Cross-laminated plate manufactured on basis of dowel rotary friction welding technology

A technology of rotational friction welding and cross-layer, which is applied in the field of cross-laminated boards, can solve problems such as the environmental impact of adhesives and nails, and achieve the effect of improving utilization

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

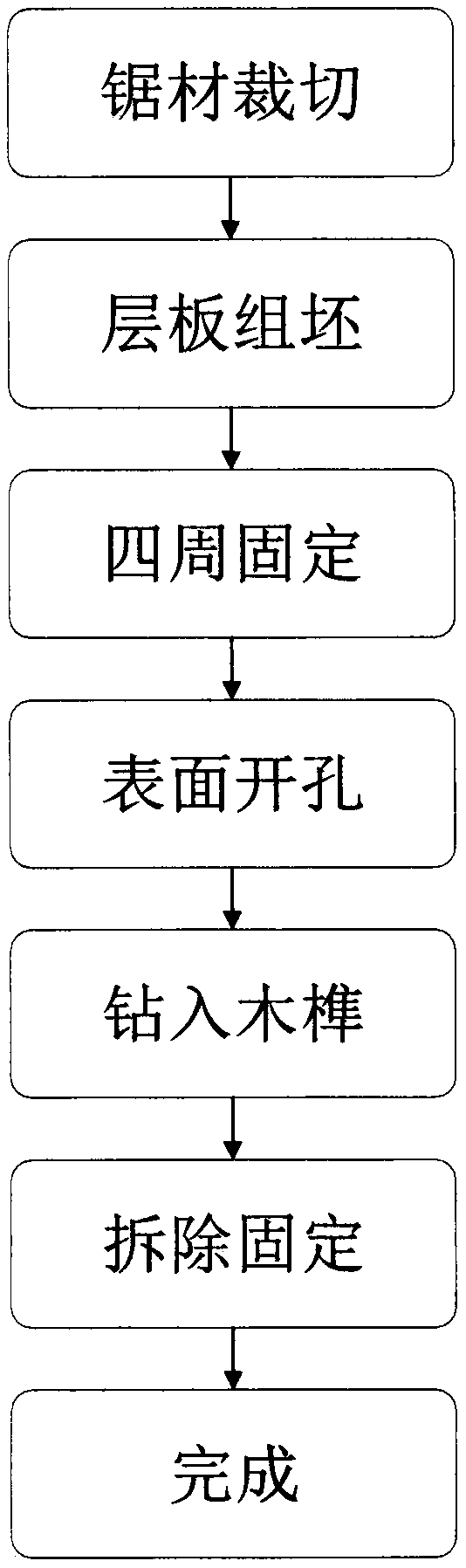

[0020] In order to have a clearer understanding of the technical features, purposes and effects of the present invention, now refer to the attached figure 1 Specific embodiments of the present invention will be described. A cross-laminated board prepared based on tenon rotary friction welding technology, characterized in that the cut longitudinal laminate 1 and the transverse laminate 2 are assembled at a certain angle, and then the surrounding is fixed with a template, and the Drill holes on the surface of the board at a certain interval and at a certain angle, drill the wooden tenons 3 fixed on the drill bit into the holes, and remove the template after all the holes are drilled into the wooden tenons 3 and the redundant wooden tenons 3 are cut off. Include the following steps:

[0021] 1) Sawn timber cutting: the size of the pre-designed cross-laminated board is 2.4m×4.8m, the thickness of the longitudinal laminate 1 and the transverse laminate 2 are both 20mm, the number ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com