

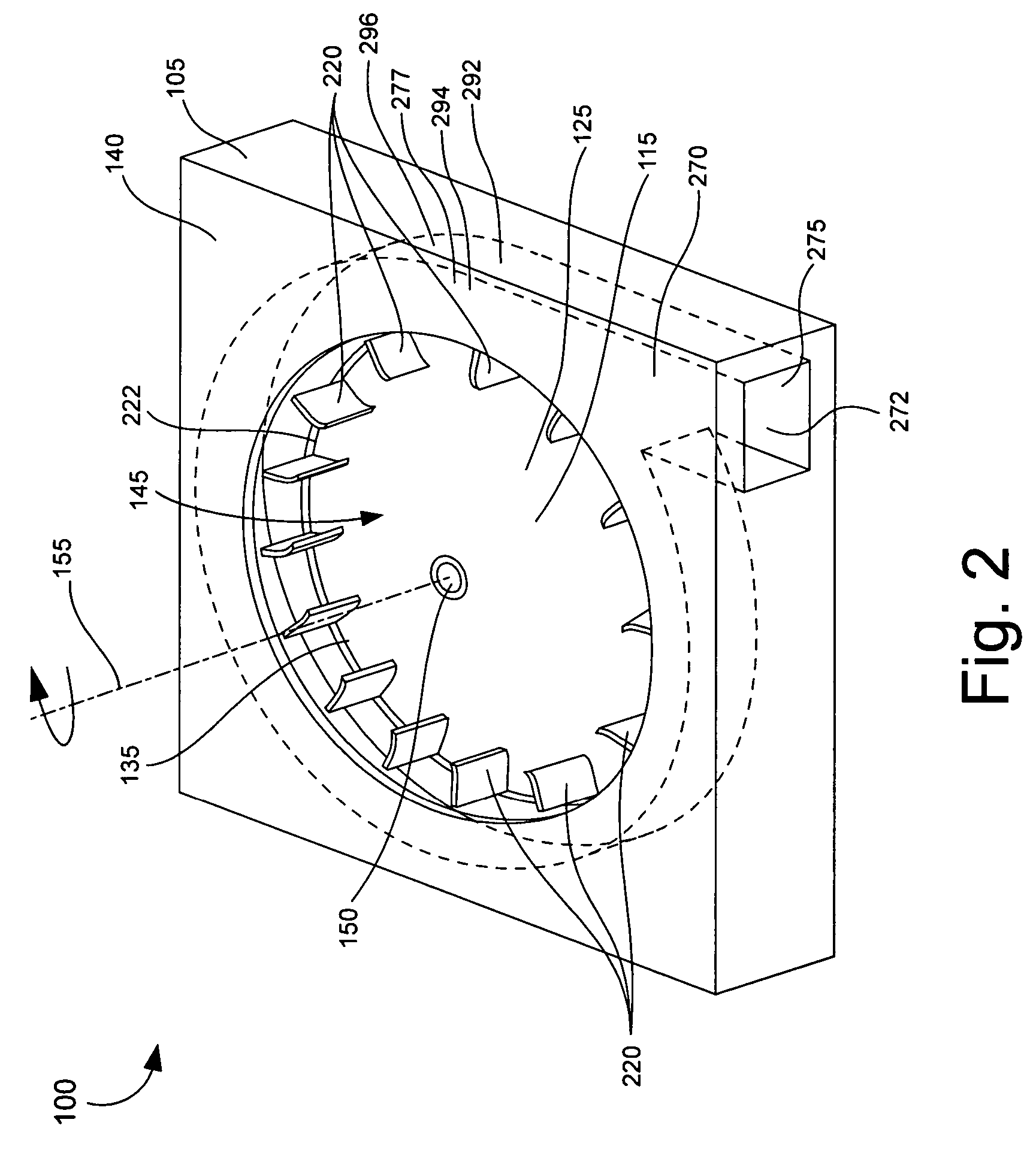

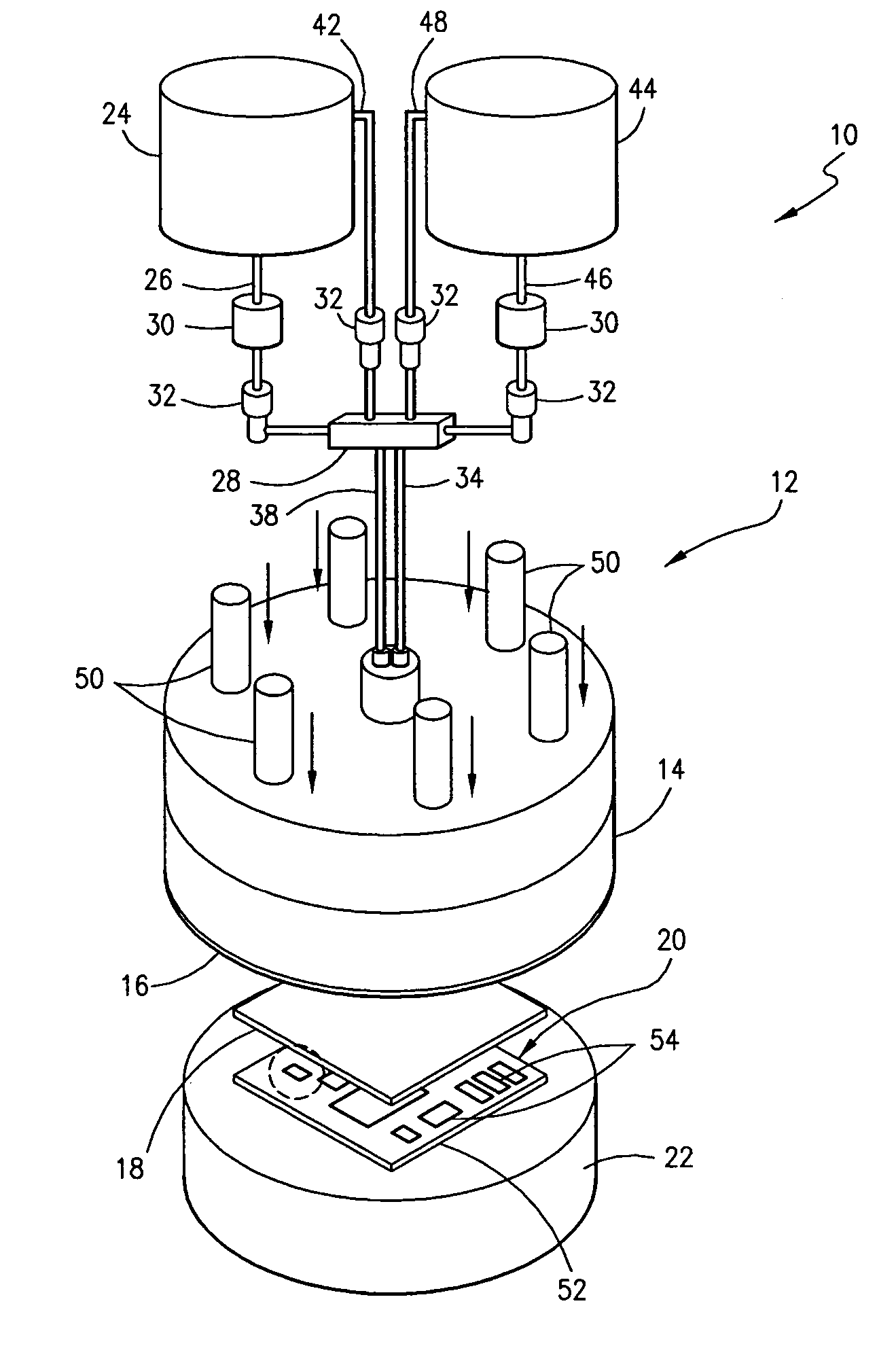

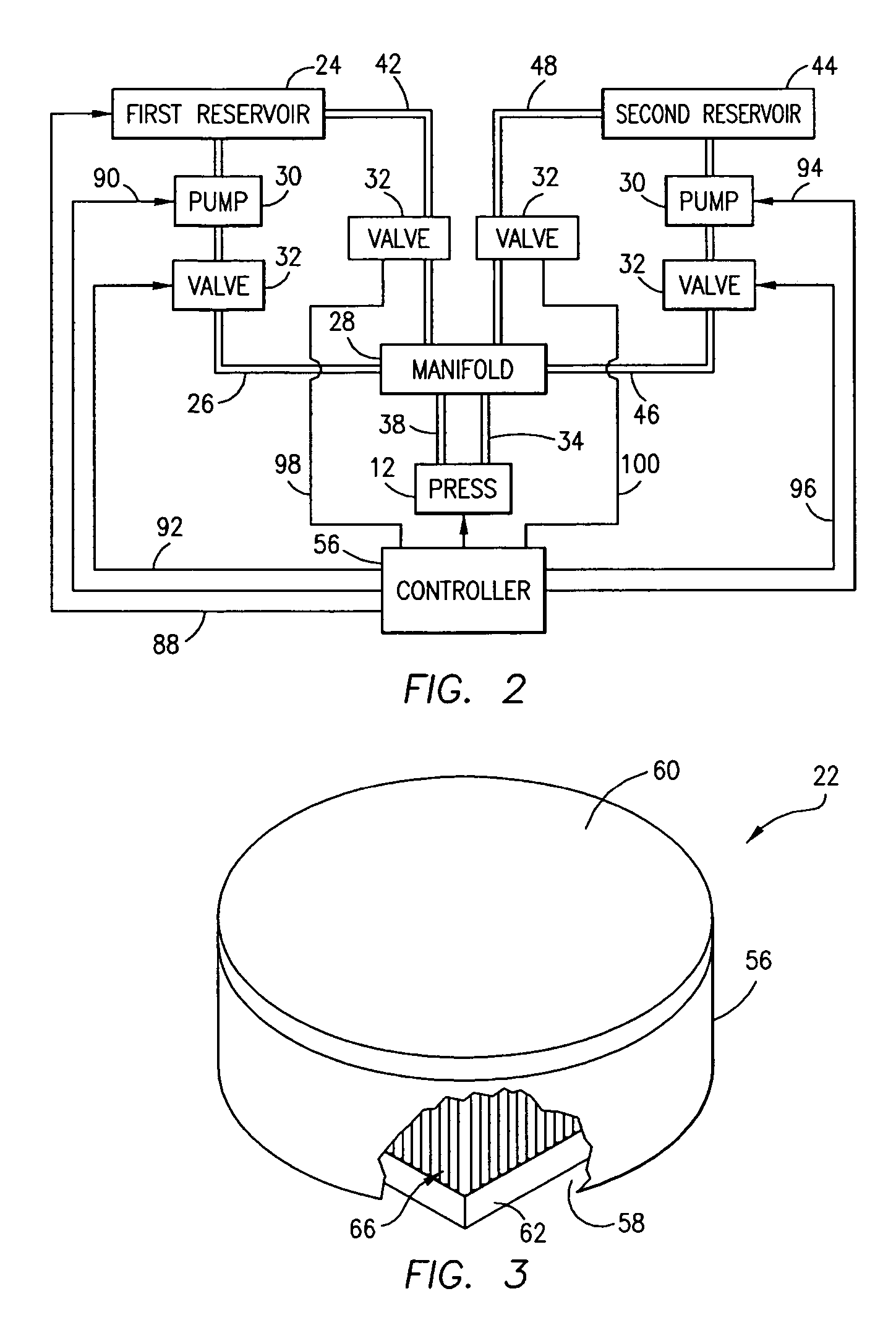

Embedded fluid pump using a homopolar motor

A fluid pump (100) having a homopolar motor (110). The homopolar motor includes a rotatable disk (115) defining at least one impeller (120). The impeller can include an orifice within the rotatable disk. The rotatable disk can be at least partially disposed within a cavity (145) defined in the substrate (105), such as a ceramic substrate, a liquid crystal polymer substrate, or a semiconductor substrate. A closed loop control circuit (335) can be included to control the rotational speed of the rotatable disk. For example, the control circuit can control a voltage source or a current source that applies voltage across the rotatable disk. The control circuit also can control a strength of a magnet (310) that applies a magnetic field (305) substantially aligned with an axis or rotation (155) of the rotatable disk.

Owner:HARRIS CORP

Method and apparatus for sealing flex circuits having heat sensitive circuit elements

ActiveUS7128801B2Easy to operateConvenient thermal protectionPrinted circuit assemblingLamination ancillary operationsFlexible circuitsHeat sensitive

Owner:HARRIS CORP

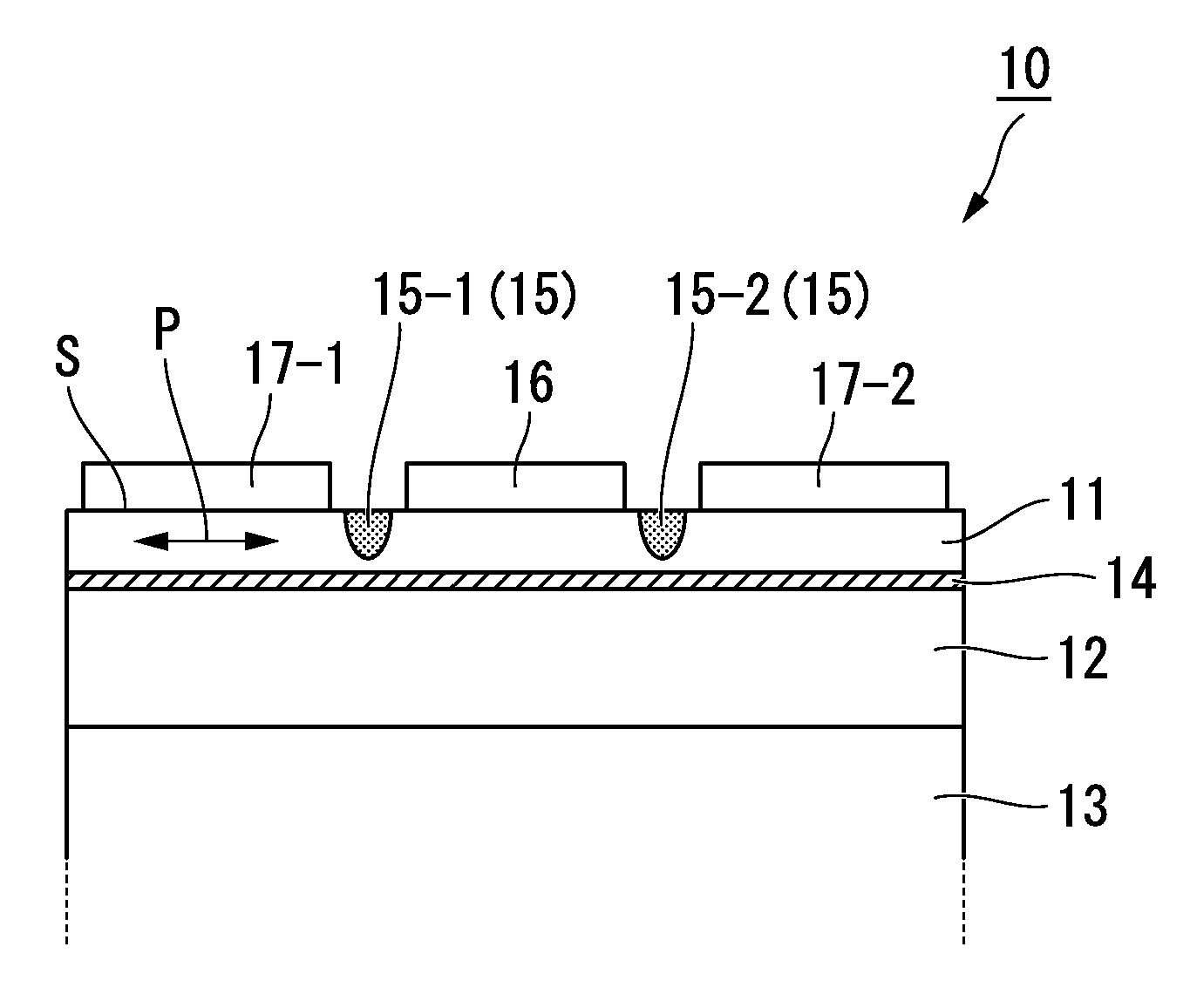

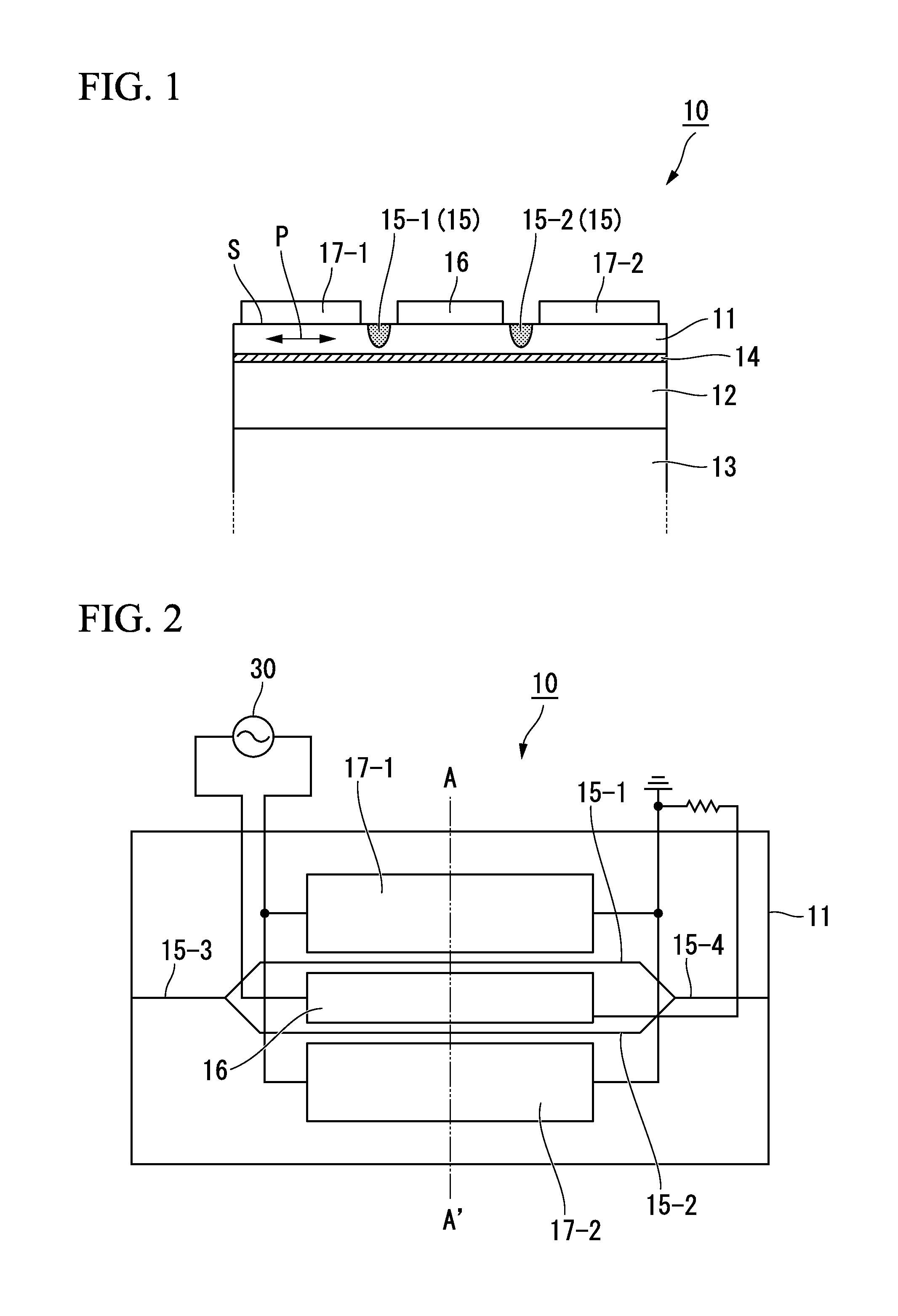

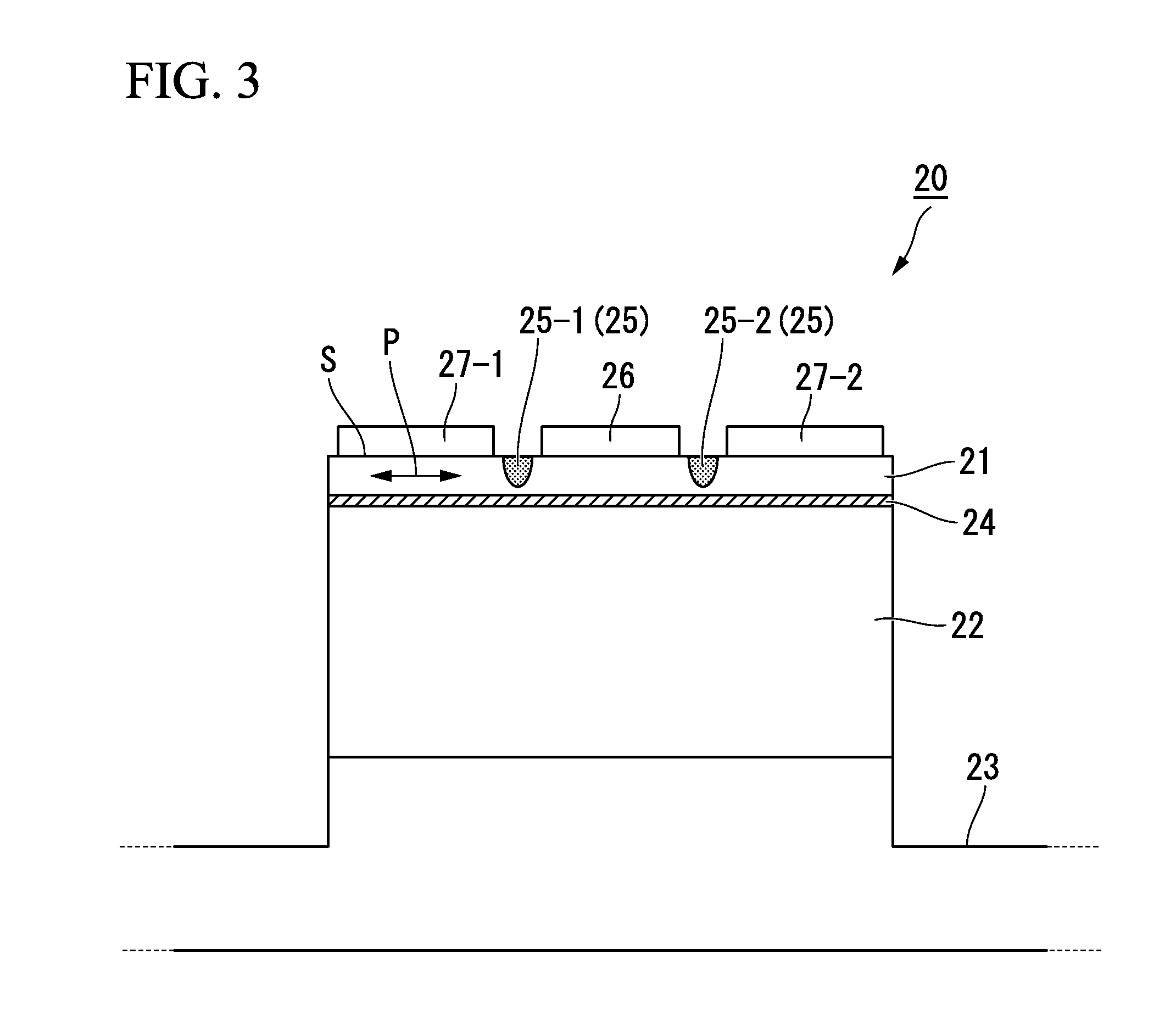

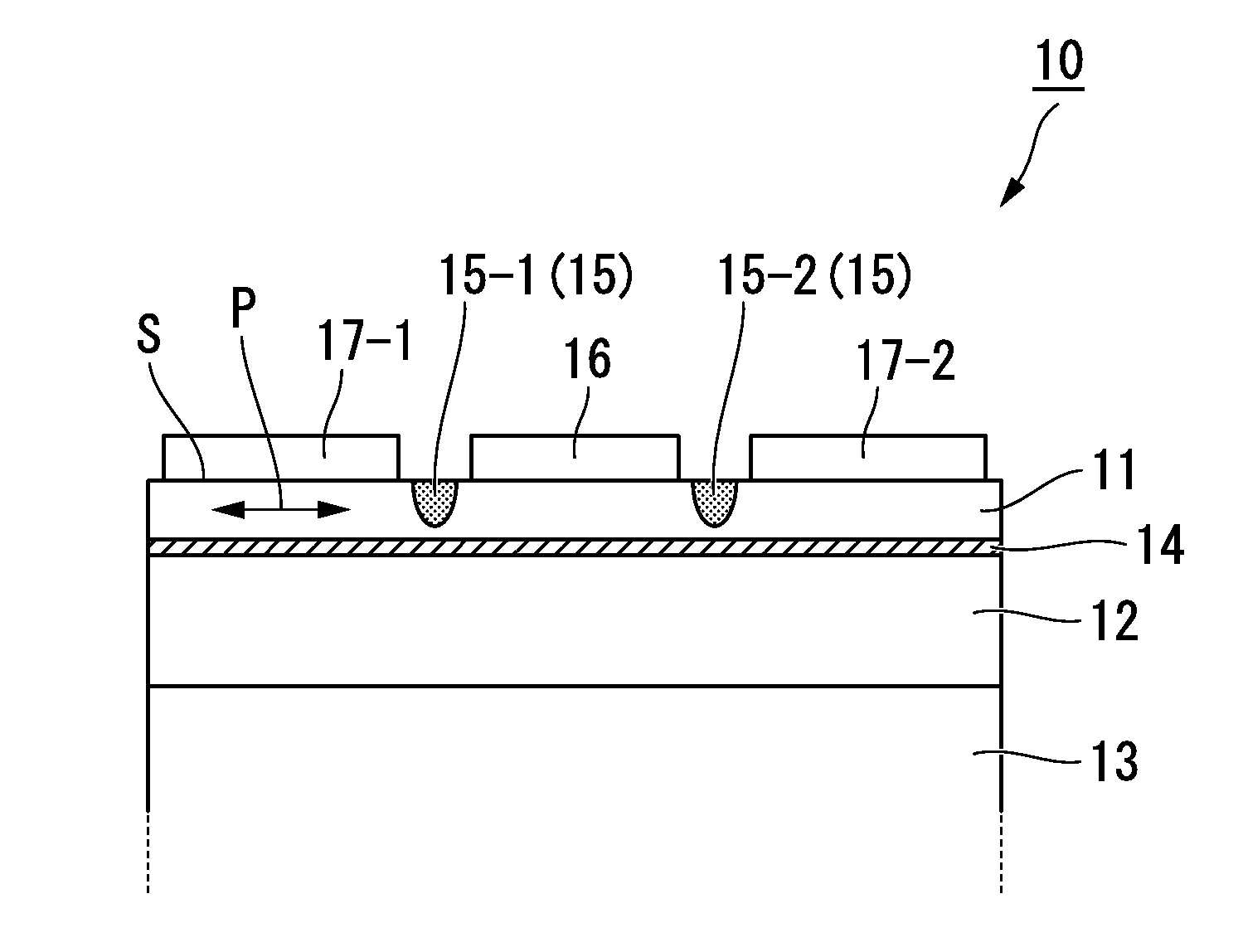

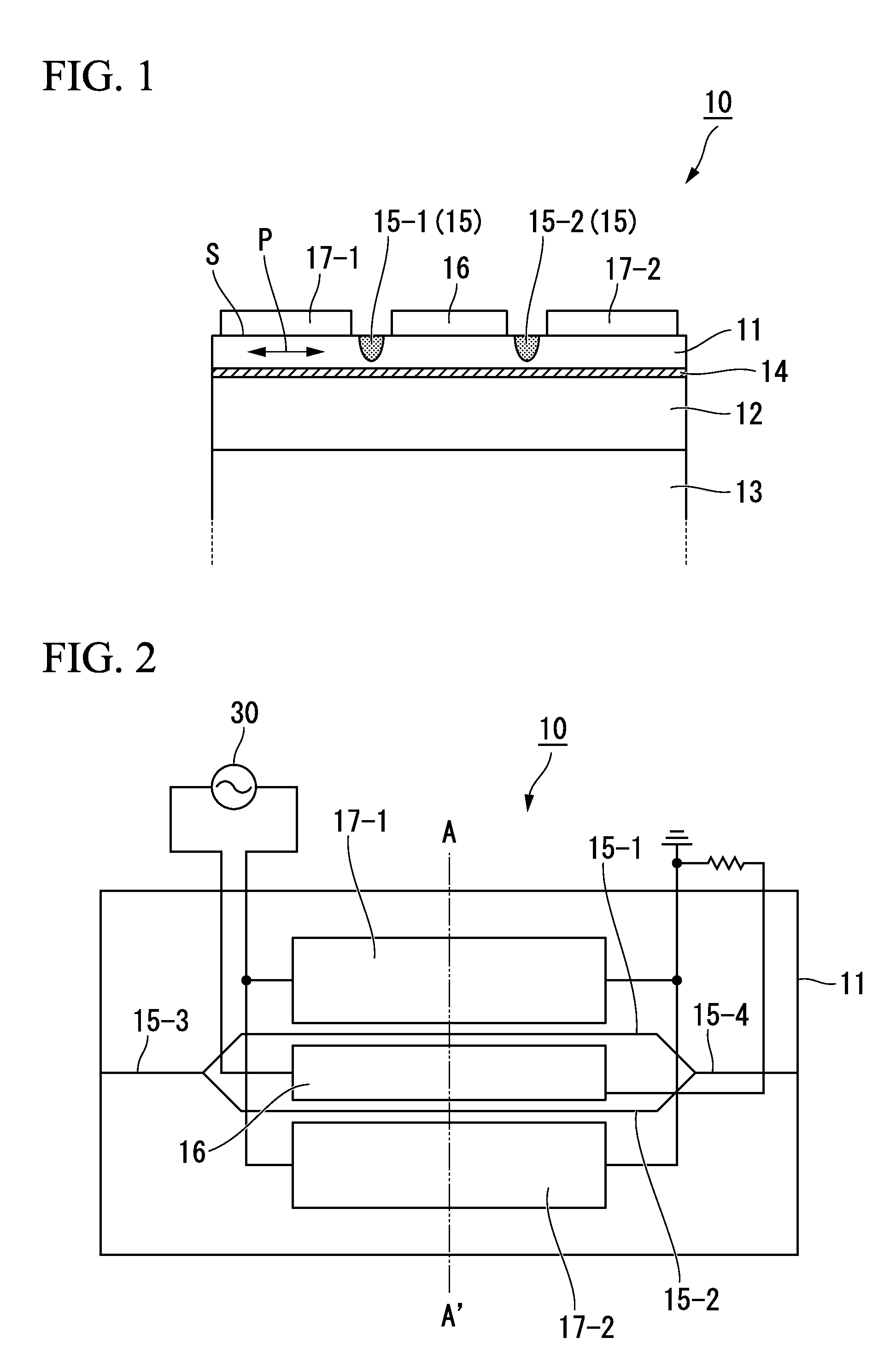

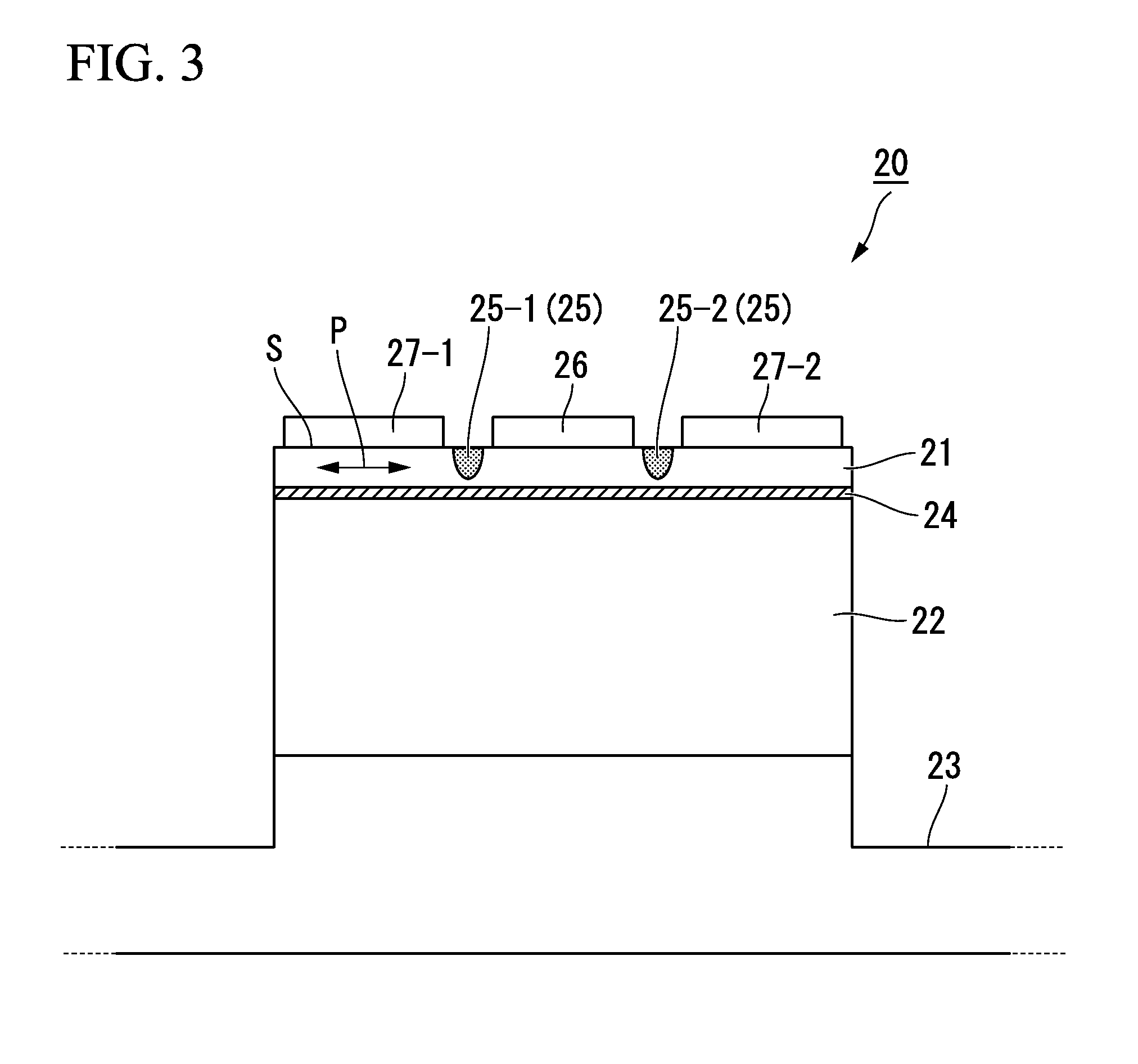

Optical waveguide device

Provided is an optical waveguide device capable of reducing stress that occurs inside an optical waveguide substrate due to a difference in a coefficient of thermal expansion. The optical waveguide device (10) includes an optical waveguide substrate (11) having a thickness of 30 μm or less, and a liquid crystal polymer substrate (12) which holds the optical waveguide substrate (11) and has permittivity lower than that of the optical waveguide substrate (11). The optical waveguide substrate (11) and the liquid crystal polymer substrate (12) are bonded to each other by an adhesive layer (14). Coefficients of thermal expansion of the optical waveguide substrate (11) and the liquid crystal polymer substrate (12) have anisotropy in each substrate plane, and a relative direction between the optical waveguide substrate (11) and the liquid crystal polymer substrate (12) is adjusted in such a manner that anisotropic axial directions of the optical waveguide substrate (11) and anisotropic axial directions the liquid crystal polymer substrate (12) are aligned.

Owner:SUMITOMO OSAKA CEMENT CO LTD

Embedded fluid mixing device using a homopolar motor

ActiveUS20060034149A1Reduced strengthOther chemical processesTransportation and packagingCircular discClosed loop

A fluid displacement device (100) having a homopolar motor (110). The homopolar motor includes a rotatable disk (115) with at least one fluid displacement structure (120) disposed thereon. The fluid displacement structure can be a blade. The rotatable disk can be disposed within a cavity (145) defined in a substrate (105), such as a ceramic substrate, a liquid crystal polymer substrate, or a semiconductor substrate. A closed loop control circuit (235) can be included to control the rotational speed of the rotatable disk. For example, the control circuit can control a voltage source or a current source that applies voltage across the rotatable disk. The control circuit also can control a strength of a magnet (210) that applies a magnetic field (205) substantially aligned with an axis or rotation (155) of the rotatable disk.

Owner:HARRIS CORP

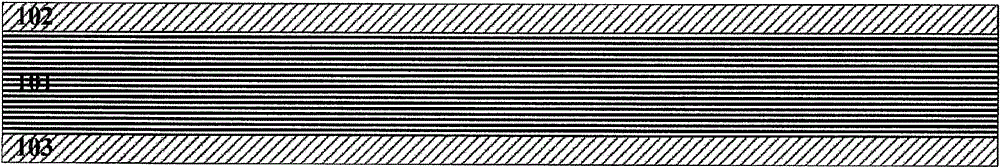

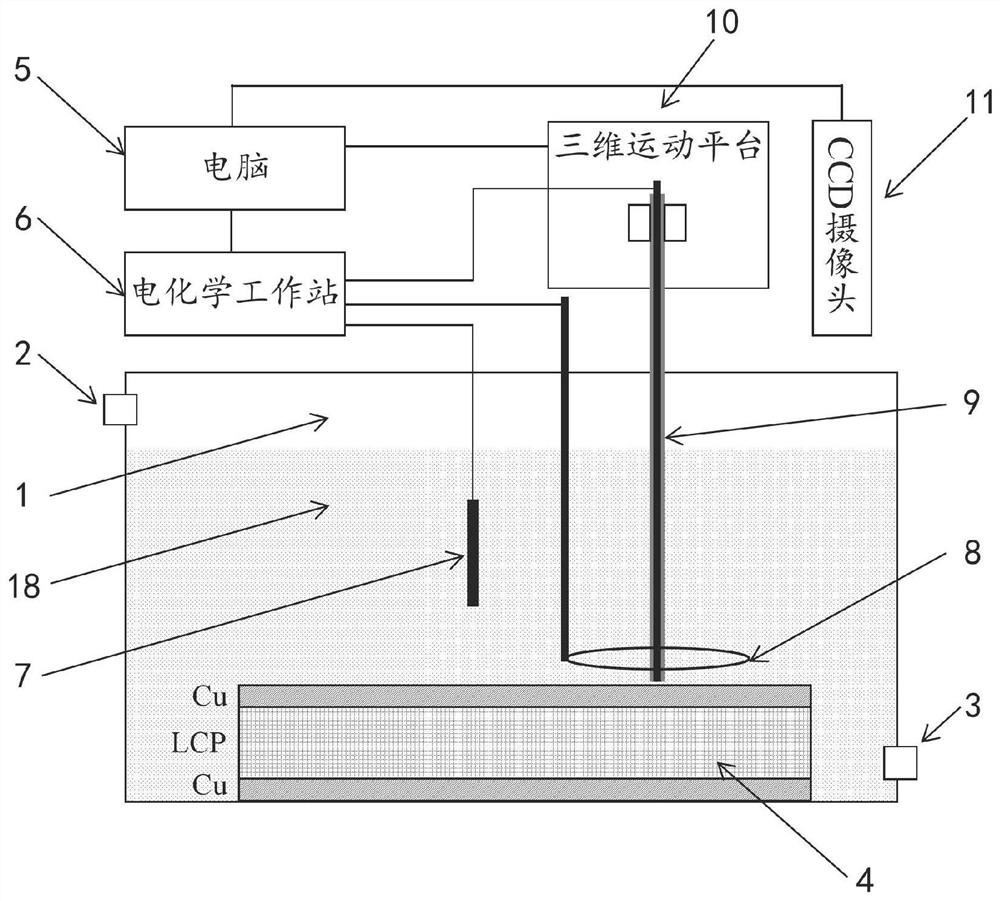

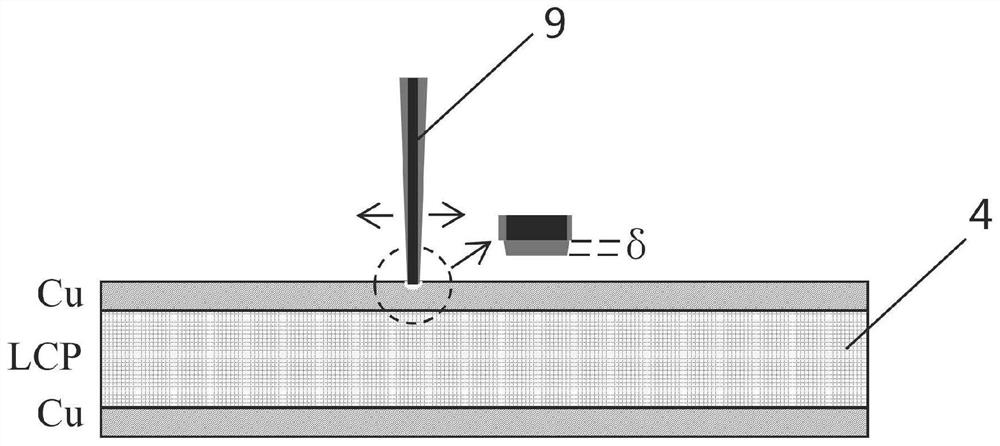

Micropore manufacturing method suitable for liquid crystal polymer substrate

PendingCN113811084AAchieve coarseningImprove efficiencyInsulating layers/substrates workingPhysical chemistryMaterials science

The invention discloses a micropore manufacturing method suitable for a liquid crystal polymer substrate, the liquid crystal polymer substrate comprises a liquid crystal polymer layer and a copper layer which are attached to each other, and the micropore manufacturing method comprises the following steps: respectively preparing electrolyte solutions of the copper layer and the liquid crystal polymer layer; manufacturing a working electrode; and utilizing working electrode, sequentially adopting the electrolyte solution of the copper layer and the electrolyte solution of the liquid crystal polymer layer to conduct electrified etching on the copper layer and the liquid crystal polymer layer, and preparing the micropores, wherein the electrolyte solution includes an etchant precursor and a constraining agent. According to the micropore manufacturing method suitable for the liquid crystal polymer flexible substrate, the micropores with tiny diameters and high depth-to-width ratios can be machined in the LCP flexible substrate; many problems caused by heat accumulation in the hole manufacturing process are avoided, and it is guaranteed that the hole pattern is good; and meanwhile, hole wall coarsening is achieved, and the efficiency is high.

Owner:AKM ELECTRONICS TECH SUZHOU +1

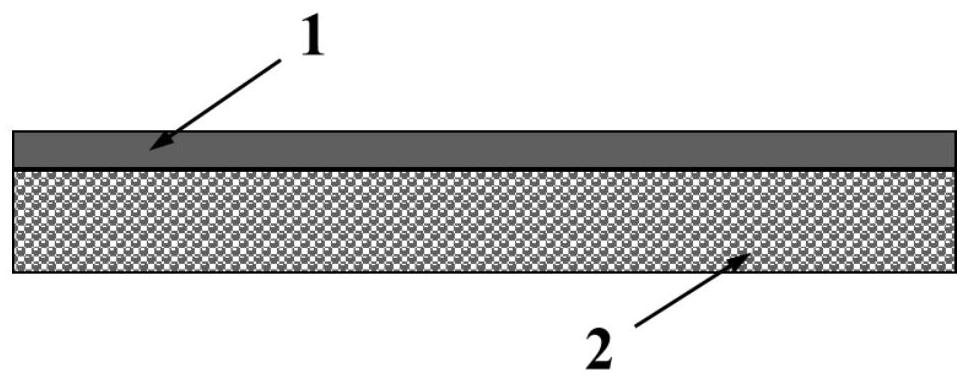

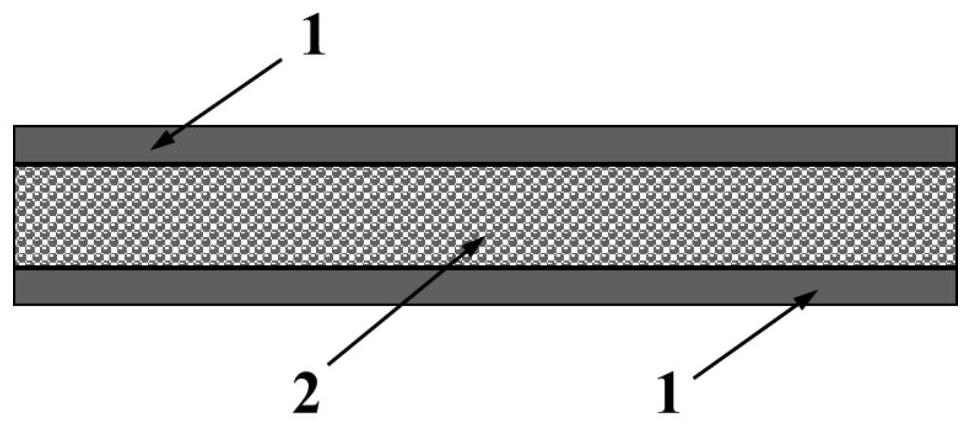

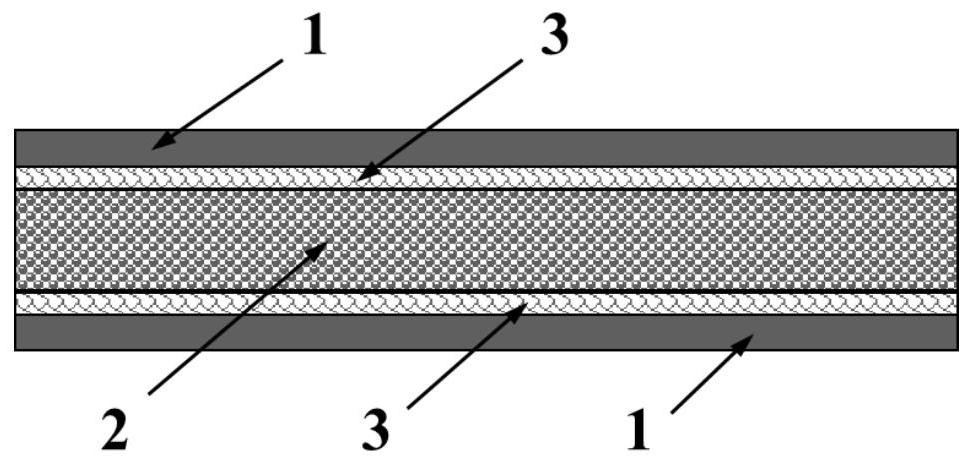

Liquid crystal polymer substrate and processing method thereof

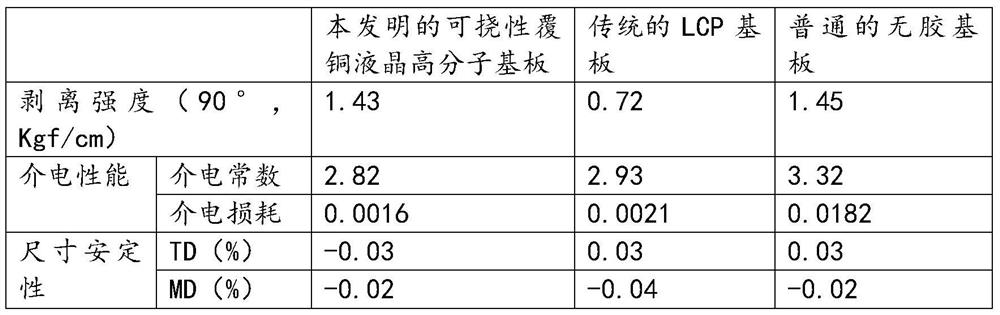

ActiveCN112433405AHigh peel strengthImprove heat resistanceNon-linear opticsPolymer sciencePolymer resin

The invention discloses a liquid crystal polymer substrate and a processing method thereof. The liquid crystal polymer substrate comprises a composite liquid crystal polymer film and a metal conductive layer covering at least one surface of the composite liquid crystal polymer film; and the composite liquid crystal polymer film comprises a liquid crystal polymer resin with a melting point of Tm1 and the liquid crystal polymer resin with the melting point of Tm2, the Tm1 is larger than the Tm2, and the liquid crystal polymer resin with the melting point of Tm2 accounts for 1.0-30.0% of the total mass of the liquid crystal polymer film. Technical problems that in the prior art, bonding strength between the liquid crystal polymer film and the metal conducting layer of a liquid crystal polymersubstrate is low, or the heat resistance of the liquid crystal polymer film is poor, or the high-frequency characteristic of the liquid crystal polymer film is poor are mainly solved.

Owner:UNIV OF SCI & TECH OF CHINA

Method for etching microchannel networks within liquid crystal polymer substrates

Owner:UNIV OF SOUTH FLORIDA

Optical waveguide device

InactiveUS20140050440A1Relieve pressureOptical waveguide light guideNon-linear opticsThermal expansionPermittivity

Provided is an optical waveguide device capable of reducing stress that occurs inside an optical waveguide substrate due to a difference in a coefficient of thermal expansion. The optical waveguide device (10) includes an optical waveguide substrate (11) having a thickness of 30 μm or less, and a liquid crystal polymer substrate (12) which holds the optical waveguide substrate (11) and has permittivity lower than that of the optical waveguide substrate (11). The optical waveguide substrate (11) and the liquid crystal polymer substrate (12) are bonded to each other by an adhesive layer (14). Coefficients of thermal expansion of the optical waveguide substrate (11) and the liquid crystal polymer substrate (12) have anisotropy in each substrate plane, and a relative direction between the optical waveguide substrate (11) and the liquid crystal polymer substrate (12) is adjusted in such a manner that anisotropic axial directions of the optical waveguide substrate (11) and anisotropic axial directions the liquid crystal polymer substrate (12) are aligned.

Owner:SUMITOMO OSAKA CEMENT CO LTD

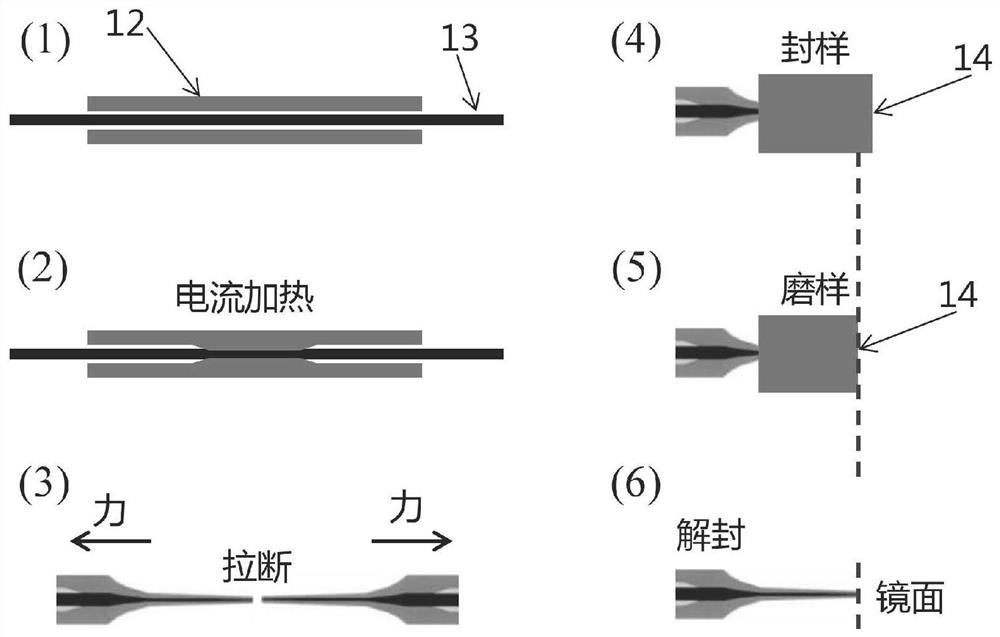

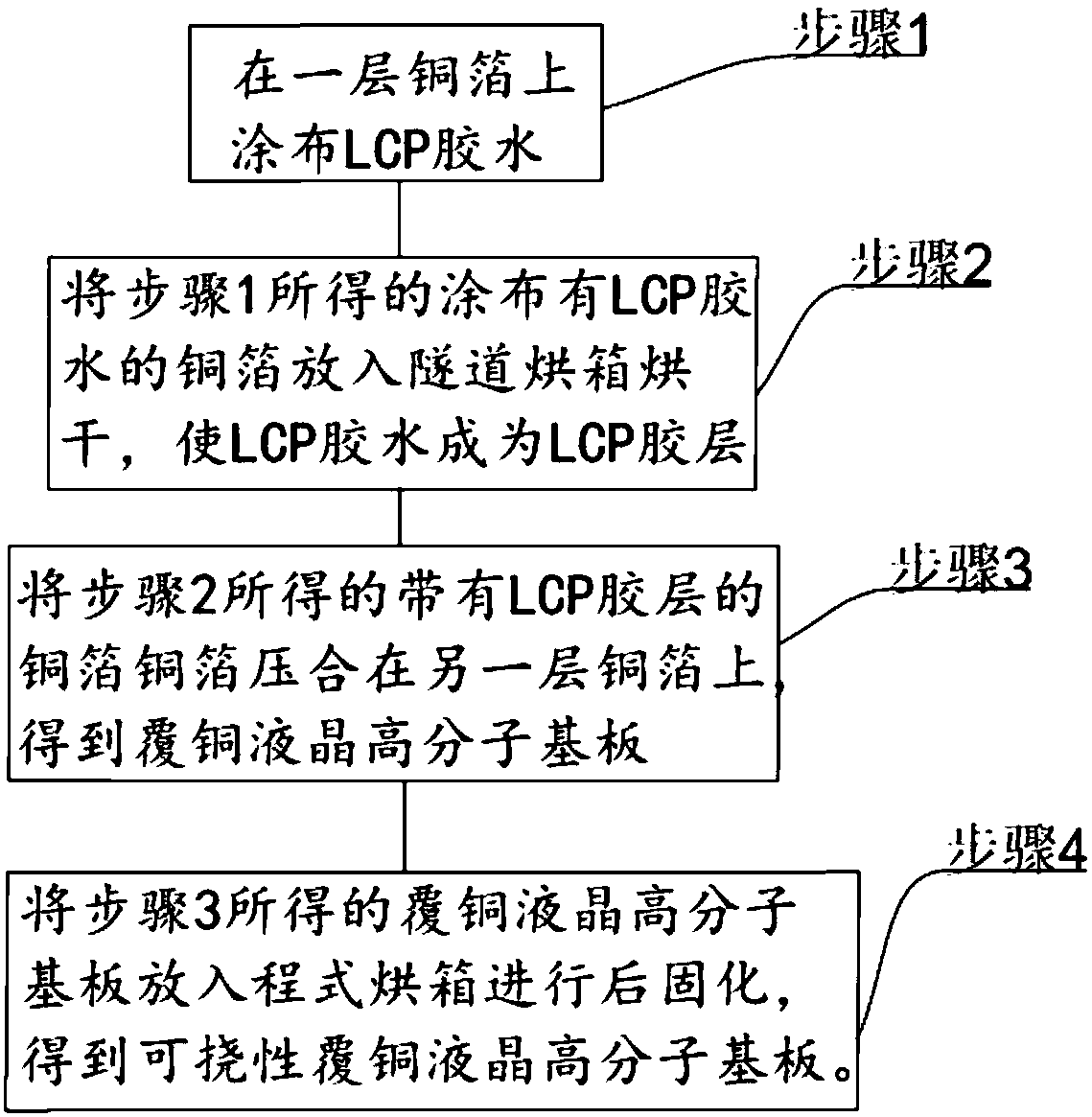

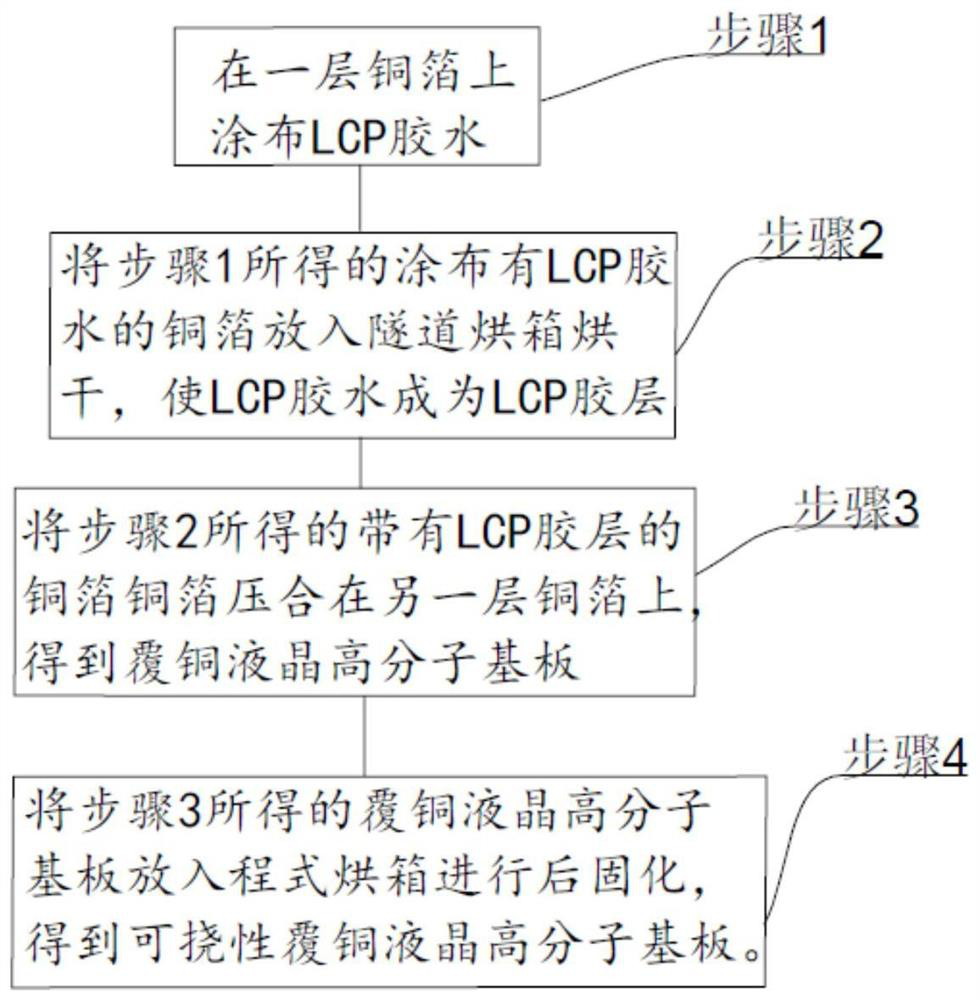

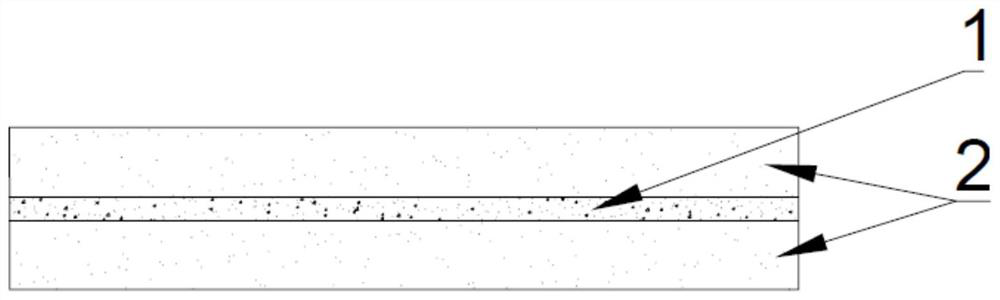

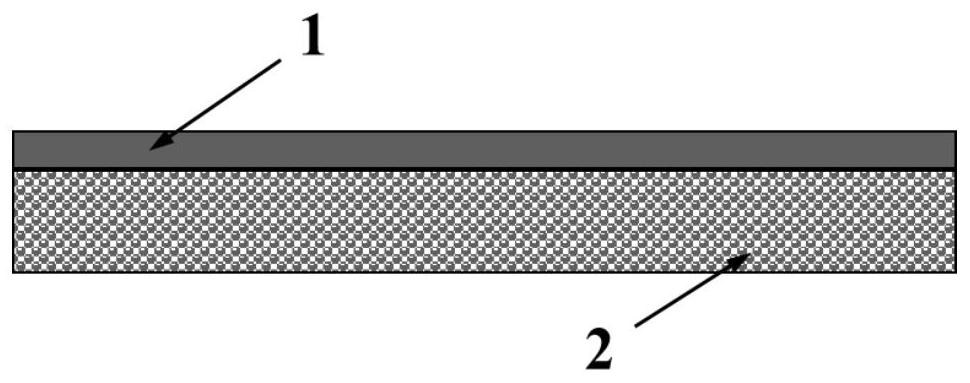

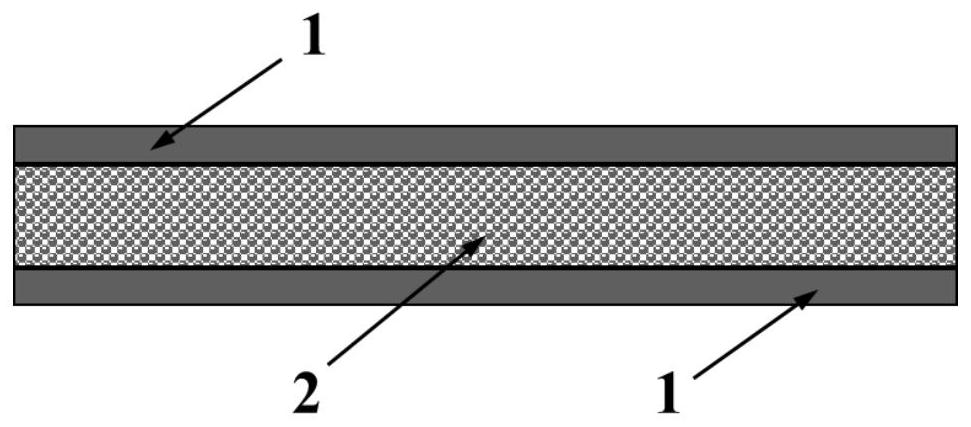

Preparation method of flexible copper clad liquid crystal high molecular substrate

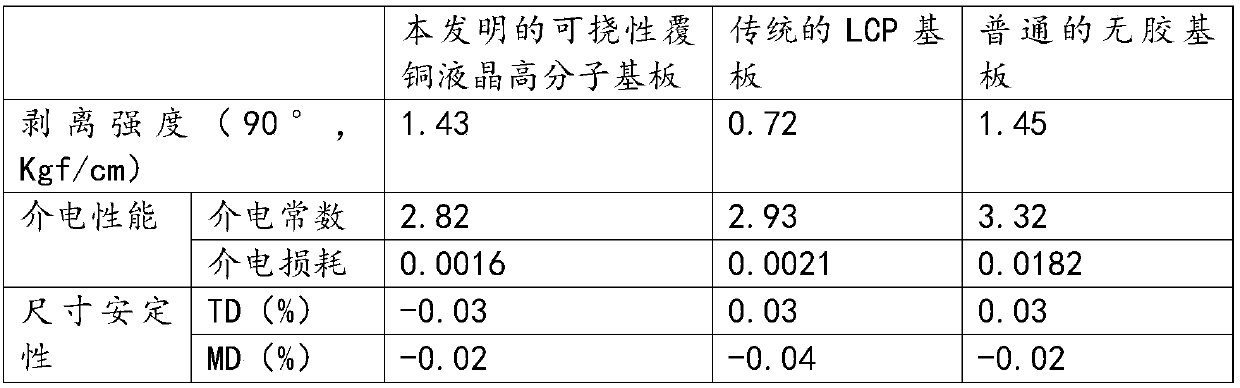

ActiveCN107791657ASimplify production stepsLow costLamination ancillary operationsLaminationCopper foilUltimate tensile strength

The invention discloses a preparation method of a flexible copper clad liquid crystal high molecular substrate. The preparation method comprises the following steps of firstly coating a layer of LCP (Liquid Crystal Polymer) glue on a layer of copper foil, afterwards, oven-drying by using a tunnel drying oven, then laminating the obtained copper foil with an LCP glue layer with another layer of copper foil, so as to obtain a substrate, and afterwards, carrying out post cure through a program drying oven, so as to obtain the flexible copper clad liquid crystal high molecular substrate. Through the method, the ultra-thinness of the thickness of the LCP glue layer is quite easily achieved; the development that an electronic product tends to be ultra-thin in future is facilitated; moreover, a high-temperature press is replaced with a low-temperature press during lamination; the cost is greatly decreased; the production capacity is also improved; a post-cure step is carried out on the laminated substrate; the internal stress is effectively removed; the bonding strength and the cohesion strength are improved and the strength of the whole flexible copper clad liquid crystal high molecularsubstrate is promoted.

Owner:CHENGDU DO ITC NEW MATERIAL

Copper foil excellent in adhesion to resin, method for producing same, and negative electrode material for printed wiring board or battery using the same

ActiveCN103857833BHigh peel strengthHigh bonding strengthInsulating substrate metal adhesion improvementElectrode carriers/collectorsEpoxyElectrolysis

The present invention provides an electrolytic copper foil. The electrolytic copper foil is an electrolytic copper foil in which roughened particles are formed on the roughened surface (M surface) of the electrolytic copper foil. It is characterized in that the average size of the roughened particles is 0.1~1.0μm. The present invention provides an electrolytic copper foil and a manufacturing method thereof. The properties of the electrolytic copper foil are not deteriorated, the roughening treatment layer on the copper foil can be improved, and the bonding strength between the copper foil and the resin substrate can be improved; especially , Compared with general-purpose epoxy resin-based substrates (FR‑4, etc.), peeling can be achieved when using a combination of a substrate for semiconductor packaging or a liquid crystal polymer substrate that generally has low adhesion to copper foil and an electrolytic copper foil. Stronger electrolytic copper foil. An object of the present invention is to provide an electrolytic copper foil useful as an electrolytic copper foil used as a negative electrode material for a printed wiring board or a battery (LiB, etc.).

Owner:JX NIPPON MINING & METALS CORP

Solidified silicon rubber combination and producing method for compound molding object of liquid crystal polymer and silicon rubber

ActiveCN1834187BOther printing matterSynthetic resin layered productsPolymer scienceLiquid-crystal display

The invention discloses to a solid silicon rubber compound used in liquid crystal polymer, which comprises the organic polysiloxane (A) with aliphatic unsaturated bond, (B) organic hydrogen polysiloxane, at least one (C) acryl, methacryloyl, or the (methyl) acrylate compound that soluble with (A), and (D) platinum group metallic catalyst. With inventive silicon rubber compound, the solid that canadhere the LCP basic plate can be prepared, especially the inventive silicon rubber compound can provides the solid with better transparence, to effectively adhere he liquid crystal polymer basic plate used in the package of light displays, while it can be effectively used in the application of basic plate of optical correlator.

Owner:SHIN ETSU CHEM IND CO LTD

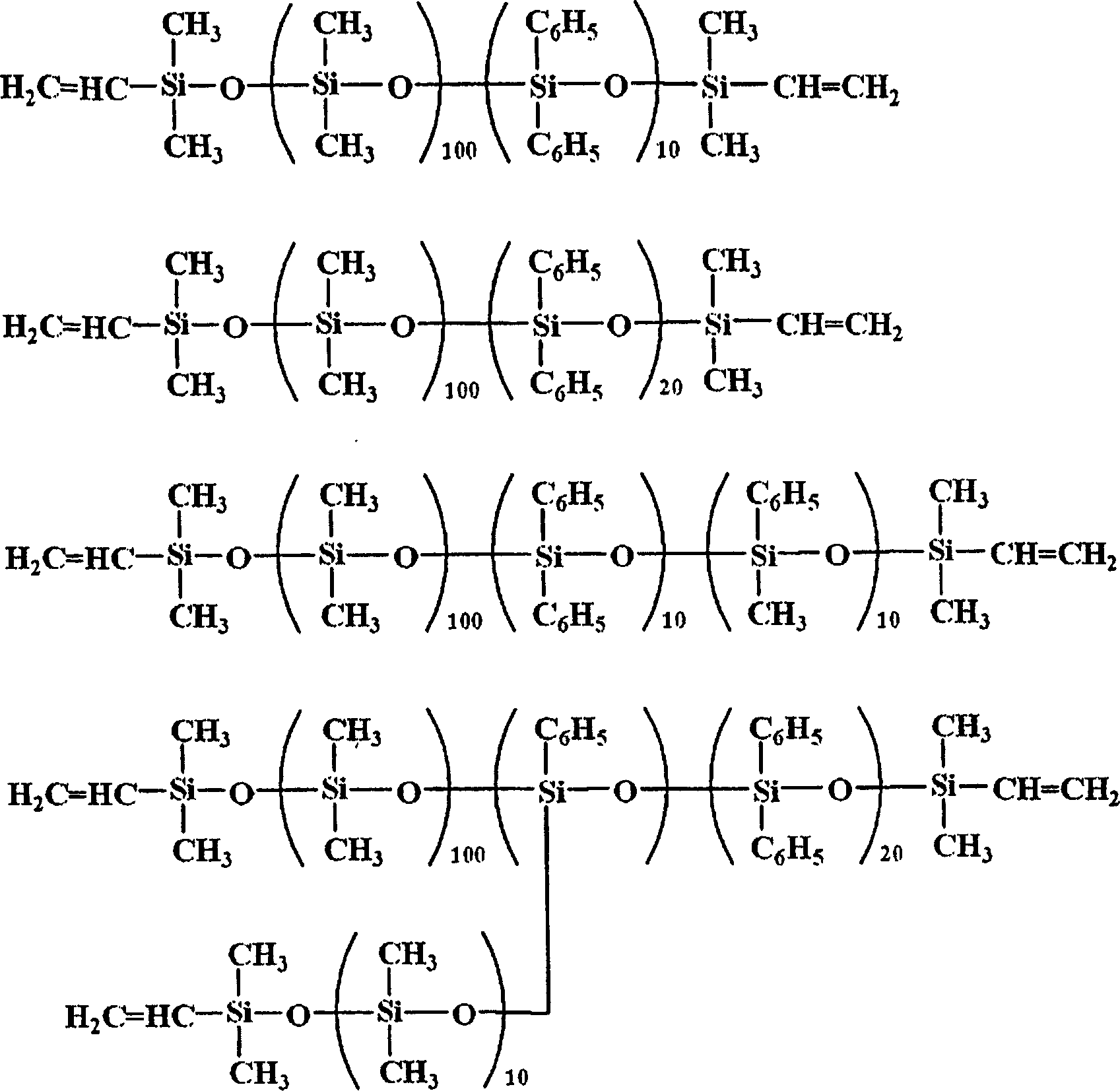

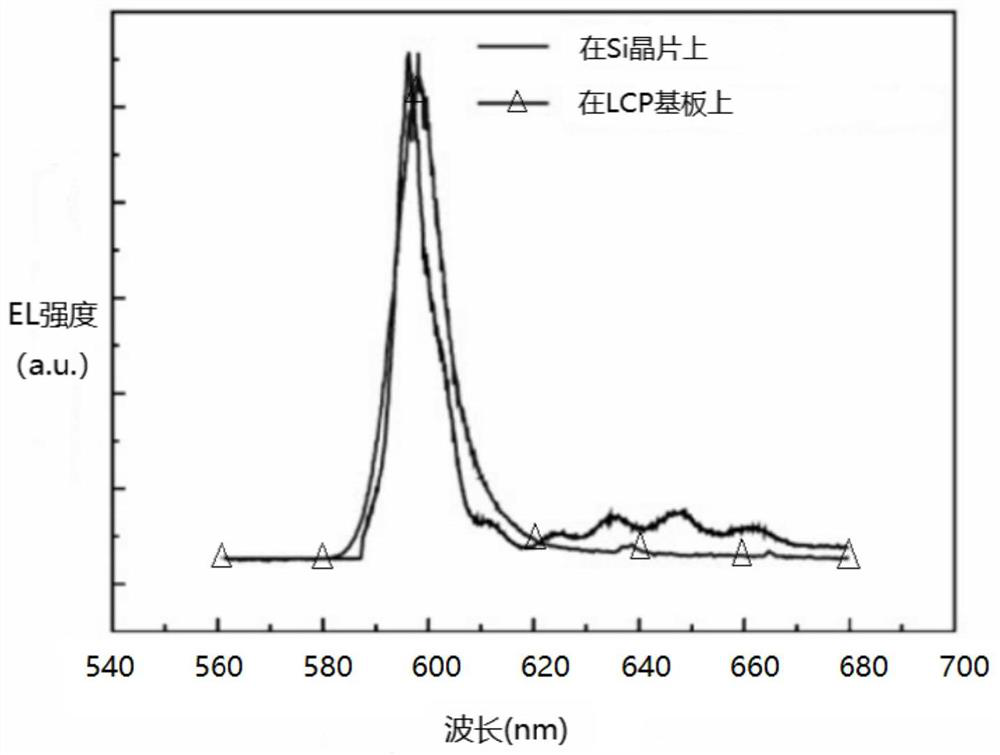

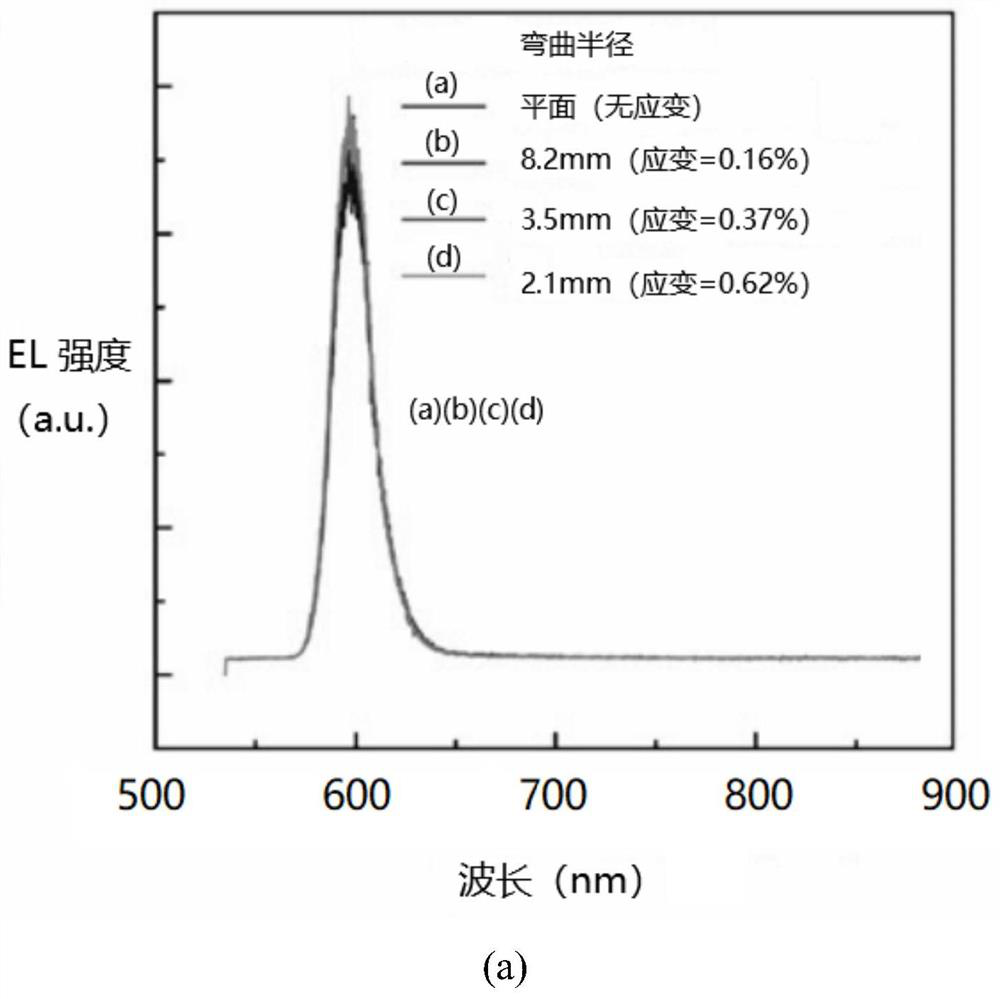

GaN optical sensing biosensing chip and preparation method and application thereof

PendingCN112216711ABiocompatibleImprove waterproof performanceBiological material analysisSolid-state devicesEngineeringBiocompatibility

The invention provides a GaN optical sensing biosensing chip and a preparation method and application thereof. The GaN-based optical sensing biosensing chip comprises an LED array and a PD array, theLED array comprises a plurality of micro columnar LED structures connected in series, the PD array comprises a plurality of micro columnar LED structures connected in series, and the LED array is externally connected with a power supply; each micro columnar LED structure of the LED array and the PD array sequentially comprises an ultraviolet photosensitive resin layer, a GaN LED epitaxial layer and a liquid crystal polymer substrate in sequence; the GaN LED epitaxial layer comprises a p-GaN layer, an In < x > Ga < 1 -x > N / GaN multi-dimensional quantum well and an n-GaN layer in sequence. TheGaN optical sensing biosensor chip taking the liquid crystal polymer substrate as the substrate is provided for the first time, has excellent waterproof performance, biocompatibility, mechanical performance and optical performance and excellent optical stability, and can be applied to the field of chemical and biological sensors.

Owner:深圳远芯光路科技有限公司

A preparation method of a flexible copper-clad liquid crystal polymer substrate

ActiveCN107791657BSimplify production stepsLow costLamination ancillary operationsLaminationPolymer scienceAdhesive glue

The invention discloses a preparation method of a flexible copper-clad liquid crystal polymer substrate. First, a layer of LCP glue is coated on a layer of copper foil, and then dried in a tunnel oven, and then the obtained copper foil with an LCP glue layer is The foil is laminated with another layer of copper foil to obtain a substrate, which is then post-cured in a programmed oven to obtain a flexible copper-clad liquid crystal polymer substrate. Through this method, the thickness of the LCP adhesive layer can be easily made ultra-thin, which is conducive to the development of ultra-thin electronic products in the future, and the low-temperature press is used to replace the high-temperature press during lamination, which greatly reduces the cost and improves the production capacity. It has also been improved, and the post-curing step is performed on the laminated substrate to effectively eliminate internal stress, improve the bonding strength and cohesive strength, and improve the strength of the entire flexible copper-clad liquid crystal polymer substrate.

Owner:CHENGDU DO ITC NEW MATERIAL

A liquid crystal polymer substrate and its processing method

ActiveCN112433405BHigh peel strengthImprove heat resistanceNon-linear opticsPolymer sciencePolymer resin

Owner:UNIV OF SCI & TECH OF CHINA

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com