Integral prefabricated cross-laminated timber (CLT) wooden plate girder bridge based on steel side stiffening

A prefabricated, steel edge technology, applied to bridges, bridge parts, bridge materials, etc., can solve the problems of wooden bridges being easily corroded by moisture and other natural factors, poor coordination ability, and difficulty in on-site construction, so as to achieve reasonable stress , Solve the effect of poor coordination ability and short construction period

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

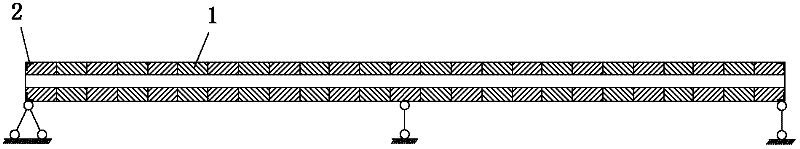

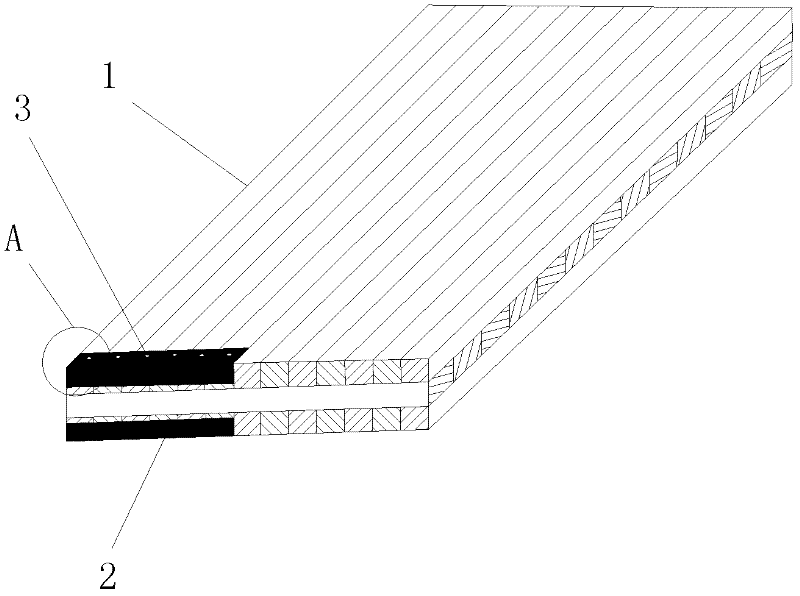

[0032] Such as figure 1 , figure 2 and image 3 As shown, the present invention includes a bridge superstructure and a bridge substructure integrally supporting the bridge superstructure, and the bridge superstructure is made of a plurality of CLT (cross-laminated timber, cross-laminated timber) wooden beams 1 Assembled girder bridge load-bearing girder with girder bridge deck on the upper part, the CLT wooden beam plate 1 is in the shape of a cuboid, and multiple pieces of the CLT wooden beam plate 1 are laid on the same level.

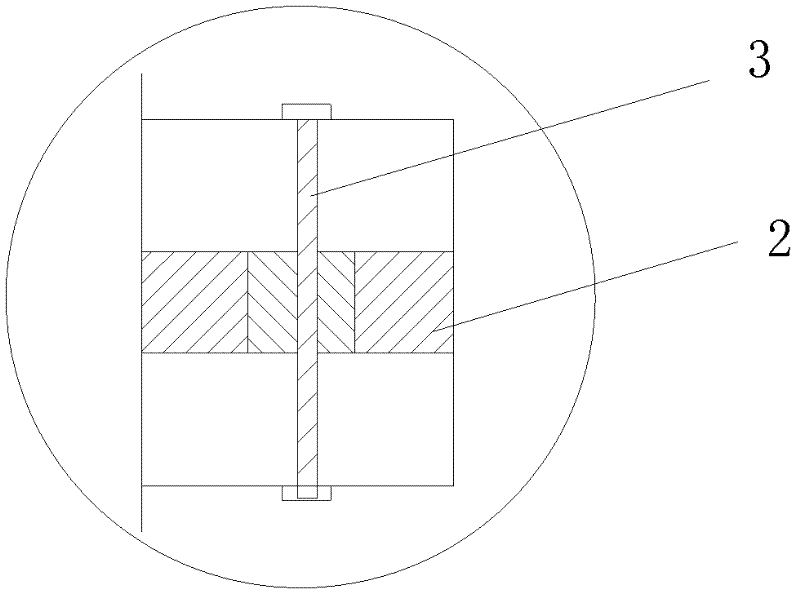

[0033] The CLT wooden beam 1 includes a cuboid-shaped beam structure made of multi-layer wooden laminates glued together, and the fastening buckles are installed on the upper and lower corners of the front and rear ends of the beam structure, and the corners are integrally reinforced The number of the wooden laminates is at least three layers, and the wooden laminates of multiple layers are stacked together from top to bottom, and the wooden lamin...

Embodiment 2

[0041] In this embodiment, the difference from Embodiment 1 is that in this embodiment, the number of multi-layer wooden laminates in the CLT wooden beam 1 is four layers, and the CLT wooden beam 1 is a four-layer structure CLT The wooden beam 1, all the square timbers in the adjacent two layers of wooden laminates (that is, the second and third wooden laminates from top to bottom) located in the middle of the CLT wooden beam 1 are arranged in parallel, and the upper beam All the square timbers in the adjacent two layers of wooden laminates (that is, the first and second wooden laminates from top to bottom) are arranged orthogonally, and the lower beams (that is, the third and fourth floors from top to bottom) All the square timbers in the adjacent two-layer wooden laminates in one layer of wooden laminates are arranged orthogonally. In this embodiment, the structure, installation method and installation process of the remaining parts are the same as those in Embodiment 1.

Embodiment 3

[0043] In this embodiment, the difference from Embodiment 1 is that in this embodiment, the number of multi-layer wooden laminates in the CLT wooden beam plate 1 is five layers, and the CLT wooden beam plate 1 is a five-layer structure CLT In the wooden beam slab 1, all the square timbers in the two adjacent wooden laminates are arranged orthogonally. In this embodiment, the structure, installation method and installation process of the remaining parts are the same as those in Embodiment 1.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com