A method of fabricating a multilayer organic liquid crystal polymer substrate structure

A liquid crystal polymer and substrate technology, applied in semiconductor/solid-state device manufacturing, instruments, electrical components, etc., can solve the problems of poor reworkability of source chips, rupture of embedded active chips, low production efficiency, etc. Good reworkability, excellent high frequency performance, and the effect of avoiding pressure damage problems

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0056] In order to make the object, technical solution and advantages of the present invention clearer, the present invention will be described in further detail below in conjunction with specific embodiments and with reference to the accompanying drawings.

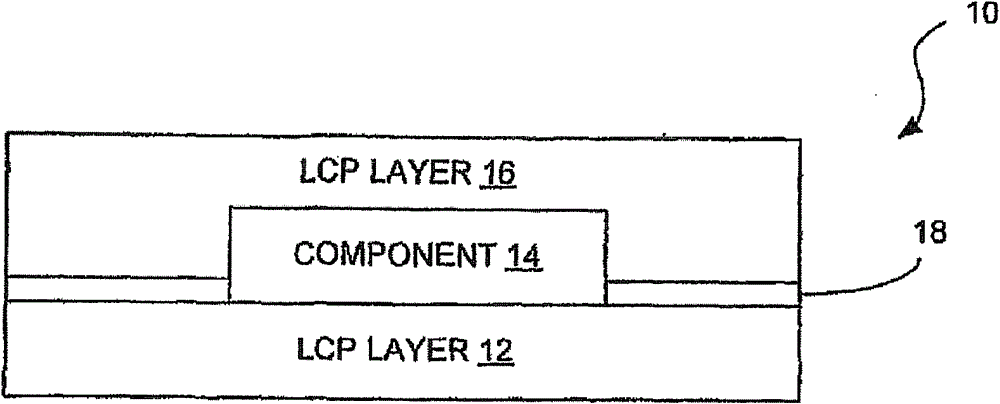

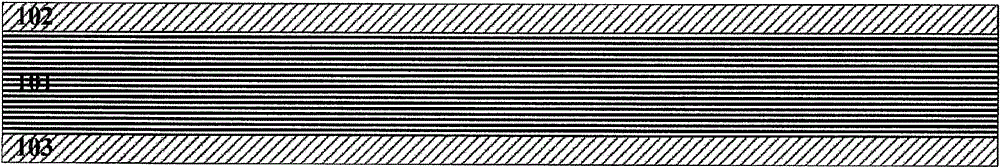

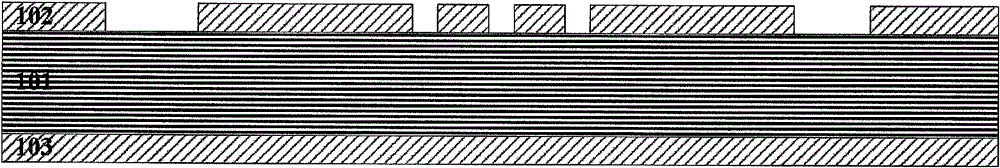

[0057] The invention is based on a new type of packaging material - liquid crystal polymer, which not only embeds active and passive devices into the multi-layer organic substrate at the same time, but also adopts a one-time pressing process to form a multi-layer liquid crystal polymer substrate. Implement the concept of system-in-package. Different from the high sintering temperature of low-temperature co-fired ceramics, the lamination temperature of the multilayer organic substrate is not very high. Not only can passive devices be embedded in the multilayer substrate, but also active devices can be embedded in the substrate. Moreover, it will not damage active devices, and is compatible with traditional semiconductor pr...

PUM

| Property | Measurement | Unit |

|---|---|---|

| melting point | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| melting point | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com