Fire-proof laminated wood frame system based on recycled concrete and construction method thereof

A technology for recycled concrete and frame systems, applied in fire prevention, special structures, building components, etc., can solve problems such as fire resistance and fire safety problems of wood structures, achieve easy assembly construction, ensure lateral resistance, and improve construction speed. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0045] The present invention will be described in detail below in conjunction with the accompanying drawings and specific embodiments. This embodiment is carried out on the premise of the technical solution of the present invention, and detailed implementation and specific operation process are given, but the protection scope of the present invention is not limited to the following embodiments.

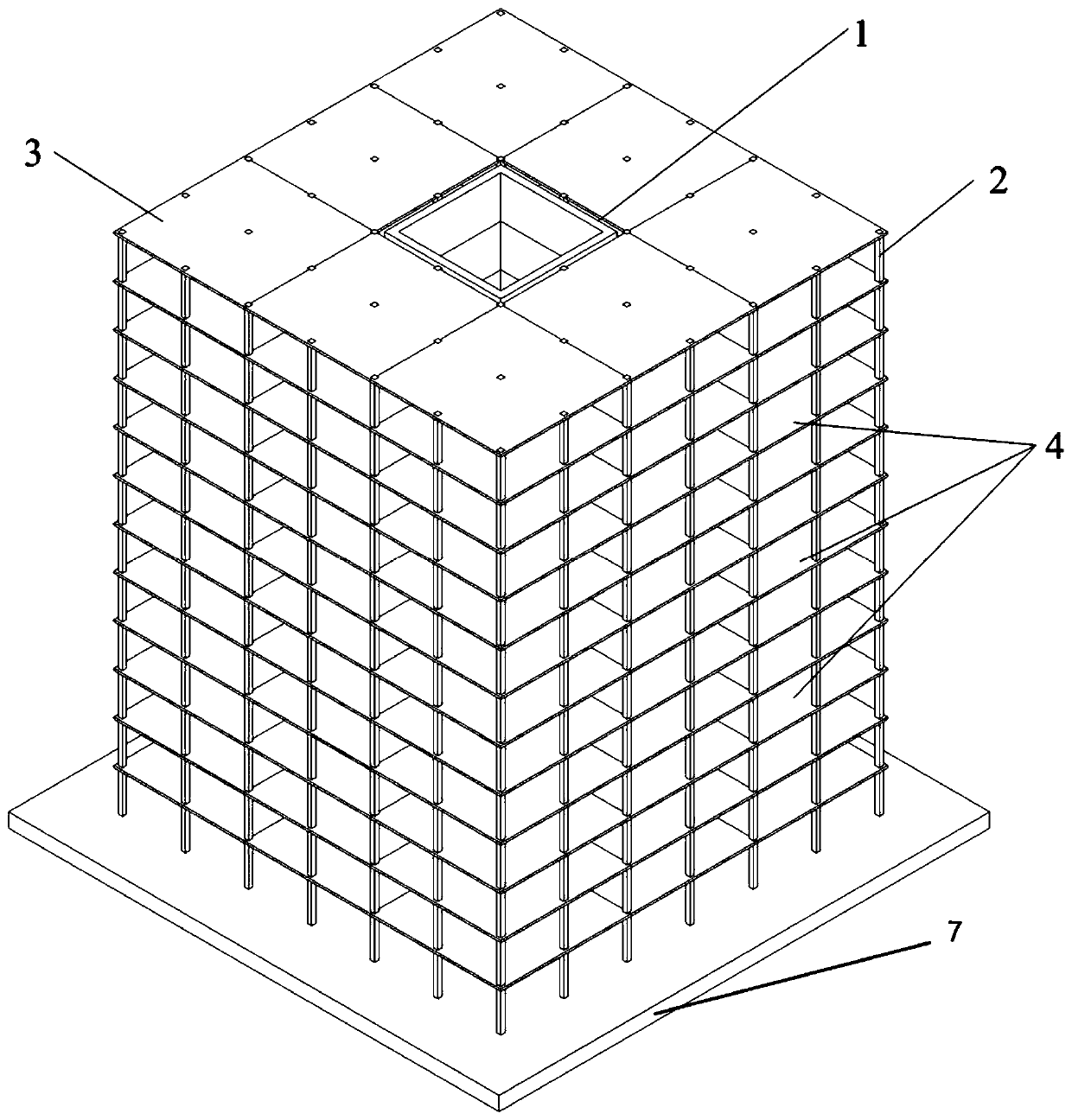

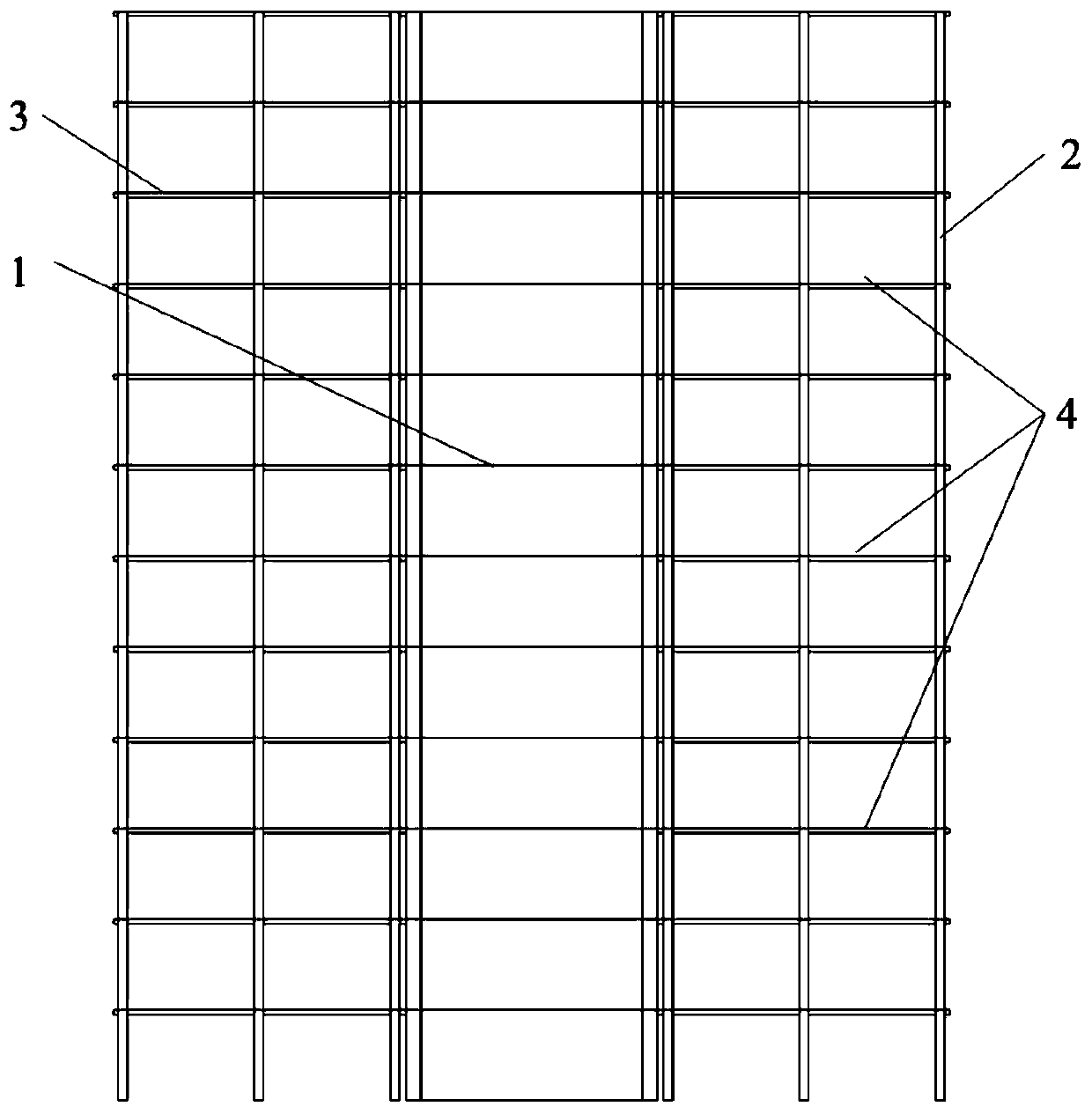

[0046] The invention provides a refractory glued wood frame system based on recycled concrete, which combines recycled concrete floor slabs with bakelite structures, and the completed wood frame system is as follows: figure 1 As shown, its side view is shown as figure 2 shown.

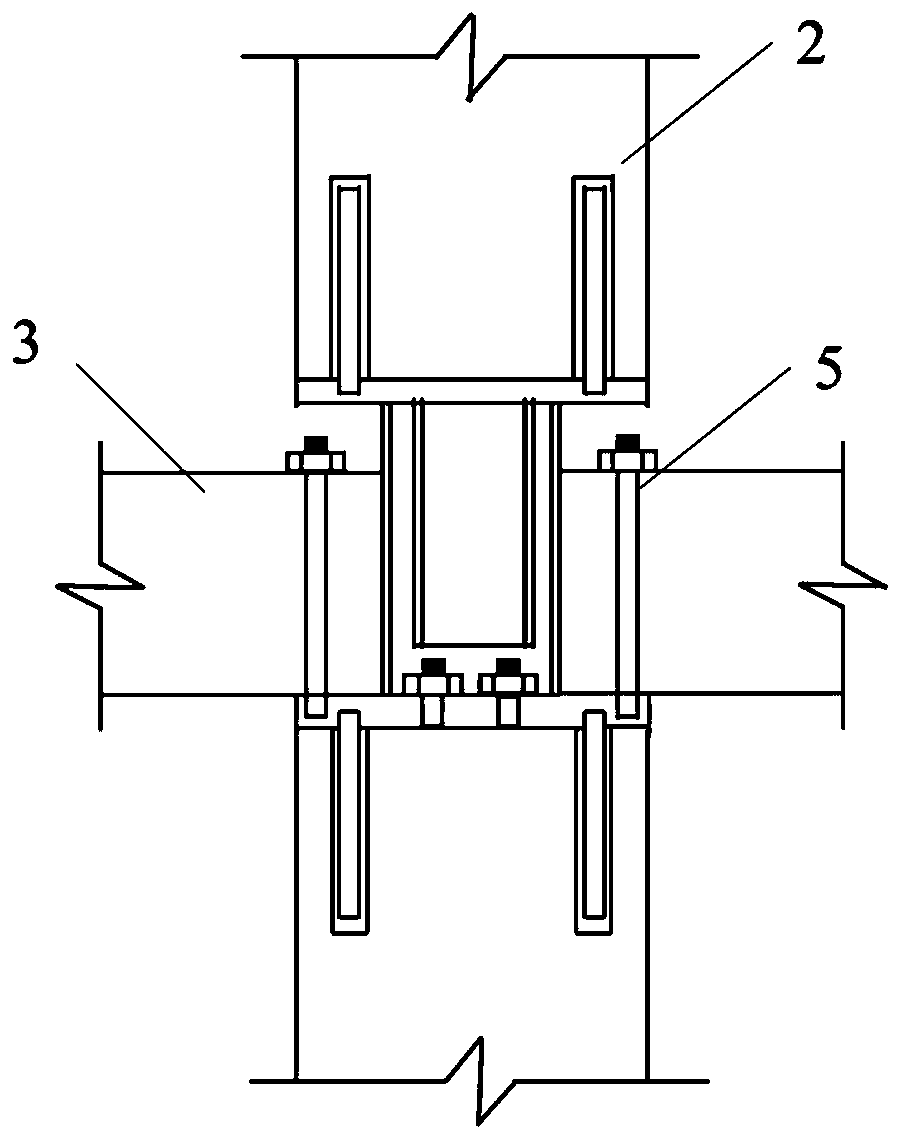

[0047] Such as figure 1 As shown, the glulam frame system is a multi-layer structure, set on the foundation 7, including core tube 1, glulam columns 2, CLT (Cross Laminated Timber) floor slab 3 and recycled concrete floor slab 4, multiple CLT floor slabs 3 are closely spliced A CLT floor is formed, and a p...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com