Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

33 results about "Aviation medicine" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Aviation medicine, also called flight medicine or aerospace medicine, is a preventive or occupational medicine in which the patients/subjects are pilots, aircrews, or astronauts. The specialty strives to treat or prevent conditions to which aircrews are particularly susceptible, applies medical knowledge to the human factors in aviation and is thus a critical component of aviation safety. A military practitioner of aviation medicine may be called a flight surgeon and a civilian practitioner is an aviation medical examiner. One of the biggest differences between the military and civilian flight doctors is the military flight surgeon's requirement to log flight hours.

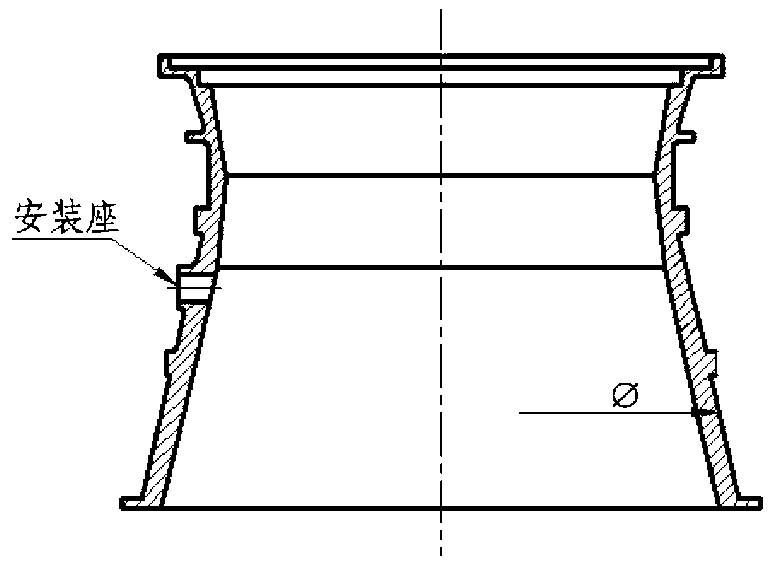

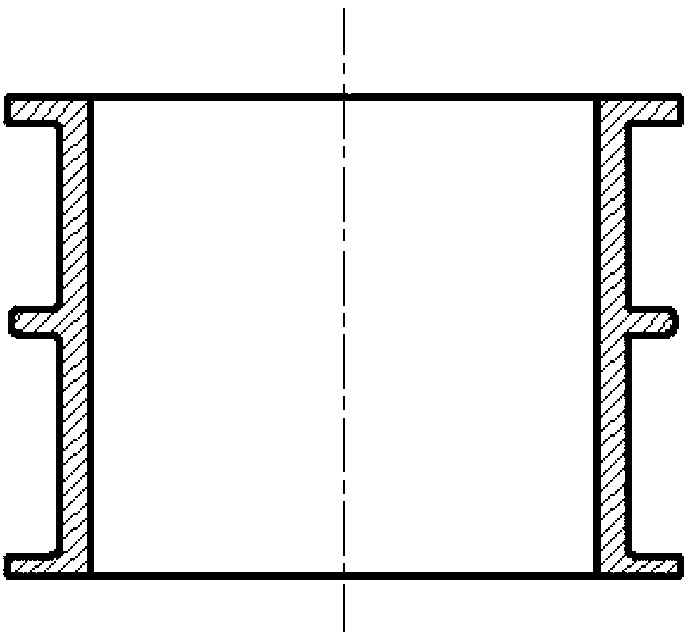

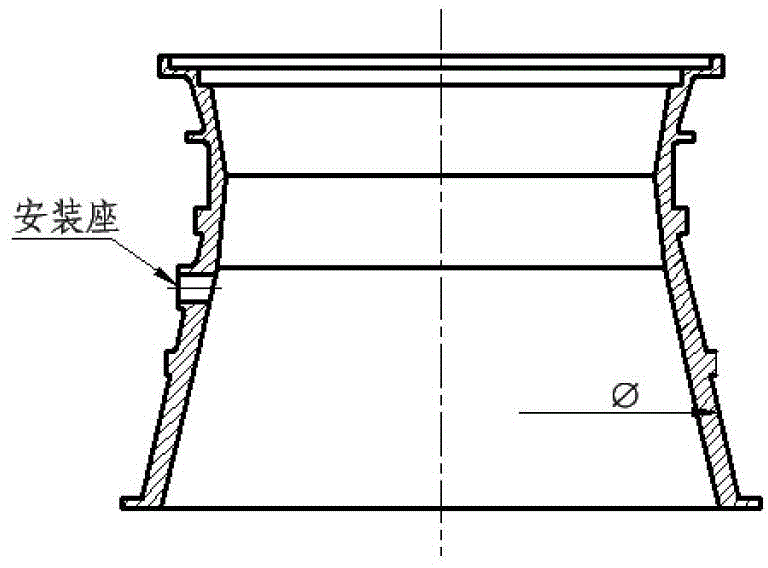

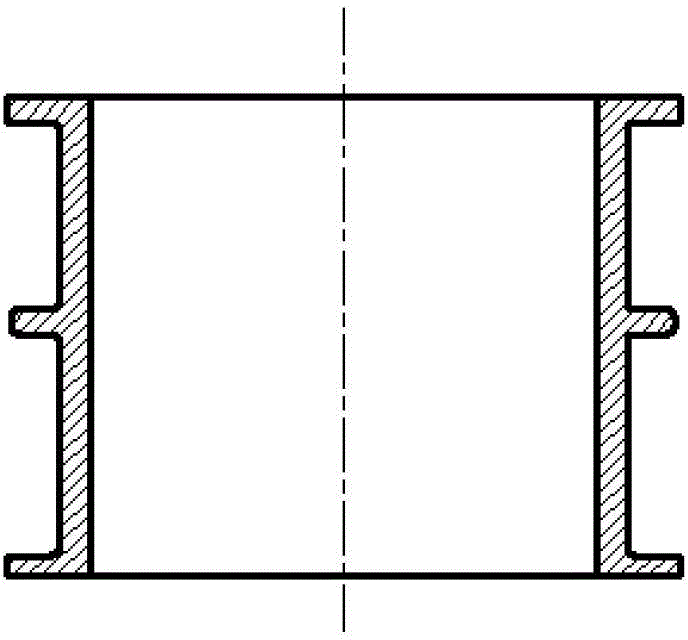

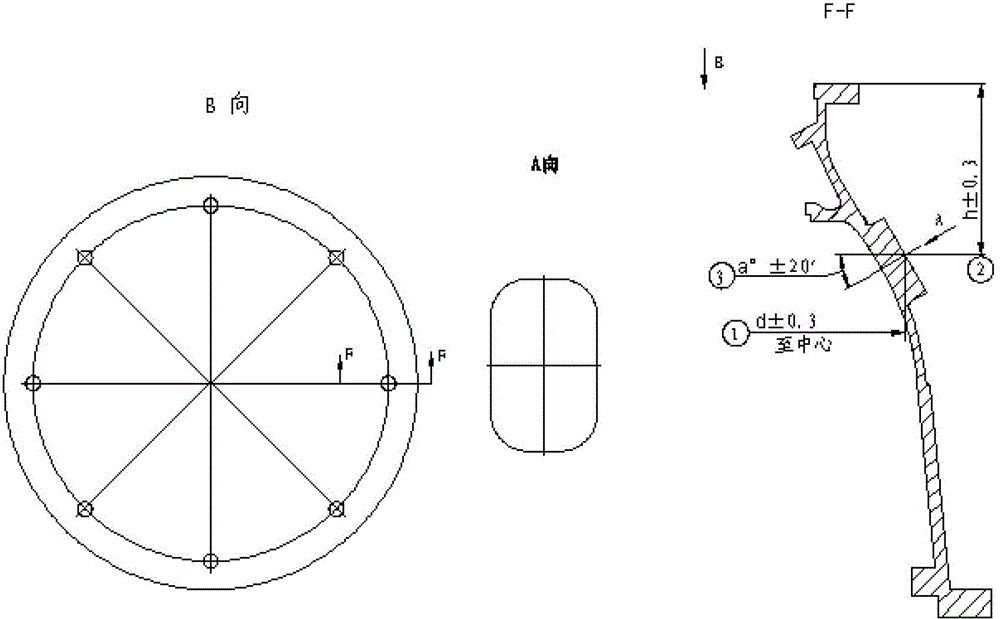

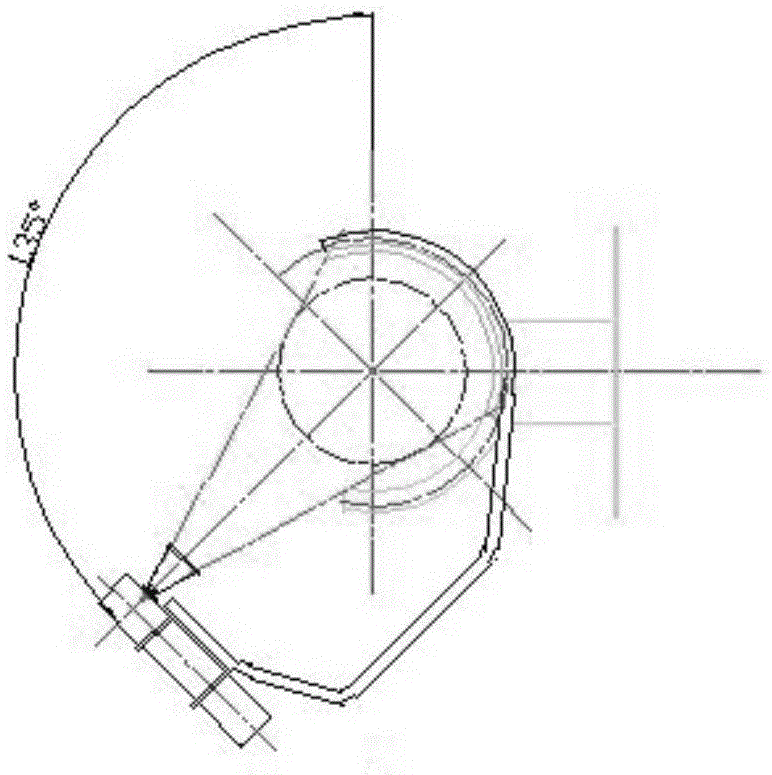

Method for detecting diameter of outer wall of tapered case of aviation engine on line

InactiveCN102927952AGuaranteed accuracyReduce manufacturing costMeasurement devicesNumerical controlAviation

The invention discloses a method for detecting the diameter of an outer wall of a tapered case of an aviation engine on line. According to the method, a five-coordinate numerical control milling center with a Renishaw MP10 trigger-type measuring head is equipped, tapered case parts and a mounting seat on the surface of a tapered case are equipped; a fine adjustment ring gauge of the used measuring head is measured on line; a point contact-type measurement mode is adopted; a machine tool siemens control system Sinumeric 840 D on-line measurement technology is adopted; and an on-line measurement quick tool path amendment and error compensation generation technology is adopted. The method has a broad application prospect; and by the on-line measurement technology, a numerically-controlled machine tool is impelled to form a machining and detecting integrated numerical control machining unit. By the method, the traditional manufacturing mode that a design characteristic is equipped with a set of measurement tool in the current industry is changed, the manufacturing cost of the tool is saved, repair labor-hour is saved, and first-pass yield of product processing is improved, so that the development period and the production cost of new products are reduced.

Owner:SHENYANG LIMING AERO-ENGINE GROUP CORPORATION

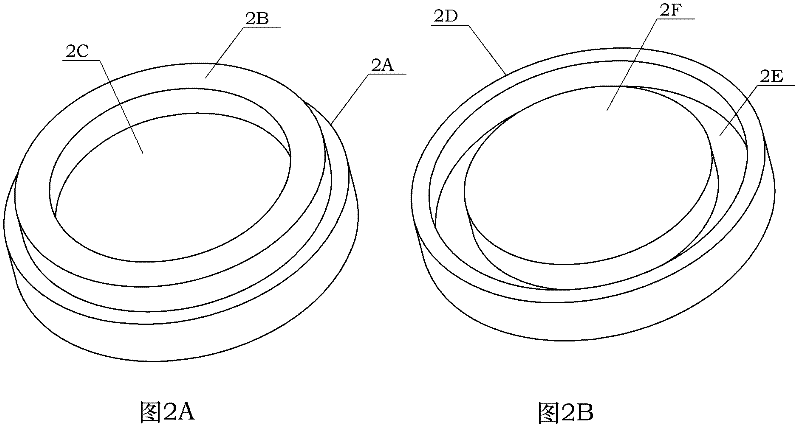

Method for manufacturing damping structural piece of aviation engine supporting system

InactiveCN102644686AWith shape memoryBoth featuresHigh internal friction springsAviationMetal rubber

The invention discloses a method for manufacturing a damping structural piece of an aviation engine supporting system; a shape memorizing alloy wire is manufactured into metal rubber through the combined processes of manufacturing an elastic wire at low temperature, heat setting, winding and full-constraint heat setting; and the damping structural piece which is manufactured through the method has a shape memorizing effect and a variable rigidity characteristic. According to the method for manufacturing the damping structural piece of the aviation engine supporting system, a damping material in the metal rubber structure is integrated with a shape memorizing alloy, and a novel metal structural functional material with the advantages of the metal rubber and the shape memorizing alloy is developed. The material has good damping performance, high deformation capability and high bearing capability, and has the advantages of active and controllable elastic modulus, strong environment adaptability and stable and reliable structure. Because the advantages of the metal rubber and the shape memorizing alloy are integrated, the method can be applied in aviation engine rotor supporting and a non-peak rotor can be realized.

Owner:BEIHANG UNIV

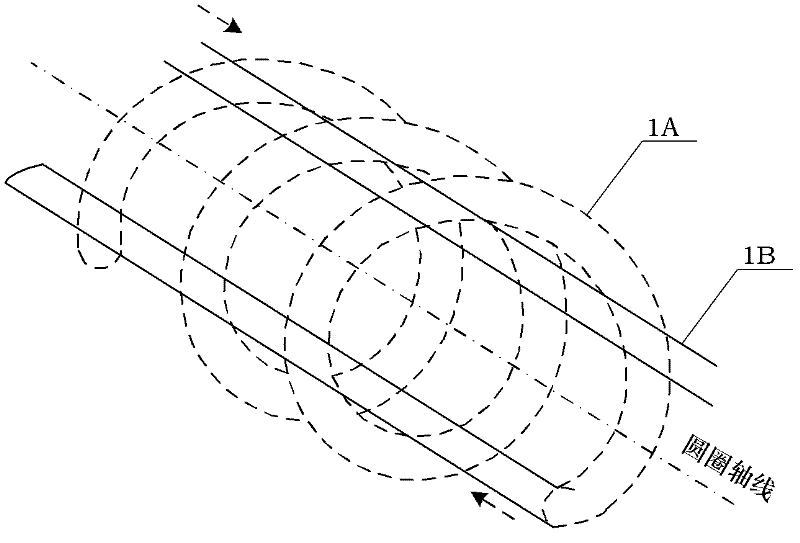

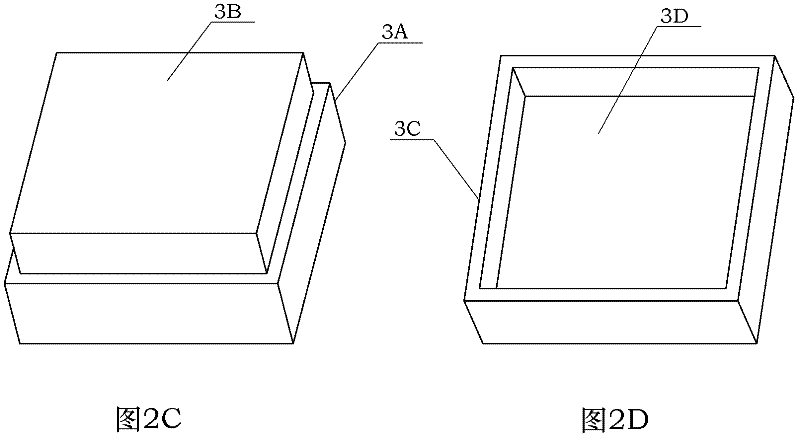

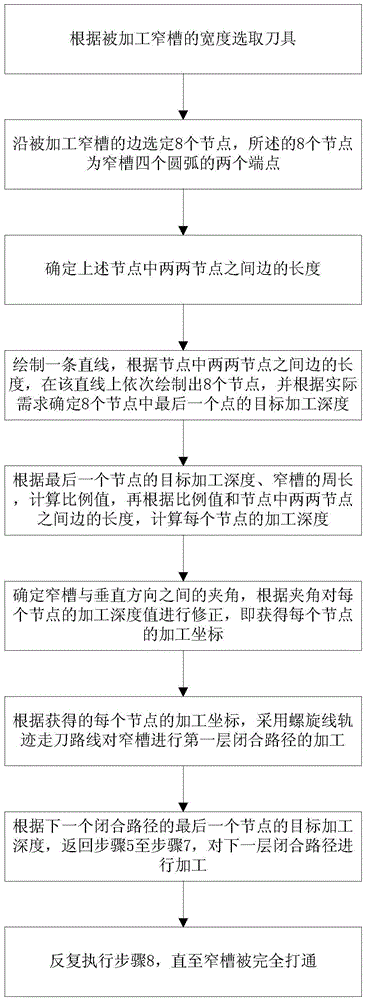

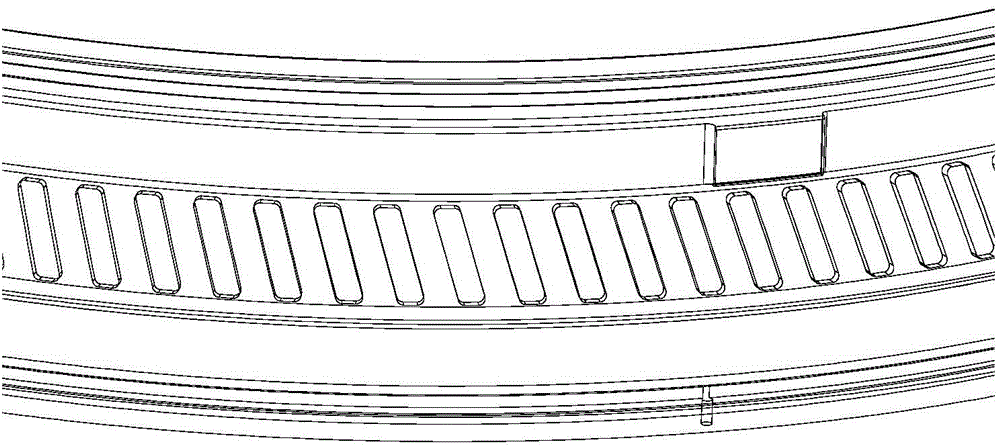

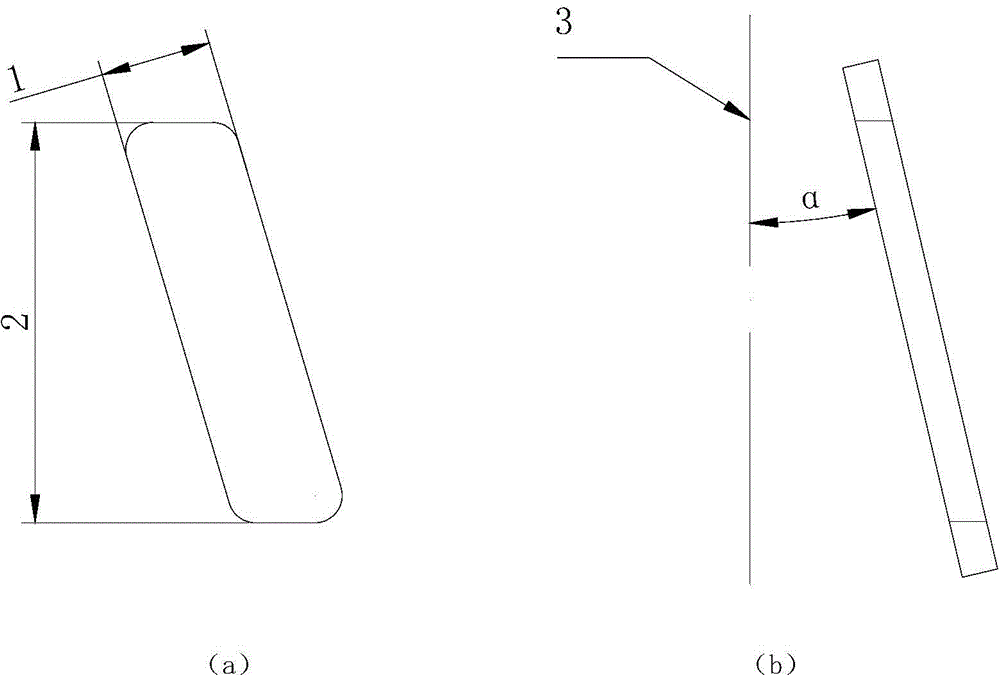

Processing method for annular type engine-case radial narrow groove

ActiveCN104475843AImprove efficiency and reduce costsGive full play to the machinabilityMilling equipment detailsHelical lineAviation

The invention discloses a processing method for annular type engine-case radial narrow groove, and belongs to the field of machinery manufacture. In consideration of the integral rigidity of a part, the method employs a layered progressive helix-track one-time milling mode for realizing small cutting depth and high feeding, fully gives play to the cutting performance of a cutter, improves the processing efficiency, guarantees the processing dimension, and successively solves the problems that numerical-control milling processing of the annular type engine-case radial narrow groove is low in efficiency and not high in quality. Also the method is applicable to processing of narrow grooves with any shapes. Along with application of the technology to annular type engine-case parts, the processing method determined by the technology possesses guidance meaning, and provides good establishment for accelerating research progress of novel aviation engines and reducing research cost. From another point of view, the method creates relatively large value for improving efficiency, reducing cost and improving quality of aviation engines in the future and being applied to large-batch production.

Owner:SHENYANG LIMING AERO-ENGINE GROUP CORPORATION

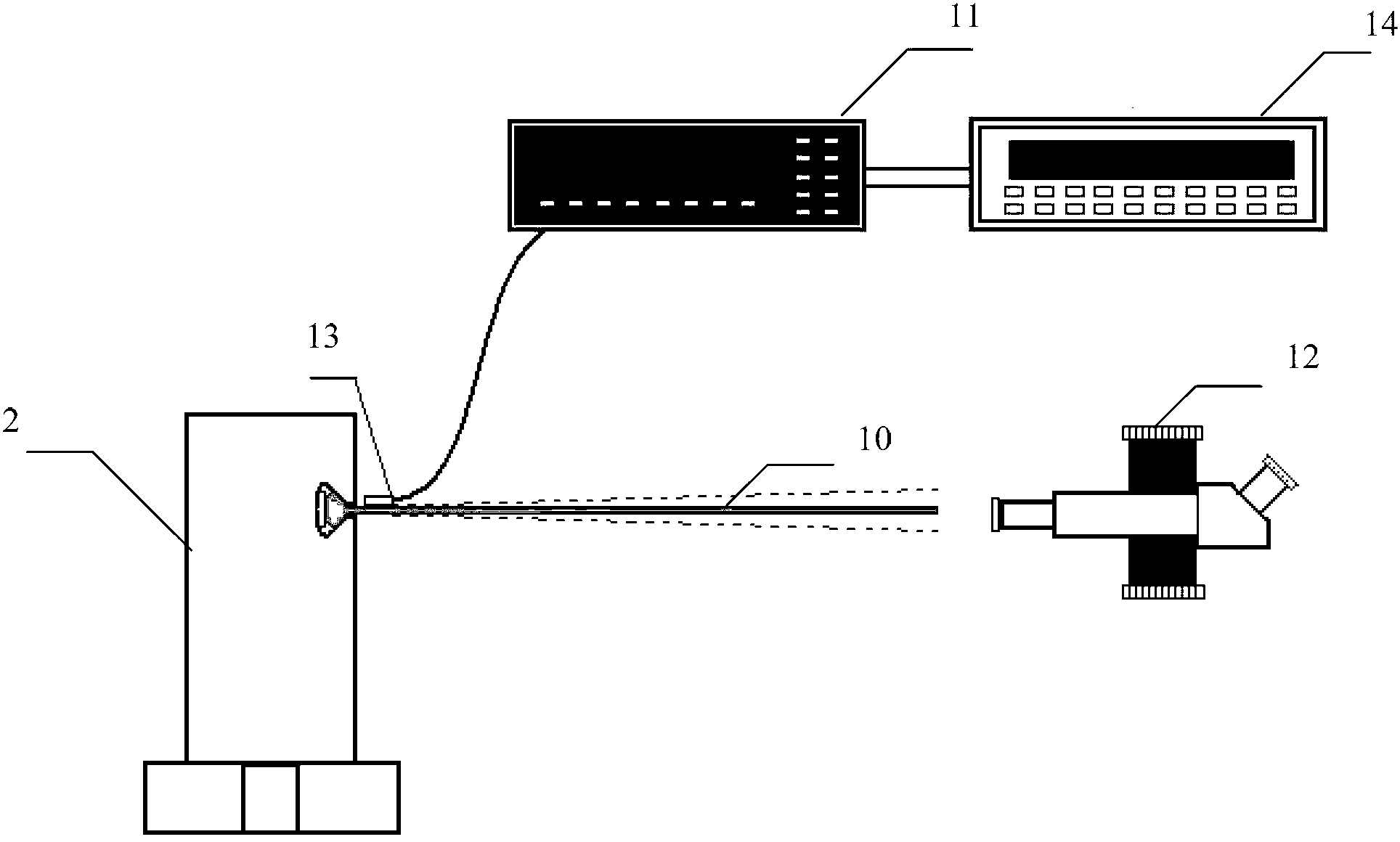

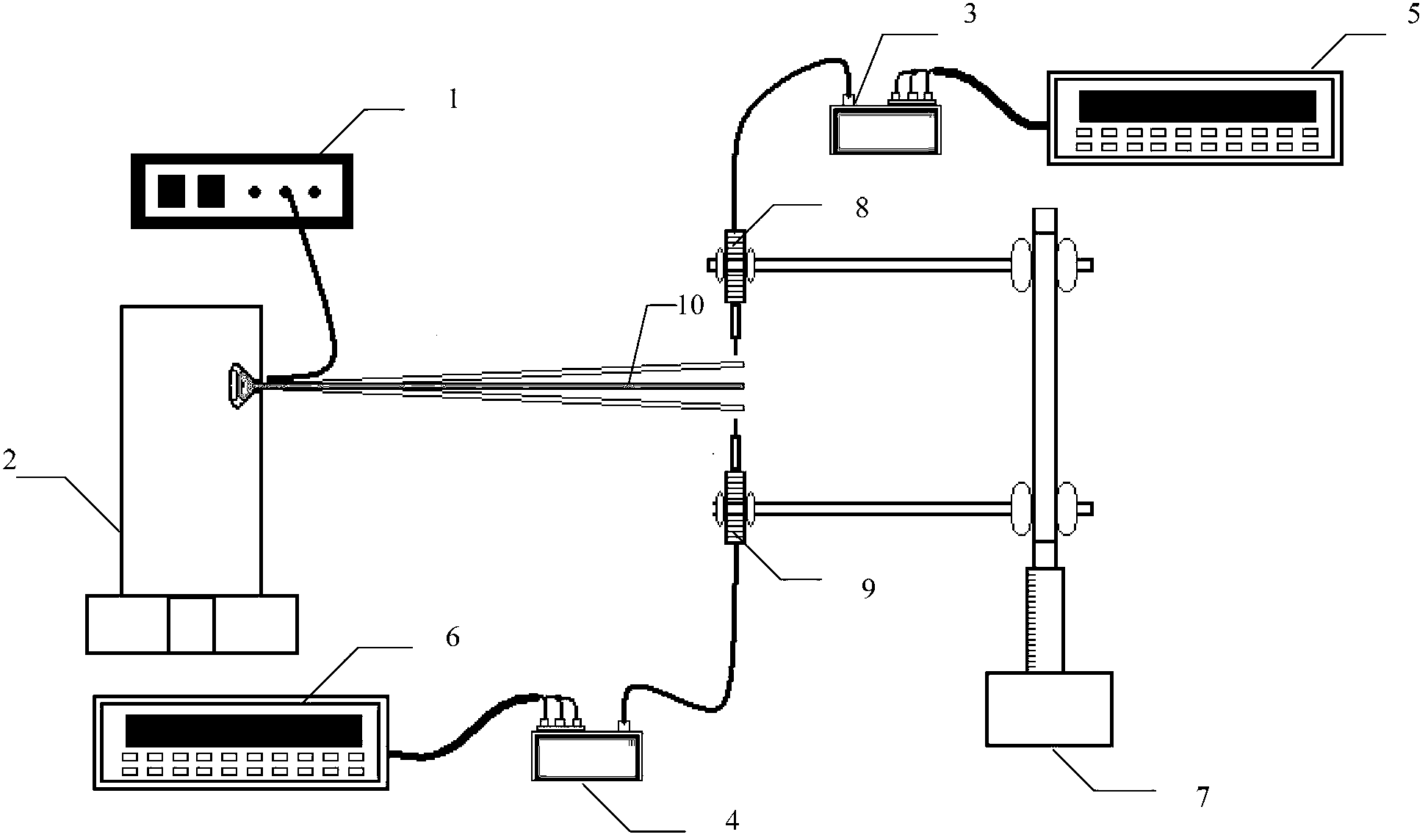

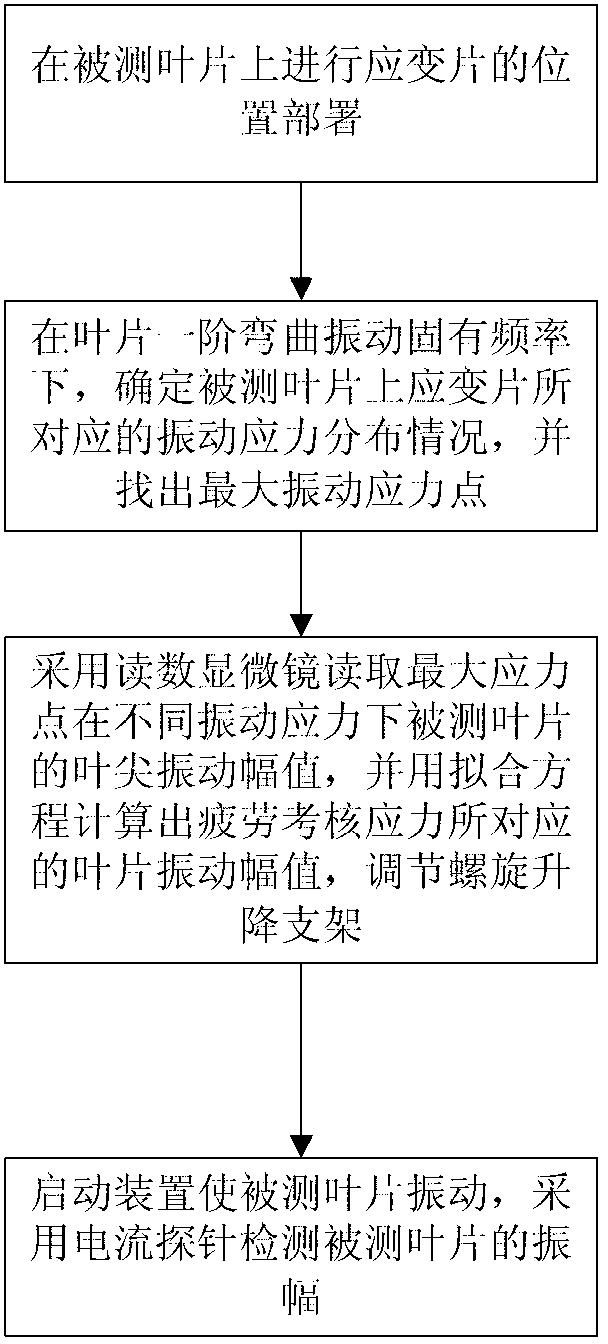

Detection device and detection method for wide-range vibration amplitude of blade of aviation engine

InactiveCN102840968ASolve the problem of difficult vibration amplitude monitoringExpansion of Vibration Stress Testing TechnologyMachine part testingSubsonic/sonic/ultrasonic wave measurementAviationVibration amplitude

The invention provides a detection device and a detection method for wide-range vibration amplitude of a blade of an aviation engine. The detection device comprises a power supply, a fixture, bridge circuit boxes, millivoltmeters, a reading microscope, a spiral lifting support and current probes, wherein two transverse fixing supports for fixing the current probes are arranged on the spiral lifting support. An output end of a first current probe is connected with an input end of a first bridge circuit box. An output end of the first bridge circuit box is connected with an input end of a first millivoltmeter. An output end of a second current probe is connected with an input end of a second bridge circuit box. An output end of the second circuit box is connected with an input end of a second millivoltmeter. The power supply is connected with a detected blade which is fixed on the fixture. The detection device and the detection method solve the problem of difficult monitoring of the wide-range vibration amplitude in a blade fatigue test, provide a completely novel test method for monitoring technology of blade and blade tip vibration amplitude in the vibration fatigue test, and expand test technology of vibration stress in the blade fatigue test.

Owner:SHENYANG LIMING AERO-ENGINE GROUP CORPORATION

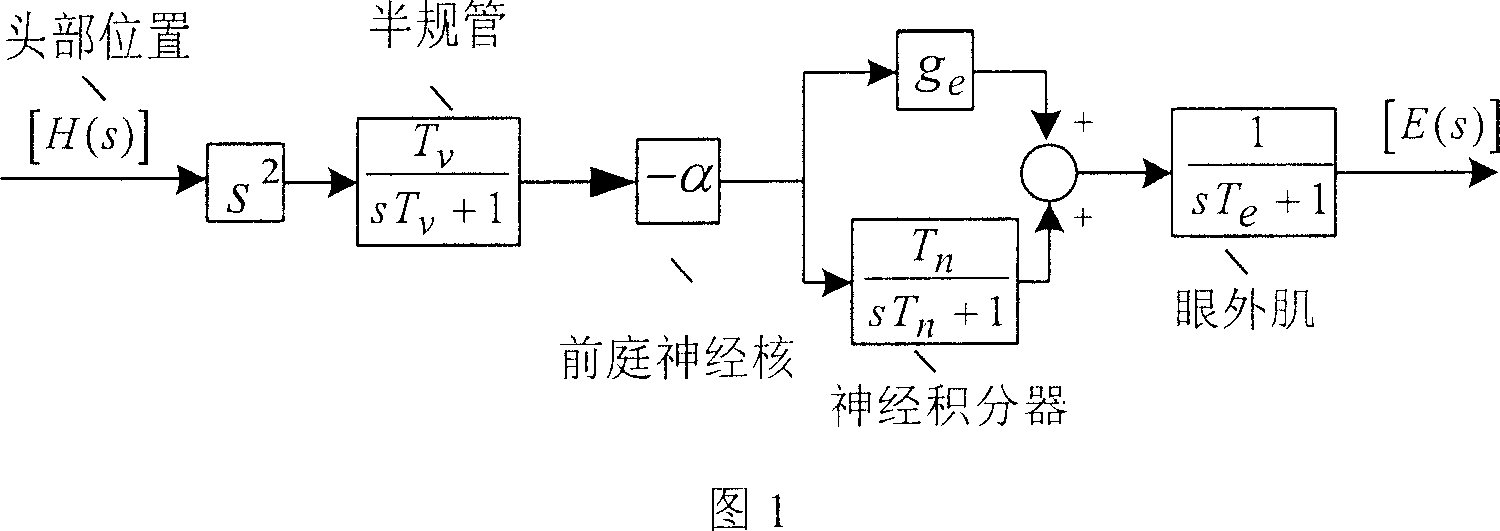

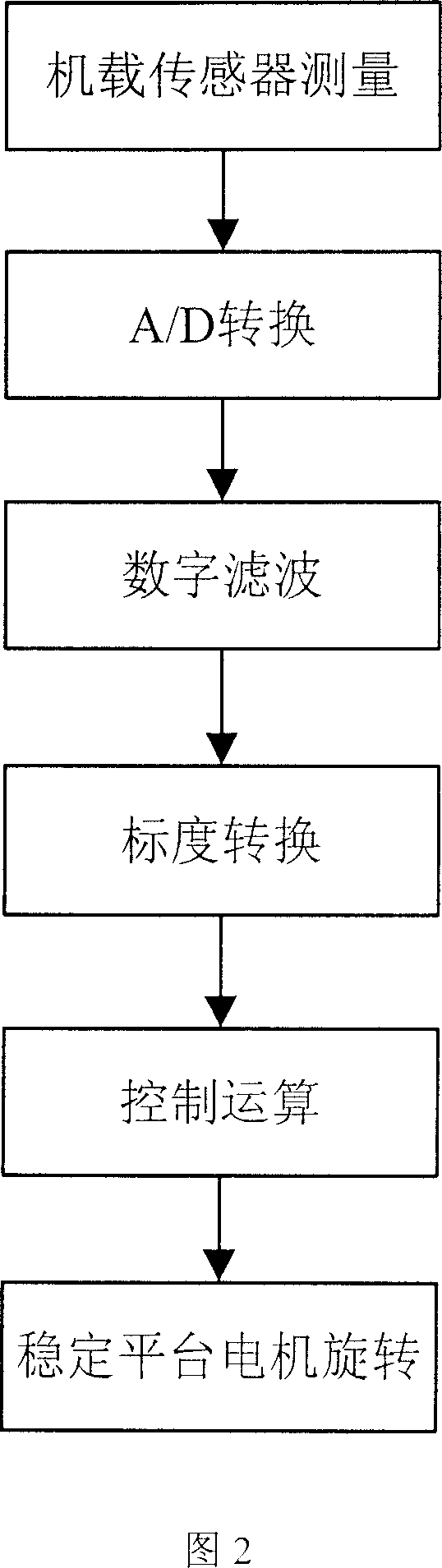

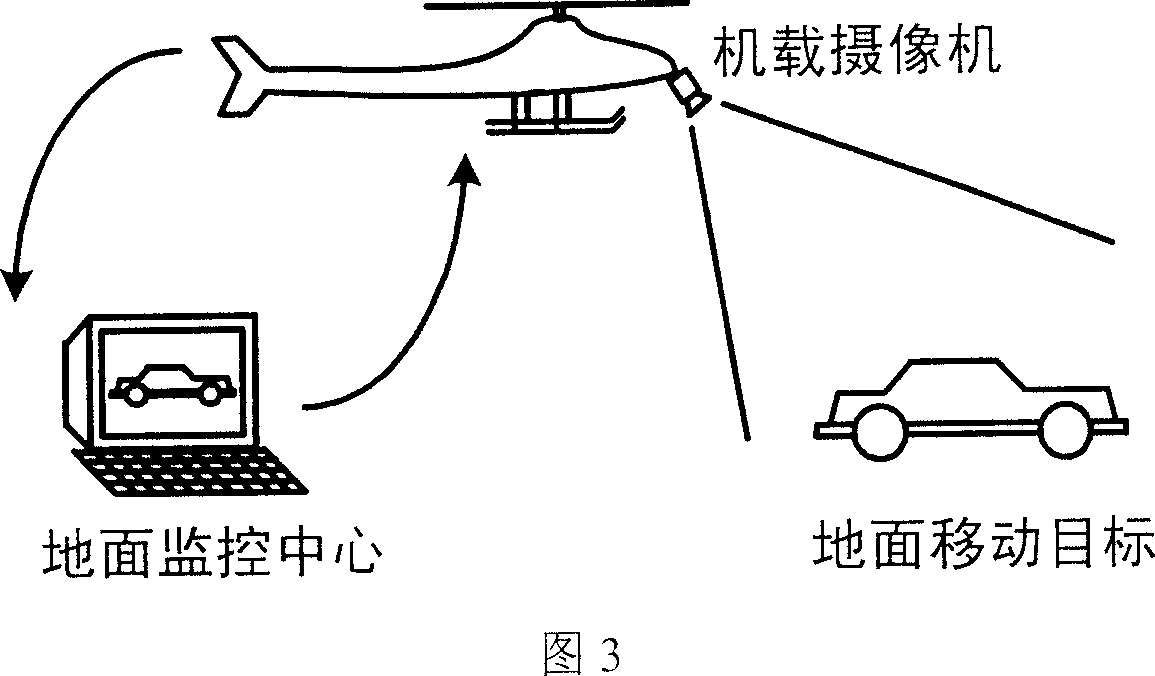

Stable control method for vestibular oculomotor reflection based aviation detection platform

InactiveCN1924736AKeep a fixed directionSimple methodProgramme controlComputer controlAviationControl signal

This invention relates to aviation scout plane stable control method based on vestibular oculomotor reflex, which adopts human eye control system mathematical module and comprises the following steps: sensor measuring rotation parameters of aviation direction, forward and turning through A / D conversion, digital filter, standard conversion and control desk by control signal to drive scout platform motor rotation. The single machine can receive sensor data for simple computation to control scout plate at certain speed and angle to compensate aviation pose change and to keep the platform in fix direction.

Owner:SHANGHAI UNIV

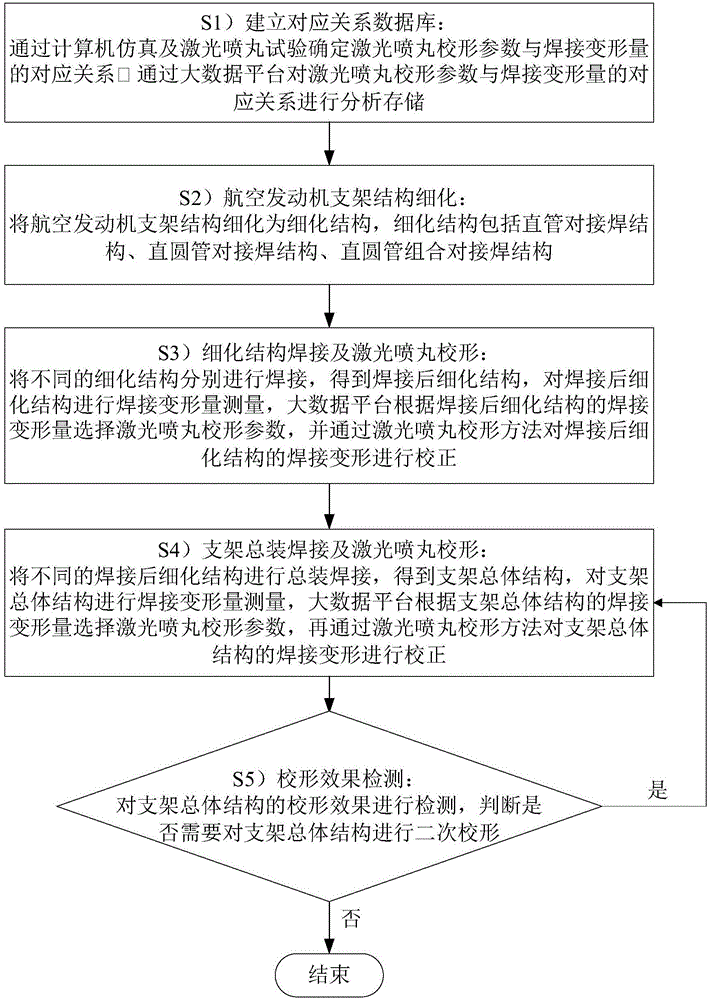

Method for controlling laser shot peening shape correction quality for aviation engine supports

ActiveCN106041344ASolve the deformationAccurate control of dimensional accuracyLaser beam welding apparatusAviationRelational database

The invention discloses a method for controlling the laser shot peening shape correction quality for aviation engine supports. The method includes steps of creating corresponding relational databases of laser shot peening shape correction parameters and welding deformation amounts by the aid of big data platforms; refining structures of the aviation engine supports; welding the refined structures and correcting the shapes of the refined structures by means of laser shot peening; welding support assemblies and correcting the shapes of the support assemblies by means of laser shot peening; detecting shape correction effects. According to the scheme, the method has the advantages that the complicated aviation engine supports are refined to obtain three types of simple refined structures, and processing sequences of progressive welding, progressive laser shot peening shape correcting, assembly welding and assembly laser shot peening shape correcting are adopted, the shapes of the various refined structures are corrected by means of laser shot peening before the assemblies are welded, accordingly, welding deformation of overall structures of the supports can be reduced, and the overall structures of the supports are easy to correct during laser shot peening shape correction; the problem of deformation of existing aviation engine supports in welding procedures can be solved by the aid of the method, the dimension precision and the shape precision of the supports can be accurately controlled by the aid of the method, and good correction effects can be realized.

Owner:GUANGDONG UNIV OF TECH

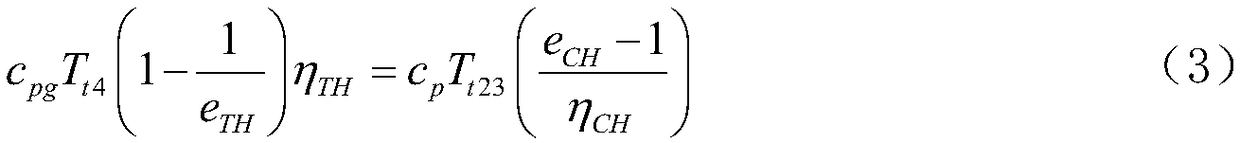

Method for obtaining control value of temperature behind turbine of aviation engine at high altitude and high speed

InactiveCN108457750AExcellent calculation resultSimple methodData processing applicationsTurbine/propulsion engine coolingAviationTemperature control

The invention relates to a method for obtaining control value of temperature behind a turbine of an aviation engine at high altitude and high speed. The method comprises the following steps of (1) screening several parameters which are mostly related with the engine efficiency from an engine logbook; (2) on the basis of using the known control values of the temperature behind the turbines of morethan hundreds of engines at high altitude and high speed as a training set, establishing a nervous network, using the selected parameters as input nodes, and using the control value of the temperaturebehind the turbine as the target value to train; after training, obtaining a nervous network model for calculating the control value of the temperature behind the turbine of the aviation engine at high altitude and high speed.

Owner:CHINA HANGFA GUIZHOU LIYANG AVIATION POWER CO LTD

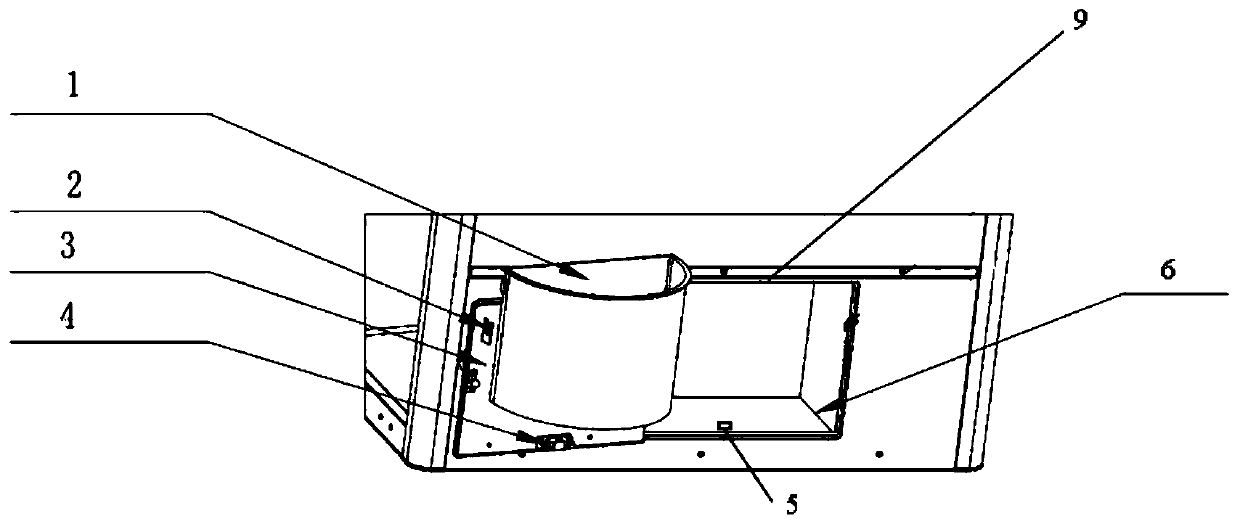

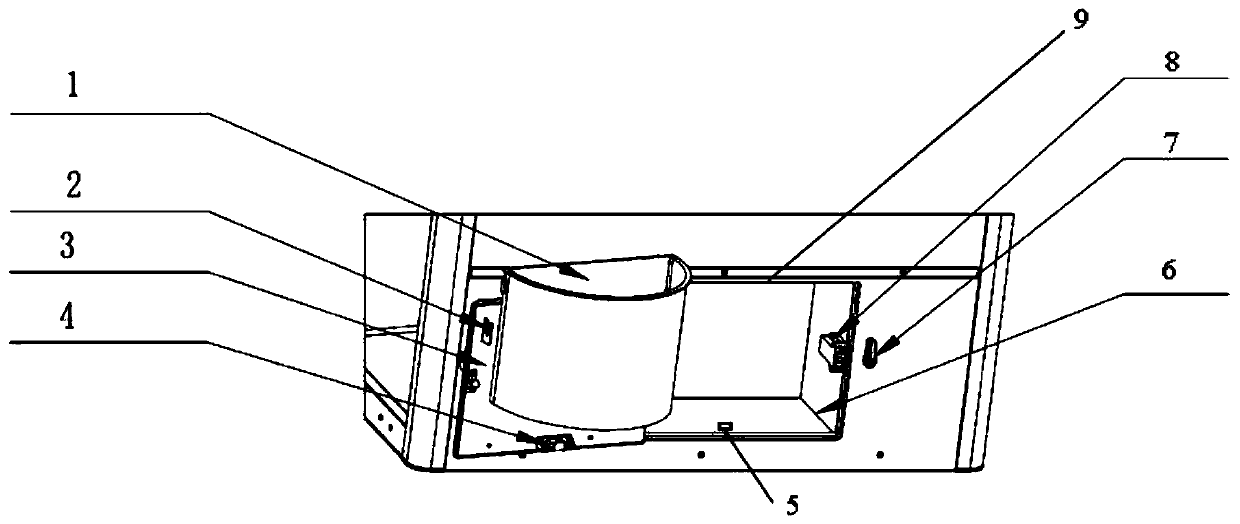

Aviation-simulated rapid decompression chamber

InactiveCN103241395AReduce or avoid damageReduce or avoid casualtiesCosmonautic condition simulationsExperimental researchElectricity

The invention belongs to the technical field of pressure chamber structures, and relates to a decompression chamber, in particular to an aviation-simulated rapid decompression chamber. The aviation-simulated rapid decompression chamber is characterized by comprising a main chamber, wherein the main chamber is connected with an auxiliary chamber by a quick-open chamber door, and is an environmental experiment chamber used for simulating and creating environments in different height and at different temperatures, and the auxiliary chamber is a rapid decompression chamber used for simulating and creating an environment in a cabin or a cockpit. The aviation-simulated rapid decompression chamber is provided with a one-chamber and two-room structure, so that the required pressure and temperature environments are achieved by adjusting pressure and temperature adjustment equipment in the chamber; when rapid decompression is required to be simulated, the quick-open door is controlled by controlling and operating an electric permanent magnet between the two chambers through an electric signal; a course of environment change when the cabin is damaged and a cockpit drops during a high-altitude flight of an airplane is simulated truly; and experimental researches such as various aeromedical researches, equipment experiment testing and the like are carried out during the course, so that the purposes of reducing or avoiding casualties and equipment damages are achieved.

Owner:烟台宏远氧业股份有限公司

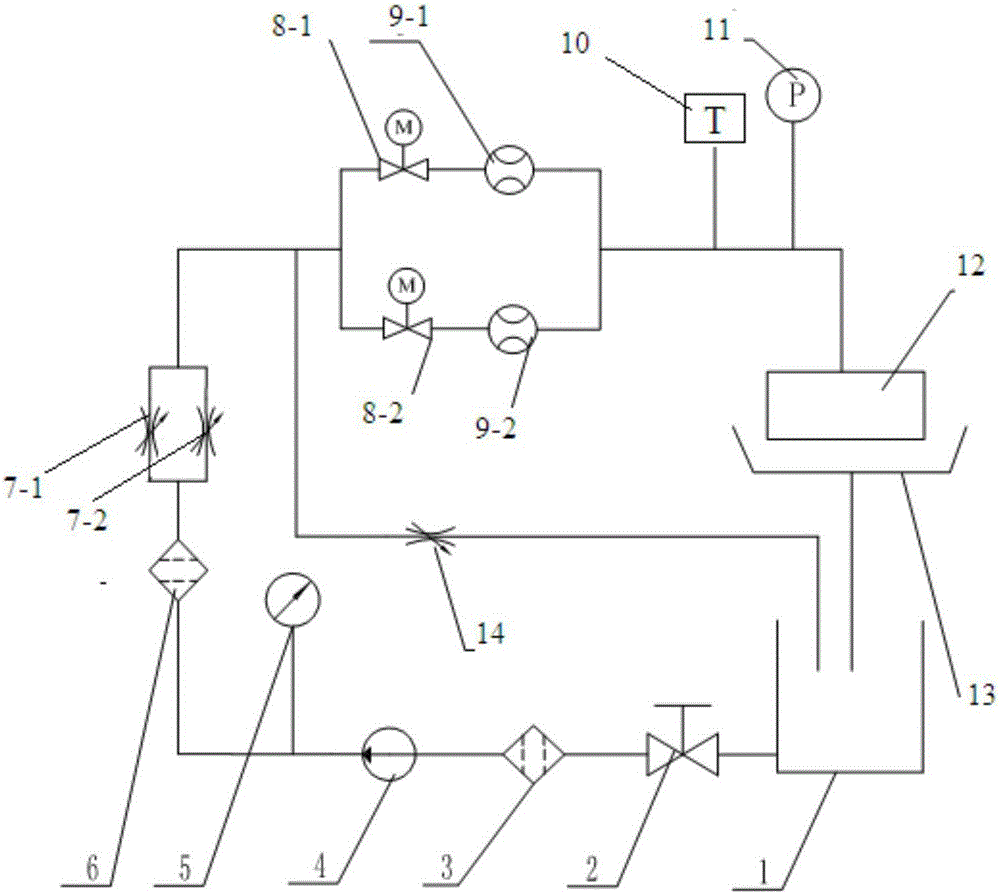

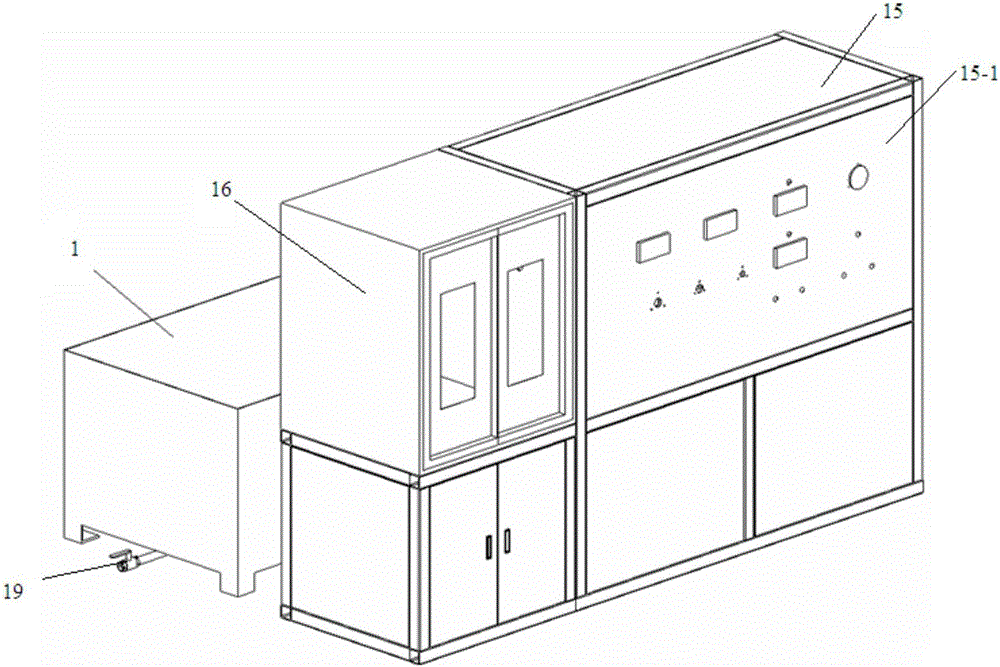

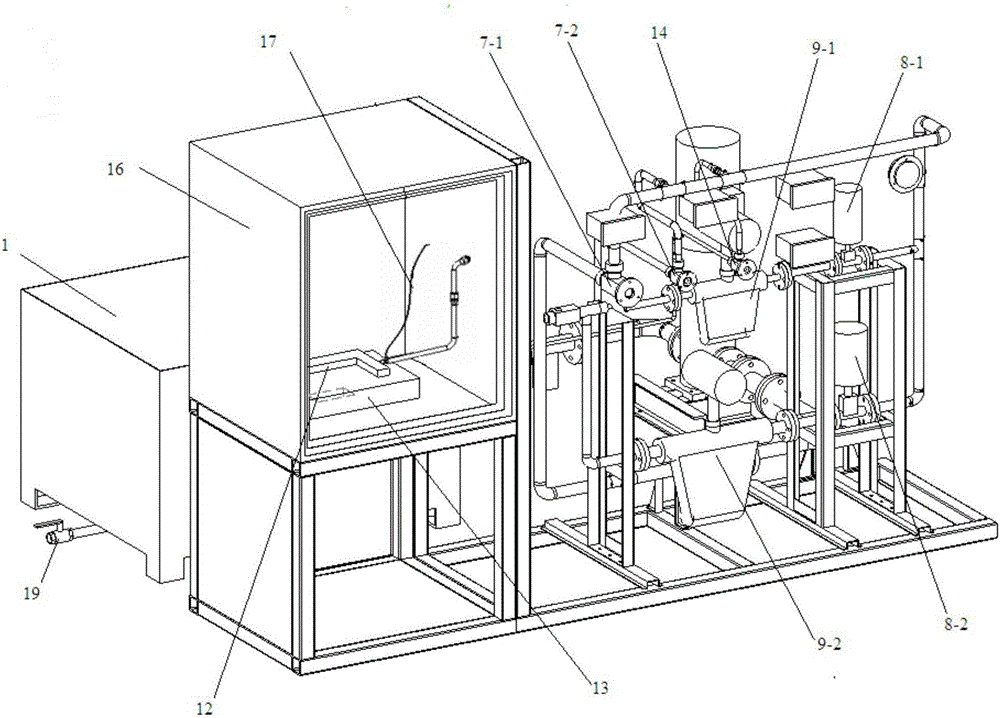

Water flow rate testing device of turbine blade of aviation engine

InactiveCN106706290AHigh measurement accuracyAvoid ineffective workMachine part testingAviationEngineering

The invention relates to a water flow rate testing device of a turbine blade of an aviation engine. The water flow rate testing device comprises a water tank, a coarse filter, a water pump, a pressure gauge, a fine filter, a main path voltage regulation valve, a blade clamp, a worktable, a bypass flow passage, at least two parallel measuring branch lines, a temperature sensor and a pressure sensor, wherein the bypass flow passage is provided with a bypass adjusting valve; a cutoff valve and a flowmeter are arranged on each measuring branch line from the water inlet end to the water outlet end; the flowmeters on the measuring branch lines have different ranges. The water flow rate testing device of the turbine blade of the aviation engine has the advantages that the water flow rates of flow passages and air film holes of different turbine blades can be measured by one testing device, and the measuring accuracy is improved.

Owner:四川成发普睿玛机械工业制造有限责任公司

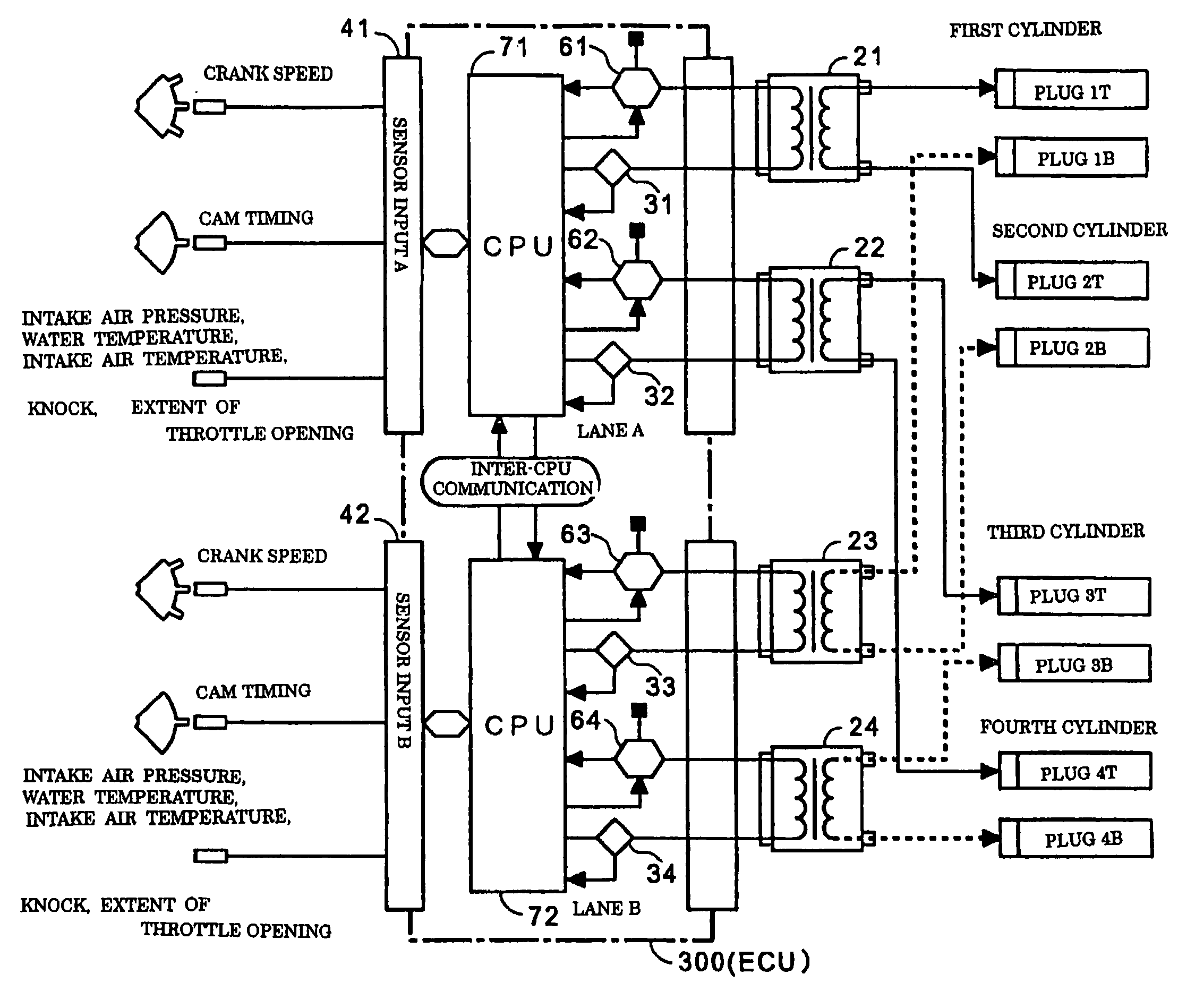

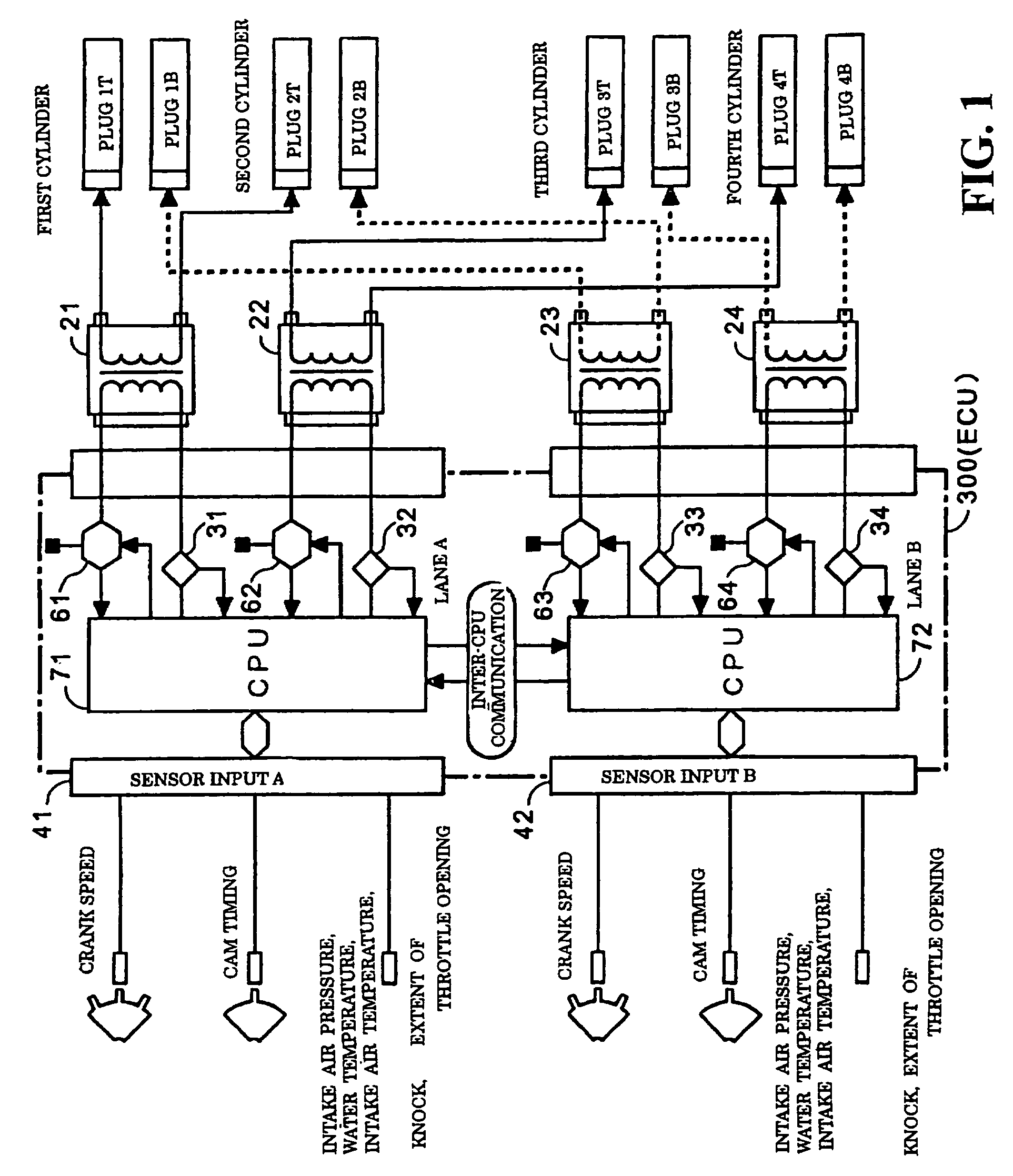

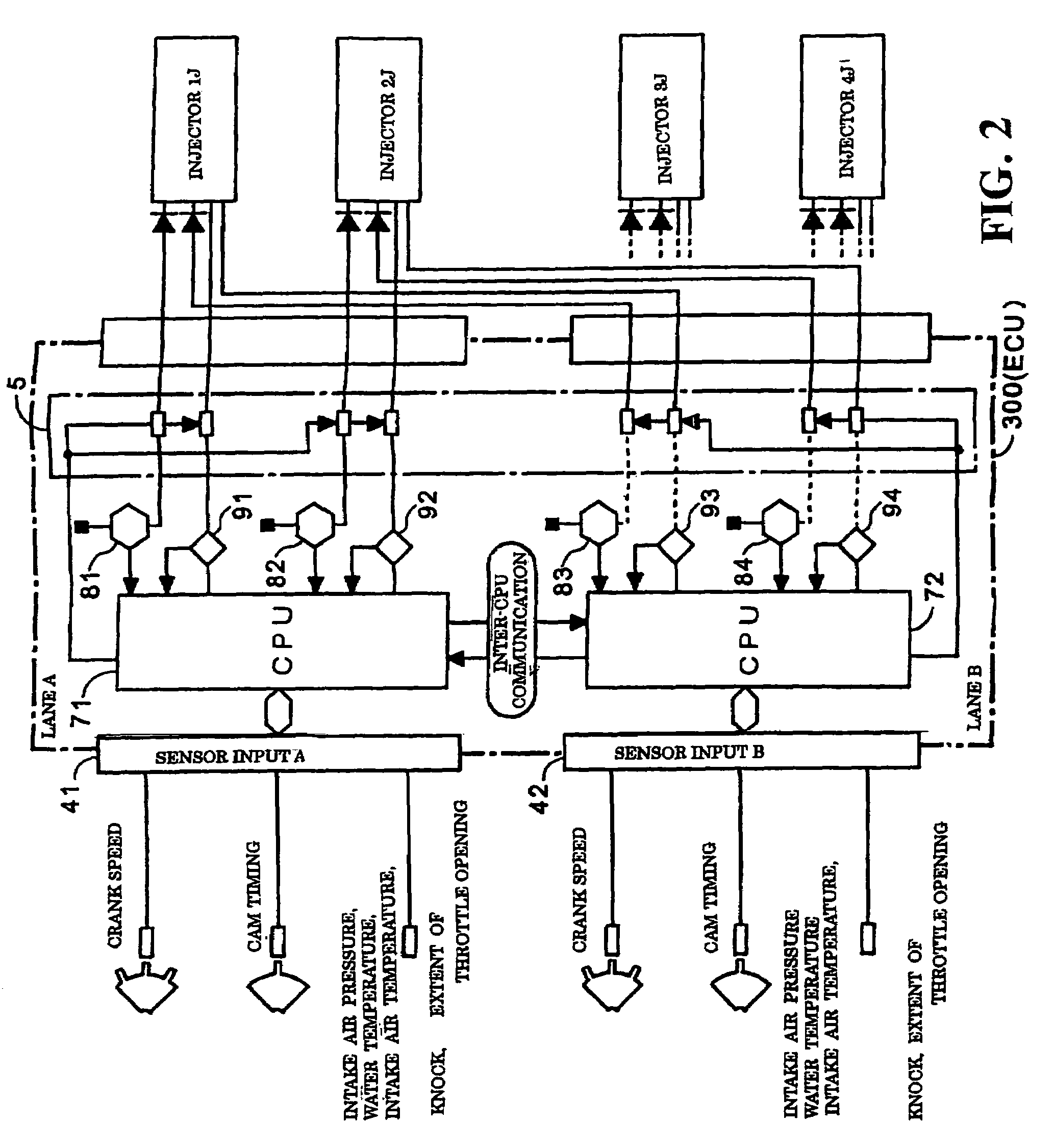

Electronic control device for aviation engine

InactiveUS7299121B2Increase redundancyAnalogue computers for vehiclesElectrical controlAviationIgnition coil

An electronic control device is provided for an aviation engine. Each cylinder of the engine is equipped with main ignition plugs and back-up ignition plugs. Lane A including a first CPU and lane B including a second CPU are included in an ECU. The ignition control system is multiplexed by the two lanes A, B. The first and second CPU independently calculate ignition timing for each cylinder based on each sensor signal, and then exchange the results of these calculations with each other. At each cylinder, ignition timing is synchronized in such a manner that ignition timing of the main ignition plugs and ignition timing of the back-up ignition plugs match. The electronic control device so configured has a high level of redundancy with a small number of CPU's. Thus, electronic control device can be provided for the aviation engine with few limitations placed in relation to installation location.

Owner:HONDA MOTOR CO LTD

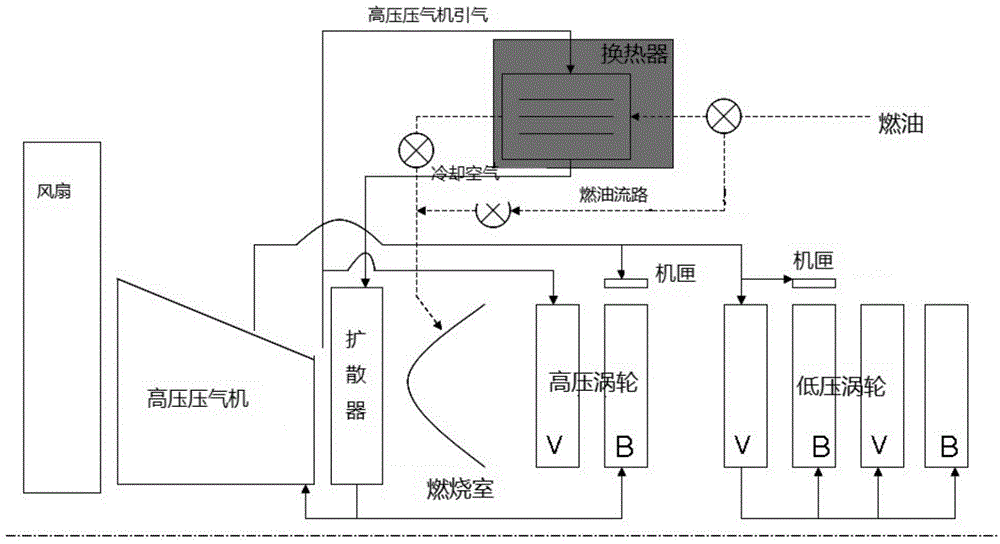

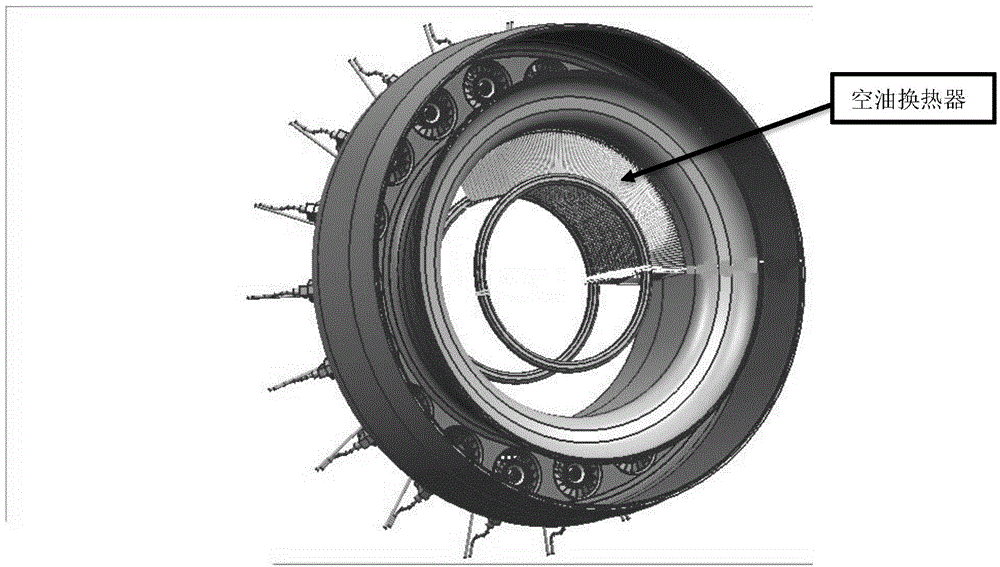

Spiral tube heat exchanger suitable for aviation engine

InactiveCN104612834AImprove heat transfer efficiencyCompact designTurbine/propulsion engine coolingAviationPlate heat exchanger

A disclosed spiral tube heat exchanger suitable for an aviation engine comprises a mixing chamber and a stainless steel tube bundle; the mixing chamber comprises a first-order mixing chamber and a second-order mixing chamber; the first-order mixing chamber comprises two '-' type circular pipes and two Z-shaped bend pipes; the second-order mixing chamber comprises N circular pipes; two ends of each of a part of circular pipes are respectively communicated with the two '-' type circular pipes, and the other end of each of the two '-' type circular pipes is enclosed; and two ends of each of the other part of circular pipes are respectively communicated with the upper ends of the two Z-shaped bend pipes, and the other end of each of the two Z-shaped bend pipes is enclosed; the stainless steel pipe bundle comprises multiple stainless steel pipes which are spiral pipes, and the stainless steel pipes are arranged in a circular radial manner for forming the stainless steel pipe bundle; and the two parts of the circular pipes are vertically corresponding and are in communication via stainless steel pipes. The spiral tube heat exchanger has the heat exchange efficiency substantially improved compared with the heat exchange efficiency of a common civil tube-bundle heat exchanger. The spiral pipe is capable of avoiding damage to heat exchanger structure and welding spots by absorbing engine self shock and forced shock during practical running of the aviation engine.

Owner:BEIHANG UNIV

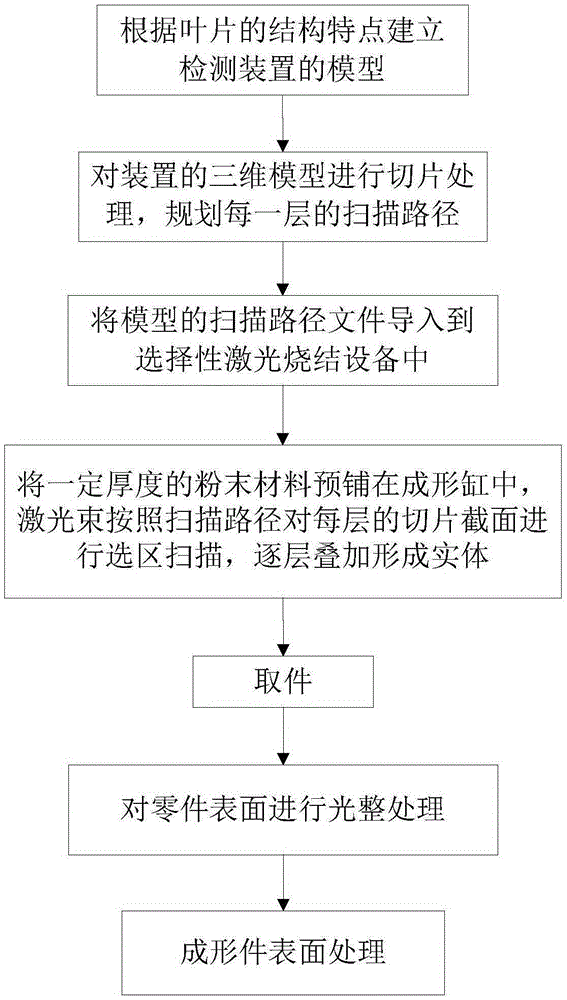

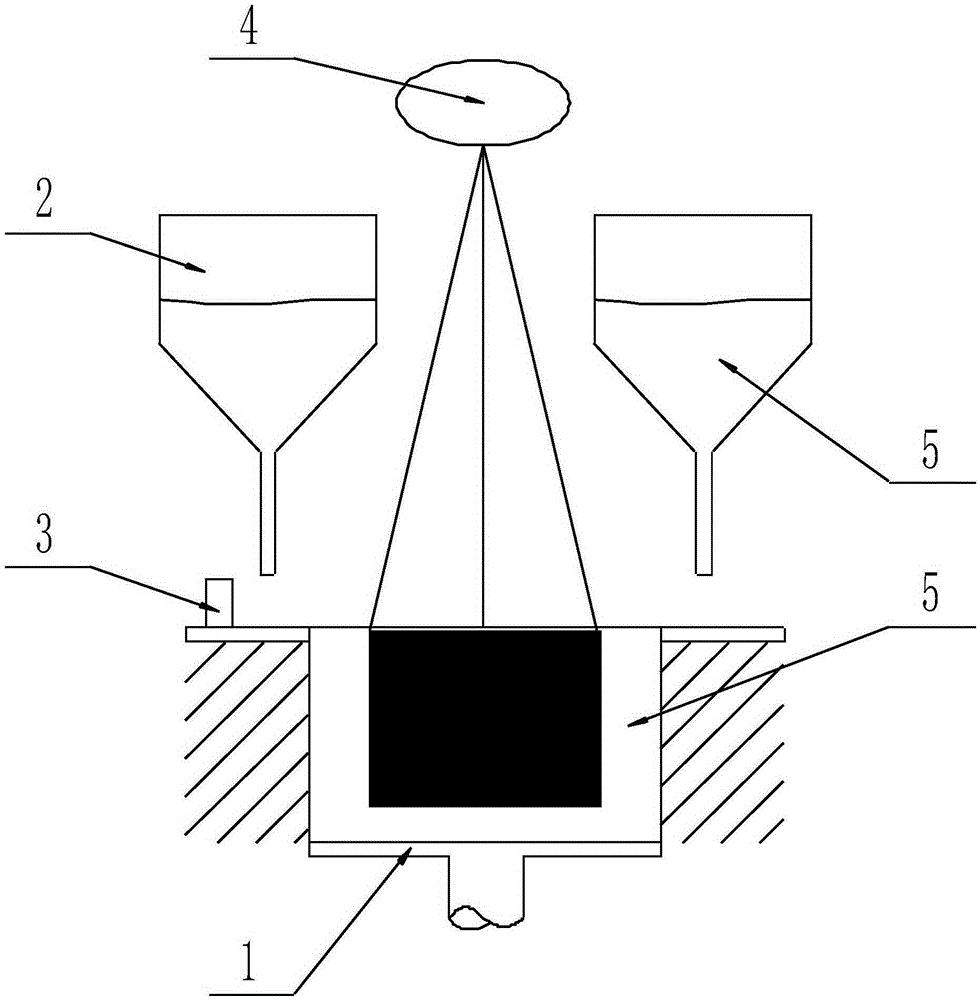

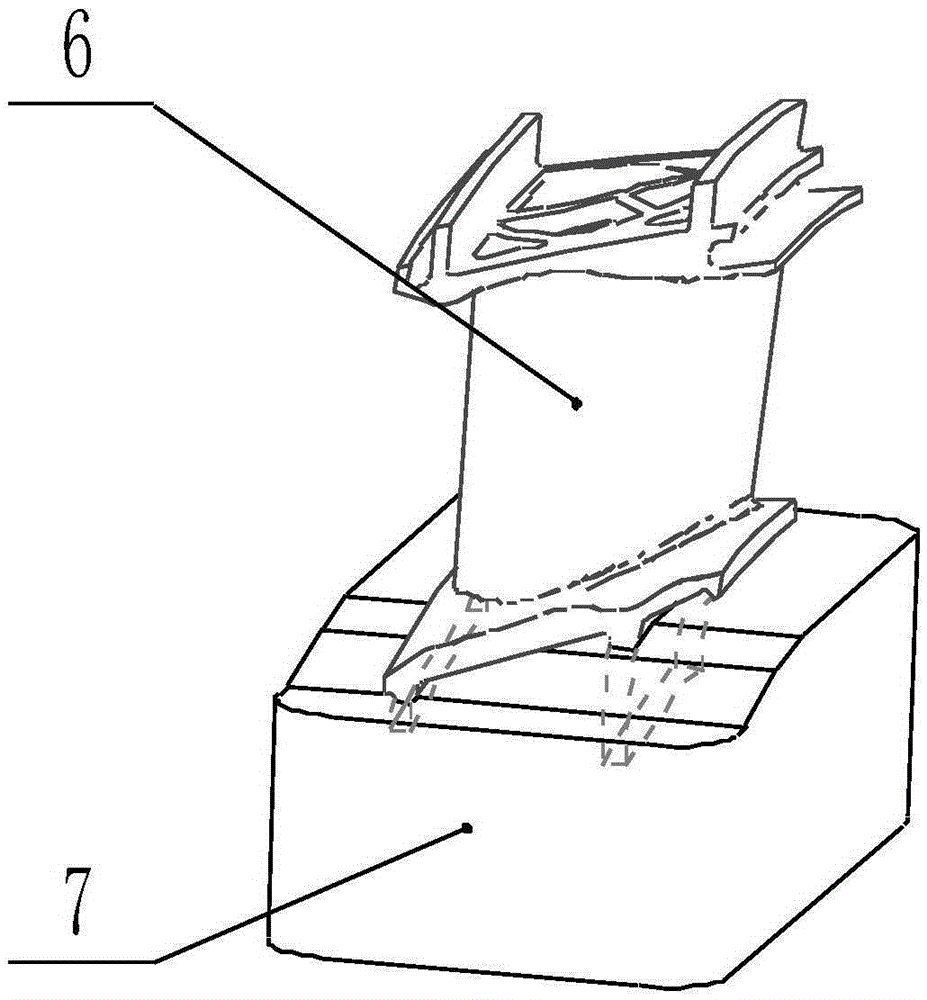

Rapid formation method of X-ray detecting device for blade of aviation engine

InactiveCN105269824ARapid Response ManufacturingImprove mechanical propertiesAdditive manufacturing apparatusAviationSelective laser sintering

The invention provides a rapid formation method of an X-ray detecting device for a blade of an aviation engine. The rapid formation method comprises the following steps: I, establishing a three-dimensional entity model of the X-ray detecting device according to the blade structure; II, slicing the model of the detecting device, and planning the laser scanning path of each layer; III, inputting the model on selective laser sintering equipment, setting the technological parameters of selective laser sintering, and adopting laser beams to scan powder material on each layer according to the planned scan path; IV, performing finishing treatment on the surface of a part after machining; V, enhancing the strength of a formed part; VI, after curing the part, removing the redundancy on the surface to obtain the X-ray detecting device. According to the rapid formation method, the technology is simple and easy to control, the operation is reliable, the production period is short, and the repeatability is high; the X-ray detecting device manufactured by adopting the rapid formation method is reliable in mechanical property, meets the operating requirements, and can realize rapid response manufacture according to different blade structures.

Owner:SHANGHAI SPACE PRECISION MACHINERY RES INST

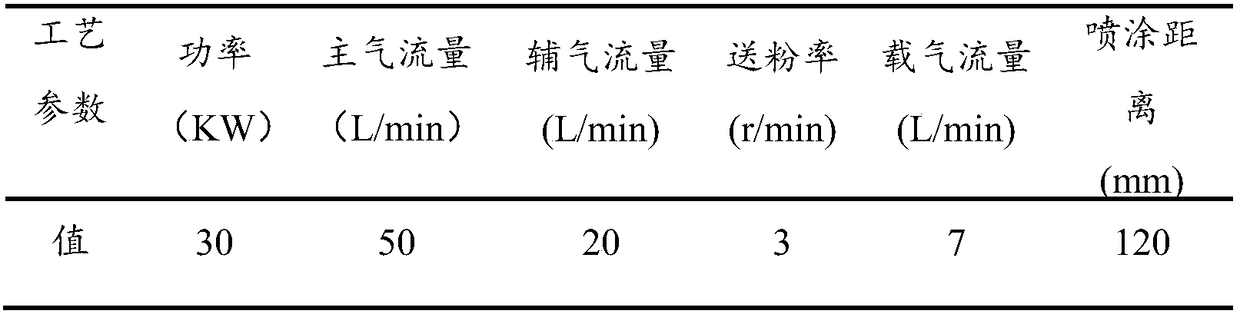

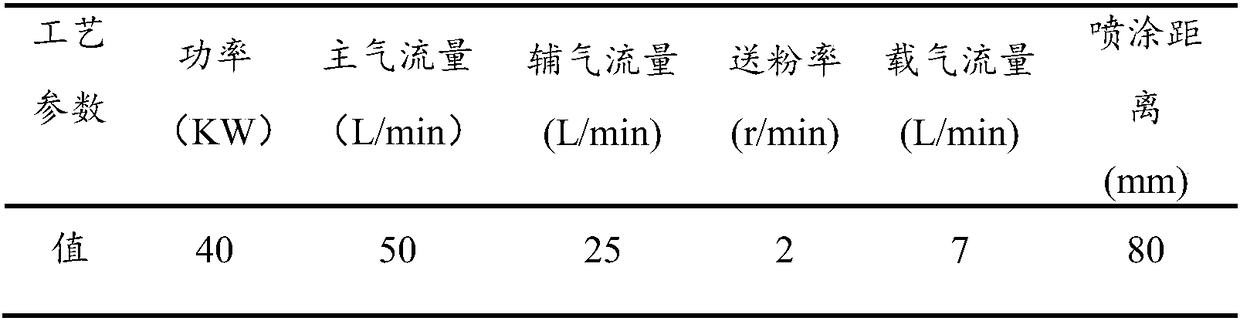

Preparation technology of thermal barrier coating of blade of aviation engine

ActiveCN108342676AHigh bonding strengthChange the thermal stress distribution stateMolten spray coatingPicosecond laserAviation

The invention relates to the technical field of laser application, and further relates to a preparation technology of a thermal barrier coating of a blade of an aviation engine. Picosecond laser is utilized for carrying out etching process treatment during a preparation process of a bonding layer-bonding layer interface of the thermal barrier coating, and an interface tenon-shaped staggering structure is obtained, so that the bonding strength between a plasma spraying ceramic layer and a bonding layer is improved. During a high-temperature cyclic oxidation process, a thermal stress distribution state of the coating interface is effectively adjusted, a concentrated stress mode of the coating is changed, a growth model of constant-speed and plane propulsion of thermally grown oxide (TGO) isbroken, and the damage of a thermal stress and the growth way of the TGO on a binding force of the bonding layer and the ceramic layer is reduced. Through a thermal shock property experiment, the service life of the thermal barrier coating impacted by the bonding layer is greatly prolonged. A thermal barrier coating interface structure adjusting method provided by the invention is simple in process, easy to operate and convenient to implement.

Owner:JIANGSU UNIV

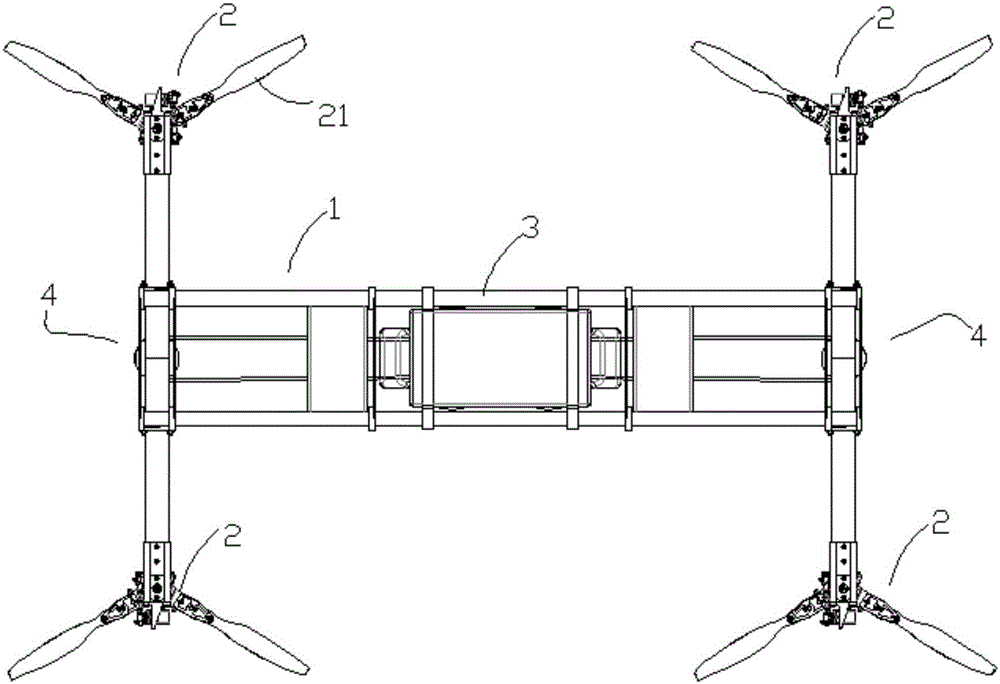

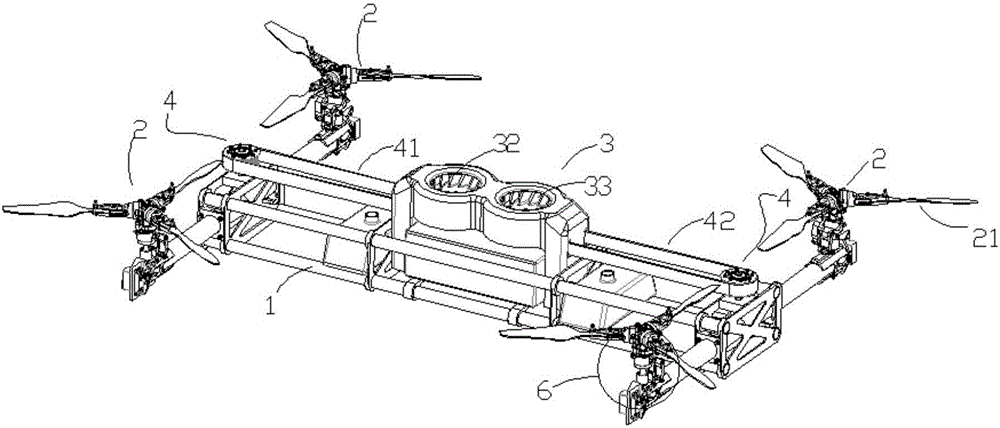

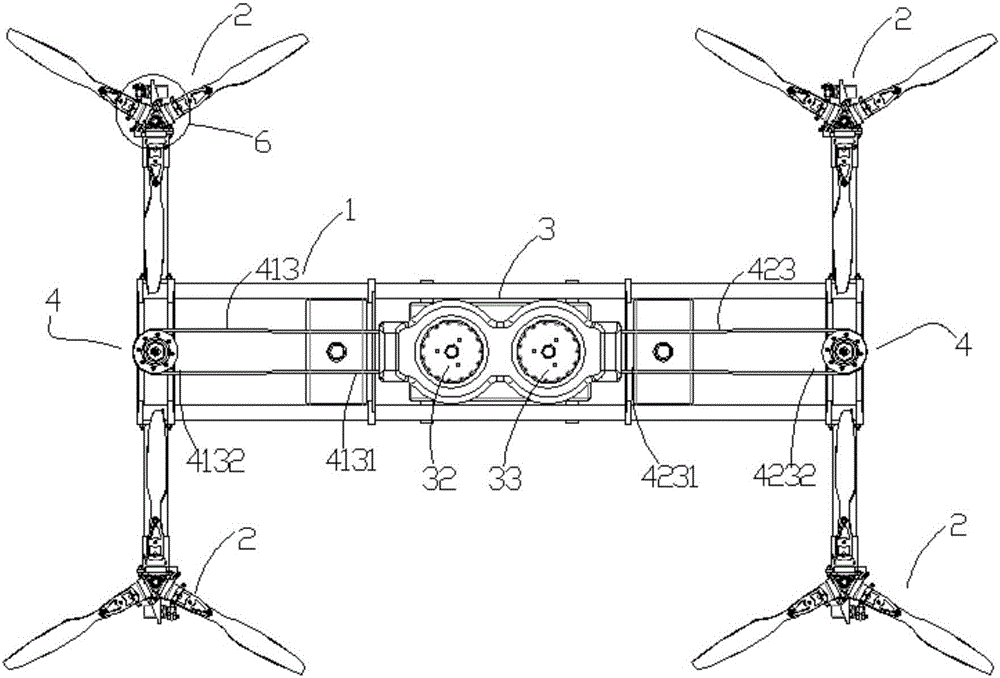

Aviation engine

ActiveCN106043680AExtend battery lifeIncrease loading capacityPower plant typeRotocraftAviationEngineering

The invention discloses an aviation engine, and belongs to the technical field of aviation. The aviation engine comprises a first power source, a second power source and a starter, wherein the first power source is provided with a first shaft; the second power source is provided with a second shaft; the starter is separately connected to the first shaft and the second shaft movably; the first shaft and the second shaft are separately connected to a rotor wing of an unmanned aerial vehicle; the rotated first shaft and the rotated second shaft are started for pressing pre-injected comburent, so that mechanical dynamic energy is generated for driving the first shaft and the second shaft to continuously rotate, and rotor rings of the unmanned aerial vehicle are driven to rotate through the first shaft and the second shaft. The aviation engine is applied to the unmanned aerial vehicle; the first power source and the second power source are arranged for combusting the pre-injected comburent to generate mechanical dynamic energy, so that power is provided for rotating the rotor rings, a conventional electric flight mode of increasing endurance time by supplying power through batteries or increasing quantity of batteries is replaced, and therefore, the unmanned aerial vehicle applying the aviation engine has characteristics of long endurance time and high load-bearing capacity.

Owner:EWATT TECH CO LTD

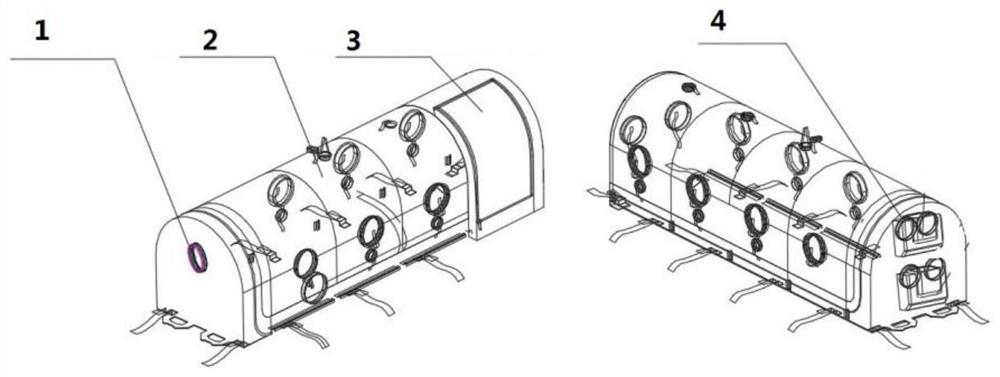

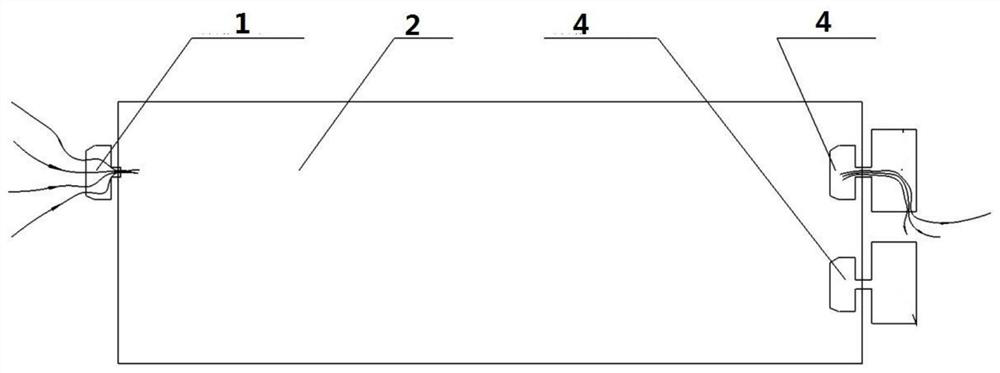

Infectious disease patient conveying and isolating unit capable of maintaining negative pressure for long time

PendingCN111658383ASolve the problem of long time transshipmentMeet the long-distance long-distance air evacuation requirementsBreathing protectionDispersed particle filtrationAviationAir cycle

The invention belongs to the technical field of aviation medical rescue, and specifically relates to an infectious disease patient conveying and isolating unit capable of maintaining negative pressurefor long time. The infectious disease patient conveying and isolating unit comprises an isolation unit cabin, an air inlet filter, exhaust filters, air circulation control systems, a filter replacement additional mechanism and a medical material supplement buffer channel, wherein the air inlet filter is arranged at the head end of the isolation unit cabin, and the tail end of the isolation unit cabin is connected with the medical material supplement buffer channel; the exhaust filters are arranged at the other end of the medical material supplement buffer channel; and the filter replacement additional mechanism and two sets of air circulation control systems are arranged in the medical material supplement buffer channel. Long-time negative pressure continuous maintaining capacity, efficient pathogen gas filtering capacity and the capacity of medical aid materials outside the isolation unit entering the isolation cabin body under the aviation environment condition are achieved, and therequirement for long-time long-distance air transportation and back delivery of infectious disease patients is met.

Owner:AIR FORCE MEDICAL CENT PLA +1

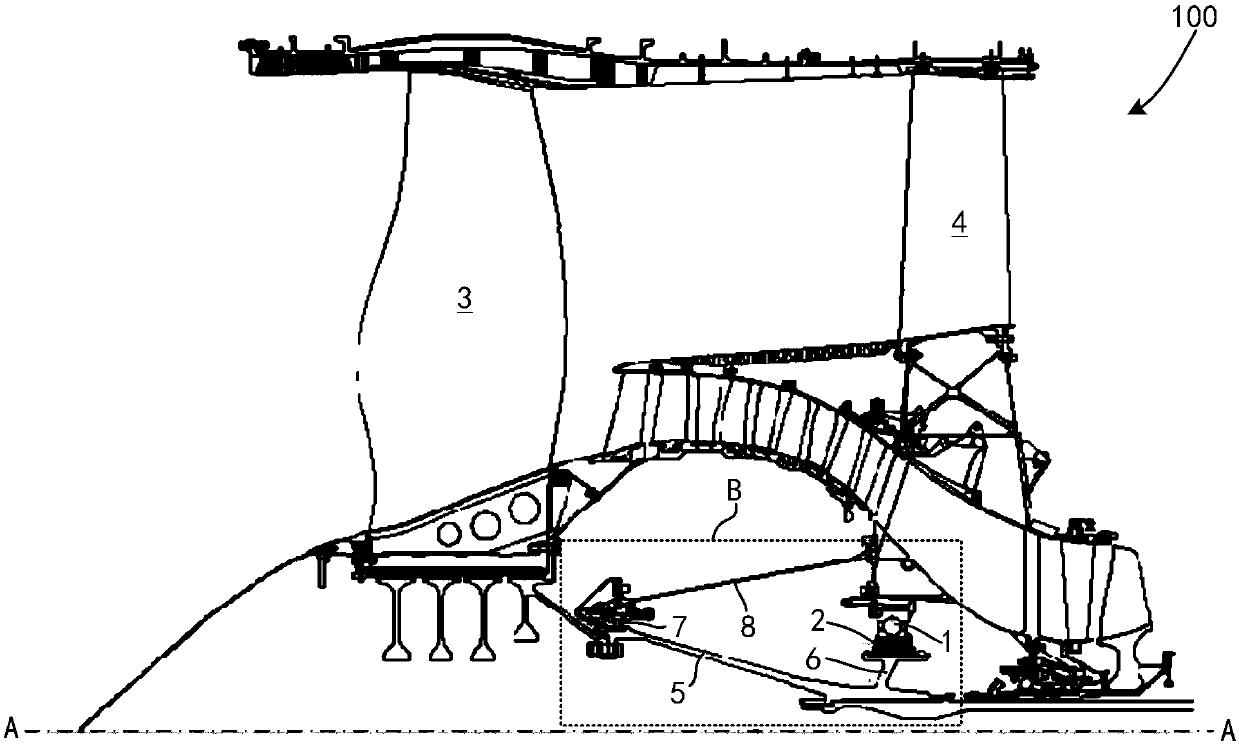

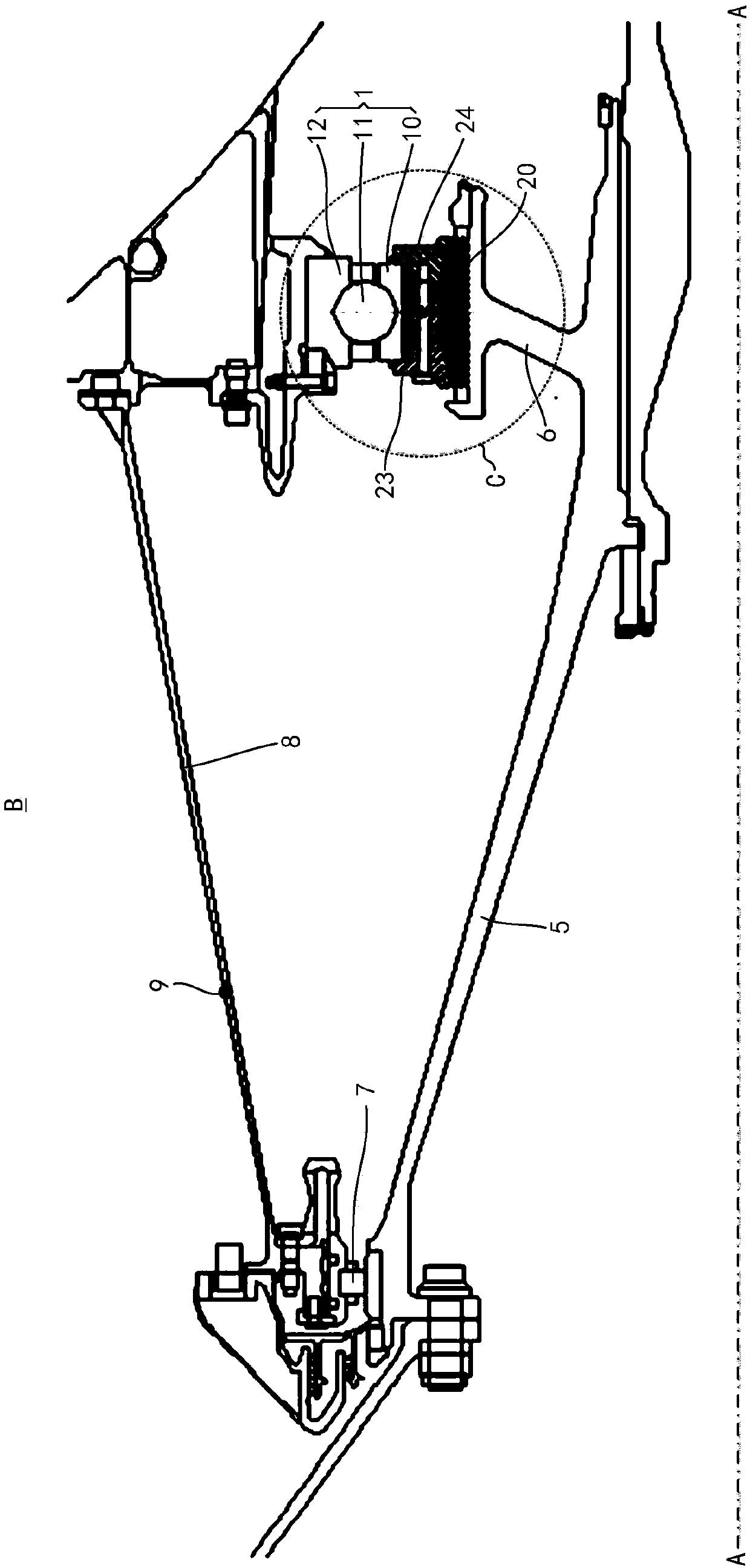

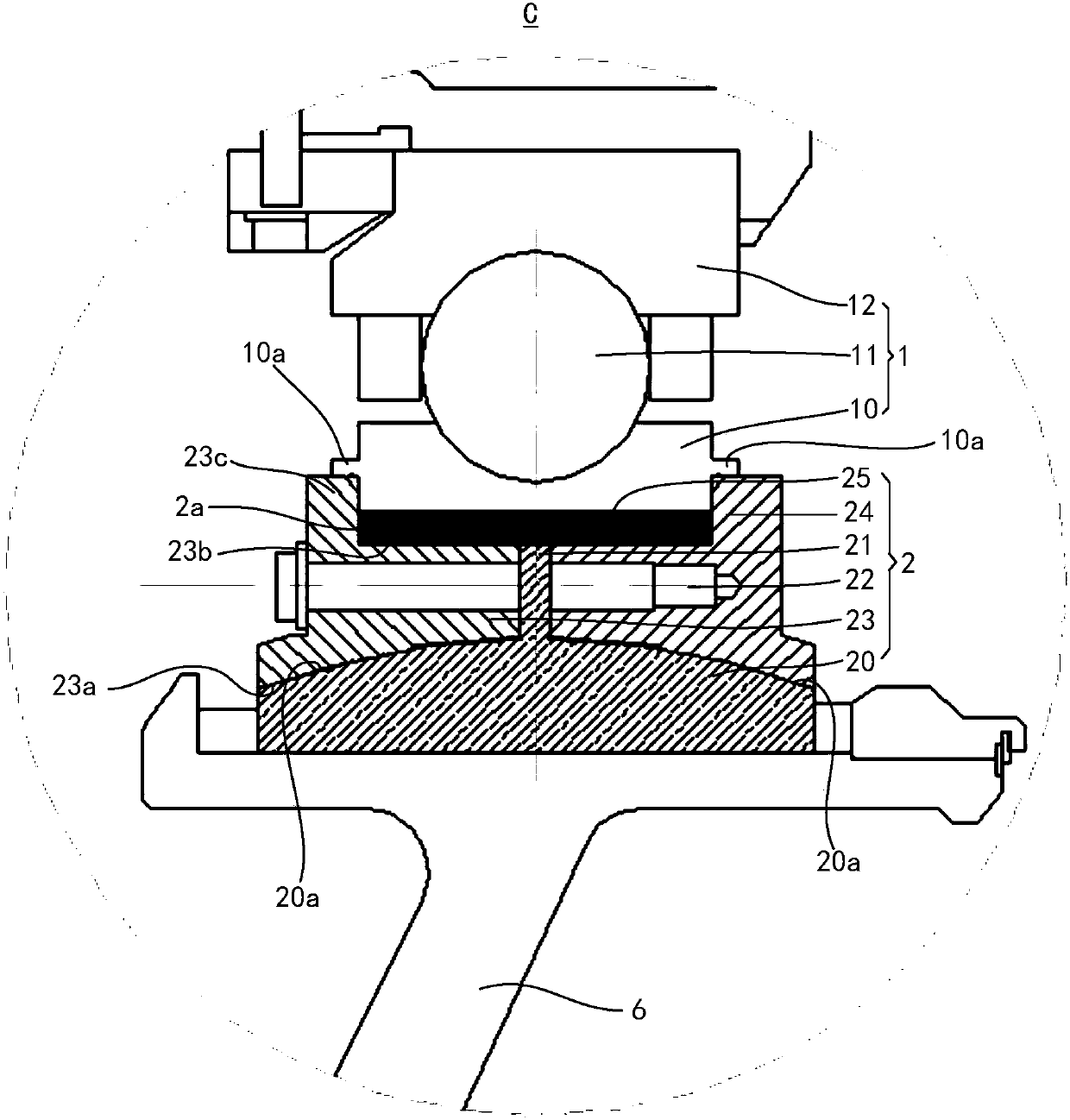

Aviation engine bearing supporting component and aviation engine

The purpose of the invention is to provide an aviation engine bearing supporting component and an aviation engine. The aviation engine bearing supporting component provided by the invention comprisesan installation seat, the installation seat is provided with an installation surface, the installation surface is part of a spherical surface, the aviation engine bearing supporting component furthercomprises a positioning ring, a connection part, a first position-limiting ring and a second position-limiting ring, the first position-limiting ring and the second position-limiting ring are in contact with the installation surface spherical surface correspondingly to be used for supporting one bearing correspondingly, the positioning ring is fixedly arranged on the installation surface, the connection part is used for fixedly connecting the first position-limiting ring, the second position-limiting ring and the positioning ring into a whole, and the positioning ring is used for bearing overload force to be separated from the installation surface. According to the aviation engine bearing supporting component, because the positioning ring is clamped, flying-off will not appear, therefore,the aviation engine bearing supporting component has high safety. The aviation engine provided by the invention comprises the aviation engine bearing supporting component, therefore, the aviation engine has high safety.

Owner:AECC COMML AIRCRAFT ENGINE CO LTD

Method for detecting diameter of outer wall of tapered case of aviation engine on line

InactiveCN102927952BReduce manufacturing costImprove automationMeasurement devicesNumerical controlAviation

Owner:SHENYANG LIMING AERO-ENGINE GROUP CORPORATION

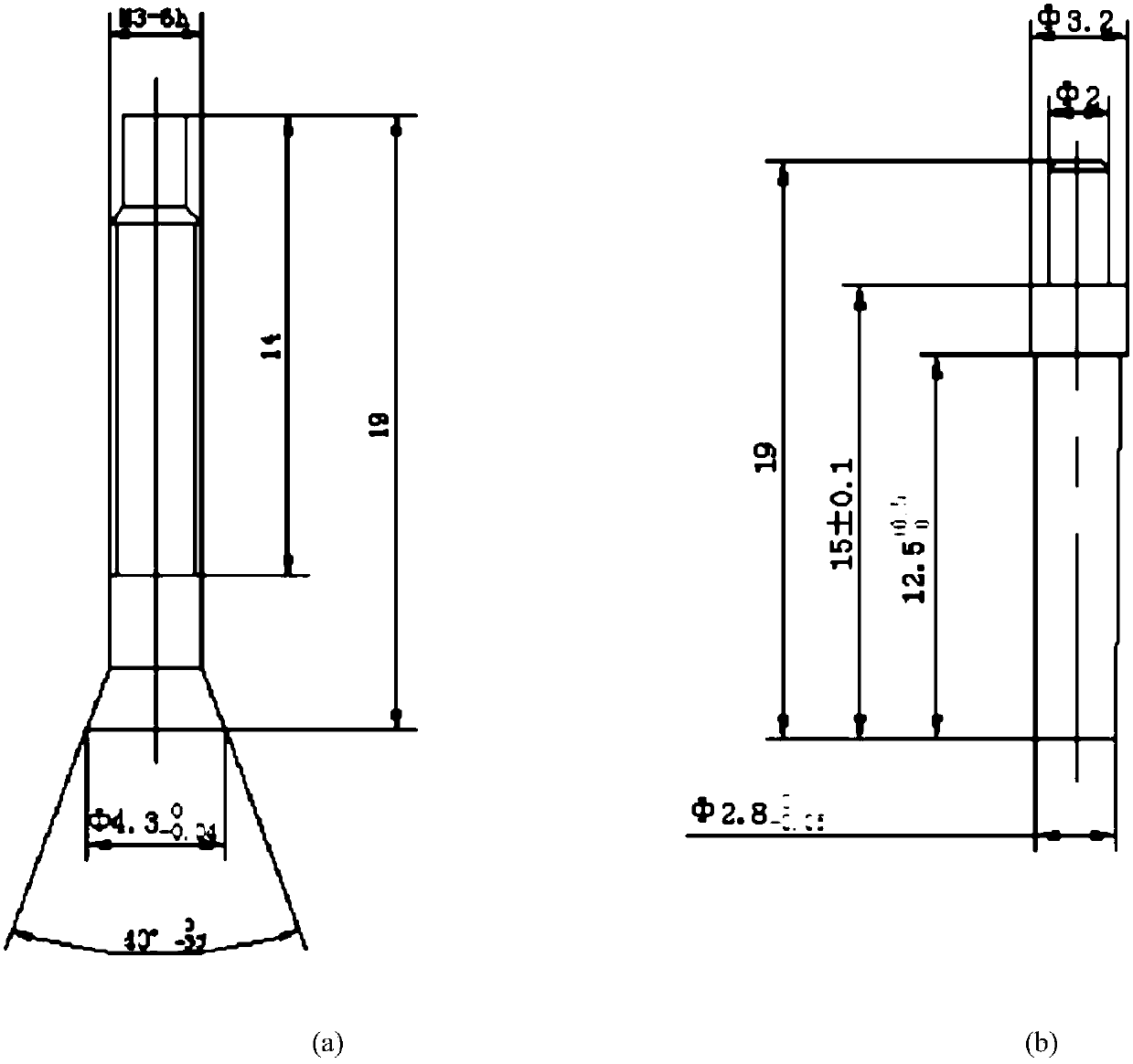

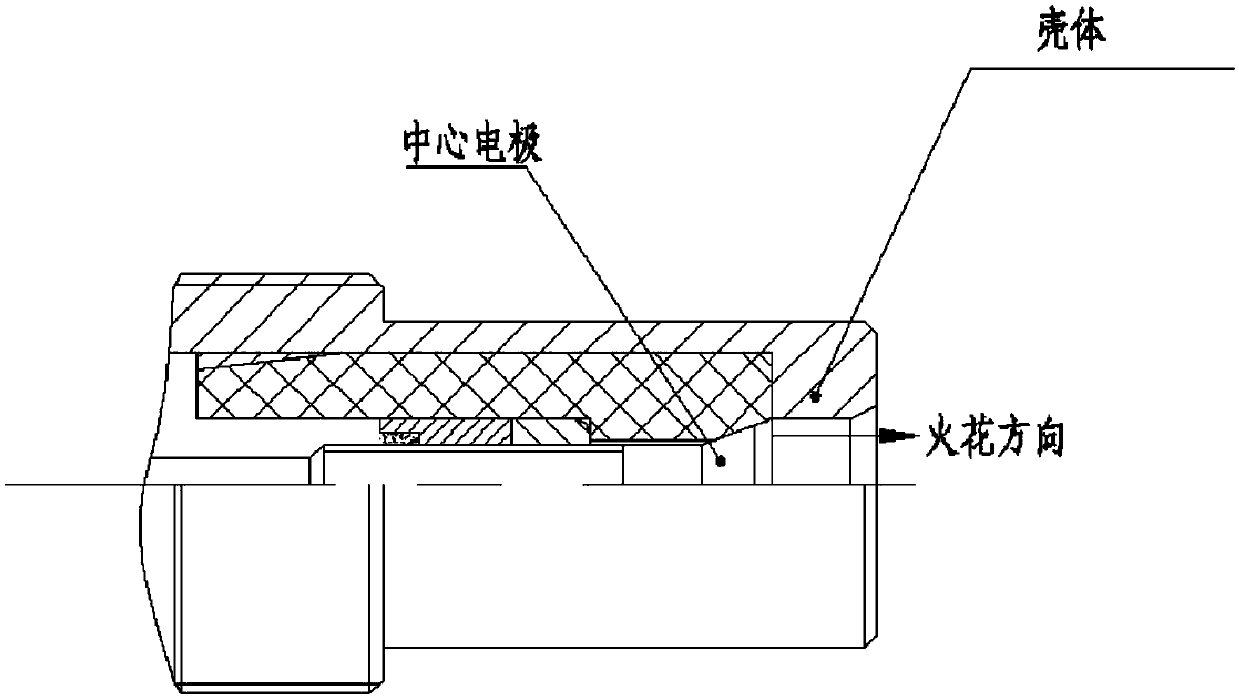

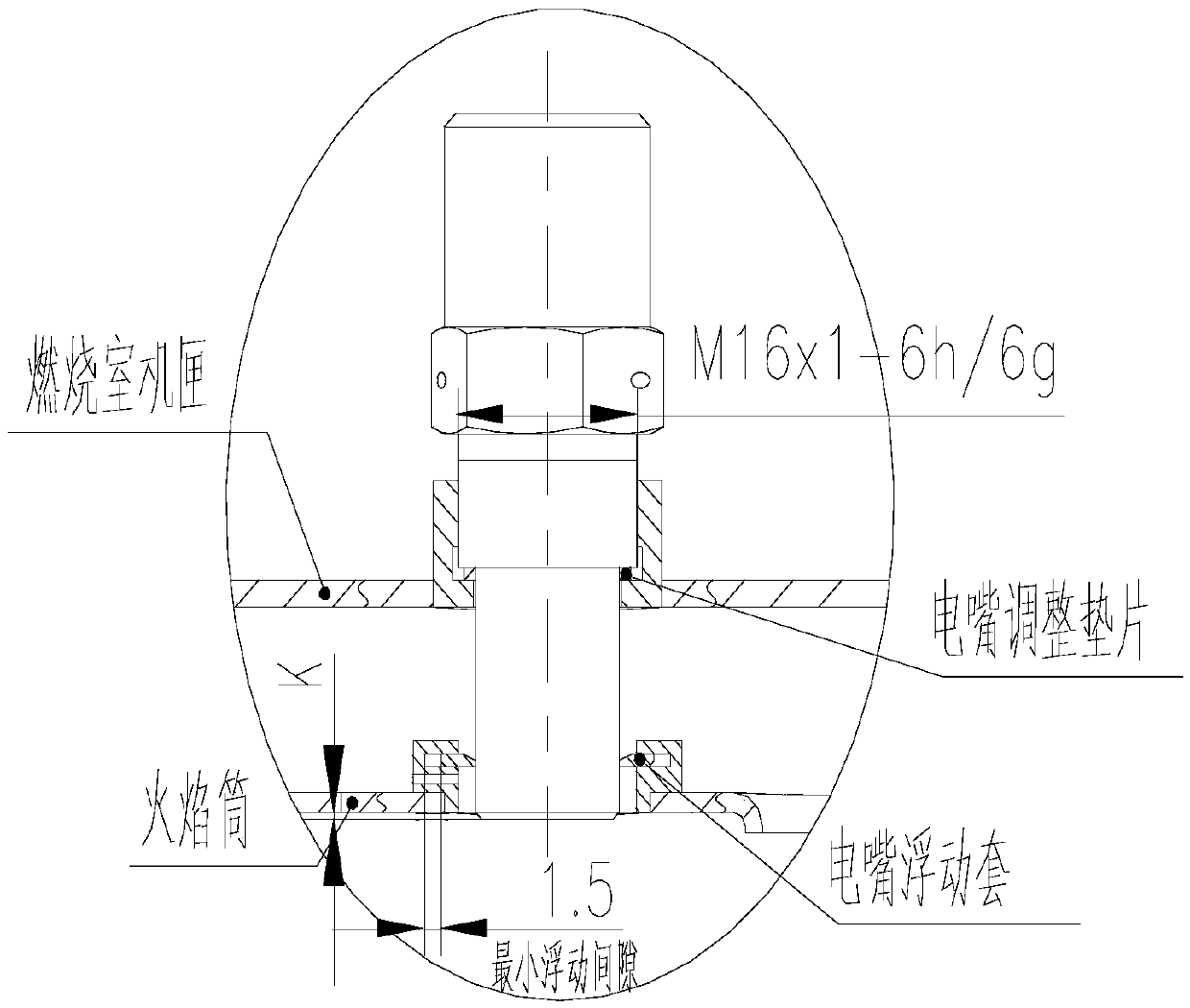

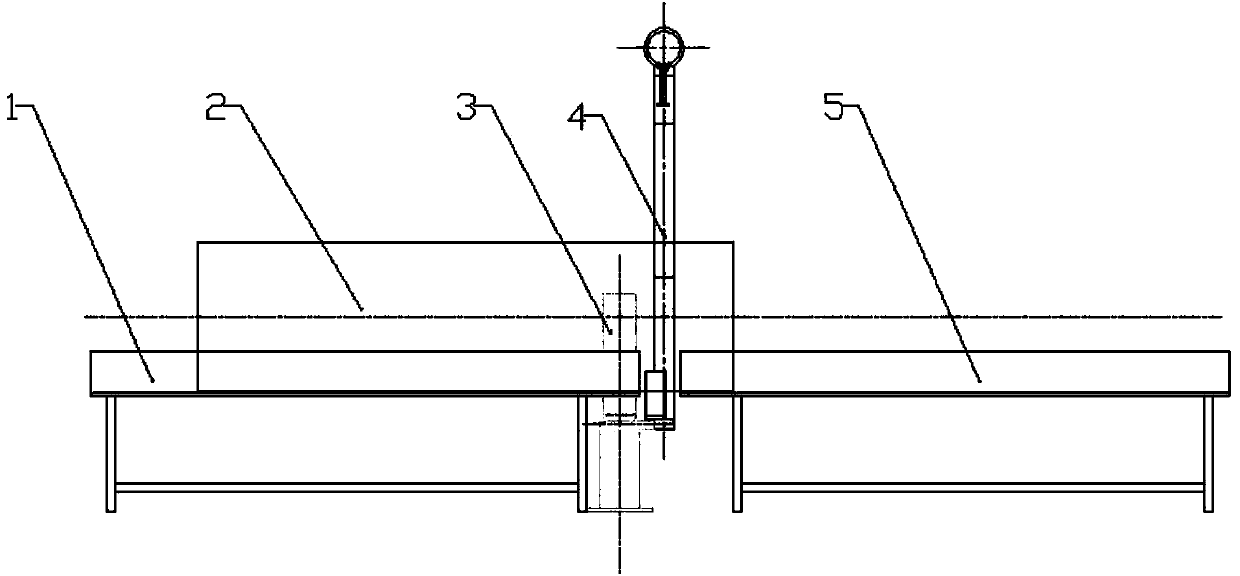

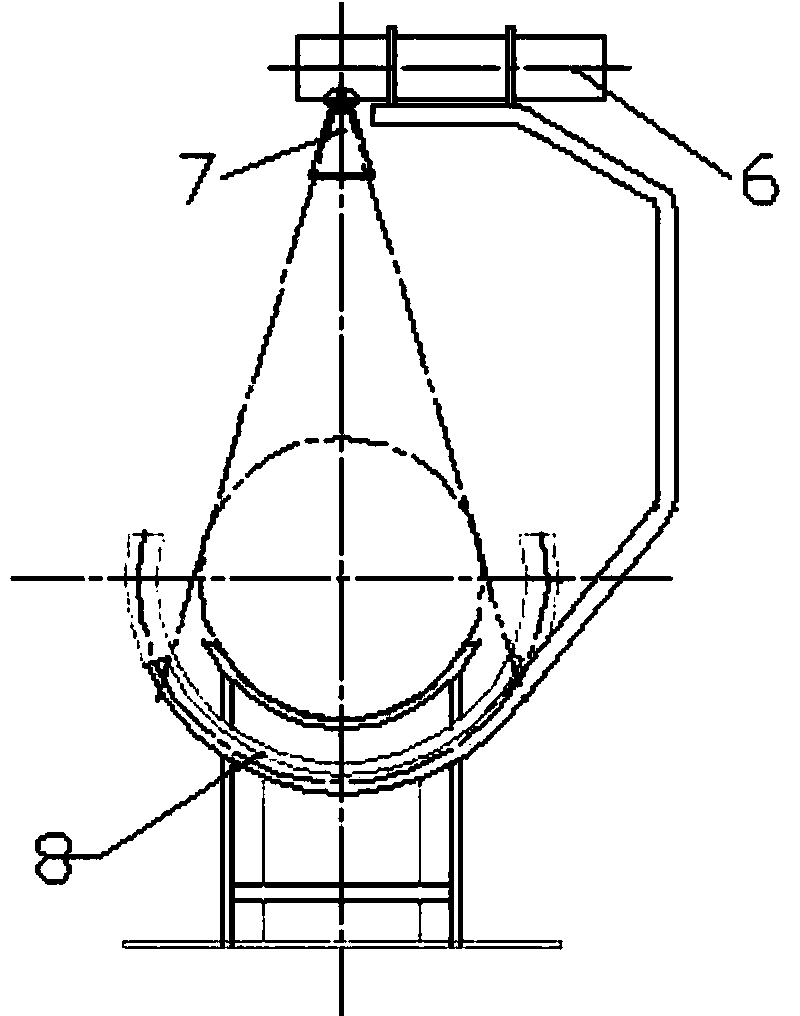

Method for improving strength of insulator at discharging end of ignition electric nozzle of aviation engine

ActiveCN109638652AMeet environmental requirementsImprove reliabilitySparking plugsGas turbine plantsAviationEngineering

The invention proposes a method for improving strength of an insulator at a discharging end of an ignition electric nozzle of aviation engine. The total length of the insulator and a central electrodeis maintained unchanged, the size of an insulator part and the size of a central electrode part are changed, and conical-surface matching between the central electrode and the insulator is changed tostraight-surface matching; with regard to the insulator, the discharging end of the insulator is changed to a straight surface to a conical surface, the wall thickness of an end part is increased by0.5 millimeter, the size of an inner hole of the discharging end is Phi 2.8 millimeters, the chamfer angle of the end part is 60 degrees, and the axial length of the chamfer angle at the end part is 0.5 millimeter; a straight table is additionally arranged at an outer circle of the insulator, and the situation that a bottom surface of the shell cannot be completely cleared to cause point contact is prevented; and with regard to the central electrode, the conical surface of the discharging end of the central electrode is changed to the straight surface, and the diameter of the discharging end of the central electrode is Phi 2.8 millimeters. The characteristics of ignition concentration and high efficiency of a sunken structure are maintained, meanwhile, the stress of a discharging end partof the insulator is reduced, the application requirement applicable to the engine environment is met, and a reliable main ignition electric nozzle is provided for the engine.

Owner:SHAANXI AVIATION ELECTRICAL

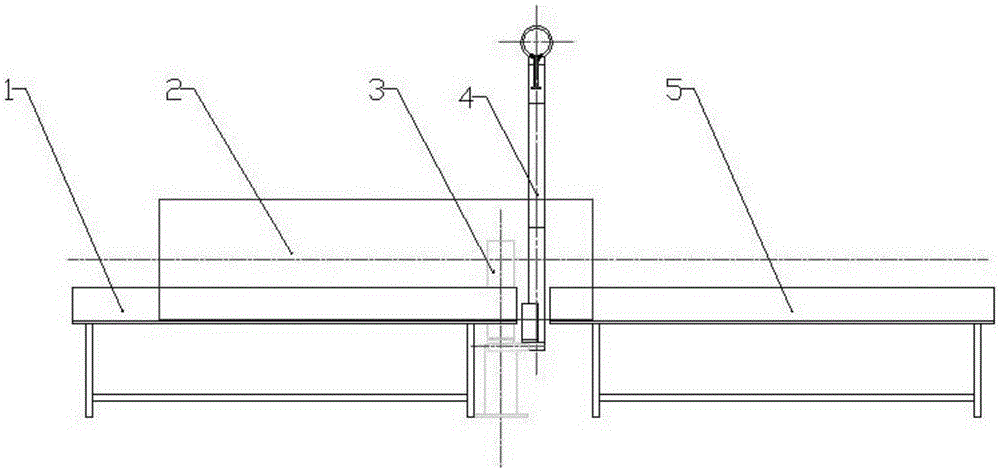

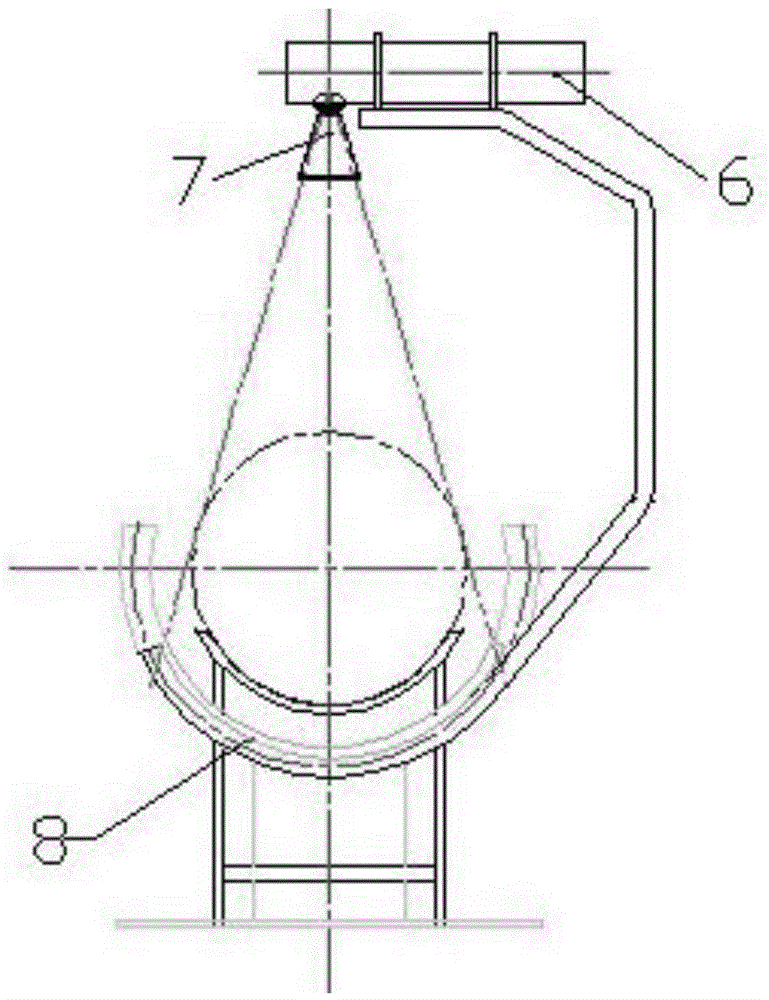

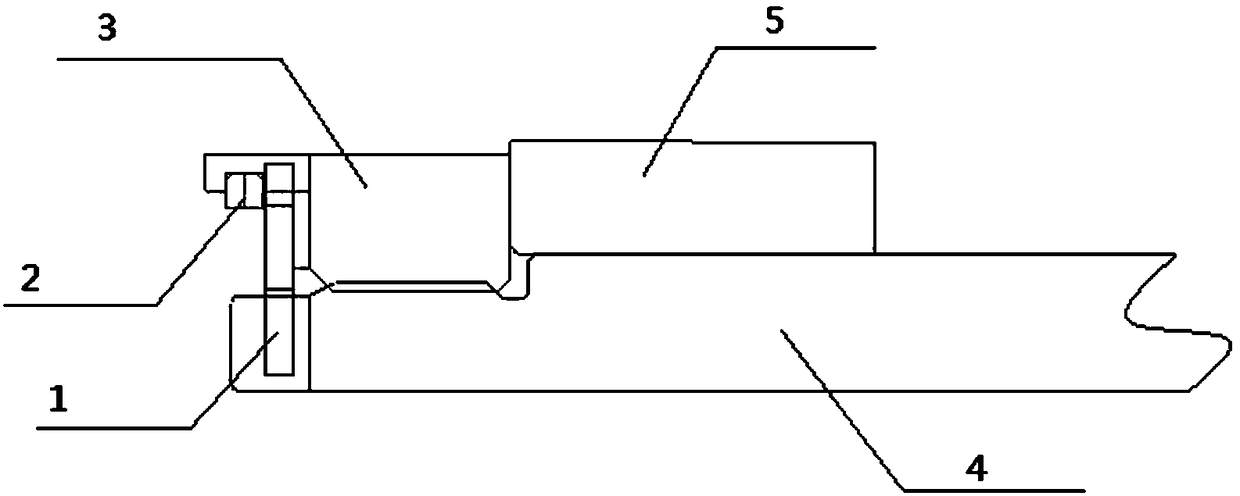

3D imaging system and method of industrial CT

InactiveCN104165895ASimple structureSimple designMaterial analysis by transmitting radiationAviationEngineering

The invention provides a 3D imaging system and method of an industrial CT. The imaging system comprises an X-ray generator, an arc-shaped detector, a primary conveyer belt and a secondary conveyer belt, wherein the X-ray generator and the arc-shaped detector are opposite to each other; the primary conveyer belt and the secondary conveyer belt are arranged on the same axis; a gap is formed between the opposite ends of the primary conveyer belt and the secondary conveyer belt; the X-ray generator and the arc-shaped detector are arranged in a manner of rotating around the primary conveyer belt and the secondary conveyer belt by taking the gas as the circle center. Through longitudinal section type scanning of the 3D imaging system, relatively long objects such as long-columnar objects of dozens of centimeters to dozens of meters as well as internal materials, meters and elements such as water suction pumps, water conservancy generators, aviation undercarriages, aviation engines, diving gears, underwater searching and rescuing devices, bridge components, aerospace vehicles and underwater moving devices can be relatively easily checked by using the 3D imaging method.

Owner:于双悦 +1

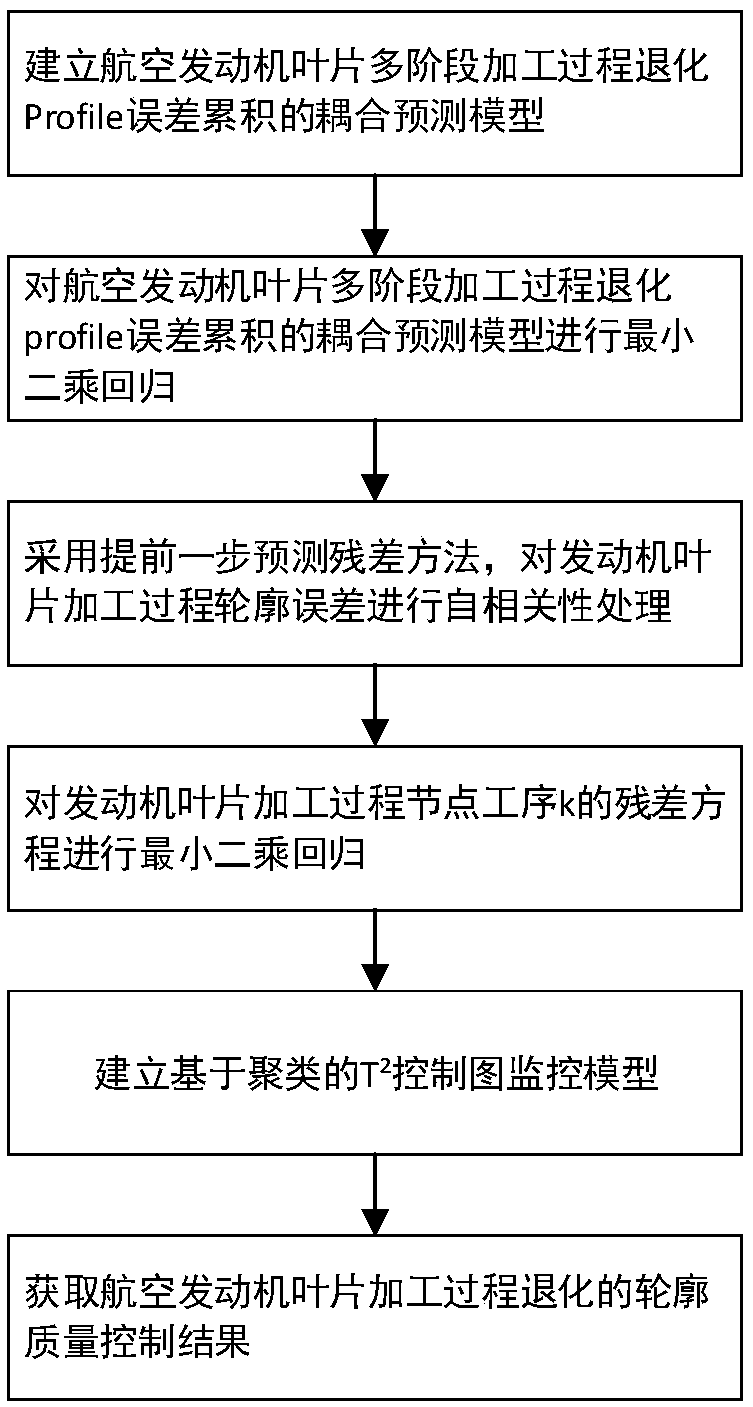

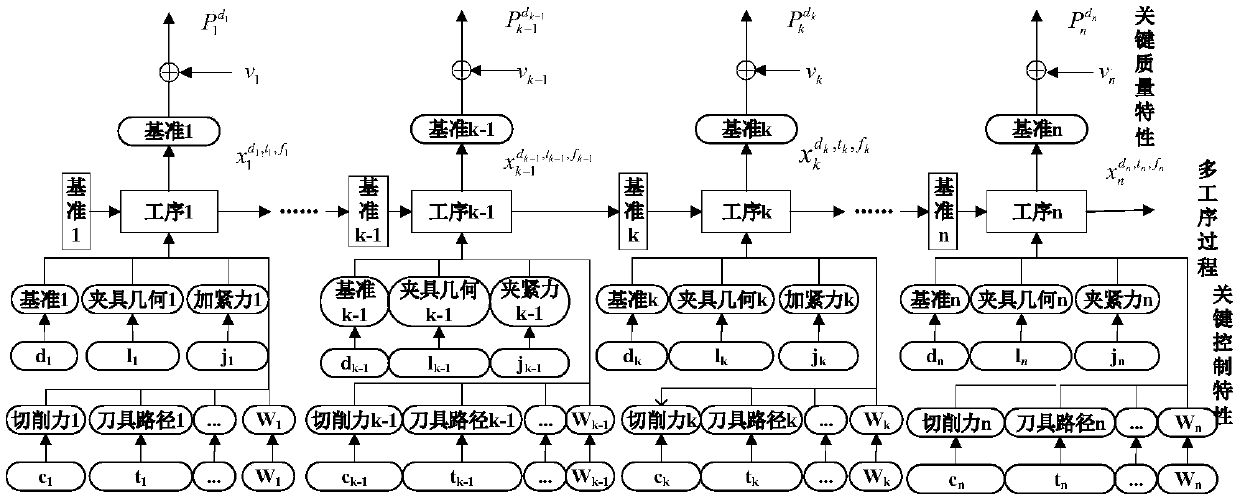

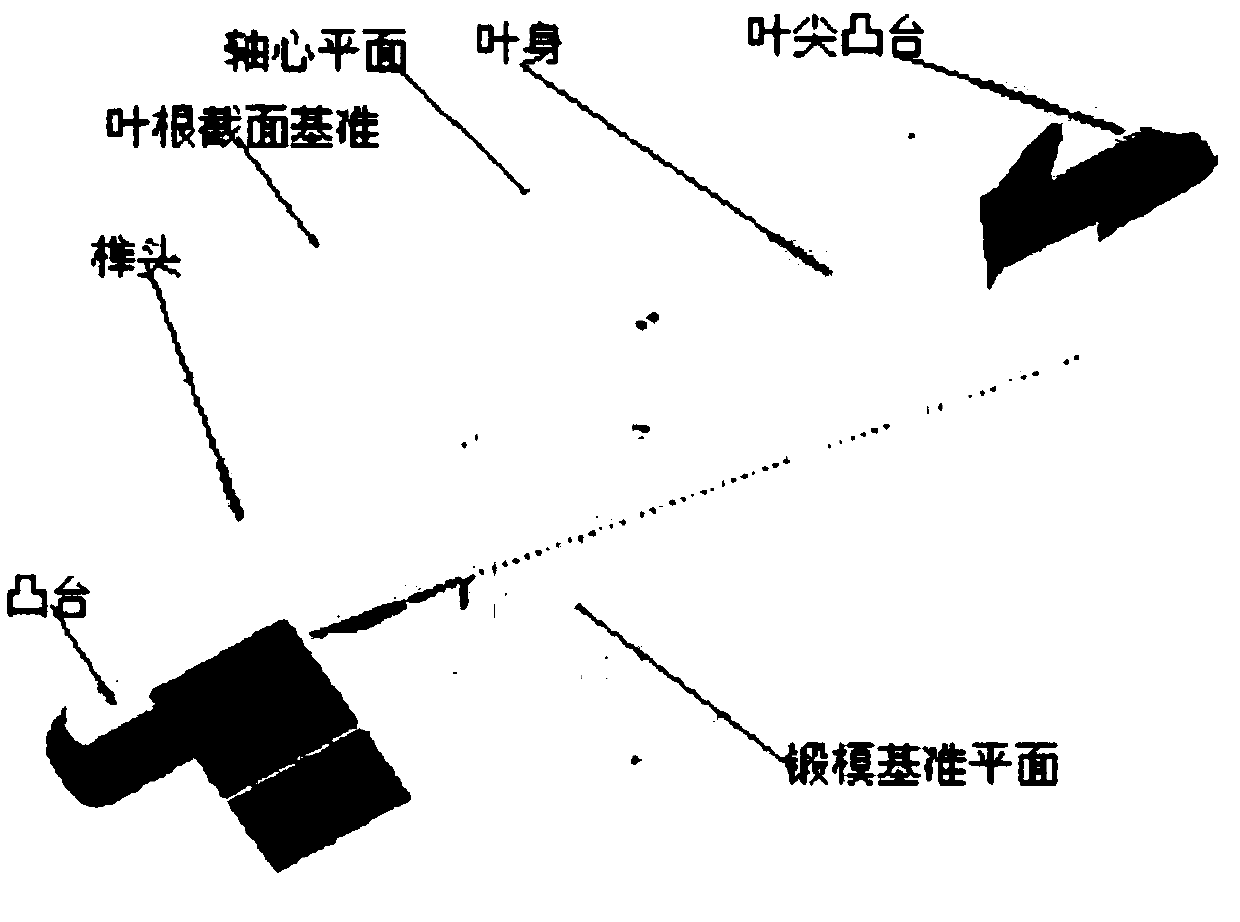

Quality control method for degraded profile in processing course of blade of aviation engine

ActiveCN108803478AMonitor qualityImproving Contour Quality Control AccuracyComputer controlSimulator controlAviationQuality control

The invention provides a quality control method for a degraded profile in a processing course of a blade of an aviation engine, and is used for solving the problem that profile quality control precision is low in an existing processing course of the blade of the aviation engine. The method comprises the following implementation steps: establishing a coupling prediction model for degraded profile error accumulation in the multi-stage processing course of the blade of the aviation engine; carrying out least square regression on the coupling prediction model for degraded profile error accumulation in the multi-stage processing course of the blade of the aviation engine; carrying out self-closing treatment on profile errors in the processing course of the blade of the engine by using a methodfor predicting residual errors ahead of time; carrying out least square regression on a residual equation of a node process k in the processing course of the blade of the engine; establishing a T2 control chart monitoring model based on clusters; and acquiring a degraded profile quality control result in the processing course of the blade of the aviation engine. The profile quality control precision of the processing course of the blade of the engine can be improved, and the method can be applied to profile quality control in the processing course of the blade of the engine in the field of aviation industry.

Owner:XIDIAN UNIV

Imaging method of 3D imaging system of industrial CT

InactiveCN104165895BSimple structureSimple designMaterial analysis by transmitting radiationAviation3d image

The invention provides a 3D imaging system and method of an industrial CT. The imaging system comprises an X-ray generator, an arc-shaped detector, a primary conveyer belt and a secondary conveyer belt, wherein the X-ray generator and the arc-shaped detector are opposite to each other; the primary conveyer belt and the secondary conveyer belt are arranged on the same axis; a gap is formed between the opposite ends of the primary conveyer belt and the secondary conveyer belt; the X-ray generator and the arc-shaped detector are arranged in a manner of rotating around the primary conveyer belt and the secondary conveyer belt by taking the gas as the circle center. Through longitudinal section type scanning of the 3D imaging system, relatively long objects such as long-columnar objects of dozens of centimeters to dozens of meters as well as internal materials, meters and elements such as water suction pumps, water conservancy generators, aviation undercarriages, aviation engines, diving gears, underwater searching and rescuing devices, bridge components, aerospace vehicles and underwater moving devices can be relatively easily checked by using the 3D imaging method.

Owner:于双悦 +1

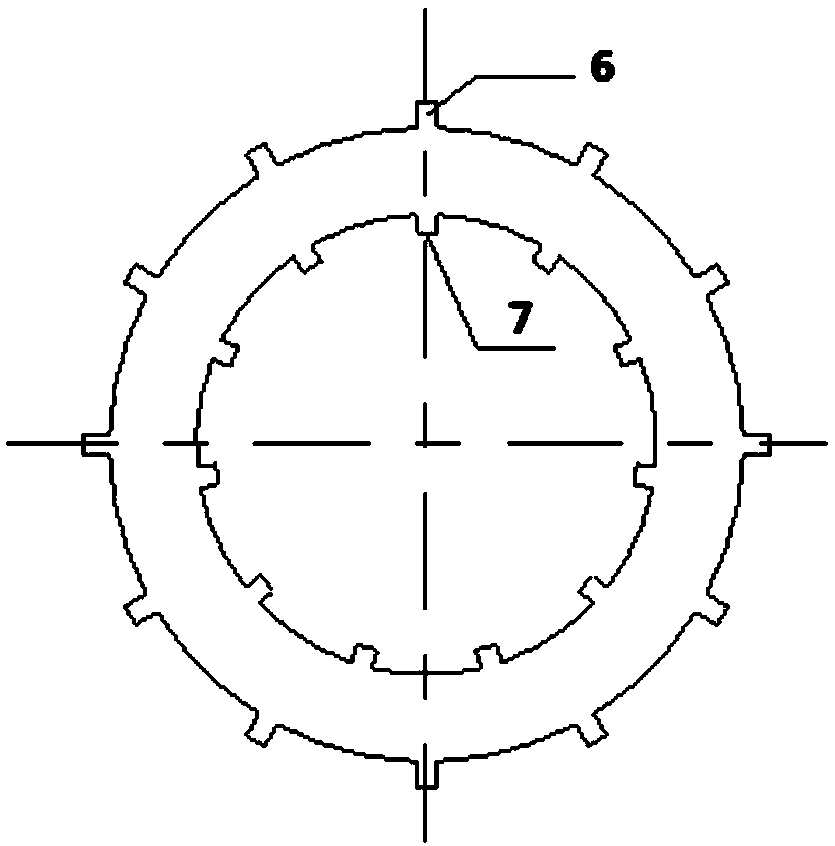

Aviation engine bearing nut locking structure

ActiveCN109505847ASolve the problem of low reliability of imitation pineSolve the requestNutsBoltsStructural deformationAviation

The invention discloses an aviation engine bearing nut locking structure. The aviation engine bearing nut locking structure is characterized in that a plurality of slots are formed in a bearing nut and a shaft neck; the aviation engine bearing nut locking structure includes a locking piece of a ring structure; inner and outer ring surfaces are provided with a plurality of internal teeth and external teeth; the internal and external teeth of the locking piece fit with the slots in the bearing nut and the shaft neck, so that the locking is completed; a retaining ring is also arranged in the bearing nut to fix the annular locking piece so that the annular locking piece can be prevented axial withdrawal. According to the aviation engine bearing nut locking structure, the problem that conventional locking pieces have low looseness prevention reliability is solved; compared with the conventional structural deformation locking pieces, the novel structural locking piece has no bending deformation during assembling and testing, the shearing areas are increased, and the ability of looseness prevention of the bearing nut is improved.

Owner:AECC SICHUAN GAS TURBINE RES INST

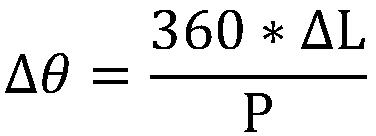

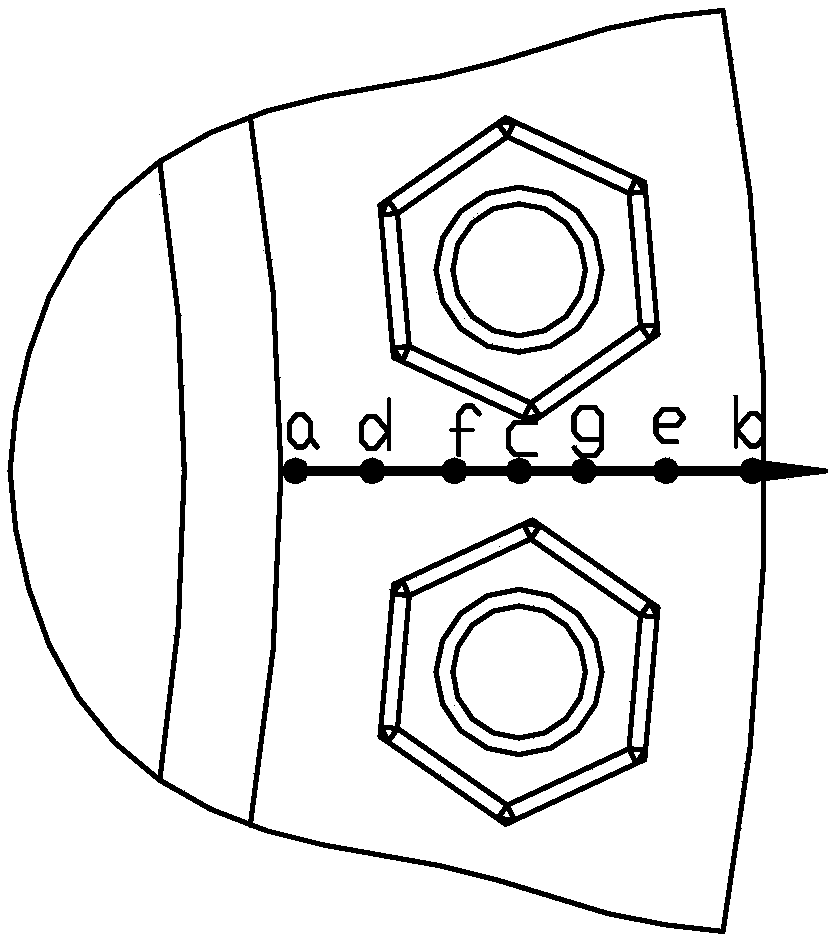

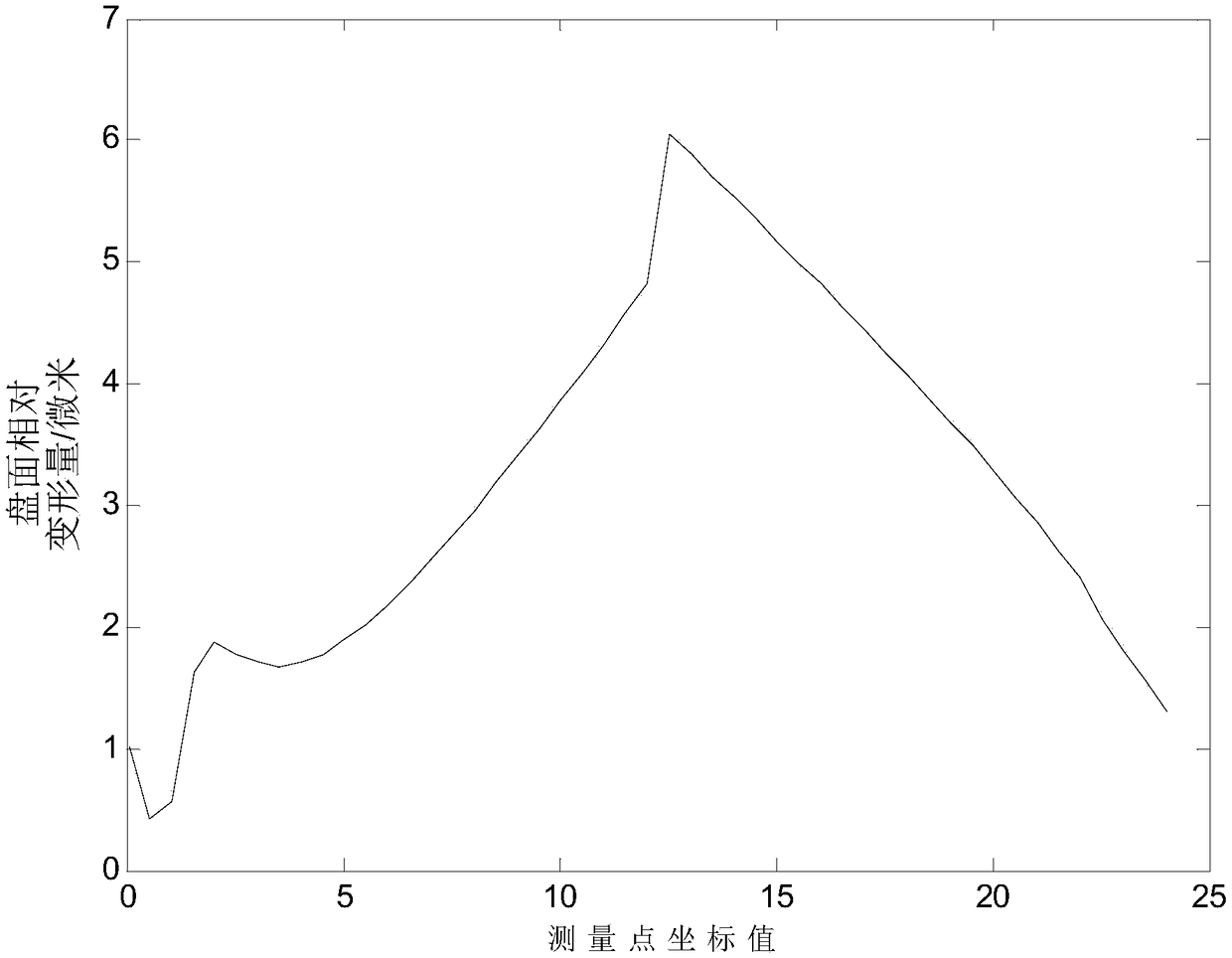

Method and device for detecting fastening force of low-pressure turbine shaft disk of aeroengine based on eddy current sensor group

ActiveCN106124615BAccurately judge the preload stateHigh precisionMeasurement of torque/twisting force while tighteningMaterial magnetic variablesRelative displacementAviation

The invention discloses a method and device for detecting the fastening force of a low-pressure turbine shaft disk of an aero-engine based on an eddy current sensor group. relationship; test the relative displacement of the upper and lower surfaces of the low-pressure turbine shaft-disc structure during or after assembly; determine whether the pre-tightening force is insufficient or too large for each bolt to be tested or adjacent bolts; determine unreasonable pre-tightening force bolts, and pre-tightening Tightness deviation value. The invention measures the relative displacement of the upper and lower disk surfaces of the low-pressure turbine shaft disk of the aero-engine, quickly and accurately judges the pre-tightening state of the bolts, does not need to destroy the bolt structure during the measurement process, and has higher precision than the current method of directly measuring the length of short bolts, and measures the relative displacement of the upper and lower disk surfaces , and the relative displacement deviation of the disk surface caused by the pretightening force deviation relative to the expected value, avoiding the influence of the basic coordinate deviation of the disk surface on the measurement data during the preloading process.

Owner:DALIAN UNIV OF TECH

Disinfection device used in infectious disease patient conveying and isolation unit

PendingCN111956849ASolve disinfection problemsRealize the use requirements of spray disinfectionLavatory sanitoryAtomized substancesDisinfectantEngineering

The invention belongs to the technical field of aviation medical rescue, and particularly relates to a disinfection device used in an infectious disease patient conveying and isolation unit. The disinfection device comprises a manual pressurizing device and a rotary spray head, wherein the manual pressurizing device is connected with the rotary spray head through a fastening mechanism. The deviceis compact in structural design, high in practicability, good in spraying disinfection effect, large in disinfection area and uniform in spraying range, the spray head rotates automatically, a disinfectant is sprayed in a mist shape, and the use requirement for uniform spraying disinfection at all positions in a buffer channel is met.

Owner:AIR FORCE MEDICAL CENT PLA

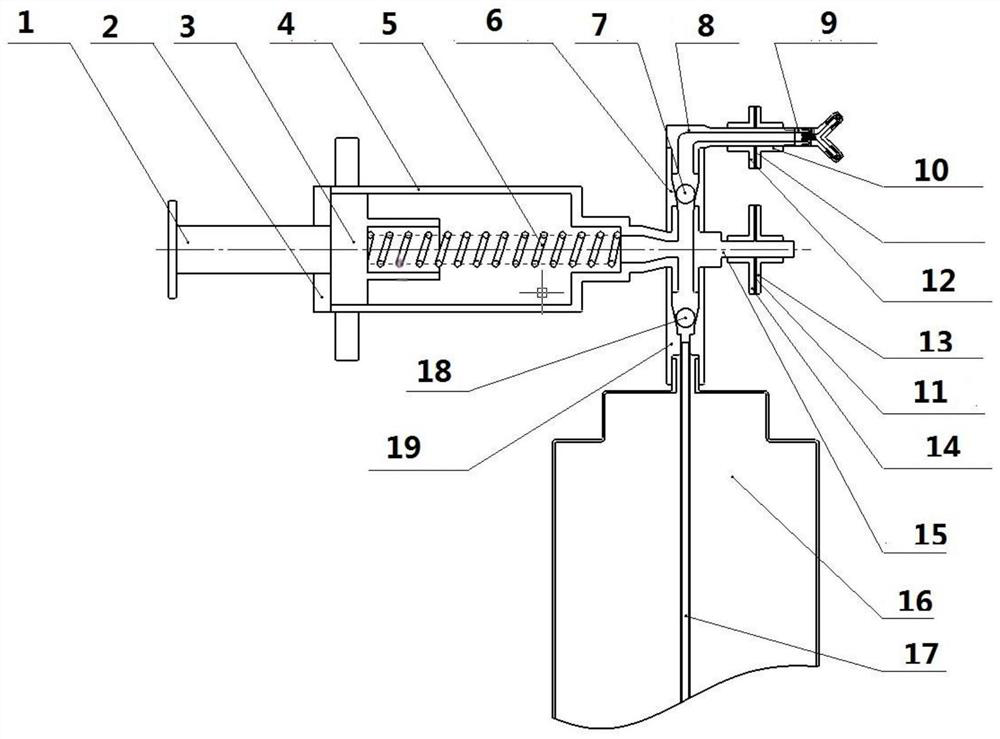

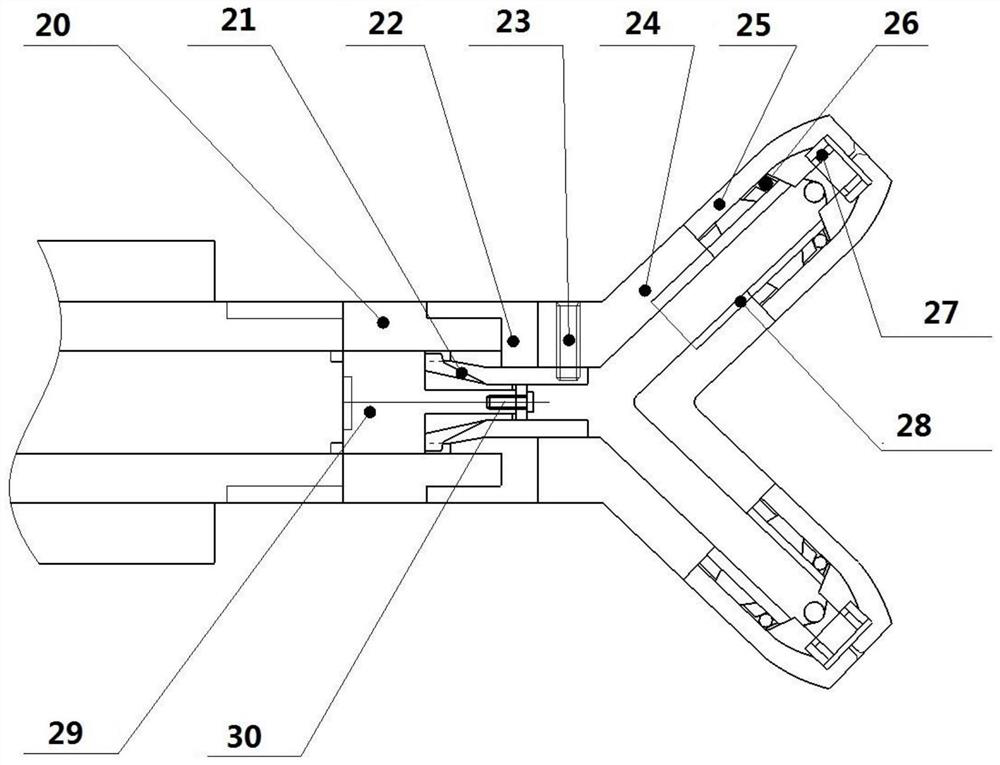

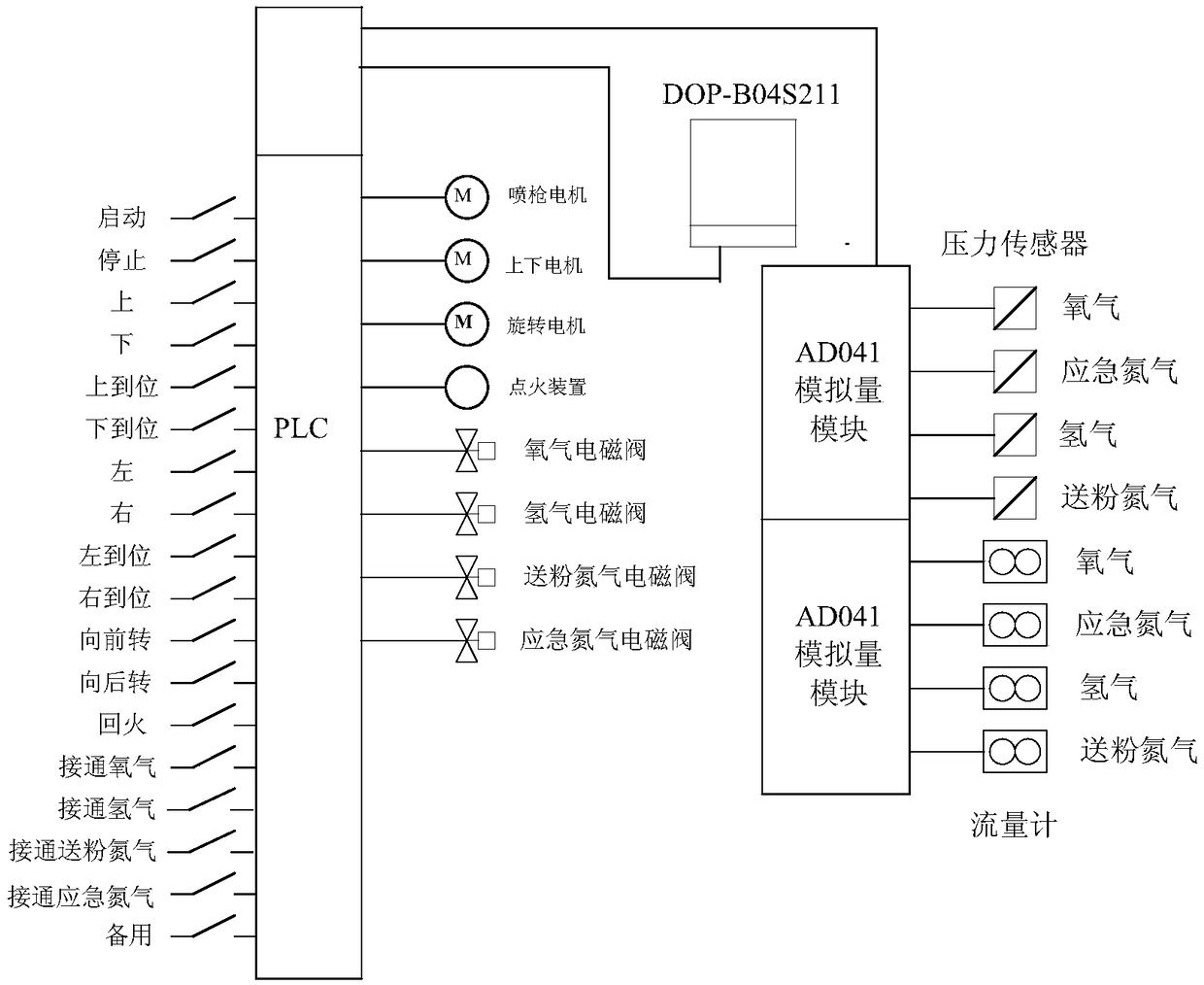

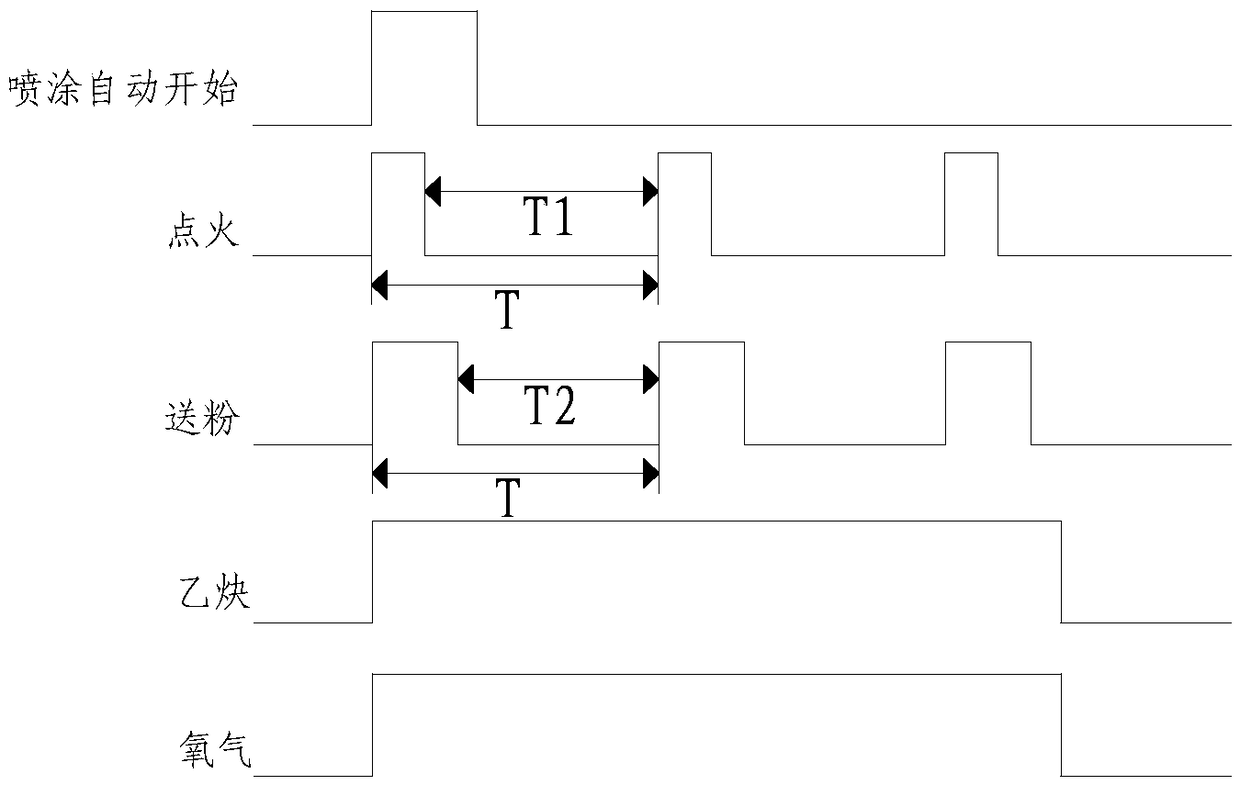

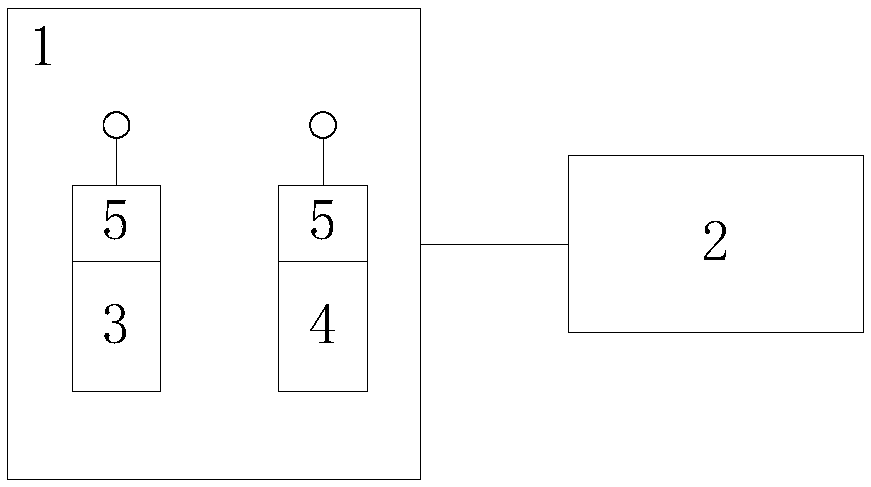

A kind of control method of explosive spraying equipment for aero-engine

ActiveCN107051763BReduce labor intensityIncrease productivityLiquid spraying apparatusProgramme control in sequence/logic controllersAviationHuman–machine interface

The invention discloses a control method for explosion spraying equipment for an aero-engine. A control system is mainly composed of a PLC, a touch screen, a servo system and other key parts. According to the related requirements of the explosion spraying technology, the explosion spraying equipment with the improved control system comprises functions of several parts including spraying process control, air path flow detection, adjustment and control, spraying parameter monitoring and the like. Corresponding control and monitoring can be conducted on an operation panel and the touch screen. A human-machine interface based on the touch screen is convenient to configure, and easy and convenient to operate. The system achieves automatic cyclic control of spraying and also combines manual control. An air path detection and adjustment part is mainly used for collecting signals of flow pressure and the like and sending the signals to the PLC, displaying is conducted on the touch screen so that operation and personnel monitoring can be convenient, and the flow pressure is adjusted so that the technology parameter requirement can be met. The control method has the beneficial effects that the production efficiency of the equipment is improved, the labor intensity of operators is lowered, the application prospects of the control method are very wide, and popularization value is achieved.

Owner:SHENYANG LIMING AERO-ENGINE GROUP CORPORATION

Test run worker training system based on aviation engine working condition simulation and control method

InactiveCN109523856AReasonable designEasy to implementCosmonautic condition simulationsSimulatorsAviationControl system

The invention relates to a test run worker training system based on aviation engine working condition simulation and a control method, and belongs to the field of engine online inspection. The training system comprises a training machine, a control machine, an engine throttle lever and an operation switch; the control method comprises the steps that 1, a test run worker operation procedure is built; 2, a trainer control system is built; 3, a test run worker operates on the training machine; 4, the trainer controls the system to obtain the training result. Due to the virtual simulation trainingfunction, the material object training operation risk is lowered, the material object training effect can be achieved, the operator master the engine test run skill proficiently, and the emergent processing capability is improved.

Owner:SHENYANG LIMING AERO-ENGINE GROUP CORPORATION

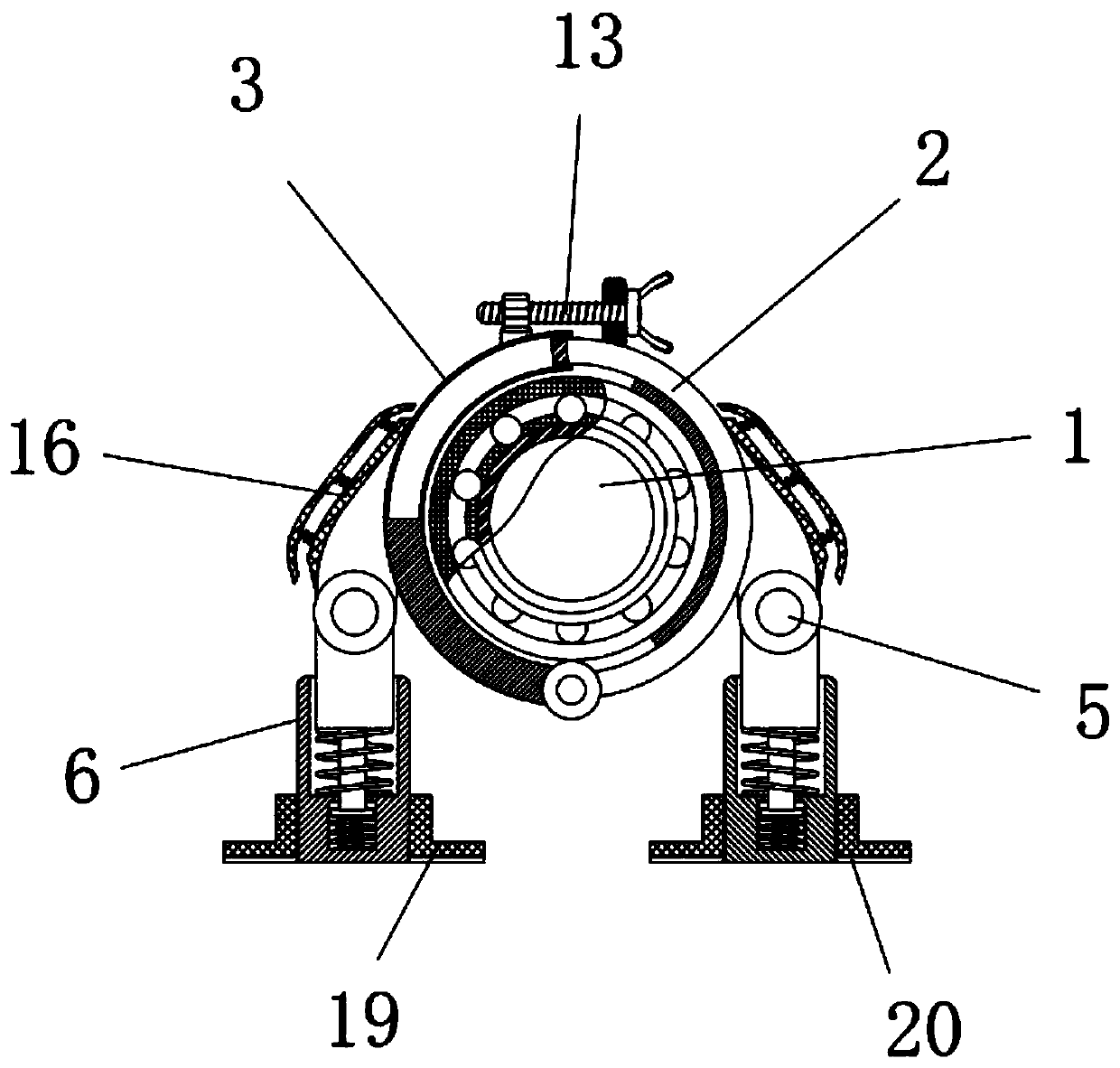

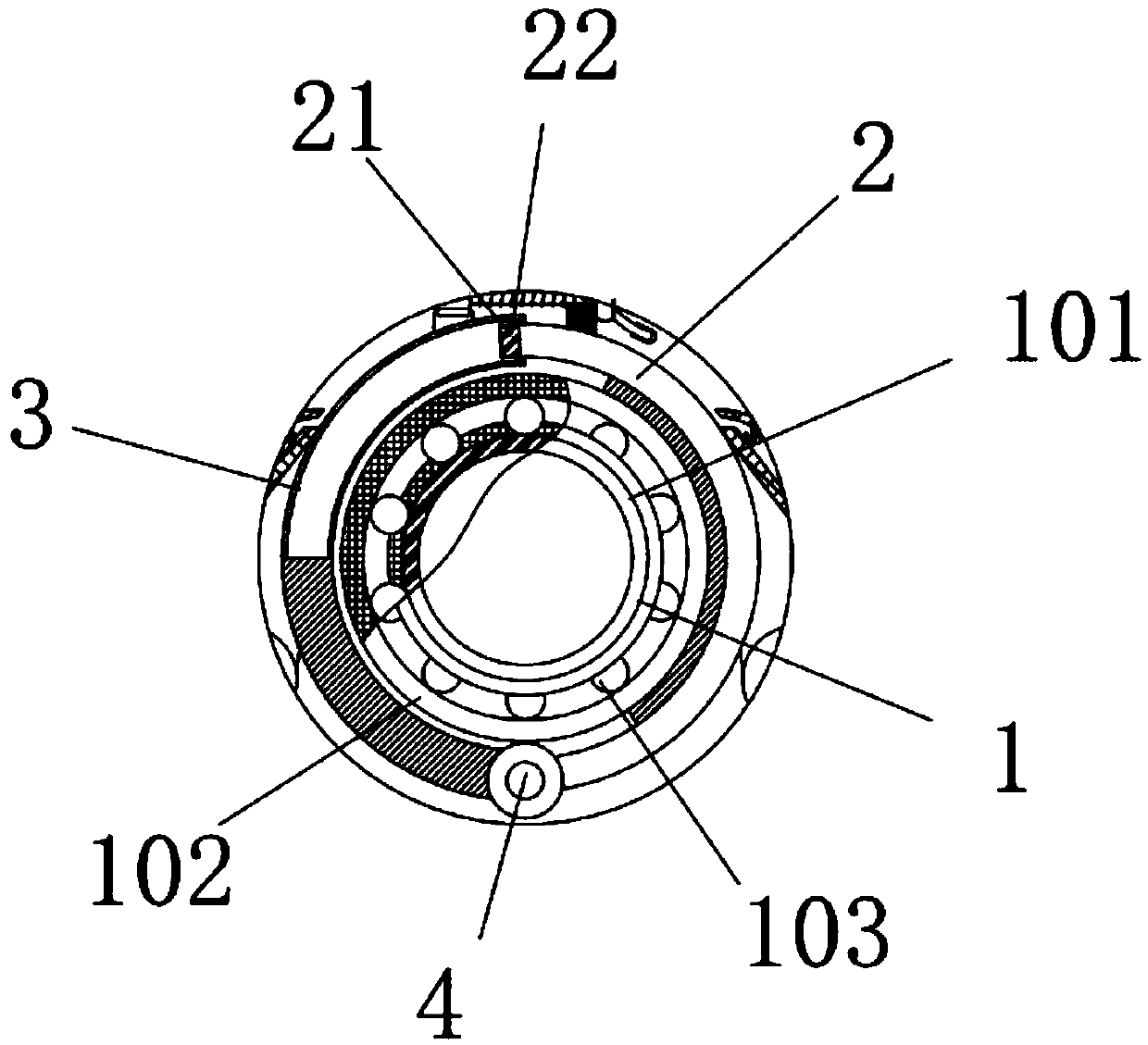

Bearing support device for aero-engine

ActiveCN107830064BPrevent looseningReduce vibrationNon-rotating vibration suppressionBearing unit rigid supportAviationSurface mounting

The invention discloses a bearing supporting device applied to an aero-engine. The bearing supporting device comprises a bearing; the bearing comprises an inner ring body; a plurality of balls are installed at the outer wall of the inner ring body; a clamping plate is installed in an inner chamber of a clamping slot; an inserting rod is installed at the upper surface of the clamping plate; the topend of the inserting rod is connected with a second upright post; and a second spring is installed at the bottom of the clamping plate and is connected with the inner wall of the clamping slot. According to the bearing supporting device applied to the aero-engine, a first clamping ring and a second clamping ring are used for clamping the bearing at the middle; a nut is tightened and the clampingplate is pressed tightly in a way of twisting a bolt so that the bearing can be clamped by the first clamping ring and the second clamping ring; when shock occurs, the first spring supports the secondupright post so that the shock is alleviated, and the clamping plate is used for limiting the relative positions of a first upright post and the second upright post; and the second spring positionedat the bottom of the clamping plate can also be used for reducing an impact force when shock occurs, so the safety of people is guaranteed.

Owner:刘和来

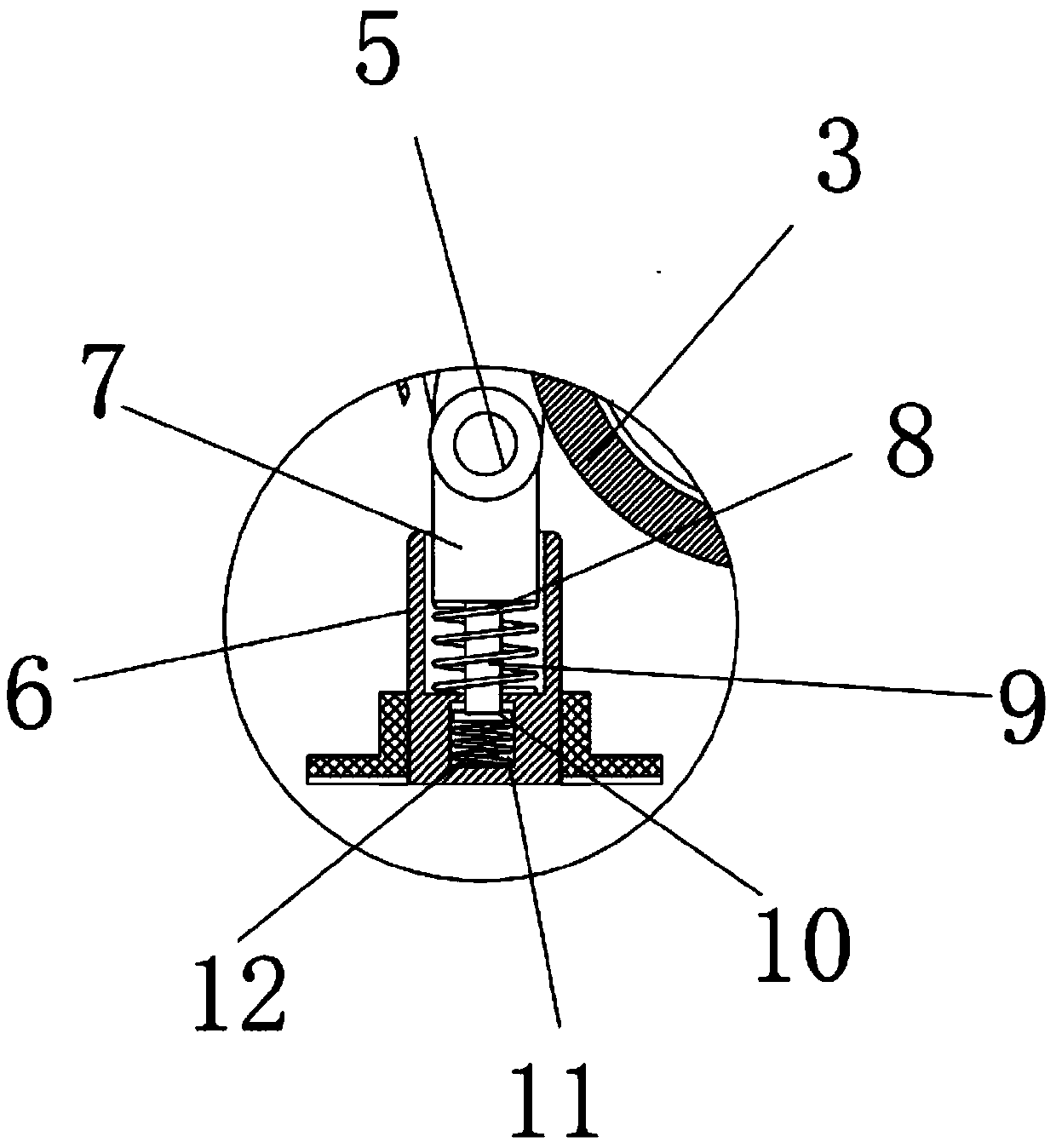

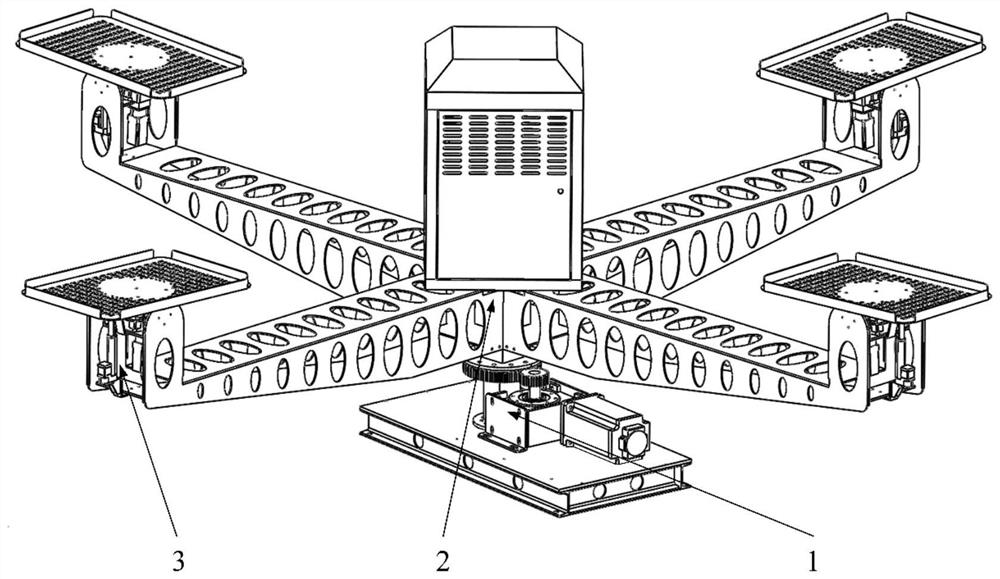

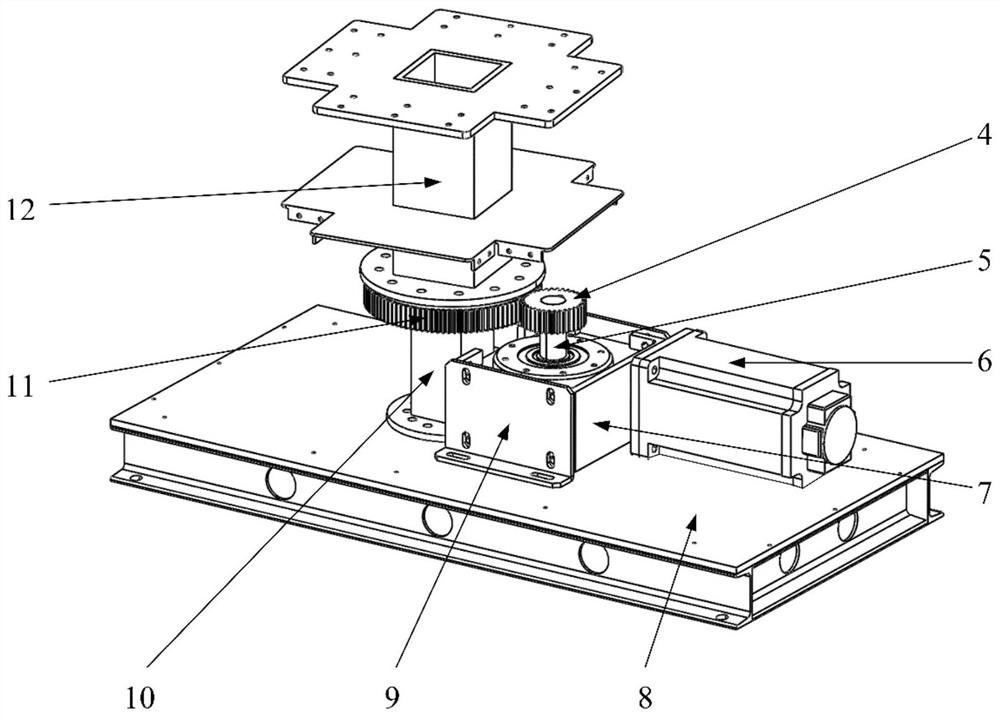

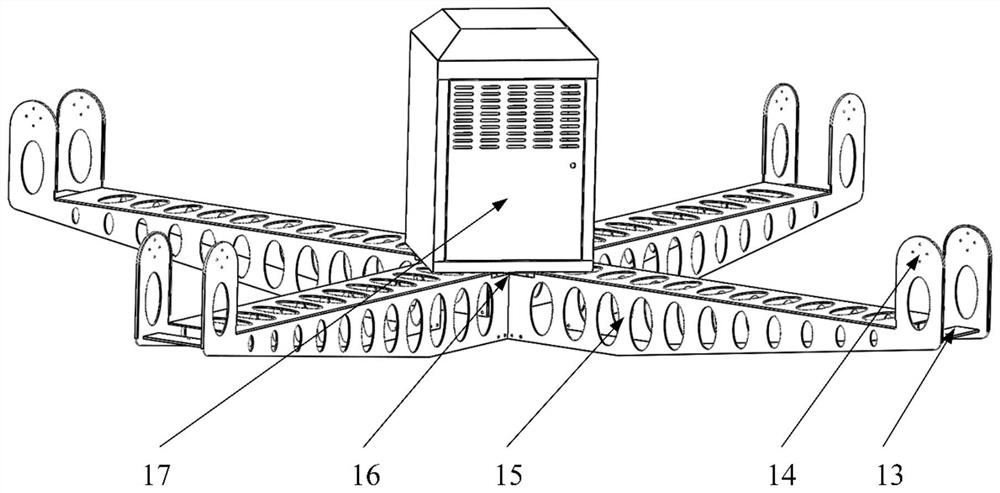

Four-rotating-arm multi-degree-of-freedom animal centrifugal machine

ActiveCN113892441ASolve the problem of centrifugationMeet the speedAvicultureOther apparatusAviationSupporting system

The invention relates to a four-rotating-arm multi-degree-of-freedom animal centrifugal machine which comprises a transmission supporting system, a four-rotating-arm system and a double-shaft rotating animal carrying table system. The transmission supporting system supports the four-rotating-arm system to rotate around the horizontal ground with a rotating main shaft as the circle center under the power effect, the four-rotating-arm system comprises a double-shaft rotating animal carrying table system, and a swing plate in the double-shaft rotating animal carrying table system can swing in a reciprocating mode around the axis of a short shaft under the effect of a stepping motor push rod. An electric rotating table is installed on the swing plate and can drive an animal fixing platform to rotate. Through composite superposition of the three motions, a real flight environment is simulated, the centrifugal acceleration and the centrifugal acceleration change rate required by an experiment are met, and the centrifugal machine has the advantages of being simple in structure, reliable in work, low in operation power consumption and the like, is used in experimental research of centrifugal treatment of animals, and is used for solving the animal centrifugal treatment problem in aeronautical medicine experiments.

Owner:FOURTH MILITARY MEDICAL UNIVERSITY

Power assisting opening medical garbage collecting device in machine-mounted checking box

PendingCN111153080AEasy to fixNot easy to dumpRefuse receptaclesRefuse cleaningAviationRefuse collection

The invention belongs to the technical field of aviation medicine rescue, and particularly relates to a power assisting opening medical garbage collecting device in a machine-mounted checking box. A medical garbage collecting inner barrel, a cabin door, an outer cabin and a damping spring hinge are included. The device is in a half cylinder shape, one face of the arc is a front face, and the backface is a plane. The medical garbage collecting inner barrel is in a half cylinder shape, one face of the arc is a front face, the back face is a plane, the front face is arranged towards the interiorof the outer cabin, and the back face is connected with the cabin door in a nesting hanging manner. The cabin door is arranged at the lower portion of the back face of the device through the dampingspring hinge. The power assisting opening medical garbage collecting device integrates a popup type garbage collecting device for clinic checking on an air transportation medical care evacuation airplane, the medical garbage collecting inner barrel is firmly fixed and is not prone to toppling, detachment can be rapid, garbage pouring is convenient, an ultraviolet disinfection lamp in the cabin canconduct disinfection and sterilization treatment on the medical garbage, and the pollution problem caused by medical garbage is solved.

Owner:AIR FORCE MEDICAL CENT PLA +1

Aviation engine thrust detecting device

ActiveCN108362426AStable forceEngine testingMeasurement of vehicle's tractive/propulsive powerAviationEngineering

The invention discloses an aviation engine thrust detecting device which comprises a base. The base is fixedly arranged on the ground. A test hole is arranged in the middle of the upper surface of thebase. A pressure device is arranged in the base. The pressure device is composed of a sliding member sleeved in the test hole, a pressure plate which is located in the sliding member and is slidablyconnected with the inner surface of the sliding member, pressure sensors which are fixedly connected with the lower surface of the pressure plate and are uniformly distributed under the pressure plate, and a signal connector which is located on the right side of a pressure sensor and is fixedly connected with the lower middle of the right surface of the pressure sensor. A fixation device is arranged above the pressure plate. A fastening device is arranged above the fixation device. The aviation engine thrust detecting device provided by the invention has the advantages of simple structure andhigh practicability.

Owner:绍兴市秀臻新能源科技有限公司

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com