Copper foil excellent in adhesion with resin, method for manufacturing same, and printed wiring board or battery negative electrode material using electrolytic copper foil

A technology of electrolytic copper foil and manufacturing method, applied in non-aqueous electrolyte storage batteries, printed circuits, printed circuits, etc., can solve problems such as limited effect, increase peel strength, improve adhesion strength, and improve the roughening treatment layer. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1)

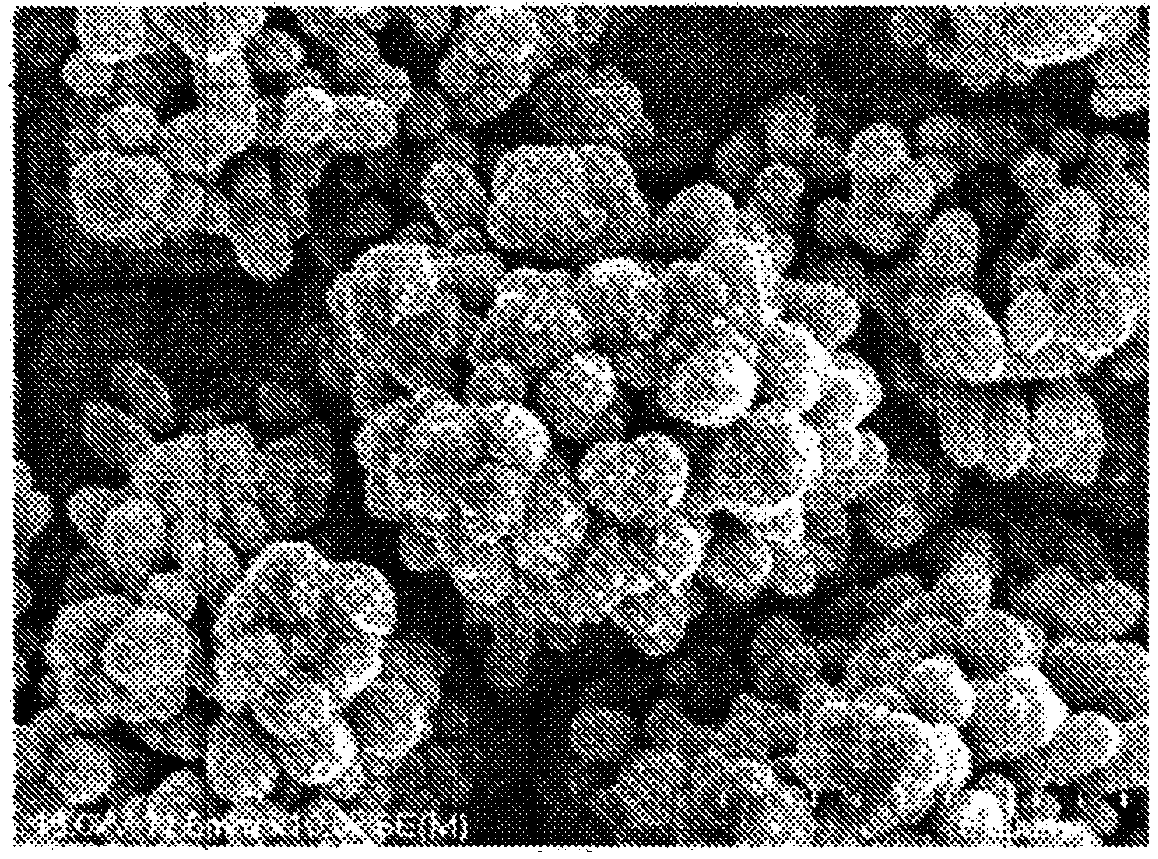

[0119] A treatment of forming roughened particles was performed on the rough surface of the copper foil using an IPC3 grade electrolytic copper foil having a thickness of 12 μm.

[0120] The plating bath composition and electrolytic treatment conditions of the treatment (electroplating) electrolytic solution for forming roughened particles are as follows.

[0121] (Electrolyte composition)

[0122] Cu: 15g / L

[0123] h 2 SO 4 : 100g / L

[0124] W addition amount: 3mg / L (added in the form of sodium tungstate dihydrate, the same below)

[0125] Addition amount of sodium decyl sulfate: 4mg / L

[0126] (Electrolyte temperature) 38°C

[0127] (current condition)

[0128] Current density: 54A / dm 2

[0129] Next, on the above-mentioned roughened surface, plating is performed with an electrolytic bath containing sulfuric acid / copper sulfate in order to prevent falling off of roughened particles and to increase peel strength. The processing conditions for plating are as follows...

Embodiment 1

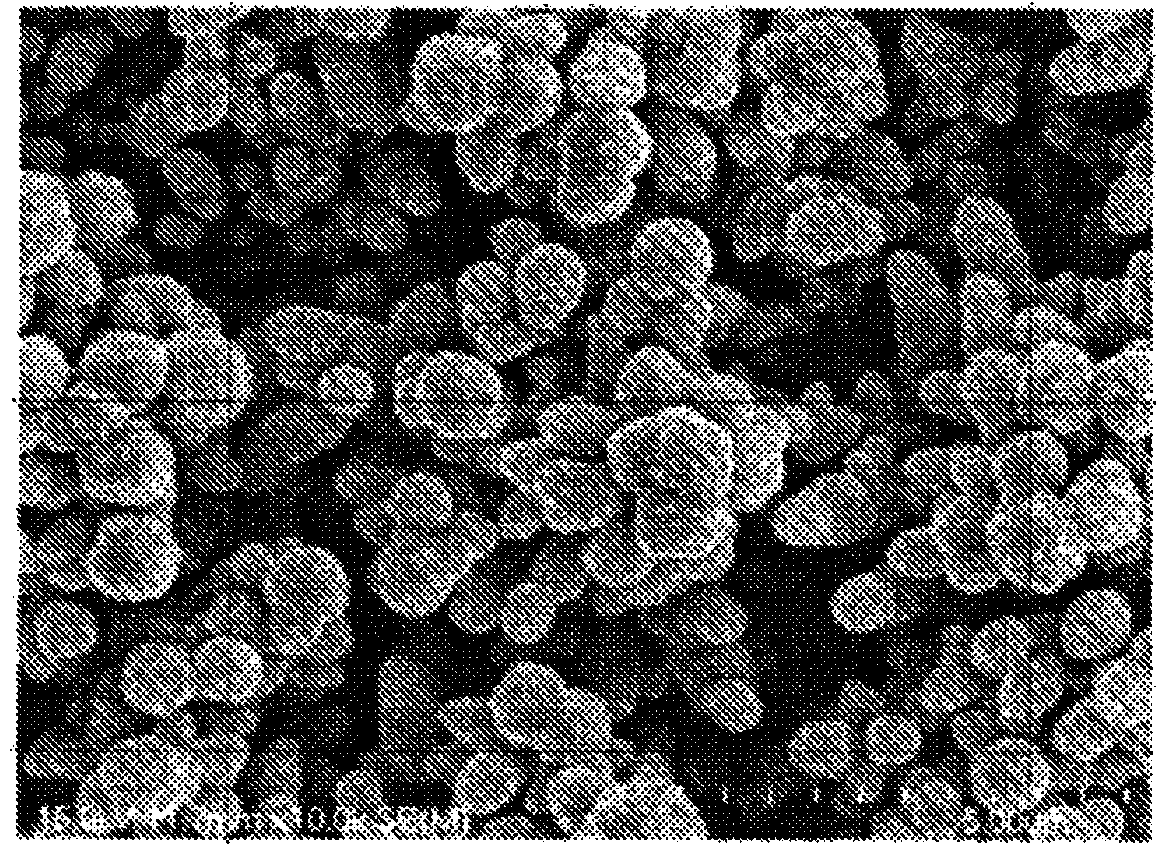

[0146] The number of coarse particles measured in Example 1 (pieces / μm 2 ), particle size (average μm), surface roughness (Ra, Rt, Rz) and peel strength (BT substrate peel strength (kN / m): normal and welded peel strength) are shown in Table 1.

[0147] Table 1

[0148]

Embodiment 2)

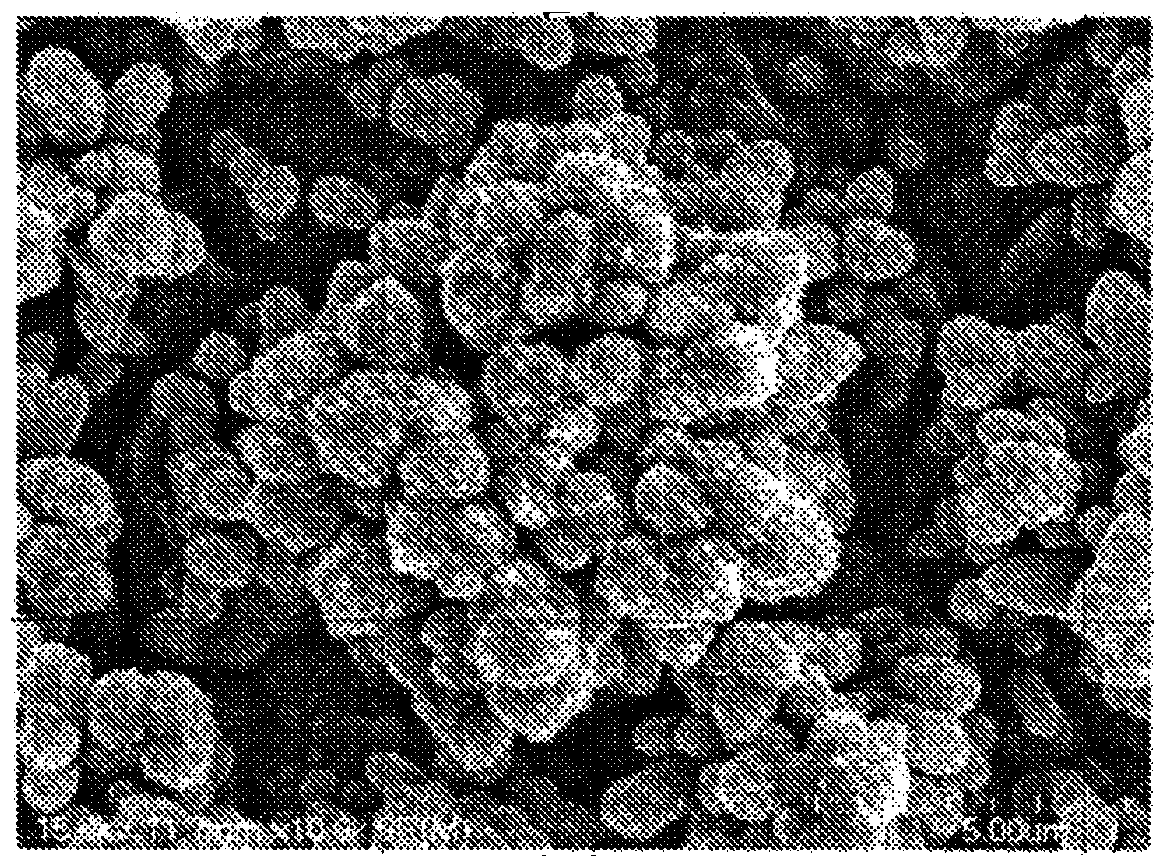

[0150] A treatment of forming roughened particles was performed on the rough surface of the copper foil using an IPC3 grade electrolytic copper foil having a thickness of 12 μm.

[0151] The plating bath composition and electrolytic treatment conditions of the electrolytic solution in the roughened particle forming treatment (electroplating) are as follows.

[0152] (Electrolyte composition)

[0153] Cu: 15g / L

[0154] h 2 SO 4 : 100g / L

[0155] W addition amount: 3mg / L (added in the form of sodium tungstate dihydrate, the same below)

[0156] Addition amount of sodium decyl sulfate: 4mg / L

[0157] (Electrolyte temperature) 38°C

[0158] (current condition)

[0159] Current density: 54A / dm 2

[0160] Next, on the above-mentioned roughened surface, plating is performed with an electrolytic bath containing sulfuric acid / copper sulfate in order to prevent falling off of roughened particles and to increase peel strength. The processing conditions for plating are as follo...

PUM

| Property | Measurement | Unit |

|---|---|---|

| surface roughness | aaaaa | aaaaa |

| peel strength | aaaaa | aaaaa |

| peel strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com