Water flow rate testing device of turbine blade of aviation engine

A technology of aero-engines and turbine blades, which is applied in the direction of measuring devices, testing of mechanical components, testing of machine/structural components, etc., can solve problems such as low measurement accuracy and errors, and achieve the effect of improving measurement accuracy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

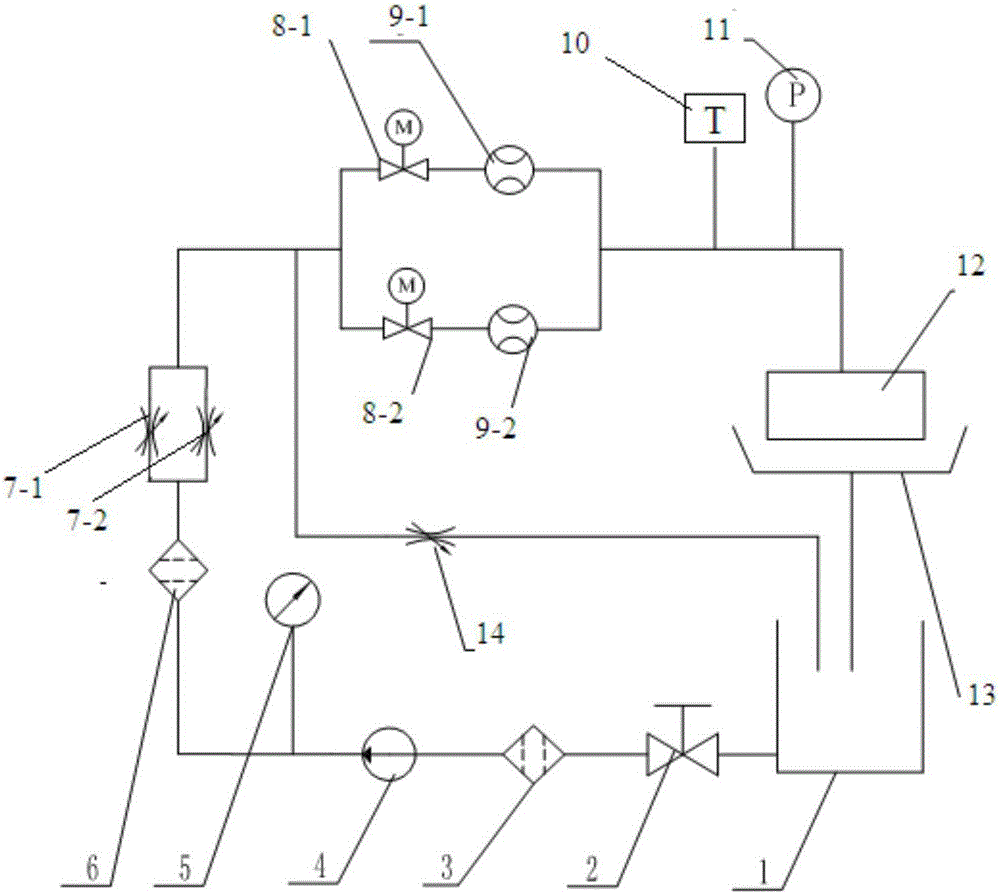

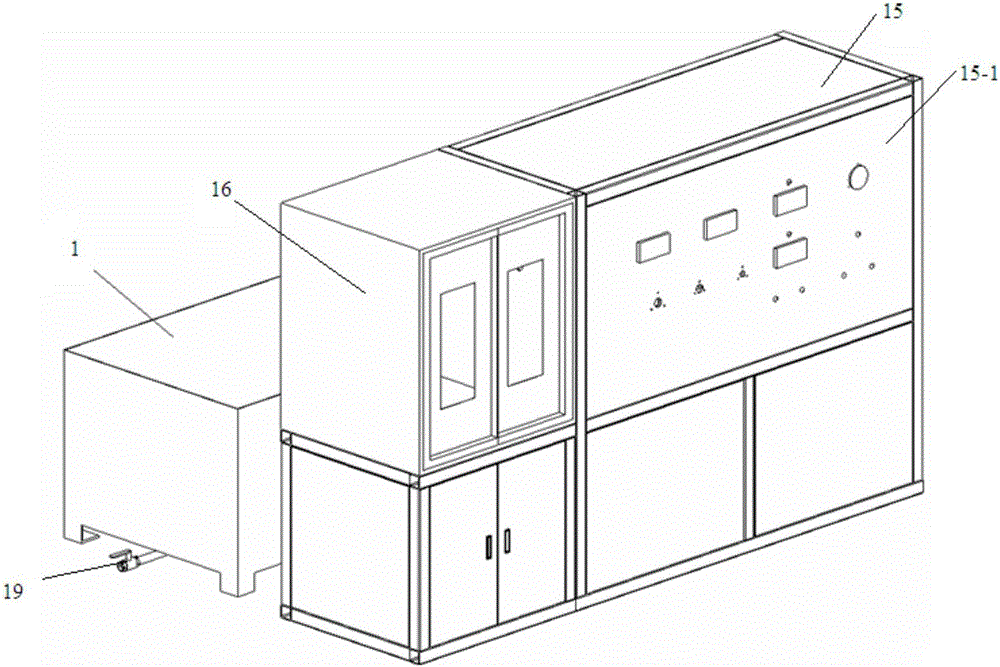

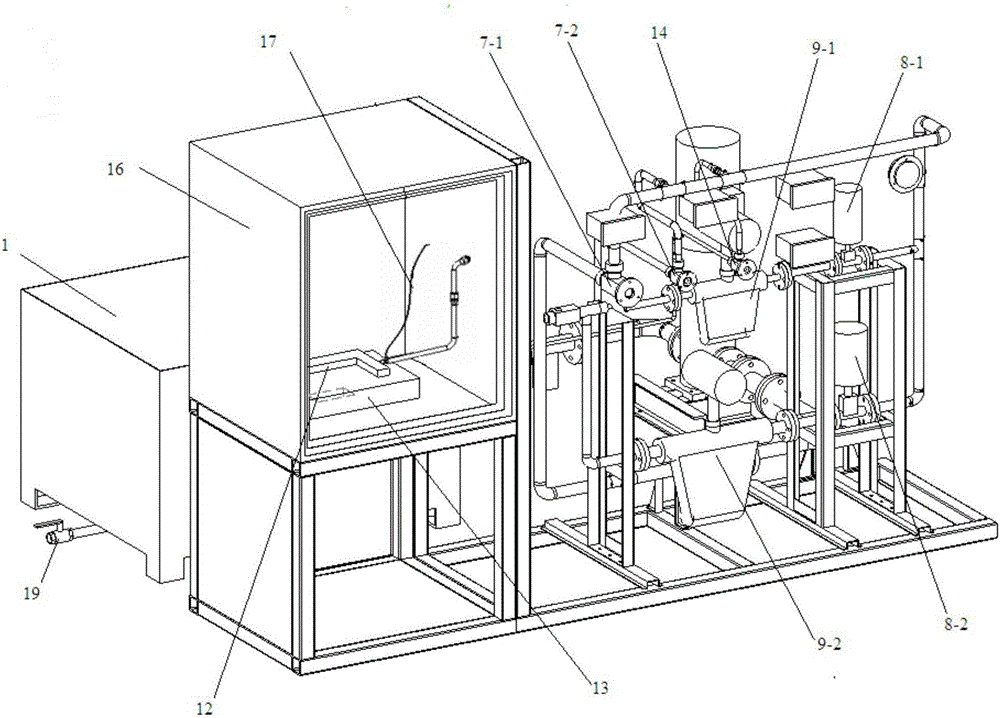

[0035] The aeroengine turbine blade water flow test device described in this embodiment has a structure such as Figure 1~5 As shown, it includes a water tank 1 provided with a drain port 19 and a top cover, a coarse filter 3, a centrifugal pump 4, a pressure gauge 5, a fine filter 6, a main road pressure regulating valve, a blade clamp 12, a workbench 13, and a The bypass flow path of the bypass regulating valve 14, two parallel measuring branches and the temperature sensor 10 and the pressure sensor 11; the two parallel measuring branches are the first measuring branch, the second measuring branch, the first measuring The first cut-off valve 8-1 and the first flowmeter 9-1 are installed in the branch from the water inlet to the water outlet in sequence, and the second cut-off valve 8-2 is installed in the second measurement branch from the water inlet to the water outlet in sequence. Two flow meters 9-2.

[0036] The water outlet of the water tank 1 is communicated with the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com