3D imaging system and method of industrial CT

An imaging system, 3D technology, applied in the direction of using radiation for material analysis, etc., to achieve the effect of a wide range of applications, simple CT structure, and simple structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0029] The present invention will be described in further detail below in conjunction with the accompanying drawings.

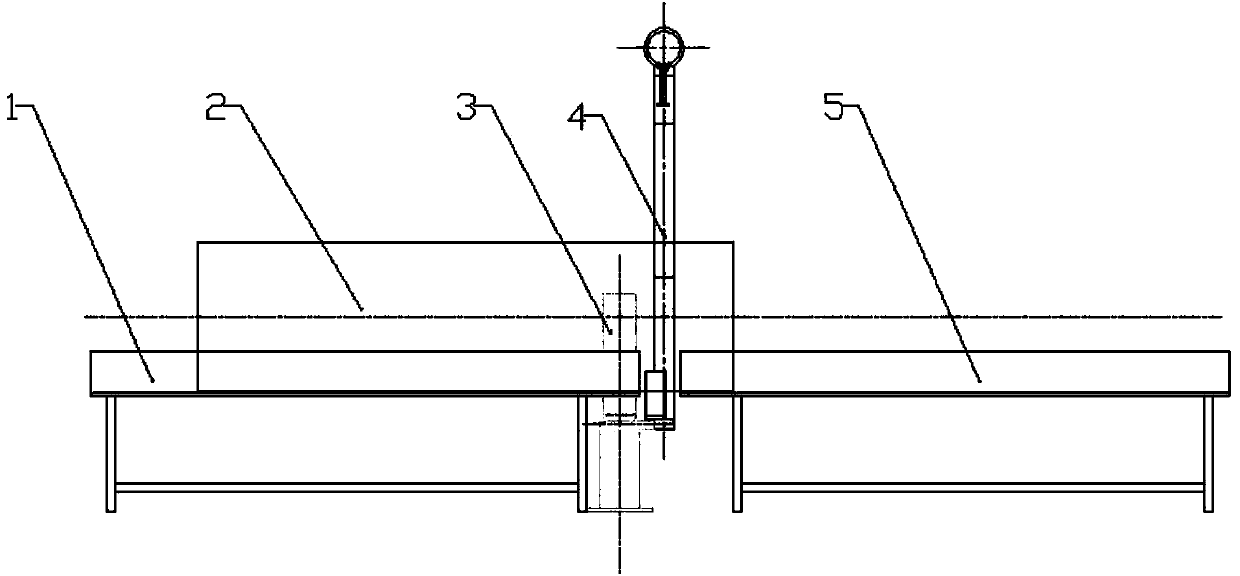

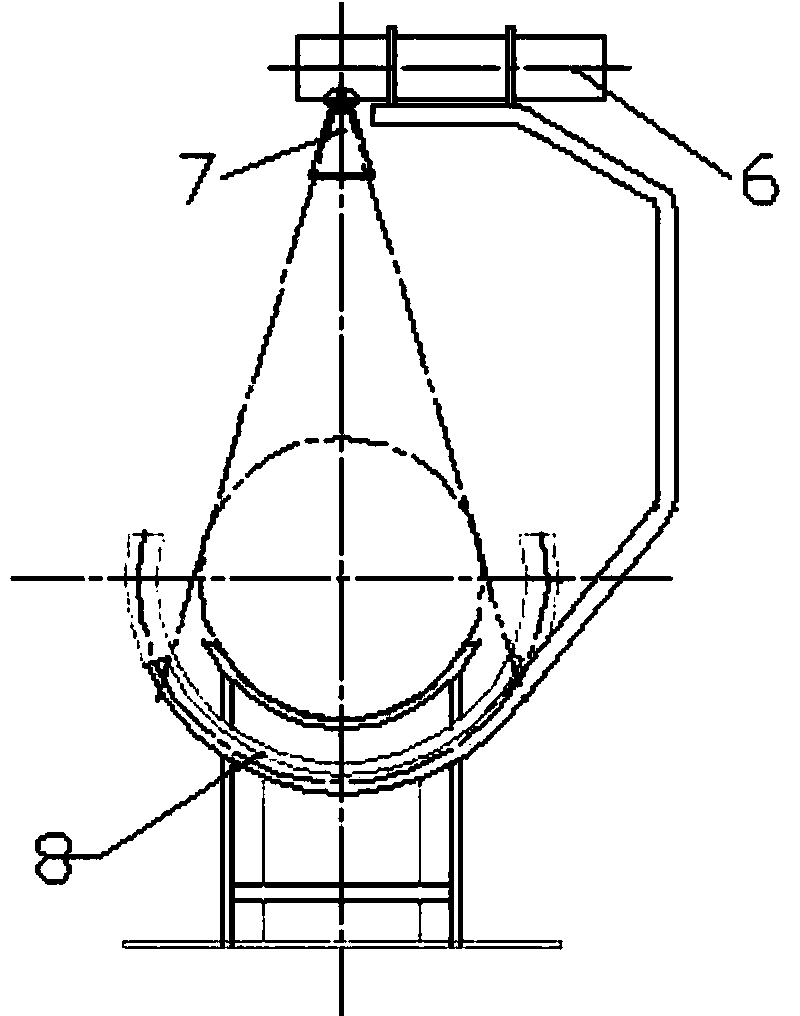

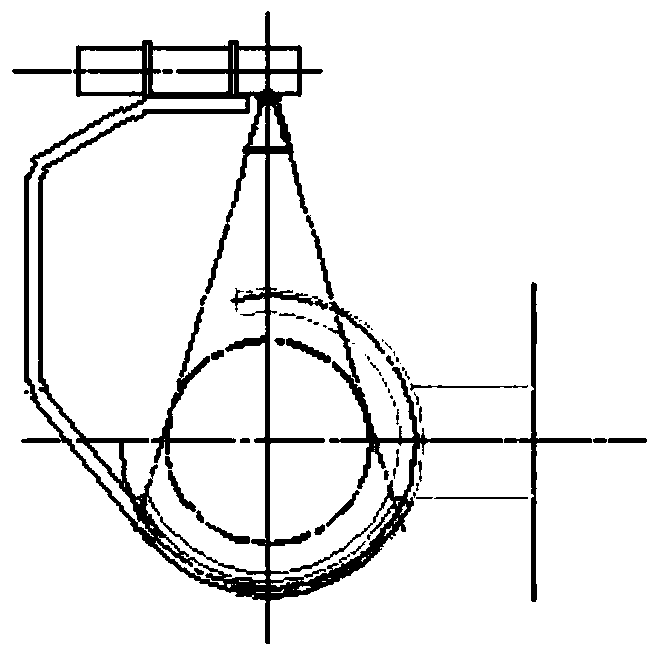

[0030] Such as figure 1 and figure 2 as shown, figure 1 It is a schematic diagram of the main view structure of the 3D imaging system of the industrial CT of the present invention, figure 2 It is a schematic diagram of the side view structure of the 3D imaging system of the industrial CT of the present invention.

[0031] A 3D imaging system for industrial CT, comprising oppositely arranged X-ray generators, arc detectors 8, a primary conveyor belt 5 and a secondary conveyor belt 1 arranged on the same axis, the primary conveyor belt 5 and the There is a gap between opposite ends of the secondary conveyor belt 1 , and the X-ray generator and the arc detector 8 are arranged to rotate around the primary conveyor belt 5 and the secondary conveyor belt 1 with the gap as the center.

[0032] Preferably, the X-ray generator includes an X-ray tube 6 and a beam...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com