Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

34 results about "Cross laminated timber" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

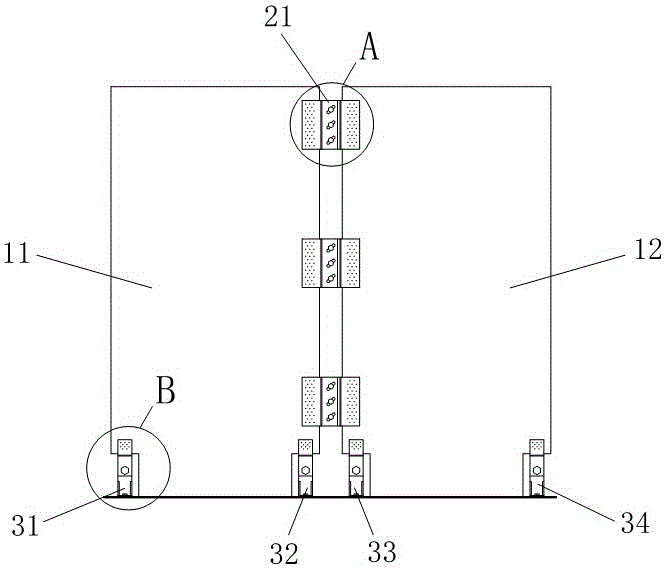

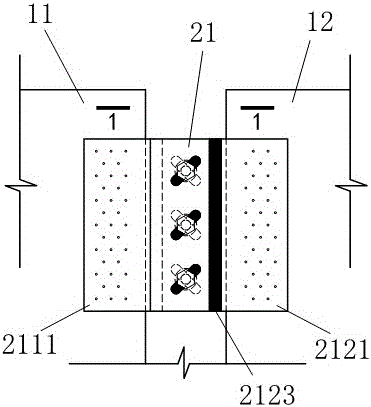

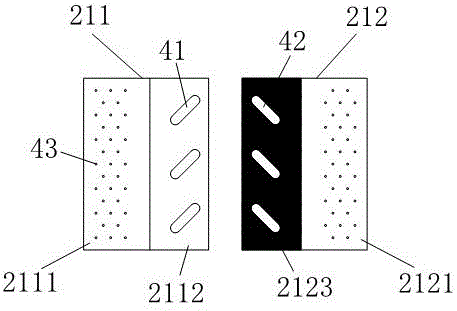

Cross laminated timber (CLT) double-board seismic wall with swinging energy-dissipation function

ActiveCN106639030AImprove deformationImprove energy consumptionWallsProtective buildings/sheltersLap jointEngineering

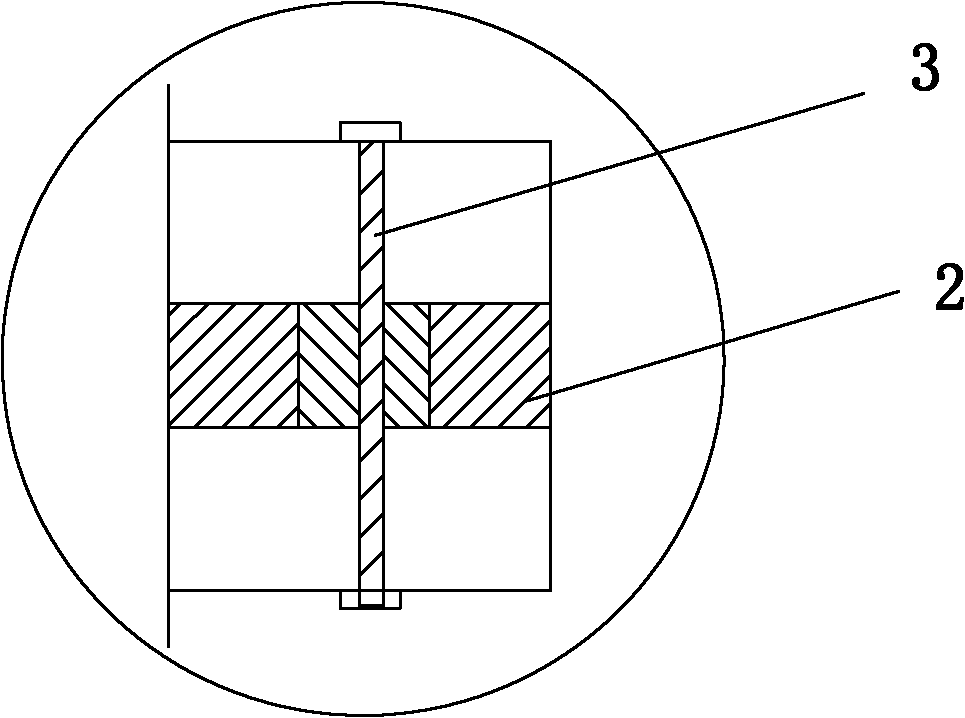

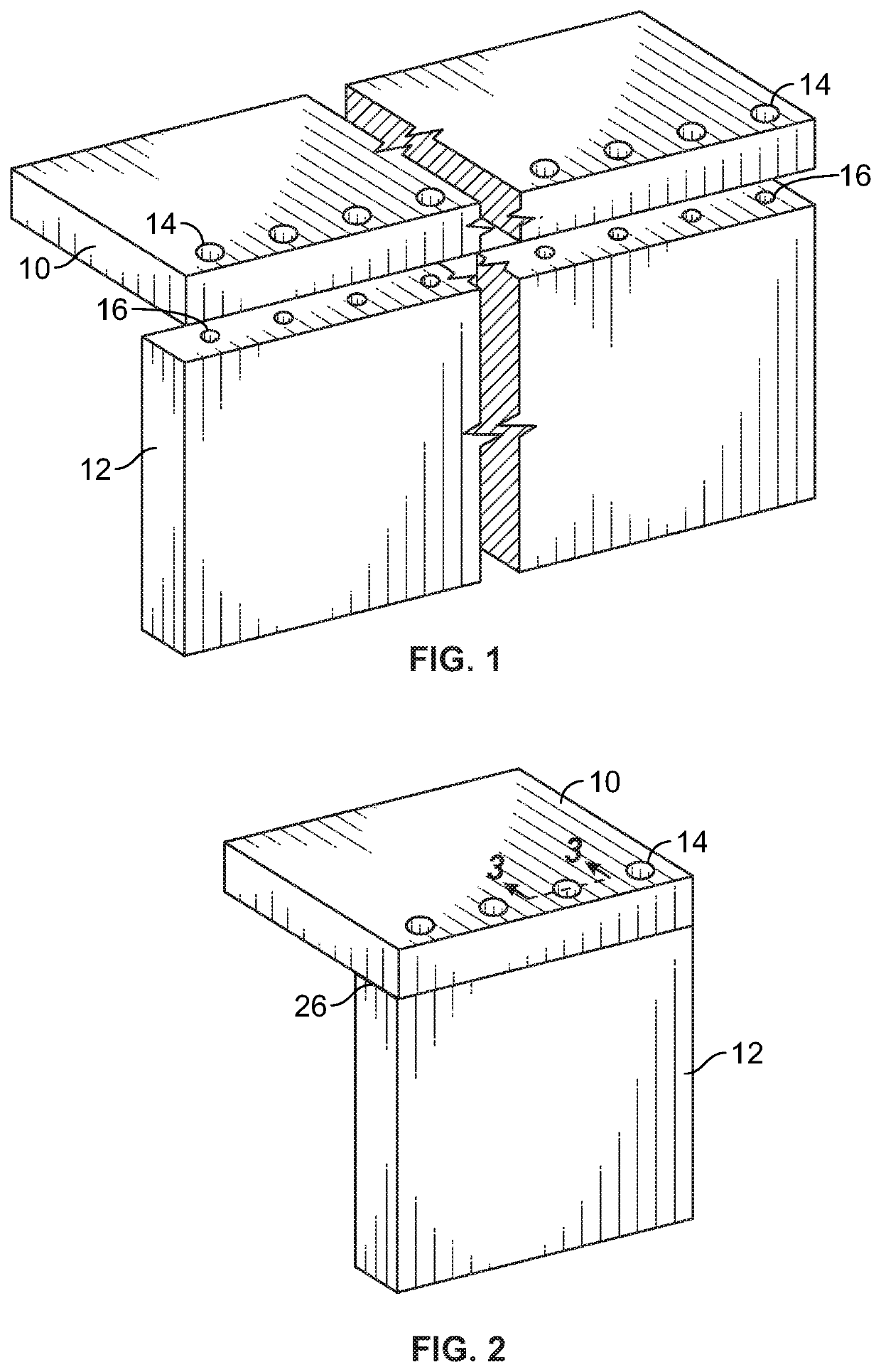

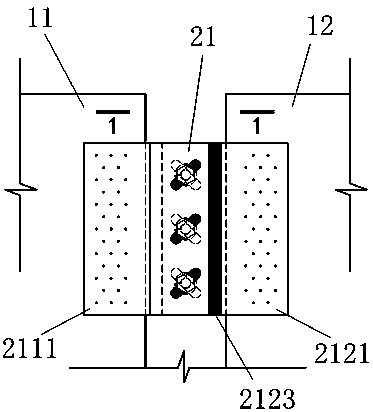

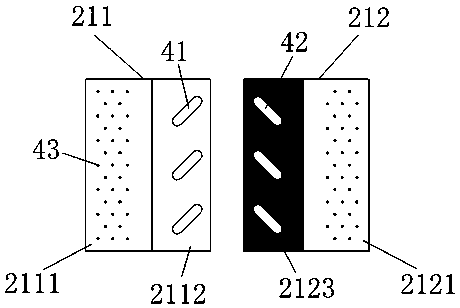

The invention relates to a cross laminated timber (CLT) double-board seismic wall with a swinging energy-dissipation function. The CLT double-board seismic wall is composed of two CLT shear walls, a friction-type vertical connecting piece and a friction-type pulling-resistant anchoring piece. The two CLT shear walls are spliced together through the friction-type vertical connecting piece, and a wall body is connected with a floor or a foundation through the friction-type pulling-resistant anchoring piece. Under the effect of an earthquake, the CLT shear walls rotate in the wall board plane, the friction-type vertical connecting piece is in shear, and lap joint friction surfaces of the friction-type vertical connecting piece slide relatively to dissipate energy; and meanwhile, the specially-designed pulling-resistant anchoring piece is matched with rotation of the CLT shear walls, and friction surfaces in the pulling-resistant anchoring piece also slide relatively to dissipate energy. The CLT shear walls are hardly damaged after the earthquake, friction sheets in the vertical connecting piece and the pulling-resistant anchoring piece are not damaged and do not need to be replaced after the earthquake, and the ideal anti-seismic property that the structure is stable under small earthquakes, the seismic wall swings but is not damaged under large earthquakes, and no post-earthquake maintenance or only a small amount of post-earthquake maintenance is needed is achieved.

Owner:TONGJI UNIV

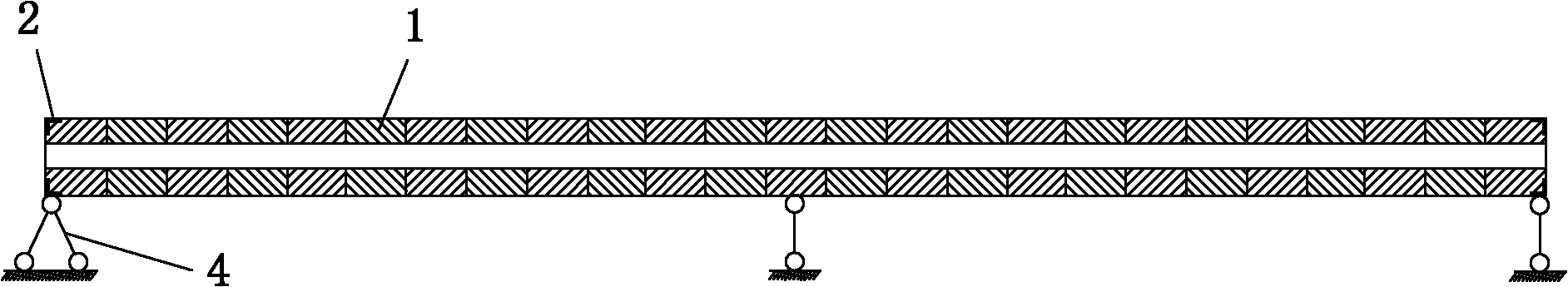

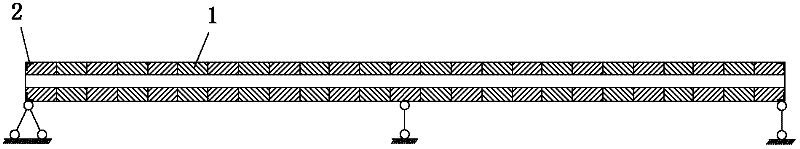

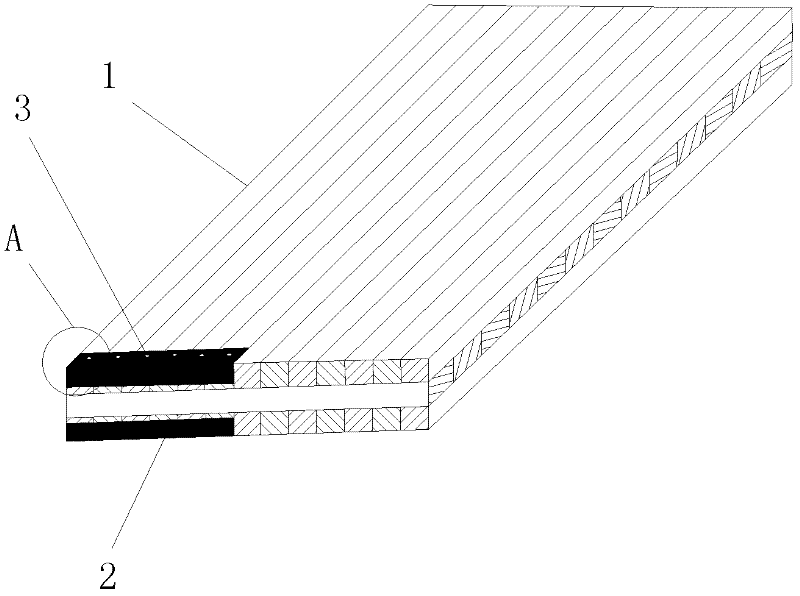

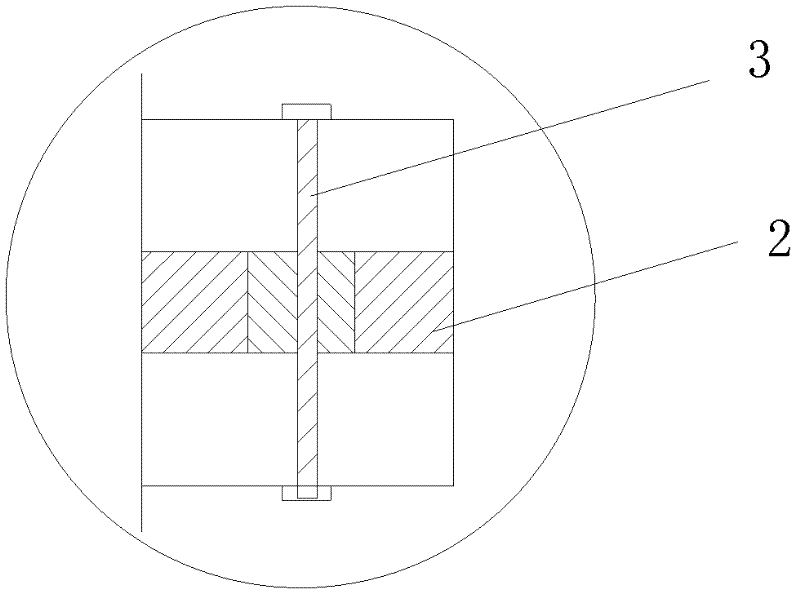

Integral prefabricated cross-laminated timber (CLT) wooden plate girder bridge based on steel side stiffening

InactiveCN102011364ASimple structureEasy to processBridge structural detailsBridge materialsEngineeringMoisture

The invention discloses an integral prefabricated cross-laminated timber (CLT) wooden plate girder bridge based on steel side stiffening, which comprises a bridge superstructure and a bridge substructure, wherein the bridge superstructure is spliced from a plurality of CLT wooden girder plates, and the upper part is provided with girder bridge spandrel girders of a girder bridge deck; each CLT wooden girder plate comprises a girder body structure and corner armor steel sides, the girder body structure is glued from at least three layers of wooden veneer sheets, and the corner armor steel sides are buckled on the upper and lower edges on the front and back ends of the girder body structure and used for stiffening the integral body; and the upper and lower edges on the front and back ends of the girder body structure are correspondingly provided with mounting notches of which the structures and dimensions correspond to those of the corner armor steel sides. The invention has the advantages of light weight, environment friendliness, simple structure, reasonable stressing and good compatibility with surrounding environment, is simple to construct, and can solve the problems of poor compatibility with surrounding environment, easy corrosion from moisture and other natural factors, on-site construction difficulty and the like in the existing bridge.

Owner:CHANGAN UNIV

Cross laminated timber combining fast growing timber material characteristics and meeting building structure requirements and preparation method thereof

PendingCN109434975AImprove mechanical propertiesImprove fire resistanceLaminationLamination apparatusMechanical propertyAdverse effect

The invention discloses cross laminated timber combining fast growing timber material characteristics and meeting building structure requirements and a preparation method thereof, and belongs to the field of timber structures. A laminated board of the cross laminated timber comprises a fast growing timber laminated board with cracks, the fast growing timber laminated board is a whole cracked board, and lengths of all laminated boards of the cross laminated timber are consistent in the horizontal direction. In the preparation method, adjacent layers formed by the fast growing timber laminated board or fast growing timber laminated board combination are assembled and configured in a manner that wood textures are perpendicular to each other in the thickness direction of laminated wood. According to the cross laminated timber combining the fast growing timber material characteristics and meeting the building structure requirements and the preparation method thereof, the material characteristics that the fast growing timber is soft in material and prone to be made into the laminated board with the cracks in a rotary cutting mode are fully utilized, structural stock lumber is replaced for preparing the cross laminated timber, the utilization of the fast growing timber in the field of building structures is expanded, the material cost of a conventional component is greatly reduced, the component preparation process is simplified, the production period is shortened, and the problem that adverse effects on the mechanical property, durability and fireproof performance of the component are caused through gaps in laminated boards of a structural material cross laminated timber component is solved.

Owner:NANJING UNIV OF TECH

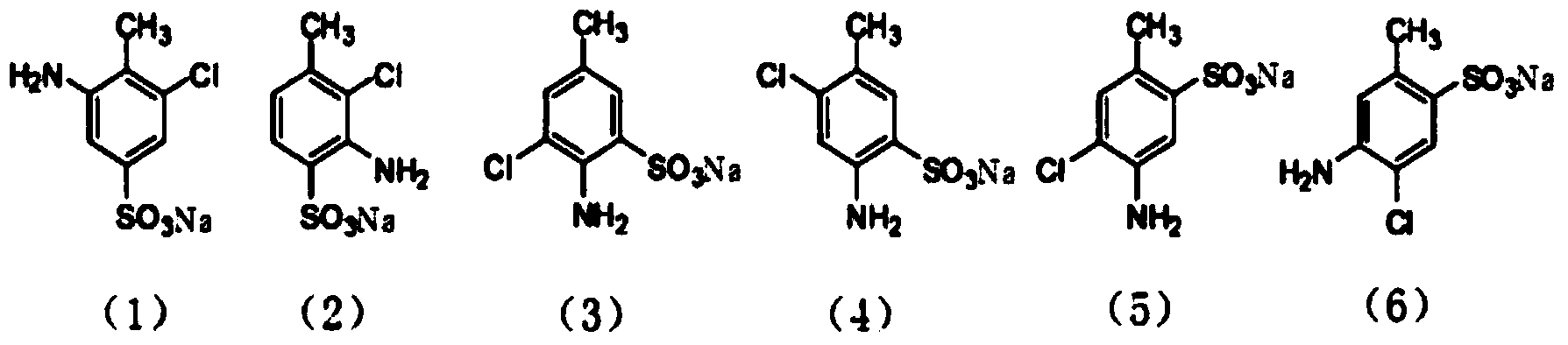

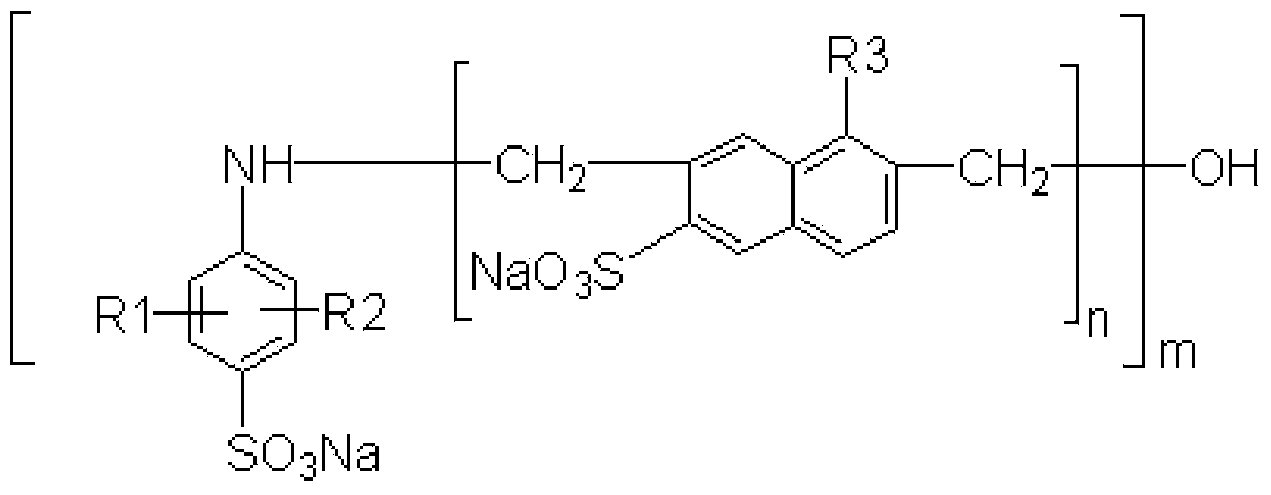

Preparation method for modified disperse dye dispersing agent and product

ActiveCN103524385AEasy to operateReduce manufacturing costTransportation and packagingSulfonic acids salts preparationDisperse dyeWastewater

The invention discloses a preparation method for a modified disperse dye dispersing agent. The preparation method comprises the following steps of heating a naphthalene compound to 130-170 DEG C, adding sulfuric acid to perform sulfonation reaction, cooling to 100-130 DEG C after the sulfonation reaction is finished, adding water, cooling to 80-100 DEG C after the reaction is finished, adding an aldehyde compound to perform primary condensation reaction under a temperature condition until the reaction is finished, adding an isomer mixture of CLT (cross laminated timber) acid, heating to 80-100 DEG C, adding the aldehyde compound again to perform secondary condensation reaction, and obtaining the modified disperse dye dispersing agent after the reaction is finished. The invention also provides a dispersing agent product obtained by the method. Wastewater produced by the CLT acid produced in an organic pigment production process is used as a part of production raw materials for producing the modified disperse dye dispersing agent, so that the production cost of the modified disperse dye dispersing agent is reduced, and the pollution caused by the production of the wastewater through the CLT acid on the environment is alleviated; the modified disperse dye dispersing agent is suitable for industrial production.

Owner:ZHEJIANG QINYAN TECH CO LTD

Cross-laminated timber transshipping transportation device

PendingCN107285051AAvoid idlingEnsure security requirementsConveyorsStorage devicesEngineeringMechanical engineering

The invention discloses a cross-laminated timber transshipping transportation device. The cross-laminated timber transshipping transportation device comprises multiple carrying vehicles, multiple pressing machines and transshipping vehicles moving along a transverse rail; a longitudinal rail is arranged on one side of the transverse rail, and the pressing machines are arranged on the other side of the transverse rail; the transshipping vehicles can be connected with the longitudinal rail when the transshipping vehicles move to the side face of the longitudinal rail along the transverse rail, and therefore the carrying vehicles can move onto the transshipping vehicles from the longitudinal rail or move out of the transshipping vehicles to move along the longitudinal rail; the transshipping vehicles can be connected with pressing machine rails arranged in the pressing machines when the transshipping vehicles move to material ports of the pressing machines along the transverse rail, and therefore the carrying vehicles can move onto the transshipping vehicles from the pressing machine rails or move out of the transshipping vehicles to move into the pressing machines along the pressing machine rails. According to the device, blank assembling can be conducted by fully utilizing the blank pressing time, blank assembling and blank pressing form good circulation, the condition that personnel and equipment are idle is avoided, the transshipping circulation transportation efficiency and the overall working efficiency are greatly improved, and the labor time is shortened; the safety is high, and the safety requirements on a timber production environment can be guaranteed.

Owner:JIANG SU GLOBAL CLT CO LTD

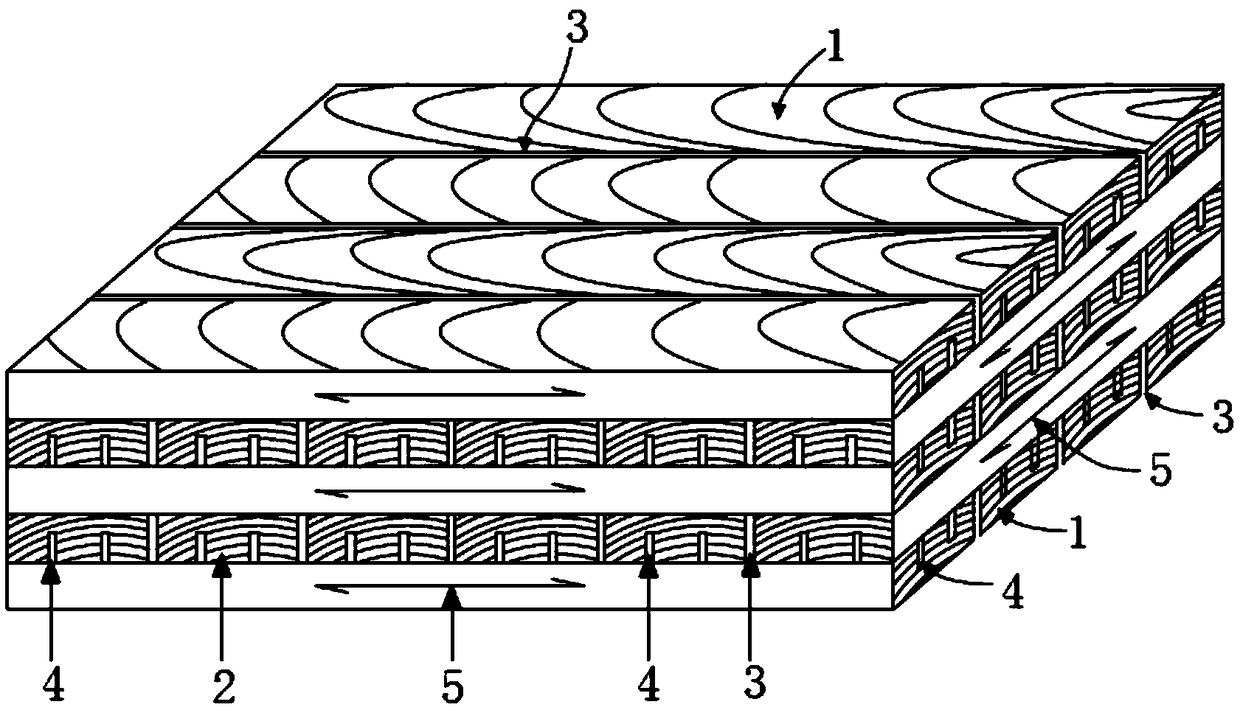

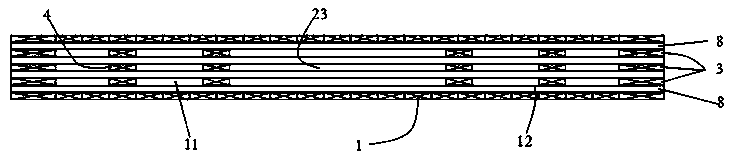

Longitudinally-reinforced cross laminated timber and manufacturing method thereof

ActiveCN108162519AReduce weightIncrease stiffnessConstruction materialTransportation and packagingPunchingEngineering

The invention discloses a longitudinally-reinforced cross laminated timber and a manufacturing method thereof, belongs to the technical field of construction engineering, and solves the deficiency ofa current cross laminated timber technology, the deficiency is the problem, that is, a large block cross laminated timber structure cannot be punched by a reinforcing steel bar so that the reinforcingsteel bar cannot run through the whole structure to be placed in the material, and slotting has a complicated process and destroys the overall performance of wood. The longitudinally-reinforced crosslaminated timber uses a hollow shaving board as a carrier for bearing the reinforcing steel bar to prepare a reinforcing body, and the reinforcing body and a converted timber are directly subjected to whole forming gluing to prepare the longitudinally-reinforced cross laminated timber. The manufacturing method includes the steps of sizing, combination, assembly and pressing. The longitudinally-reinforced cross laminated timber manufactured by the method provided by the invention has a simple process, is formed by one-time hot pressing, does not need punching or slotting, does not damage integrality of components, can improve the mechanical properties, connection strength and rigidity of the cross laminated timber components, reduces the mass of the cross laminated timber components, savesmaterials, and has better promotion value.

Owner:SHANGHAI CONSTRUCTION GROUP

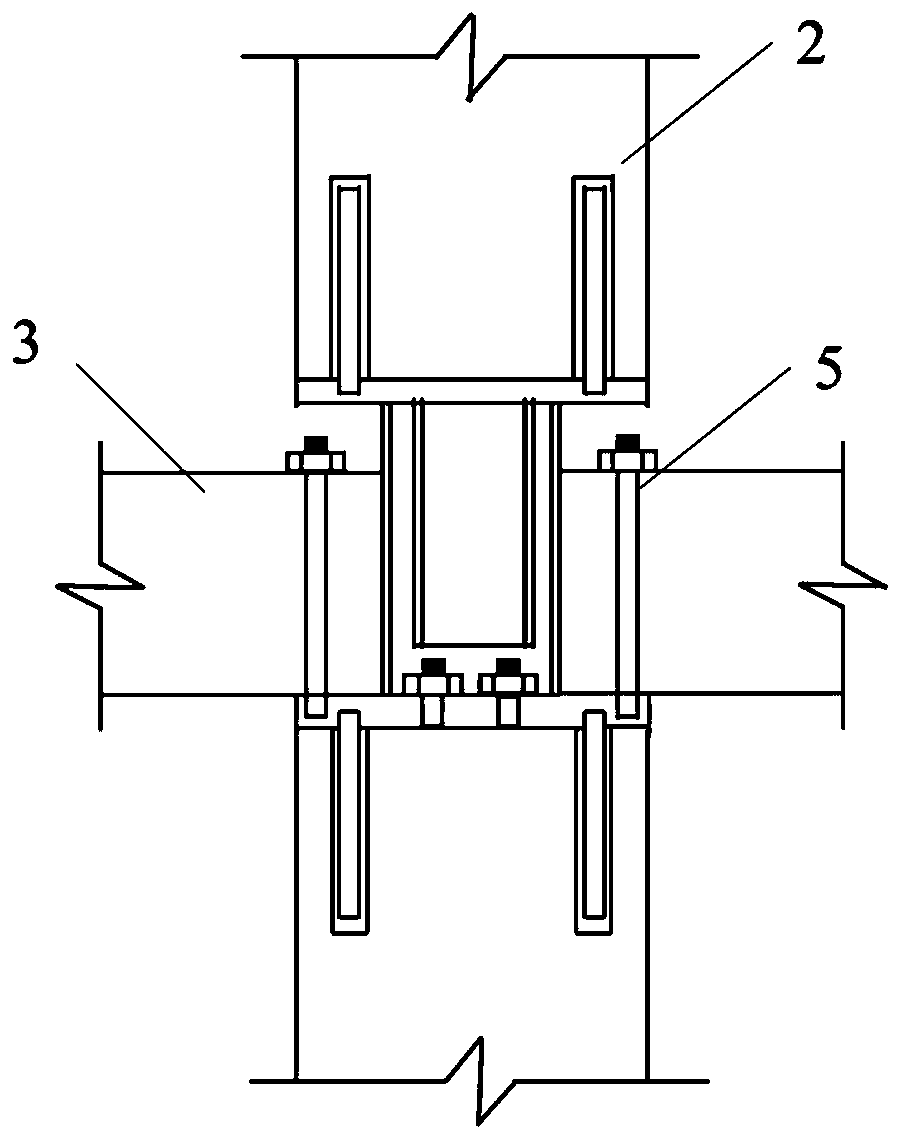

Fire-proof laminated wood frame system based on recycled concrete and construction method thereof

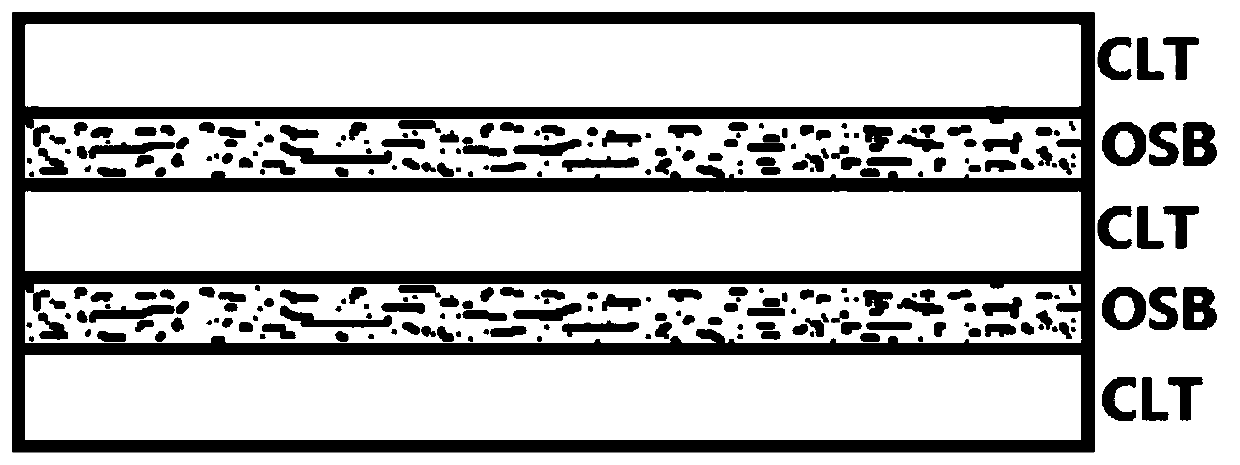

ActiveCN109881781AGuaranteed anti-side performanceSolve the fire resistance problemStrutsFloorsPrecast concreteMultiple layer

The invention relates to a fire-proof laminated wood frame system based on recycled concrete and a construction method thereof. The laminated wood frame system comprises a core tube (1), laminated wood columns (2), a plurality of cross laminated timber (CLT) slabs and recycled concrete slabs (4); the multiple CLT slabs are spliced tightly to form CLT slab layers, the multiple recycled concrete slabs (4) are spliced tightly to form recycled concrete slab layers, the core tube (1) is located at the center of the whole system, the CLT slab layers and the recycled concrete slab layers are arrangedon the periphery of the core tube (1) according to the regularity that one layers of recycled concrete slab layers are alternately arranged between the multiple layers of CLT slab layers, and the slab layers are connected through the laminated wood columns (2). Compared with the prior art, the fire-proof laminated wood frame system based on recycled concrete and the construction method thereof combine recycled concrete and the laminated wood frame system, and sustainability and environmental protection properties are achieved; and precast concrete slabs and a wood structure are adopted, assembling construction is easy to carry out, and the construction speed is high.

Owner:TONGJI UNIV

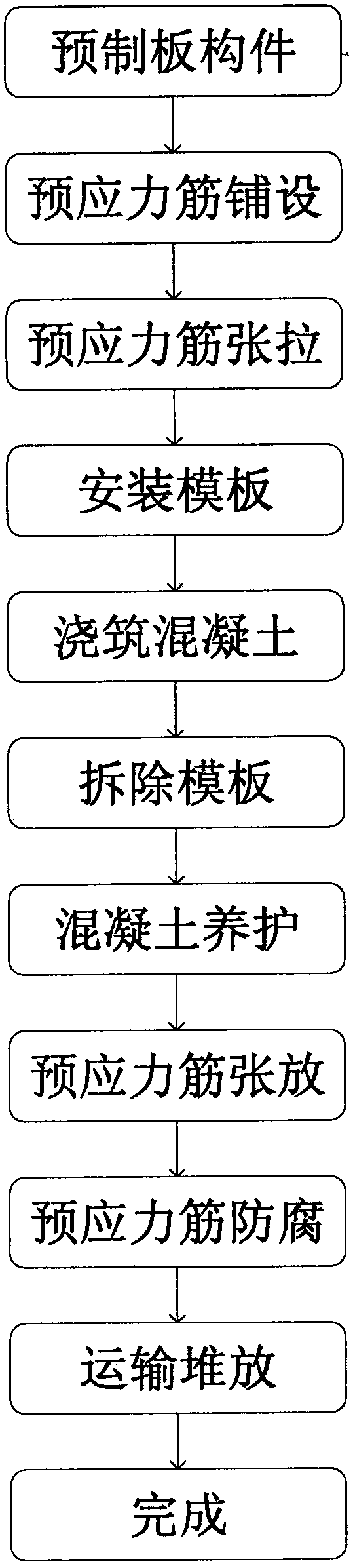

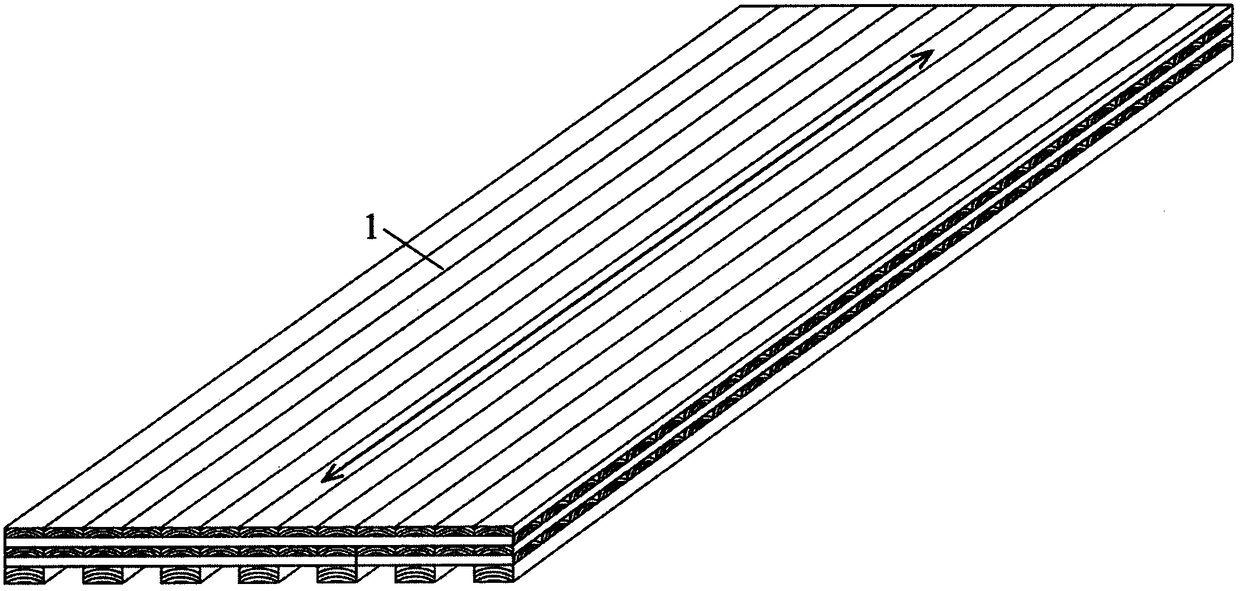

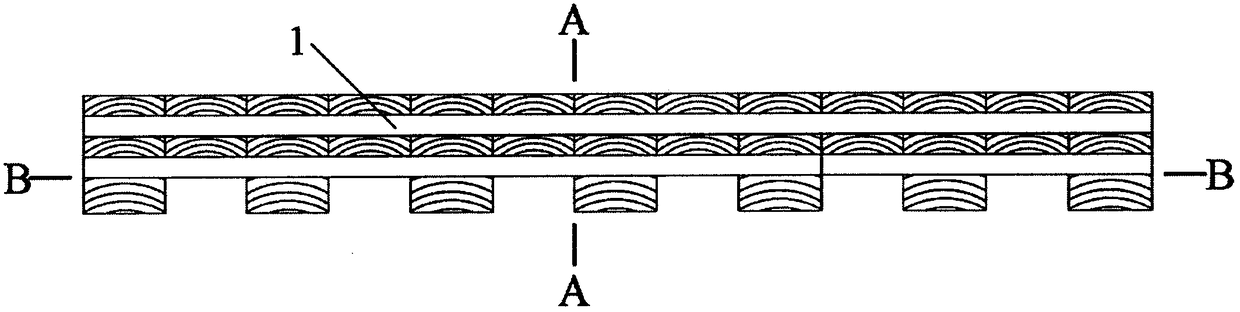

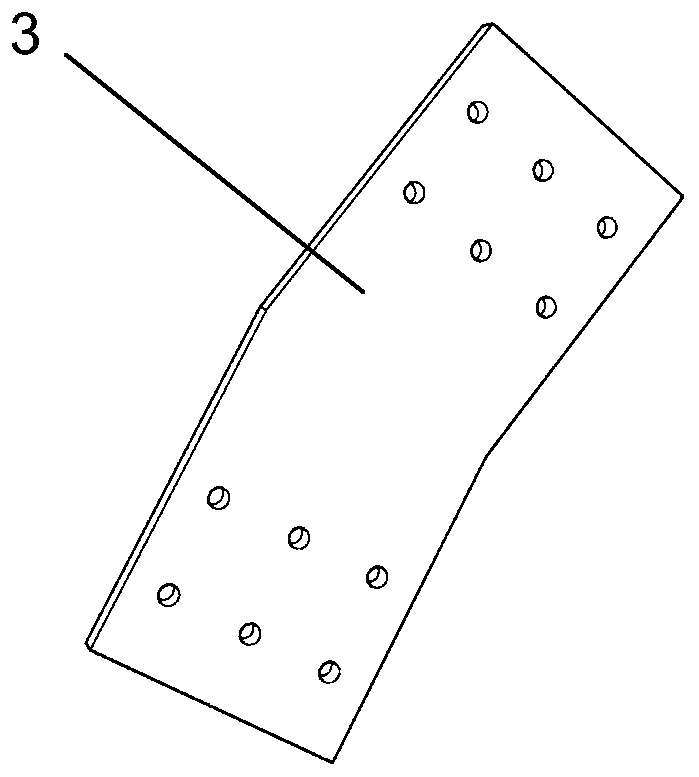

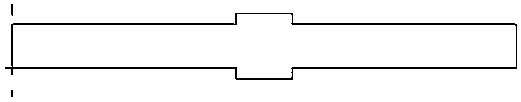

Manufacturing method of prestressed plate components manufactured by adopting cross-laminated timbers

PendingCN108867962AReduce member sectionLight weightFloorsBridge structural detailsPre stressEngineering

The invention discloses a manufacturing method of prestressed slab components manufactured by adopting cross-laminated timbers. The manufacturing method is characterized in that prestressed tendon (3)is positioned in a geometric space formed by drawing out a laminated plate arranged on one side of the outermost layer of a prefabricated cross-laminated timber (1); after the prestressed tendon (3)is subjected to tensioning, an end die is mounted on the end part of the geometric space formed by drawing out the laminated plate arranged on one side of the outermost layer of the prefabricated cross-laminated timber (1); successively, concrete (2) is poured and is then vibrated and leveled; when the strength of the concrete (2) is more than or equal to 2.5MPa, the end die is removed, tensioningis carried out when the concrete (2) is conserved to ensure that the strength is not less than 75 percent of a designed value, and a corrosion prevention measure on an exposed part of the prestressedtendon (3) is made, so that the manufacturing of the prestressed slab components based on the cross-laminated timbers is realized. According to the manufacturing method disclosed by the invention, the problem that the applied prestress of the cross-laminated timber plate components is limited because of the properties of the own materials and the prestress loss is too high after the prestress isapplied to the prestressed tendon are solved.

Owner:NANJING FORESTRY UNIV

Cross-laminated timber wall dovetail tenon connecting technology and manufacturing method

InactiveCN107476445AEasy to prepareThe preparation method is feasibleBuilding constructionsMortise and tenonTongue and groove

The invention relates to a cross-laminated timber wall dovetail tenon connecting technology and a manufacturing method and belongs to the technical field of timber engineering. A cross-laminated timber wall dovetail tenon connecting structure comprises a dovetail tenon wall and a dovetail mortise wall. A dovetail tenon of the dovetail tenon wall is processed in the end face of cross-laminated timber in the longitudinal direction of the wall, a dovetail mortise of the dovetail mortise wall is milled in the plane of the cross-laminated timber in the longitudinal direction of the wall, and the dovetail tenon and the dovetail mortise are in angle fit to be processed. When a building of a timber structure is constructed, the dovetail tenon wall and the dovetail mortise wall are aligned to be driven in a hoisted mode, and accordingly connection is completed. The cross-laminated timber wall dovetail tenon connecting technology is mainly applied to connecting of the building walls of the cross-laminated timber structure, a mortise and tenon structure in an ancient building in China and a modern timer structure are combined, the strength requirement of a wall connecting joint can be met, factory prefabrication can be achieved, and rapid site construction can be achieved.

Owner:BEIJING FORESTRY UNIVERSITY

Cross laminated timber (CLT) decorating plate and connecting device thereof

PendingCN109898670AHigh impact strengthImprove the decorative effectConstruction materialConstructions elementsEngineeringUltimate tensile strength

The invention discloses a cross laminated timber (CLT) decorating plate and a connecting device thereof, and belongs to the field of building materials. The CLT decorating plate comprises a first decorating layer, a buffer layer, a CLT layer and a second decorating layer, wherein the first decorating layer, the buffer layer, the CLT layer and the second decorating layer are sequentially arranged from top to bottom, and a non-Newtonian fluid is arranged in the buffer layer. The invention further provides a connecting device. The connecting device comprises a supporting body and connecting blocks arranged on the supporting body, the supporting body is of a cuboid structure, the cross section of the supporting body is in a square shape, and the side length of the square-shaped cross section is the same as the thickness of the decorating plate; and the connecting blocks are matched with connecting grooves. According to the CLT decorating plate, the decorative effect can be improved, when the CLT decorating plate is impacted, the impact force can be dispersed to the whole CLP plate, and the uniform distribution damage of the CLT plate caused by single-point stress is avoided. Accordingto the connecting device, the connecting stress of the CLT plate can be partly transferred to the connecting device, and the intensity requirement on the CLT plate is reduced depending on the structure intensity of the connecting device.

Owner:SOUTHWEST FORESTRY UNIVERSITY

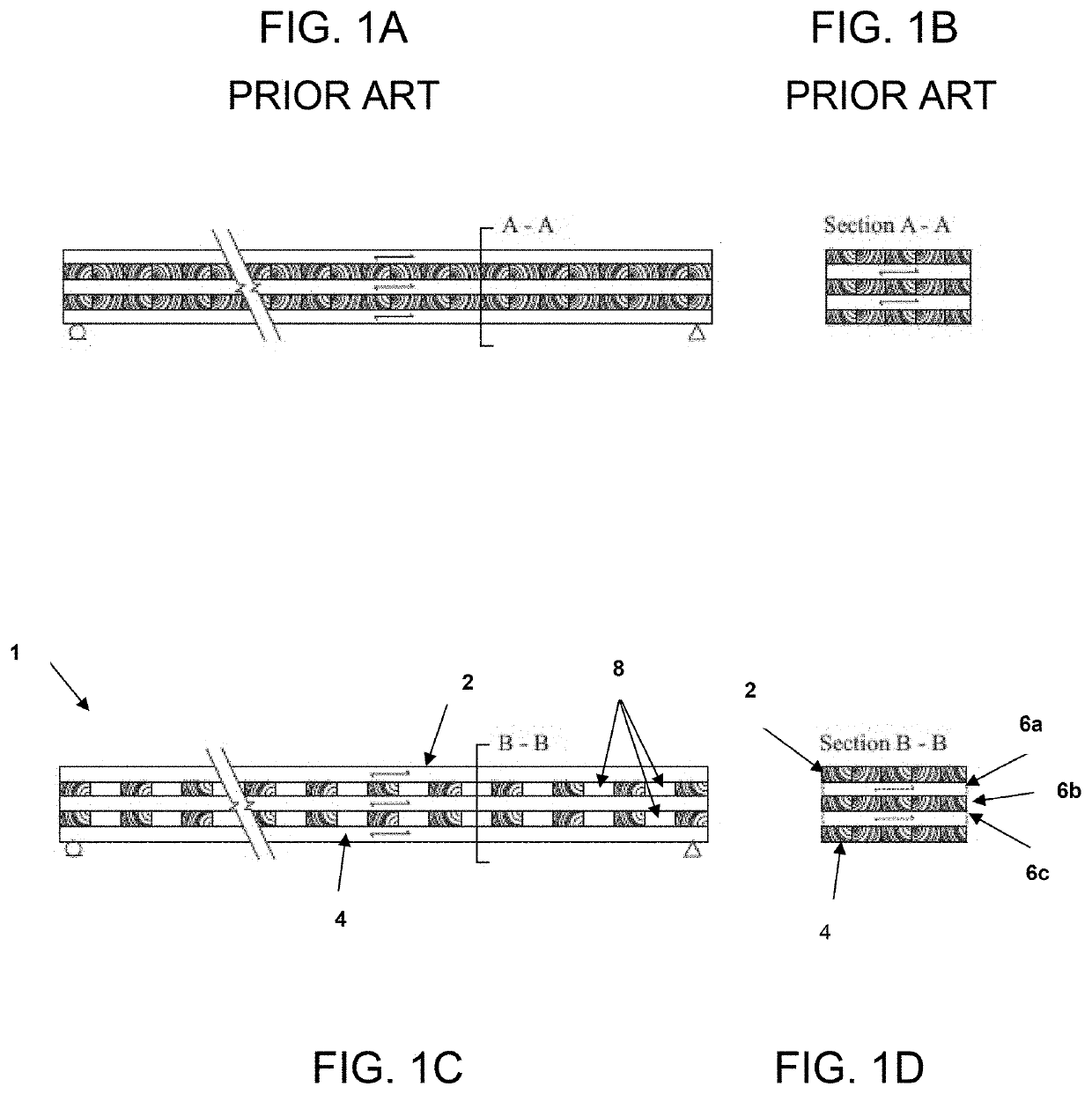

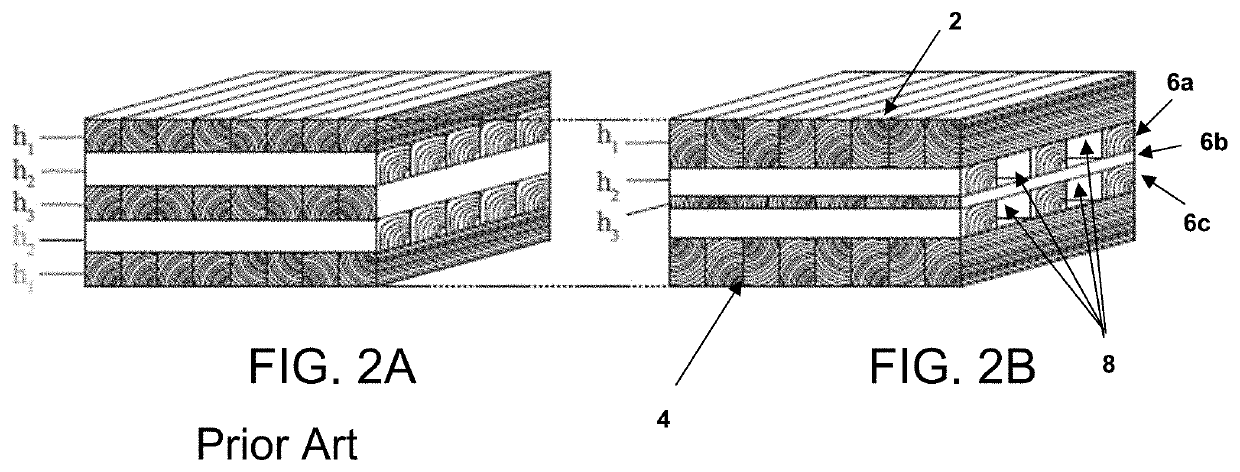

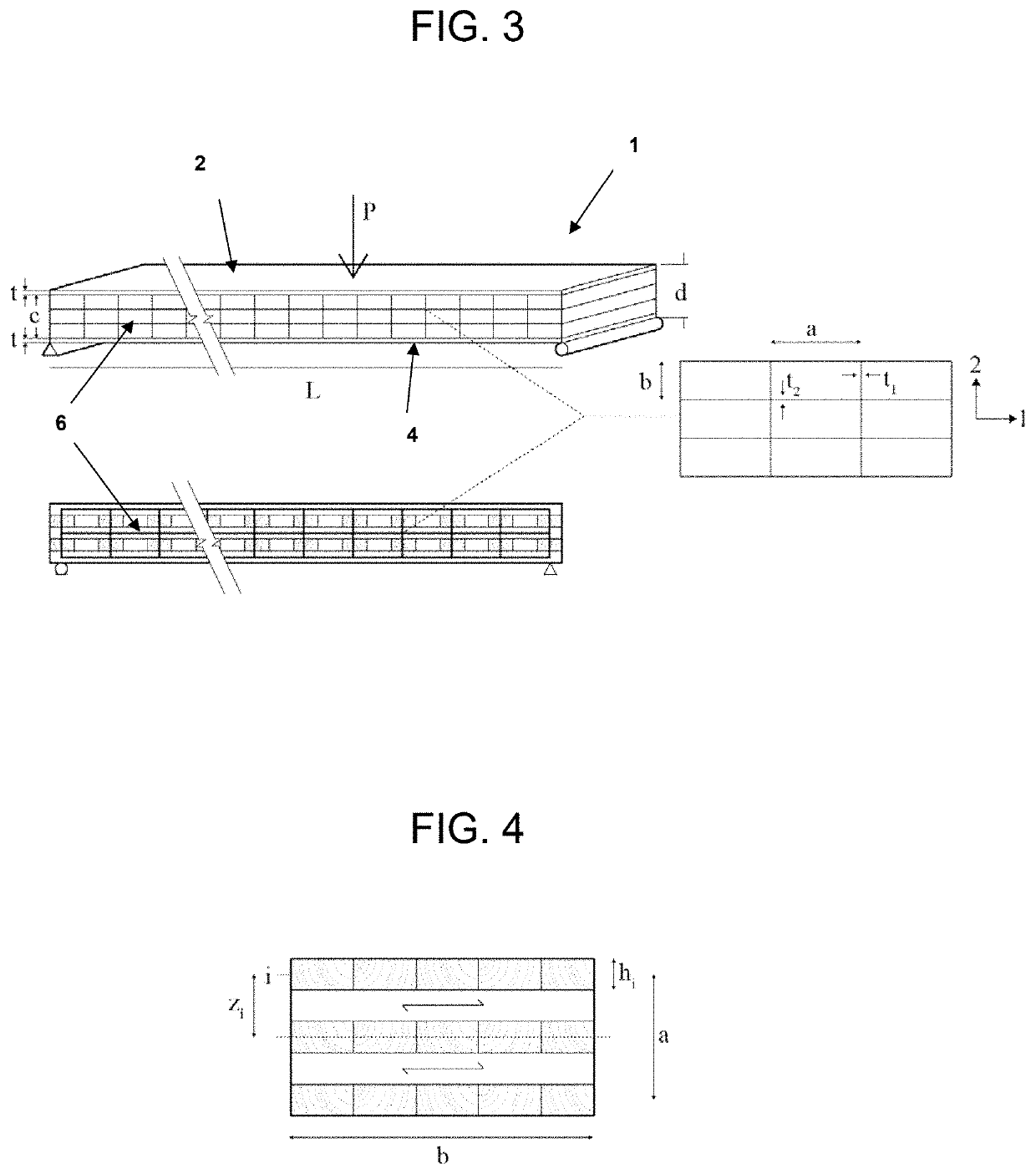

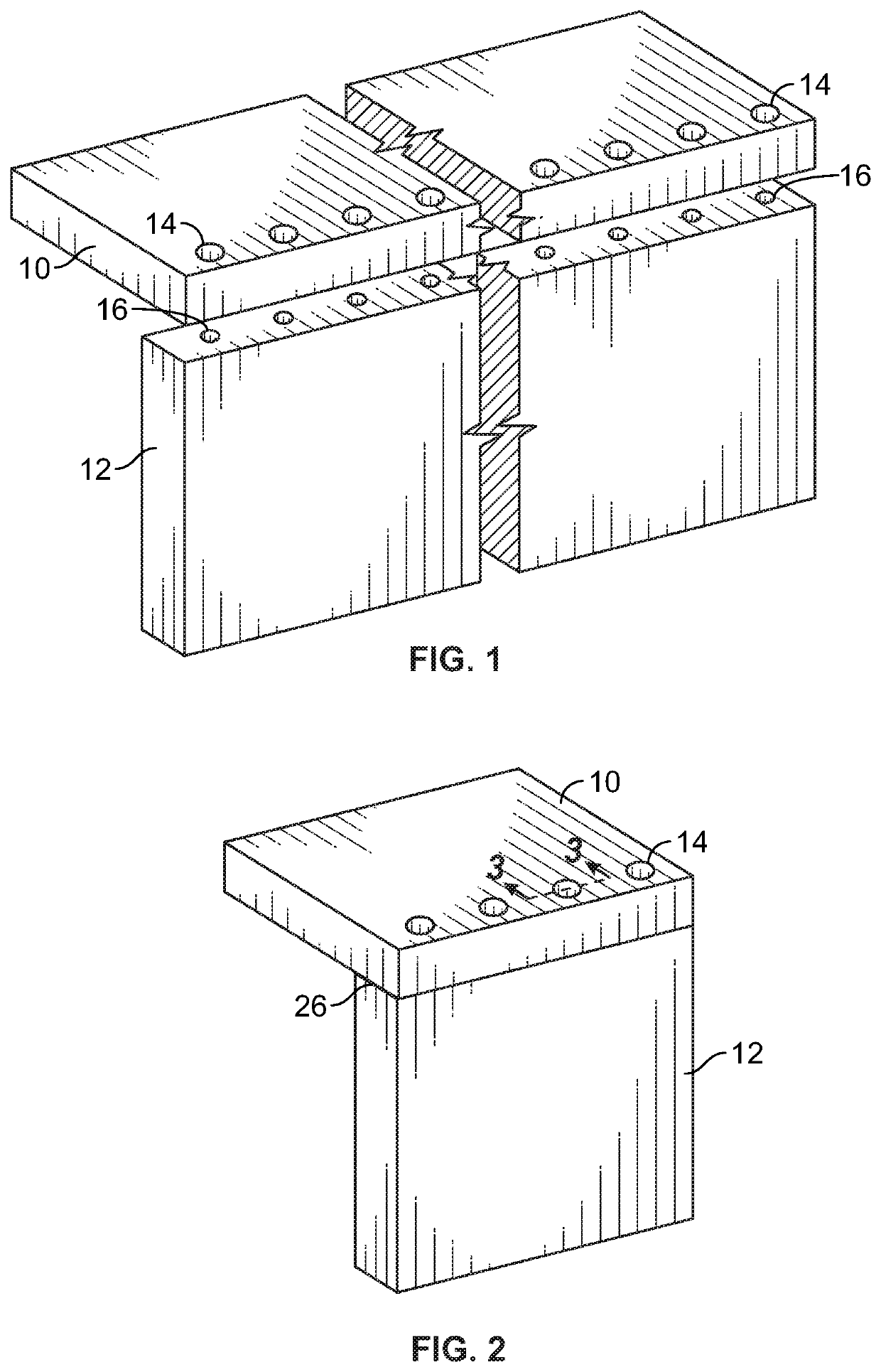

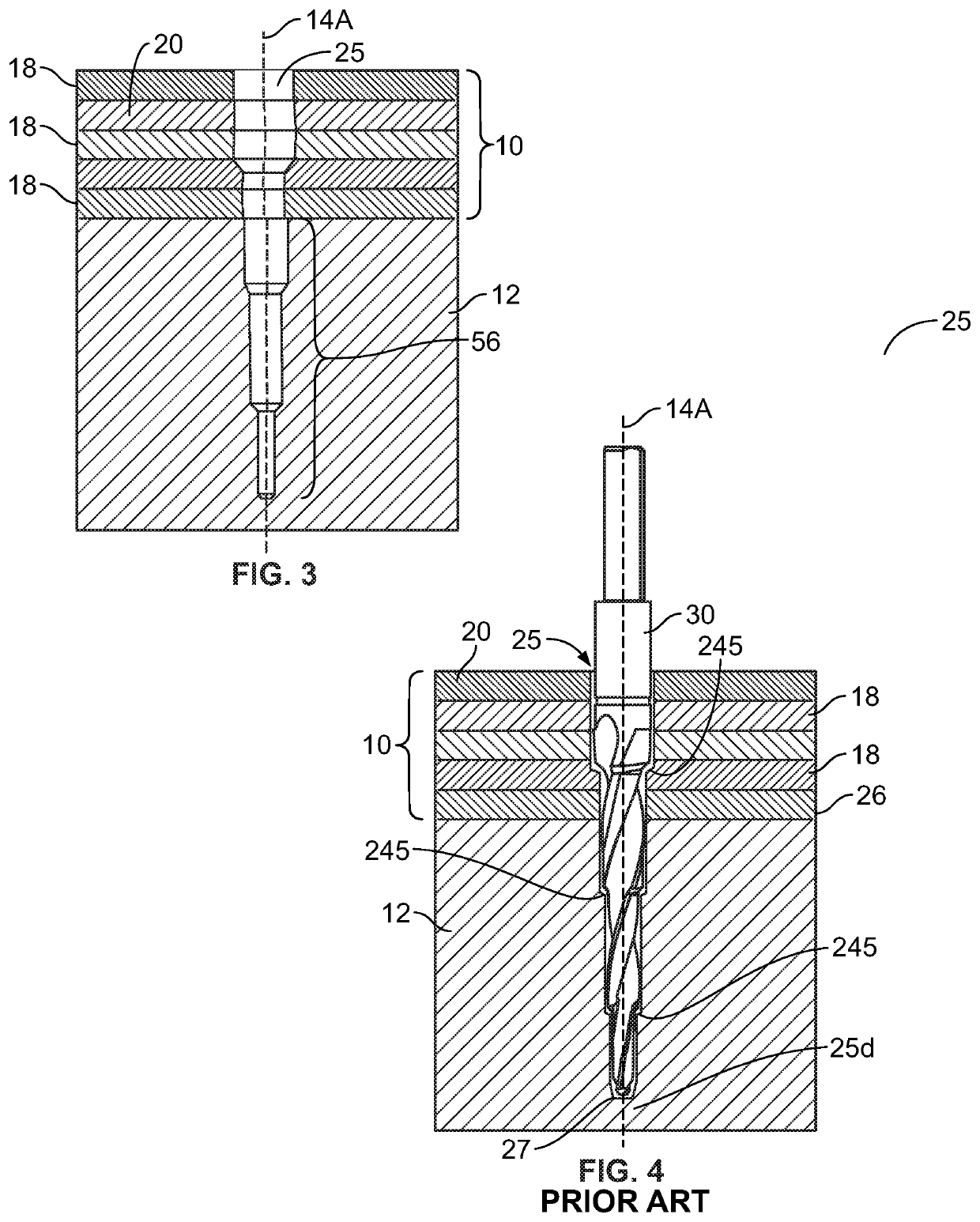

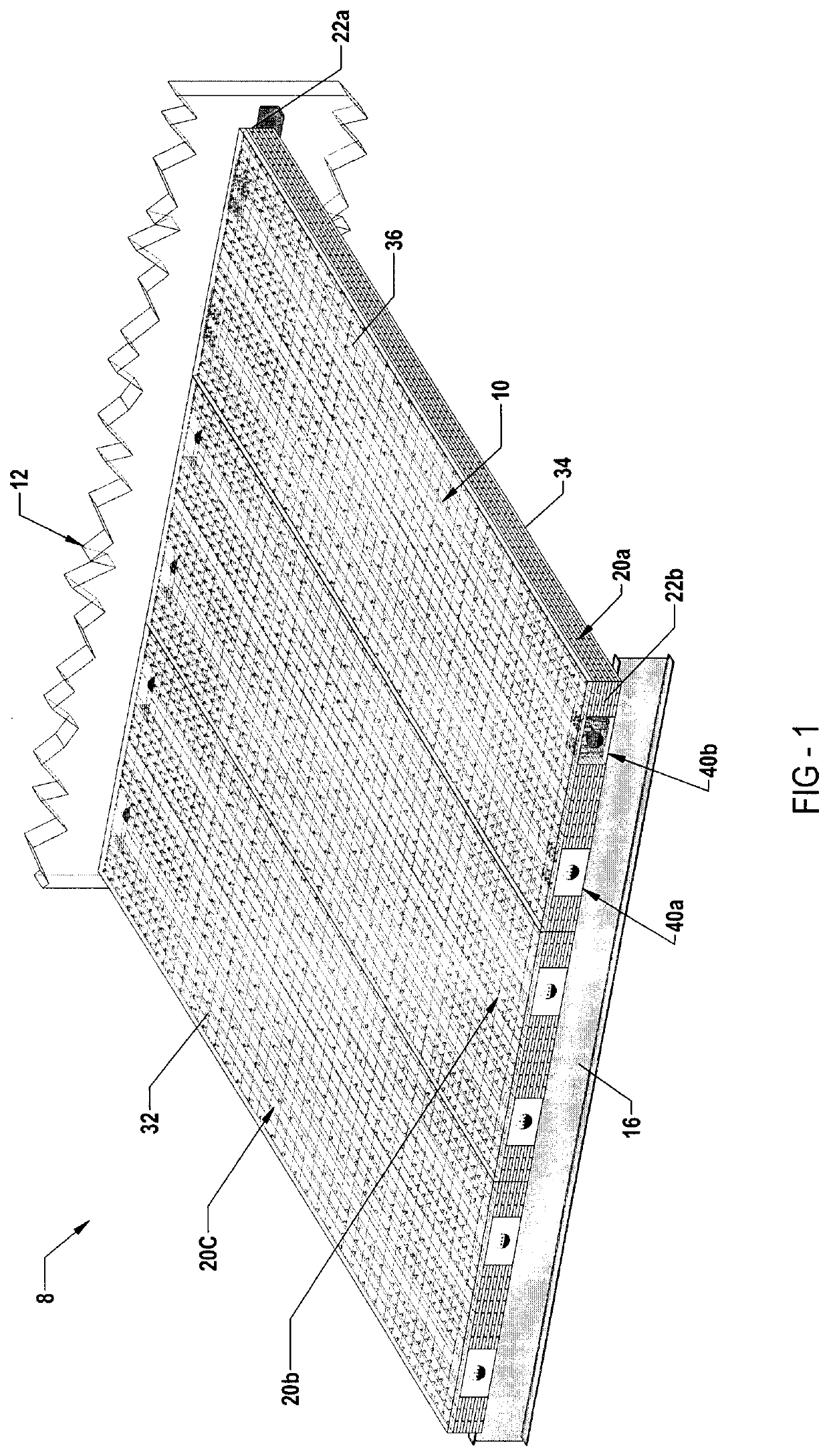

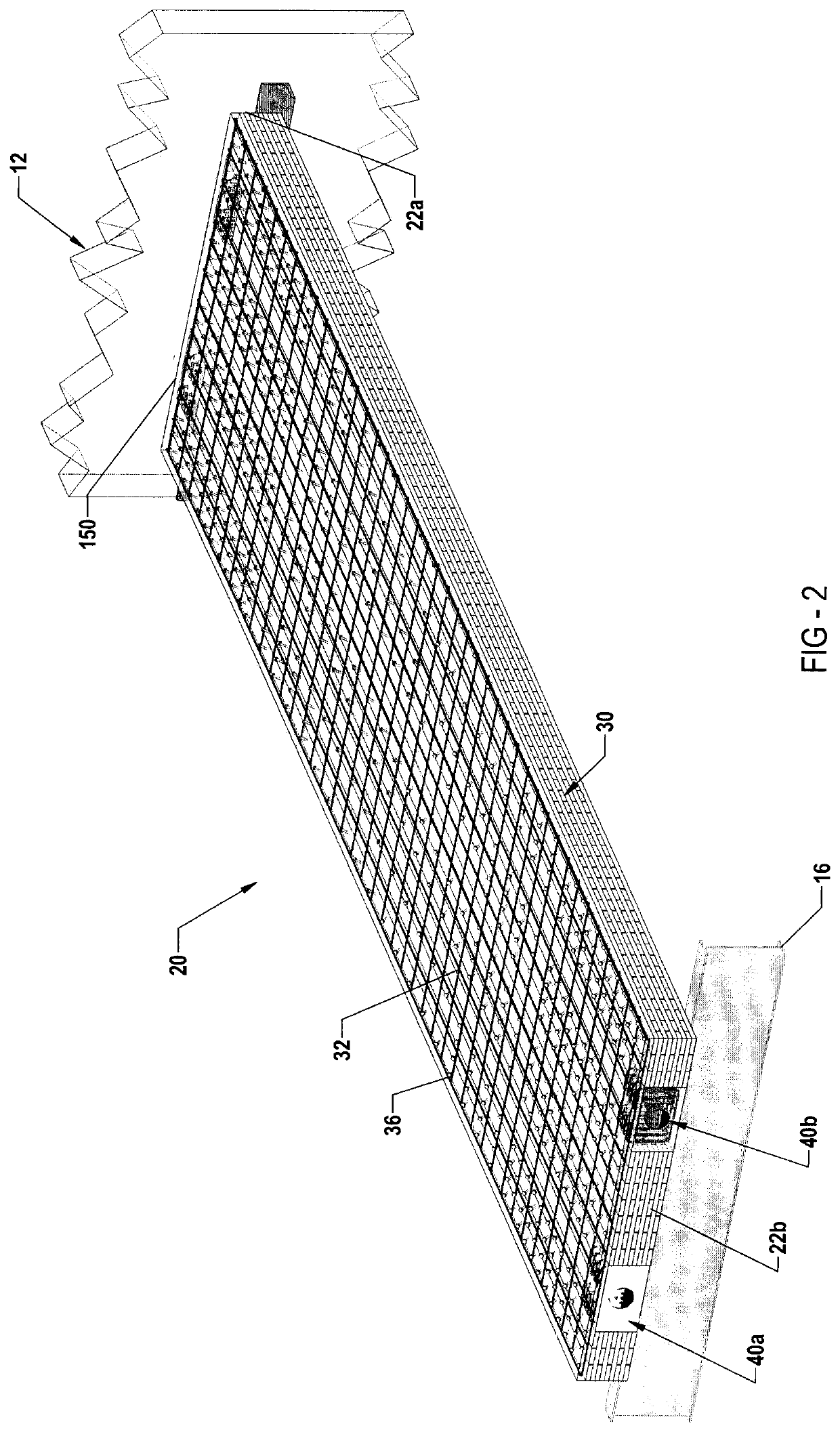

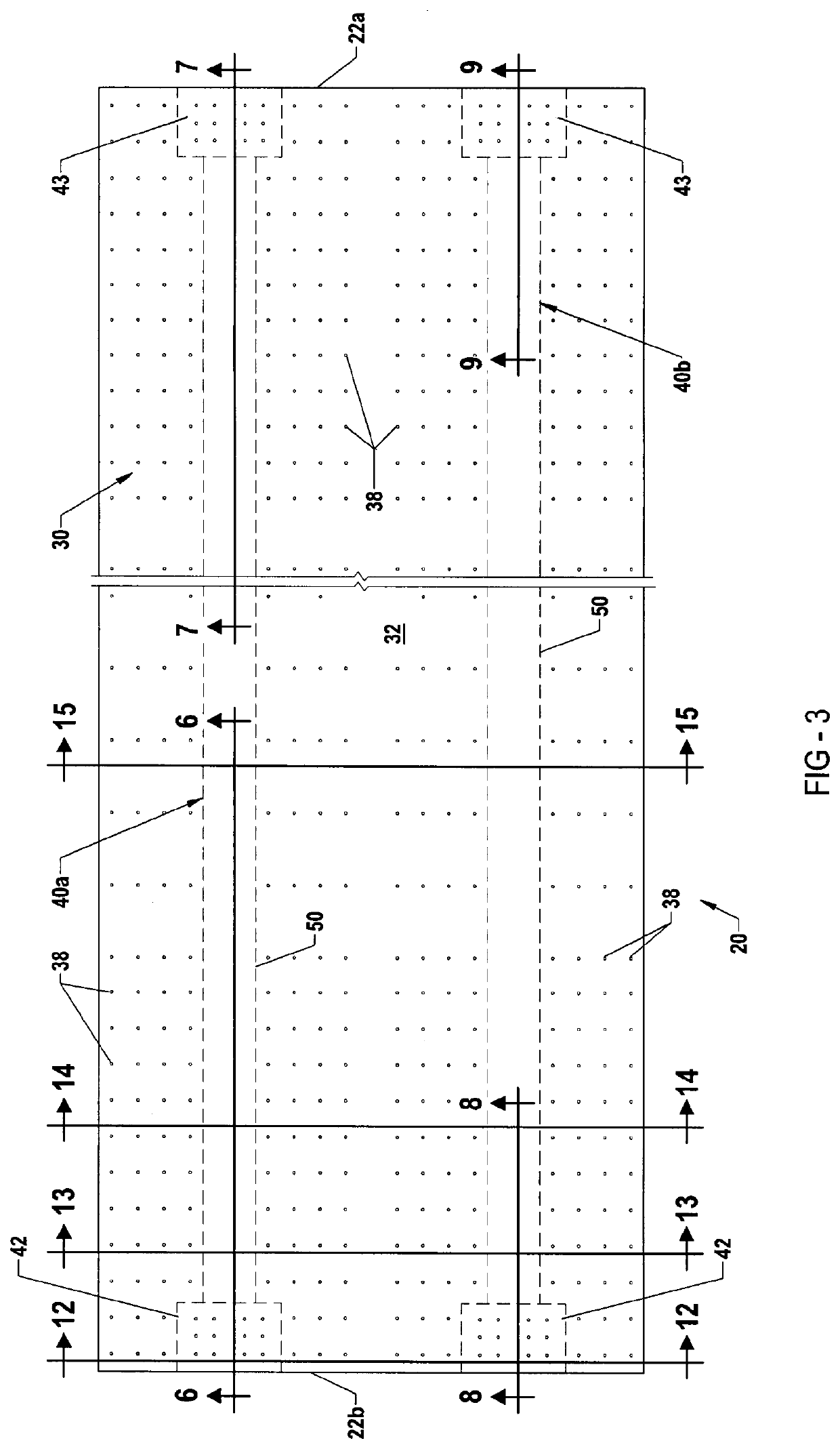

Cross-laminated timber structures having reduced inner-layer material and methods of optimization

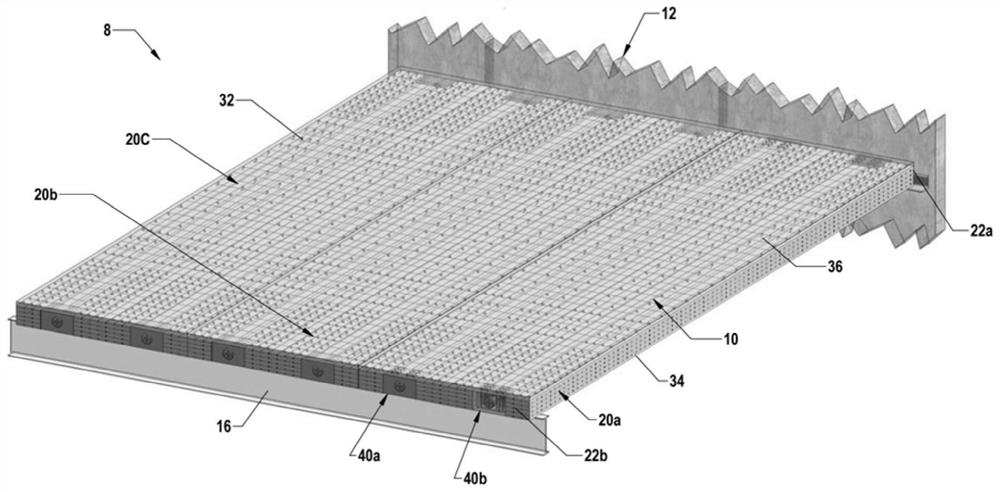

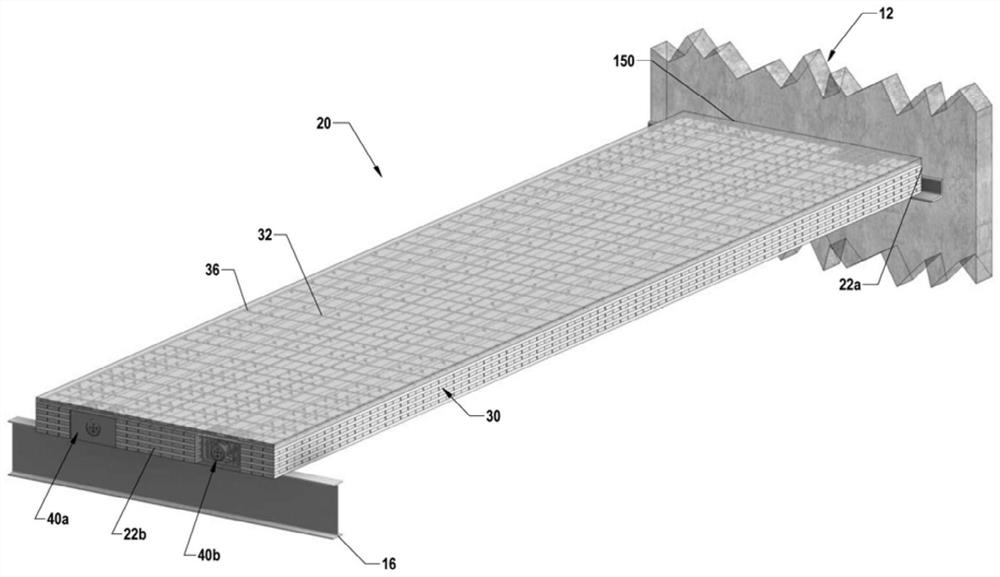

InactiveUS20200016873A1Improved stiffness to weight ratioWood working apparatusWood layered productsMaterial consumptionCross laminated timber

A cross-laminated timber (CLT) panel formed of multiple layers of alternating perpendicularly aligned lumber, where one or more portions of one or more inner layers are selectively removed and where one or more layers have a thickness different than one or more other layers of the CLT panel. Further, a system for optimizing the CLT panel by determining the design for the selective removal of one or more portions of one or more inner layers and, optionally, one or more varying layer thicknesses, provides a CLT panel with an improved stiffness to weight ratio and reduced material consumption.

Owner:MASSACHUSETTS INST OF TECH

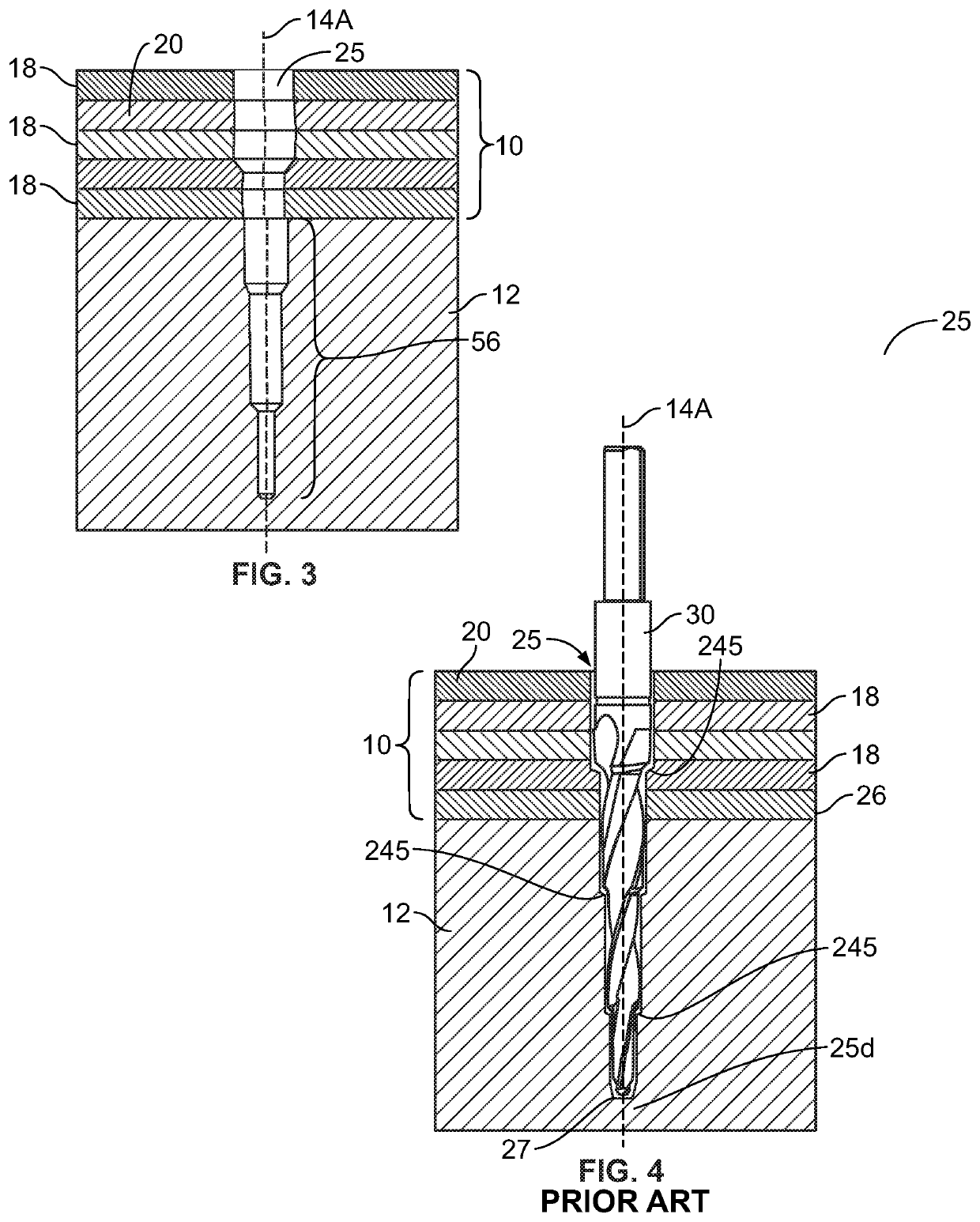

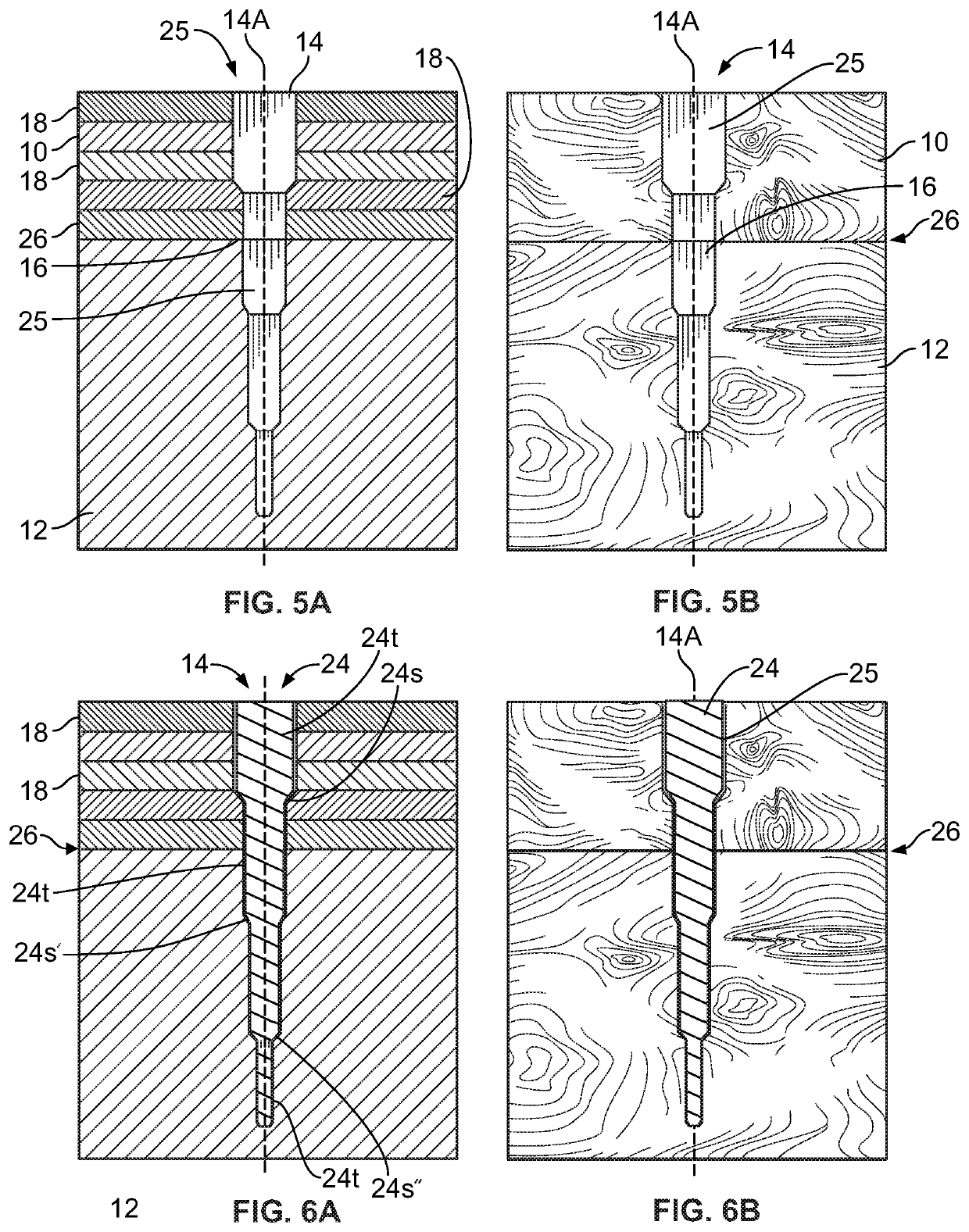

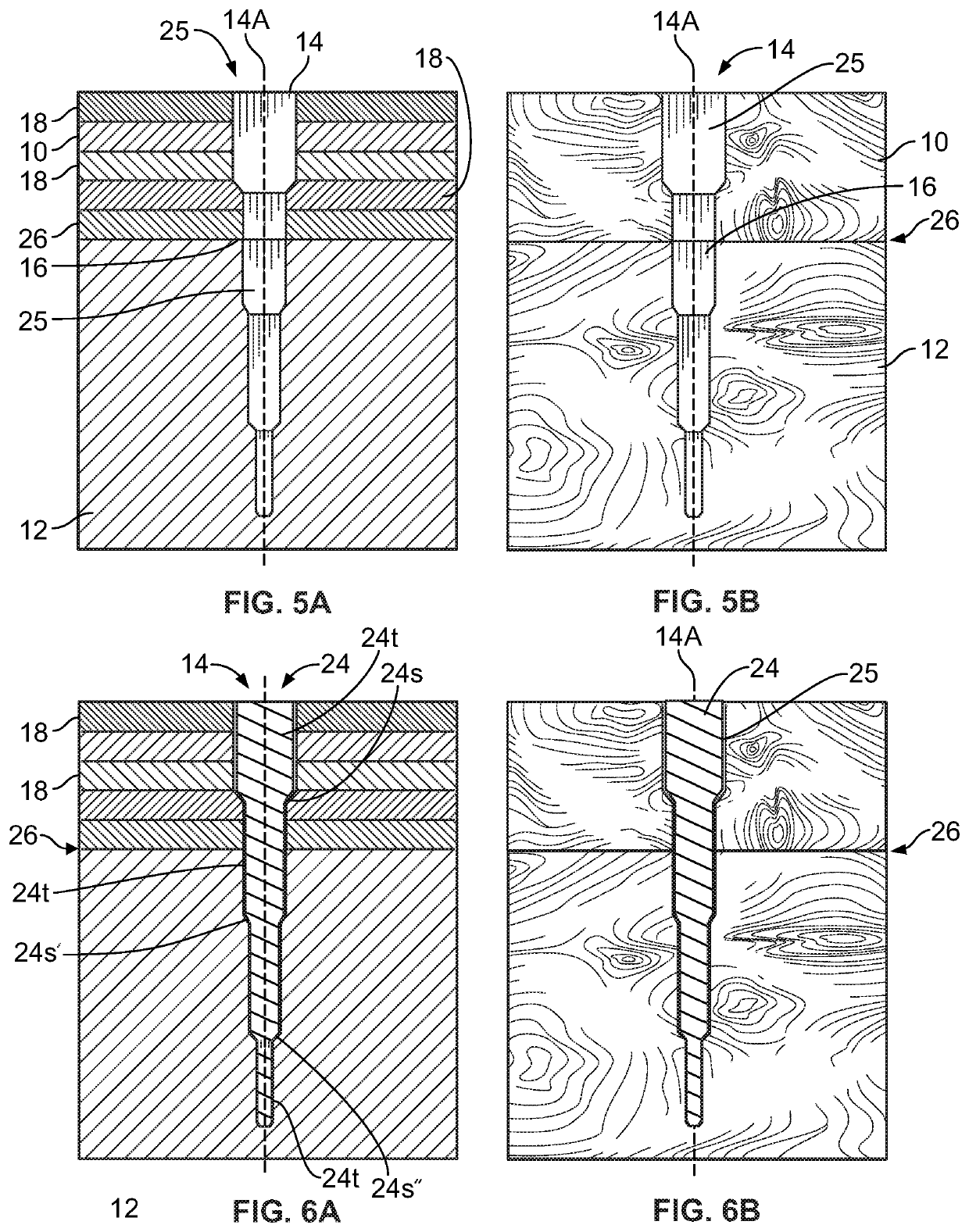

Stepped drill bit with alternately sharpened edges to clean-out obscured fastener openings in cross laminated timber joints

ActiveUS20200316694A1Easy to driveAccurate shapeWood turning toolsTransportation and packagingClassical mechanicsEngineering

A drill bit for use with construction using cross laminated timbers (CLT) is provided. The bit has both sharpened and dull portions of the cutting element of the bit, so that it can clean-out an opening in the CLT that has been partially obscured by shifts in the laminated constituents of the CLT, without elongating or otherwise changing the shape of the fastener opening. The use of the bit is made at the construction site in fastener openings previously made and otherwise obscured, thereby allowing the quick assembly and construction of a structure made of CLT.

Owner:THE MILLER DOWEL CO

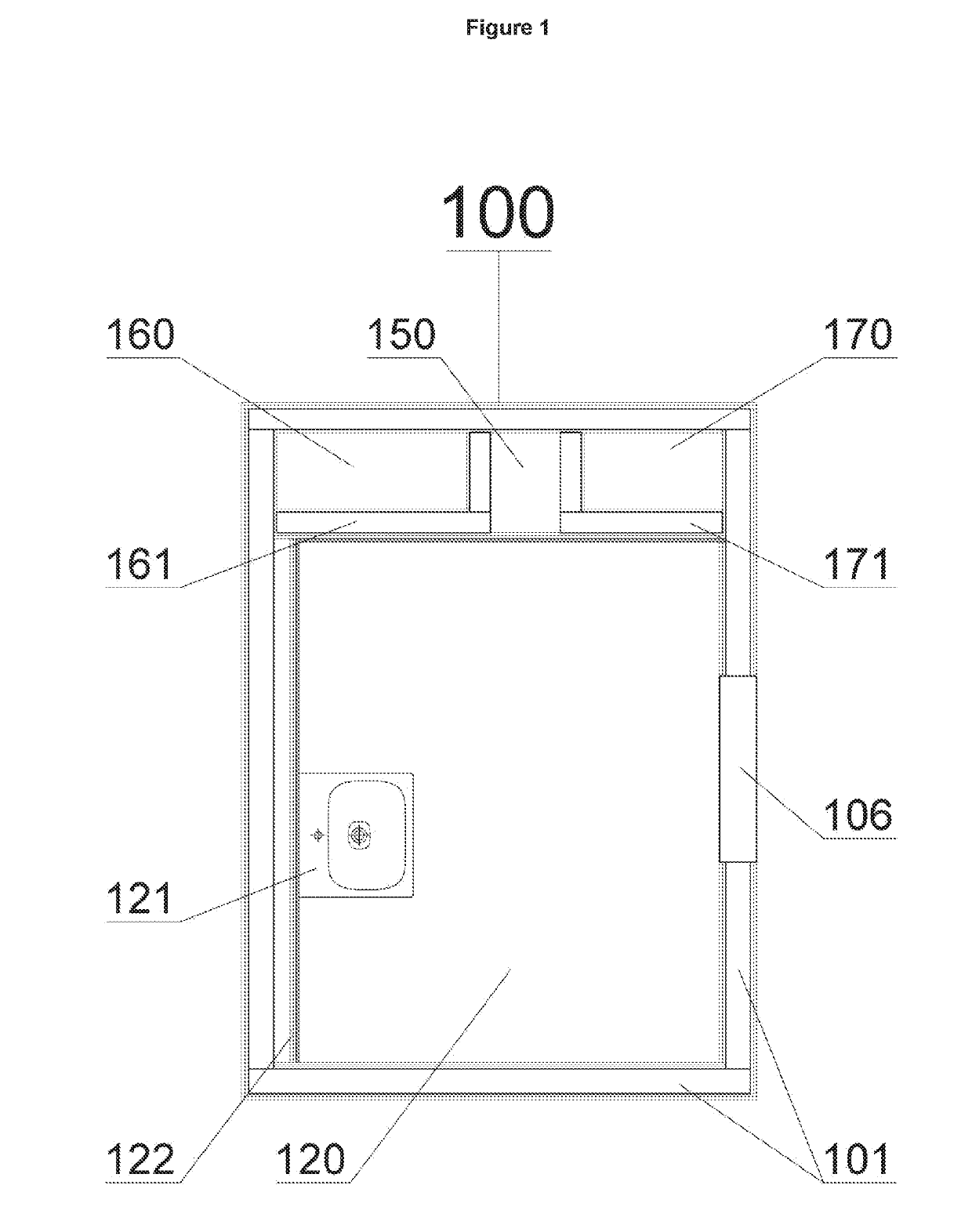

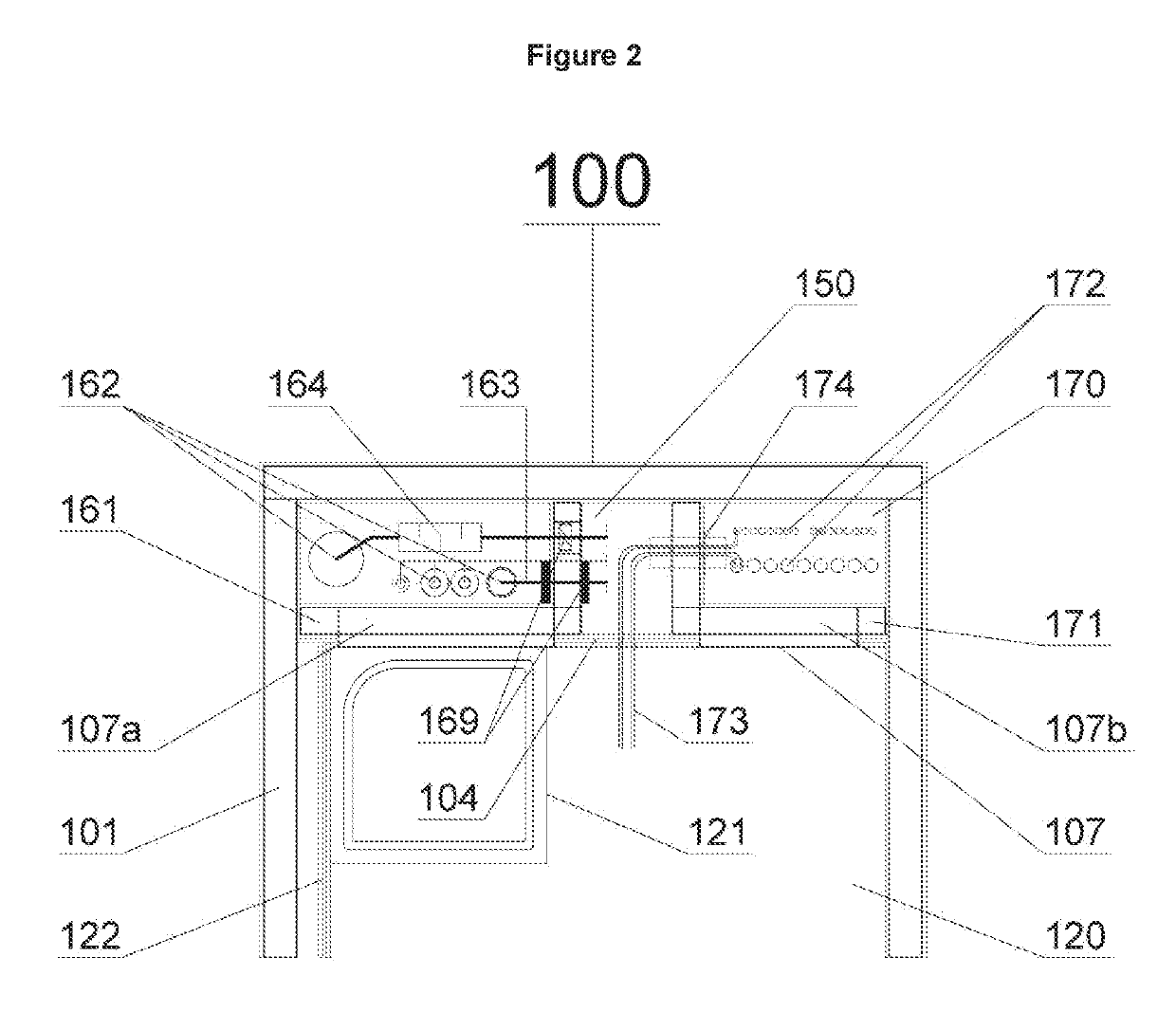

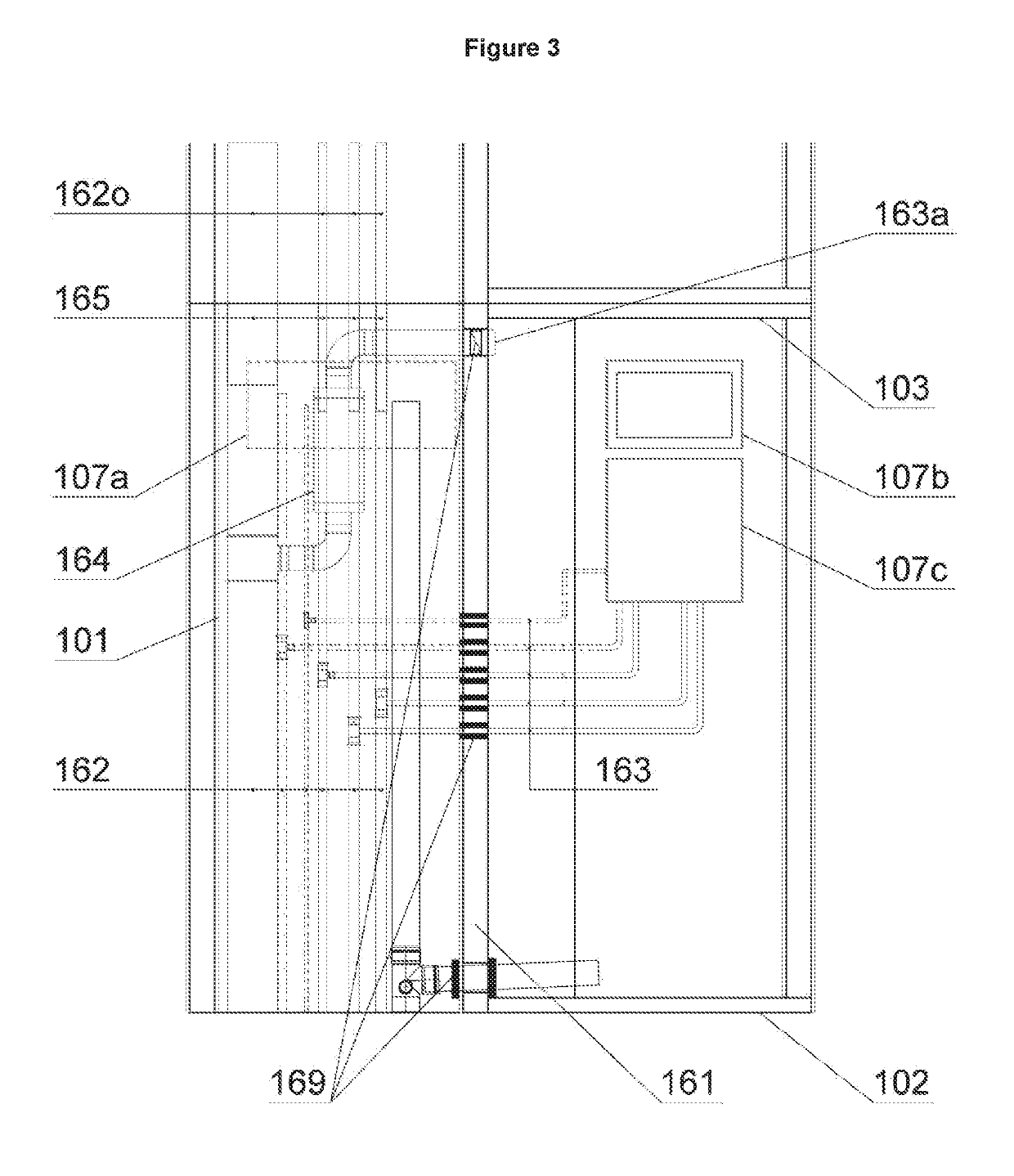

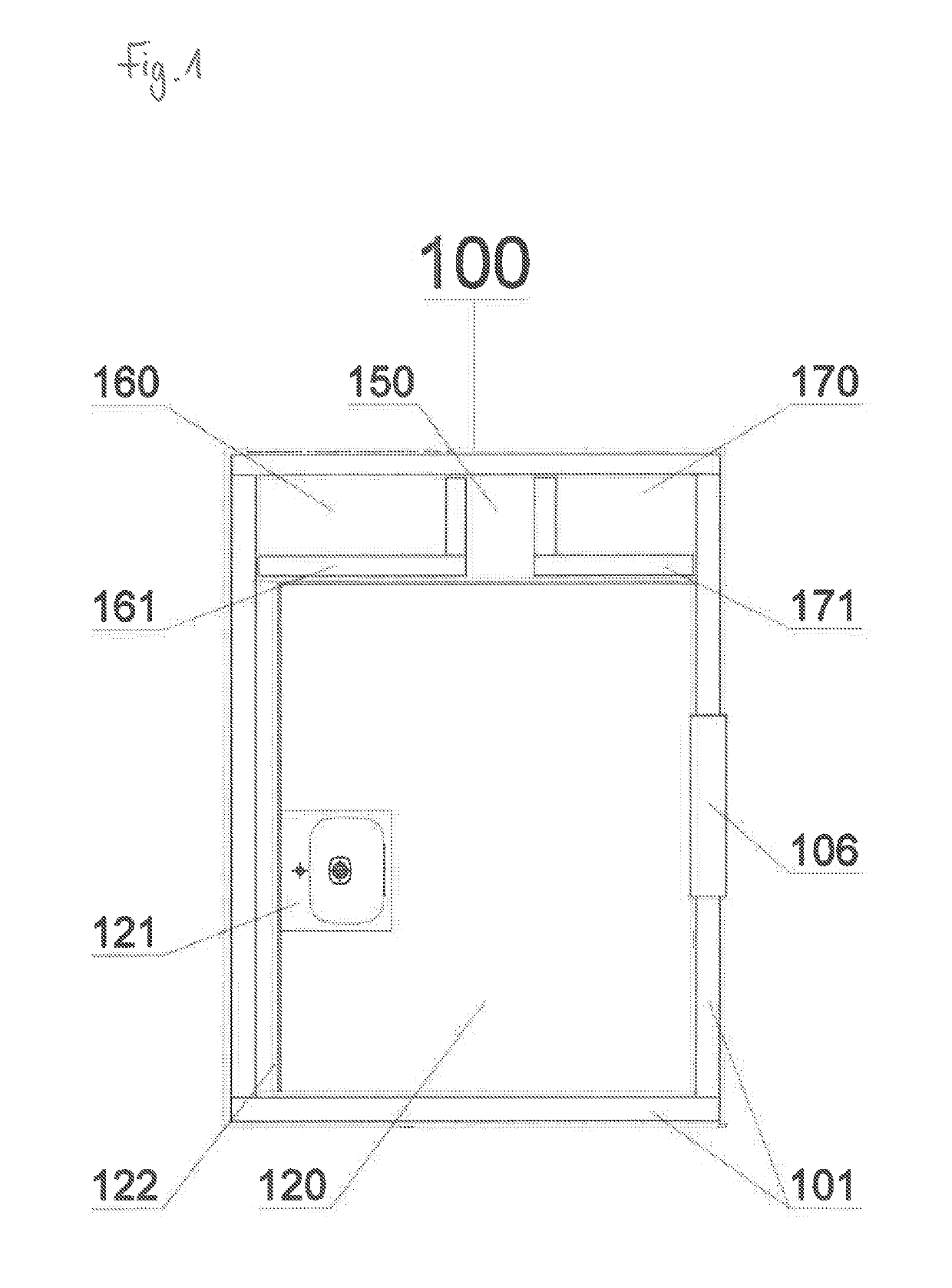

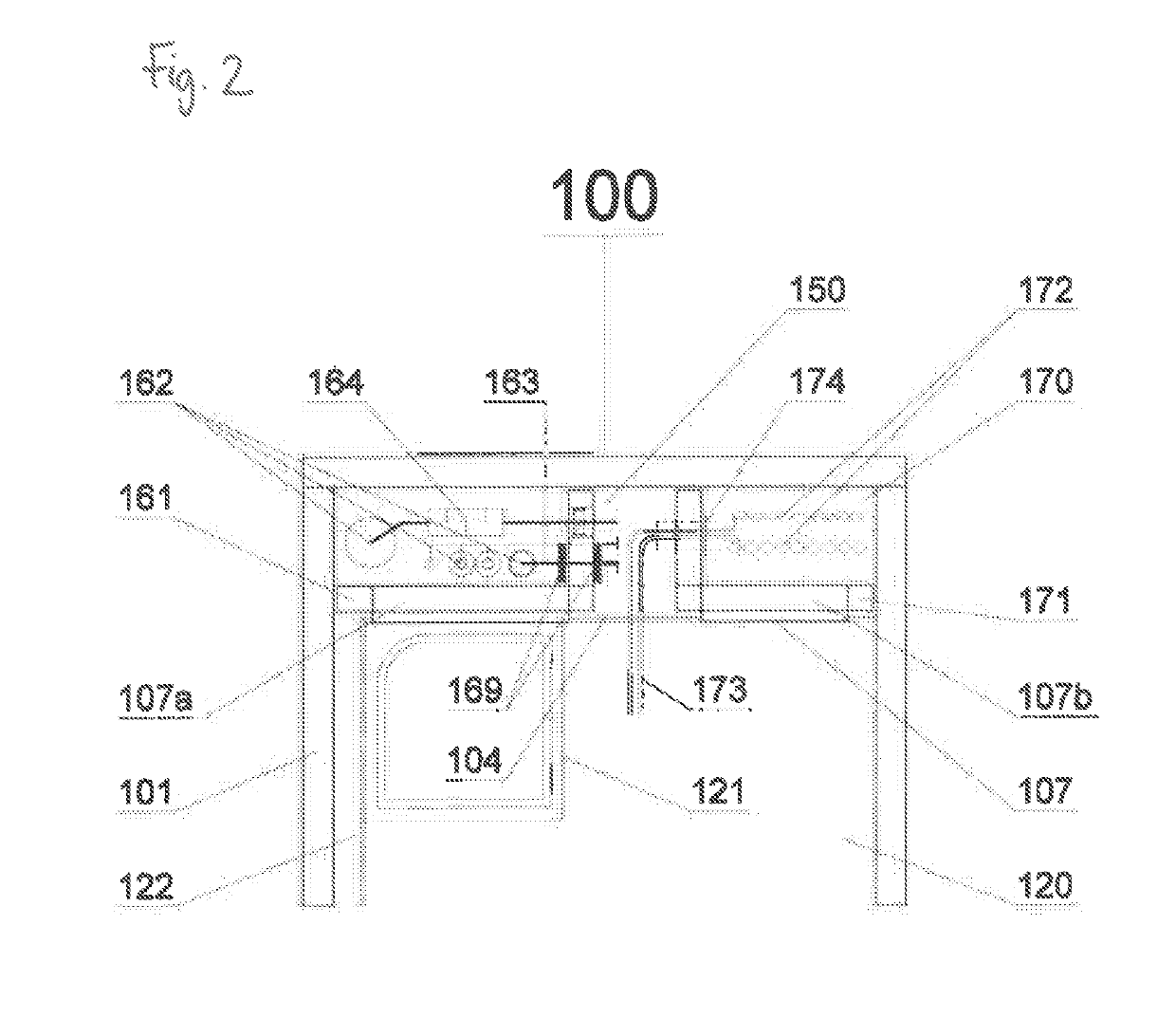

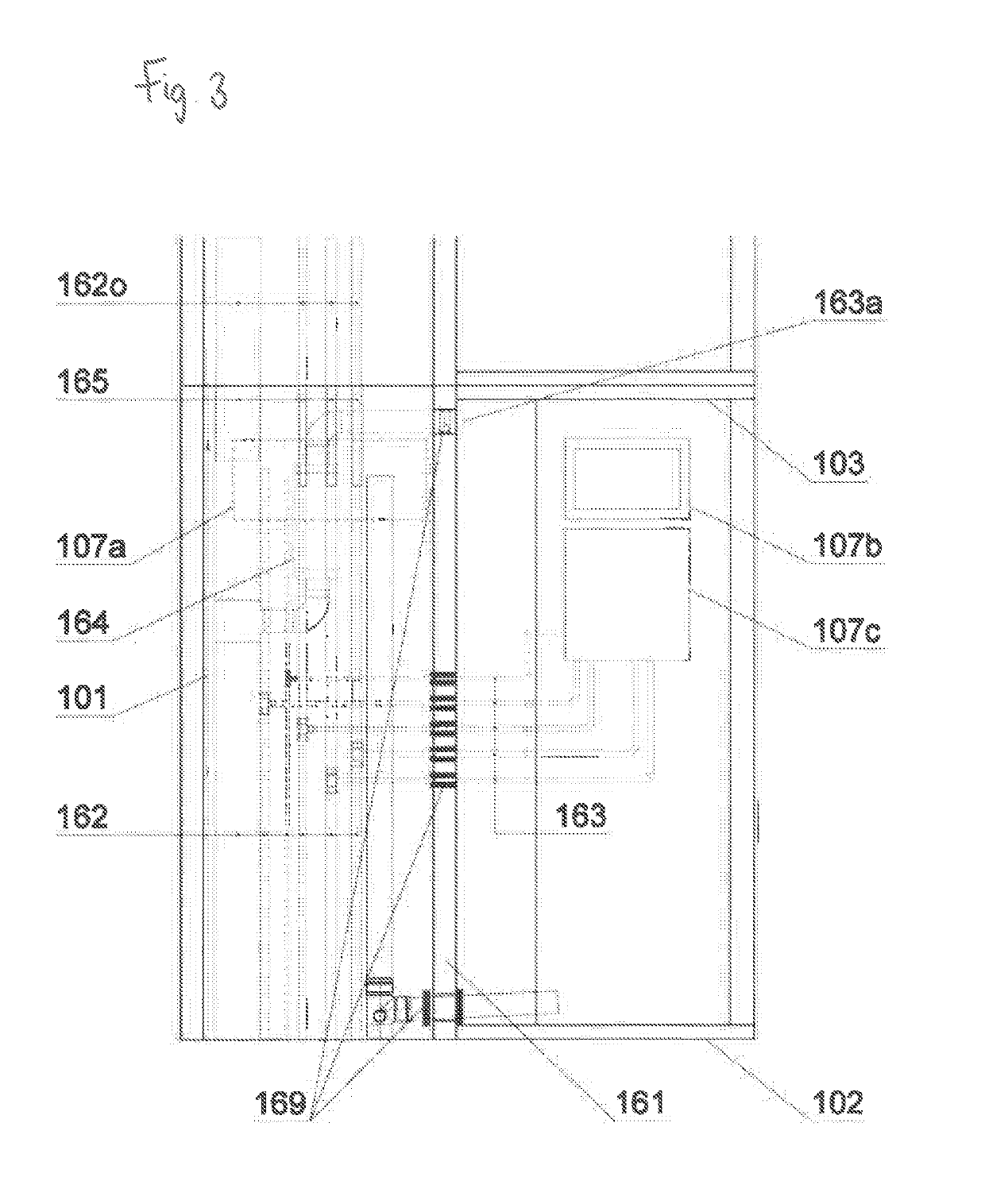

Module for use in the erection of buildings in modular construction

InactiveUS20190136509A1Small overall lengthSpecial buildingBuilding constructionsEngineeringMechanical engineering

A module for use in the erection of buildings in modular construction has a parallelepiped-shaped basic design and has outer walls, a floor, and a ceiling, with the supporting components of some, and preferably all, of the outer walls being cross laminated timber boards. The module includes a useful area and at least two separate vertical ducts, with both vertical ducts running through the module from bottom to top and each being included between at least one outer wall and at least one duct wall.

Owner:BINDER BET AG

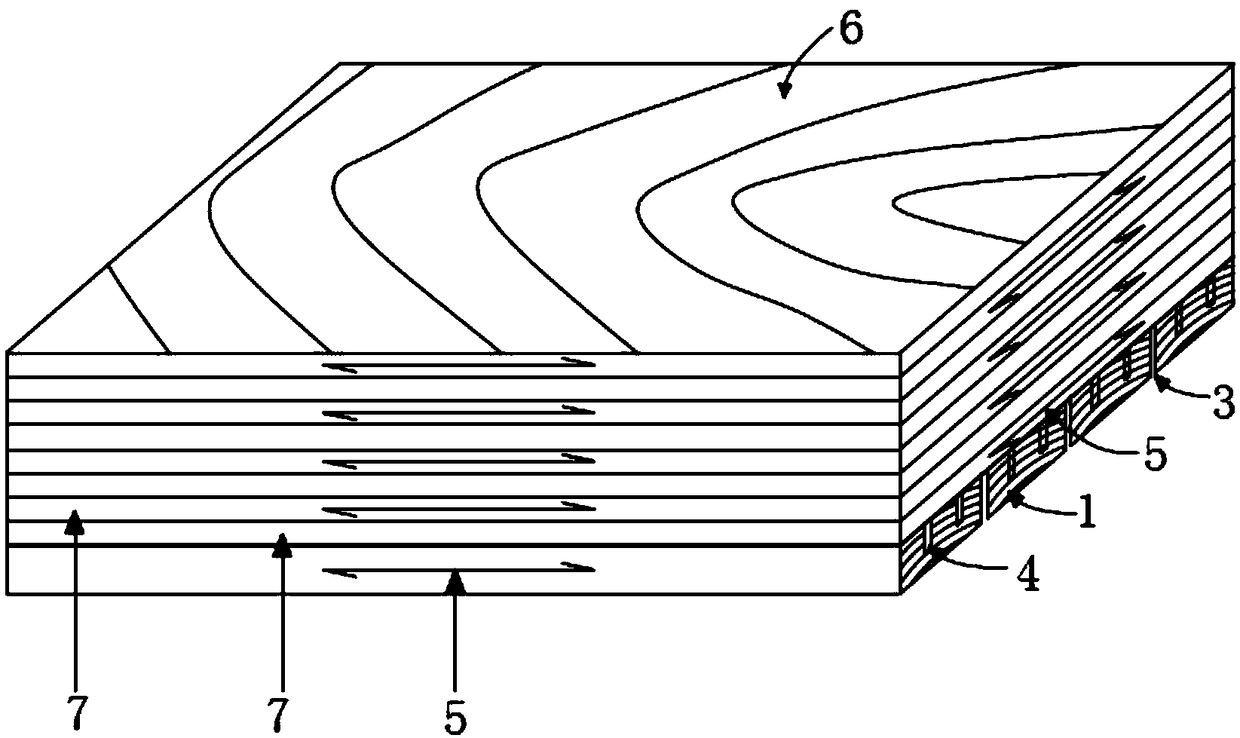

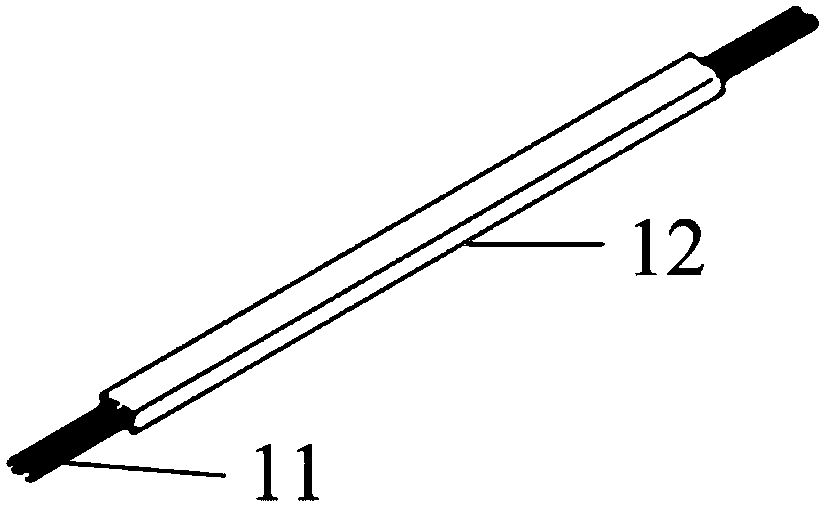

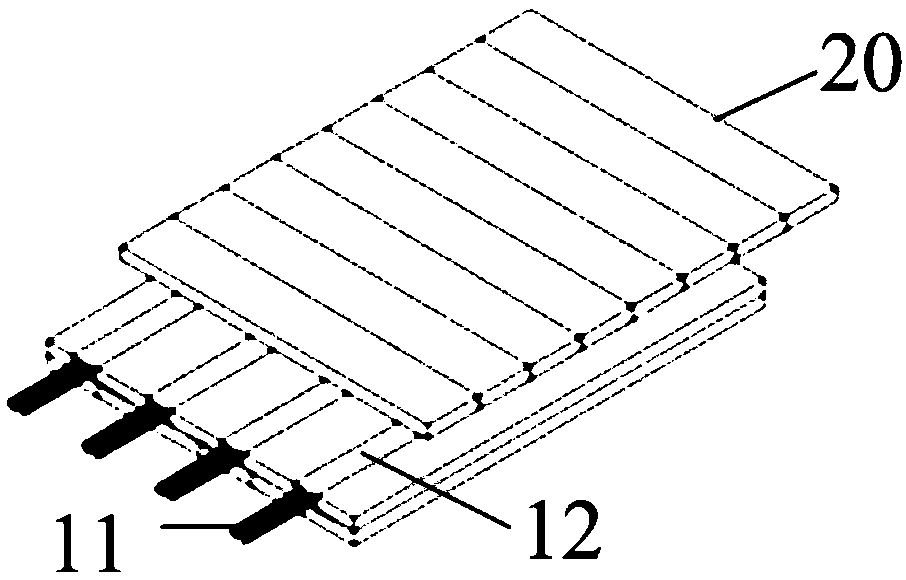

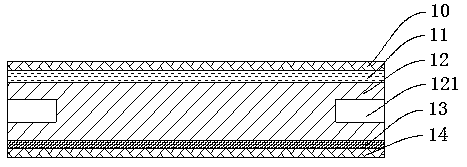

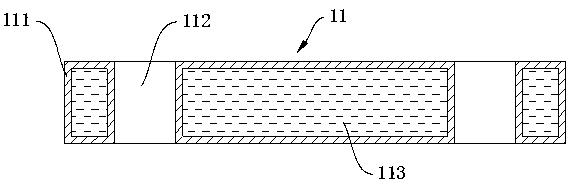

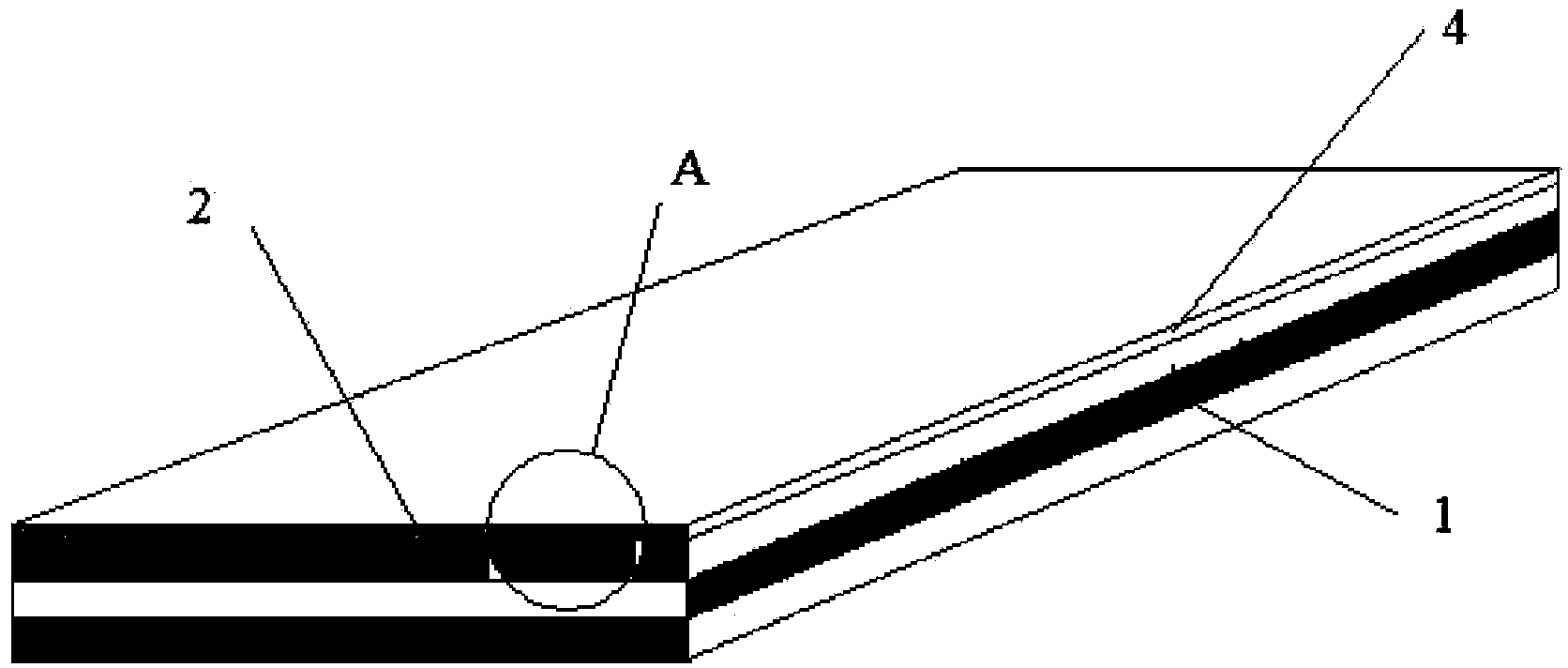

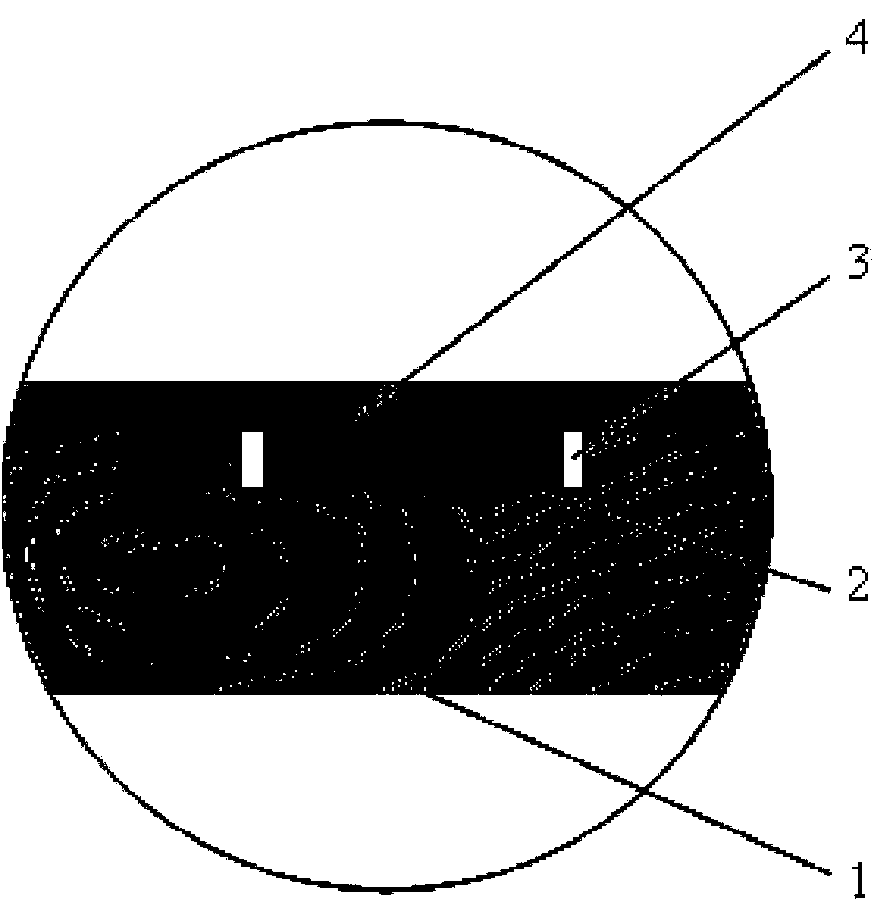

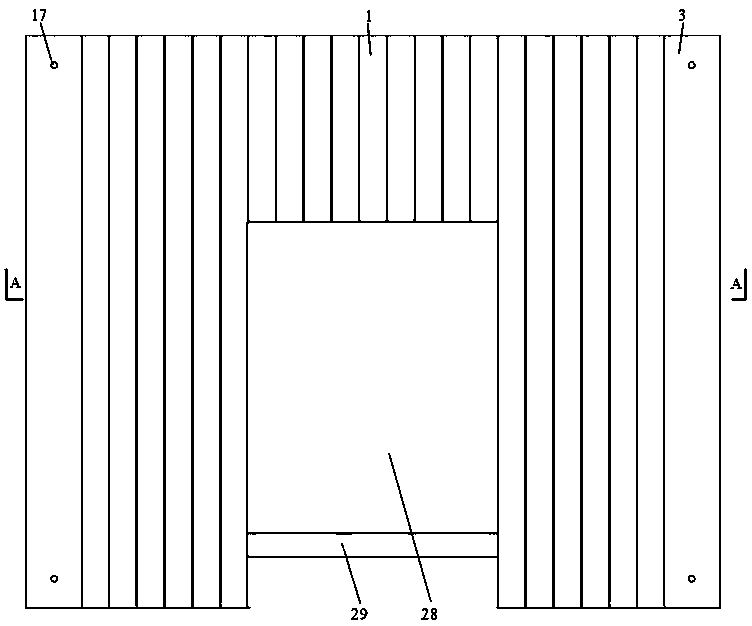

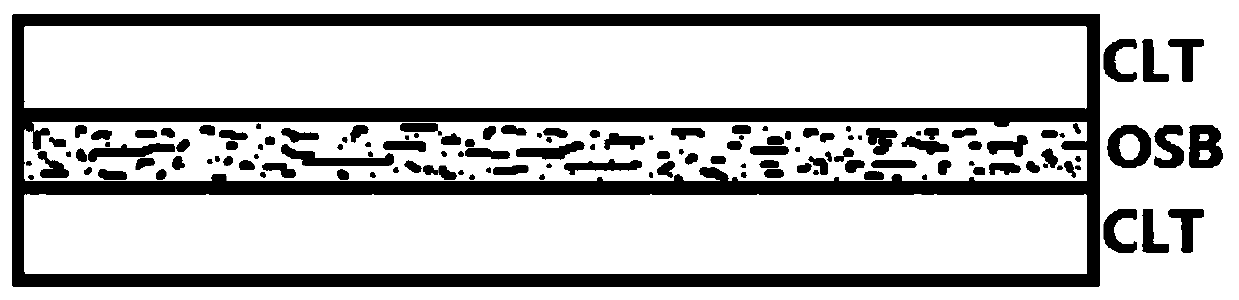

Electric heating floor blank based on CLT (Cross-Laminated Timber) board and manufacturing method thereof

InactiveCN103963373AGood dimensional stabilityImprove wear resistanceWood layered productsFlooringSolid woodCross laminated timber

The invention discloses an electric heating floor blank based on a CLT (Cross-Laminated Timber) board and a manufacturing method thereof. The electric heating floor blank comprises a base plate layer (1) and a thin plate layer (4), wherein the base plate layer (1) is a CLT board formed by vertically and horizontally stacking and gluing a plurality layers of single wood boards in a crossed manner; a plurality of grooves (3) are formed in the upper surface of the base plate layer (1); the length directions of the grooves (3) are parallel to the length direction of the uppermost single wood board laminated and stacked in the CLT board of the base plate layer (1); a heating film (2) is placed in each groove (3); the thin plate layer (4) made from valuable timber sheets further covers the base plate layer (1). The manufacturing method comprises the following steps: milling a plurality of grooves on one surface of the CLT board, placing the heating films inside the grooves, and covering the grooves with the valuable timber sheets. Compared with an ordinary solid wood compound electric heating floor, the solid wood compound electric heating floor manufactured by utilizing the method has high stability, and power failure and blank deguming and cracking generated by cracking of the heating films after long-time use are avoided.

Owner:NANJING FORESTRY UNIV

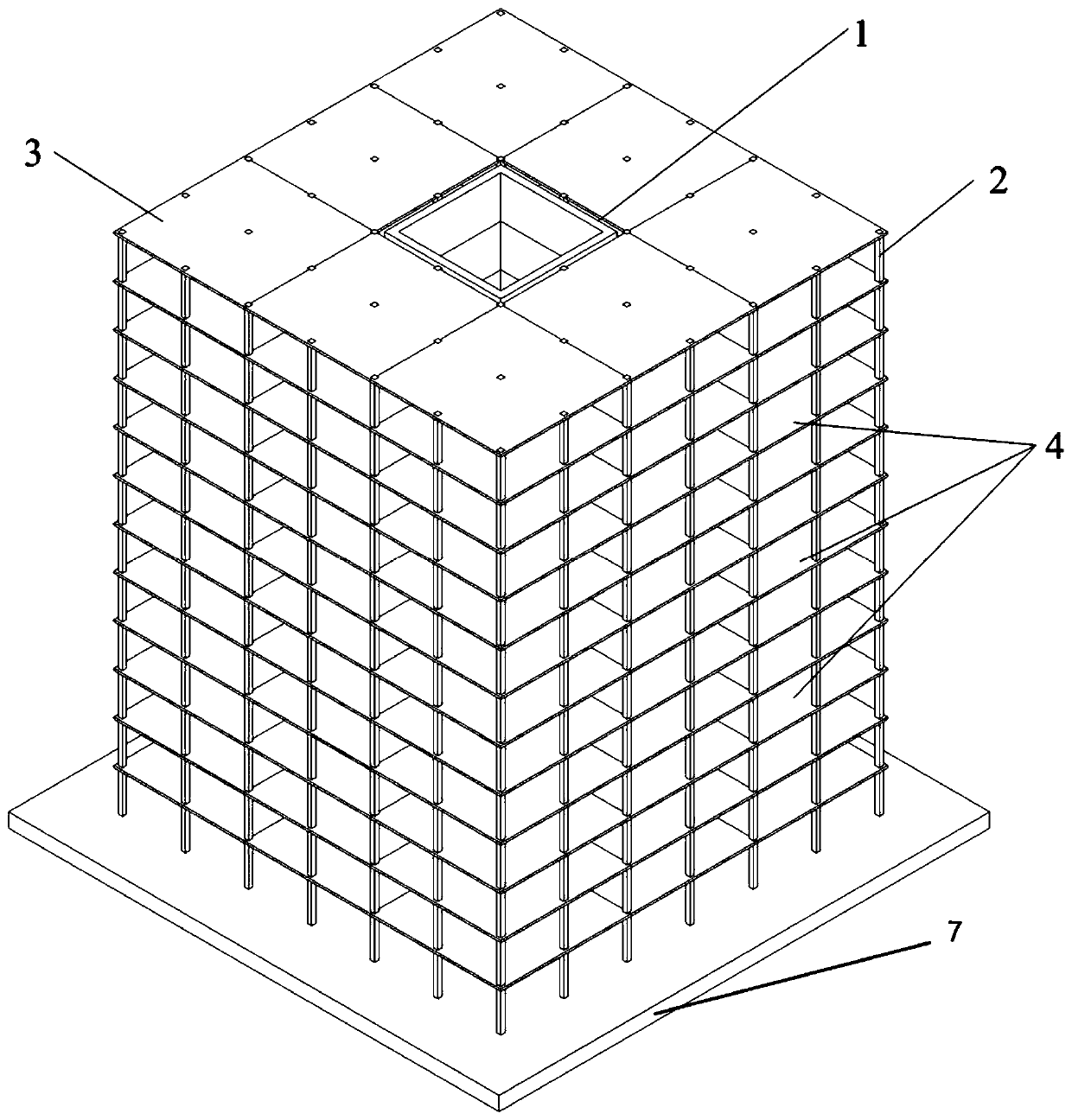

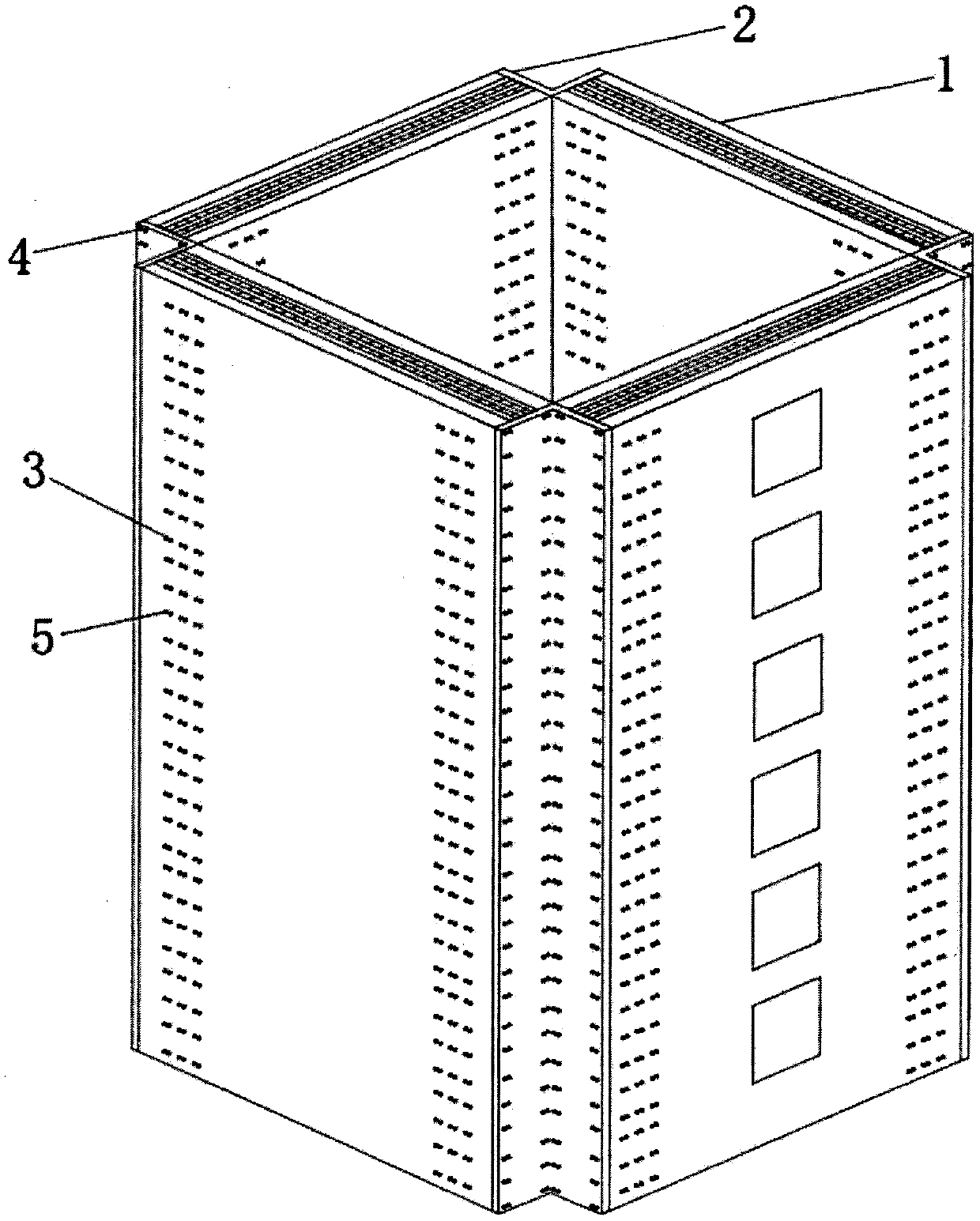

Prefabricated type cross laminated timber concrete multiple-layer core cylinder structure

PendingCN110714549AImprove stabilityImprove seismic performanceWallsProtective buildings/sheltersArchitectural engineeringWood plank

The invention provides a prefabricated type cross laminated timber concrete multiple-layer core cylinder structure. The prefabricated type cross laminated timber concrete multiple-layer core cylinderstructure comprises multiple-layer shear walls, equal leg angles, bolts and nuts. Each multiple-layer shear wall is composed of an outer side precast concrete wall, an interlayer cross laminated timber plate, an inner side precast concrete wall and an embedded bolt, wherein a bolt hole is reserved in the multiple-layer shear wall, a bolt hole is reserved in the outer side precast concrete wall, abolt hole is reserved in the interlayer cross laminated timber plate, a bolt hole is reserved in the inner side precast concrete wall, and bolt holes are reserved in the equal leg angles. The adjacentmultiple-layer shear walls are anchored together by the equal leg angles through the embedded bolts, the outer side precast concrete walls, the interlayer cross laminated timber plates and the innerside precast concrete walls are anchored through the bolts. The precast concrete walls have the advantages of being good in bearing capacity, high in construction speed and stable in quality. CLT anti-shear bearing force is good, cleanliness and environment friendliness are achieved, and a combined structure has the advantages of being light and good in anti-vibration property. The prefabricated type cross laminated timber concrete multiple-layer core cylinder structure is good in integrality, high in construction efficiency and reliable in quality.

Owner:NANJING FORESTRY UNIV

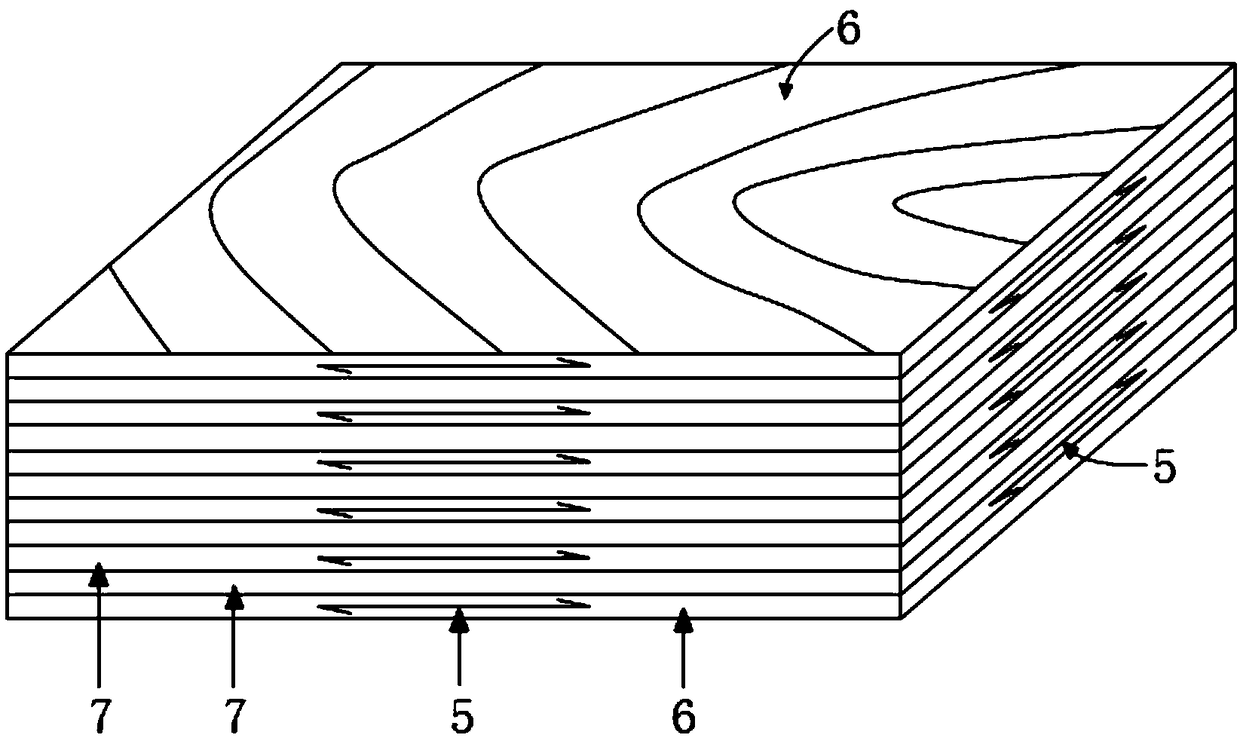

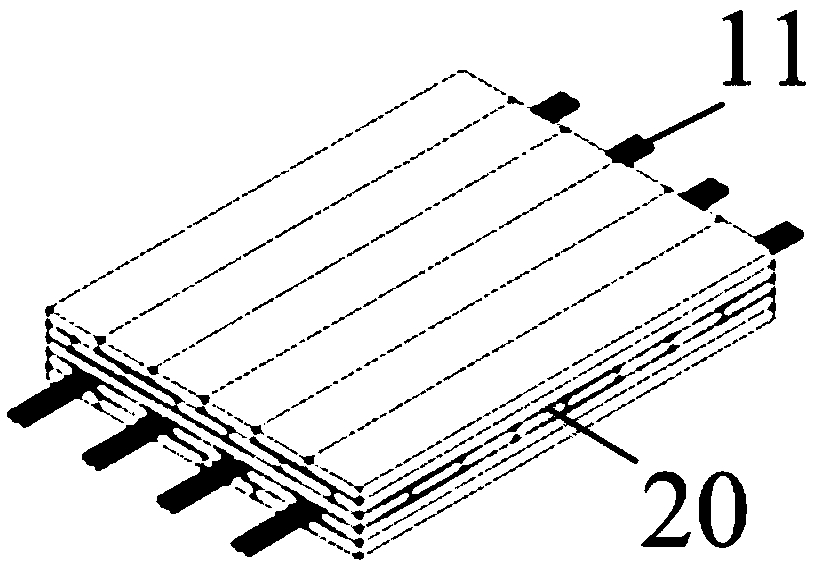

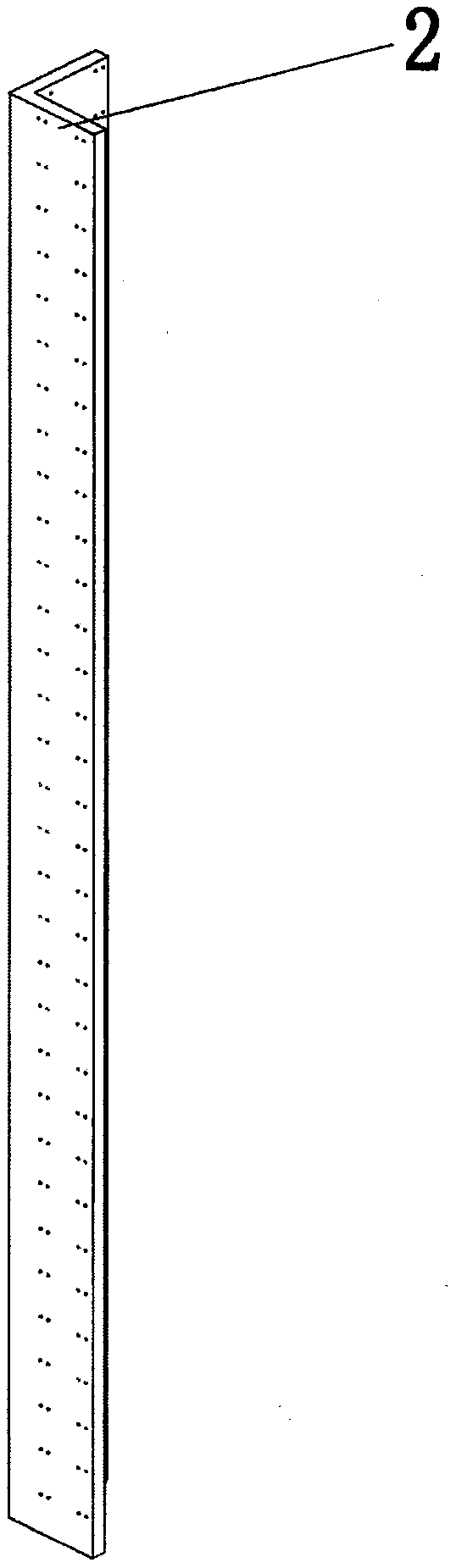

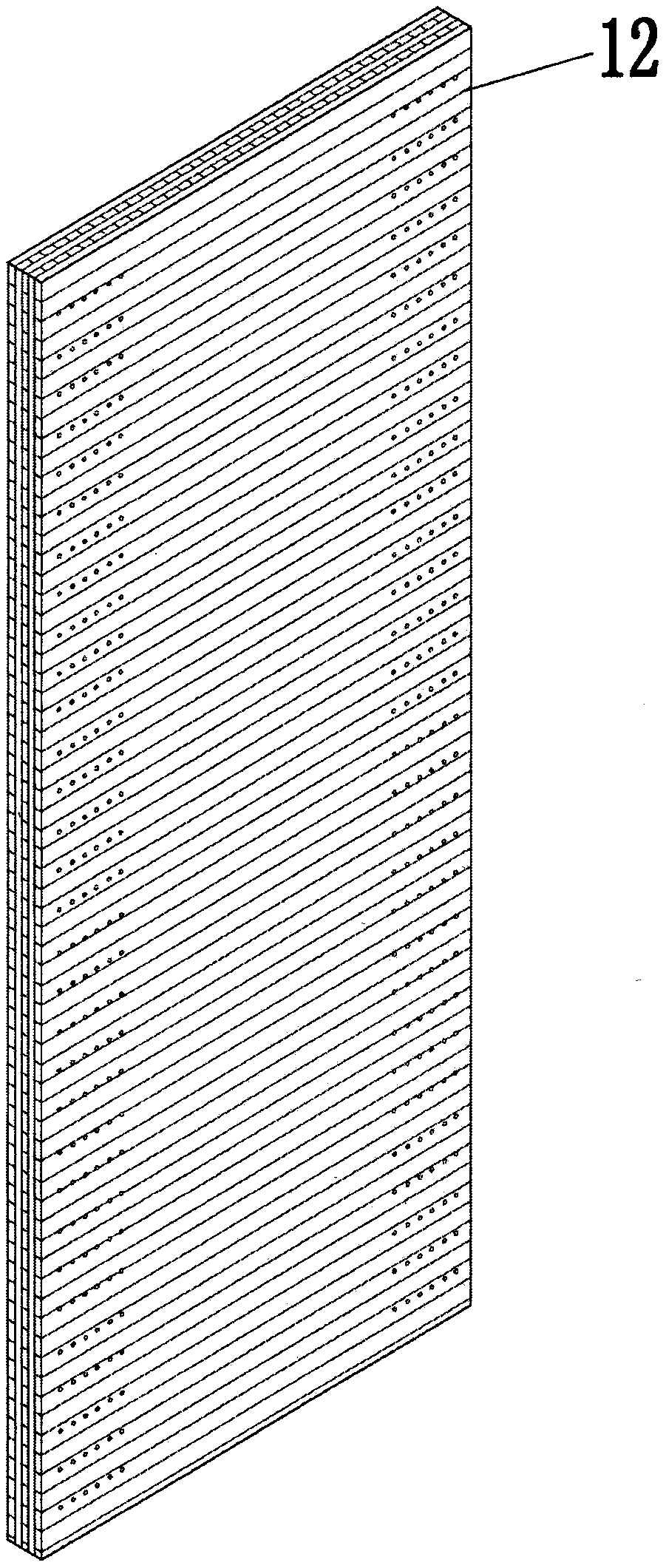

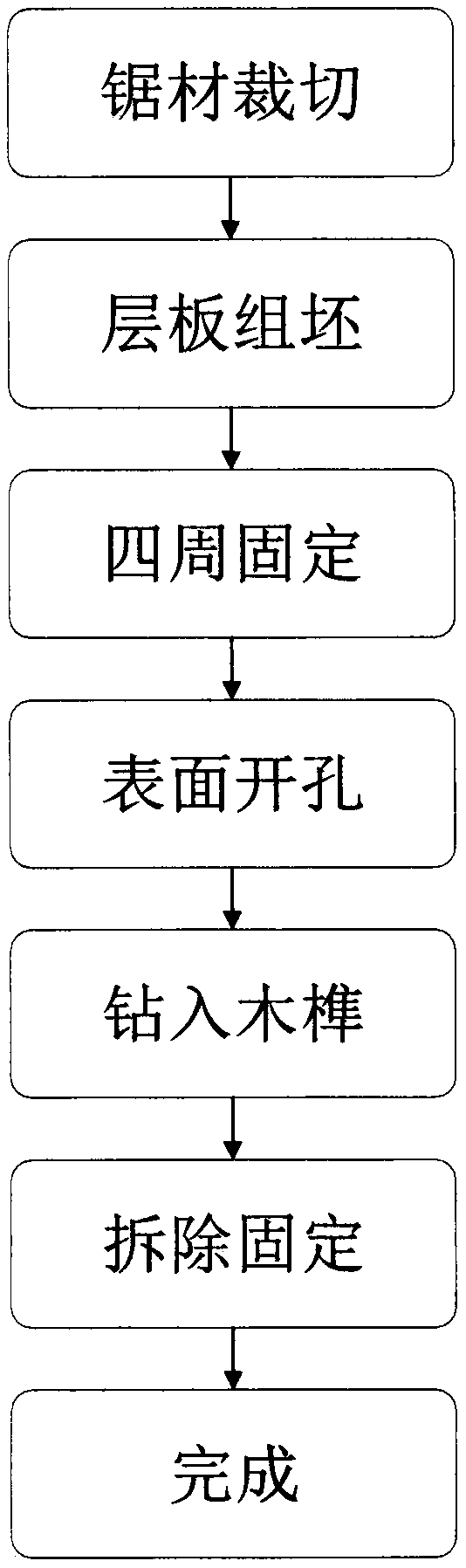

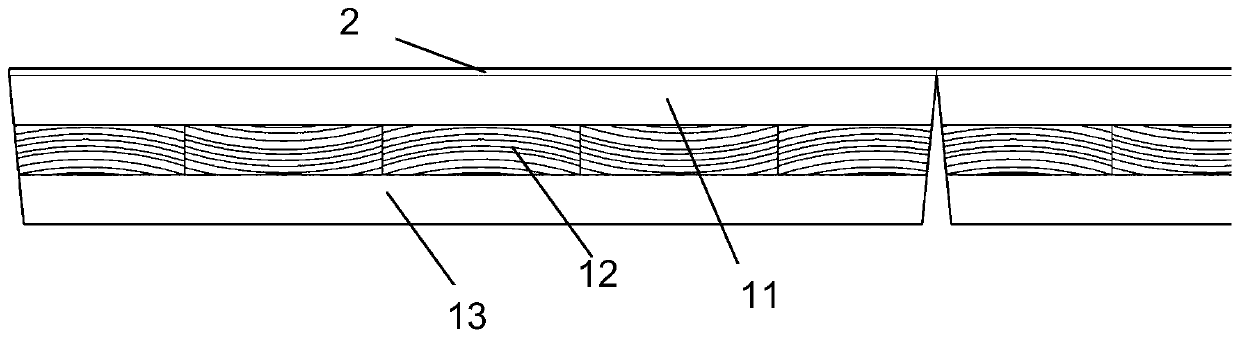

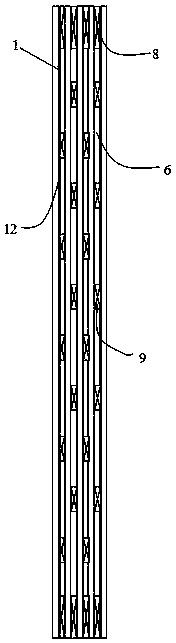

Cross-laminated plate manufactured on basis of dowel rotary friction welding technology

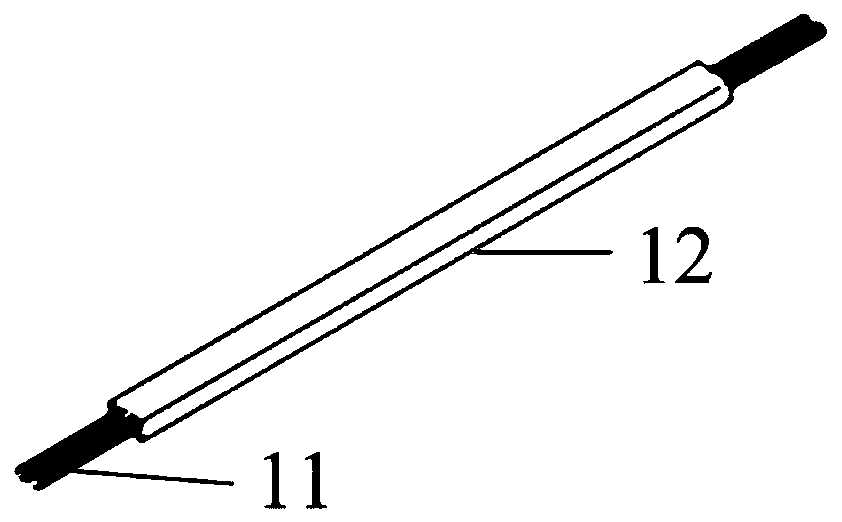

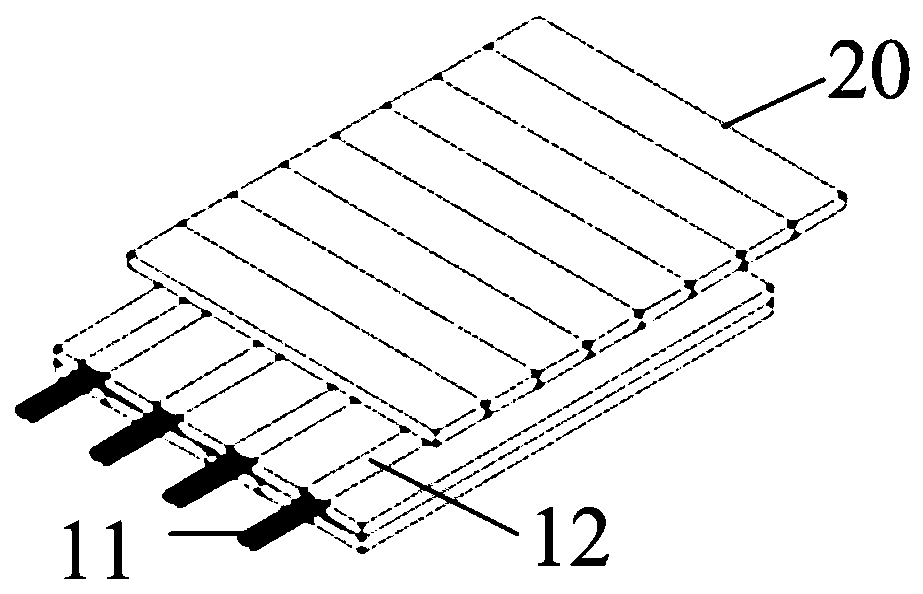

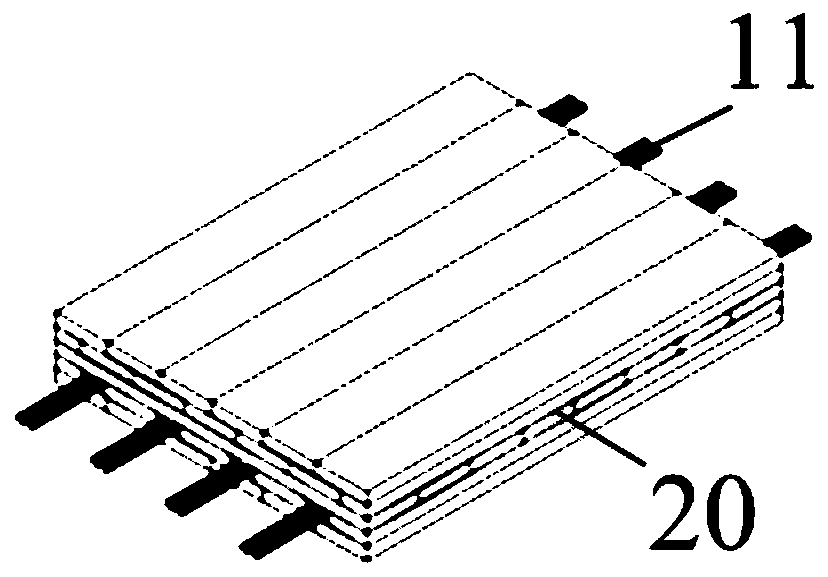

A cross-laminated plate manufactured on the basis of a dowel rotary friction welding technology is characterized in that longitudinal laminated plates (1) which are cut and transverse laminated plates(2) which are cut are assembled according to a certain angle, then the peripheries of the plates are fixed by a formwork, punching operation is conducted on the plate surfaces at intervals accordingto a certain angle, dowels (3) which are fixed to a drill bit are put into holes in a drilling mode, and the formwork is disassembled after the dowels (3) are put into all the holes in the drilling mode and the redundant dowels (3) are cut away. The dowel rotary friction welding technology is adopted to optimize a conventional production technology of cross-laminated timber, and the improved technology is free of usage of adhesives and nails and is greener and more environmentally friendly. Due to the fact that plate components are designed in advance, secondary cutting is not required after the formwork is disassembled, and the utilization rate of raw materials is improved.

Owner:NANJING FORESTRY UNIV

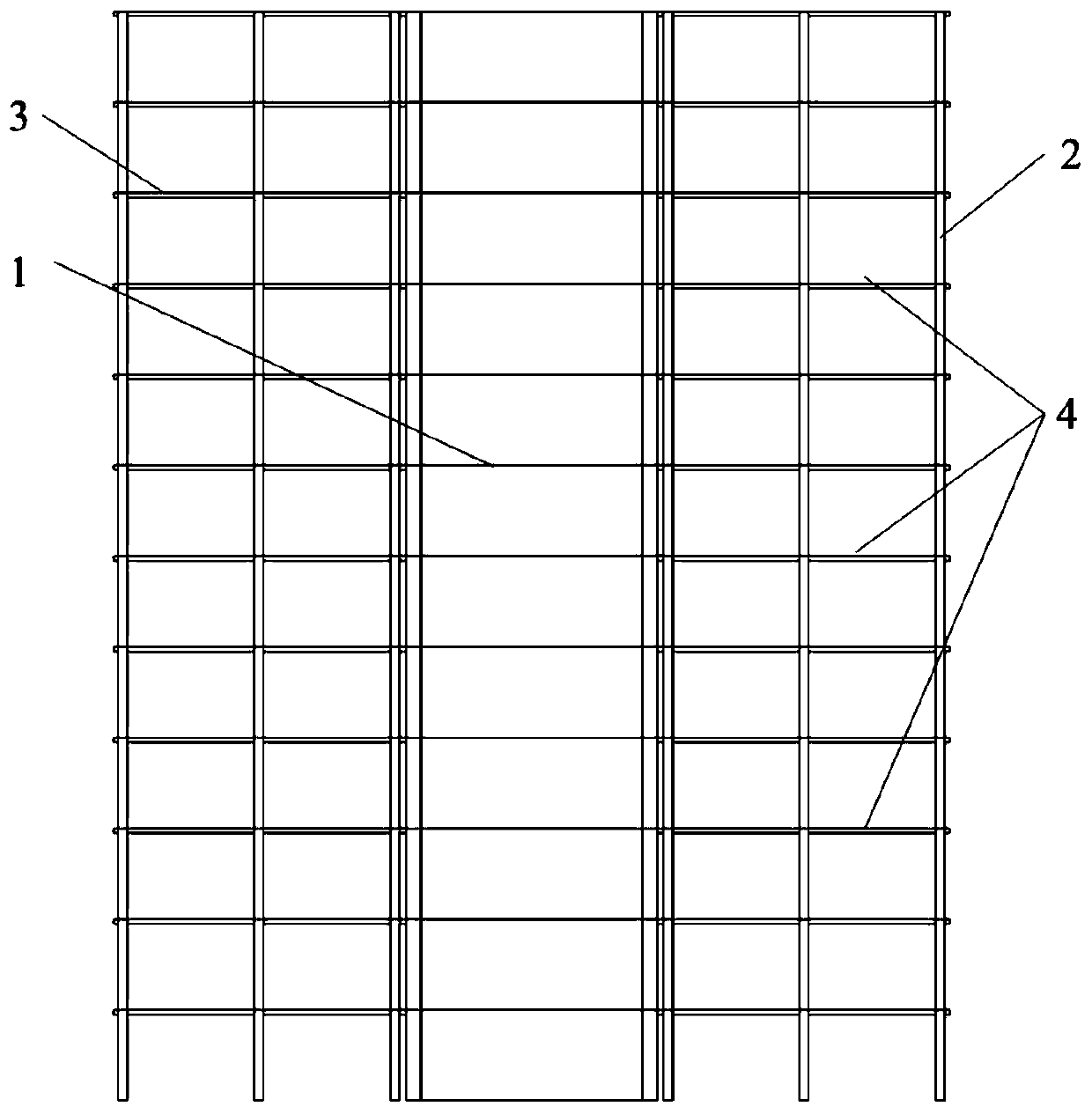

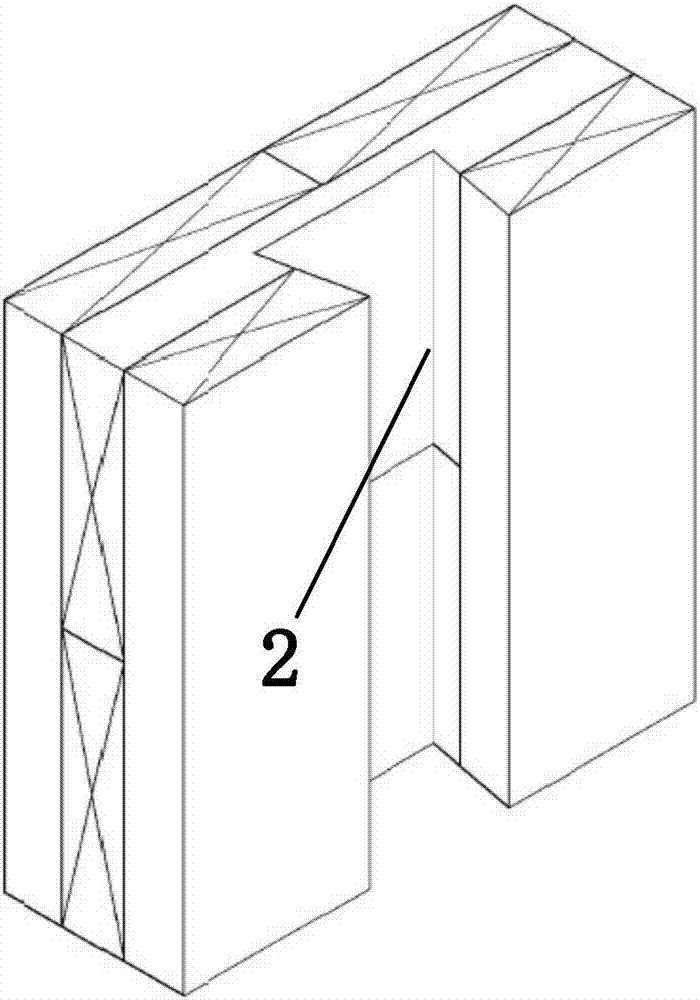

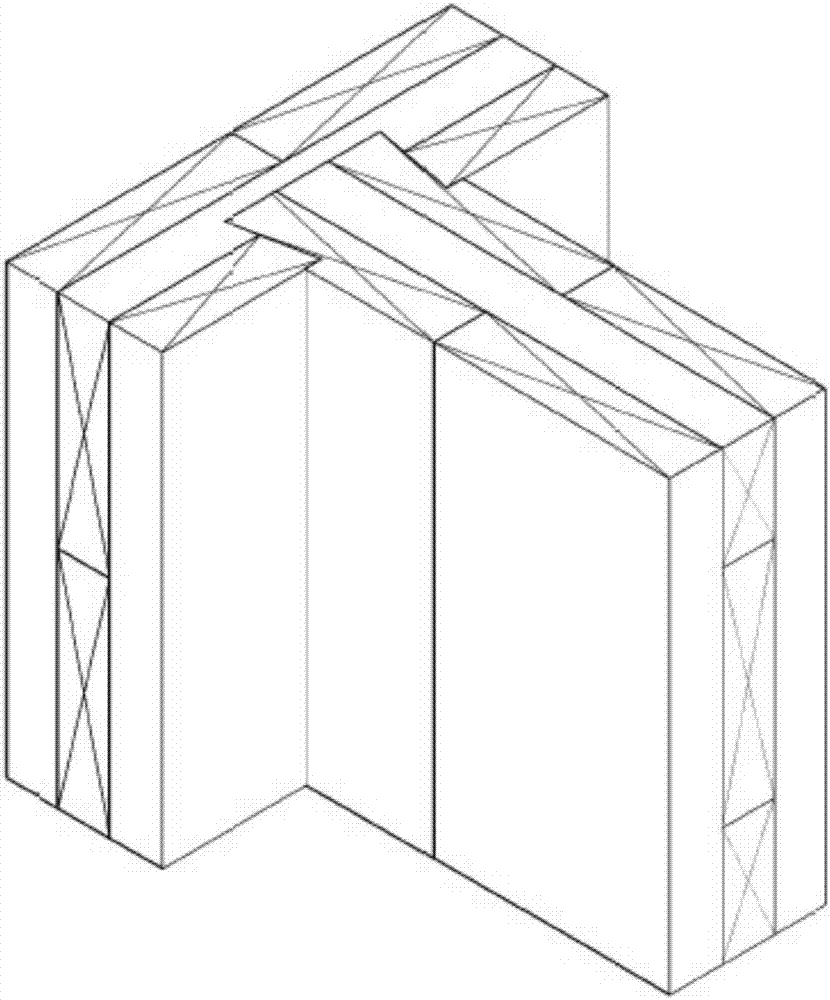

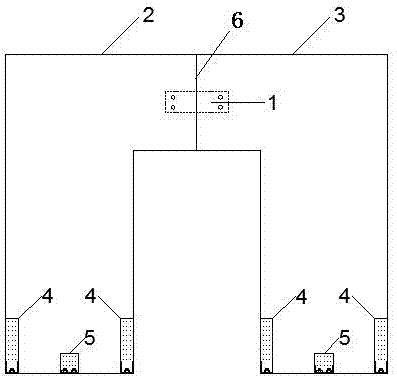

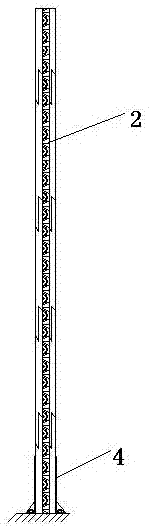

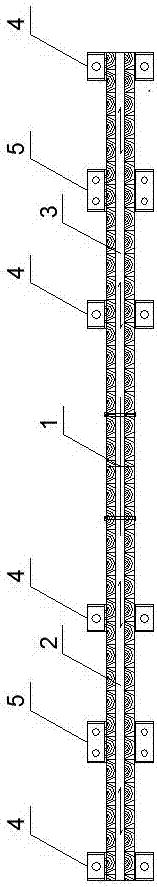

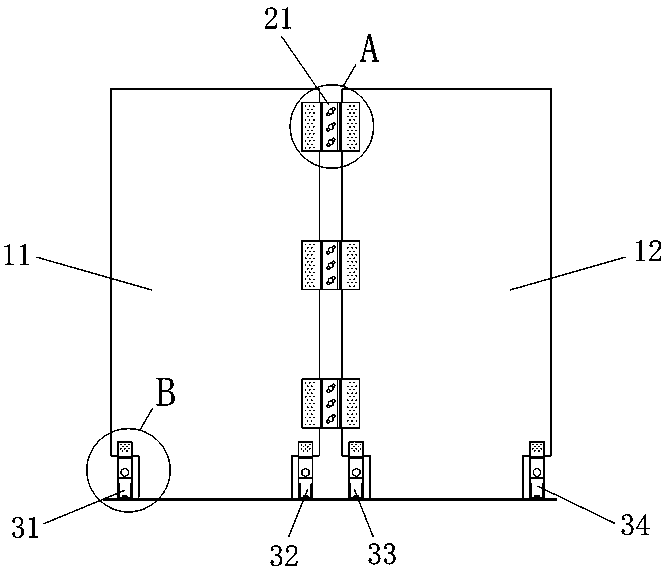

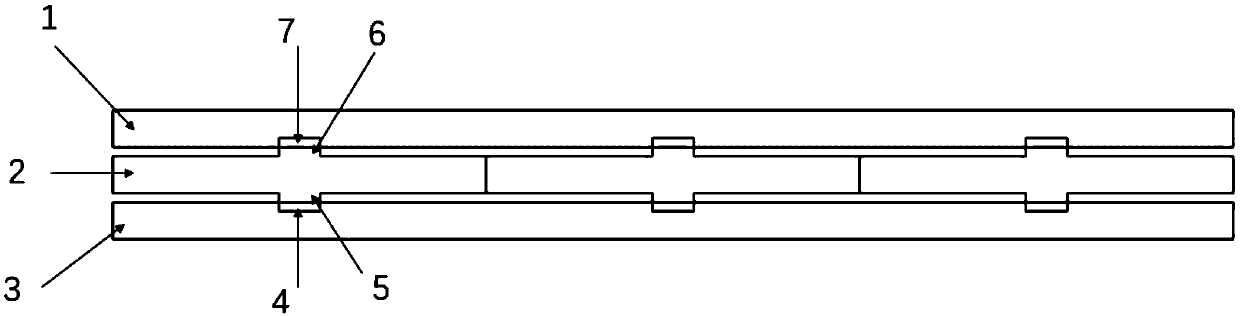

Opening crossed-laminated-timber shear wall with energy-dissipation connecting piece

ActiveCN107574951AHorizontal linkDissipative seismic actionWallsProtective buildings/sheltersFloor slabEngineering

An opening crossed-laminated-timber shear wall with an energy-dissipation connecting piece comprises a first crossed-laminated-timber shear wall (2) and a second crossed-laminated-timber shear wall (3). The first crossed-laminated-timber shear wall (2) and the second crossed-laminated-timber shear wall (3) are vertically spliced to form a vertical seam (6) above an opening. The crossed-laminated-timber shear wall (2) and the second crossed-laminated-timber shear wall (3) are assembled to a floor through first metal connecting pieces (4) and second metal connecting pieces (5). The opening crossed-laminated-timber shear wall is characterized in that the vertical seam is connected through the energy-dissipation metal piece (1). According to the opening crossed-laminated-timber shear wall withthe energy-dissipation connecting piece, the rigidity degeneration mode of the crossed-laminated-timber shear wall is improved to have a section of rigidity retention from full descent while the safety and reliability of the crossed-laminated-timber shear wall are guaranteed. After an energy dissipation device is destroyed, the crossed-laminated-timber with the energy dissipation device can continuously bear the load, and compared with a common crossed-laminated-timber shear wall, the ultimate displacement of the opening crossed-laminated-timber shear wall is increased by 45%, and the energydissipation capacity under the earthquake effect is improved.

Owner:NANJING UNIV OF TECH

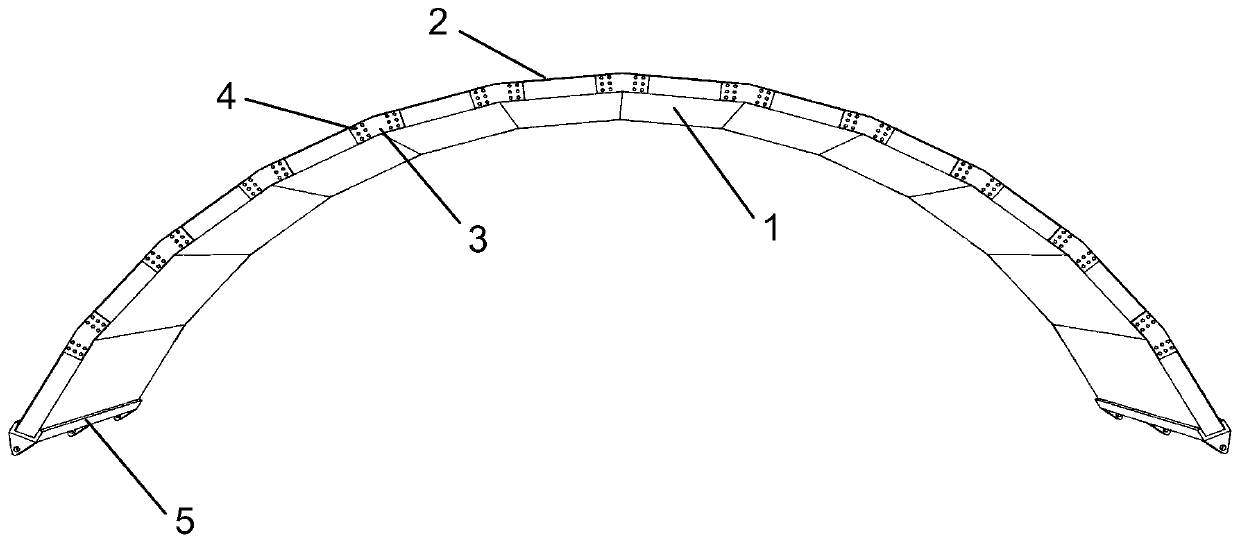

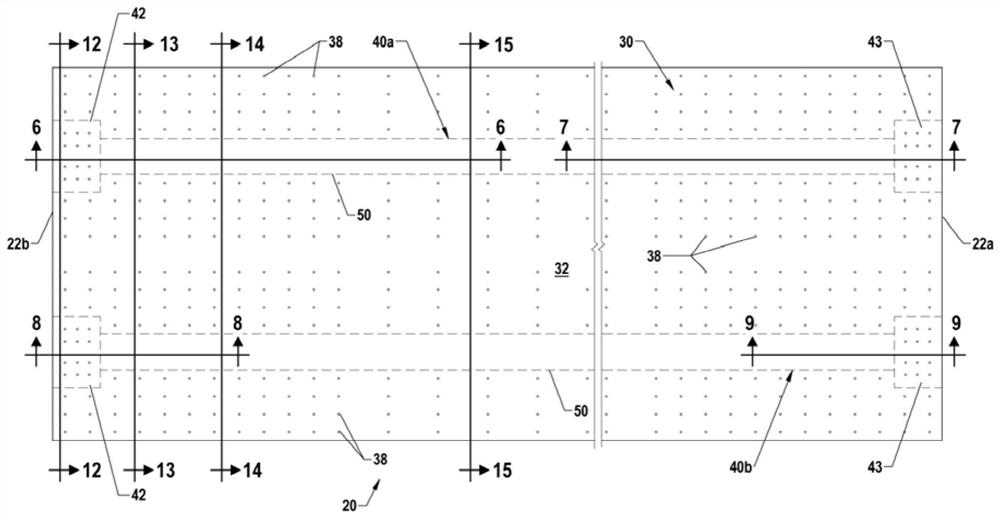

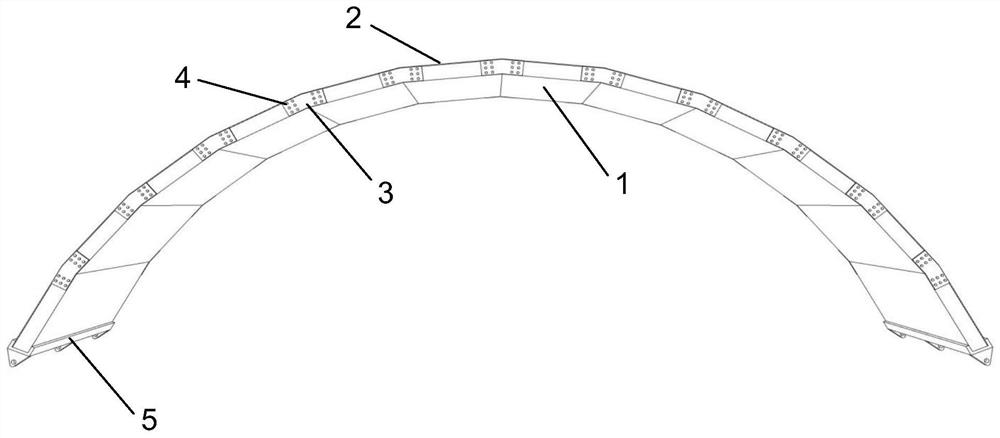

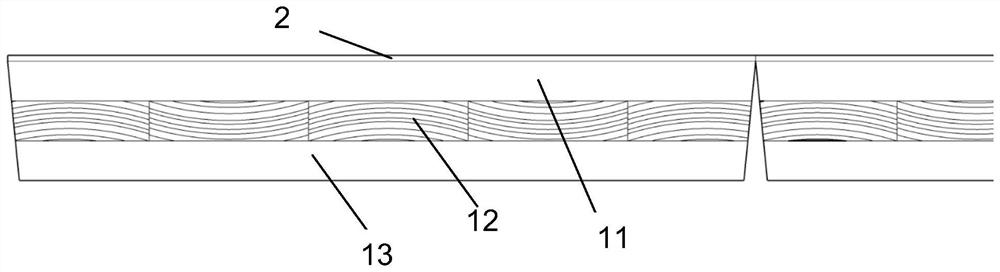

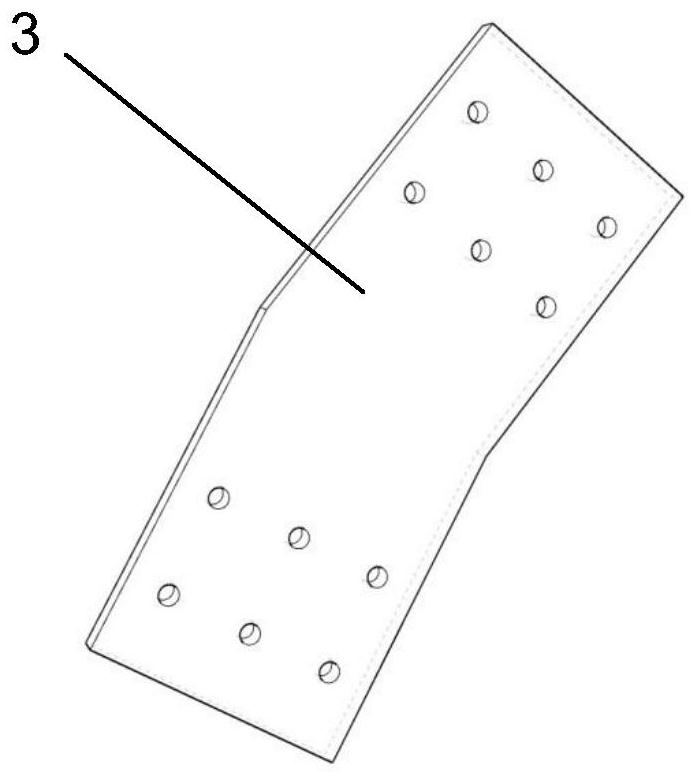

Cross laminated timber-assembled wood arch structure

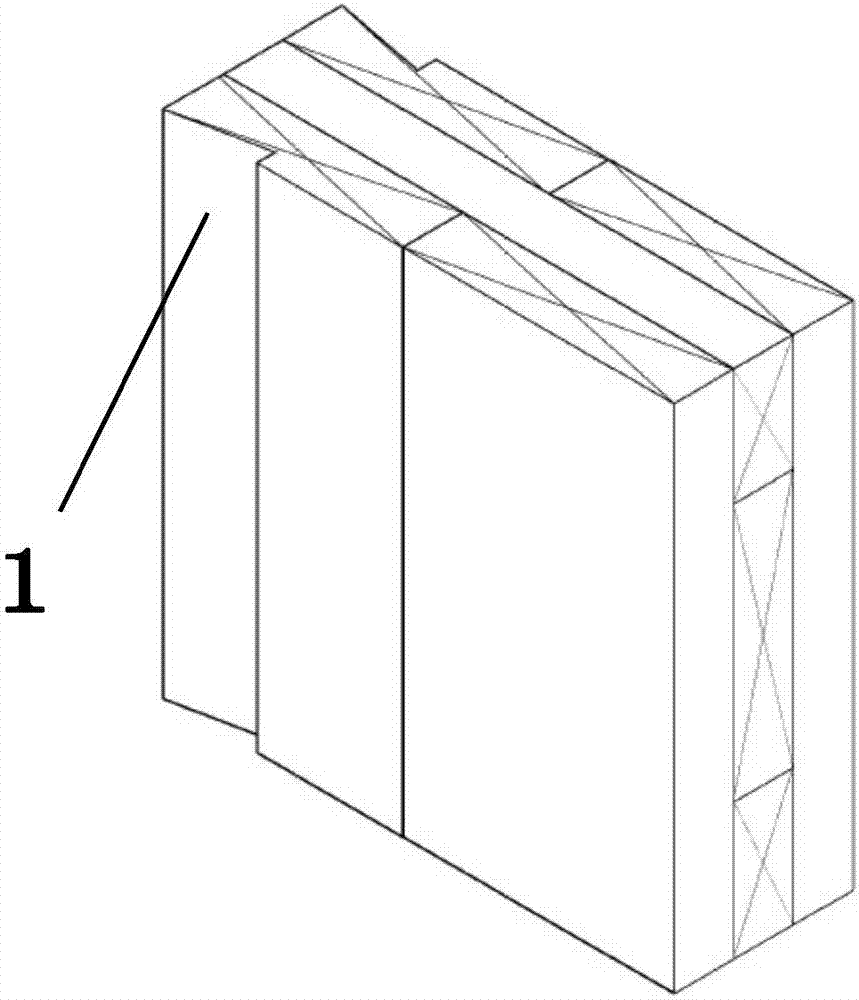

ActiveCN109914219AGood dimensional stabilityConsistent sizeBuilding roofsFloorsIsosceles trapezoidGlass fiber

The invention discloses a cross laminated timber (CLT)-assembled wood arch structure which comprises one or more wood arch bodies arranged along a width direction of a wood arch, wherein each wood arch body is respectively formed by splicing a plurality of CLTs in sequence along a length direction of the wood arch; two adjacent CLTs are fixed by side connecting metal pieces; one or more compositefastening and tensioning layers are fixed on an upper surface of each wood arch body; each CLT has a cross section of isosceles trapezoid and has an upper surface longer than a lower surface; the composite fastening and tensioning layers are carbon fiber layers, glass fiber layers or steel strips; and the wood arch bodies and the composite fastening and tensioning layers thereon are in an arched state after being mounted in place and are in a flat plate state when being transported and stacked for storage. The CLT-assembled wood arch structure is convenient to be transported, simple and rapidto be assembled, and short in on-site construction time by adopting a manner of factory prefabrication and on-site local assembly, and is capable of effectively utilizing dimensional stability of theCLTs and greatly improving a utilization rate of compressive strength.

Owner:INST OF WOOD INDUDTRY CHINESE ACAD OF FORESTRY

Method of manufacturing wall elements for buildings

ActiveUS20190136519A1Small overall lengthConstruction materialWallsEngineeringCross laminated timber

A method of manufacturing wall elements for buildings, cross laminated timber panels of a specific width and length stocks in a store, and the panels are sawed up transversely to the longitudinal direction to obtain cross laminated timber panels of the same width and smaller length. A plurality of panels are placed onto a conveying track transversely to the direction of running, and indeed such that the panels are flush at the top and bottom and the side edges of consecutive panels contact one another. The panels on the conveying track are connected along the contacting longitudinal sides to form a cross laminated timber apron. The apron is sawed up transversely to the direction of running of the conveying track to obtain cross laminated timber boards of a defined width.

Owner:BINDER BET AG

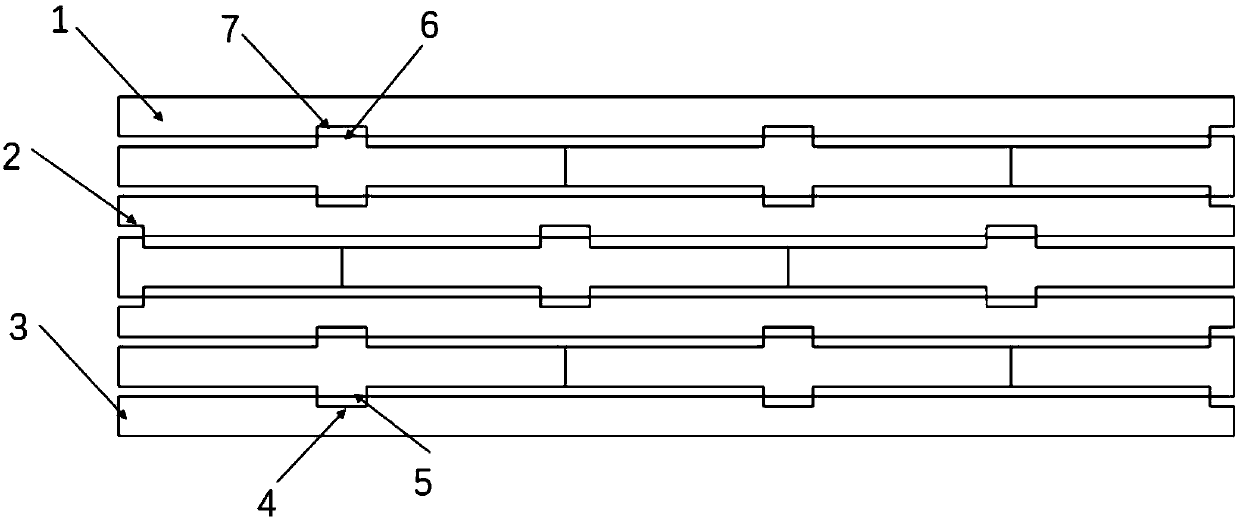

NCCLT (NC cross-laminated timber) Insulation plate with door opening and connection method thereof

The invention provides an NCCLT (NC cross-laminated timber) insulation plate with a door opening, comprising an NCCLT insulation plate with a door opening in the flat end, an NCCLT insulation plate with a door opening in the single stepped end, and an NCCLT insulation plate with door openings in the double stepped ends. The NCCLT insulation plate with the door opening in the flat end is formed ofa plurality of plies, each ply is composed of multiple dimensioned wood blocks, and parallel grains of the adjacent plies are perpendicular to each other; the inner and outer plies are continuous longitudinal plies, a plurality of longitudinal wood plies having an inner cavity and a plurality of transverse wood plies having an inner cavity are arranged between the two continuous longitudinal plies. One end of each of the top and bottom continuous longitudinal plies of the NCCLT insulation plate with the door opening in the flat end is provided with a connection stepped edge. The NCCLT insulation plate with the door opening has the advantages that factory premanufacturing is completely achieved, durability is significantly improved, no damage is caused to ecology, the yield is greatly increased, sound insulation and heat insulation are integrated, inner holes are maximized, the rigidity and strength of the plate are greatly improved, material consumption is reduced, and the plate has excellent load-bearing capacity and incomparable ability to restore from deformation.

Owner:SHENYANG JIANZHU UNIVERSITY

Stepped drill bit with alternately sharpened edges to clean-out obscured fastener openings in cross laminated timber joints

ActiveUS11351615B2Easy to driveAccurate shapeWood turning toolsTransportation and packagingClassical mechanicsEngineering

A drill bit for use with construction using cross laminated timbers (CLT) is provided. The bit has both sharpened and dull portions of the cutting element of the bit, so that it can clean-out an opening in the CLT that has been partially obscured by shifts in the laminated constituents of the CLT, without elongating or otherwise changing the shape of the fastener opening. The use of the bit is made at the construction site in fastener openings previously made and otherwise obscured, thereby allowing the quick assembly and construction of a structure made of CLT.

Owner:THE MILLER DOWEL CO

A swingable energy-dissipating cross-laminated timber double-panel seismic wall

ActiveCN106639030BImprove deformationImprove energy consumptionWallsProtective buildings/sheltersEngineeringEnergy consumption

The invention relates to a cross laminated timber (CLT) double-board seismic wall with a swinging energy-dissipation function. The CLT double-board seismic wall is composed of two CLT shear walls, a friction-type vertical connecting piece and a friction-type pulling-resistant anchoring piece. The two CLT shear walls are spliced together through the friction-type vertical connecting piece, and a wall body is connected with a floor or a foundation through the friction-type pulling-resistant anchoring piece. Under the effect of an earthquake, the CLT shear walls rotate in the wall board plane, the friction-type vertical connecting piece is in shear, and lap joint friction surfaces of the friction-type vertical connecting piece slide relatively to dissipate energy; and meanwhile, the specially-designed pulling-resistant anchoring piece is matched with rotation of the CLT shear walls, and friction surfaces in the pulling-resistant anchoring piece also slide relatively to dissipate energy. The CLT shear walls are hardly damaged after the earthquake, friction sheets in the vertical connecting piece and the pulling-resistant anchoring piece are not damaged and do not need to be replaced after the earthquake, and the ideal anti-seismic property that the structure is stable under small earthquakes, the seismic wall swings but is not damaged under large earthquakes, and no post-earthquake maintenance or only a small amount of post-earthquake maintenance is needed is achieved.

Owner:TONGJI UNIV

Cellulose-based structural floor panel assembly

A cellulose-based structural building panel assembly includes a cross-laminated wood (CLT) core that is reinforced by one or more back ribs subjected to a preselected tension force after placement as part of the panel assembly. The ribs are provided within a sleeve that is grouted through channels formed in the lower side of the core and, after post-tensioning of the ribs, is filled with an adhesive that stabilizes the ribs in a fully bonded configuration.

Owner:DIALOG IP CORP

A cross-laminated timber assembled timber arch structure

ActiveCN109914219BGood dimensional stabilityConsistent sizeBuilding roofsBridge materialsIsosceles trapezoidGlass fiber

The invention discloses a cross laminated timber (CLT)-assembled wood arch structure which comprises one or more wood arch bodies arranged along a width direction of a wood arch, wherein each wood arch body is respectively formed by splicing a plurality of CLTs in sequence along a length direction of the wood arch; two adjacent CLTs are fixed by side connecting metal pieces; one or more compositefastening and tensioning layers are fixed on an upper surface of each wood arch body; each CLT has a cross section of isosceles trapezoid and has an upper surface longer than a lower surface; the composite fastening and tensioning layers are carbon fiber layers, glass fiber layers or steel strips; and the wood arch bodies and the composite fastening and tensioning layers thereon are in an arched state after being mounted in place and are in a flat plate state when being transported and stacked for storage. The CLT-assembled wood arch structure is convenient to be transported, simple and rapidto be assembled, and short in on-site construction time by adopting a manner of factory prefabrication and on-site local assembly, and is capable of effectively utilizing dimensional stability of theCLTs and greatly improving a utilization rate of compressive strength.

Owner:INST OF WOOD INDUDTRY CHINESE ACAD OF FORESTRY

A longitudinally reinforced cross-laminated timber and its manufacturing method

ActiveCN108162519BReduce weightIncrease stiffnessConstruction materialTransportation and packagingPunchingRebar

The invention discloses a longitudinally-reinforced cross laminated timber and a manufacturing method thereof, belongs to the technical field of construction engineering, and solves the deficiency ofa current cross laminated timber technology, the deficiency is the problem, that is, a large block cross laminated timber structure cannot be punched by a reinforcing steel bar so that the reinforcingsteel bar cannot run through the whole structure to be placed in the material, and slotting has a complicated process and destroys the overall performance of wood. The longitudinally-reinforced crosslaminated timber uses a hollow shaving board as a carrier for bearing the reinforcing steel bar to prepare a reinforcing body, and the reinforcing body and a converted timber are directly subjected to whole forming gluing to prepare the longitudinally-reinforced cross laminated timber. The manufacturing method includes the steps of sizing, combination, assembly and pressing. The longitudinally-reinforced cross laminated timber manufactured by the method provided by the invention has a simple process, is formed by one-time hot pressing, does not need punching or slotting, does not damage integrality of components, can improve the mechanical properties, connection strength and rigidity of the cross laminated timber components, reduces the mass of the cross laminated timber components, savesmaterials, and has better promotion value.

Owner:SHANGHAI CONSTRUCTION GROUP

A kind of high-strength multi-layer wooden structural material and its manufacturing method

ActiveCN107297932BImprove performanceHigh strengthMonocarboxylic acid ester polymer adhesivesNon-macromolecular adhesive additivesAdhesiveHigh intensity

Owner:贵州剑河园方林业投资开发有限公司

Thermoplastic poly acrylated glycerol adhesives useful in cellulosic products

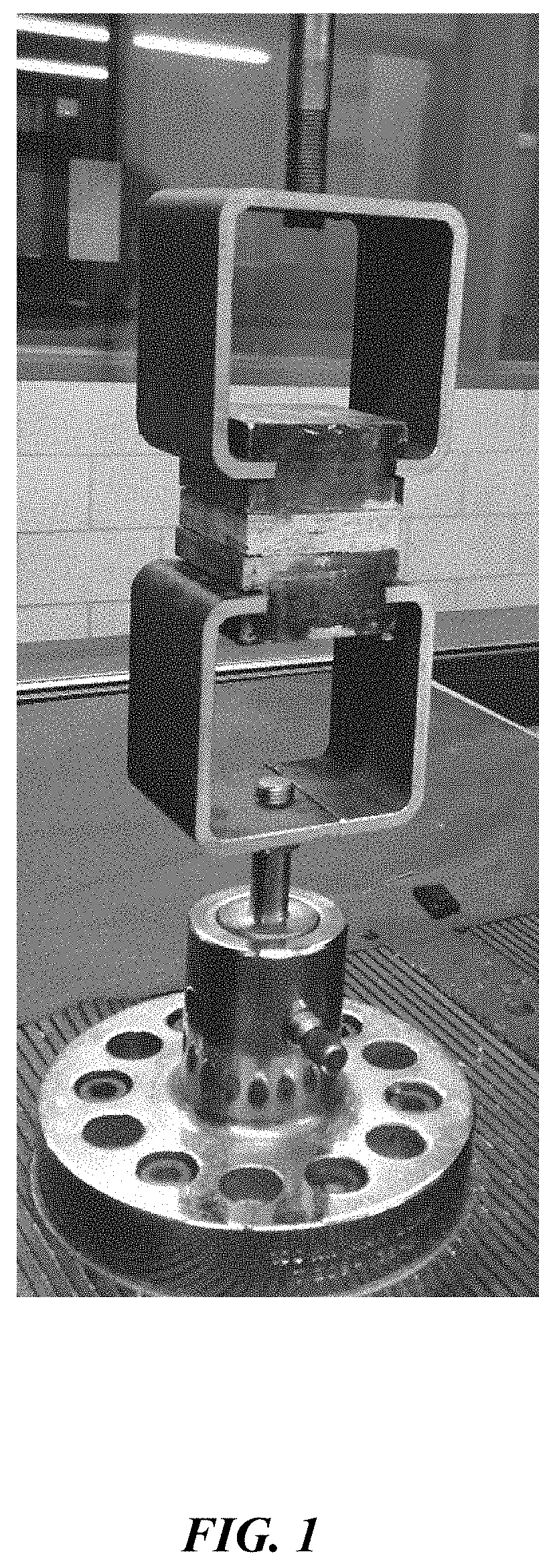

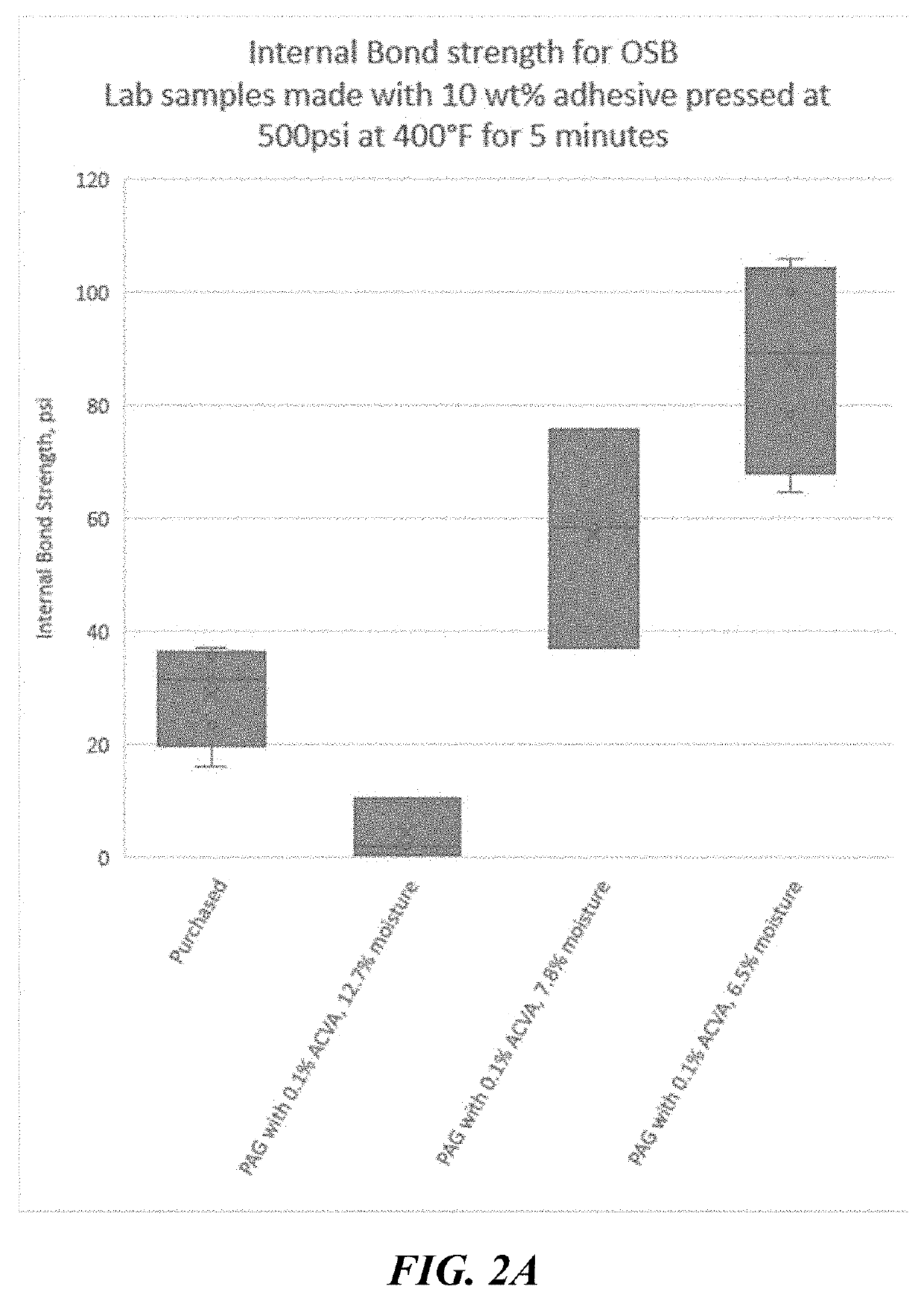

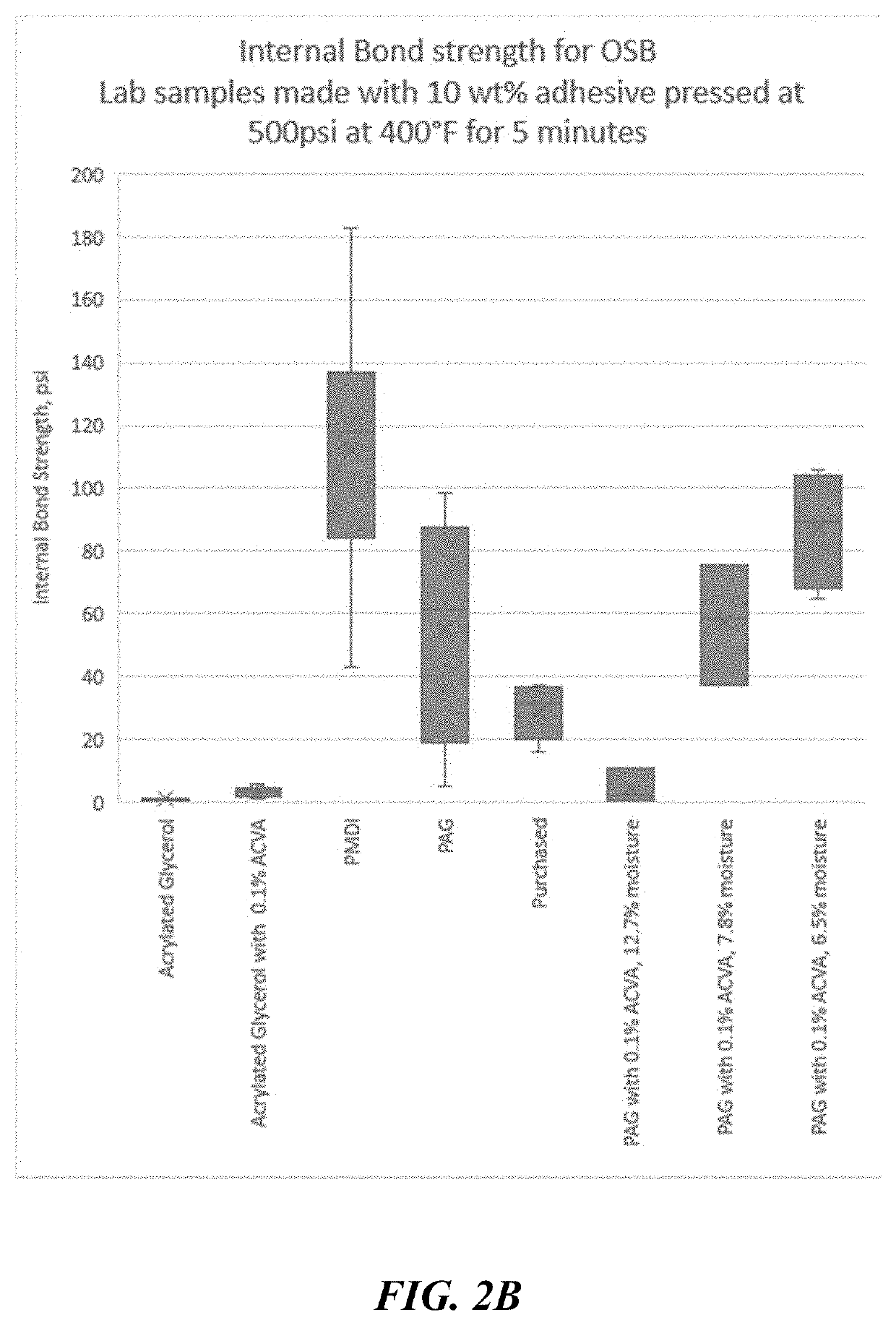

ActiveUS20190345369A1Low costCleaner machined surfacesPolyureas/polyurethane adhesivesWood working apparatusThermoplasticCellulose

The present invention relates to an adhesive comprising a thermoplastic polyacrylated glycerol polymer, water, and a cross linker that is reactive with the polyacrylated glycerol polymer. This adhesive is useful in the formation of cellulosic products including oriented strand board (OSB), particle board, oriented structural straw board, chipboard, plywood, laminated veneer lumber (LVL), pressed wood, glued laminated timber (glulam), cross-laminated timber (CLT), and other wood products. Methods of producing the adhesive and cellulosic products are also disclosed.

Owner:IOWA STATE UNIV RES FOUND +1

Cellulose-based structural flooring panel assembly

PendingUS20220243470A1Reduce interferenceProvide structureConstruction materialTransportation and packagingCelluloseEngineering

A cellulose-based structural building panel assembly includes a cross-laminated timber (CLT) core which is reinforced with one or more post-tensioned tendons stressed to a pre-selected tensioning force, following the placement as part of the panel assembly. The tendons are provided within a sleeve which is grouted with a channel formed in an underside of the core and which after post-tensioning of tendons is infilled with a binder securing the tendons in a fully bonded configuration.

Owner:DIALOG IP CORP

Integral prefabricated cross-laminated timber (CLT) wooden plate girder bridge based on steel side stiffening

InactiveCN102011364BSimple structureEasy to processBridge structural detailsBridge materialsEngineeringMoisture

The invention discloses an integral prefabricated cross-laminated timber (CLT) wooden plate girder bridge based on steel side stiffening, which comprises a bridge superstructure and a bridge substructure, wherein the bridge superstructure is spliced from a plurality of CLT wooden girder plates, and the upper part is provided with girder bridge spandrel girders of a girder bridge deck; each CLT wooden girder plate comprises a girder body structure and corner armor steel sides, the girder body structure is glued from at least three layers of wooden veneer sheets, and the corner armor steel sides are buckled on the upper and lower edges on the front and back ends of the girder body structure and used for stiffening the integral body; and the upper and lower edges on the front and back ends of the girder body structure are correspondingly provided with mounting notches of which the structures and dimensions correspond to those of the corner armor steel sides. The invention has the advantages of light weight, environment friendliness, simple structure, reasonable stressing and good compatibility with surrounding environment, is simple to construct, and can solve the problems of poor compatibility with surrounding environment, easy corrosion from moisture and other natural factors, on-site construction difficulty and the like in the existing bridge.

Owner:CHANGAN UNIV

Novel CLT (Cross-laminated Timber) board adopting saw-tooth-shaped interlaminar gluing manner

PendingCN109591402AImprove integrityImprove stabilityWood veneer joiningConstructions elementsEpoxySurface layer

The invention provides a novel CLT (Cross-laminated Timber) board adopting a saw-tooth-shaped interlaminar gluing manner. The novel CLT board is composed of a core layer and a surface layer, wherein each of the core layer and the surface layer is provided with a corresponding concave (convex) groove; the CLT board is commonly formed by gluing odd layers of panels; the middle core layer is formed by laminating a panel with the concave (convex) grooves in two faces and core layers which are provided with the concave (convex) grooves in two adjacent faces and are located at two sides; the layersare laminated in sequence according to the panel layers needed by the engineering through the manner until the final surface layer is laminated with the adjacent core layer by adopting the concave (convex) groove at the single side; in a lamination process, the concave grooves and the convex grooves (the convex grooves and the concave grooves) of the adjacent panels are embedded together; and allthe panels are orthogonally glued together by utilizing an epoxy resin structure adhesive. Compared with an existing gluing manner, the novel CLT board has the advantages that the panels of all the layers are arranged in a manner of embedding of the concave and convex grooves and the panels can be more tightly connected and are not easy to peel off, so that the whole performance of the CLT board is improved.

Owner:XI'AN UNIVERSITY OF ARCHITECTURE AND TECHNOLOGY

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com