Cross laminated timber combining fast growing timber material characteristics and meeting building structure requirements and preparation method thereof

A building structure and glulam technology, applied in the field of cross-laminated wood, cross-laminated wood and its preparation, can solve the problems of reduced mechanical properties of components, weakened fire resistance, and high manufacturing costs, and achieves low processing loss and mechanical properties. And the effect of improving fire resistance and strong dimensional stability of components

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0061] A preparation method of cross-glued wood, specifically comprising the following steps:

[0062] S1. Laminate preparation process: choose an initial moisture content of not less than 50%, and a corresponding air-dry density of 0.3g / cm 3 ~0.45g / cm 3 The fast-growing wood is rotary cut into fast-growing wood laminates with a thickness of 8mm to 15mm;

[0063] S2. Laminate drying process: reduce the moisture content of the fast-growing wood laminate to 8% to 15% by drying;

[0064] S3. Plywood gluing process: use one-component polyurethane, or melamine-urea-formaldehyde resin, or resorcinol-phenolic resin and other structural adhesives to coat the surface of the plywood to be glued, and the sizing amount is 200g / m 2 ~500g / m 2 ;

[0065] S4. Cross-glued wood laminate assembly: According to the regulations on the size and stress state of the cross-glued wood final product, arrange the texture assembly of several layers of laminates;

[0066] S5. Cross-glued wood pressing...

Embodiment 1

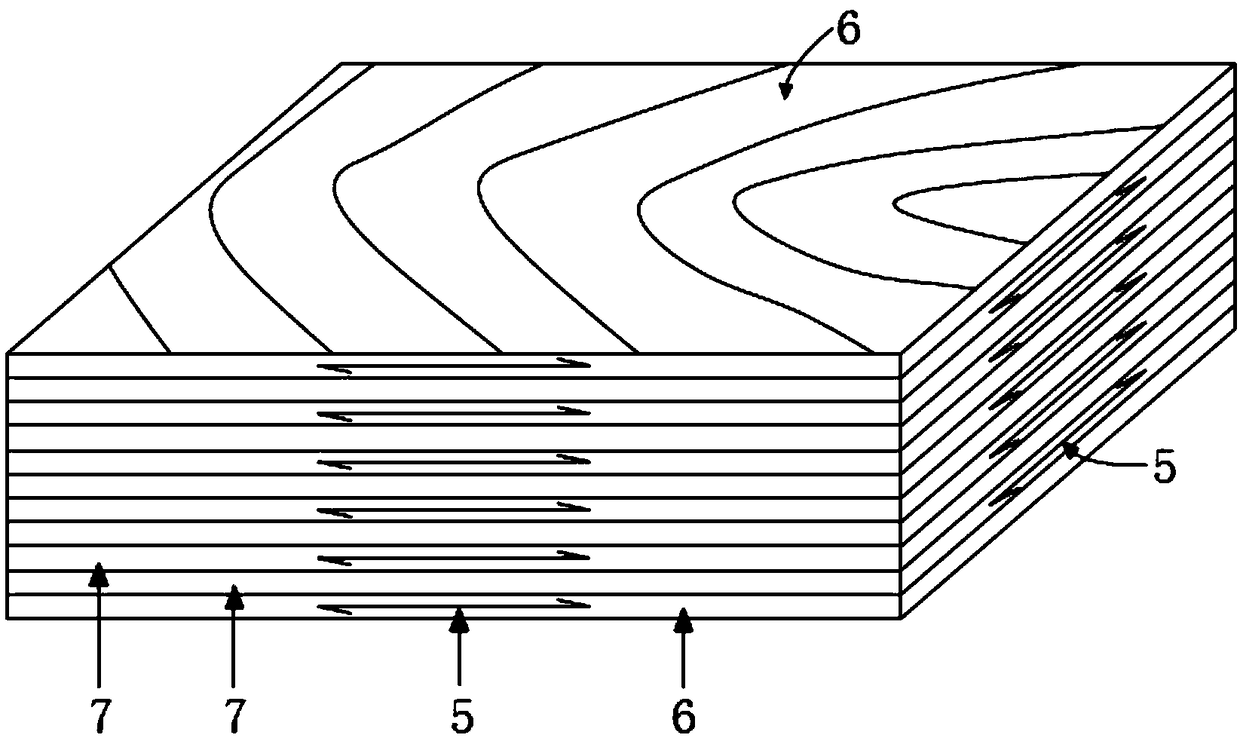

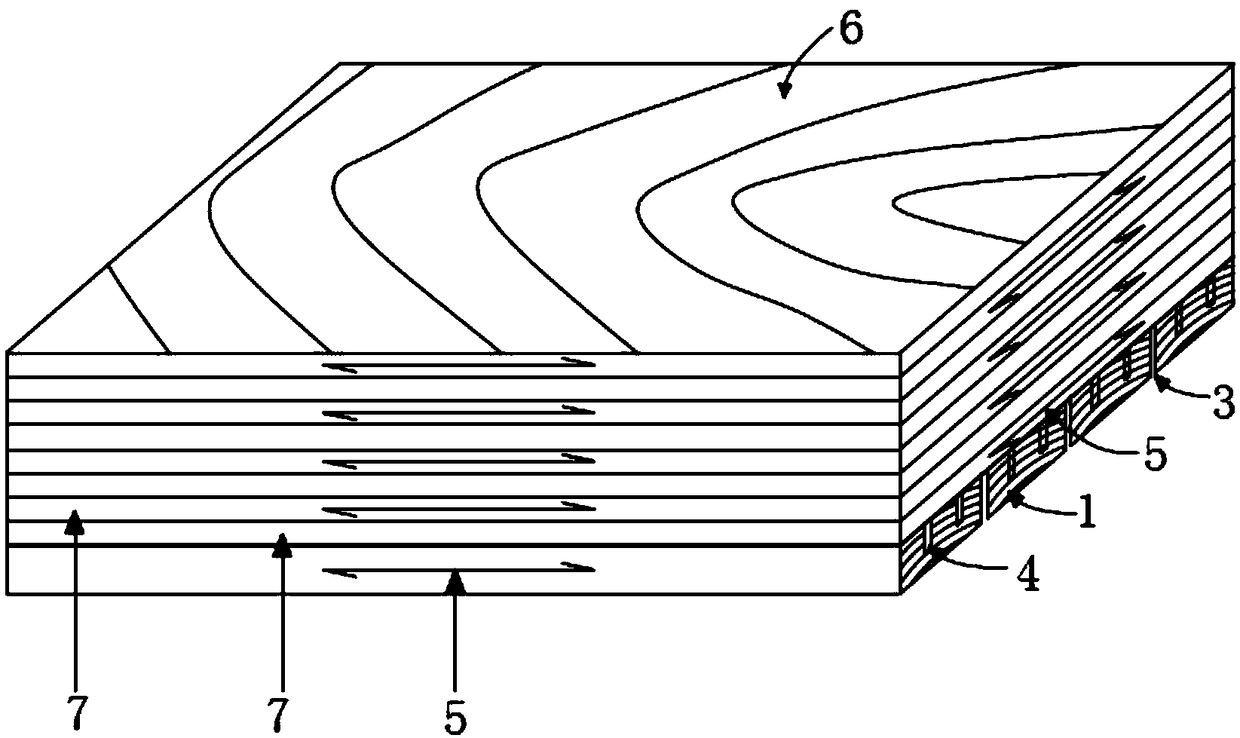

[0072] Such as figure 2 As shown, for the cross-glued timber that combines the material characteristics of fast-growing wood and the requirements of the building structure, all layers of the components are made of fast-growing wood laminates, and the density of the fast-growing wood used is 0.45g / cm 3 , the thickness of the rotary cut layer is 8mm. During the pressurization process of the billet assembly, the pressure is taken as the pressure value corresponding to the total compression ratio of the fast-growing material from the thickness to 6.67%, and the microwave-assisted heating method is used to make the internal temperature of the component reach 50 ℃~60℃.

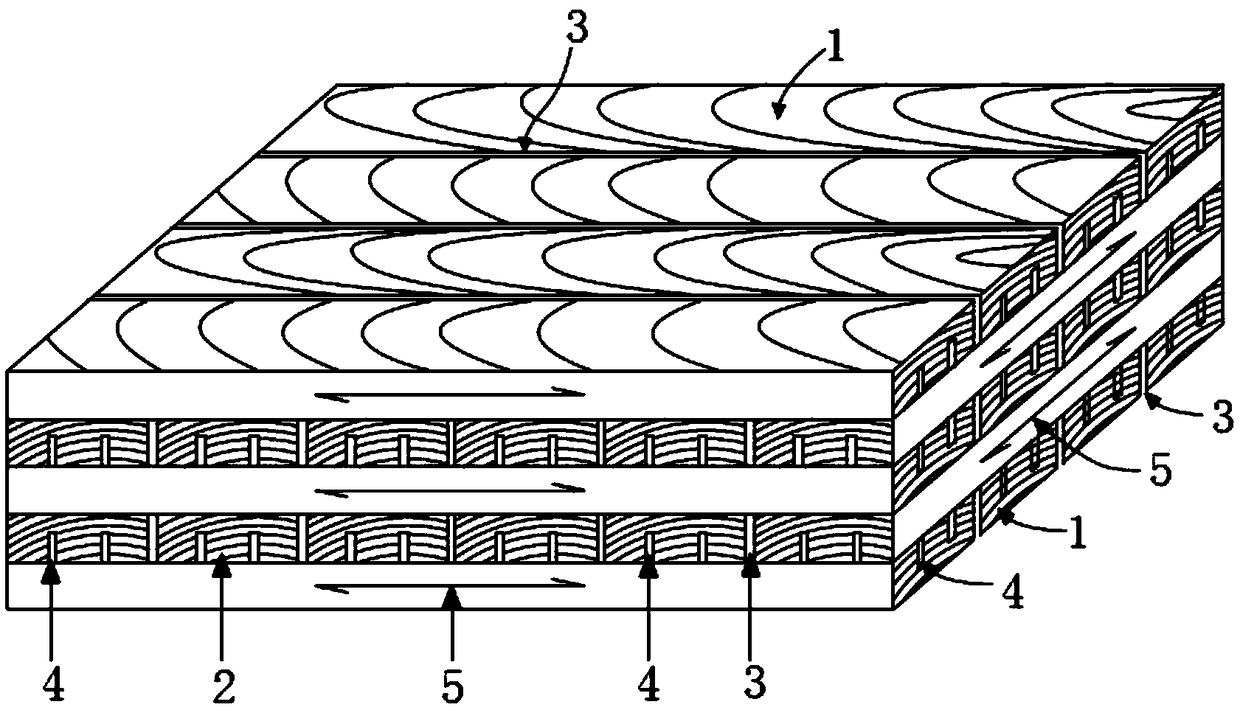

[0073] The cross-glued timber member with a length × width × thickness of 4444mm × 1000mm × 225mm (volume 1.0m 3 ) for comparison, the blank assembly is shown as figure 1 As shown, that is, the adjacent layers composed of gauge lumber 1 for the outermost layer structure and gauge lumber 2 for the inner layer stru...

Embodiment 2

[0076] Such as figure 2 As shown, for the cross-glued timber that combines the material characteristics of fast-growing wood and the requirements of the building structure, all layers of the components are made of fast-growing wood laminates, and the density of the fast-growing wood used is 0.30g / cm 3 , the thickness of the rotary-cut laminate is 15mm. During the pressurization process of the blank assembly, the pressure is taken as the pressure value corresponding to the total compression rate of the fast-growing wood laminate thickness reaching 13.33%, and the pressing is completed at room temperature.

[0077] The cross-glued timber member with a length × width × thickness of 4444mm × 1000mm × 225mm (volume 1.0m 3 ) as an example, taking the standard timber with a thickness of 38mm and a length of not less than 3050mm as an example, the cost of timber is 2500÷60%=4167 yuan / m 3 , the adhesive cost is 6×0.35×60×4.444×(1+10%)=616 yuan / m 3 , the total material cost is 4783 y...

PUM

| Property | Measurement | Unit |

|---|---|---|

| density | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com